LAND ROVER DISCOVERY 1995 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 181 of 873

Mpi

23

REPAIR CHECK CAMSHAFT DRIVE BELT

Service repair no - 12.65.17

CAUTION: This check must be carried out

at the service intervals specified and

whenever carrying out any repair which

requires the timing belt to be disturbed. Pay

particular attention for signs of belt splitting at

base of teeth.

1.Remove 5 bolts securing timing belt upper cover

2.Remove upper cover.

3.Using a socket and extension bar on the

crankshaft pulley bolt, rotate engine to allow the

timing belt to be inspected.

CAUTION: Do not use camshaft gears or

retaining bolts to rotate engine.

4.Check timing belt condition, renew any belt that

shows signs of oil contamination, cracking,

fraying or splitting at base of teeth.

CAUTION: Cause of oil contamination, if

present, must be rectified.

5.Clean timing belt upper cover.

6.Position upper cover.

7.Fit upper cover securing bolts.

Page 182 of 873

Mpi

1

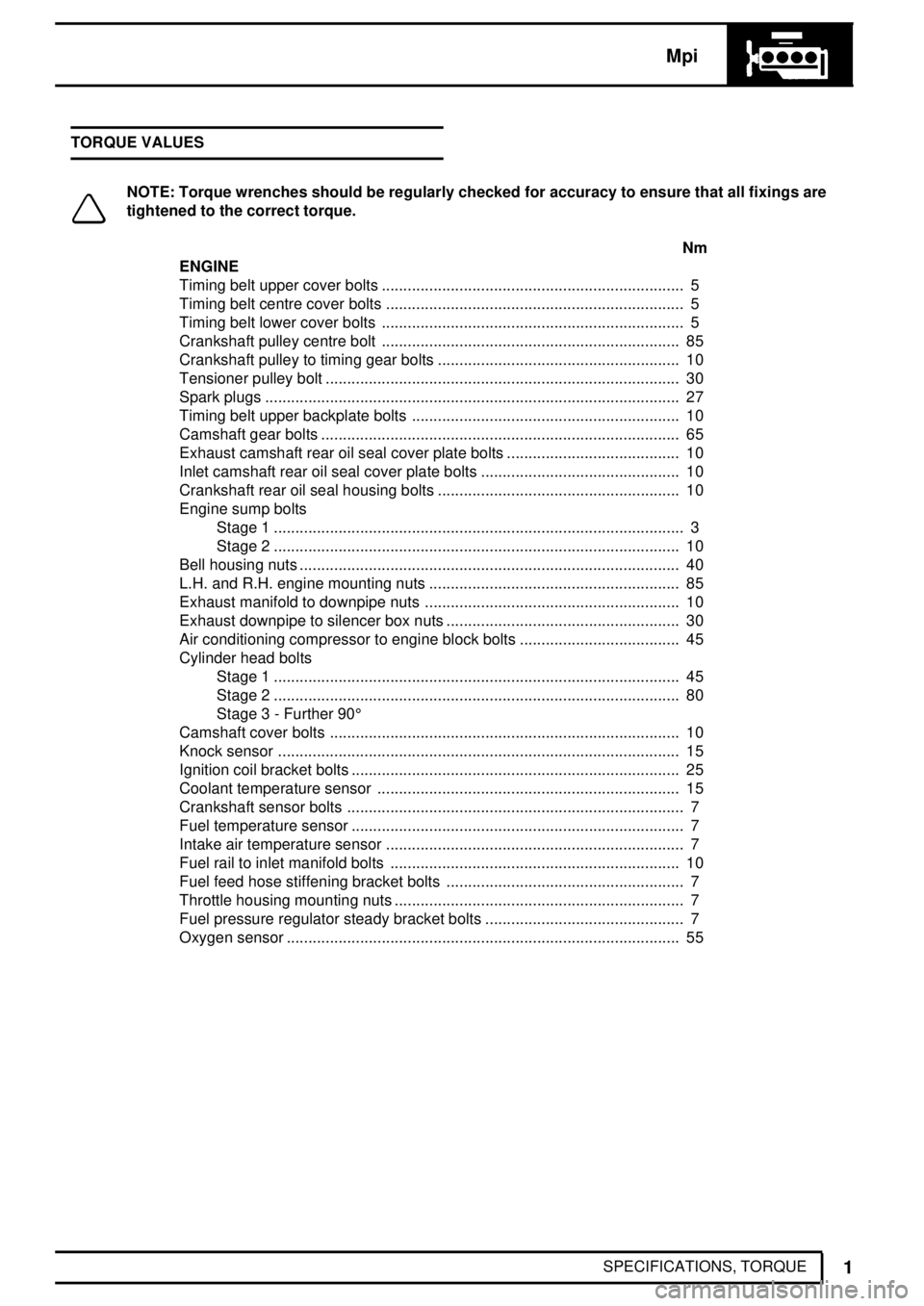

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

ENGINE

Timing belt upper cover bolts 5......................................................................

