LAND ROVER DISCOVERY 1995 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 261 of 873

MFI

15

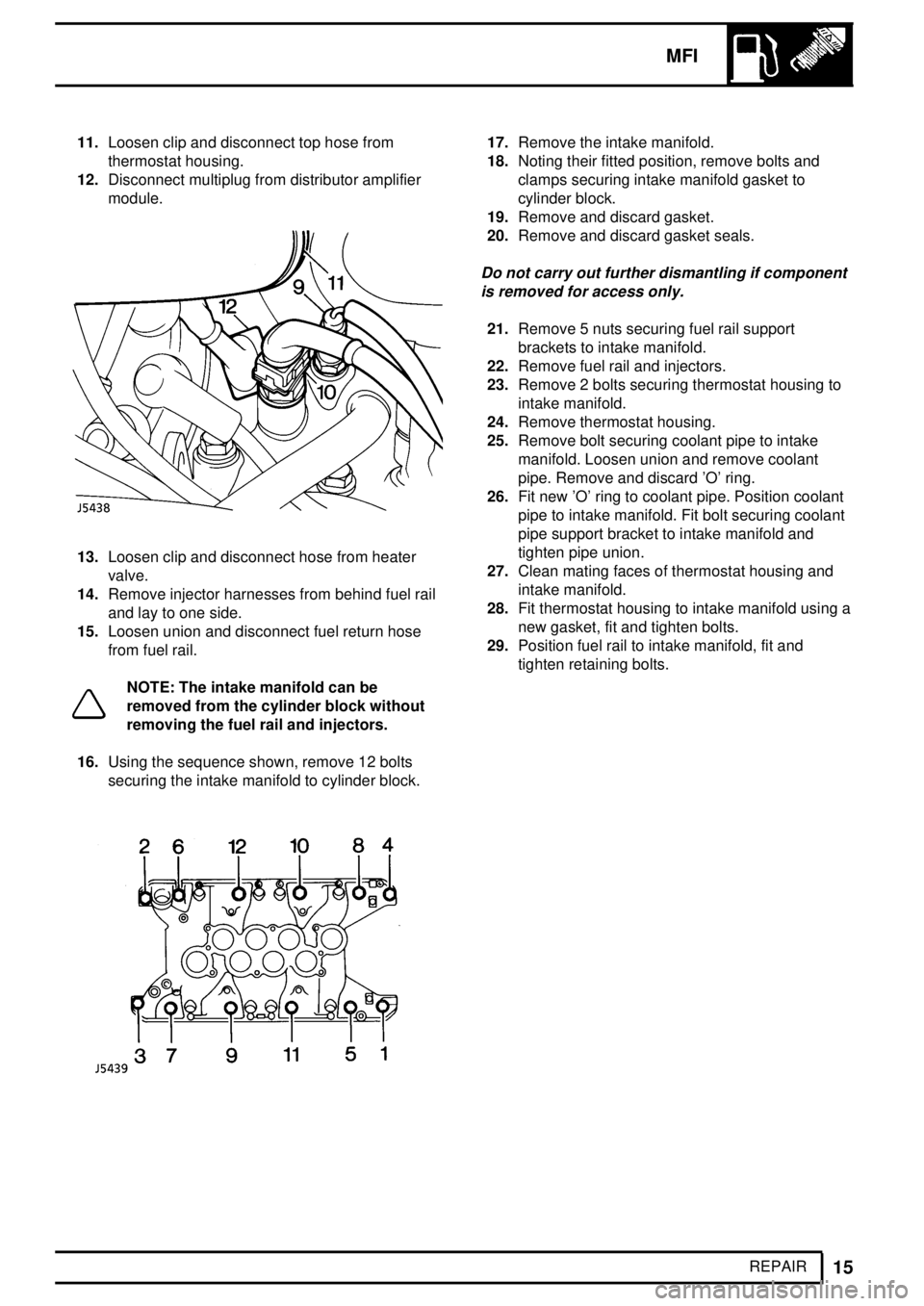

REPAIR 11.Loosen clip and disconnect top hose from

thermostat housing.

12.Disconnect multiplug from distributor amplifier

module.

13.Loosen clip and disconnect hose from heater

valve.

