KIA CARNIVAL 2007 Workshop Manual

Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 351 of 1575

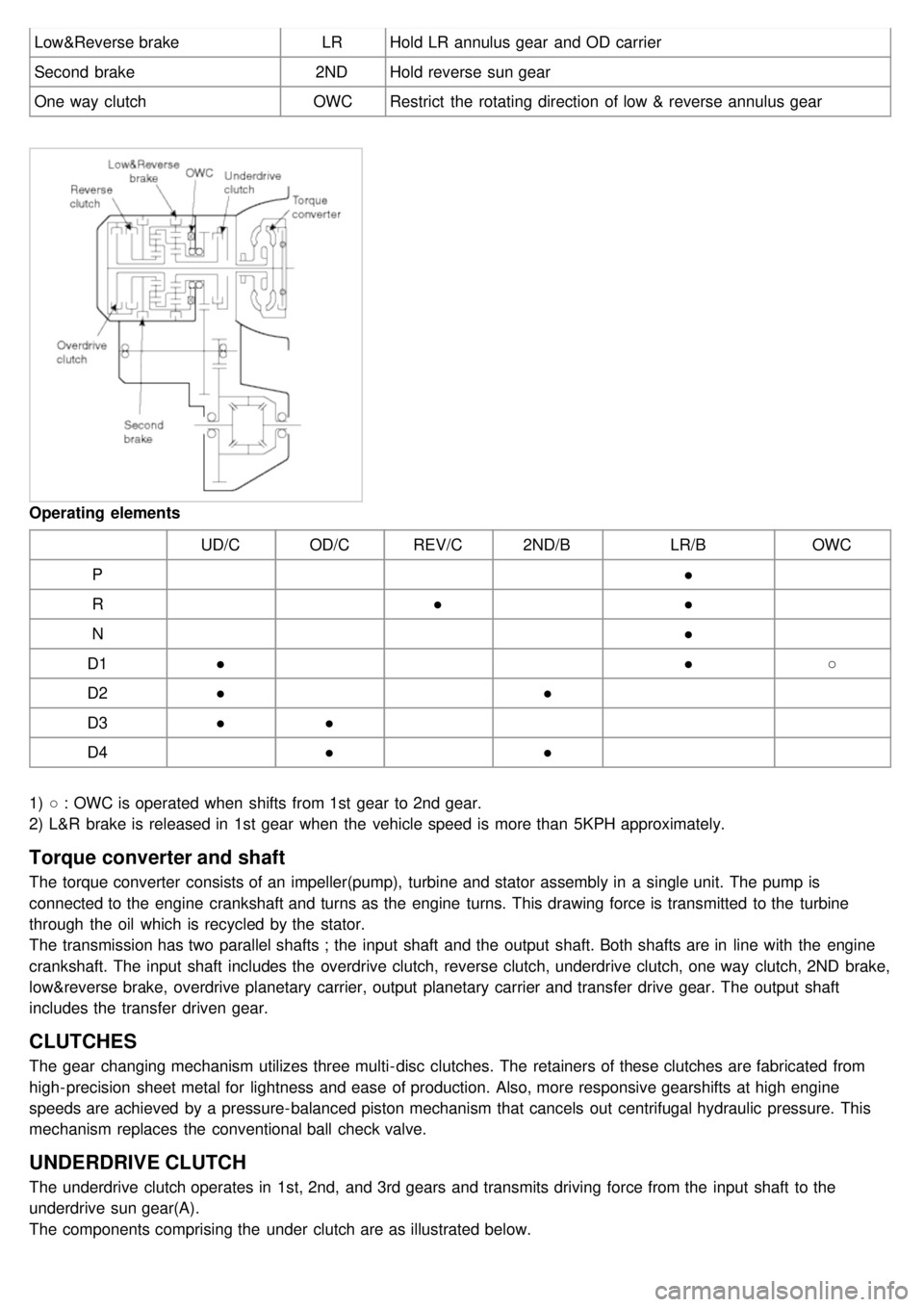

Low&Reverse brakeLRHold LR annulus gear and OD carrier

Second brake 2NDHold reverse sun gear

One way clutch OWCRestrict the rotating direction of low & reverse annulus gear

Operating elements

UD/COD/CREV/C 2ND/B LR/BOWC

P ●

R ●●

N ●

D1 ● ●○

D2 ● ●

D3 ●●

D4 ●●

1) ○ : OWC is operated when shifts from 1st gear to 2nd gear.

2) L&R brake is released in 1st gear when the vehicle speed is more than 5KPH approximately.

Torque converter and shaft

The torque converter consists of an impeller(pump), turbine and stator assembly in a single unit. The pump is

connected to the engine crankshaft and turns as the engine turns. This drawing force is transmitted to the turbine

through the oil which is recycled by the stator.

The transmission has two parallel shafts ; the input shaft and the output shaft. Both shafts are in line with the engine

crankshaft. The input shaft includes the overdrive clutch, reverse clutch, underdrive clutch, one way clutch, 2ND brake,

low&reverse brake, overdrive planetary carrier, output planetary carrier and transfer drive gear. The output shaft

includes the transfer driven gear.

CLUTCHES

The gear changing mechanism utilizes three multi- disc clutches. The retainers of these clutches are fabricated from

high- precision sheet metal for lightness and ease of production. Also, more responsive gearshifts at high engine

speeds are achieved by a pressure- balanced piston mechanism that cancels out centrifugal hydraulic pressure. This

mechanism replaces the conventional ball check valve.

UNDERDRIVE CLUTCH

The underdrive clutch operates in 1st, 2nd, and 3rd gears and transmits driving force from the input shaft to the

underdrive sun gear(A).

The components comprising the under clutch are as illustrated below.

