LAND ROVER DISCOVERY 1995 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 241 of 873

MFI

5

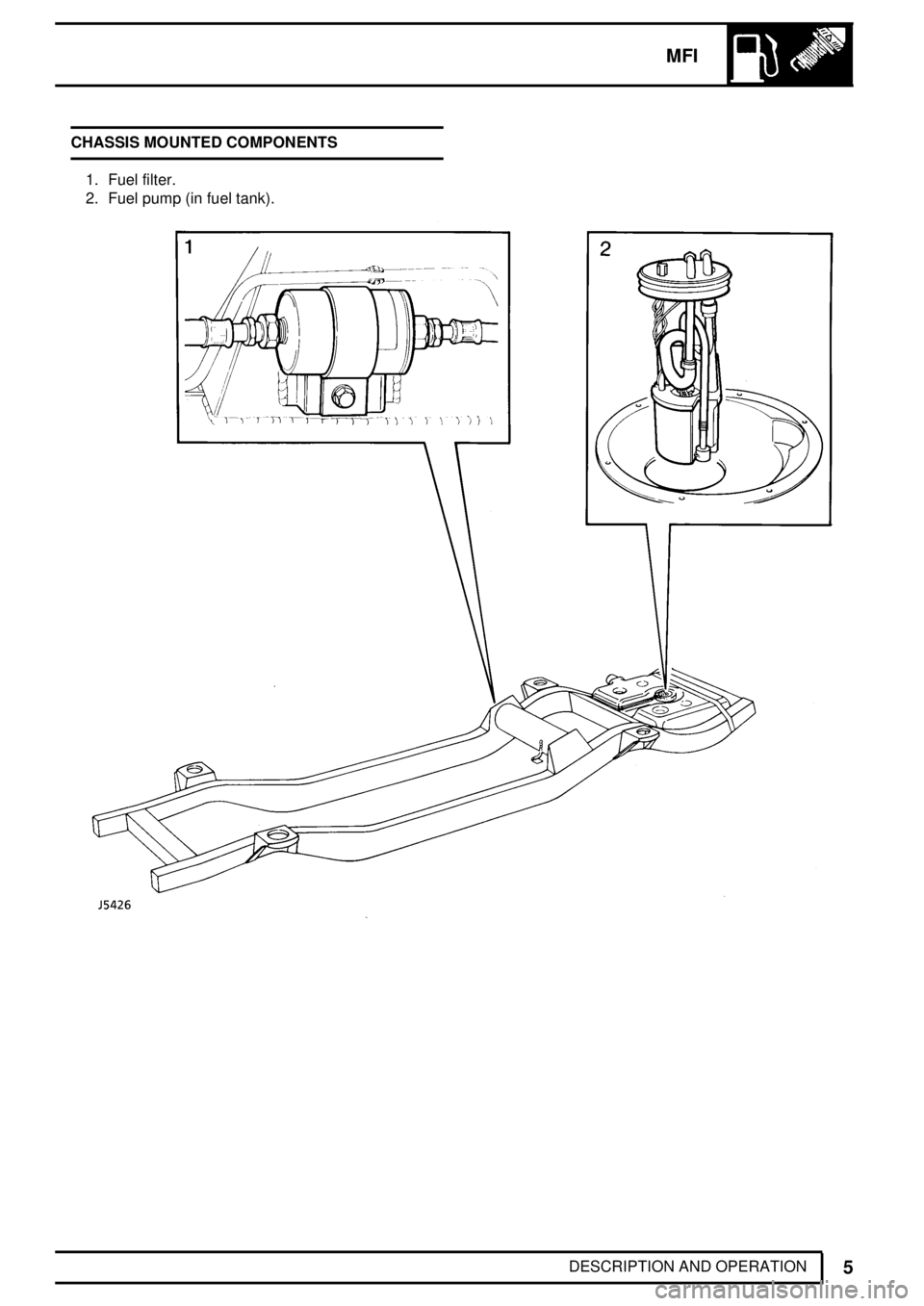

DESCRIPTION AND OPERATION CHASSIS MOUNTED COMPONENTS

1. Fuel filter.

2. Fuel pump (in fuel tank).

Page 242 of 873

19FUEL SYSTEM

6

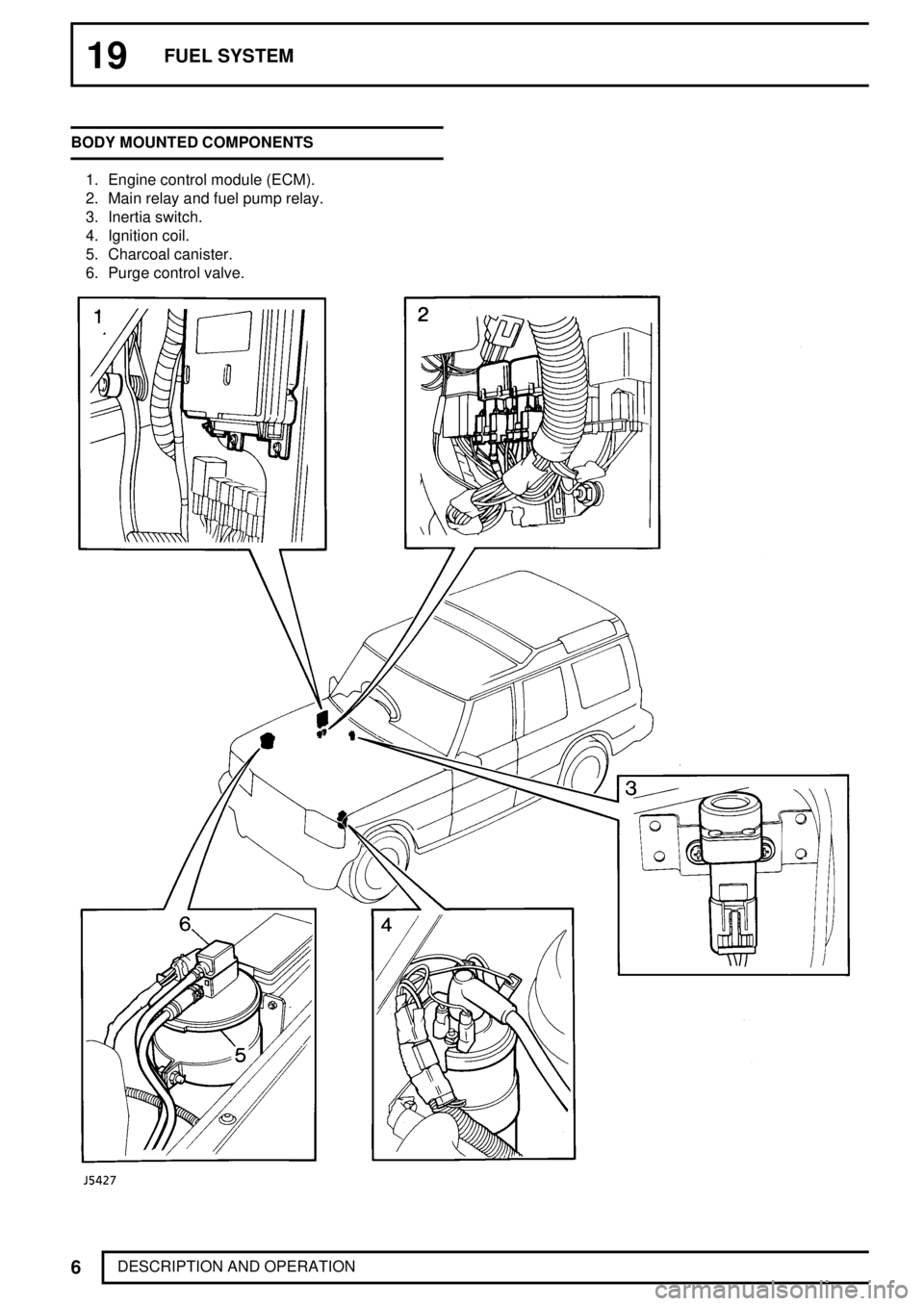

DESCRIPTION AND OPERATION BODY MOUNTED COMPONENTS

1. Engine control module (ECM).

2. Main relay and fuel pump relay.

3. Inertia switch.

4. Ignition coil.

5. Charcoal canister.

6. Purge control valve.

Page 243 of 873

MFI

7

DESCRIPTION AND OPERATION MICRO PROCESSOR POWER CHECK

(Instrument binnacle - Service use only)

As part of the engine starting procedure, this symbol

will illuminate momentarily.

FUEL INJECTION SYSTEM

CAUTION: The fuel system incorporates

fine metering components that would be

affected by any dirt in the system;

therefore it is essential that working conditions

are scrupulously clean. If it is necessary to

disconnect any part of the fuel injection system,

the system MUST be depressurized. All openings

left open after the removal of any component from

the fuel system, MUST be sealed off to prevent

ingress of dirt.ENGINE SETTING PROCEDURE

If a major overhaul has been undertaken of the fuel

injection/engine system, the following check and

adjustments must be carried out before attempting to

start the engine.

1.Spark plug gaps.

See ENGINE TUNING DATA,

Information, Engine 3.9 V8i

2.Ignition timing.See ELECTRICAL,

Adjustment, Ignition Timing

CAUTION: Catalyst vehicle - if the engine

is misfiring, it should be immediately shut