14.Remove injector harnesses from behind fuel rail

and lay to one side.

15.Loosen union and disconnect fuel return hose

from fuel rail.

NOTE: The intake manifold can be

removed from the cylinder block without

removing the fuel rail and injectors.

16.Using the sequence shown, remove 12 bolts

securing the intake manifold to cylinder block.

17.Remove the intake manifold.

18.Noting their fitted position, remove bolts and

clamps securing intake manifold gasket to

cylinder block.

19.Remove and discard gasket.

20.Remove and discard gasket seals.

Do not carry out further dismantling if component

is removed for access only.

21.Remove 5 nuts securing fuel rail support

brackets to intake manifold.

22.Remove fuel rail and injectors.

23.Remove 2 bolts securing thermostat housing to

intake manifold.

24.Remove thermostat housing.

25.Remove bolt securing coolant pipe to intake

manifold. Loosen union and remove coolant

pipe. Remove and discard 'O' ring.

26.Fit new 'O' ring to coolant pipe. Position coolant

pipe to intake manifold. Fit bolt securing coolant

pipe support bracket to intake manifold and

tighten pipe union.

27.Clean mating faces of thermostat housing and

intake manifold.

28.Fit thermostat housing to intake manifold using a

new gasket, fit and tighten bolts.

29.Position fuel rail to intake manifold, fit and

tighten retaining bolts.