Page 352 of 1575

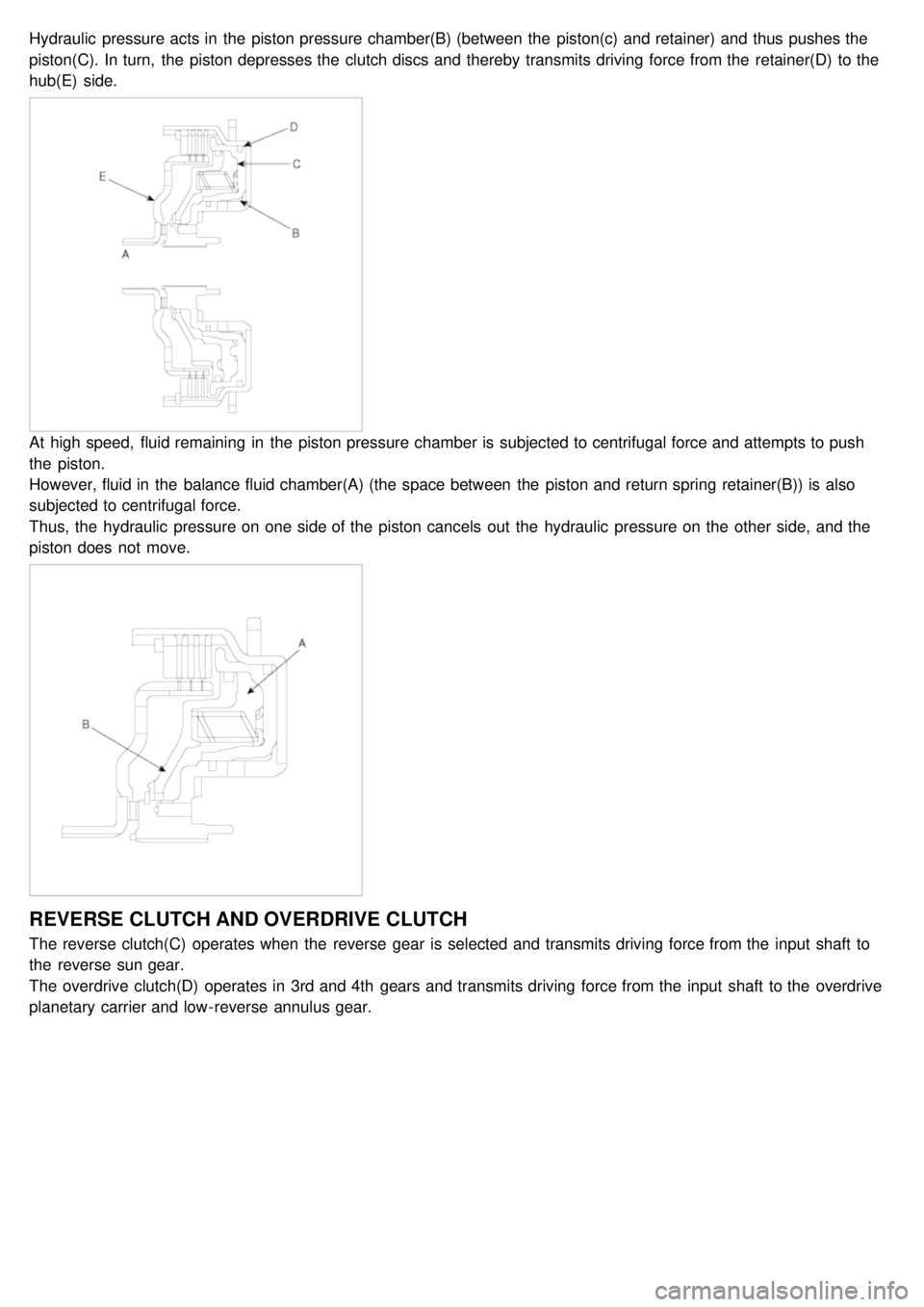

Hydraulic pressure acts in the piston pressure chamber(B) (between the piston(c) and retainer) and thus pushes the

piston(C). In turn, the piston depresses the clutch discs and thereby transmits driving force from the retainer(D) to the

hub(E) side.

At high speed, fluid remaining in the piston pressure chamber is subjected to centrifugal force and attempts to push

the piston.

However, fluid in the balance fluid chamber(A) (the space between the piston and return spring retainer(B)) is also

subjected to centrifugal force.

Thus, the hydraulic pressure on one side of the piston cancels out the hydraulic pressure on the other side, and the

piston does not move.

REVERSE CLUTCH AND OVERDRIVE CLUTCH

The reverse clutch(C) operates when the reverse gear is selected and transmits driving force from the input shaft to

the reverse sun gear.

The overdrive clutch(D) operates in 3rd and 4th gears and transmits driving force from the input shaft to the overdrive

planetary carrier and low- reverse annulus gear.

