JEEP XJ 1995 Service And Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1781 of 2158

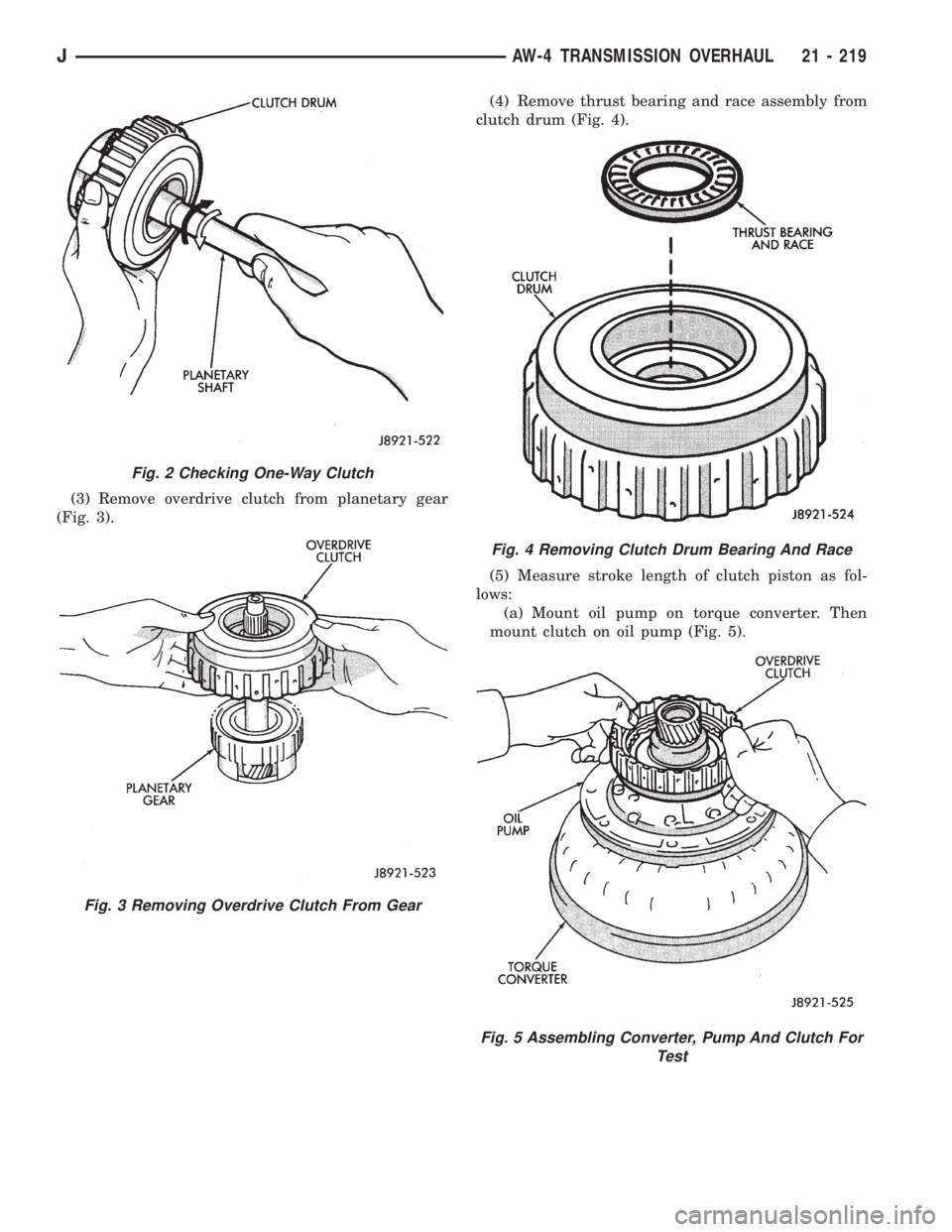

(3) Remove overdrive clutch from planetary gear

(Fig. 3).(4) Remove thrust bearing and race assembly from

clutch drum (Fig. 4).

(5) Measure stroke length of clutch piston as fol-

lows:

(a) Mount oil pump on torque converter. Then

mount clutch on oil pump (Fig. 5).