Page 262 of 873

19FUEL SYSTEM

16

REPAIR Refit

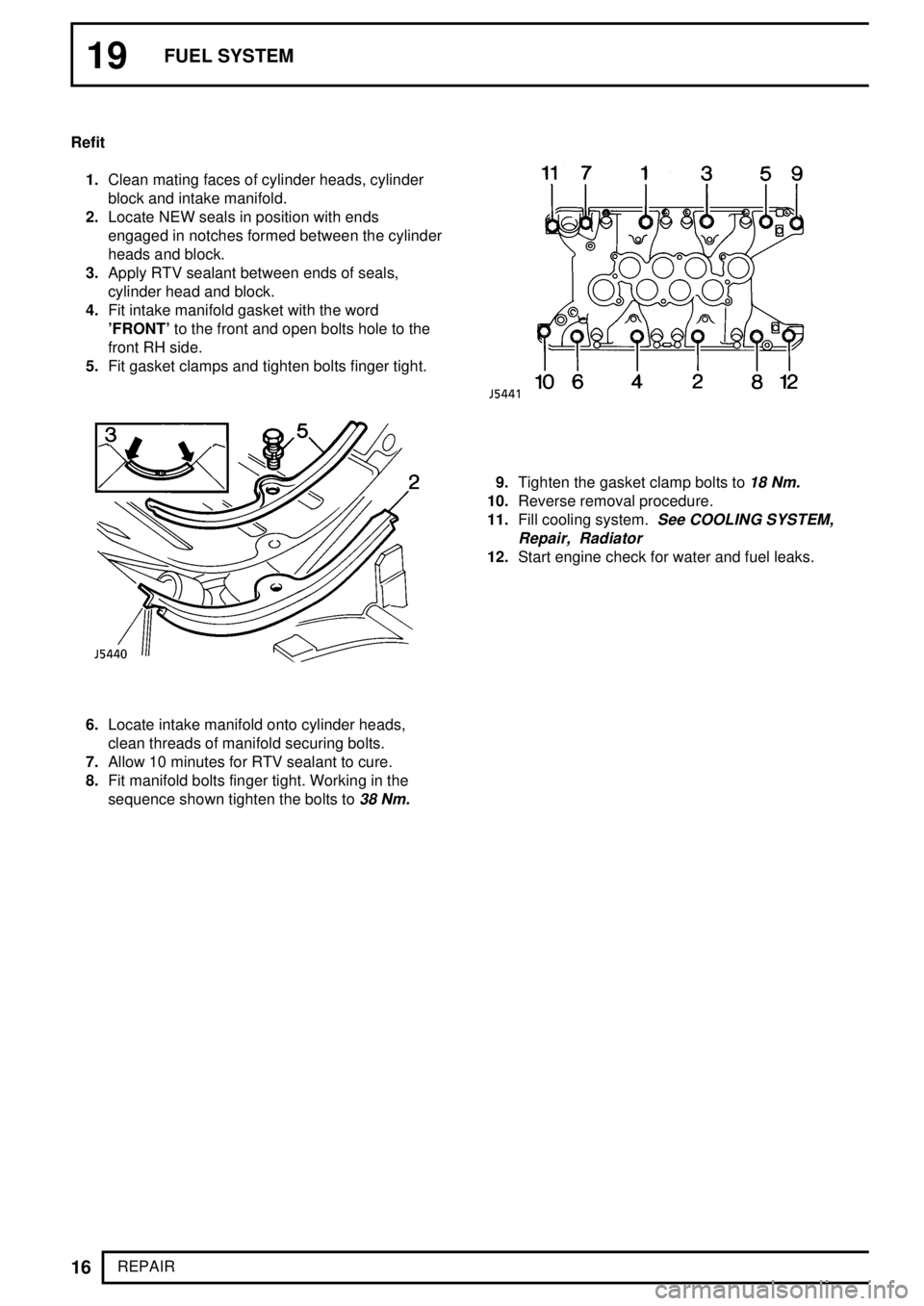

1.Clean mating faces of cylinder heads, cylinder

block and intake manifold.

2.Locate NEW seals in position with ends

engaged in notches formed between the cylinder

heads and block.

3.Apply RTV sealant between ends of seals,

cylinder head and block.

4.Fit intake manifold gasket with the word

'FRONT'to the front and open bolts hole to the

front RH side.

5.Fit gasket clamps and tighten bolts finger tight.

6.Locate intake manifold onto cylinder heads,

clean threads of manifold securing bolts.

7.Allow 10 minutes for RTV sealant to cure.

8.Fit manifold bolts finger tight. Working in the

sequence shown tighten the bolts to

38 Nm.

9.Tighten the gasket clamp bolts to18 Nm.

10.Reverse removal procedure.

11.Fill cooling system.

See COOLING SYSTEM,

Repair, Radiator

12.Start engine check for water and fuel leaks.

Page 263 of 873

MFI

17

REPAIR FUEL FILTER

Service repair no - 19.25.02

Remove

WARNING: Spilling of fuel is unavoidable

during this operation. Ensure all

necessary precautions are taken to

prevent fire and explosion.

WARNING: Ensure fuel handling

precautions given in Section 01 -

Introduction are strictly adhered to when

carrying out following instructions.

1.Depressurise fuel system.

See Depressurising

Fuel System

2.Access to filter is gained through right hand rear

wheel arch.