down and the cause rectified. Failure to do

so will result in irreparable damage to the

catalysts.

NOTE: If the previous checks and

adjustments are satisfactory but the

engine will not start, the ignition and fuel

injection electrical circuits must be checked using

the appropriate recommended equipment.

Page 244 of 873

MFI

1

FAULT DIAGNOSIS ENGINE TUNING

Circuit fault diagnosis may be carried out on all V8i

vehicles, using Testbook. Testbook will guide the

operator by visual prompts through a series of

diagnostic checks.

Before commencing any fault diagnosis, the following

preminary checks must be carried out.

Preliminary checks

CAUTION: Catalyst exhaust: If engine is

misfiring or fails to start within 12 seconds

the cause must be rectified. Failure to do

so will result in irreparable damage to the

catalysts. After rectification the engine must be

run at 1500 rev/min (no load) for 3 minutes to

purge any accumulation of fuel in the system.

1.Check that the inertia fuel shut off switch is not

tripped.

2.Check fuse in main fuse panel.

3.Check for ample fuel in tank.

4.Check air inlet system for possible leaks into the

intake manifold.

5.Check HT cables for correct firing order and

routing.

6.Check ignition timing.

Only when the above checks have been carried out,

should circuit diagnosis begin.

See Electrical

Trouble Shooting Manual.

INJECTOR TESTS

NOTE: Before removing any of the

injectors, remove and examine the spark

plugs, check for consistent colouration of

plugs. A leaking injector will result in the

appropriate spark plug being 'sooted up'.

