belt KIA CARNIVAL 2007 Owner's Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 75 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

1.Remove the drive plate(A).

2.Remove the rear plate(A).

3.Remove timing belt.

4. Remove intake manifold.

5. Remove exhaust manifold.

6. Remove generator from engine.(Refer to 'ST' group).

7. Remove power steering pump from engine.(Refer to 'HA' group).

8. Remove cylinder head.

9. Remove A/C compressor from engine.(Refer to 'EE' group).

10. Remove water pump assembly.

INSTALLATION

1.Install the water pump.

2. Install the air conditioning compressor.(Refer to 'HA' group).

3. Install the cylinder head.

4. Install the power steering pump.(Refer to 'ST' group).

5. Install the generator.

6. Install the intake manifold.

7. Install the exhaust manifold.

8. Install the timing belt.

9. Install the rear plate(A).

Tightening torque

Page 92 of 1575

Piston pin- to- connecting rod interference

- 0.033 ~ - 0.016mm ( - 0.0013 ~ - 0.0006in.)

REASSEMBLY

a.Thoroughly clean all parts before reassembling.

b. Before installing the parts, apply fresh engine oil to all sliding and rotating surfaces.

c. Replace all gaskets, O - rings and oil seals with new parts.

1. Assemble the piston and the connecting rod.

(1) Use a hydraulic press for installation.

(2) The piston front mark(A) and the connecting rod front mark must face the timing belt side of the engine.

2.Install piston rings.

(1) Install the oil ring spacer and 2 side rails by hand.

(2) Using a piston ring expander, install the 2 compression rings with the code mark facing upward.

(3) Position the piston rings so that the ring ends are as shown.

3.Install the connecting rod bearings.

(1) Align the bearing(A) claw with the groove of the connecting rod or connecting rod cap(B).

(2) Install the bearings(A) in the connecting rod and connecting rod cap(B).

Page 103 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

WATER PUMP

1. Drain the engine coolant.

System is under high pressure when the engine is hot. To avoid danger of releasing scalding engine coolant,

remove the cap only when the engine is cool.

2. Remove drive belt(A).

3.Remove the timing belt.

4. Remove the water pump(A) and gasket(B).

WATER TEMPERATURE CONTROL ASSEMBLY

1.Drain the engine coolant.