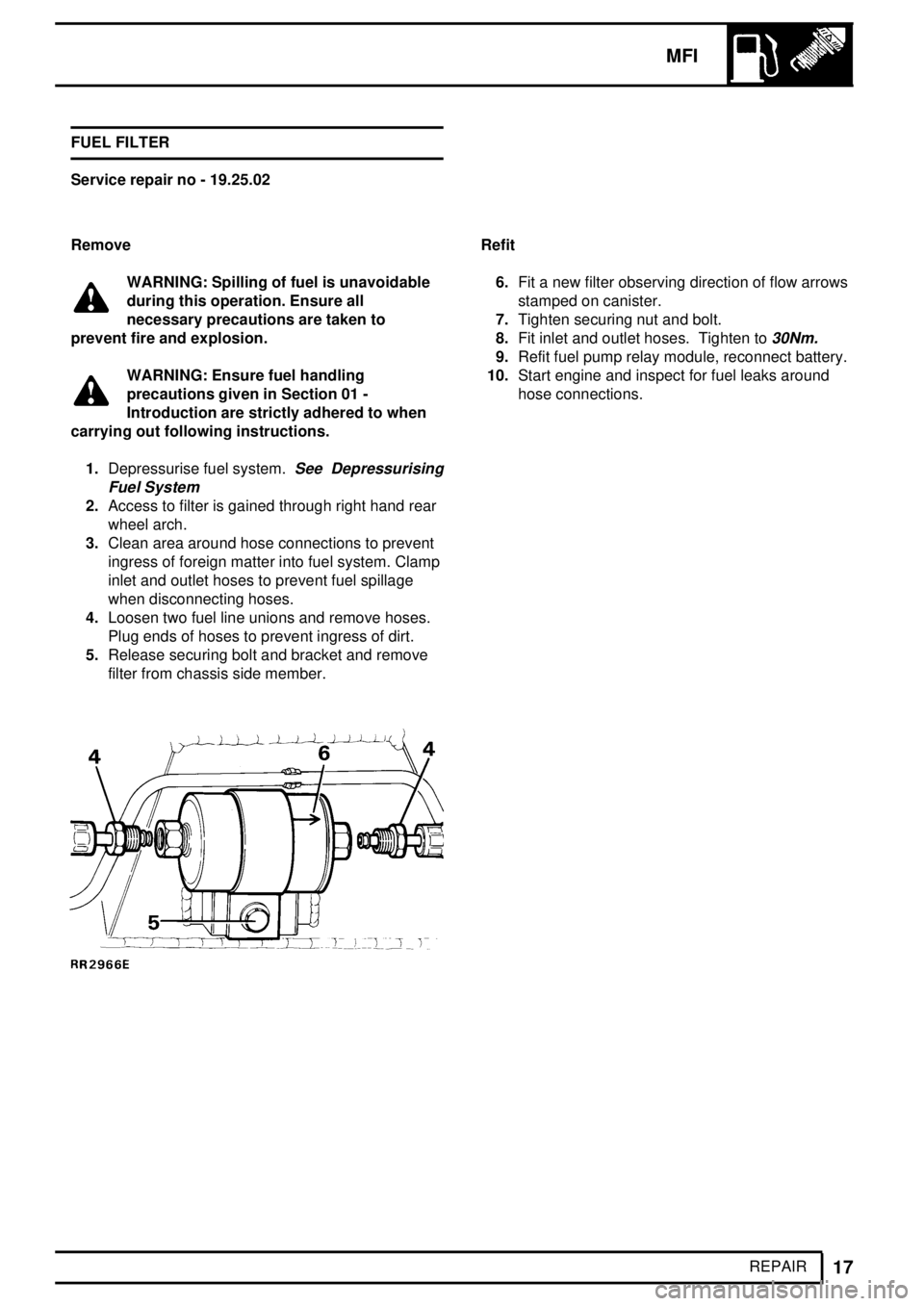

3.Clean area around hose connections to prevent

ingress of foreign matter into fuel system. Clamp

inlet and outlet hoses to prevent fuel spillage

when disconnecting hoses.

4.Loosen two fuel line unions and remove hoses.

Plug ends of hoses to prevent ingress of dirt.

5.Release securing bolt and bracket and remove

filter from chassis side member.

Refit

6.Fit a new filter observing direction of flow arrows

stamped on canister.

7.Tighten securing nut and bolt.

8.Fit inlet and outlet hoses. Tighten to

30Nm.

9.Refit fuel pump relay module, reconnect battery.

10.Start engine and inspect for fuel leaks around

hose connections.

