KIA CARNIVAL 2007 Owner's Guide

CARNIVAL 2007

KIA

KIA

https://www.carmanualsonline.info/img/2/57045/w960_57045-0.png

KIA CARNIVAL 2007 Owner's Guide

Page 289 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

FUNCTION AND OPERATION PRICIPLE

Knocking is a phenomenon characterized by undesirable vibration and noise and can cause engine damage. Knock

Sensor (KS) senses engine knocking and the two sensors are installed inside the V- valley of the cylinder block. When

knocking occurs, the vibration from the cylinder block is applied as pressure to the piezoelectric element. At this time,

this sensor transfers the voltage signal higher than the specified value to the PCM and the PCM retards the ignition

timing. If the knocking disappears after retarding the ignition timing, the PCM will advance the ignition timing. This

sequential control can improve engine power, torque and fuel economy.

SPECIFICATION

Item Specification

Capacitance (pF) 950 ~ 1,350pF

WAVEFORM

Page 292 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

FUNCTION AND OPERATION PRICIPLE

Crankshaft Position Sensor (CKPS) detects the crankshaft position and is one of the most important sensors of the

engine control system. If there is no CKPS signal input, fuel is not supplied and the main relay does not operate. That

is, vehicle can't run without CKPS signal. This sensor is installed on transaxle housing and generates alternating

current by magnetic flux field which is made by the sensor and the target wheel when engine runs. The target wheel

consists of 58 slots and 2 missing slots on 360 CA (Crank Angle).

WAVEFORM

CIRCUIT DIAGRAM

Page 299 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

FUNCTION AND OPERATION PRICIPLE

Based on information from various sensors, the PCM measures the fuel injection amount. The fuel injector is a

solenoid- operated valve and the fuel injection amount is controlled by length of time that the fuel injector is held open.

The PCM controls each injector by grounding the control circuit. When the PCM energizes the injector by grounding

the control circuit, the circuit voltage should be low (theoretically 0V) and the fuel is injected. When the PCM de-

energizes the injector by opening control circuit, the fuel injector is closed and circuit voltage should momentarily peak.

If an injector connector is disconnected for more than 46 seconds while the engine runs, the PCM will determine

that the cylinder is misfiring and cut fuel supply. So be careful not to exceed 46 seconds. But the engine runs

normally in 10 seconds after turning the ignition key off.

SPECIFICATION

Item Specification

Coil Resistance (Ω) 13.8 ~ 15.2Ω at 20°C (68°F)

CIRCUIT DIAGRAM

Page 312 of 1575

MODE 1FORCED ENGINE

SHUTDOWN Engine stop algorithm procedure

a. Fatal PCM internal programming error

b. Faulty intake system or throttle body

MODE 2 FORCED IDLE &

POWER

MANAGEMENT Forced idle state controlled by

fuel quantity regulation and

ignition timing adjustment a.

ETC system can't control engine power

via throttle device

b. Disabled throttle control or broken throttle

position information

MODE 3 FORCED IDLE Forced idle state and no response

for accelerator activation a.

No information about the accelerator

position

a. Malfuctioning APS 1 and 2, faulty A/D

converter or internal controller

MODE 4 LIMIT

PERFORMANCE & POWER

MANAGEMENT Engine power is determined by

accelerator position and idle

power requirement (Limited

vehicle running)

a.

ETC system can't securely control engine

power

MODE 5 LIMIT

PERFORMANCE a.

Engine power varies with

accelerator position, but driver

perceives lack of engine

power.

b. MIL ON (Normal vehicle

running) a.

Not reliable accelerator position signal or

bad maximum power generation

a. Faulty APS, ignition voltage or internal

controller

MODE 6 NORMALNormal

COMPONENT INSPECTION

1.Connect a scantool on Diagnoisis Link Connector (DLC).

2. Start engine and check output voltages of TPS 1 and 2 at C.T and W.O.T.

Condition Output Voltage (V)

TPS 1 TPS 2

C.T 0.25 ~ 0.9V Min. 4.0V

W.O.T Min. 4.0V 0.25 ~ 0.9V

3. Turn ignition switch OFF and disconnect the scantool from the DLC.

4. Disconnect ETC module connector and measure resistance between ETC module terminals 4 and 1 (TPS 1).

5. Measure resistance between ETC module terminals 7 and 6 (TPS 2).

Specification: Refer to SPECIFICATION.