Fig. 2 Checking One-Way Clutch

Fig. 3 Removing Overdrive Clutch From Gear

Fig. 4 Removing Clutch Drum Bearing And Race

Fig. 5 Assembling Converter, Pump And Clutch For

Test

JAW-4 TRANSMISSION OVERHAUL 21 - 219

Page 1782 of 2158

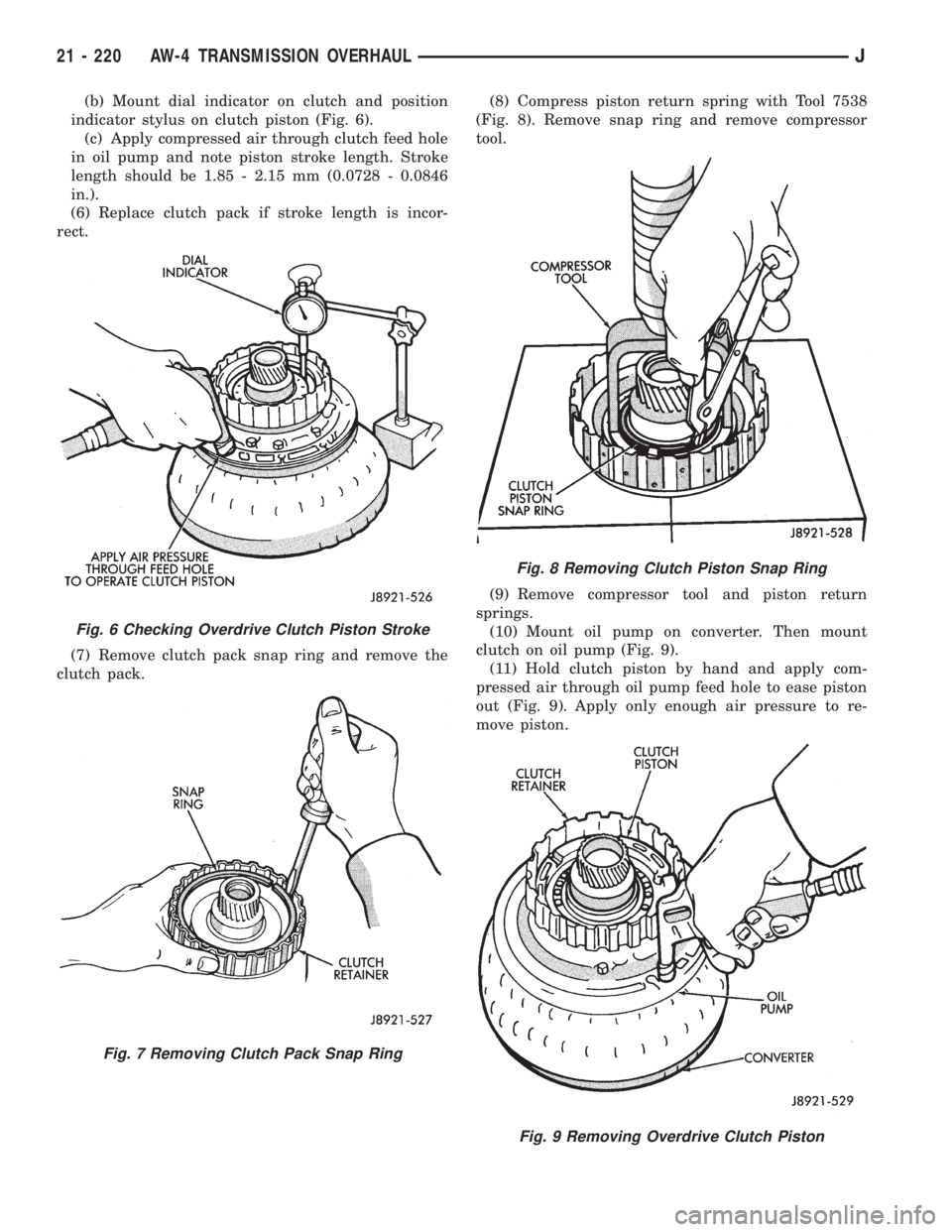

(b) Mount dial indicator on clutch and position

indicator stylus on clutch piston (Fig. 6).

(c) Apply compressed air through clutch feed hole

in oil pump and note piston stroke length. Stroke

length should be 1.85 - 2.15 mm (0.0728 - 0.0846

in.).

(6) Replace clutch pack if stroke length is incor-

rect.

(7) Remove clutch pack snap ring and remove the

clutch pack.(8) Compress piston return spring with Tool 7538

(Fig. 8). Remove snap ring and remove compressor

tool.

(9) Remove compressor tool and piston return

springs.

(10) Mount oil pump on converter. Then mount

clutch on oil pump (Fig. 9).

(11) Hold clutch piston by hand and apply com-

pressed air through oil pump feed hole to ease piston

out (Fig. 9). Apply only enough air pressure to re-

move piston.

