belt KIA CARNIVAL 2007 User Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 27 of 1575

a.When pressing the rod, use a vertical vice certainly.

b. There is a high possibility for air to get in the high pressure chamber, when using a horizotal vice.

c. Do not apply more load than 400N on the rod.

d. Do not press the rod until its position is below 2.5mm from the body surface.

e. The projection of the rod is secured more than 2.5mm.

a.Repairing orders when disassembling the auto tensioner and reassembling it to the engine, or pulling

the pin out before its installation ;

a. Stand it vertically for about five minutes.

b. Press the rod with the force, 150~200N.

c. If the rod has a stiffness, press it slowly and insert the pin into the set hole.

d. If not(the tensioner is in 'sponge' state), press the rod slowly from its maximum projection to 2.9mm

position(the meeting point with the rod and the hole of the body) two or three times.

Afterwards, if stiffness is sensed, insert the pin into the hole. However, if not, scrap the tensioner.

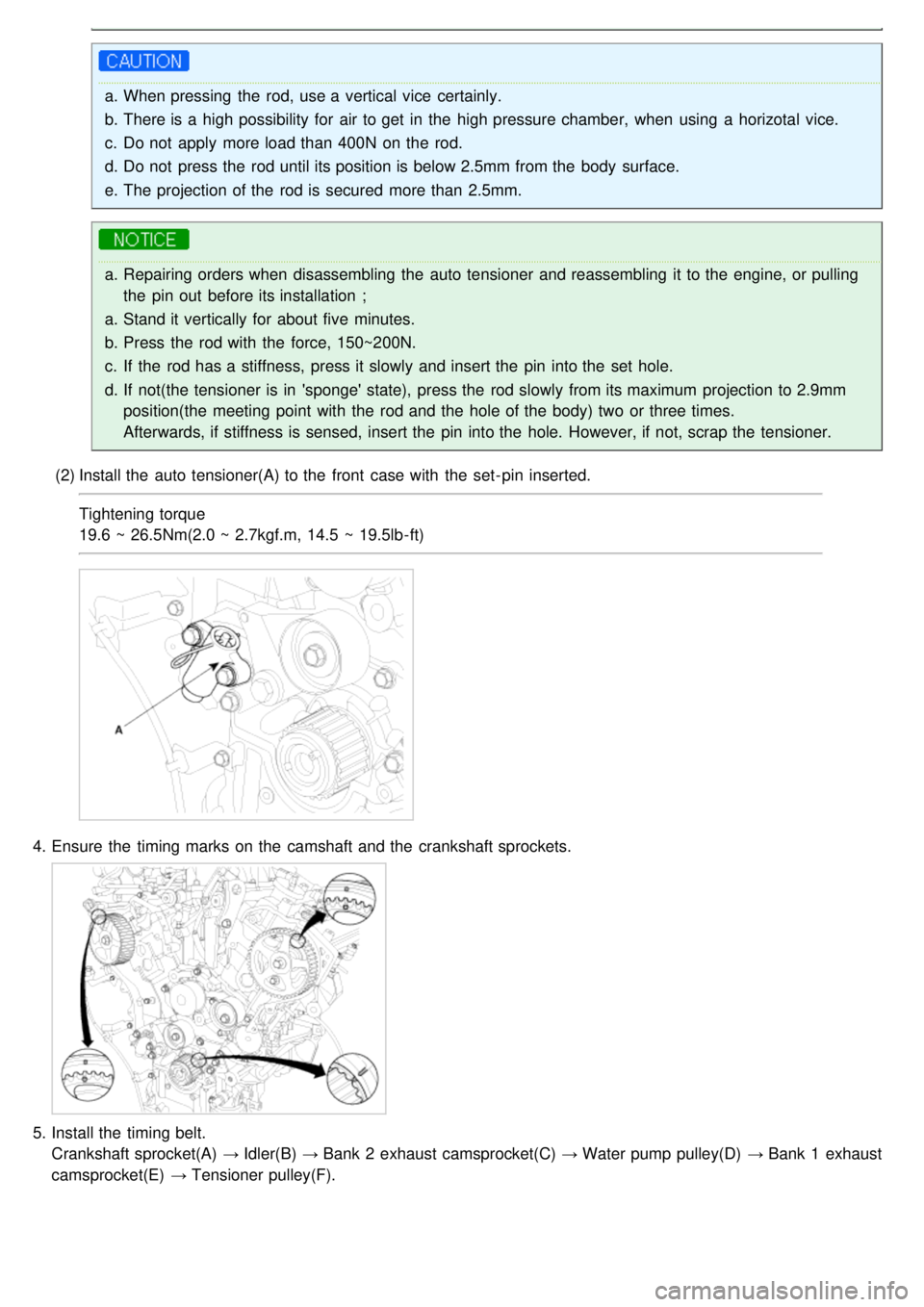

(2) Install the auto tensioner(A) to the front case with the set- pin inserted.