Page 353 of 1575

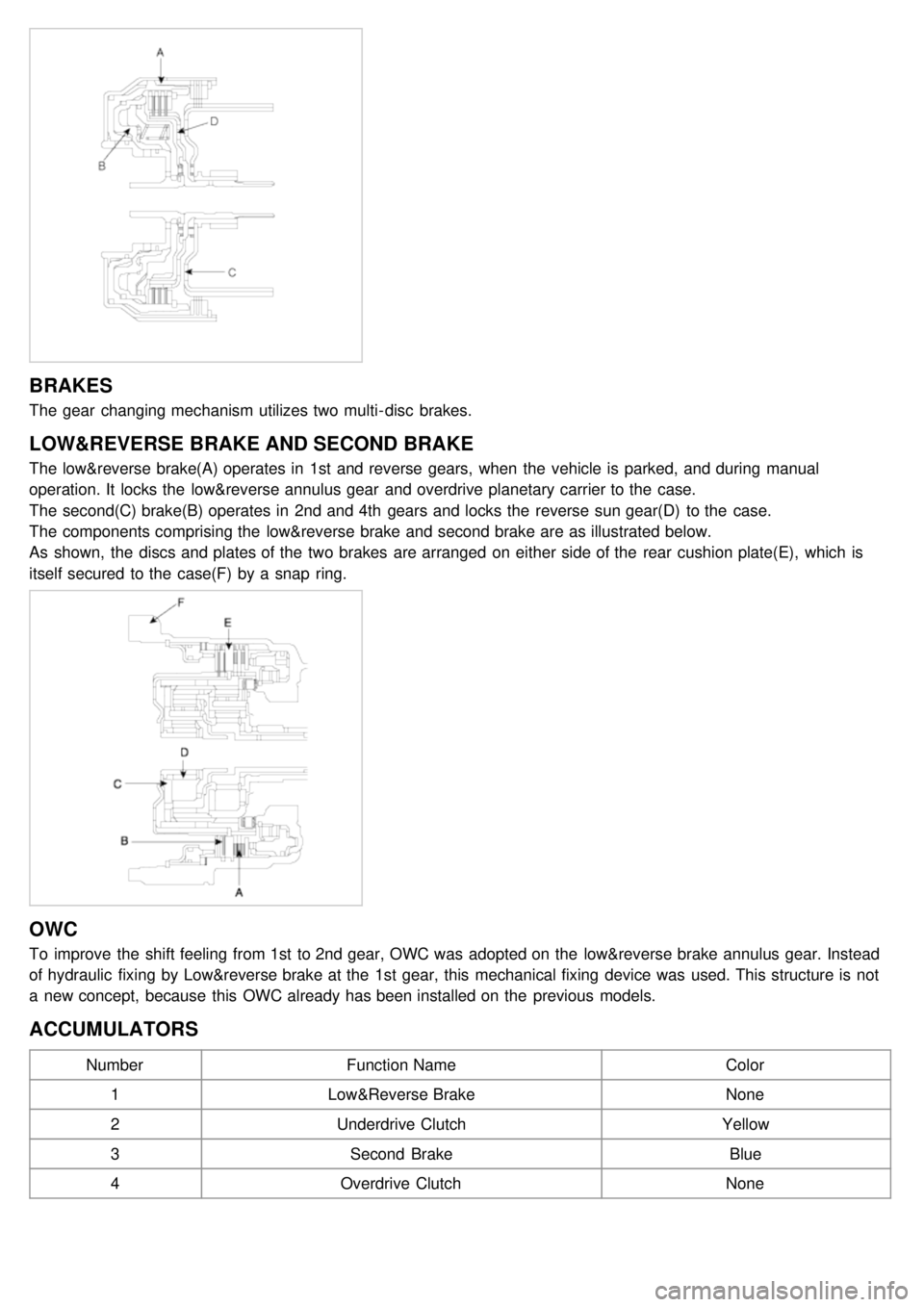

BRAKES

The gear changing mechanism utilizes two multi- disc brakes.

LOW&REVERSE BRAKE AND SECOND BRAKE

The low&reverse brake(A) operates in 1st and reverse gears, when the vehicle is parked, and during manual

operation. It locks the low&reverse annulus gear and overdrive planetary carrier to the case.

The second(C) brake(B) operates in 2nd and 4th gears and locks the reverse sun gear(D) to the case.

The components comprising the low&reverse brake and second brake are as illustrated below.

As shown, the discs and plates of the two brakes are arranged on either side of the rear cushion plate(E), which is

itself secured to the case(F) by a snap ring.

OWC

To improve the shift feeling from 1st to 2nd gear, OWC was adopted on the low&reverse brake annulus gear. Instead

of hydraulic fixing by Low&reverse brake at the 1st gear, this mechanical fixing device was used. This structure is not

a new concept, because this OWC already has been installed on the previous models.

