LAND ROVER DISCOVERY 1995 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 171 of 873

Mpi

13

REPAIR 19.Connect crankshaft sensor, knock sensor, air

conditioning compressor, fuel injector harness,

inlet manifold air temperature and fuel

temperature sensor multiplugs.

20.Connect fuel hose to pressure regulator and

secure with clip.

21.Fit and tighten fuel pipe to fuel rail union.

22.Connect multiplugs to throttle housing.

23.Connect vacuum hose to manifold.

24.Connect oil pressure switch multiplug.

25.Connect brake servo hose to manifold, secure

with clip.

26.Connect throttle cable to cam.

27.Position engine harness and connect breather

hose to inlet manifold, secure with clip.

28.Connect coolant temperature sensor multiplugs,

secure harness with cable tie.

29.Connect oxygen sensor multiplug, secure

harness with cable tie.

30.Connect alternator harness.

31.Connect heater hose to heater rail and secure

with clip.

32.Connect hose to coolant pump and secure with

clip.

33.Connect inlet hose to power steering pump and

secure with clip.

34.Fit and tighten outlet pipe union to power

steering pump.

35.Connect bypass and top hose, secure with clip.

36.Connect air cleaner to throttle housing hose and

secure with clip.

37.Remove engine lifting bracket.

38.Position spark plug cover and secure with

screws.

39.Fill engine with oil.

40.Fit bonnet [hood].

See CHASSIS AND BODY,

Repair, Bonnet [Hood]

41.Fit radiator.See COOLING SYSTEM, Repair,

Radiator - Mpi

42.Adjust throttle cable.See FUEL SYSTEM,

Adjustment, Throttle Cable Adjustment

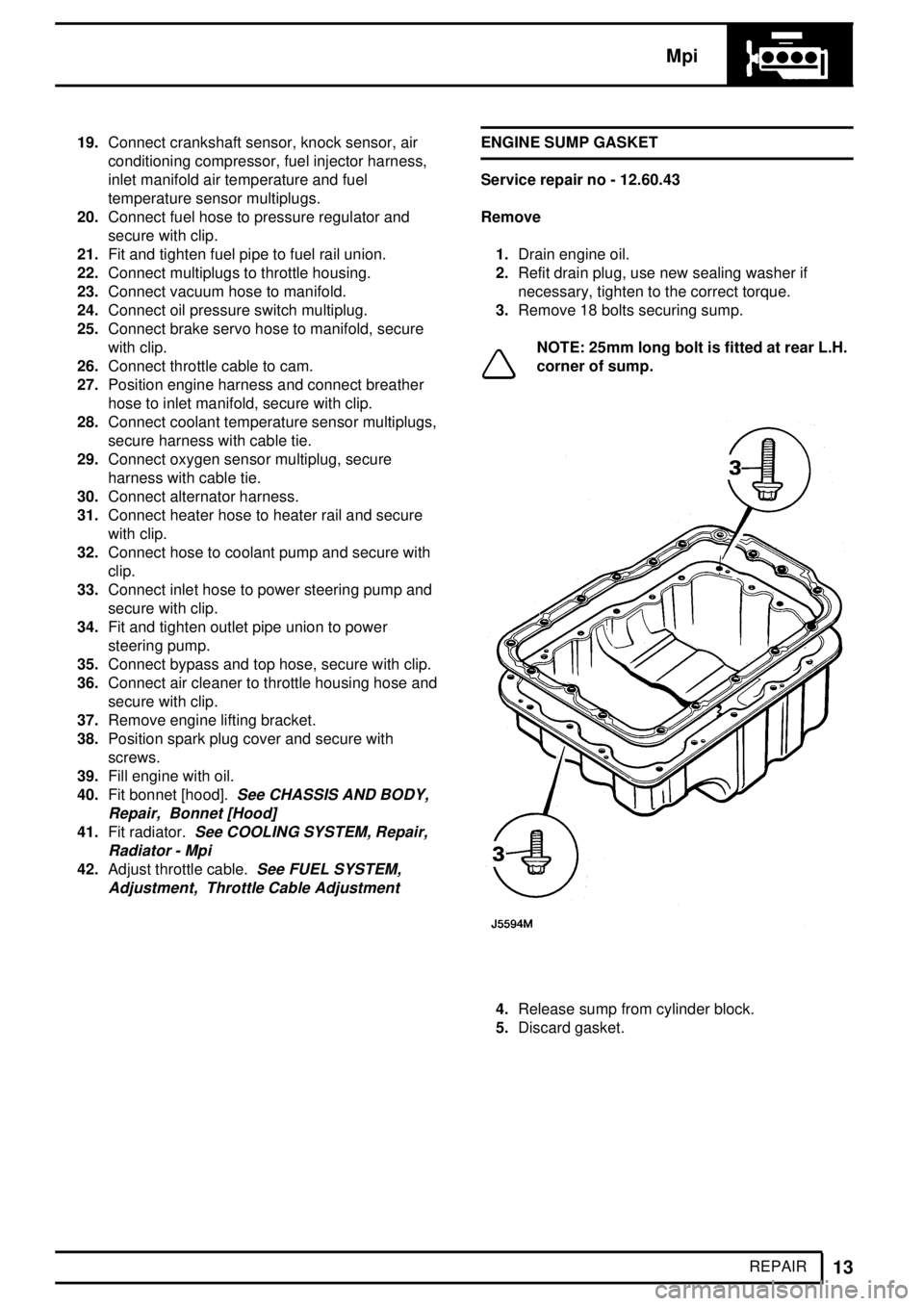

ENGINE SUMP GASKET

Service repair no - 12.60.43

Remove

1.Drain engine oil.