2. Remove the air cleaner assembly.

3. Disconnect the radiator upper and lower hose(A, B).

Page 108 of 1575

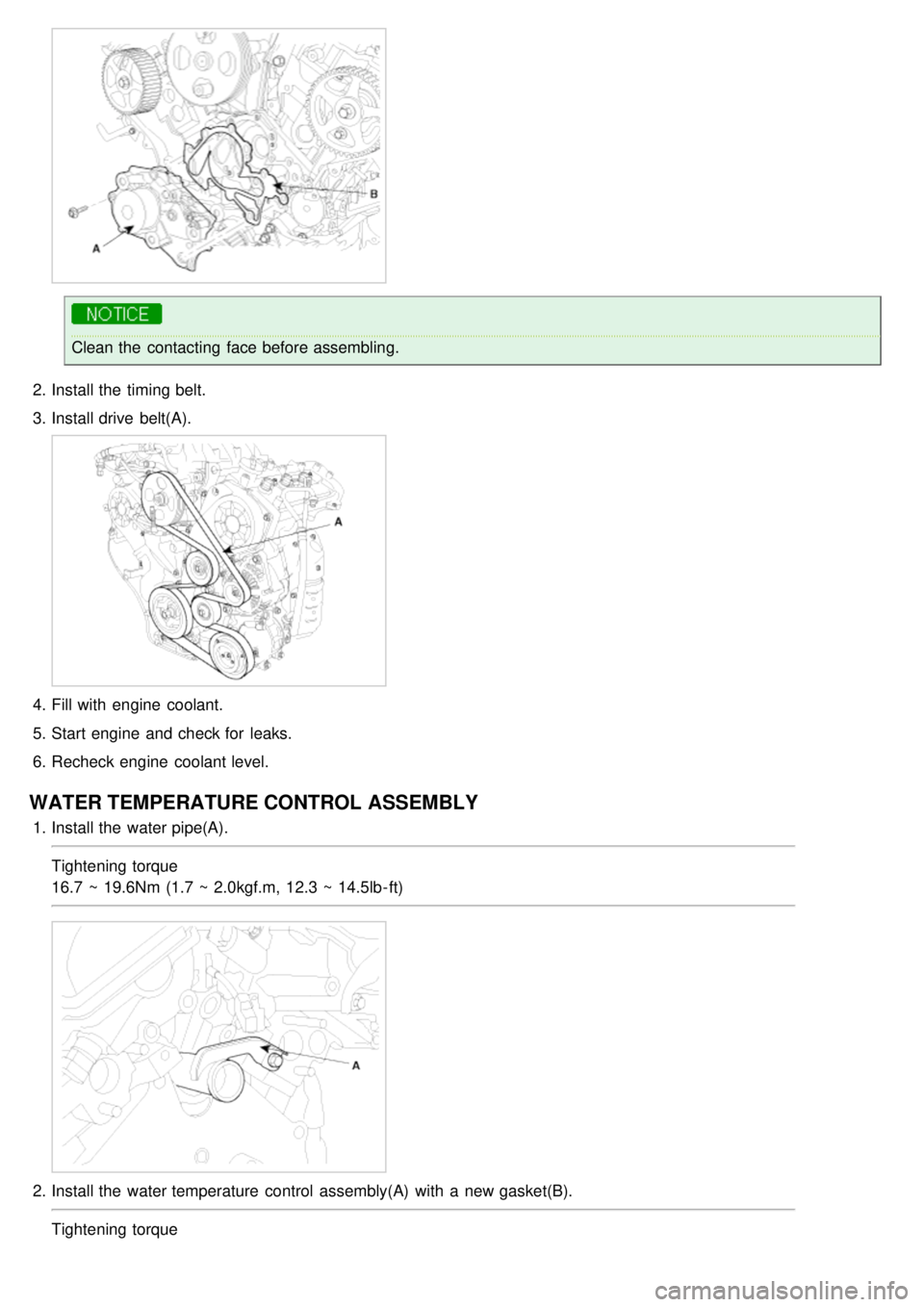

Clean the contacting face before assembling.

2. Install the timing belt.

3. Install drive belt(A).

4.Fill with engine coolant.

5. Start engine and check for leaks.

6. Recheck engine coolant level.

WATER TEMPERATURE CONTROL ASSEMBLY

1.Install the water pipe(A).

Tightening torque

16.7 ~ 19.6Nm (1.7 ~ 2.0kgf.m, 12.3 ~ 14.5lb- ft)

2.Install the water temperature control assembly(A) with a new gasket(B).

