ECU LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 310 of 873

SFI

27

REPAIR ADD: 09/95

11.Disconnect vent line quickfit connector from

liquid/vapour separator.

12.Remove torque screw cap from hose to tank

filler neck clip.

13.Loosen clip screw securing hose to tank filler

neck.

14.Release hose from filler neck and internal filler

neck breather hose from fuel tank.

15.Remove and discard fuel filler neck clip.

16.Disconnect the pressure sensor breather pipe

connection.

17.Disconnect the vent line hose connection.

18.Fit ignition key to fuel filler flap lock and open

flap.

19.Release fuel filler cap from filler neck.

20.Remove filler neck assembly from vehicle.

Do not carry out further dismantling if

component is removed for access only.

21.Remove torque screw cap from hose to filler

neck clip.

22.Loosen clip screw securing hose to filler neck.

23.Remove hose from filler neck.

24.Remove and discard fuel filler hose clip.

25.Remove vent line from filler neck.

Page 311 of 873

19FUEL SYSTEM

28

REPAIRADD: 09/95 Refit

26.Fit vent line to filler neck.

27.Fit NEW clip to filler neck hose.

28.Fit hose to filler neck.

29.Position filler neck hose clip and tighten until

head shears.

30.Fit filler neck assembly to vehicle.

NOTE: To aid fitment of filler neck through

body grommet apply a soap solution to lip

of grommet.

31.Fit NEW clip to fuel filler neck hose.

32.Connect fuel filler neck internal breather to tank.

33.Connect fuel filler neck hose to tank.

34.Position fuel filler neck hose clip and tighten until

head shears.

35.Connect vent line quickfit connector to

liquid/vapour separator.

36.Connect the pressure sensor breather pipe

connection.

37.Connect the vent line hose connection.

38.Fit mud flap and secure with nuts and bolts.

39.Position filler neck support bracket and earth

strap to mud flap bracket and secure with nut

and bolt.

40.Remove stand(s) and lower vehicle.

41.Reposition loadspace sound insulation and

carpet.

42.Fit RH luggage compartment side panel.

See

CHASSIS AND BODY, Repair,

43.Fit tail door tread strip and secure with screws.

44.Refill tank with drained fuel.

45.Fit fuel filler cap to filler neck.

46.Close filler flap, lock with ignition key and

remove key.