2.Refit drain plug, use new sealing washer if

necessary, tighten to the correct torque.

3.Remove 18 bolts securing sump.

NOTE: 25mm long bolt is fitted at rear L.H.

corner of sump.

4.Release sump from cylinder block.

5.Discard gasket.

Page 172 of 873

12ENGINE

14

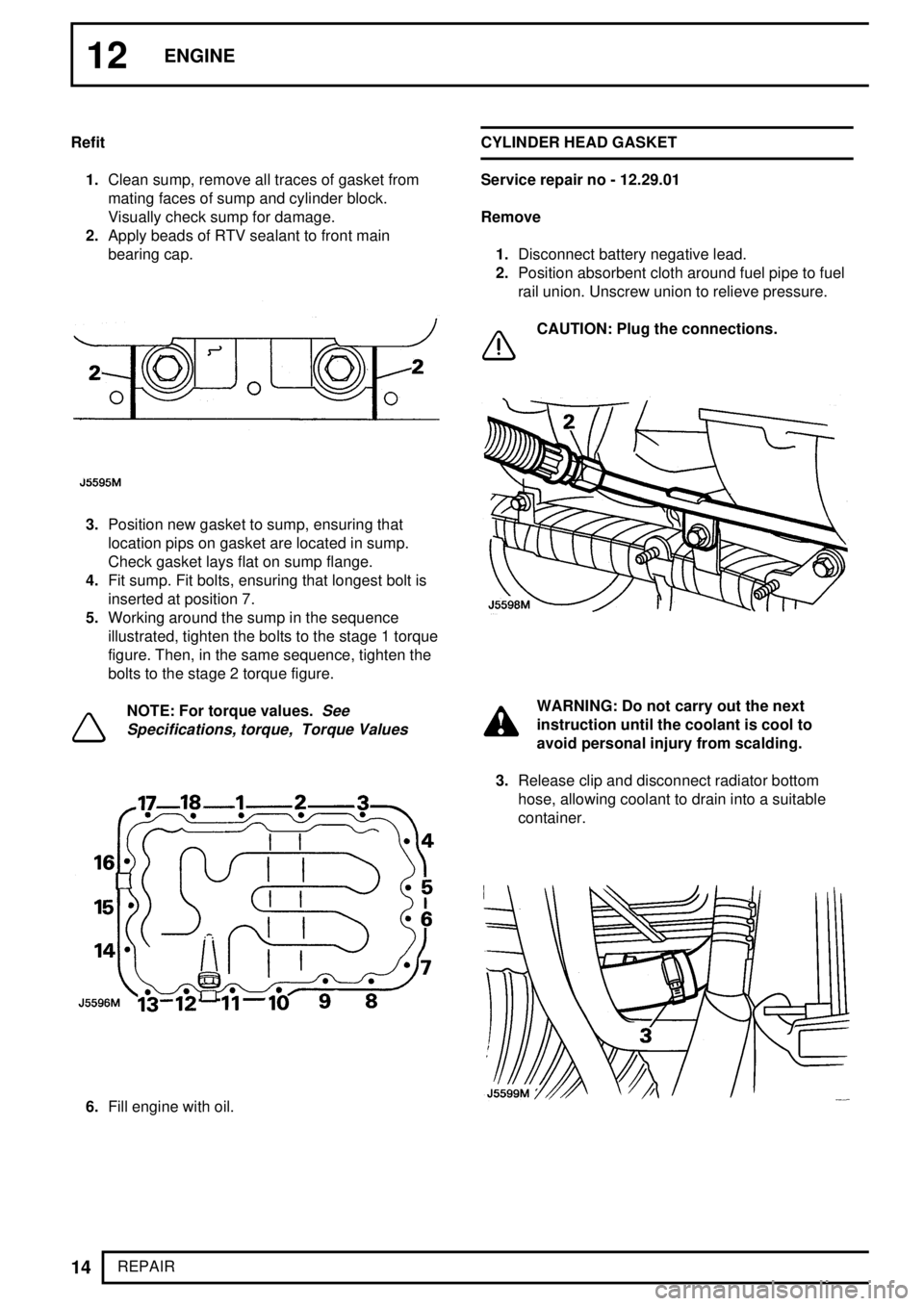

REPAIR Refit

1.Clean sump, remove all traces of gasket from

mating faces of sump and cylinder block.

Visually check sump for damage.