Tightening torque

Page 117 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

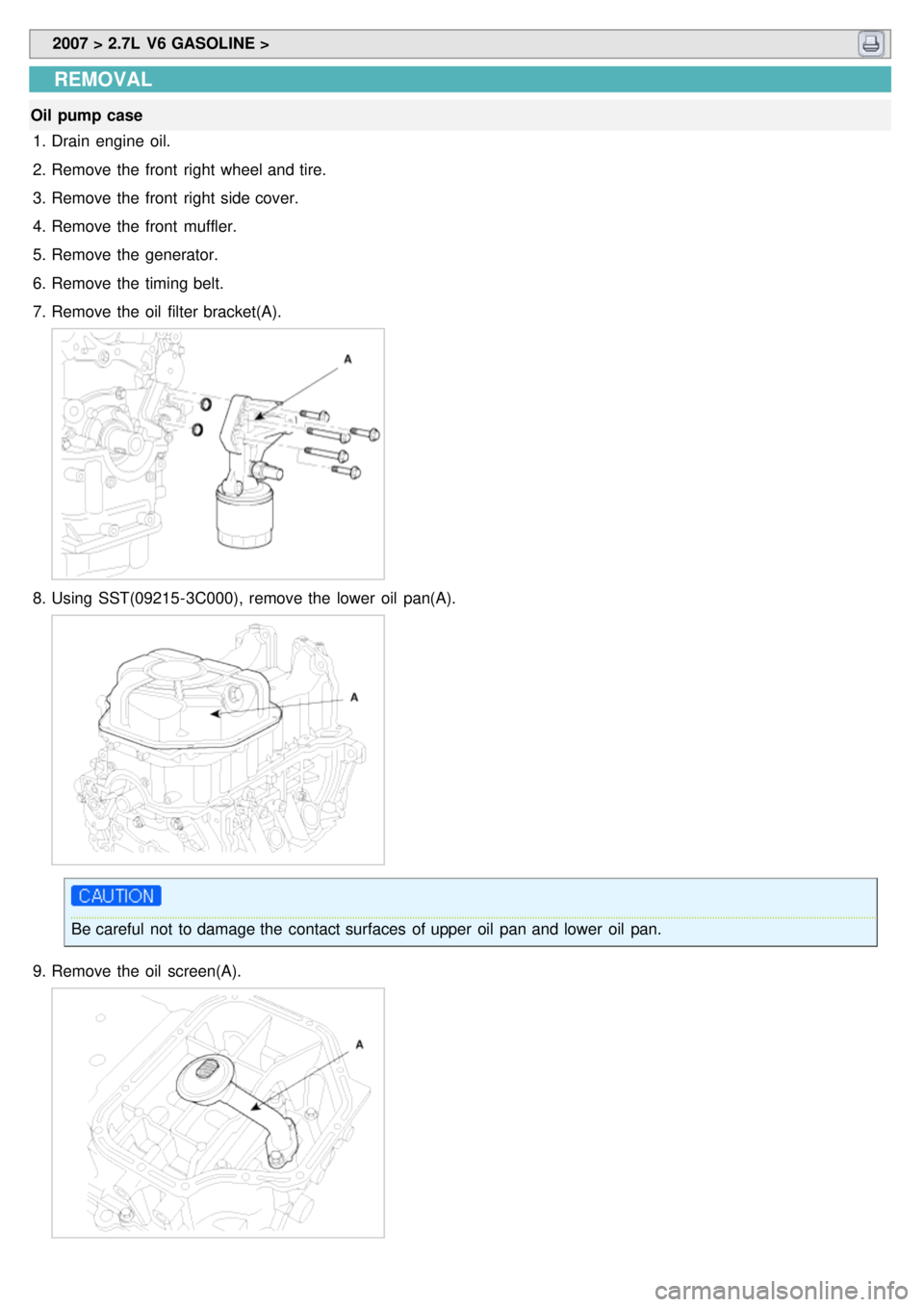

Oil pump case

1. Drain engine oil.

2. Remove the front right wheel and tire.

3. Remove the front right side cover.

4. Remove the front muffler.

5. Remove the generator.

6. Remove the timing belt.

7. Remove the oil filter bracket(A).

8.Using SST(09215- 3C000), remove the lower oil pan(A).

Be careful not to damage the contact surfaces of upper oil pan and lower oil pan.