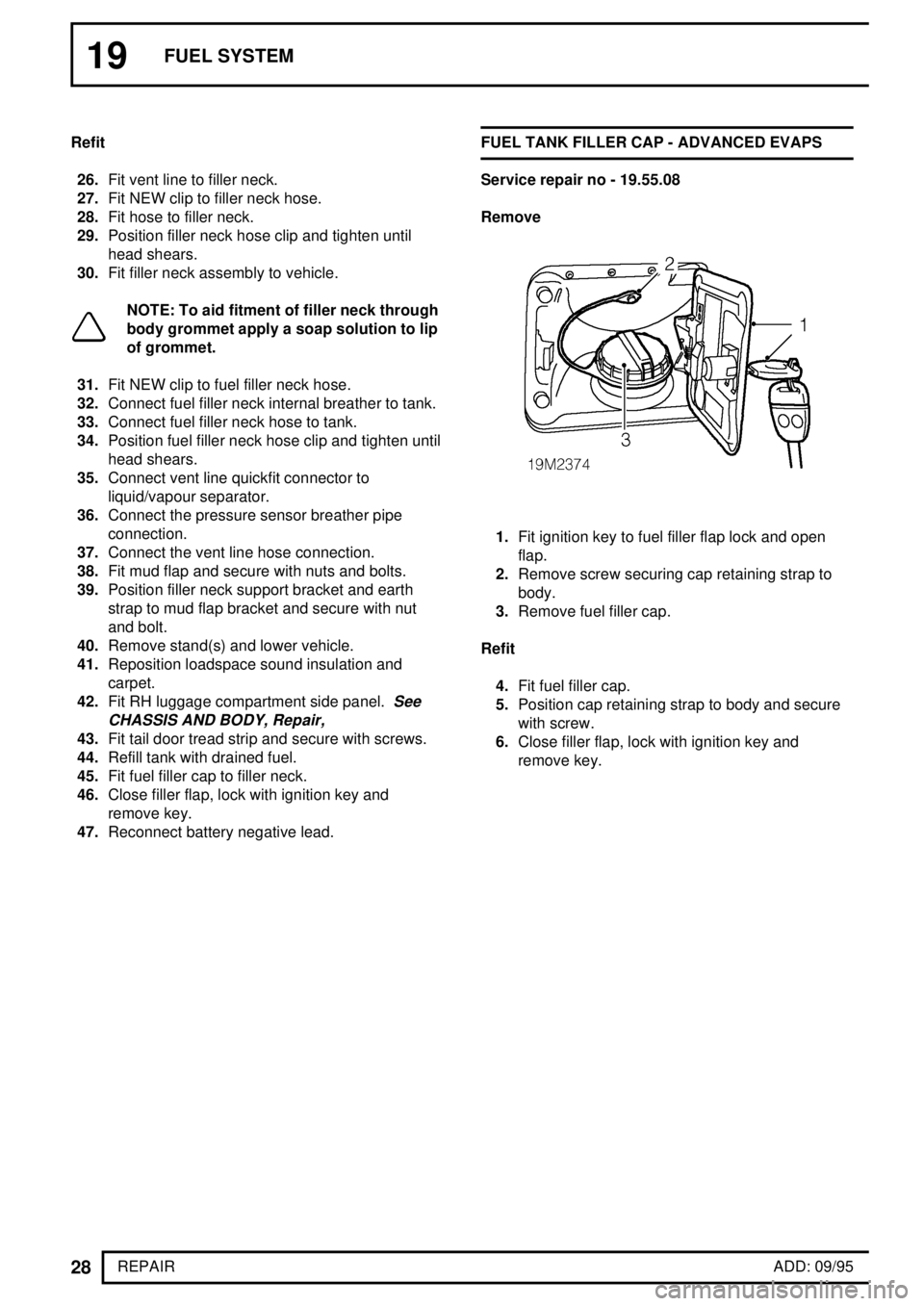

47.Reconnect battery negative lead.FUEL TANK FILLER CAP - ADVANCED EVAPS

Service repair no - 19.55.08

Remove

1.Fit ignition key to fuel filler flap lock and open

flap.

2.Remove screw securing cap retaining strap to

body.

3.Remove fuel filler cap.

Refit

4.Fit fuel filler cap.

5.Position cap retaining strap to body and secure

with screw.

6.Close filler flap, lock with ignition key and

remove key.