The following test may only be carried out using

suitable injector test equipment.

Leak Test

Leak test with the injectors closed but pressurise to

2.54 Kgf/cm

2. No injector should leak more than 2

drops of fuel per minute.

Fuel Delivery Test

Fuel delivery test with the injector open and

pressurised as above, fuel delivery from each injector

should be 160-175cc per minute using white spirit, or

180-195cc per minute using petrol at 20°C±2°C.

Page 245 of 873

19FUEL SYSTEM

2

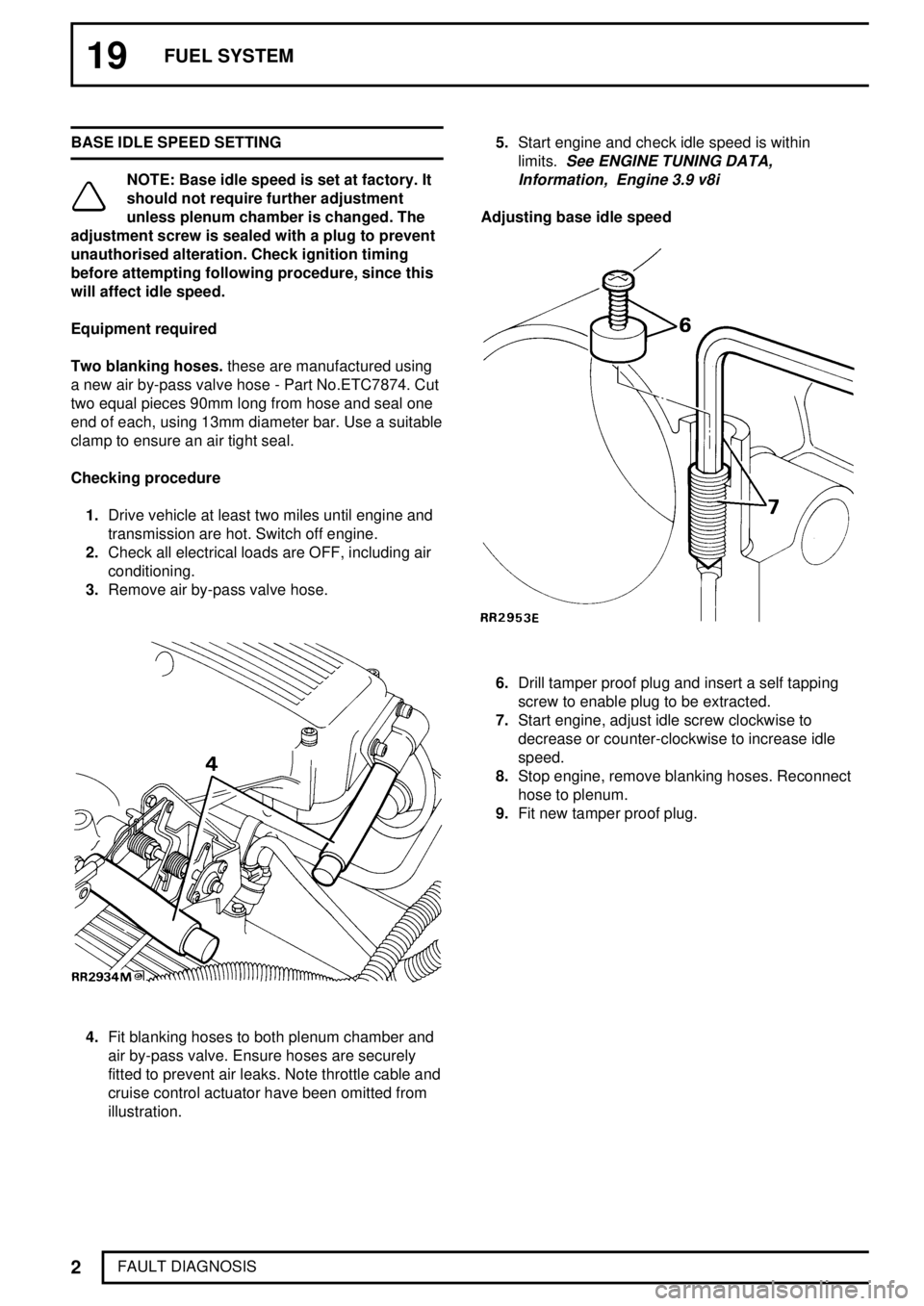

FAULT DIAGNOSIS BASE IDLE SPEED SETTING

NOTE: Base idle speed is set at factory. It

should not require further adjustment

unless plenum chamber is changed. The

adjustment screw is sealed with a plug to prevent

unauthorised alteration. Check ignition timing

before attempting following procedure, since this

will affect idle speed.

Equipment required

Two blanking hoses.these are manufactured using

a new air by-pass valve hose - Part No.ETC7874. Cut

two equal pieces 90mm long from hose and seal one

end of each, using 13mm diameter bar. Use a suitable

clamp to ensure an air tight seal.

Checking procedure

1.Drive vehicle at least two miles until engine and

transmission are hot. Switch off engine.

2.Check all electrical loads are OFF, including air

conditioning.

3.Remove air by-pass valve hose.

4.Fit blanking hoses to both plenum chamber and

air by-pass valve. Ensure hoses are securely

fitted to prevent air leaks. Note throttle cable and

cruise control actuator have been omitted from

illustration.5.Start engine and check idle speed is within

limits.