Page 264 of 873

19FUEL SYSTEM

18

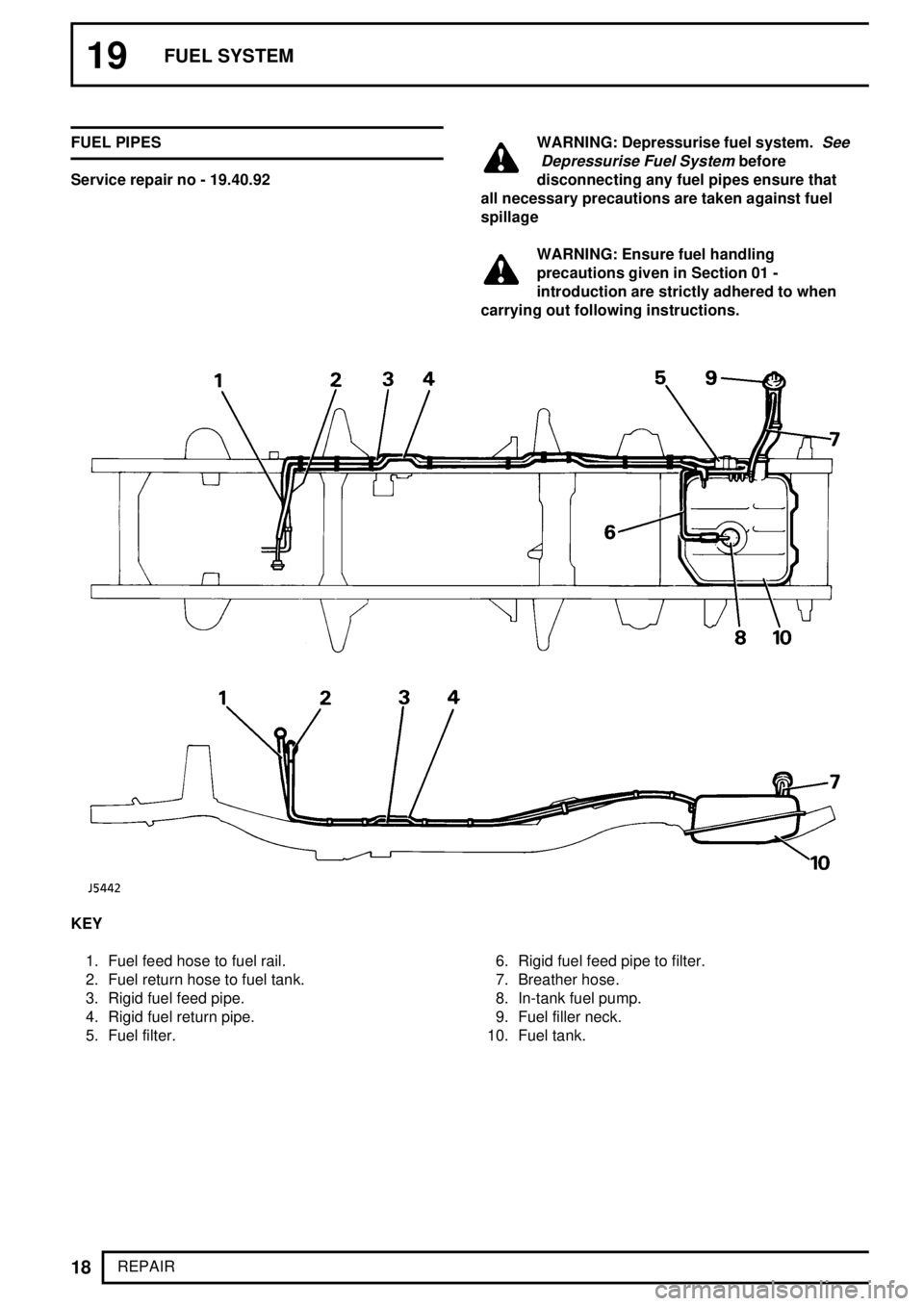

REPAIR FUEL PIPES

Service repair no - 19.40.92

WARNING: Depressurise fuel system.See

Depressurise Fuel System

before

disconnecting any fuel pipes ensure that

all necessary precautions are taken against fuel

spillage

WARNING: Ensure fuel handling

precautions given in Section 01 -

introduction are strictly adhered to when

carrying out following instructions.