Fig. 6 Checking Overdrive Clutch Piston Stroke

Fig. 7 Removing Clutch Pack Snap Ring

Fig. 8 Removing Clutch Piston Snap Ring

Fig. 9 Removing Overdrive Clutch Piston

21 - 220 AW-4 TRANSMISSION OVERHAULJ

Page 1783 of 2158

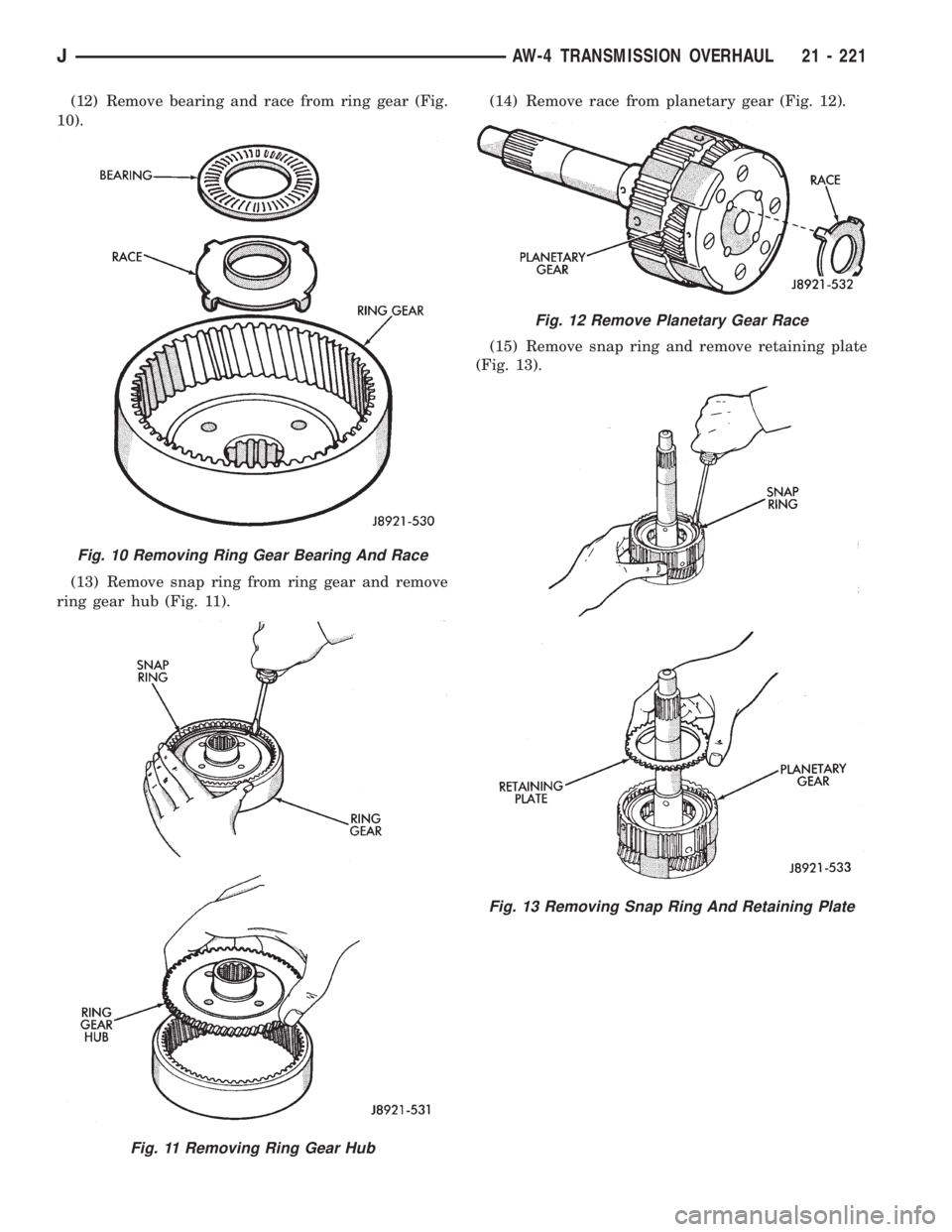

(12) Remove bearing and race from ring gear (Fig.

10).

(13) Remove snap ring from ring gear and remove

ring gear hub (Fig. 11).(14) Remove race from planetary gear (Fig. 12).

(15) Remove snap ring and remove retaining plate

(Fig. 13).

Fig. 10 Removing Ring Gear Bearing And Race

Fig. 11 Removing Ring Gear Hub

Fig. 12 Remove Planetary Gear Race

Fig. 13 Removing Snap Ring And Retaining Plate

JAW-4 TRANSMISSION OVERHAUL 21 - 221

Page 1784 of 2158

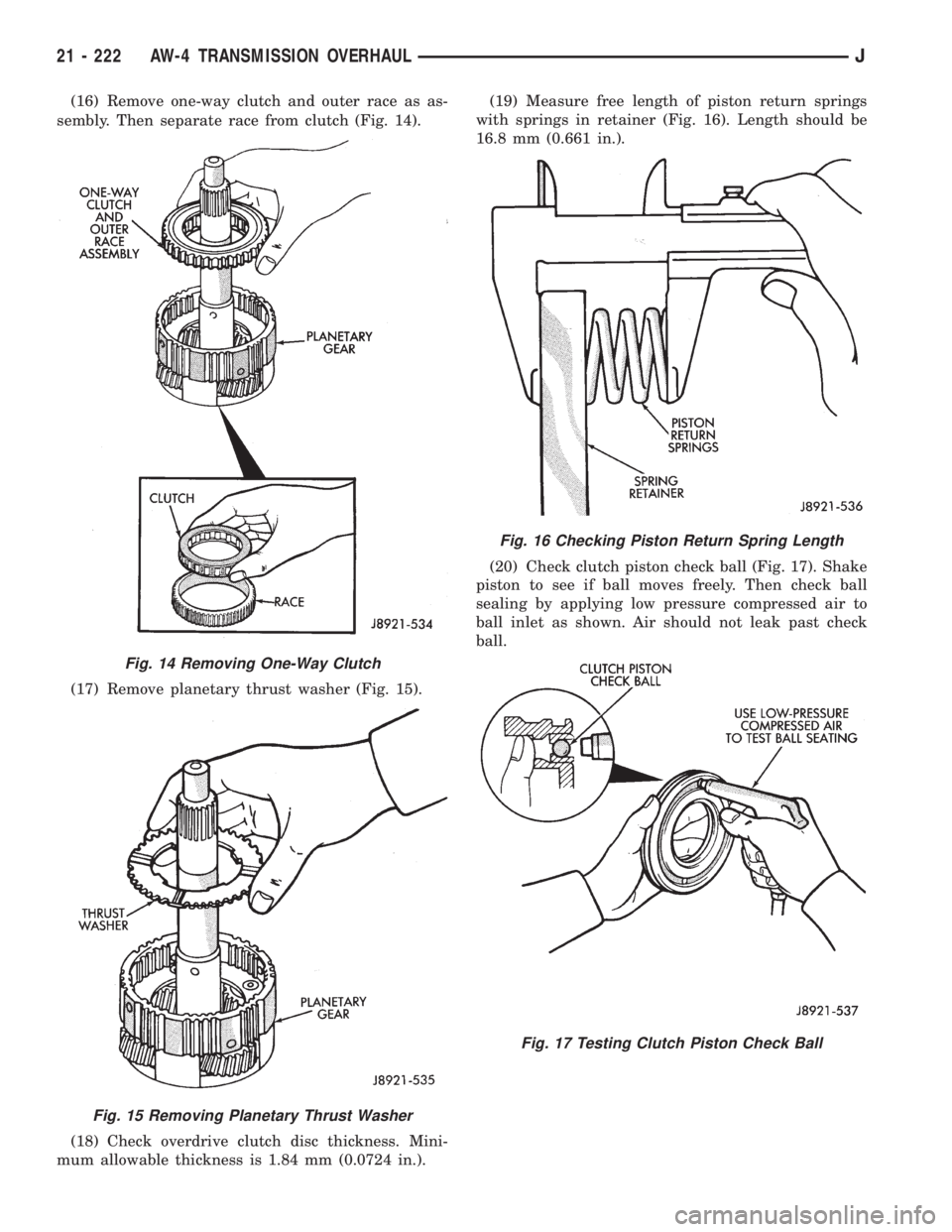

(16) Remove one-way clutch and outer race as as-

sembly. Then separate race from clutch (Fig. 14).