ACCUMULATORS

NumberFunction Name Color

1 Low&Reverse Brake None

2 Underdrive Clutch Yellow

3 Second Brake Blue

4 Overdrive Clutch None

Page 354 of 1575

Objective

* Energy (hydraulic pressure) storage

* Impact and pulsation damping when solenoid valves operating

* Operation as spring element

* Smooth shifting by preventing sudden operation of clutches and brakes

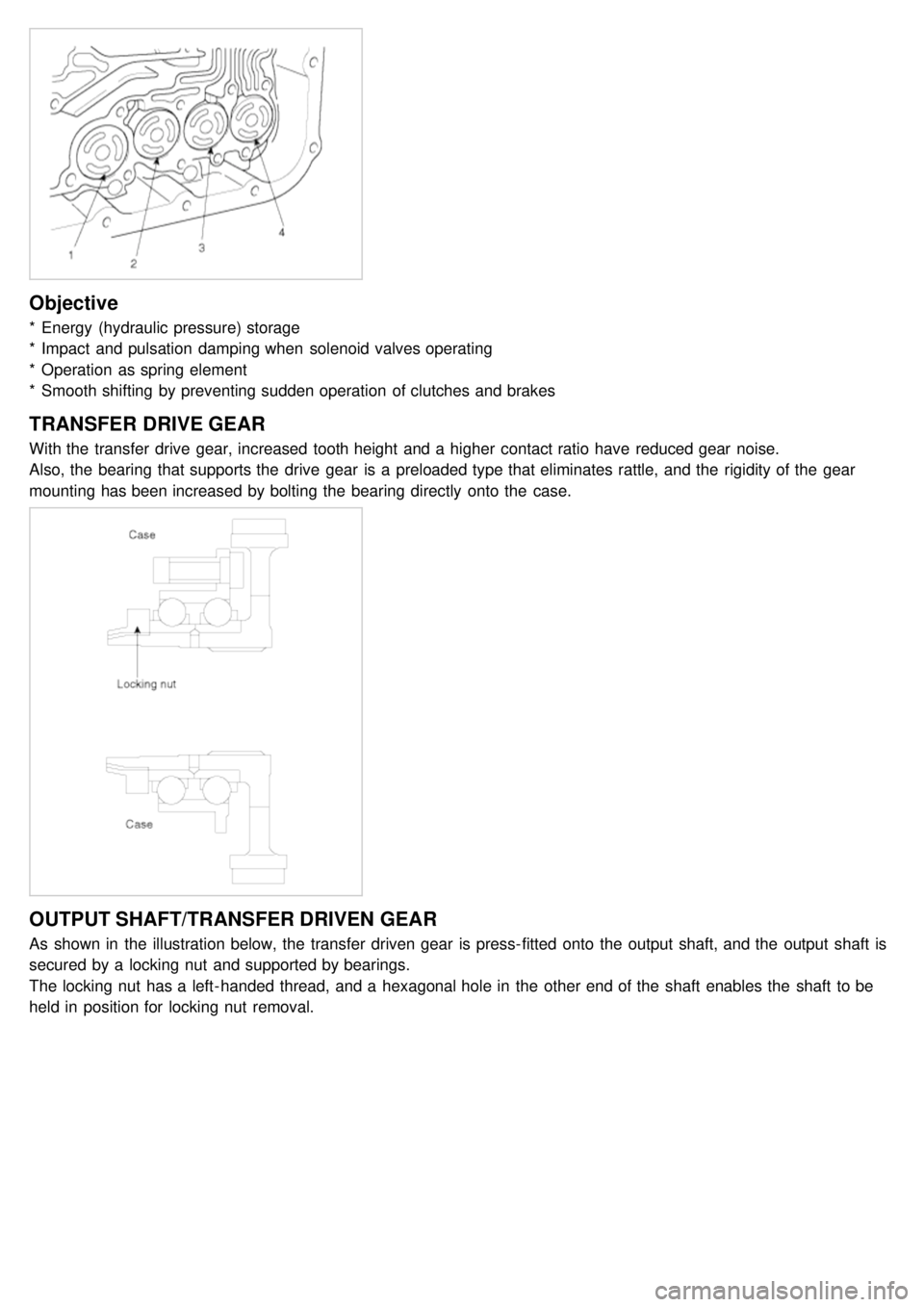

TRANSFER DRIVE GEAR

With the transfer drive gear, increased tooth height and a higher contact ratio have reduced gear noise.

Also, the bearing that supports the drive gear is a preloaded type that eliminates rattle, and the rigidity of the gear

mounting has been increased by bolting the bearing directly onto the case.

OUTPUT SHAFT/TRANSFER DRIVEN GEAR

As shown in the illustration below, the transfer driven gear is press- fitted onto the output shaft, and the output shaft is

secured by a locking nut and supported by bearings.

The locking nut has a left- handed thread, and a hexagonal hole in the other end of the shaft enables the shaft to be

held in position for locking nut removal.

Page 355 of 1575

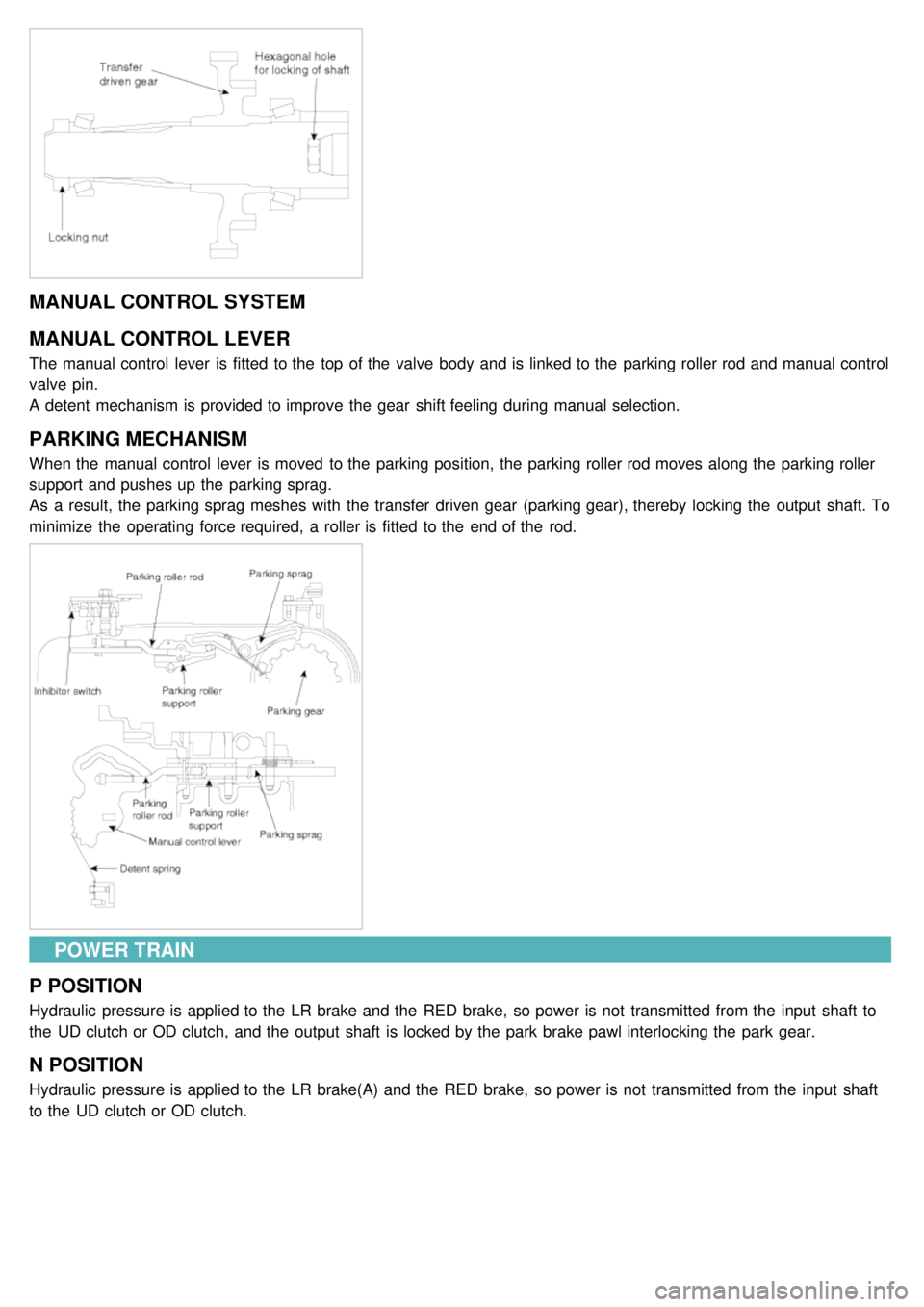

MANUAL CONTROL SYSTEM

MANUAL CONTROL LEVER

The manual control lever is fitted to the top of the valve body and is linked to the parking roller rod and manual control

valve pin.