Page 312 of 873

SFI

29

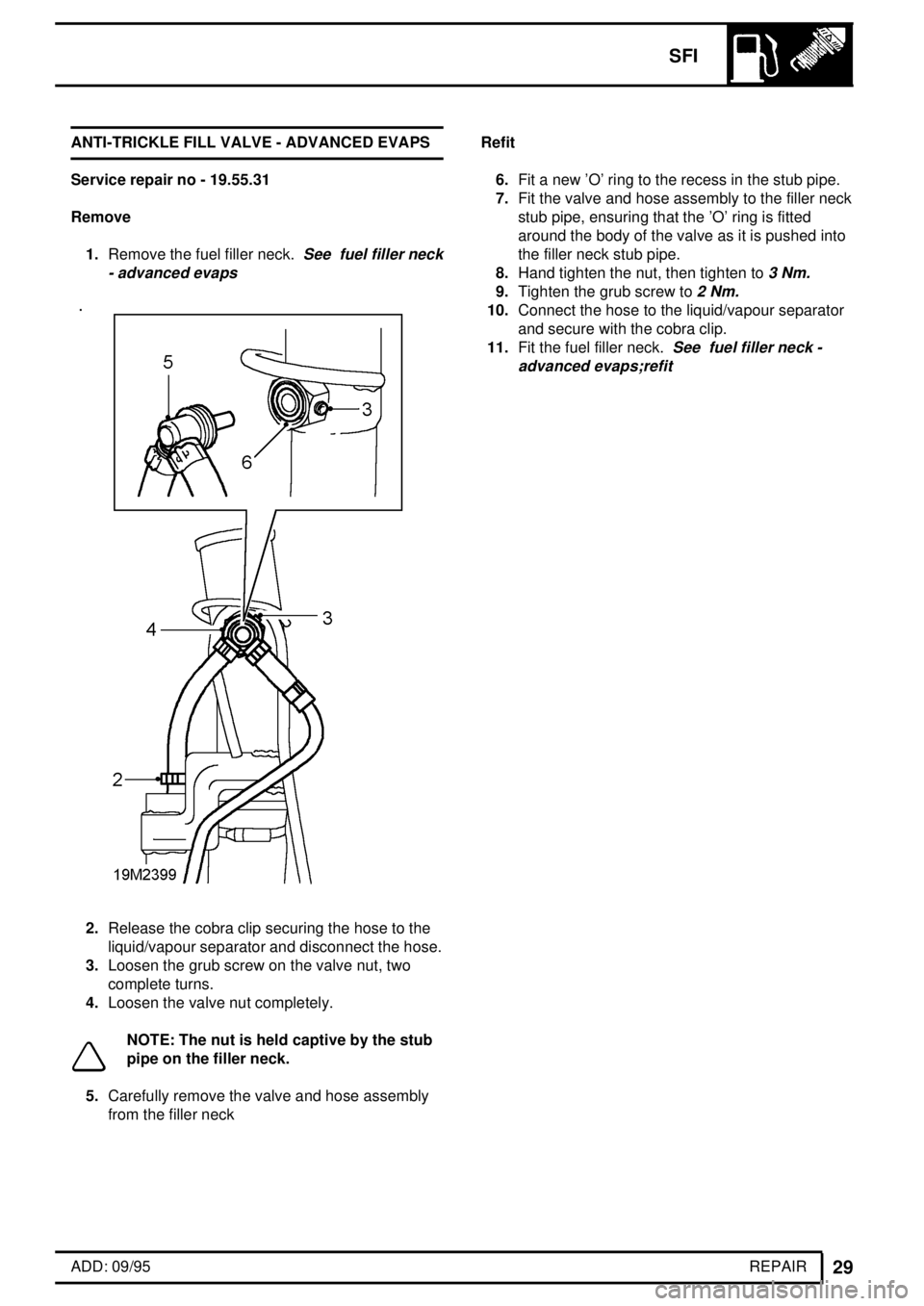

REPAIR ADD: 09/95 ANTI-TRICKLE FILL VALVE - ADVANCED EVAPS

Service repair no - 19.55.31

Remove

1.Remove the fuel filler neck.

See fuel filler neck

- advanced evaps

2.Release the cobra clip securing the hose to the

liquid/vapour separator and disconnect the hose.

3.Loosen the grub screw on the valve nut, two

complete turns.

4.Loosen the valve nut completely.

NOTE: The nut is held captive by the stub

pipe on the filler neck.

5.Carefully remove the valve and hose assembly

from the filler neckRefit

6.Fit a new 'O' ring to the recess in the stub pipe.

7.Fit the valve and hose assembly to the filler neck

stub pipe, ensuring that the 'O' ring is fitted

around the body of the valve as it is pushed into

the filler neck stub pipe.

8.Hand tighten the nut, then tighten to

3 Nm.

9.Tighten the grub screw to2 Nm.

10.Connect the hose to the liquid/vapour separator

and secure with the cobra clip.

11.Fit the fuel filler neck.

See fuel filler neck -

advanced evaps;refit

Page 324 of 873

Mpi

1

REPAIR KNOCK SENSOR

Service repair no - 18.30.18

Remove

1.Disconnect multiplug from knock sensor.

2.Remove knock sensor.

Refit

3.Clean mating face of cylinder block.

4.Fit knock sensor. Tighten to

15 Nm

5.Connect multiplug.IGNITION COILS

Service repair no - 18.20.40 - 1 & 4 Cylinders

Service repair no - 18.20.41 - 2 & 3 Cylinders

Remove

1.Disconnect battery negative lead.

2.Disconnect 4 h.t. leads from coils.

NOTE: Mark the position of the h.t. leads

to ensure correct refitment.

3.Disconnect 2 multiplugs from coils.

4.Disconnect crankshaft sensor multiplug.

5.Remove screw securing crankshaft sensor

multiplug to coil bracket.

6.Remove 3 bolts securing coil bracket to bell

housing.

NOTE: Access to the rear bolts is from

under the vehicle.

7.Remove coil assembly.

Refit

8.Position coil assembly to bell housing.

9.Fit 3 bolts and tighten to the correct torque.

10.Secure crankshaft sensor multiplug to coil

bracket with screw.

11.Connect crankshaft sensor multiplug.

12.Connect multiplugs and h.t. leads to coils.

13.Reconnect battery negative lead.

Page 325 of 873

19FUEL SYSTEM

2

REPAIR COOLANT TEMPERATURE SENSOR

Service repair no - 18.30.10

Remove

1.Position drain tin below coolant pump hose.

2.Disconnect sensor multiplug.

3.Release harness clip and harness.

4.Remove sensor.

Refit

5.Clean sensor.