2.Apply beads of RTV sealant to front main

bearing cap.

3.Position new gasket to sump, ensuring that

location pips on gasket are located in sump.

Check gasket lays flat on sump flange.

4.Fit sump. Fit bolts, ensuring that longest bolt is

inserted at position 7.

5.Working around the sump in the sequence

illustrated, tighten the bolts to the stage 1 torque

figure. Then, in the same sequence, tighten the

bolts to the stage 2 torque figure.

NOTE: For torque values.See

Specifications, torque, Torque Values

6.Fill engine with oil.CYLINDER HEAD GASKET

Service repair no - 12.29.01

Remove

1.Disconnect battery negative lead.

2.Position absorbent cloth around fuel pipe to fuel

rail union. Unscrew union to relieve pressure.

CAUTION: Plug the connections.

WARNING: Do not carry out the next

instruction until the coolant is cool to

avoid personal injury from scalding.

3.Release clip and disconnect radiator bottom

hose, allowing coolant to drain into a suitable

container.

Page 173 of 873

Mpi

15

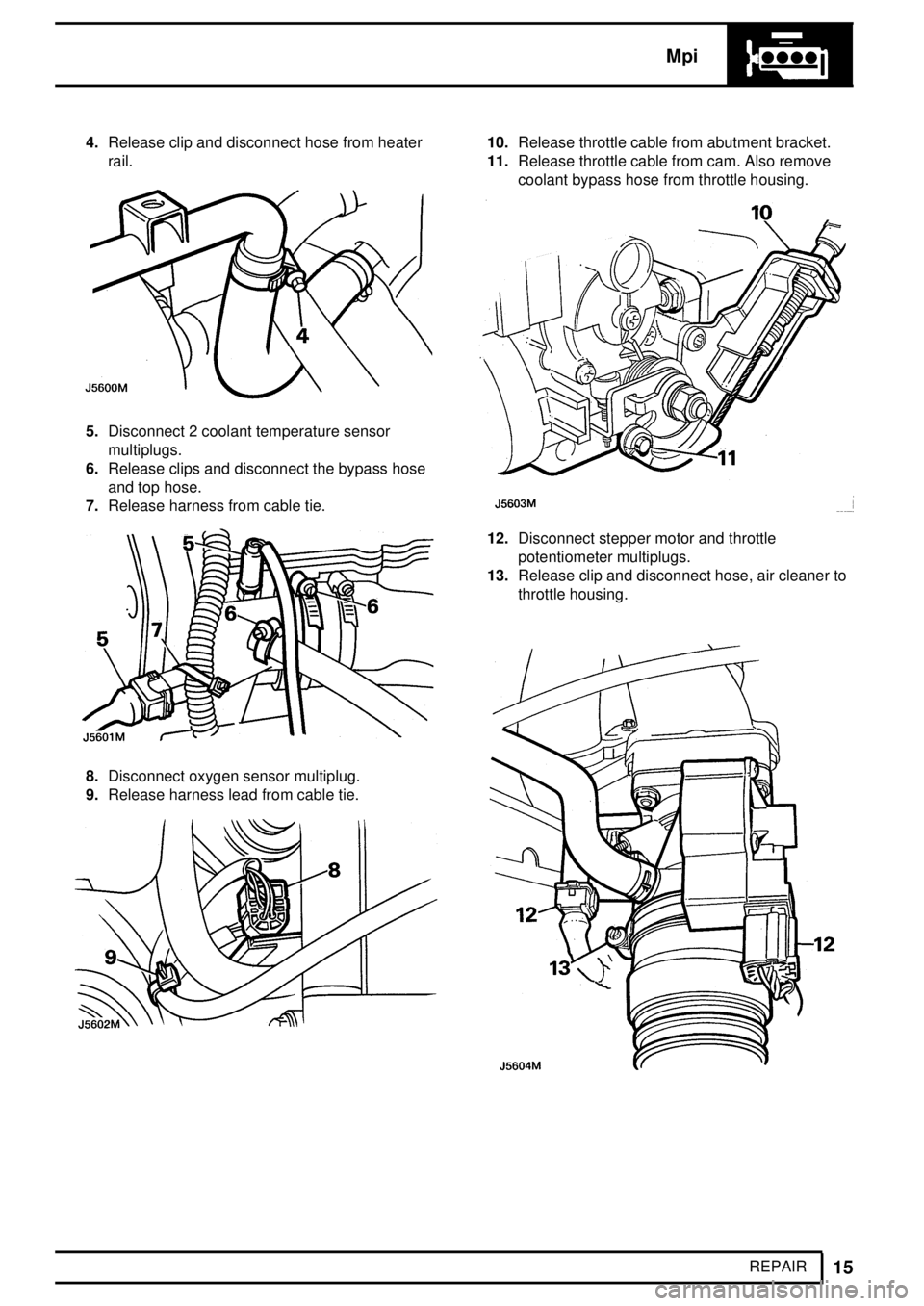

REPAIR 4.Release clip and disconnect hose from heater

rail.

5.Disconnect 2 coolant temperature sensor

multiplugs.