Tightening torque

19.6 ~ 26.5Nm(2.0 ~ 2.7kgf.m, 14.5 ~ 19.5lb- ft)

4.Ensure the timing marks on the camshaft and the crankshaft sprockets.

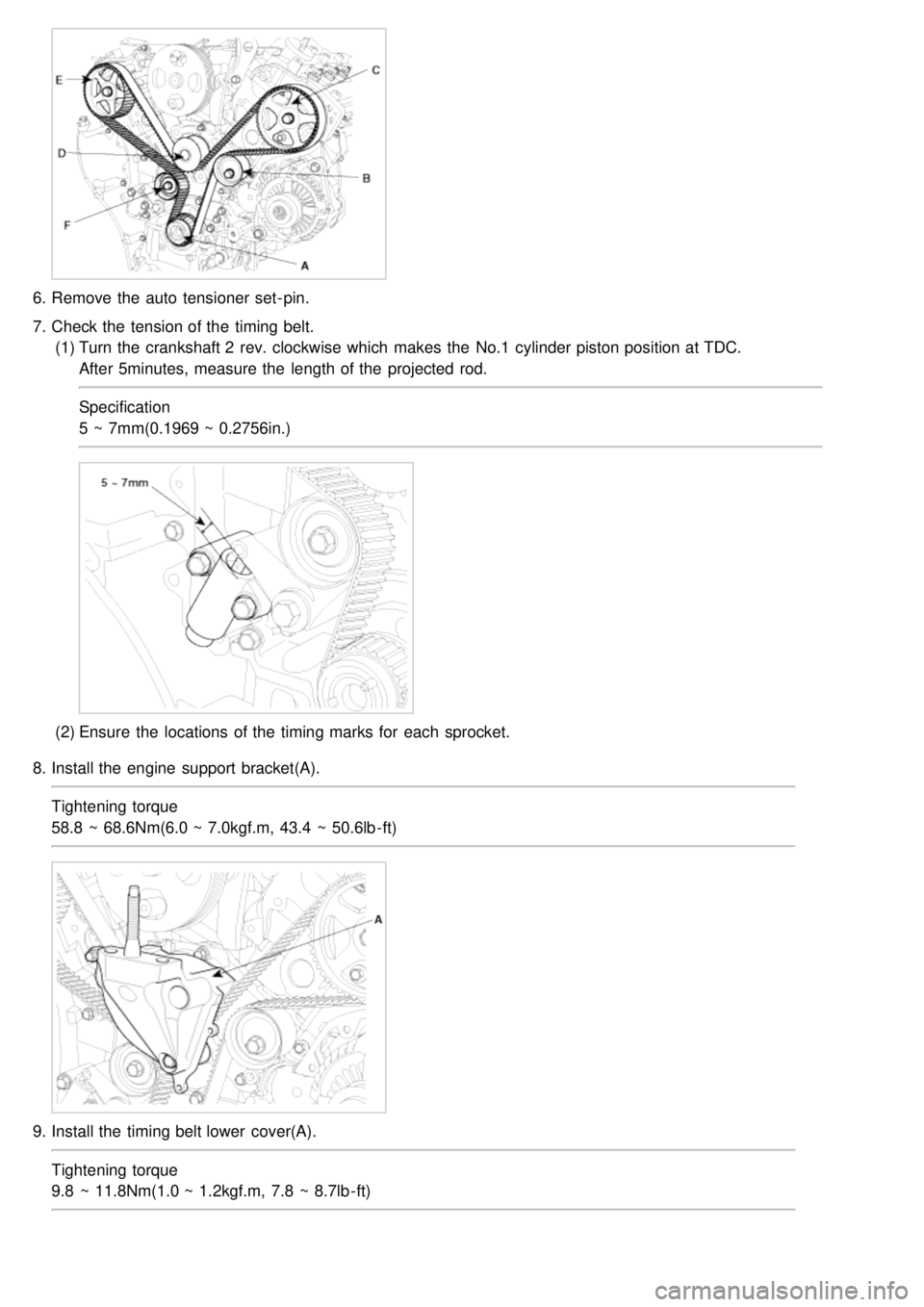

5.Install the timing belt.