See ENGINE TUNING DATA,

Information, Engine 3.9 v8i

Adjusting base idle speed

6.Drill tamper proof plug and insert a self tapping

screw to enable plug to be extracted.

7.Start engine, adjust idle screw clockwise to

decrease or counter-clockwise to increase idle

speed.

8.Stop engine, remove blanking hoses. Reconnect

hose to plenum.

9.Fit new tamper proof plug.

Page 246 of 873

MFI

3

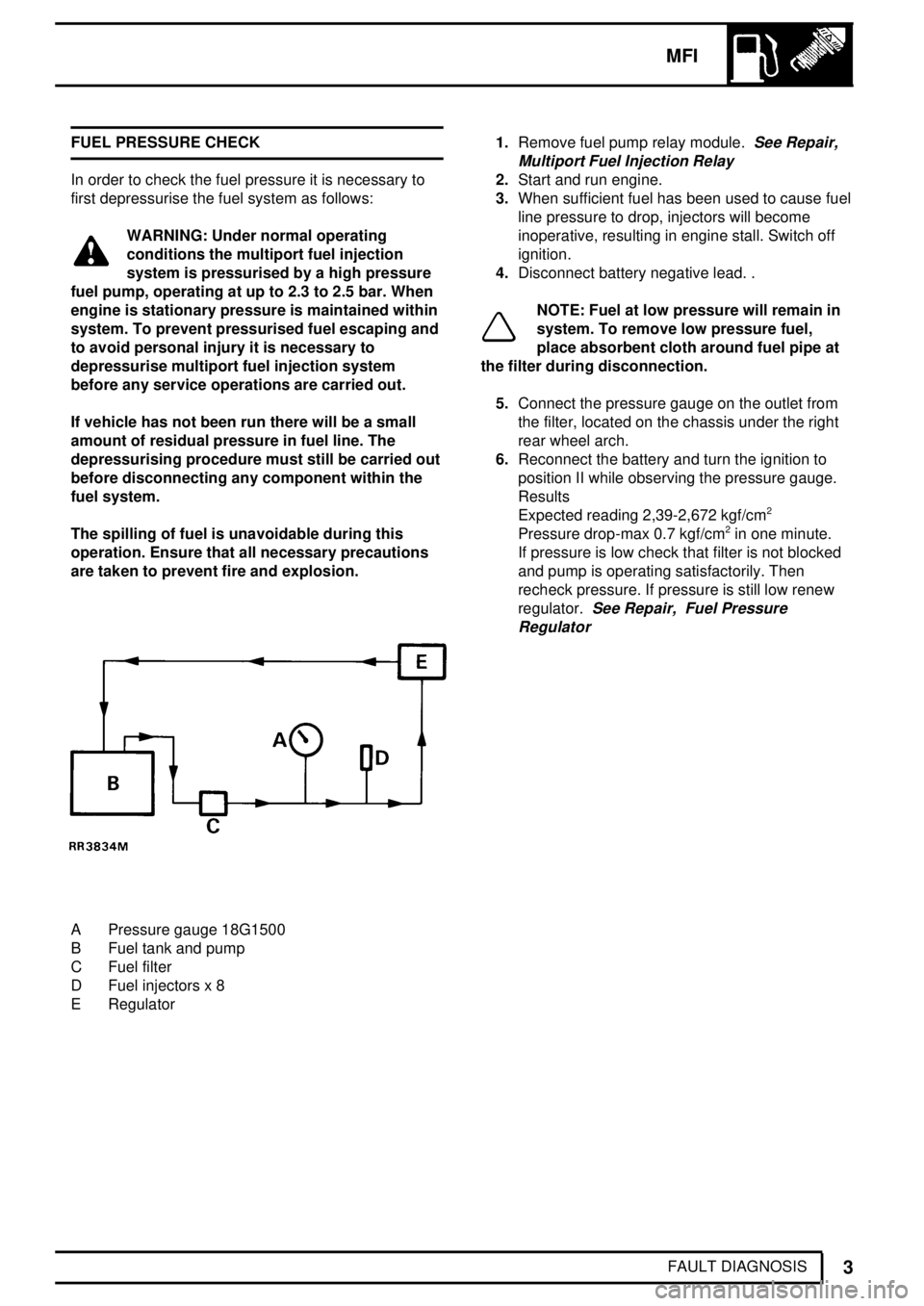

FAULT DIAGNOSIS FUEL PRESSURE CHECK

In order to check the fuel pressure it is necessary to

first depressurise the fuel system as follows:

WARNING: Under normal operating

conditions the multiport fuel injection

system is pressurised by a high pressure

fuel pump, operating at up to 2.3 to 2.5 bar. When

engine is stationary pressure is maintained within

system. To prevent pressurised fuel escaping and

to avoid personal injury it is necessary to

depressurise multiport fuel injection system

before any service operations are carried out.

If vehicle has not been run there will be a small

amount of residual pressure in fuel line. The

depressurising procedure must still be carried out

before disconnecting any component within the

fuel system.

The spilling of fuel is unavoidable during this

operation. Ensure that all necessary precautions

are taken to prevent fire and explosion.

A Pressure gauge 18G1500

B Fuel tank and pump

C Fuel filter

D Fuel injectors x 8

E Regulator1.Remove fuel pump relay module.

See Repair,

Multiport Fuel Injection Relay

2.Start and run engine.