6.Fit sensor and tighten to the correct torque.

7.Position harness and secure with clip.

8.Connect multiplug.

9.Top-up cooling system.CRANKSHAFT SENSOR

Service repair no - 18.30.12

Remove

1.Position vehicle on ramp [hoist].

2.Disconnect multiplug from crankshaft sensor

flylead.

3.Remove screw, release lead from bracket.

4.Raise ramp [hoist].

5.Remove 2 bolts securing crankshaft sensor.

6.Remove crankshaft sensor.

Refit

7.Clean crankshaft sensor and mating surface of

backplate.

8.Fit crankshaft sensor, fit bolts. Tighten to

7Nm

9.Lower vehicle.

10.Position lead to bracket, fit and tighten screw.

11.Connect multiplug

Page 326 of 873

Mpi

3

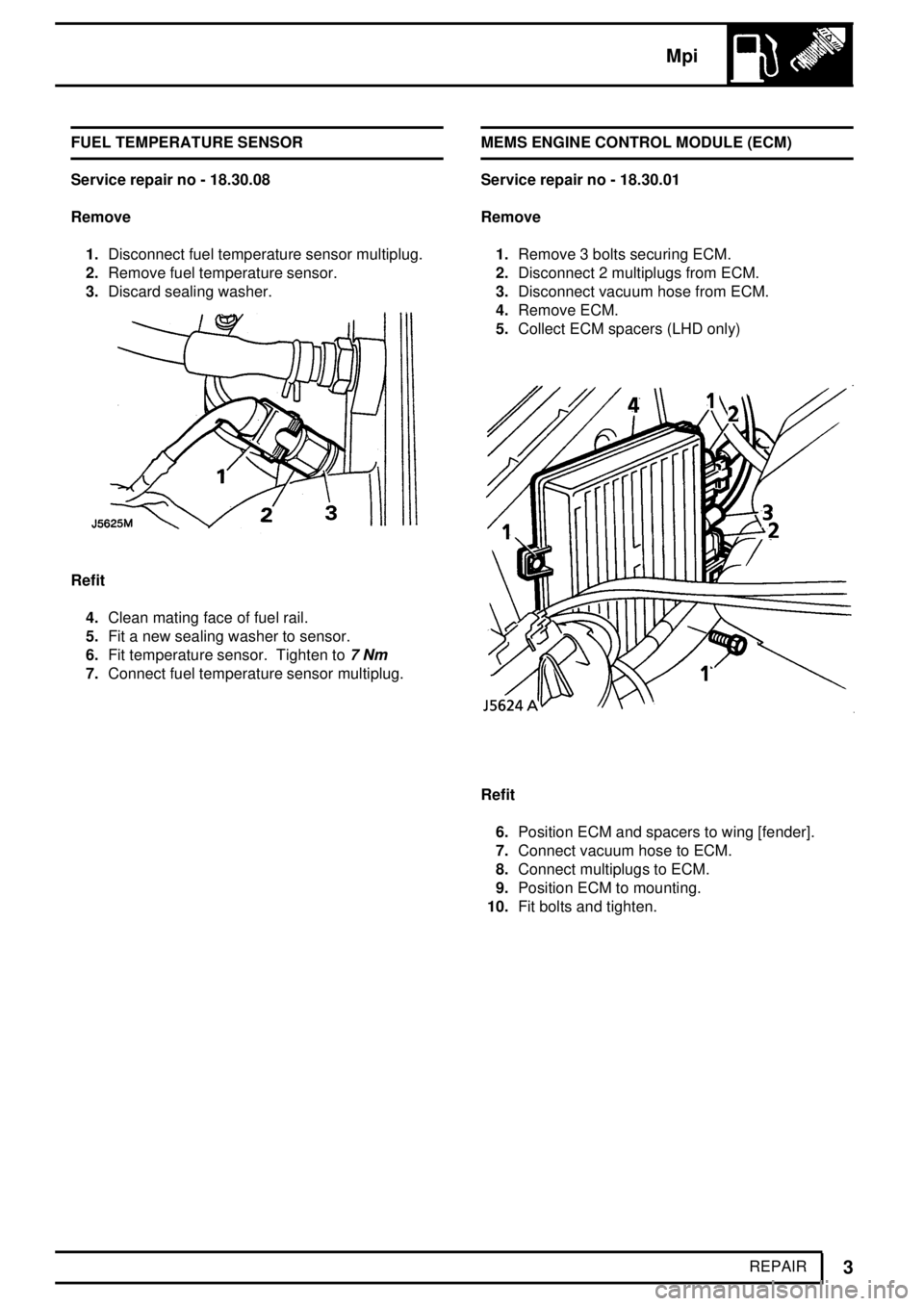

REPAIR FUEL TEMPERATURE SENSOR

Service repair no - 18.30.08

Remove

1.Disconnect fuel temperature sensor multiplug.