6.Release clips and disconnect the bypass hose

and top hose.

7.Release harness from cable tie.

8.Disconnect oxygen sensor multiplug.

9.Release harness lead from cable tie.

10.Release throttle cable from abutment bracket.

11.Release throttle cable from cam. Also remove

coolant bypass hose from throttle housing.

12.Disconnect stepper motor and throttle

potentiometer multiplugs.

13.Release clip and disconnect hose, air cleaner to

throttle housing.

Page 174 of 873

12ENGINE

16

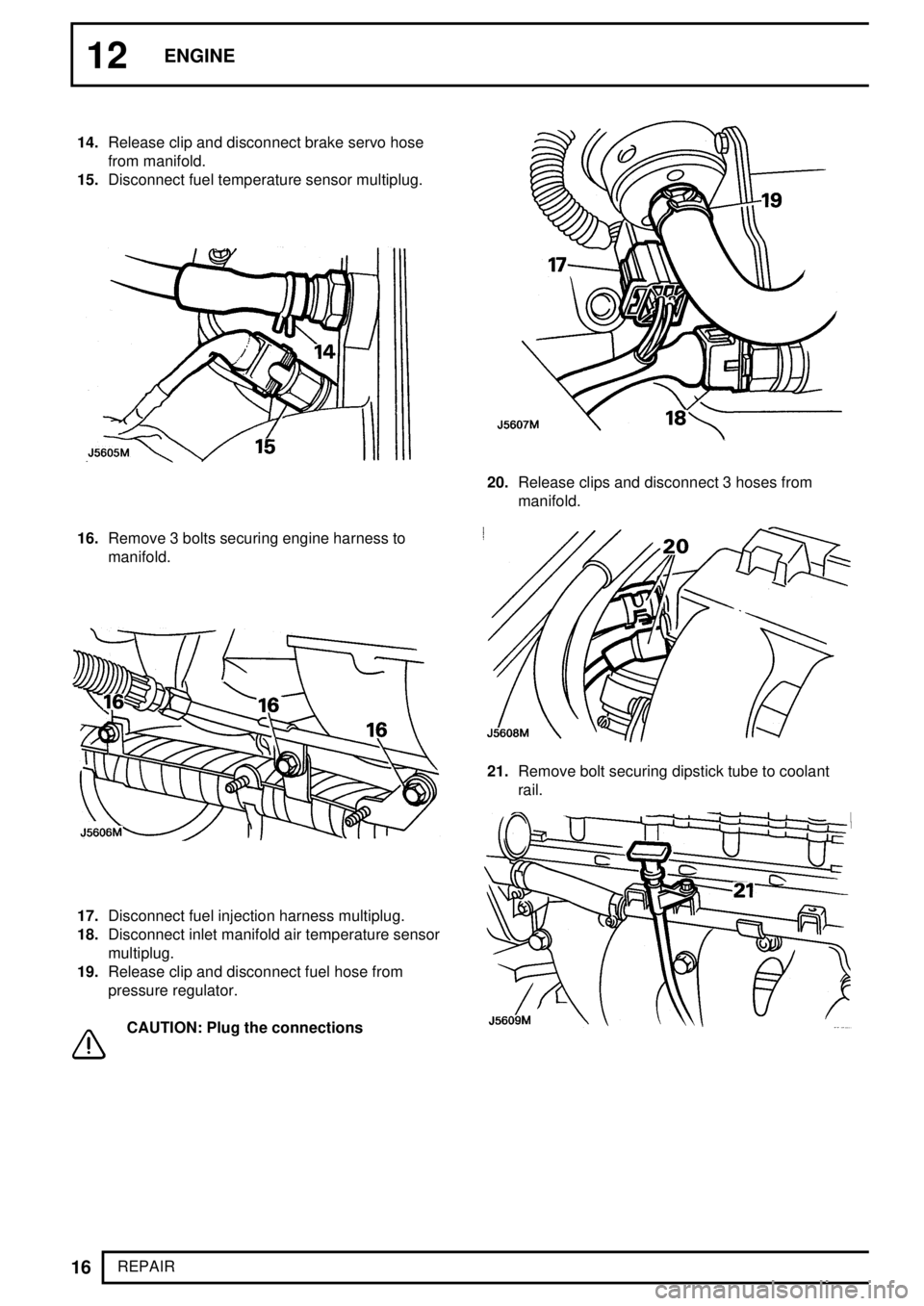

REPAIR 14.Release clip and disconnect brake servo hose

from manifold.

15.Disconnect fuel temperature sensor multiplug.

16.Remove 3 bolts securing engine harness to

manifold.

17.Disconnect fuel injection harness multiplug.

18.Disconnect inlet manifold air temperature sensor

multiplug.

19.Release clip and disconnect fuel hose from

pressure regulator.

CAUTION: Plug the connections

20.Release clips and disconnect 3 hoses from

manifold.

21.Remove bolt securing dipstick tube to coolant

rail.