ETC MOTOR

1.Disconnect ETC module connector and measure resistance between ETC module terminals 5 and 8.

Page 314 of 1575

Page 316 of 1575

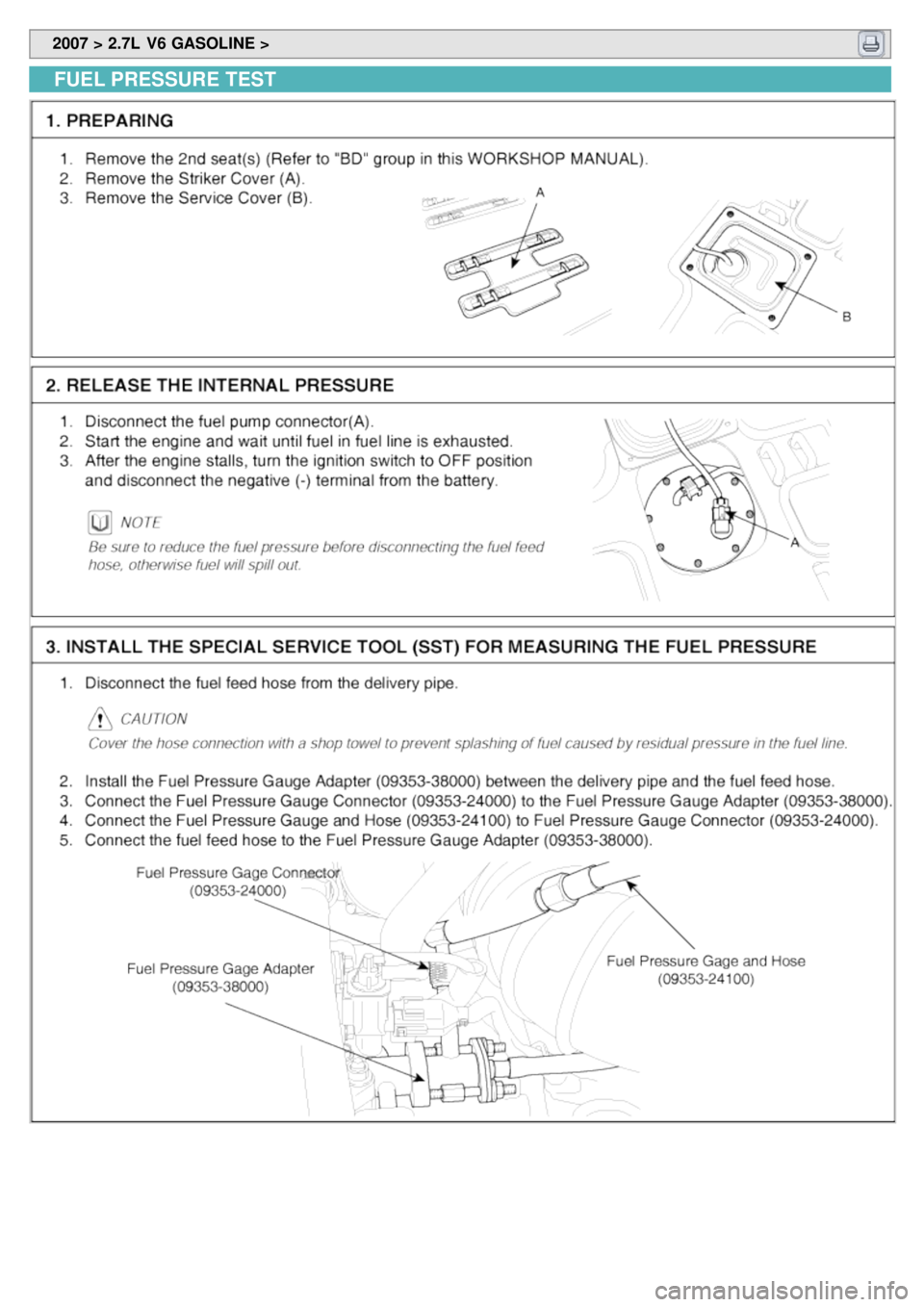

2007 > 2.7L V6 GASOLINE >

FUEL PRESSURE TEST

Page 319 of 1575

Page 320 of 1575

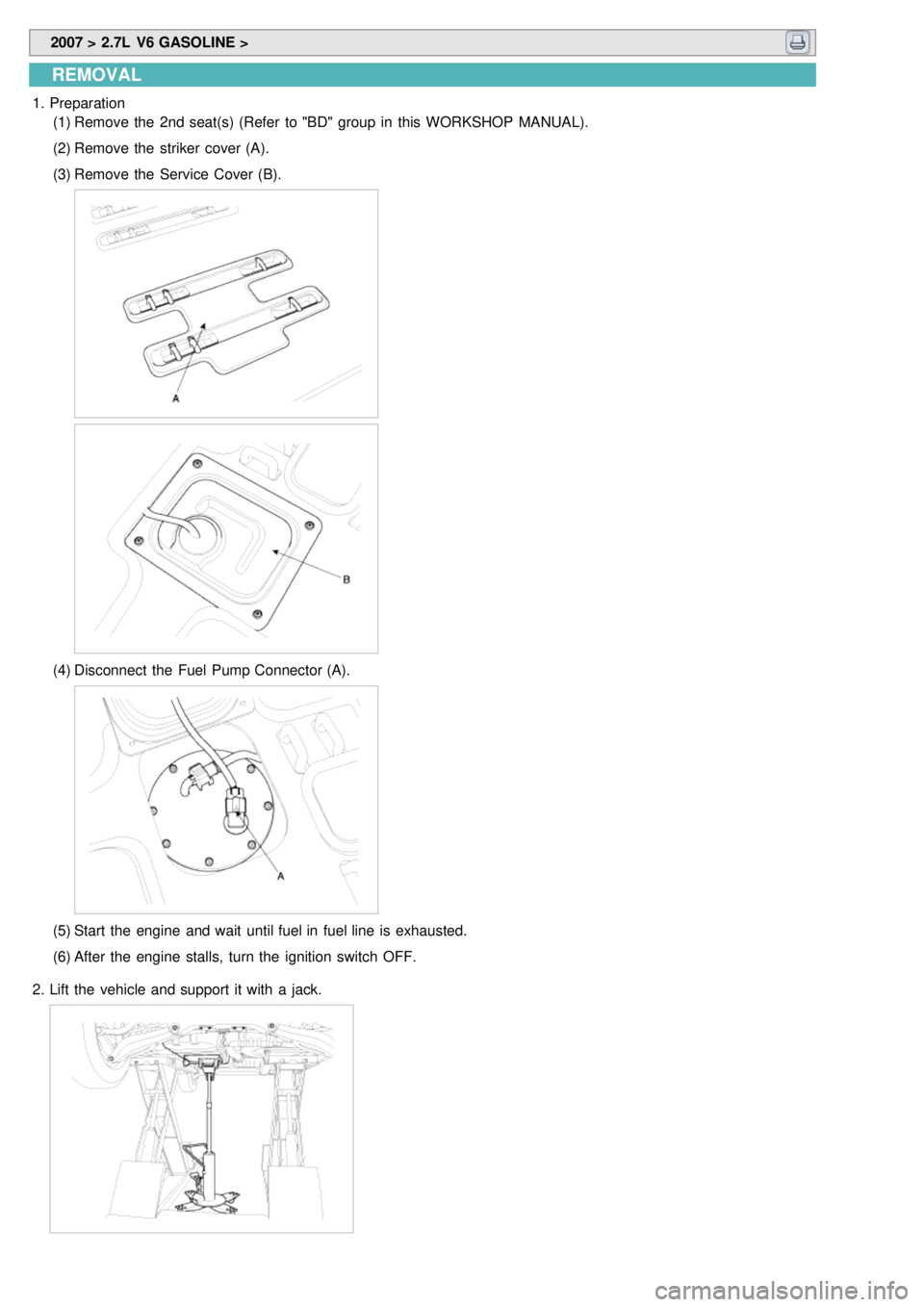

2007 > 2.7L V6 GASOLINE >

REMOVAL

1.Preparation

(1) Remove the 2nd seat(s) (Refer to "BD" group in this WORKSHOP MANUAL).

(2) Remove the striker cover (A).

(3) Remove the Service Cover (B).

(4)Disconnect the Fuel Pump Connector (A).

(5)Start the engine and wait until fuel in fuel line is exhausted.

(6) After the engine stalls, turn the ignition switch OFF.