Timing belt centre cover bolts 5.....................................................................

Timing belt lower cover bolts 5......................................................................

Crankshaft pulley centre bolt 85.....................................................................

Crankshaft pulley to timing gear bolts 10........................................................

Tensioner pulley bolt 30..................................................................................

Spark plugs 27................................................................................................

Timing belt upper backplate bolts 10..............................................................

Camshaft gear bolts 65...................................................................................

Exhaust camshaft rear oil seal cover plate bolts 10........................................

Inlet camshaft rear oil seal cover plate bolts 10..............................................

Crankshaft rear oil seal housing bolts 10........................................................

Engine sump bolts

Stage 1 3...............................................................................................

Stage 2 10..............................................................................................

Bell housing nuts 40........................................................................................

L.H. and R.H. engine mounting nuts 85..........................................................

Exhaust manifold to downpipe nuts 10...........................................................

Exhaust downpipe to silencer box nuts 30......................................................

Air conditioning compressor to engine block bolts 45.....................................

Cylinder head bolts

Stage 1 45..............................................................................................

Stage 2 80..............................................................................................

Stage 3 - Further 90°

Camshaft cover bolts 10.................................................................................

Knock sensor 15.............................................................................................

Ignition coil bracket bolts 25............................................................................

Coolant temperature sensor 15......................................................................

Crankshaft sensor bolts 7..............................................................................

Fuel temperature sensor 7.............................................................................

Intake air temperature sensor 7.....................................................................

Fuel rail to inlet manifold bolts 10...................................................................

Fuel feed hose stiffening bracket bolts 7.......................................................

Throttle housing mounting nuts 7...................................................................

Fuel pressure regulator steady bracket bolts 7..............................................

Oxygen sensor 55...........................................................................................

Page 183 of 873

Mpi

1

SERVICE TOOLS ENGINE

LRT-12-056 Engine lifting bracket

18G 1644

LRT-12-058 Location pin valve timing

18G 1523

LRT-12-059 Crankshaft pulley locking tool

18G 1641

LRT-12-060 Locking tool crankshaft gear

18G 1524

Page 184 of 873

12ENGINE

2

SERVICE TOOLS

LRT-12-061 Protection sleeve crankshaft rear oil

18G 1108 seal

LRT-12-063 Remover camshaft oil seals

18G 1476

LRT-12-064 Replacer pilot camshaft front

18G 1475

LRT-12-069 Replacer crankshaft front oil seal

18G 1509

Page 185 of 873

Mpi

3

SERVICE TOOLS

LRT-12-070 Sleeve crankshaft front oil seal

18G 1510

LRT-12-072 Replacer drift camshaft front oil seals

LRT-12-073 Remover crankshaft front oil seal

LRT-12-074 Remover adapter bit

Page 186 of 873

12ENGINE

4

SERVICE TOOLS

LRT-12-076 Replacer needle crankshaft bearing

Page 187 of 873

EMISSION CONTROL

1

DESCRIPTION AND OPERATION REV: 09/95 EMISSION CONTROL

Three systems are used to control the vehicle

atmospheric emissions these are:

Engine crankcase fume emissions.

Fuel tank Evaporative emissions

Engine exhaust gas emissions.

Crankcase ventilation system - 3.9 MFi models

only

The crankcase ventilation system which is an integral

part of the air supply to the engine combustion

chambers, is often overlooked when diagnosing

problems associated with engine performance. A

blocked ventilation pipe or filter or excessive air leak

into the inlet system through a damaged pipe or

leaking gasket can effect the mixture, performance

and economy of the engine.