3.When sufficient fuel has been used to cause fuel

line pressure to drop, injectors will become

inoperative, resulting in engine stall. Switch off

ignition.

4.Disconnect battery negative lead. .

NOTE: Fuel at low pressure will remain in

system. To remove low pressure fuel,

place absorbent cloth around fuel pipe at

the filter during disconnection.

5.Connect the pressure gauge on the outlet from

the filter, located on the chassis under the right

rear wheel arch.

6.Reconnect the battery and turn the ignition to

position II while observing the pressure gauge.

Results

Expected reading 2,39-2,672 kgf/cm

2

Pressure drop-max 0.7 kgf/cm2in one minute.

If pressure is low check that filter is not blocked

and pump is operating satisfactorily. Then

recheck pressure. If pressure is still low renew

regulator.

See Repair, Fuel Pressure

Regulator

Page 247 of 873

MFI

1

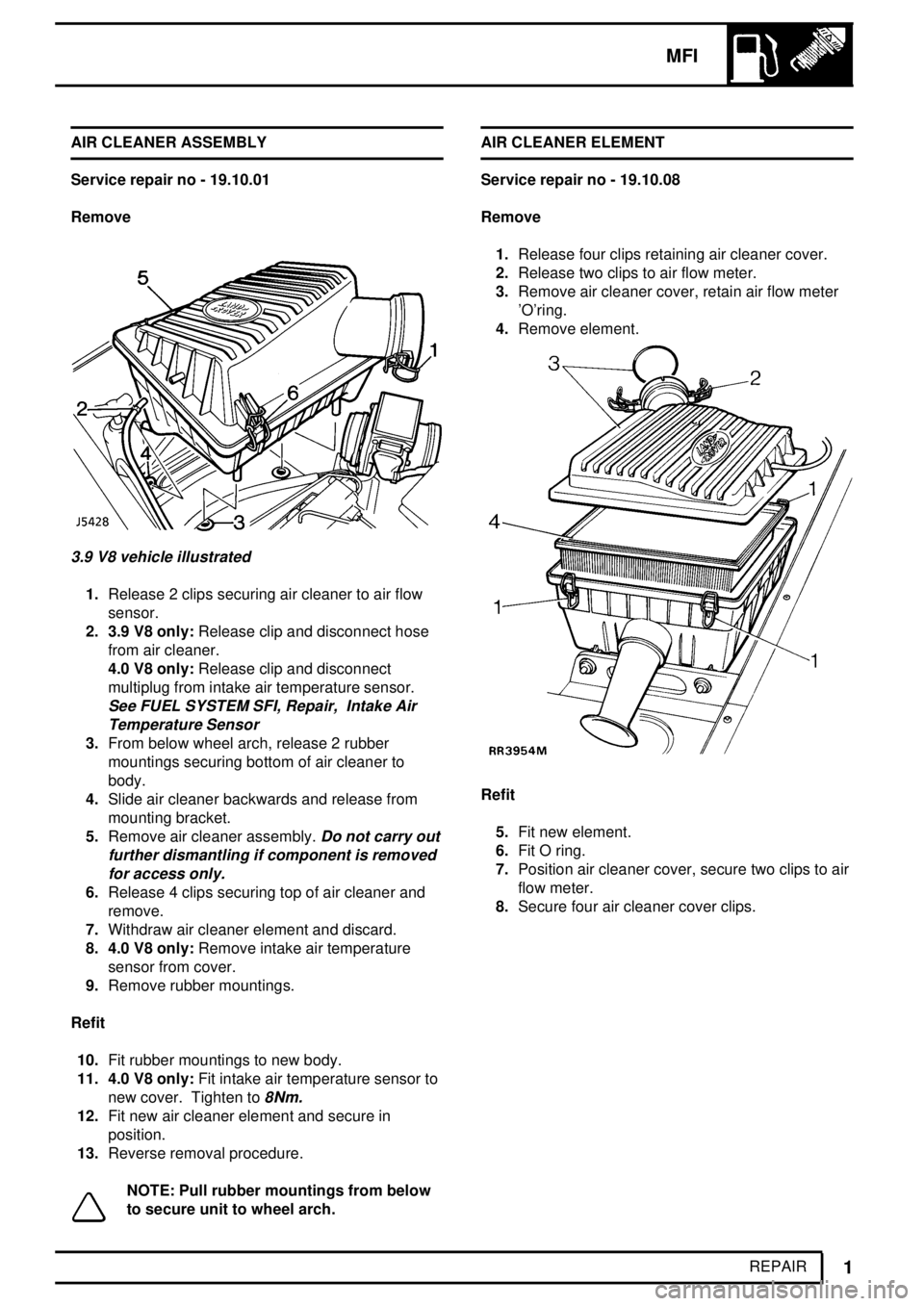

REPAIR AIR CLEANER ASSEMBLY

Service repair no - 19.10.01

Remove

3.9 V8 vehicle illustrated

1.Release 2 clips securing air cleaner to air flow

sensor.

2. 3.9 V8 only:Release clip and disconnect hose

from air cleaner.

4.0 V8 only:Release clip and disconnect

multiplug from intake air temperature sensor.

See FUEL SYSTEM SFI, Repair, Intake Air

Temperature Sensor

3.From below wheel arch, release 2 rubber

mountings securing bottom of air cleaner to

body.

4.Slide air cleaner backwards and release from

mounting bracket.

5.Remove air cleaner assembly.