A detent mechanism is provided to improve the gear shift feeling during manual selection.

PARKING MECHANISM

When the manual control lever is moved to the parking position, the parking roller rod moves along the parking roller

support and pushes up the parking sprag.

As a result, the parking sprag meshes with the transfer driven gear (parking gear), thereby locking the output shaft. To

minimize the operating force required, a roller is fitted to the end of the rod.

POWER TRAIN

P POSITION

Hydraulic pressure is applied to the LR brake and the RED brake, so power is not transmitted from the input shaft to

the UD clutch or OD clutch, and the output shaft is locked by the park brake pawl interlocking the park gear.

N POSITION

Hydraulic pressure is applied to the LR brake(A) and the RED brake, so power is not transmitted from the input shaft

to the UD clutch or OD clutch.

Page 356 of 1575

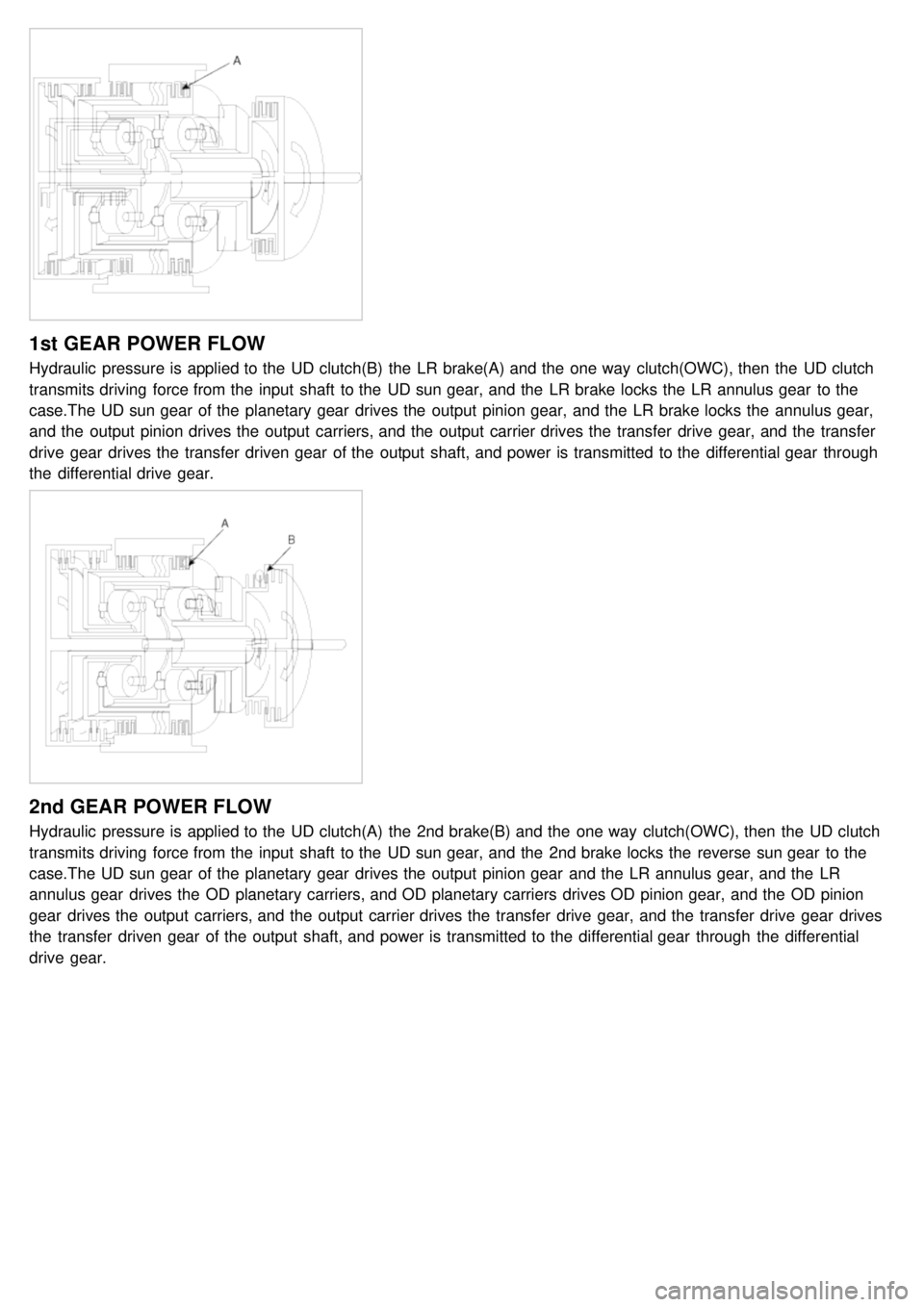

1st GEAR POWER FLOW

Hydraulic pressure is applied to the UD clutch(B) the LR brake(A) and the one way clutch(OWC), then the UD clutch

transmits driving force from the input shaft to the UD sun gear, and the LR brake locks the LR annulus gear to the

case.The UD sun gear of the planetary gear drives the output pinion gear, and the LR brake locks the annulus gear,

and the output pinion drives the output carriers, and the output carrier drives the transfer drive gear, and the transfer

drive gear drives the transfer driven gear of the output shaft, and power is transmitted to the differential gear through

the differential drive gear.