1. Three way connector

2. Air filter

3. Oil separatorThe purpose of the crankcase ventilation system is to

ensure that any noxious gas generated in the engine

crankcase is rendered harmless by burning in the

combustion chambers as follows:

Oil laden noxious gas in the engine crankcase is

drawn through an oil separator 3 located on the right

cylinder head rocker cover, where the oil is separated

and returned to the sump. The gas flows through a

restrictor in the three way connection 1 and into the

inlet plenum chamber where it is drawn into the

combustion chambers and burned. The volume of

fresh air which is drawn from the atmospheric side of

the throttle butterfly to mix with the gas, depends on

the position of the throttle and the engine speed.

The air filter 2 fitted to the left cylinder head rocker

cover, must be maintained in clean condition to

ensure sufficient air enters the crankcase under

varying throttle openings and manifold depression, to

prevent excessive crankcase pressure or depression

developing.

Page 188 of 873

17EMISSION CONTROL

2

DESCRIPTION AND OPERATION REV: 09/95 Exhaust emission control.

The fuel injection system provides accurately metered

quantities of fuel to the combustion chambers to

ensure the most efficient air to fuel ratio under all

conditions of operation. A further improvement to

combustion is made by measuring the oxygen content

of the exhaust gases to enable the quantity of fuel

injected to be varied, according to conditions, to

correct any unsatisfactory composition of the exhaust.

The main components of the exhaust emission

system are two Catalytic converters which are an

integral part of the front exhaust pipe assembly. The

Catalytic converters are included in the system to

reduce the emission, to atmosphere, of carbon

monoxide, oxides of nitrogen, and hydrocarbons. The

active constituents of the converters are platinum and

rhodium. The correct functioning of the converters is

dependent upon close control of the oxygen

concentration in the exhaust gas entering the catalyst.

The oxygen content of the exhaust gas is monitored

by the heated oxygen sensors. Information on the

heated oxygen sensors is contained in the relevant

Fuel System section,

See FUEL SYSTEM MFI,

Description and operation, or See FUEL SYSTEM

SFI, Description and operation,

The ECM can then

make an appropriate adjustment to the fuel supply to

correct the composition of the exhaust.

CAUTION: Unleaded fuel only must be

used on vehicles fitted with catalytic

converters. As a reminder,a label to

indicate this is adhered to the inside of the fuel

filler flap. Furthermore the filler neck is designed

to accommodate only unleaded fuel pump

nozzles.