(17) Remove planetary thrust washer (Fig. 15).

(18) Check overdrive clutch disc thickness. Mini-

mum allowable thickness is 1.84 mm (0.0724 in.).(19) Measure free length of piston return springs

with springs in retainer (Fig. 16). Length should be

16.8 mm (0.661 in.).

(20) Check clutch piston check ball (Fig. 17). Shake

piston to see if ball moves freely. Then check ball

sealing by applying low pressure compressed air to

ball inlet as shown. Air should not leak past check

ball.

Fig. 14 Removing One-Way Clutch

Fig. 15 Removing Planetary Thrust Washer

Fig. 16 Checking Piston Return Spring Length

Fig. 17 Testing Clutch Piston Check Ball

21 - 222 AW-4 TRANSMISSION OVERHAULJ

Page 1785 of 2158

(21) Check inside diameter of clutch drum bush-

ings with bore gauge or inside micrometer (Fig. 18).

Maximum inside diameter is 27.11 mm (1.0673 in.).

Replace drum if bushing inside diameter is greater

than specified.

(22) Check inside diameter of planetary gear bush-

ing (Fig. 19). Maximum inside diameter is 11.27 mm

(0.4437 in.). Replace planetary gear if bushing inside

diameter is greater then specified.

Assembling Gear And Clutch

(1) Install thrust washer in planetary gear (Fig.

20).Grooved side of washer faces up and to-

ward front.(2) Install one-way clutch in race (Fig. 21). Flanged

side of clutch must face upward as shown.

(3) Install assembled one-way clutch and outer

race in planetary gear. Be sure flanged side of clutch

is facing upward.

(4) Install clutch pack retaining plate and snap

ring in planetary gear.

(5) Coat planetary race with petroleum jelly and

install it on planetary gear. Outside diameter of race

is 41.8 mm (1.646 in.); inside diameter is 27.1 mm

(1.067 in.).