9. Remove the oil screen(A).

Page 124 of 1575

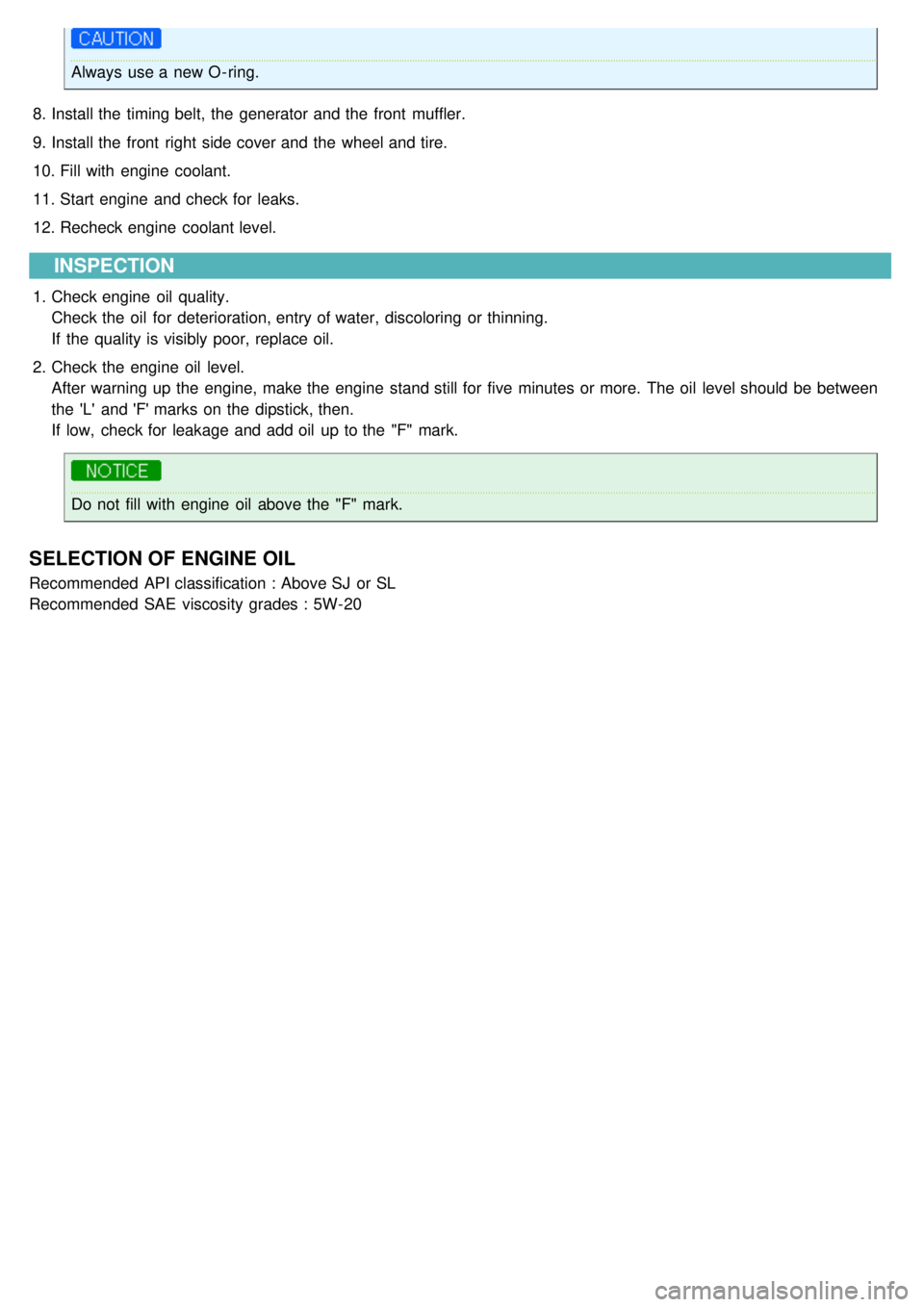

Always use a new O - ring.

8. Install the timing belt, the generator and the front muffler.

9. Install the front right side cover and the wheel and tire.

10. Fill with engine coolant.

11. Start engine and check for leaks.

12. Recheck engine coolant level.

INSPECTION

1.Check engine oil quality.

Check the oil for deterioration, entry of water, discoloring or thinning.

If the quality is visibly poor, replace oil.

2. Check the engine oil level.

After warning up the engine, make the engine stand still for five minutes or more. The oil level should be between

the 'L' and 'F' marks on the dipstick, then.

If low, check for leakage and add oil up to the "F" mark.

Do not fill with engine oil above the "F" mark.