Crankshaft sprocket(A) → Idler(B) → Bank 2 exhaust camsprocket(C) → Water pump pulley(D) → Bank 1 exhaust

camsprocket(E) → Tensioner pulley(F).

Page 28 of 1575

6.Remove the auto tensioner set- pin.

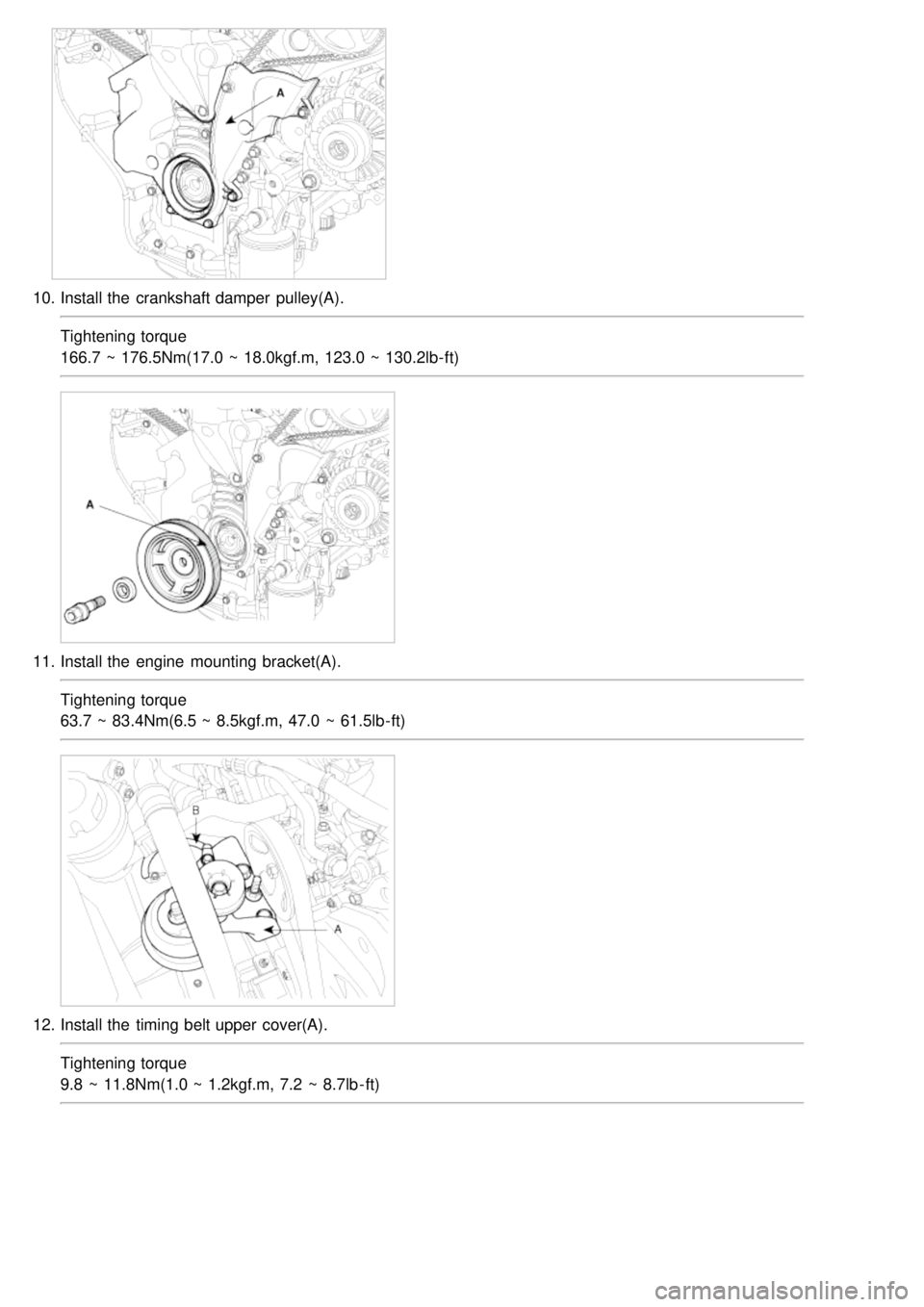

7. Check the tension of the timing belt.

(1) Turn the crankshaft 2 rev. clockwise which makes the No.1 cylinder piston position at TDC.