Page 175 of 873

Mpi

17

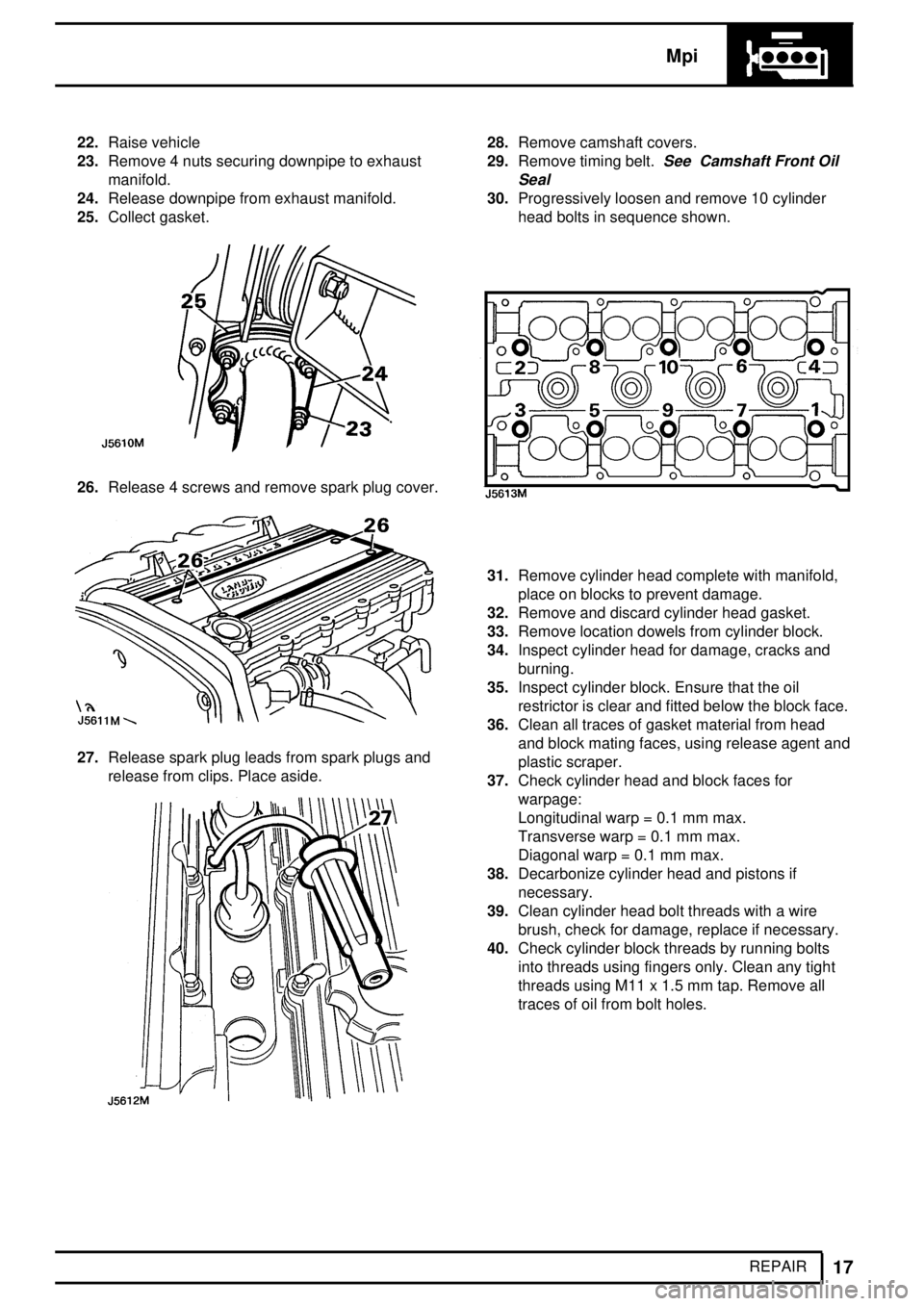

REPAIR 22.Raise vehicle

23.Remove 4 nuts securing downpipe to exhaust

manifold.

24.Release downpipe from exhaust manifold.

25.Collect gasket.

26.Release 4 screws and remove spark plug cover.

27.Release spark plug leads from spark plugs and

release from clips. Place aside.

28.Remove camshaft covers.

29.Remove timing belt.

See Camshaft Front Oil

Seal

30.Progressively loosen and remove 10 cylinder

head bolts in sequence shown.

31.Remove cylinder head complete with manifold,

place on blocks to prevent damage.

32.Remove and discard cylinder head gasket.

33.Remove location dowels from cylinder block.

34.Inspect cylinder head for damage, cracks and

burning.

35.Inspect cylinder block. Ensure that the oil

restrictor is clear and fitted below the block face.

36.Clean all traces of gasket material from head

and block mating faces, using release agent and

plastic scraper.

37.Check cylinder head and block faces for

warpage:

Longitudinal warp = 0.1 mm max.

Transverse warp = 0.1 mm max.

Diagonal warp = 0.1 mm max.

38.Decarbonize cylinder head and pistons if

necessary.