SELECTION OF ENGINE OIL

Recommended API classification : Above SJ or SL

Recommended SAE viscosity grades : 5W- 20

Page 147 of 1575

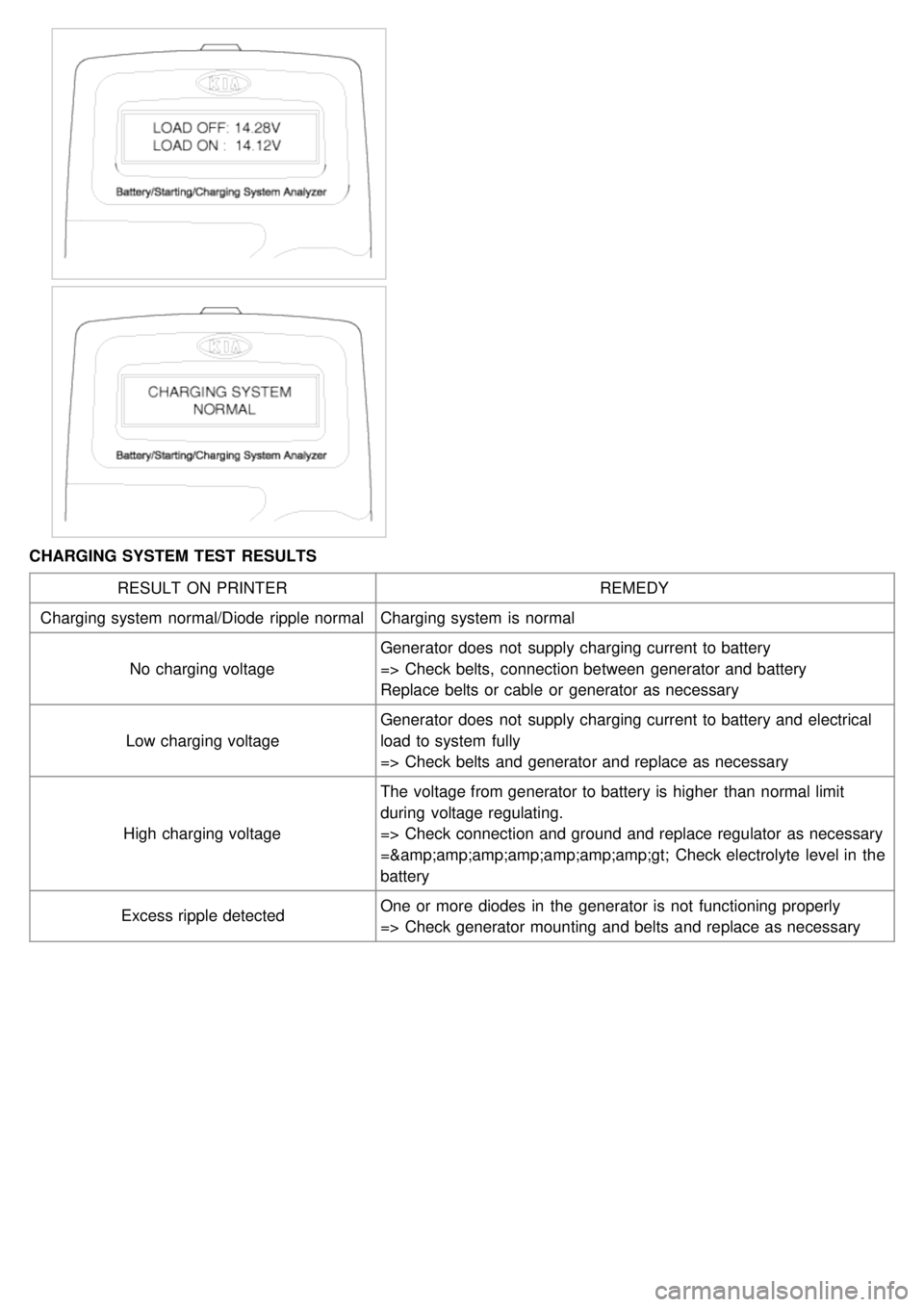

CHARGING SYSTEM TEST RESULTSRESULT ON PRINTER REMEDY

Charging system normal/Diode ripple normal Charging system is normal

No charging voltage Generator does not supply charging current to battery

=> Check belts, connection between generator and battery

Replace belts or cable or generator as necessary

Low charging voltage Generator does not supply charging current to battery and electrical

load to system fully

=> Check belts and generator and replace as necessary

High charging voltage The voltage from generator to battery is higher than normal limit

during voltage regulating.