2.Remove fuel temperature sensor.

3.Discard sealing washer.

Refit

4.Clean mating face of fuel rail.

5.Fit a new sealing washer to sensor.

6.Fit temperature sensor. Tighten to

7Nm

7.Connect fuel temperature sensor multiplug.MEMS ENGINE CONTROL MODULE (ECM)

Service repair no - 18.30.01

Remove

1.Remove 3 bolts securing ECM.

2.Disconnect 2 multiplugs from ECM.

3.Disconnect vacuum hose from ECM.

4.Remove ECM.

5.Collect ECM spacers (LHD only)

Refit

6.Position ECM and spacers to wing [fender].

7.Connect vacuum hose to ECM.

8.Connect multiplugs to ECM.

9.Position ECM to mounting.

10.Fit bolts and tighten.

Page 327 of 873

19FUEL SYSTEM

4

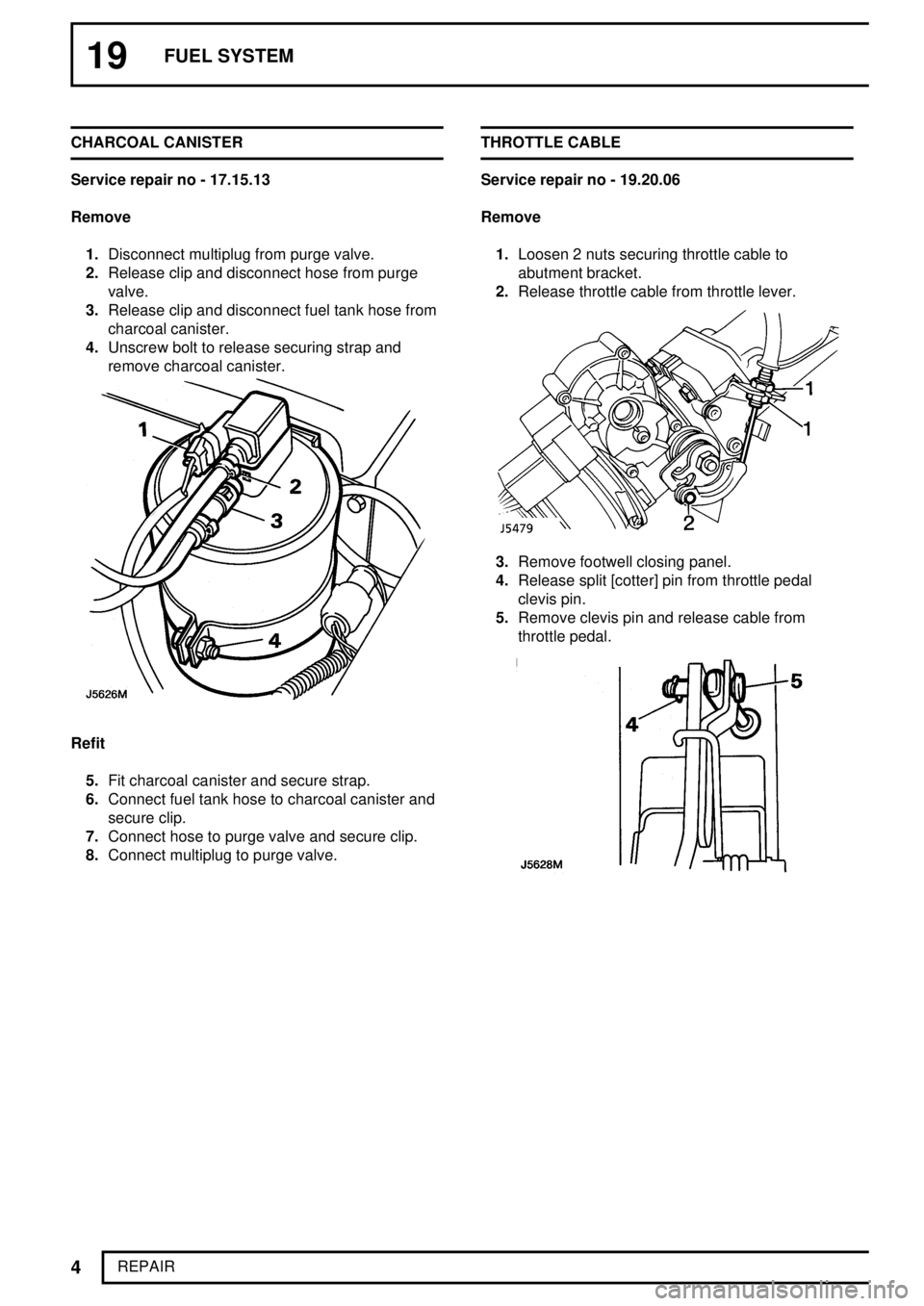

REPAIR CHARCOAL CANISTER

Service repair no - 17.15.13

Remove

1.Disconnect multiplug from purge valve.

2.Release clip and disconnect hose from purge

valve.

3.Release clip and disconnect fuel tank hose from

charcoal canister.

4.Unscrew bolt to release securing strap and

remove charcoal canister.

Refit

5.Fit charcoal canister and secure strap.

6.Connect fuel tank hose to charcoal canister and

secure clip.

7.Connect hose to purge valve and secure clip.

8.Connect multiplug to purge valve.THROTTLE CABLE

Service repair no - 19.20.06

Remove

1.Loosen 2 nuts securing throttle cable to

abutment bracket.

2.Release throttle cable from throttle lever.

3.Remove footwell closing panel.

4.Release split [cotter] pin from throttle pedal

clevis pin.

5.Remove clevis pin and release cable from

throttle pedal.

Page 328 of 873

Mpi

5

REPAIR 6.Remove nut securing throttle cable bracket to

brake servo and release cable.

7.Release grommet from bulkhead and withdraw

cable.

8.Locate cable in bulkhead.

9.Connect cable to throttle pedal.

10.Connect cable to cam.

11.Adjust throttle cable.THROTTLE POTENTIOMETER

Service repair no - 19.22.49

Remove

1.Disconnect throttle potentiometer multiplug.

2.Remove 2 screws securing throttle

potentiometer, remove potentiometer.

Refit