2. Lift the vehicle and support it with a jack.

Page 321 of 1575

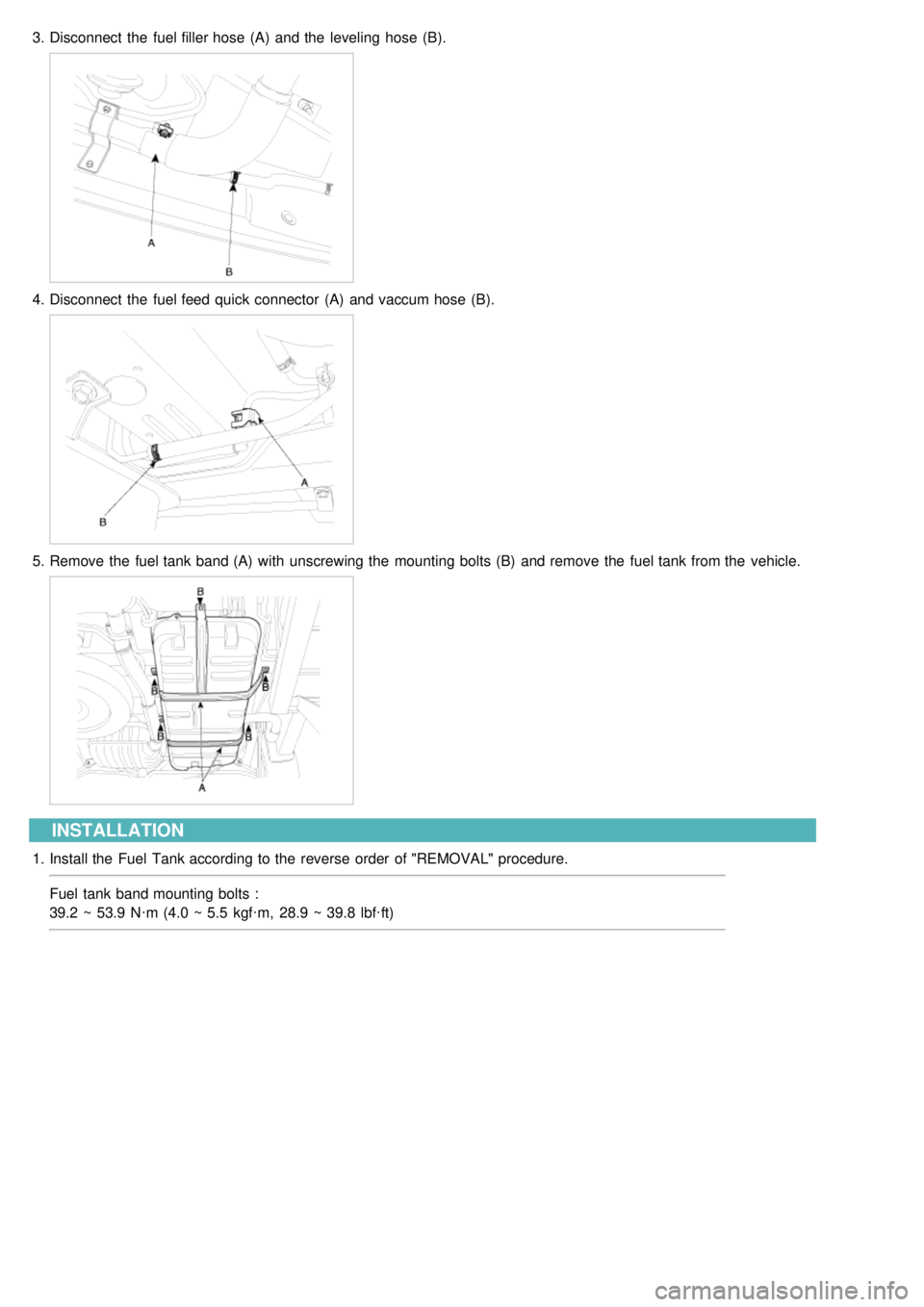

3.Disconnect the fuel filler hose (A) and the leveling hose (B).

4.Disconnect the fuel feed quick connector (A) and vaccum hose (B).

5.Remove the fuel tank band (A) with unscrewing the mounting bolts (B) and remove the fuel tank from the vehicle.

INSTALLATION

1.Install the Fuel Tank according to the reverse order of "REMOVAL" procedure.

Fuel tank band mounting bolts :

39.2 ~ 53.9 N·m (4.0 ~ 5.5 kgf·m, 28.9 ~ 39.8 lbf·ft)

Page 322 of 1575