=> Check connection and ground and replace regulator as necessary

=> Check electrolyte level in the

battery

Excess ripple detected One or more diodes in the generator is not functioning properly

=> Check generator mounting and belts and replace as necessary

Page 149 of 1575

2007 > 2.7L V6 GASOLINE >

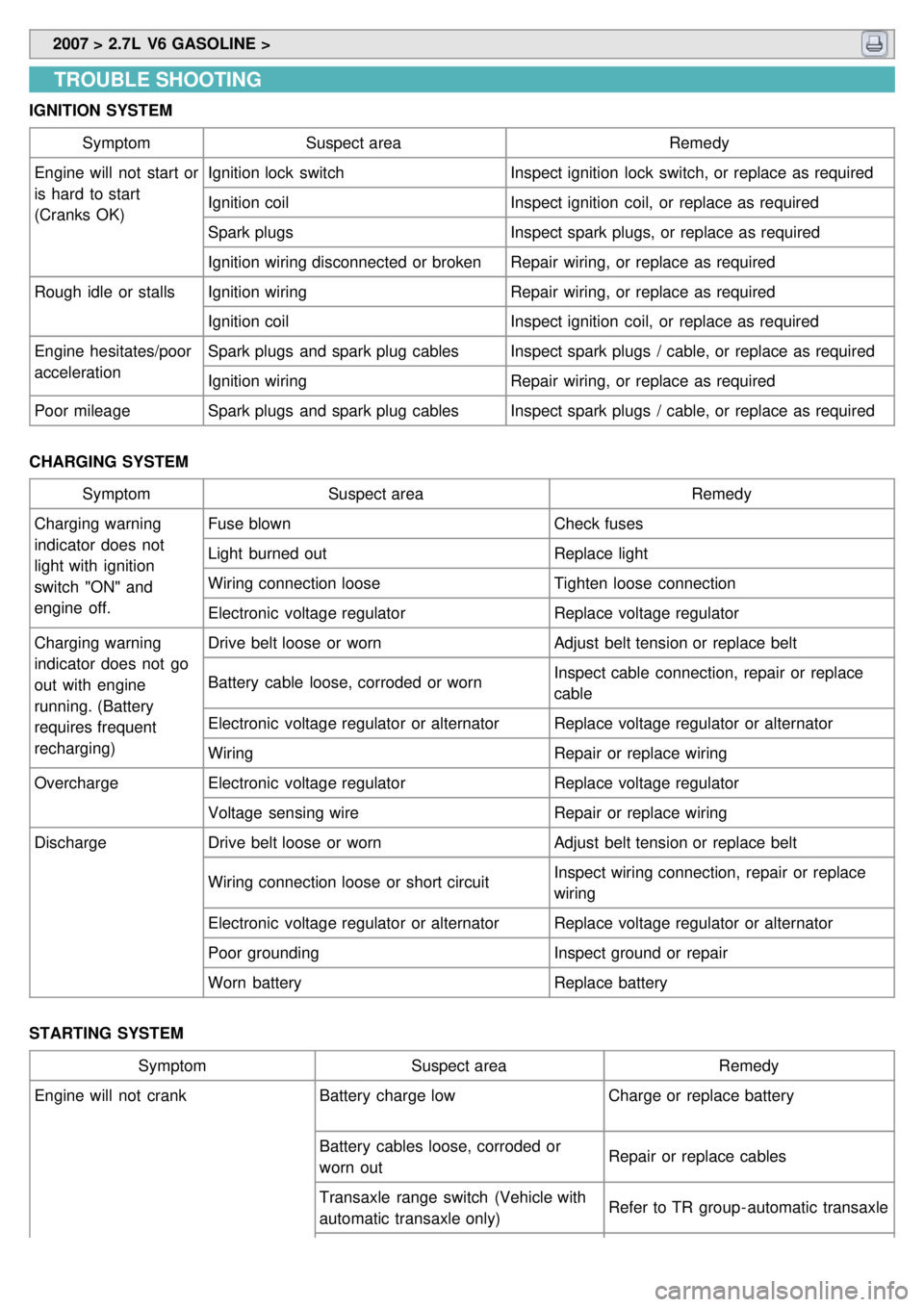

TROUBLE SHOOTING

IGNITION SYSTEM

Symptom Suspect area Remedy

Engine will not start or

is hard to start

(Cranks OK) Ignition lock switch

Inspect ignition lock switch, or replace as required

Ignition coil Inspect ignition coil, or replace as required

Spark plugs Inspect spark plugs, or replace as required

Ignition wiring disconnected or broken Repair wiring, or replace as required

Rough idle or stalls Ignition wiring Repair wiring, or replace as required

Ignition coil Inspect ignition coil, or replace as required

Engine hesitates/poor

acceleration Spark plugs and spark plug cables

Inspect spark plugs / cable, or replace as required

Ignition wiring Repair wiring, or replace as required

Poor mileage Spark plugs and spark plug cables Inspect spark plugs / cable, or replace as required