3.Clean mating faces of throttle potentiometer and

throttle housing.

4.Fit throttle potentiometer, fit and tighten screws.

CAUTION: Ensure throttle potentiometer is

correctly engaged with throttle cam and

that wiring outlet faces downwards.

5.Connect multiplug.

6.Check with diagnostic equipment.

Page 329 of 873

19FUEL SYSTEM

6

REPAIR INTAKE AIR TEMPERATURE SENSOR

Service repair no - 18.30.09

Remove

1.Disconnect multiplug from temperature sensor.

2.Remove sensor from inlet manifold.

Refit

3.Clean sensor threads and mating face.

4.Fit sensor to inlet manifold. Tighten to

7Nm

5.Connect multiplug to sensor.PURGE CONTROL VALVE

Service repair no - 17.15.39

Remove

1.Disconnect multiplug from purge control valve.

2.Release clip and disconnect hose from valve.

3.Release valve from charcoal canister.

4.Remove valve.

5.Discard 'O' ring.

Refit

6.Clean valve and valve location.

7.Position and secure valve to charcoal canister.

8.Connect hose to purge valve and secure with

clip.

9.Connect multiplug to valve.

Page 330 of 873

Mpi

7

REPAIR FUEL RAIL AND INJECTORS

Service repair no - 19.60.04 - Rail

Service repair no - 19.60.10 - Injectors

Remove

1.Remove inlet manifold chamber gasket.

See

MANIFOLD AND EXHAUST SYSTEM, Repair,

Manifold Chamber Gasket - Mpi

2.Remove pressure regulator.

3.Remove 4 bolts securing fuel feed hose flange

stiffening bracket, remove stiffening bracket.

4.Release fuel feed hose from fuel rail.

5.Discard 'O' ring.

6.Disconnect 4 injector multiplugs.

7.Move injector harness aside.

8.Remove 2 bolts securing fuel rail to inlet

manifold.

9.Release 4 injectors from inlet manifold.

10.Remove fuel rail complete with injectors.

11.Discard outlet 'O' rings from injectors.

12.Fix protective cap to each injector.

Do not carry out further dismantling if component

is removed for access only.

13.Remove clip(s) securing injector(s) to fuel rail.

14.Remove injector(s).

15.Discard inlet 'O' ring(s) from injector(s).

16.Remove fuel temperature sensor.