Page 189 of 873

EMISSION CONTROL

3

DESCRIPTION AND OPERATION REV: 09/95

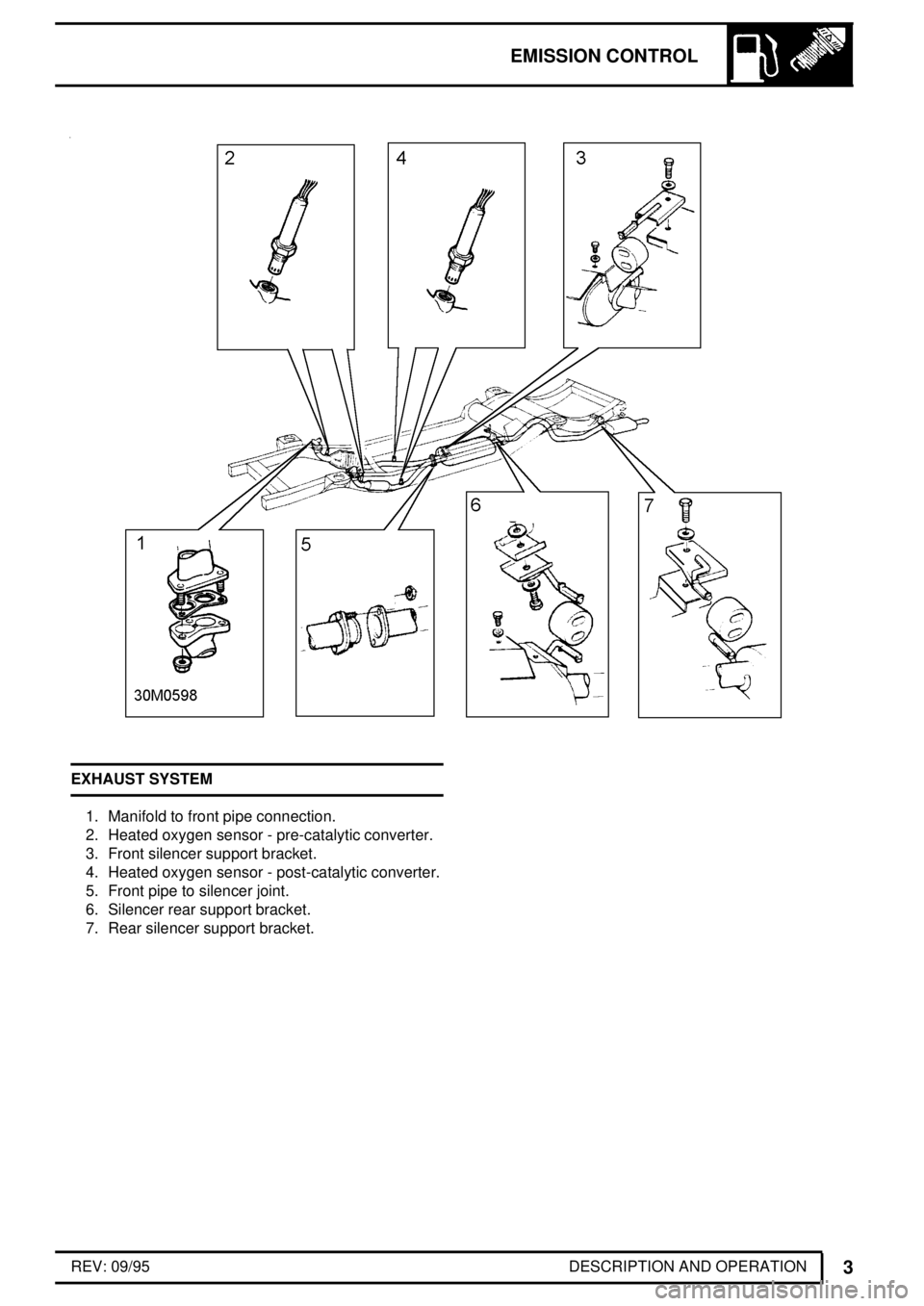

EXHAUST SYSTEM

1. Manifold to front pipe connection.

2. Heated oxygen sensor - pre-catalytic converter.

3. Front silencer support bracket.

4. Heated oxygen sensor - post-catalytic converter.

5. Front pipe to silencer joint.

6. Silencer rear support bracket.

7. Rear silencer support bracket.

Page 190 of 873

17EMISSION CONTROL

4

DESCRIPTION AND OPERATION REV: 09/95 Evaporative emission control system - pre

advanced EVAPS.

The system is designed to prevent harmful fuel vapour

from escaping to the atmosphere. The system

consists of a vapour separator tank, connected to the

fuel tank and located between the body inner and

outer panels on the right hand side of the vehicle near

the rear wheel arch. An adsorbtion canister,

containing activated charcoal, is positioned in the

engine compartment attached to the front right

valance. The two components are connected by a

pipe running the length of the chassis.

A Pressure relief to atmosphere.

B From fuel tank to separator.

C To adsorbtion canister.

D Pressure relief valve.

E Pressure relief valve.

F Shut-off valve.

G "Speed Fit" connectors.A pressure relief valve is fitted in the hose which is

open to atmosphere. This valve acts as a safety valve

should a build-up of pressure occur in the system, for

example if a hose became blocked or kinked. The

volume of vapour emitted, in such an instance, would

be acceptable.

A pressure relief valve is also fitted in the hose

connected to the adsorbtion canister and releases

vapor to the canister when the pressure in the

separator reaches between 5 and 7 Kpa.

In the top of the separator a shut-off valve is

incorporated in the vapor exit port to prevent the

possible presence of any liquid fuel being transmitted

to the adsorbtion canister should the vehicle roll over.

The adsorbtion canister, which is connected by a hose

to the plenum chamber, absorbs and stores the fuel

vapour from the fuel tank while the engine is not

running. When the engine is started, the vapour is

purged from the canister by air drawn through an

orifice in the base of the canister and by the influence

of vacuum at the top. The vapour drawn into the

plenum chamber through a solenoid operated purge

valve is finally burnt in the combustion chambers.

The purge valve, which is attached to the adsorbtion

canister support bracket, is controlled by the Engine

Control Module ECM which determines the most

emission acceptable time at which purging should

take place. This will normally be at engine speeds

above idle and when the vehicle is in motion. A signal

from the ECM to the purge valve operates the

solenoid and opens the valve to purge the canister of

fuel vapour.