Fig. 18 Checking Clutch Drum Bushings

Fig. 19 Checking Planetary Bushing

Fig. 20 Install Planetary Thrust Washer

Fig. 21 Assembling One-Way Clutch And Race

JAW-4 TRANSMISSION OVERHAUL 21 - 223

Page 1786 of 2158

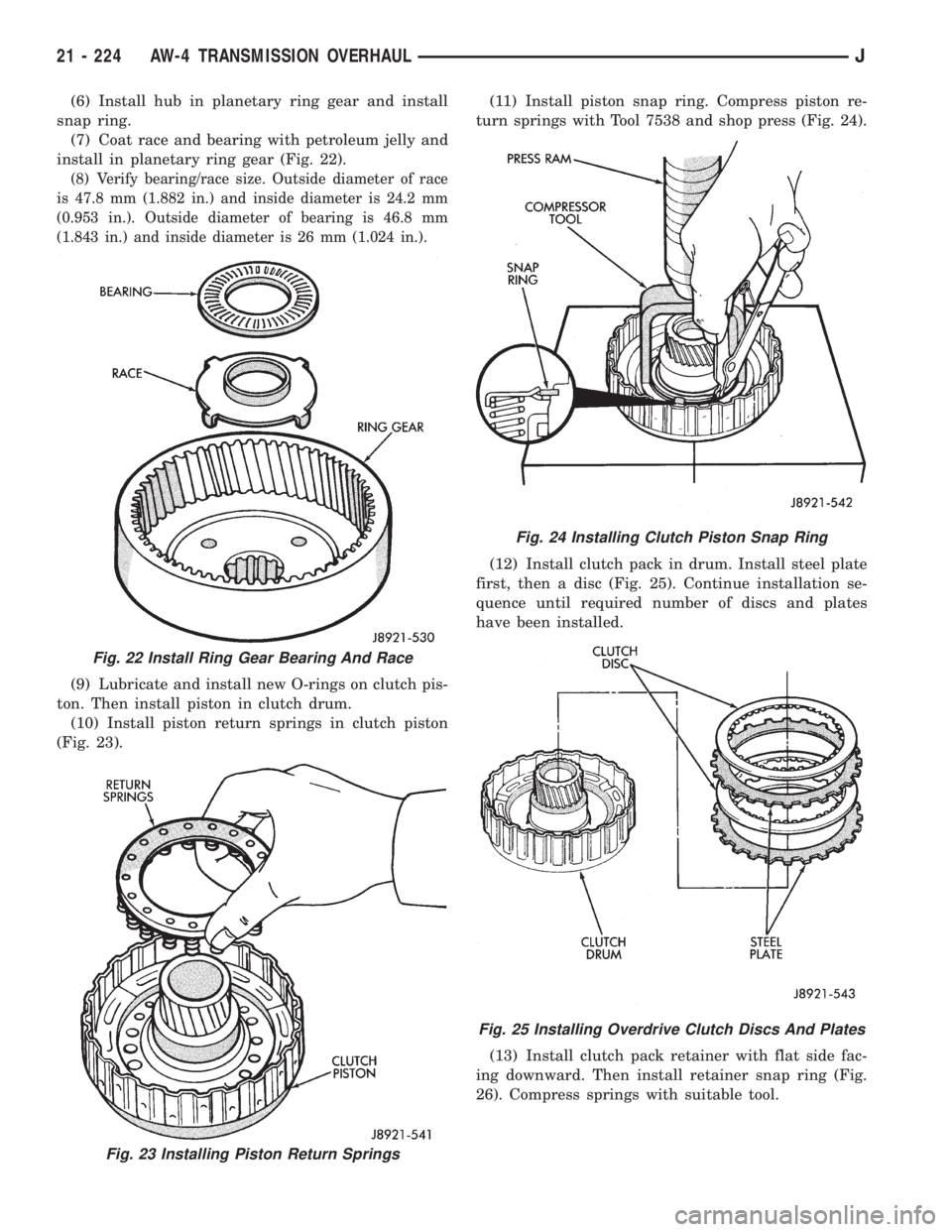

(6) Install hub in planetary ring gear and install

snap ring.

(7) Coat race and bearing with petroleum jelly and

install in planetary ring gear (Fig. 22).

(8) Verify bearing/race size. Outside diameter of race

is 47.8 mm (1.882 in.) and inside diameter is 24.2 mm

(0.953 in.). Outside diameter of bearing is 46.8 mm

(1.843 in.) and inside diameter is 26 mm (1.024 in.).

(9) Lubricate and install new O-rings on clutch pis-

ton. Then install piston in clutch drum.

(10) Install piston return springs in clutch piston

(Fig. 23).(11) Install piston snap ring. Compress piston re-

turn springs with Tool 7538 and shop press (Fig. 24).

(12) Install clutch pack in drum. Install steel plate

first, then a disc (Fig. 25). Continue installation se-

quence until required number of discs and plates

have been installed.

(13) Install clutch pack retainer with flat side fac-

ing downward. Then install retainer snap ring (Fig.

26). Compress springs with suitable tool.