CHARGING SYSTEM Symptom Suspect area Remedy

Charging warning

indicator does not

light with ignition

switch "ON" and

engine off. Fuse blown

Check fuses

Light burned out Replace light

Wiring connection loose Tighten loose connection

Electronic voltage regulator Replace voltage regulator

Charging warning

indicator does not go

out with engine

running. (Battery

requires frequent

recharging) Drive belt loose or worn

Adjust belt tension or replace belt

Battery cable loose, corroded or worn Inspect cable connection, repair or replace

cable

Electronic voltage regulator or alternator Replace voltage regulator or alternator

Wiring Repair or replace wiring

Overcharge Electronic voltage regulator Replace voltage regulator

Voltage sensing wire Repair or replace wiring

Discharge Drive belt loose or worn Adjust belt tension or replace belt

Wiring connection loose or short circuit Inspect wiring connection, repair or replace

wiring

Electronic voltage regulator or alternator Replace voltage regulator or alternator

Poor grounding Inspect ground or repair

Worn battery Replace battery

STARTING SYSTEM Symptom Suspect area Remedy

Engine will not crank Battery charge low Charge or replace battery

Battery cables loose, corroded or

worn out Repair or replace cables

Transaxle range switch (Vehicle with

automatic transaxle only) Refer to TR group - automatic transaxle

Page 159 of 1575

2007 > 2.7L V6 GASOLINE >

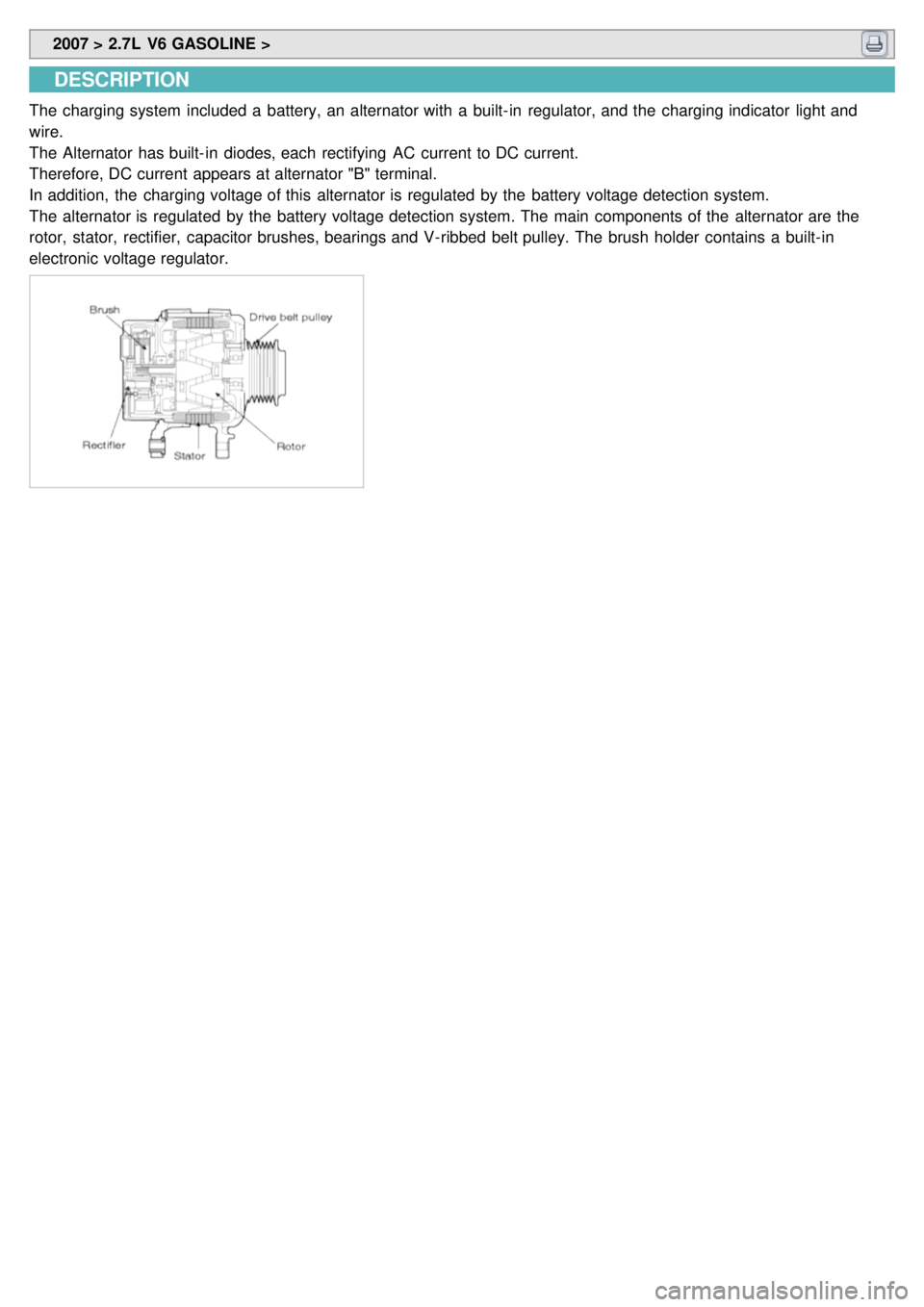

DESCRIPTION

The charging system included a battery, an alternator with a built- in regulator, and the charging indicator light and

wire.

The Alternator has built- in diodes, each rectifying AC current to DC current.

Therefore, DC current appears at alternator "B" terminal.

In addition, the charging voltage of this alternator is regulated by the battery voltage detection system.

The alternator is regulated by the battery voltage detection system. The main components of the alternator are the

rotor, stator, rectifier, capacitor brushes, bearings and V- ribbed belt pulley. The brush holder contains a built- in