Do not carry out

further dismantling if component is removed

for access only.

6.Release 4 clips securing top of air cleaner and

remove.

7.Withdraw air cleaner element and discard.

8. 4.0 V8 only:Remove intake air temperature

sensor from cover.

9.Remove rubber mountings.

Refit

10.Fit rubber mountings to new body.

11. 4.0 V8 only:Fit intake air temperature sensor to

new cover. Tighten to

8Nm.

12.Fit new air cleaner element and secure in

position.

13.Reverse removal procedure.

NOTE: Pull rubber mountings from below

to secure unit to wheel arch.AIR CLEANER ELEMENT

Service repair no - 19.10.08

Remove

1.Release four clips retaining air cleaner cover.

2.Release two clips to air flow meter.

3.Remove air cleaner cover, retain air flow meter

'O'ring.

4.Remove element.

Refit

5.Fit new element.

6.Fit O ring.

7.Position air cleaner cover, secure two clips to air

flow meter.

8.Secure four air cleaner cover clips.

Page 248 of 873

19FUEL SYSTEM

2

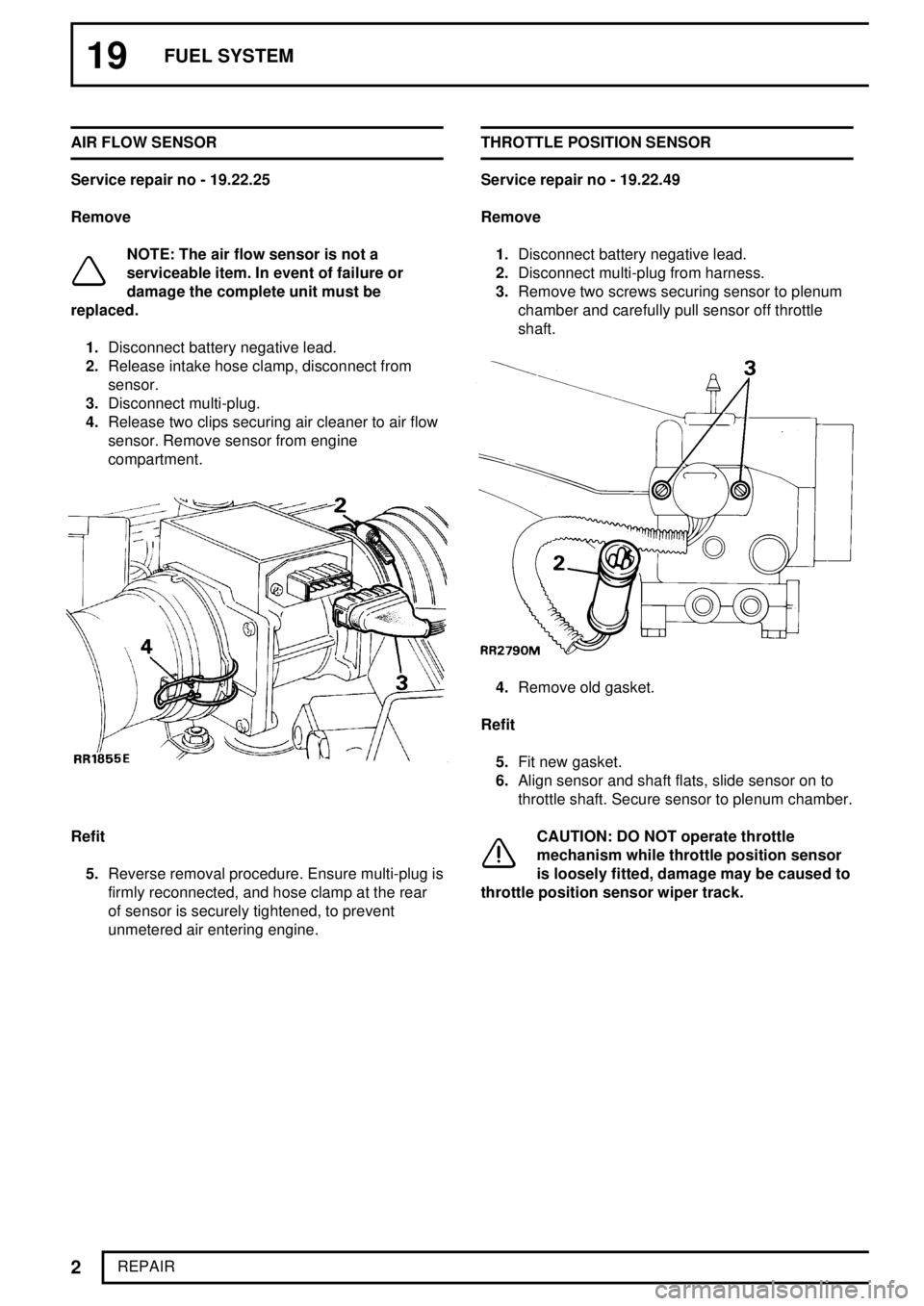

REPAIR AIR FLOW SENSOR

Service repair no - 19.22.25

Remove

NOTE: The air flow sensor is not a

serviceable item. In event of failure or

damage the complete unit must be

replaced.

1.Disconnect battery negative lead.

2.Release intake hose clamp, disconnect from

sensor.

3.Disconnect multi-plug.

4.Release two clips securing air cleaner to air flow

sensor. Remove sensor from engine

compartment.