Fig. 22 Install Ring Gear Bearing And Race

Fig. 23 Installing Piston Return Springs

Fig. 24 Installing Clutch Piston Snap Ring

Fig. 25 Installing Overdrive Clutch Discs And Plates

21 - 224 AW-4 TRANSMISSION OVERHAULJ

Page 1787 of 2158

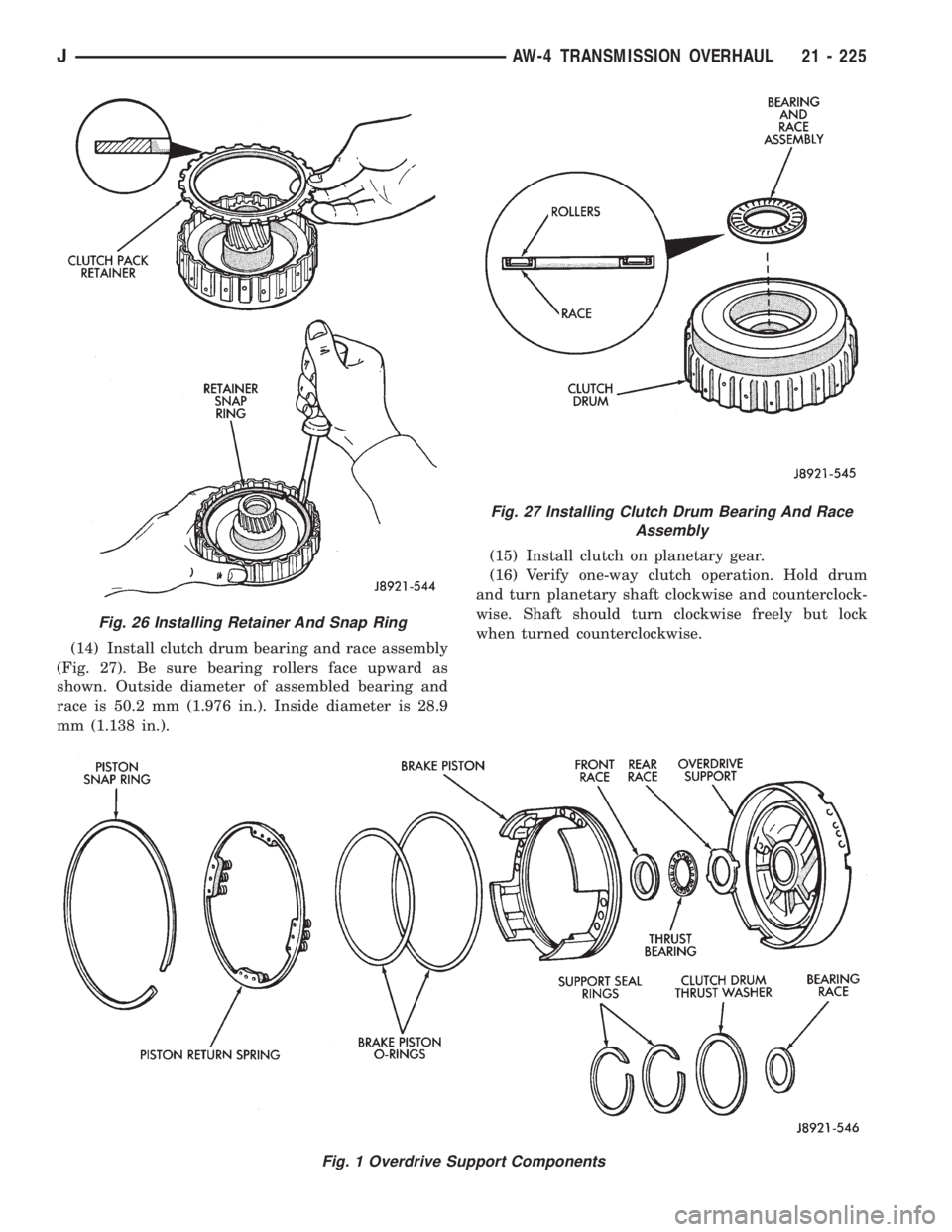

(14) Install clutch drum bearing and race assembly

(Fig. 27). Be sure bearing rollers face upward as

shown. Outside diameter of assembled bearing and

race is 50.2 mm (1.976 in.). Inside diameter is 28.9

mm (1.138 in.).(15) Install clutch on planetary gear.

(16) Verify one-way clutch operation. Hold drum

and turn planetary shaft clockwise and counterclock-

wise. Shaft should turn clockwise freely but lock

when turned counterclockwise.

Fig. 1 Overdrive Support Components

Fig. 26 Installing Retainer And Snap Ring

Fig. 27 Installing Clutch Drum Bearing And Race

Assembly

JAW-4 TRANSMISSION OVERHAUL 21 - 225

Page 1788 of 2158

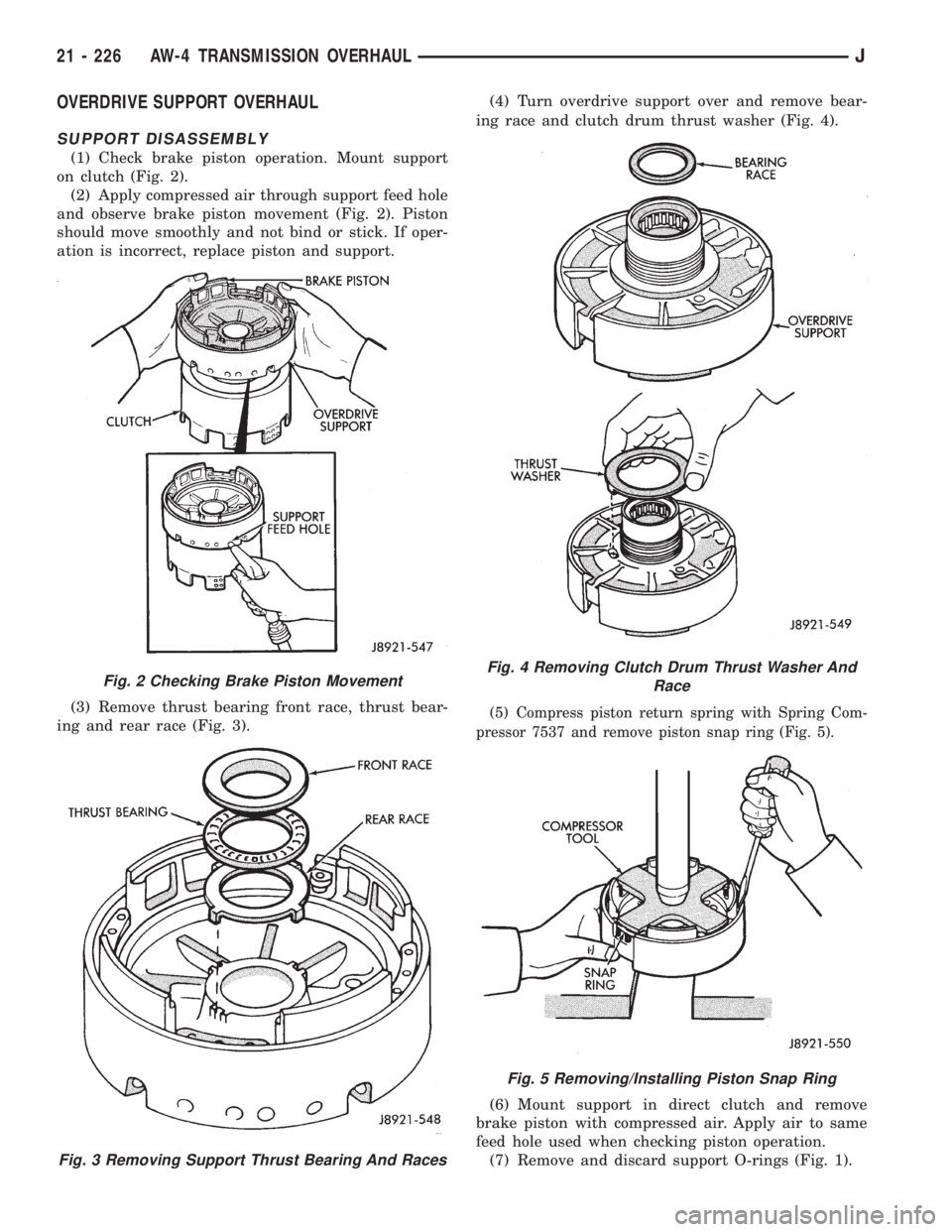

OVERDRIVE SUPPORT OVERHAUL

SUPPORT DISASSEMBLY

(1) Check brake piston operation. Mount support

on clutch (Fig. 2).

(2) Apply compressed air through support feed hole

and observe brake piston movement (Fig. 2). Piston

should move smoothly and not bind or stick. If oper-

ation is incorrect, replace piston and support.