2nd GEAR POWER FLOW

Hydraulic pressure is applied to the UD clutch(A) the 2nd brake(B) and the one way clutch(OWC), then the UD clutch

transmits driving force from the input shaft to the UD sun gear, and the 2nd brake locks the reverse sun gear to the

case.The UD sun gear of the planetary gear drives the output pinion gear and the LR annulus gear, and the LR

annulus gear drives the OD planetary carriers, and OD planetary carriers drives OD pinion gear, and the OD pinion

gear drives the output carriers, and the output carrier drives the transfer drive gear, and the transfer drive gear drives

the transfer driven gear of the output shaft, and power is transmitted to the differential gear through the differential

drive gear.

Page 357 of 1575

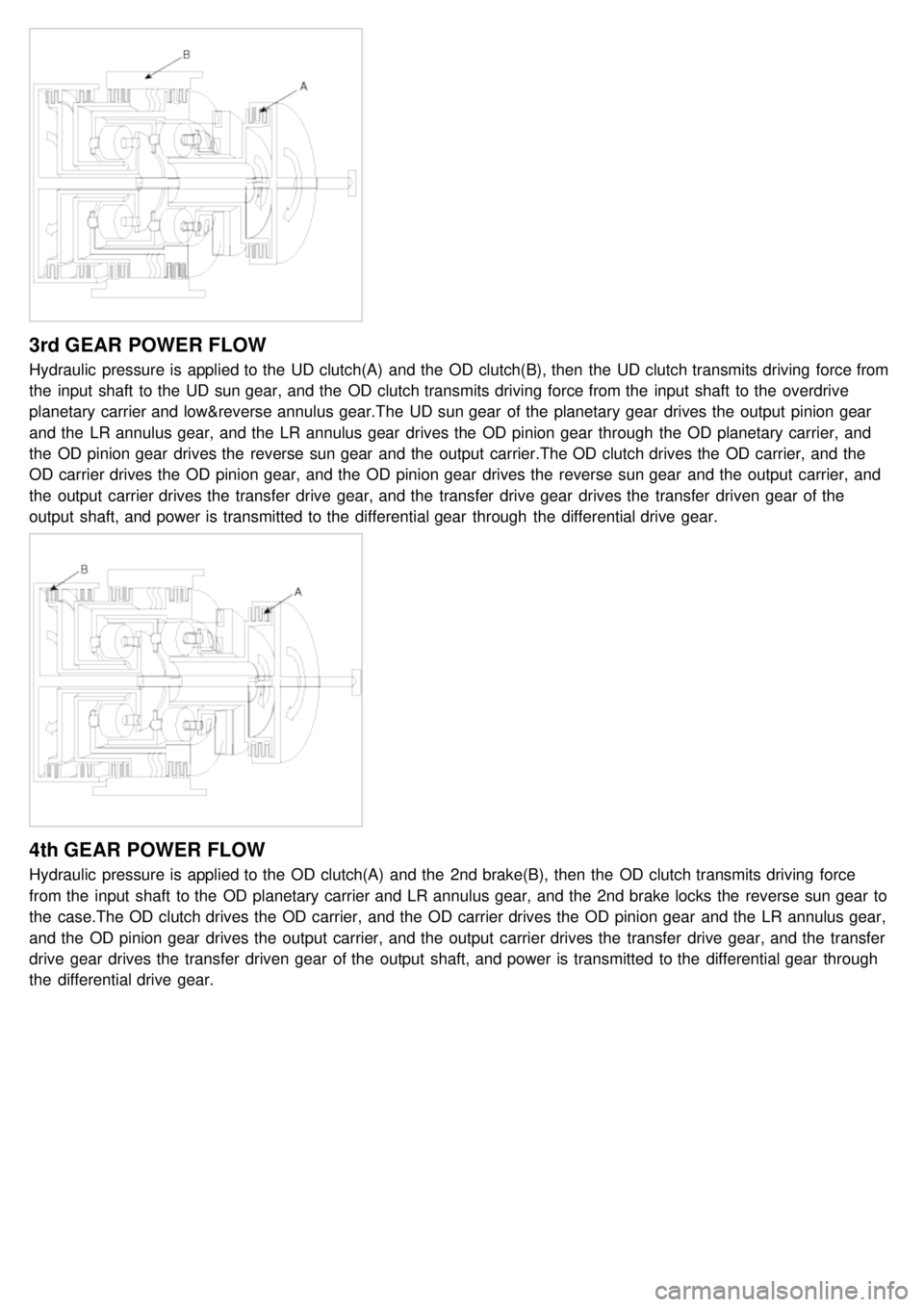

3rd GEAR POWER FLOW

Hydraulic pressure is applied to the UD clutch(A) and the OD clutch(B), then the UD clutch transmits driving force from

the input shaft to the UD sun gear, and the OD clutch transmits driving force from the input shaft to the overdrive

planetary carrier and low&reverse annulus gear.The UD sun gear of the planetary gear drives the output pinion gear

and the LR annulus gear, and the LR annulus gear drives the OD pinion gear through the OD planetary carrier, and

the OD pinion gear drives the reverse sun gear and the output carrier.The OD clutch drives the OD carrier, and the

OD carrier drives the OD pinion gear, and the OD pinion gear drives the reverse sun gear and the output carrier, and

the output carrier drives the transfer drive gear, and the transfer drive gear drives the transfer driven gear of the

output shaft, and power is transmitted to the differential gear through the differential drive gear.

4th GEAR POWER FLOW

Hydraulic pressure is applied to the OD clutch(A) and the 2nd brake(B), then the OD clutch transmits driving force

from the input shaft to the OD planetary carrier and LR annulus gear, and the 2nd brake locks the reverse sun gear to

the case.The OD clutch drives the OD carrier, and the OD carrier drives the OD pinion gear and the LR annulus gear,

and the OD pinion gear drives the output carrier, and the output carrier drives the transfer drive gear, and the transfer

drive gear drives the transfer driven gear of the output shaft, and power is transmitted to the differential gear through

the differential drive gear.