electronic voltage regulator.

Page 160 of 1575

2007 > 2.7L V6 GASOLINE >

ON-VEHICLE INPECTION

a.Check that the battery cables are connected to the correct terminals.

b. Disconnect the battery cables when the battery is given a quick charge.

c. Never disconnect the battery while the engine is running.

CHECK BATTERY VOLTAGE

1.If 20 minutes have not passed since the engine was stopped, turn the ignition switch ON and turn on the electrical

system (headlamp, blower motor, rear defogger etc.) for 60 seconds to remove the surface charge.

2. Turn the ignition switch OFF and turn off the electrical systems.

3. Measure the battery voltage between the negative ( - ) and positive (+) terminals of the battery.

Standard voltage : 12.5 ~ 12.9V at 20°C(68°F)

If the voltage is less than specification, charge the battery.

CHECK THE BATTERY TERMINALS AND FUSES

1.Check that the battery terminals are not loose or corroded.

2. Check the fuses for continuity.

INSPECT DRIVE BELT

Visually check the belt for excessive wear, frayed cords etc.

If any defect has been found, replace the drive belt.

Cracks on the rib side of a belt are considered acceptable. If the belt has chunks missing from the ribs, it should

be replaced.

VISUALLY CHECK ALTERNATOR WIRING AND LISTEN FOR ABNORMAL NOISES

1.Check that the wiring is in good condition.

2. Check that there is no abnormal noise from the alternator while the engine is running.

CHECK DISCHARGE WARNING LIGHT CIRCUIT

1.Warm up the engine and then turn it off.

2. Turn off all accessories.

3. Turn the ignition switch "ON". Check that the discharge warning light is lit.

4. Start the engine. Check that the light is lit.

If the light does not go off as specified, troubleshoot the discharge light circuit.

INSPECT CHARGING SYSTEM

VOLTAGE DROP TEST OF ALTERNATOR OUTPUT WIRE

This test determines whether or not the wiring between the alternator "B" terminal and the battery (+) terminal is good

by the voltage drop method.

PREPARATION