(3) Remove thrust bearing front race, thrust bear-

ing and rear race (Fig. 3).(4) Turn overdrive support over and remove bear-

ing race and clutch drum thrust washer (Fig. 4).

(5) Compress piston return spring with Spring Com-

pressor 7537 and remove piston snap ring (Fig. 5).

(6) Mount support in direct clutch and remove

brake piston with compressed air. Apply air to same

feed hole used when checking piston operation.

(7) Remove and discard support O-rings (Fig. 1).

Fig. 2 Checking Brake Piston Movement

Fig. 3 Removing Support Thrust Bearing And Races

Fig. 4 Removing Clutch Drum Thrust Washer And

Race

Fig. 5 Removing/Installing Piston Snap Ring

21 - 226 AW-4 TRANSMISSION OVERHAULJ

Page 1789 of 2158

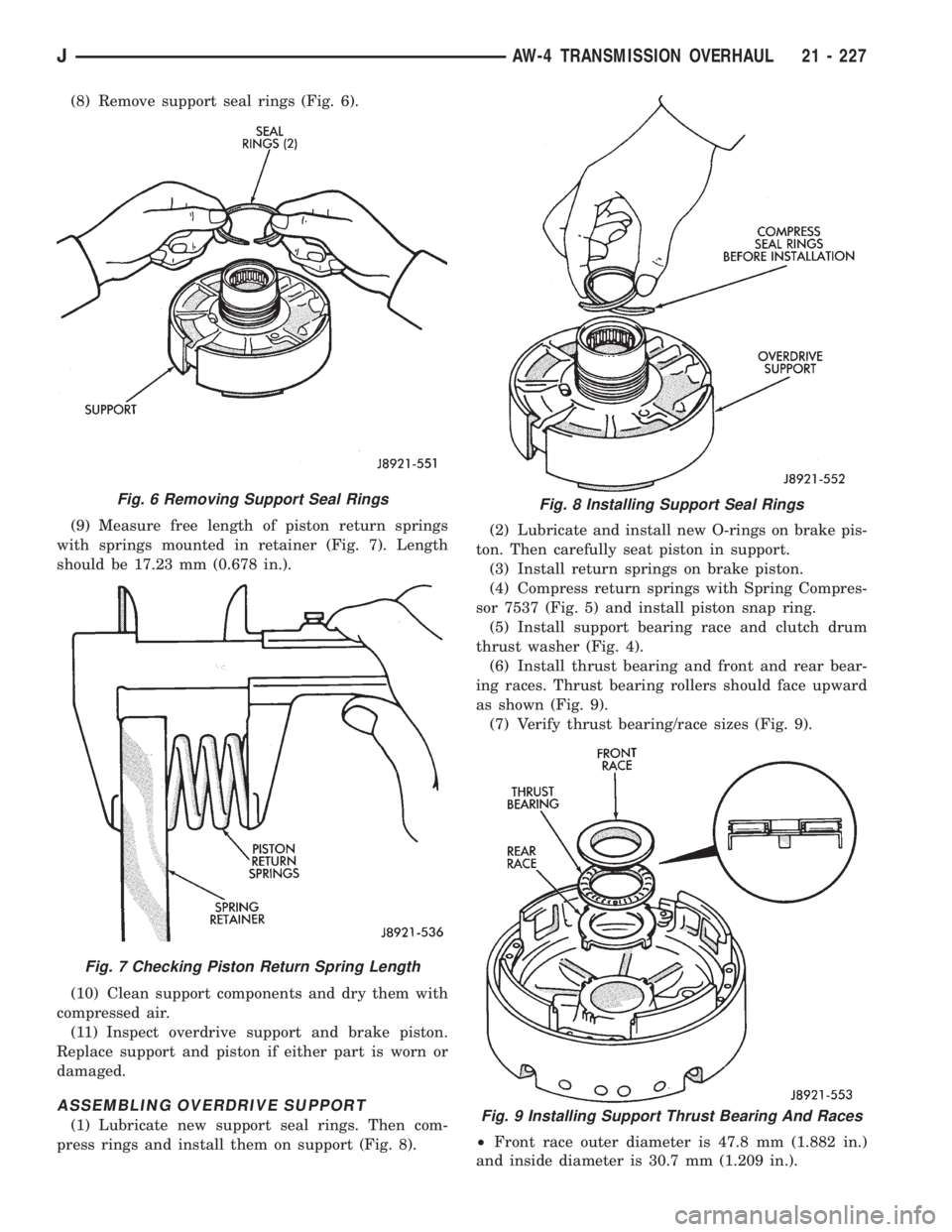

(8) Remove support seal rings (Fig. 6).

(9) Measure free length of piston return springs

with springs mounted in retainer (Fig. 7). Length

should be 17.23 mm (0.678 in.).

(10) Clean support components and dry them with

compressed air.

(11) Inspect overdrive support and brake piston.

Replace support and piston if either part is worn or

damaged.

ASSEMBLING OVERDRIVE SUPPORT

(1) Lubricate new support seal rings. Then com-

press rings and install them on support (Fig. 8).(2) Lubricate and install new O-rings on brake pis-

ton. Then carefully seat piston in support.

(3) Install return springs on brake piston.

(4) Compress return springs with Spring Compres-

sor 7537 (Fig. 5) and install piston snap ring.

(5) Install support bearing race and clutch drum

thrust washer (Fig. 4).

(6) Install thrust bearing and front and rear bear-

ing races. Thrust bearing rollers should face upward

as shown (Fig. 9).

(7) Verify thrust bearing/race sizes (Fig. 9).

²Front race outer diameter is 47.8 mm (1.882 in.)

and inside diameter is 30.7 mm (1.209 in.).