39.Clean cylinder head bolt threads with a wire

brush, check for damage, replace if necessary.

40.Check cylinder block threads by running bolts

into threads using fingers only. Clean any tight

threads using M11 x 1.5 mm tap. Remove all

traces of oil from bolt holes.

Page 176 of 873

12ENGINE

18

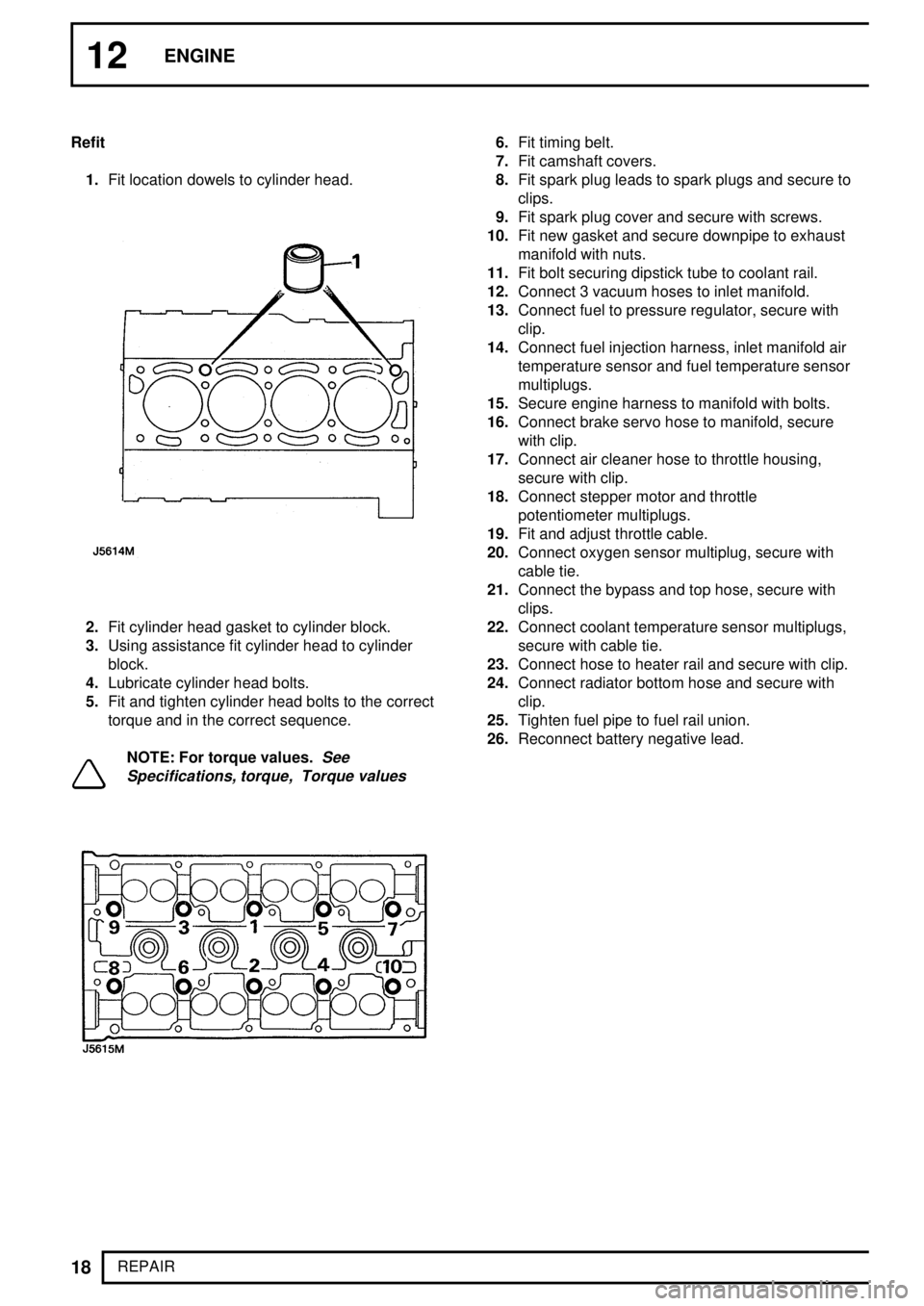

REPAIR Refit

1.Fit location dowels to cylinder head.

2.Fit cylinder head gasket to cylinder block.

3.Using assistance fit cylinder head to cylinder

block.

4.Lubricate cylinder head bolts.

5.Fit and tighten cylinder head bolts to the correct

torque and in the correct sequence.

NOTE: For torque values.See

Specifications, torque, Torque values

6.Fit timing belt.

7.Fit camshaft covers.

8.Fit spark plug leads to spark plugs and secure to

clips.

9.Fit spark plug cover and secure with screws.

10.Fit new gasket and secure downpipe to exhaust

manifold with nuts.

11.Fit bolt securing dipstick tube to coolant rail.

12.Connect 3 vacuum hoses to inlet manifold.

13.Connect fuel to pressure regulator, secure with

clip.