Refit

5.Reverse removal procedure. Ensure multi-plug is

firmly reconnected, and hose clamp at the rear

of sensor is securely tightened, to prevent

unmetered air entering engine.THROTTLE POSITION SENSOR

Service repair no - 19.22.49

Remove

1.Disconnect battery negative lead.

2.Disconnect multi-plug from harness.

3.Remove two screws securing sensor to plenum

chamber and carefully pull sensor off throttle

shaft.

4.Remove old gasket.

Refit

5.Fit new gasket.

6.Align sensor and shaft flats, slide sensor on to

throttle shaft. Secure sensor to plenum chamber.

CAUTION: DO NOT operate throttle

mechanism while throttle position sensor

is loosely fitted, damage may be caused to

throttle position sensor wiper track.

Page 249 of 873

MFI

3

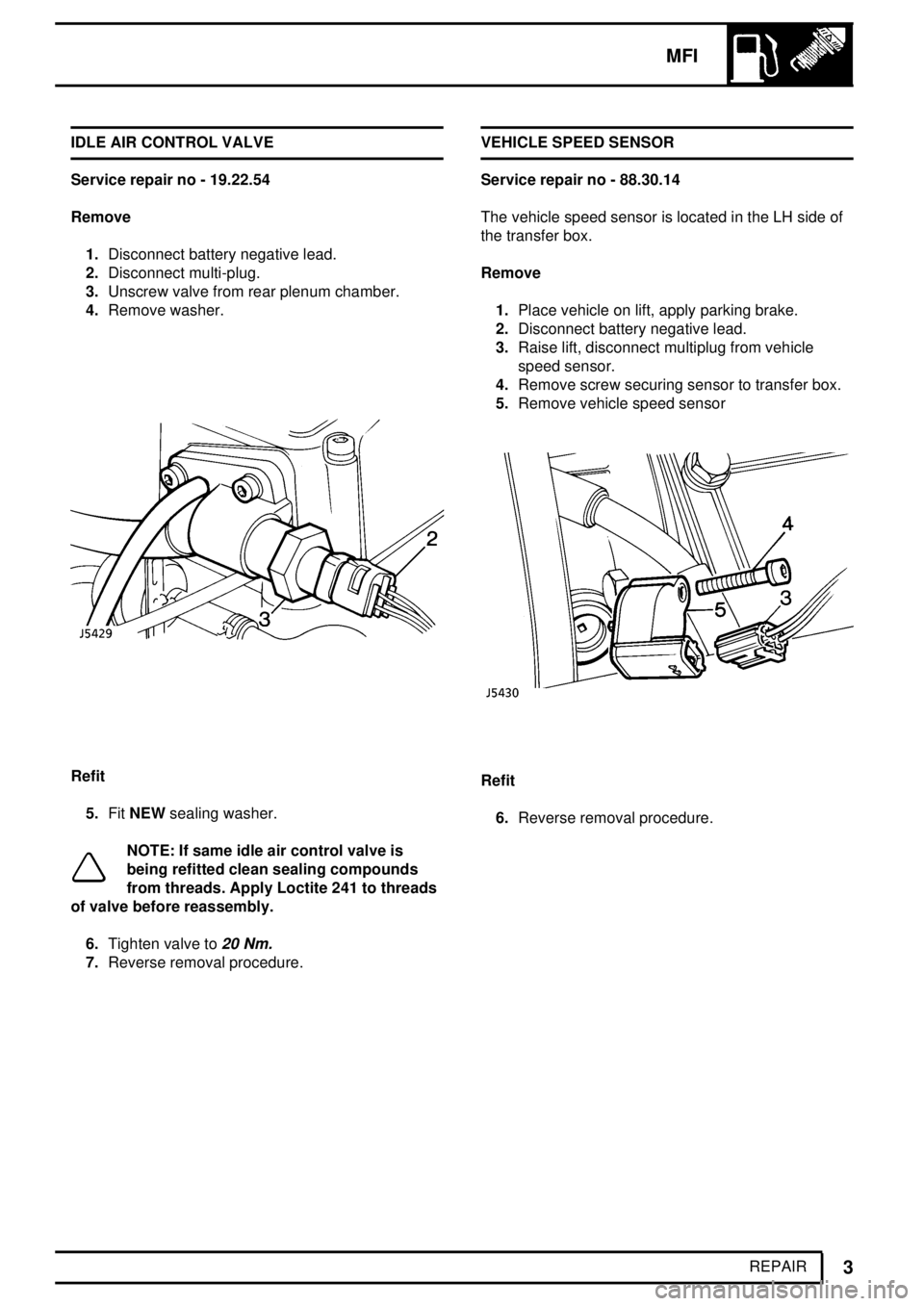

REPAIR IDLE AIR CONTROL VALVE

Service repair no - 19.22.54

Remove

1.Disconnect battery negative lead.

2.Disconnect multi-plug.

3.Unscrew valve from rear plenum chamber.

4.Remove washer.

Refit

5.FitNEWsealing washer.

NOTE: If same idle air control valve is

being refitted clean sealing compounds

from threads. Apply Loctite 241 to threads

of valve before reassembly.

6.Tighten valve to

20 Nm.

7.Reverse removal procedure.VEHICLE SPEED SENSOR

Service repair no - 88.30.14

The vehicle speed sensor is located in the LH side of

the transfer box.

Remove

1.Place vehicle on lift, apply parking brake.

2.Disconnect battery negative lead.