Page 358 of 1575

Reverse GEAR POWER FLOW

Hydraulic pressure is applied to the reverse clutch(A) and the LR brake(B), then the reverse clutch transmits driving

force from the input shaft to the reverse sun gear, and the LR brake locks the LR annulus gear and OD planetary

carrier to the case.The reverse clutch drives the reverse sun gear, and the reverse sun gear drives the output carrier

through the OD pinion gear, and the output carrier drives the transfer drive gear, and the transfer drive gear drives the

transfer driven gear of the output shaft, and power is transmitted to the differential gear through the differential drive

gear.

Page 359 of 1575

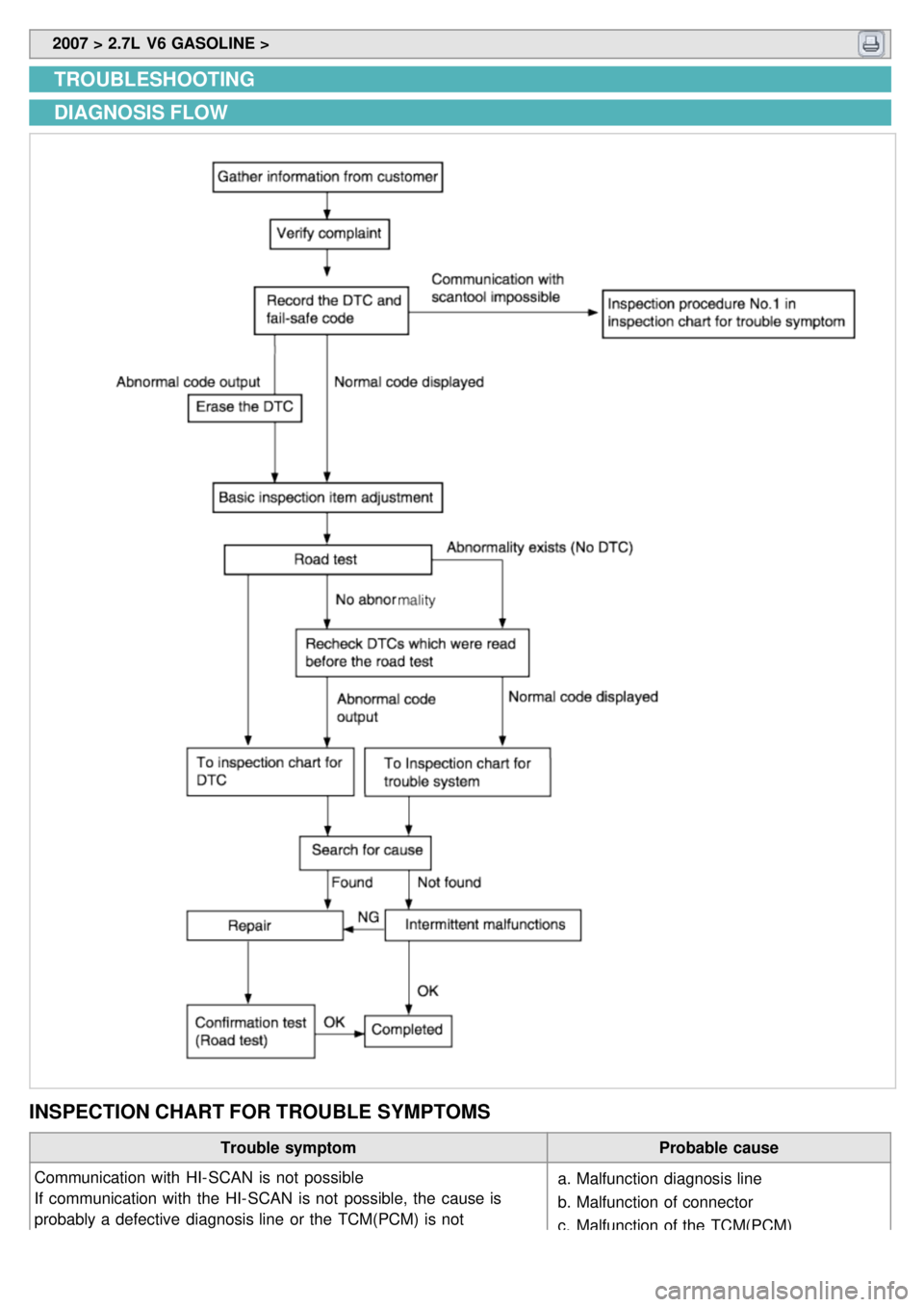

2007 > 2.7L V6 GASOLINE >

TROUBLESHOOTING

DIAGNOSIS FLOW

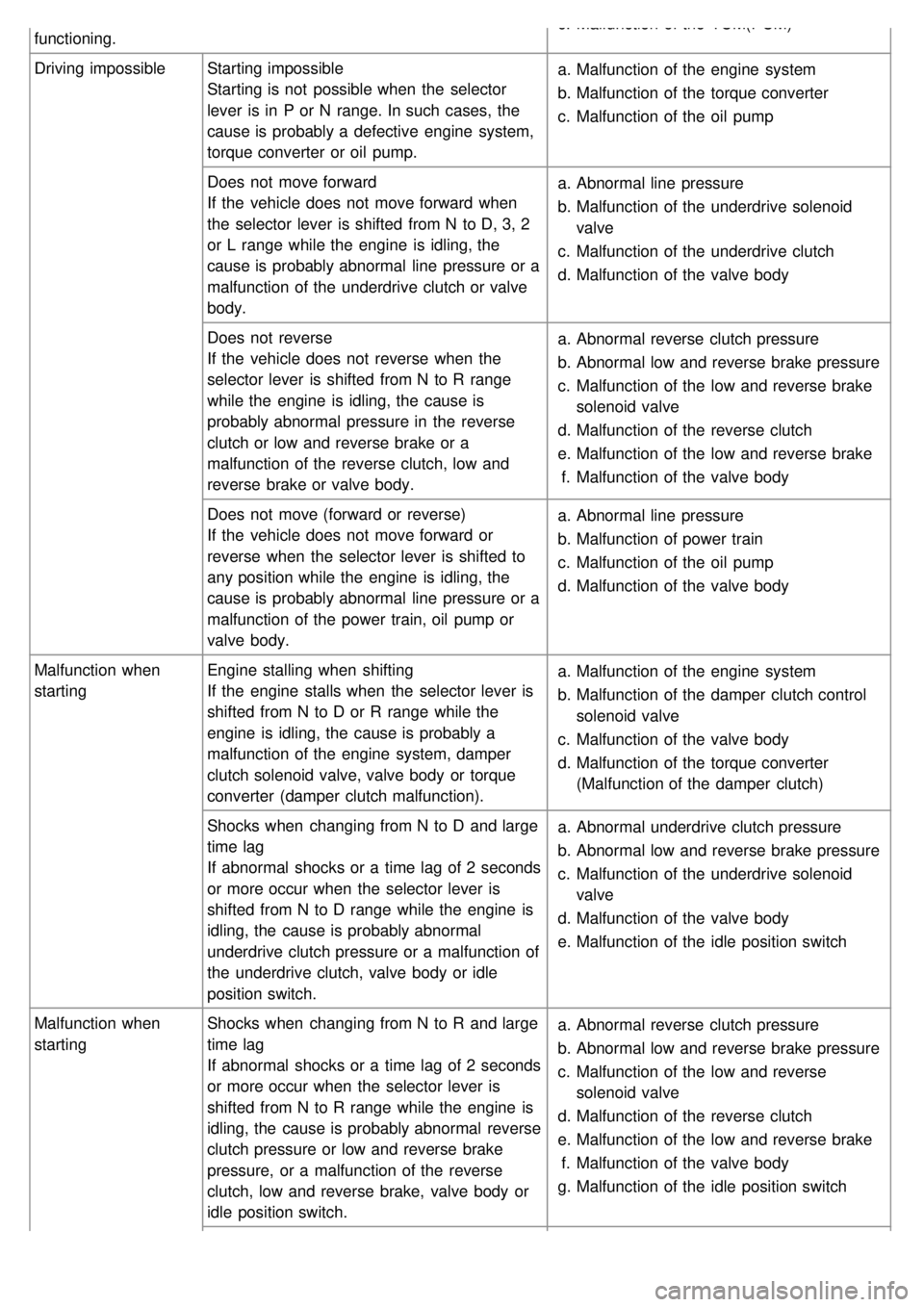

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptom Probable cause

Communication with HI- SCAN is not possible

If communication with the HI- SCAN is not possible, the cause is

probably a defective diagnosis line or the TCM(PCM) is not

functioning. a.

Malfunction diagnosis line

b. Malfunction of connector

c. Malfunction of the TCM(PCM)

Page 360 of 1575

functioning.c.

Malfunction of the TCM(PCM)

Driving impossible Starting impossible

Starting is not possible when the selector

lever is in P or N range. In such cases, the

cause is probably a defective engine system,

torque converter or oil pump. a.

Malfunction of the engine system

b. Malfunction of the torque converter

c. Malfunction of the oil pump

Does not move forward

If the vehicle does not move forward when

the selector lever is shifted from N to D, 3, 2

or L range while the engine is idling, the

cause is probably abnormal line pressure or a

malfunction of the underdrive clutch or valve

body. a.

Abnormal line pressure

b. Malfunction of the underdrive solenoid

valve

c. Malfunction of the underdrive clutch

d. Malfunction of the valve body

Does not reverse

If the vehicle does not reverse when the

selector lever is shifted from N to R range

while the engine is idling, the cause is

probably abnormal pressure in the reverse

clutch or low and reverse brake or a

malfunction of the reverse clutch, low and

reverse brake or valve body. a.

Abnormal reverse clutch pressure

b. Abnormal low and reverse brake pressure