14.Connect fuel injection harness, inlet manifold air

temperature sensor and fuel temperature sensor

multiplugs.

15.Secure engine harness to manifold with bolts.

16.Connect brake servo hose to manifold, secure

with clip.

17.Connect air cleaner hose to throttle housing,

secure with clip.

18.Connect stepper motor and throttle

potentiometer multiplugs.

19.Fit and adjust throttle cable.

20.Connect oxygen sensor multiplug, secure with

cable tie.

21.Connect the bypass and top hose, secure with

clips.

22.Connect coolant temperature sensor multiplugs,

secure with cable tie.

23.Connect hose to heater rail and secure with clip.

24.Connect radiator bottom hose and secure with

clip.

25.Tighten fuel pipe to fuel rail union.

26.Reconnect battery negative lead.

Page 177 of 873

Mpi

19

REPAIR CAMSHAFT COVER GASKET

Service repair no - 12.29.40 - Exhaust

Service repair no - 12.29.41 - Inlet

Remove

1.Release 4 screws from spark plug cover.

2.Remove spark plug cover.

Inlet only

3.Release clips and disconnect 2 breather hoses

from camshaft cover.

4.Remove 4 bolts securing support brackets to

manifold and cover.

5.Remove support brackets.

6.Remove 12 bolts from camshaft cover.

Exhaust only

7.Remove 13 bolts from camshaft cover.

Inlet and exhaust

8.Remove camshaft cover assemblies.

9.Remove and discard baffle/gasket plate(s).

Refit

1.Place protective cloth over tappets.

2.Using an M8 x 1,25 mm tap, remove all traces of

sealing compound from camshaft housing bolt

holes.

3.Blow out bolt holes using an airline.

4.Ensure all traces of oil are removed from bolt

holes, remove protective cloth.

5.Clean camshaft cover(s) and mating face of

camshaft housing(s).

6.Position new baffle/gasket plate to camshaft

housing(s).

NOTE: Fit baffle/gasket dry.

7.Fit camshaft cover(s).

Inlet only

8.Position spacers and manifold support brackets.

9.Fit bolts finger tight.

10.Working from the centre outwards, progressively

tighten bolts to torque.

10Nm

11.Tighten support bracket to inlet manifold bolts.

12.Connect breather hoses to camshaft cover.

Page 178 of 873

12ENGINE

20

REPAIR

Exhaust only

13.Fit bolts finger tight.

14.Working from the centre outwards, progressively

tighten bolts to the correct torque.

10Nm

Inlet and exhaust

15.Fit spark plug cover to camshaft cover, tighten

screws.CAMSHAFT DRIVE BELT

Service repair no - 12.65.17

Remove

NOTE: If the timing belt is to be removed

from the camshaft gears only, it is not

necessary to remove the drive belt,

crankshaft pulley or timing belt lower cover.

1.Remove drive belt.

2.Remove 5 bolts securing timing belt top cover.

3.Remove top cover.

4.Remove 5 bolts securing timing belt centre

cover.

5.Remove timing belt centre cover.

6.Rotate crankshaft to align timing marks on

camshaft gears - 90°BTDC.

Page 179 of 873

Mpi

21

REPAIR

CAUTION: Never use the camshaft gears,

gear retaining bolts or timing belt to rotate

crankshaft.

7.Fit tool LRT-12-058 to lock flywheel.

8.Position tool LRT-12-060 to lock camshaft gears.

9.Loosen camshaft belt tensioner pulley bolt.

10.Move tensioner to release timing belt tension.

11.Retighten tensioner pulley bolt.

12.Remove 4 bolts securing crankshaft pulley to

crankshaft timing gear.13.Fit tool LRT-12-059 to crankshaft pulley, fit 2

pulley bolts to retain tool.

14.Restrain crankshaft pulley using tool LRT-12-059

and remove crankshaft pulley bolt.

15.Remove bolts securing tool LRT-12-059, remove

crankshaft pulley.

16.Remove timing belt lower cover.

17.If timing belt is to be refitted, mark direction of

rotation of belt.

18.Remove timing belt.