3.Raise lift, disconnect multiplug from vehicle

speed sensor.

4.Remove screw securing sensor to transfer box.

5.Remove vehicle speed sensor

Refit

6.Reverse removal procedure.

Page 250 of 873

19FUEL SYSTEM

4

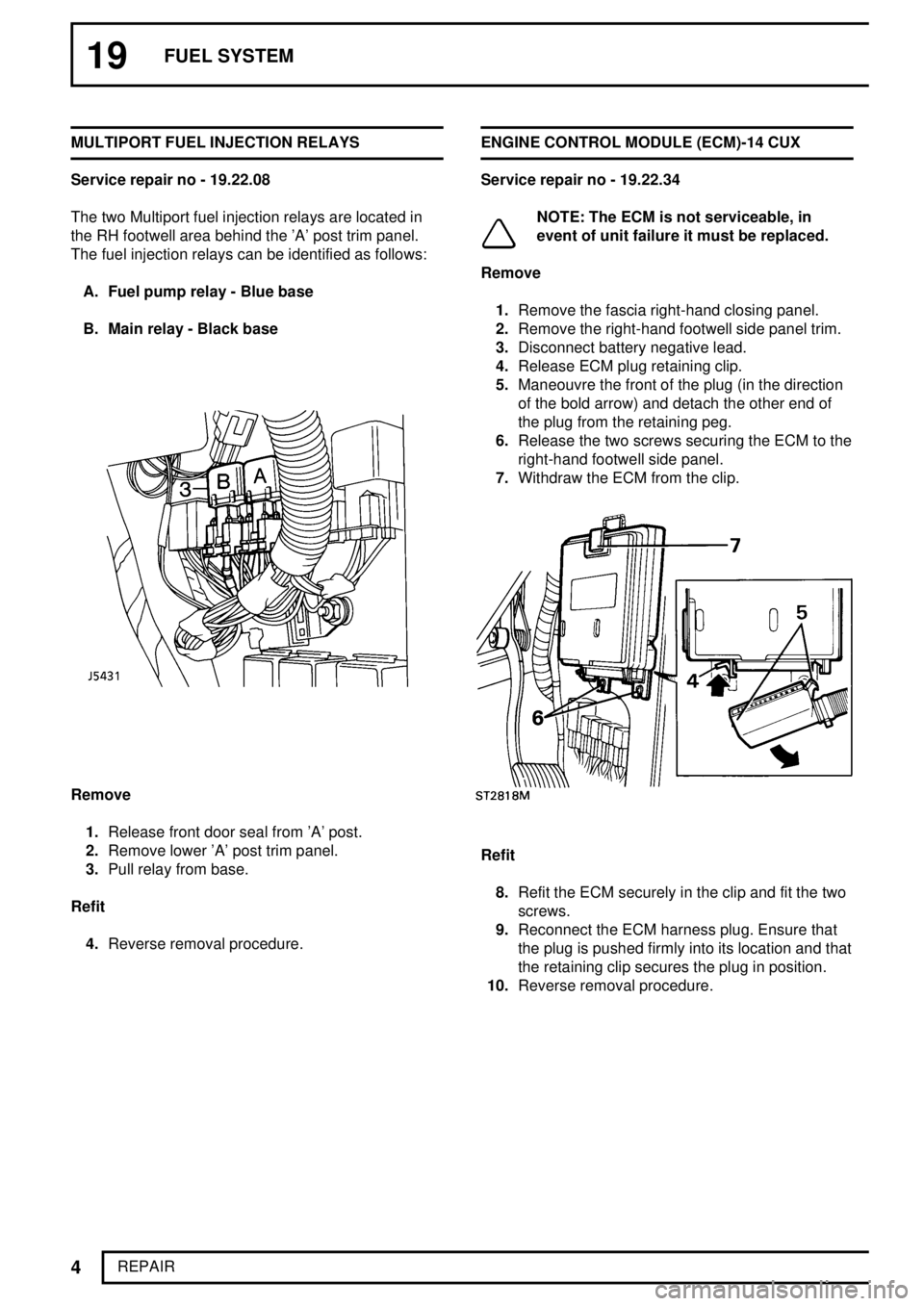

REPAIR MULTIPORT FUEL INJECTION RELAYS

Service repair no - 19.22.08

The two Multiport fuel injection relays are located in

the RH footwell area behind the 'A' post trim panel.

The fuel injection relays can be identified as follows:

A. Fuel pump relay - Blue base

B. Main relay - Black base

Remove

1.Release front door seal from 'A' post.

2.Remove lower 'A' post trim panel.

3.Pull relay from base.

Refit

4.Reverse removal procedure.ENGINE CONTROL MODULE (ECM)-14 CUX

Service repair no - 19.22.34

NOTE: The ECM is not serviceable, in

event of unit failure it must be replaced.

Remove

1.Remove the fascia right-hand closing panel.

2.Remove the right-hand footwell side panel trim.

3.Disconnect battery negative lead.

4.Release ECM plug retaining clip.

5.Maneouvre the front of the plug (in the direction

of the bold arrow) and detach the other end of

the plug from the retaining peg.

6.Release the two screws securing the ECM to the

right-hand footwell side panel.

7.Withdraw the ECM from the clip.

Refit

8.Refit the ECM securely in the clip and fit the two

screws.

9.Reconnect the ECM harness plug. Ensure that

the plug is pushed firmly into its location and that

the retaining clip secures the plug in position.

10.Reverse removal procedure.