After 5minutes, measure the length of the projected rod.

Specification

5 ~ 7mm(0.1969 ~ 0.2756in.)

(2)Ensure the locations of the timing marks for each sprocket.

8. Install the engine support bracket(A).

Tightening torque

58.8 ~ 68.6Nm(6.0 ~ 7.0kgf.m, 43.4 ~ 50.6lb- ft)

9.Install the timing belt lower cover(A).

Tightening torque

9.8 ~ 11.8Nm(1.0 ~ 1.2kgf.m, 7.8 ~ 8.7lb - ft)

Page 29 of 1575

10.Install the crankshaft damper pulley(A).

Tightening torque

166.7 ~ 176.5Nm(17.0 ~ 18.0kgf.m, 123.0 ~ 130.2lb- ft)

11.Install the engine mounting bracket(A).

Tightening torque

63.7 ~ 83.4Nm(6.5 ~ 8.5kgf.m, 47.0 ~ 61.5lb- ft)

12.Install the timing belt upper cover(A).

Tightening torque

9.8 ~ 11.8Nm(1.0 ~ 1.2kgf.m, 7.2 ~ 8.7lb - ft)

Page 30 of 1575

13.Install the drive belt tensioner(C).

Tightening torque

34.3 ~ 53.9Nm(3.5 ~ 5.5kgf.m, 25.3 ~ 39.8lb- ft)