Page 180 of 873

12ENGINE

22

REPAIR

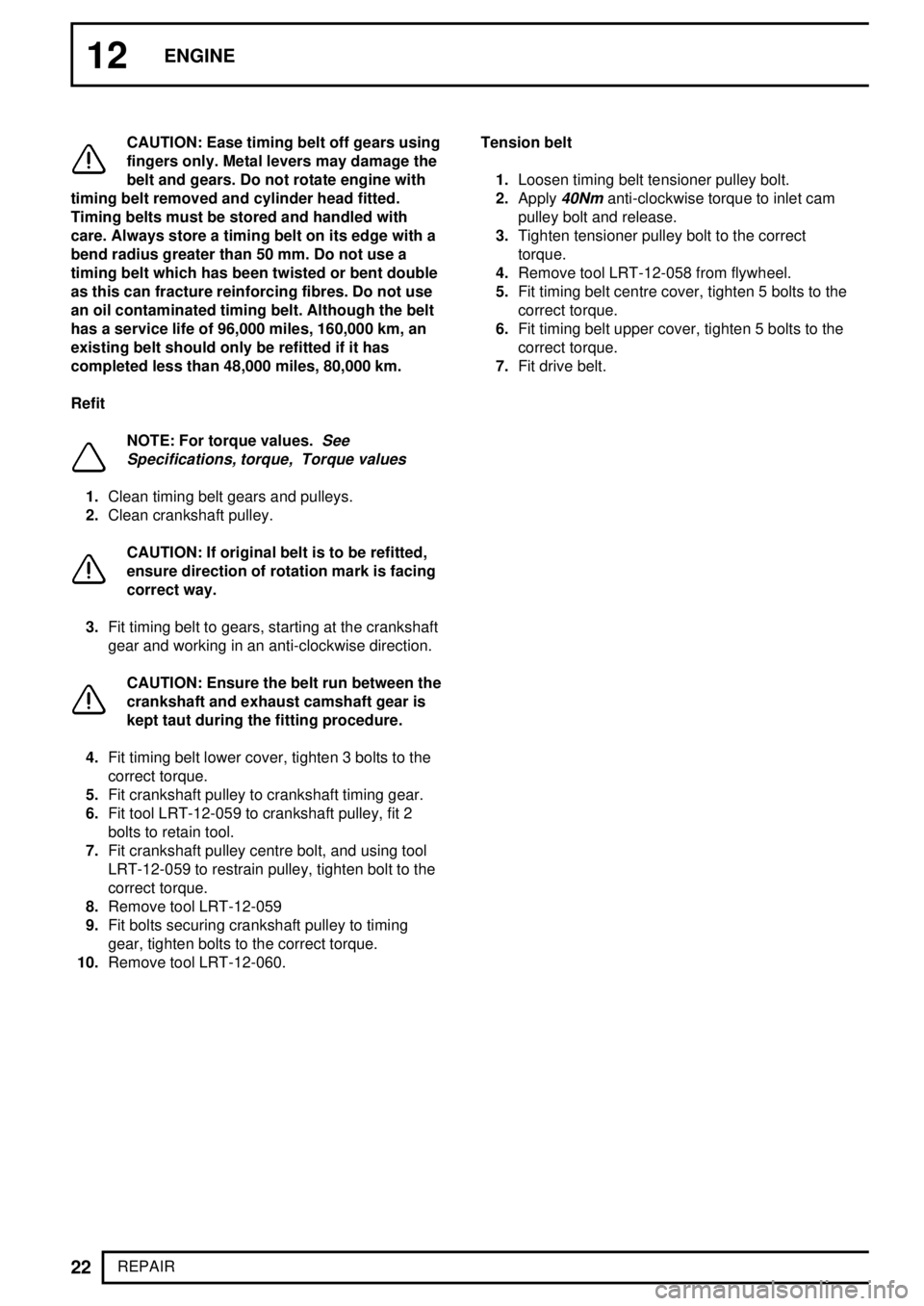

CAUTION: Ease timing belt off gears using

fingers only. Metal levers may damage the

belt and gears. Do not rotate engine with

timing belt removed and cylinder head fitted.

Timing belts must be stored and handled with

care. Always store a timing belt on its edge with a

bend radius greater than 50 mm. Do not use a

timing belt which has been twisted or bent double

as this can fracture reinforcing fibres. Do not use

an oil contaminated timing belt. Although the belt

has a service life of 96,000 miles, 160,000 km, an

existing belt should only be refitted if it has

completed less than 48,000 miles, 80,000 km.

Refit

NOTE: For torque values.See

Specifications, torque, Torque values

1.Clean timing belt gears and pulleys.

2.Clean crankshaft pulley.

CAUTION: If original belt is to be refitted,

ensure direction of rotation mark is facing

correct way.

3.Fit timing belt to gears, starting at the crankshaft

gear and working in an anti-clockwise direction.

CAUTION: Ensure the belt run between the

crankshaft and exhaust camshaft gear is

kept taut during the fitting procedure.

4.Fit timing belt lower cover, tighten 3 bolts to the

correct torque.

5.Fit crankshaft pulley to crankshaft timing gear.

6.Fit tool LRT-12-059 to crankshaft pulley, fit 2

bolts to retain tool.

7.Fit crankshaft pulley centre bolt, and using tool

LRT-12-059 to restrain pulley, tighten bolt to the

correct torque.

8.Remove tool LRT-12-059

9.Fit bolts securing crankshaft pulley to timing

gear, tighten bolts to the correct torque.

10.Remove tool LRT-12-060.Tension belt

1.Loosen timing belt tensioner pulley bolt.

2.Apply

40Nmanti-clockwise torque to inlet cam

pulley bolt and release.

3.Tighten tensioner pulley bolt to the correct

torque.

4.Remove tool LRT-12-058 from flywheel.

5.Fit timing belt centre cover, tighten 5 bolts to the

correct torque.

6.Fit timing belt upper cover, tighten 5 bolts to the

correct torque.

7.Fit drive belt.