Fig. 6 Removing Support Seal Rings

Fig. 7 Checking Piston Return Spring Length

Fig. 8 Installing Support Seal Rings

Fig. 9 Installing Support Thrust Bearing And Races

JAW-4 TRANSMISSION OVERHAUL 21 - 227

Page 1790 of 2158

²Rear race outer diameter is 47.8 mm (1.882 in.)

and inside diameter is 34.3 mm (1.350 in.).

²Bearing outer diameter is 47.7 mm (1.878 in.) and

inside diameter is 32.7 mm (1.287 in.).

(8) Verify brake piston operation. Use same proce-

dure described at beginning of disassembly. Piston

should operate smoothly and not bind or stick.

DIRECT CLUTCH OVERHAUL

CLUTCH DISASSEMBLY

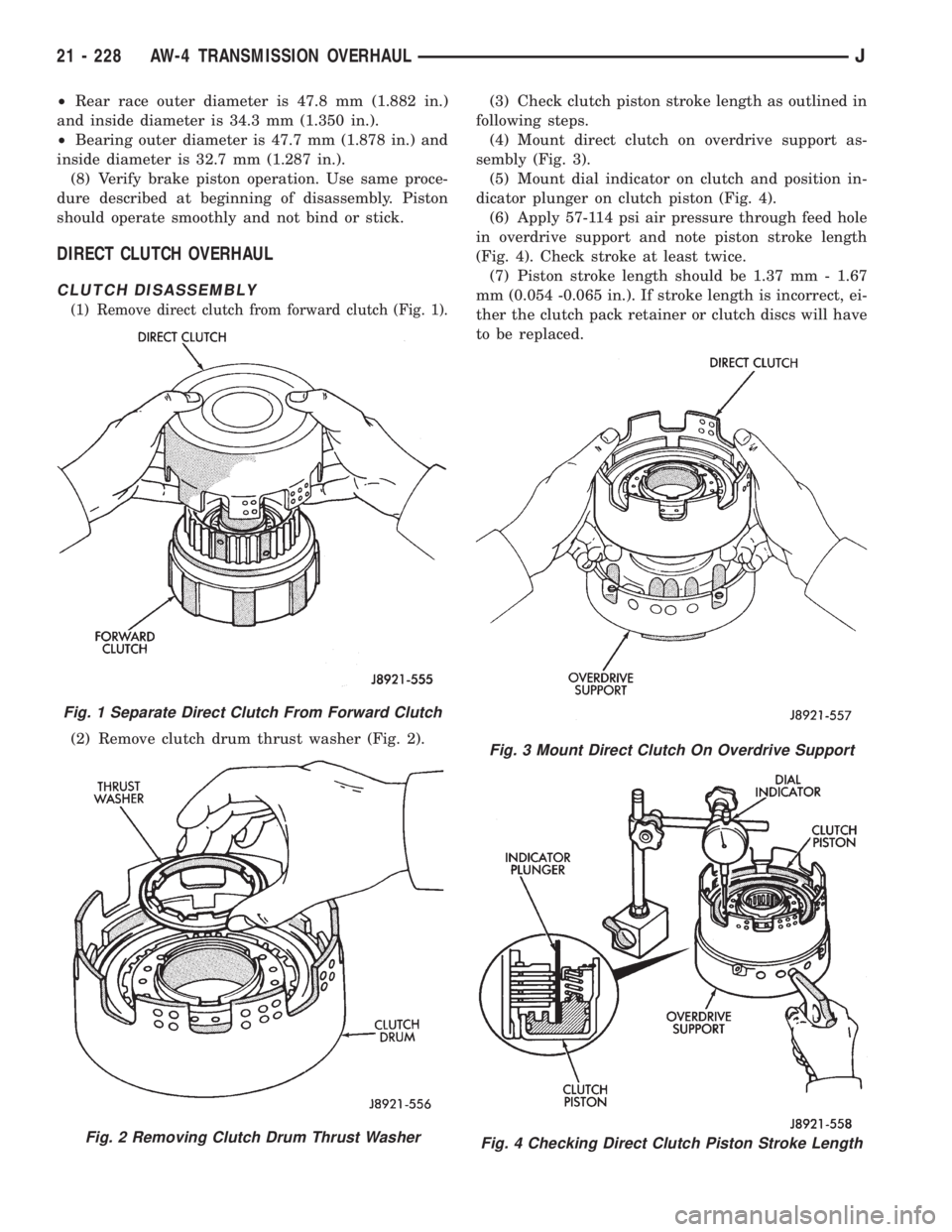

(1) Remove direct clutch from forward clutch (Fig. 1).

(2) Remove clutch drum thrust washer (Fig. 2).(3) Check clutch piston stroke length as outlined in

following steps.

(4) Mount direct clutch on overdrive support as-

sembly (Fig. 3).

(5) Mount dial indicator on clutch and position in-

dicator plunger on clutch piston (Fig. 4).

(6) Apply 57-114 psi air pressure through feed hole

in overdrive support and note piston stroke length

(Fig. 4). Check stroke at least twice.

(7) Piston stroke length should be 1.37 mm - 1.67

mm (0.054 -0.065 in.). If stroke length is incorrect, ei-

ther the clutch pack retainer or clutch discs will have

to be replaced.

Fig. 1 Separate Direct Clutch From Forward Clutch

Fig. 2 Removing Clutch Drum Thrust Washer

Fig. 3 Mount Direct Clutch On Overdrive Support

Fig. 4 Checking Direct Clutch Piston Stroke Length

21 - 228 AW-4 TRANSMISSION OVERHAULJ