c. Malfunction of the low and reverse brake

solenoid valve

d. Malfunction of the reverse clutch

e. Malfunction of the low and reverse brake

f. Malfunction of the valve body

Does not move (forward or reverse)

If the vehicle does not move forward or

reverse when the selector lever is shifted to

any position while the engine is idling, the

cause is probably abnormal line pressure or a

malfunction of the power train, oil pump or

valve body. a.

Abnormal line pressure

b. Malfunction of power train

c. Malfunction of the oil pump

d. Malfunction of the valve body

Malfunction when

starting Engine stalling when shifting

If the engine stalls when the selector lever is

shifted from N to D or R range while the

engine is idling, the cause is probably a

malfunction of the engine system, damper

clutch solenoid valve, valve body or torque

converter (damper clutch malfunction). a.

Malfunction of the engine system

b. Malfunction of the damper clutch control

solenoid valve

c. Malfunction of the valve body

d. Malfunction of the torque converter

(Malfunction of the damper clutch)

Shocks when changing from N to D and large

time lag

If abnormal shocks or a time lag of 2 seconds

or more occur when the selector lever is

shifted from N to D range while the engine is

idling, the cause is probably abnormal

underdrive clutch pressure or a malfunction of

the underdrive clutch, valve body or idle

position switch. a.

Abnormal underdrive clutch pressure

b. Abnormal low and reverse brake pressure

c. Malfunction of the underdrive solenoid

valve

d. Malfunction of the valve body

e. Malfunction of the idle position switch

Malfunction when

starting Shocks when changing from N to R and large

time lag

If abnormal shocks or a time lag of 2 seconds

or more occur when the selector lever is

shifted from N to R range while the engine is

idling, the cause is probably abnormal reverse

clutch pressure or low and reverse brake

pressure, or a malfunction of the reverse

clutch, low and reverse brake, valve body or

idle position switch. a.

Abnormal reverse clutch pressure

b. Abnormal low and reverse brake pressure

c. Malfunction of the low and reverse

solenoid valve

d. Malfunction of the reverse clutch

e. Malfunction of the low and reverse brake

f. Malfunction of the valve body

g. Malfunction of the idle position switch