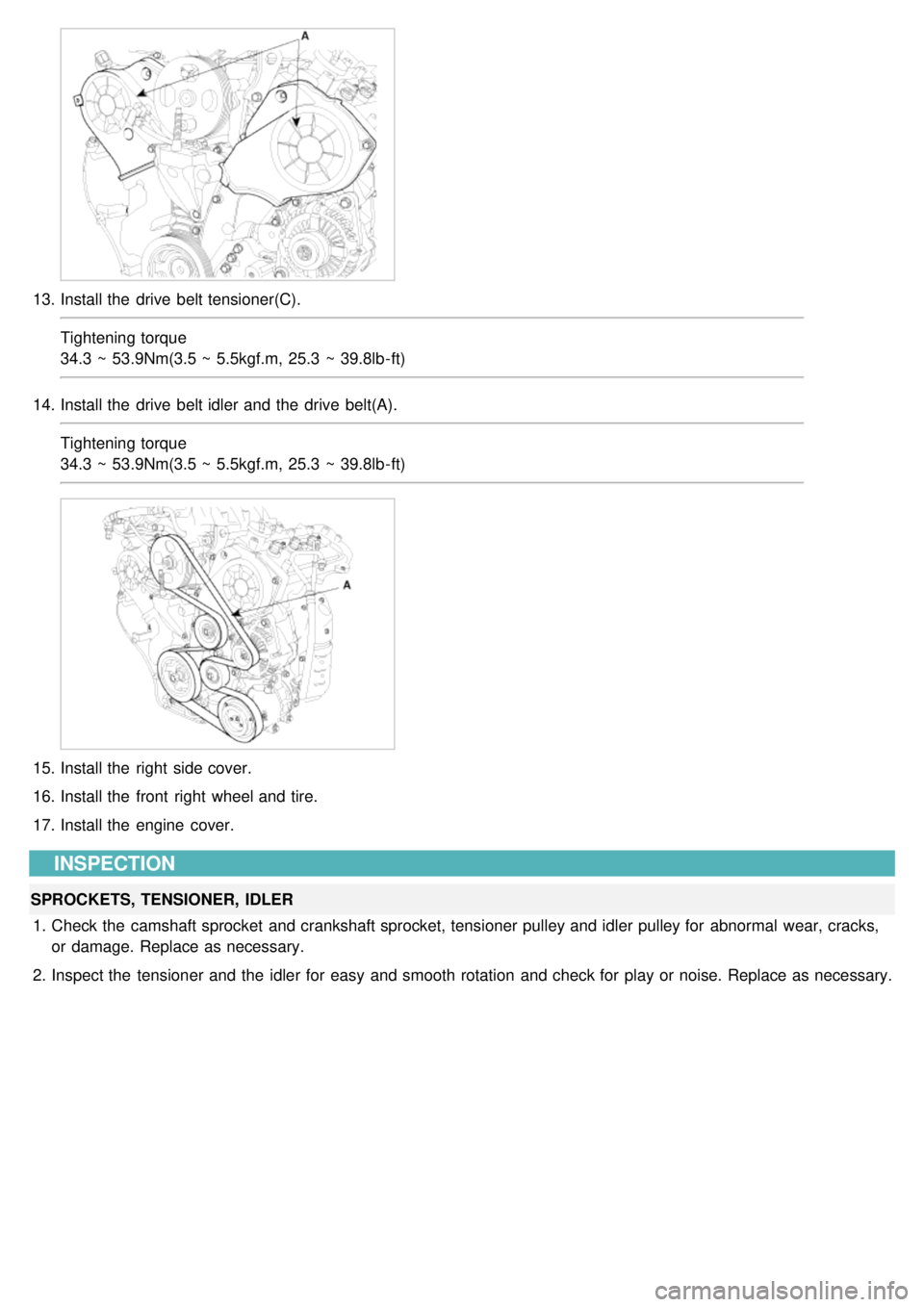

14. Install the drive belt idler and the drive belt(A).

Tightening torque

34.3 ~ 53.9Nm(3.5 ~ 5.5kgf.m, 25.3 ~ 39.8lb- ft)

15.Install the right side cover.

16. Install the front right wheel and tire.

17. Install the engine cover.

INSPECTION

SPROCKETS, TENSIONER, IDLER

1. Check the camshaft sprocket and crankshaft sprocket, tensioner pulley and idler pulley for abnormal wear, cracks,

or damage. Replace as necessary.

2. Inspect the tensioner and the idler for easy and smooth rotation and check for play or noise. Replace as necessary.

Page 31 of 1575

3.Replace the tensioner and the idler if grease is leaked from bearings.

TIMING BELT

1.Check the belt for oil or dust deposits.

Replace, if necessary.

Small deposits should be wiped away with a dry cloth or paper. Do not clean with solvent.

2. When the engine is overhauled or belt tension adjusted, check the belt carefully. If any of the following flaws are

evident, replace the belt.

a.Do not bend, twist or turn the timing belt inside out.

b. Do not allow the timing belt to come into contact with oil, water and steam.

3. Inspect the idler for easy and smooth rotation and check for play or noise.

Page 39 of 1575

8.Disconnect the brake vaccume hose(A).

9.Remove the heater hoses.

10. Remove the drive belt(A).

11.Remove the power steering pump.(Refer to 'ST' group).

12. Remove the exhaust manifold assembly.(Refer to 'Intake and exhause system').

13. Remove the intake manifold assembly.(Refer to 'Intake and exhause system').

14. Remove the timing belt.(Refer to 'Timing system').

15. Remove the ignition coils.

16. Remove the water temp. control assembly.

17. Remove the cylinder head cover(A).

Page 40 of 1575

18.Remove the camshaft bearing cap(A).

19.Remove the timing chain tensioner(A).

20.Remove the camshaft.

21. Remove the bank 2 timing belt rear cover(A).

22.Remove the bank 1 timing belt rear cover(A).

Page 46 of 1575

7.Using the SST(09214- 21000), install the camshaft oil seal.

a.Befor installing, apply engine oil.

b. The camshaft cap surface should adhere to the cylinder head assembly.

c. Do not press an eccentric load.

8. Install the CKP sensor connector bracket(A).

9.Install the bank 1 timing belt rear cover(A).

10. Install the bank 2 timing belt rear cover(A).

Page 47 of 1575

The length of the bolt(B) is longer than that of the bolt(C).

11. Install the timing belt.(Refer to 'Timing system').

12. Check and adjust the valve clearance.

13. Install the cylinder head cover.

(1) Remove oil, dust or sealant on the upper surface of the cylinder before assembling cylinder head cover.

(2) Assemble the cylinder head cover in five minites after applying liquid gasket(LOCTITE 5900) on the camshaft

cap and packing part.

(3)Tighten the cylinder head cover bolts as following order(A).

Tightening torque

7.8~9.8Nm(0.8~1.0kgf.m, 5.8~7.2lb- ft)

Page 48 of 1575

a.Do not start engine for thirty minites after assembling the cylinder head cover.

b. Do not reuse the cylinder head cover gasket.

14. Install the water temp. control assembly.

15. Install the intake manifold assembly.

16. Install the exhaust mainfold assembly.

17. Install the power steering pump.(Refer to 'ST' group).

18. Install the drive belt(A).

19.Install the heater hose.

20. Connect the brake vaccume hose(A).

21.Install the PCV(Pulge Control Valve) hose(A).

22.Connect the engine wiring harness connectors.

(1) Connect the bank 1 CMP sensor connector(A).