KEY

1. Fuel feed hose to fuel rail.

2. Fuel return hose to fuel tank.

3. Rigid fuel feed pipe.

4. Rigid fuel return pipe.

5. Fuel filter.6. Rigid fuel feed pipe to filter.

7. Breather hose.

8. In-tank fuel pump.

9. Fuel filler neck.

10. Fuel tank.

Page 265 of 873

MFI

19

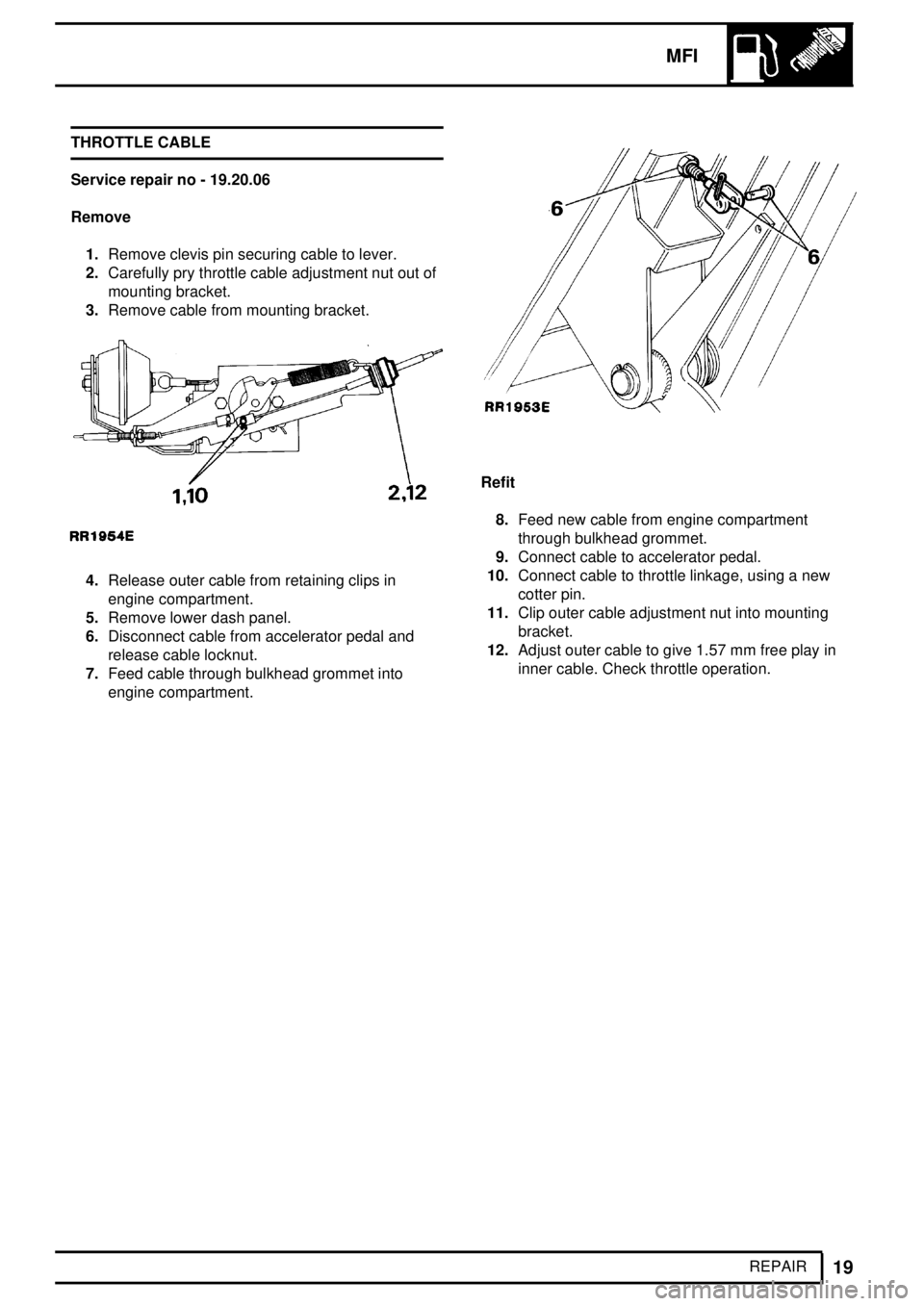

REPAIR THROTTLE CABLE

Service repair no - 19.20.06

Remove

1.Remove clevis pin securing cable to lever.

2.Carefully pry throttle cable adjustment nut out of

mounting bracket.

3.Remove cable from mounting bracket.

4.Release outer cable from retaining clips in

engine compartment.

5.Remove lower dash panel.

6.Disconnect cable from accelerator pedal and

release cable locknut.

7.Feed cable through bulkhead grommet into

engine compartment.

Refit

8.Feed new cable from engine compartment

through bulkhead grommet.

9.Connect cable to accelerator pedal.

10.Connect cable to throttle linkage, using a new

cotter pin.

11.Clip outer cable adjustment nut into mounting

bracket.

12.Adjust outer cable to give 1.57 mm free play in

inner cable. Check throttle operation.

Page 266 of 873

19FUEL SYSTEM

20

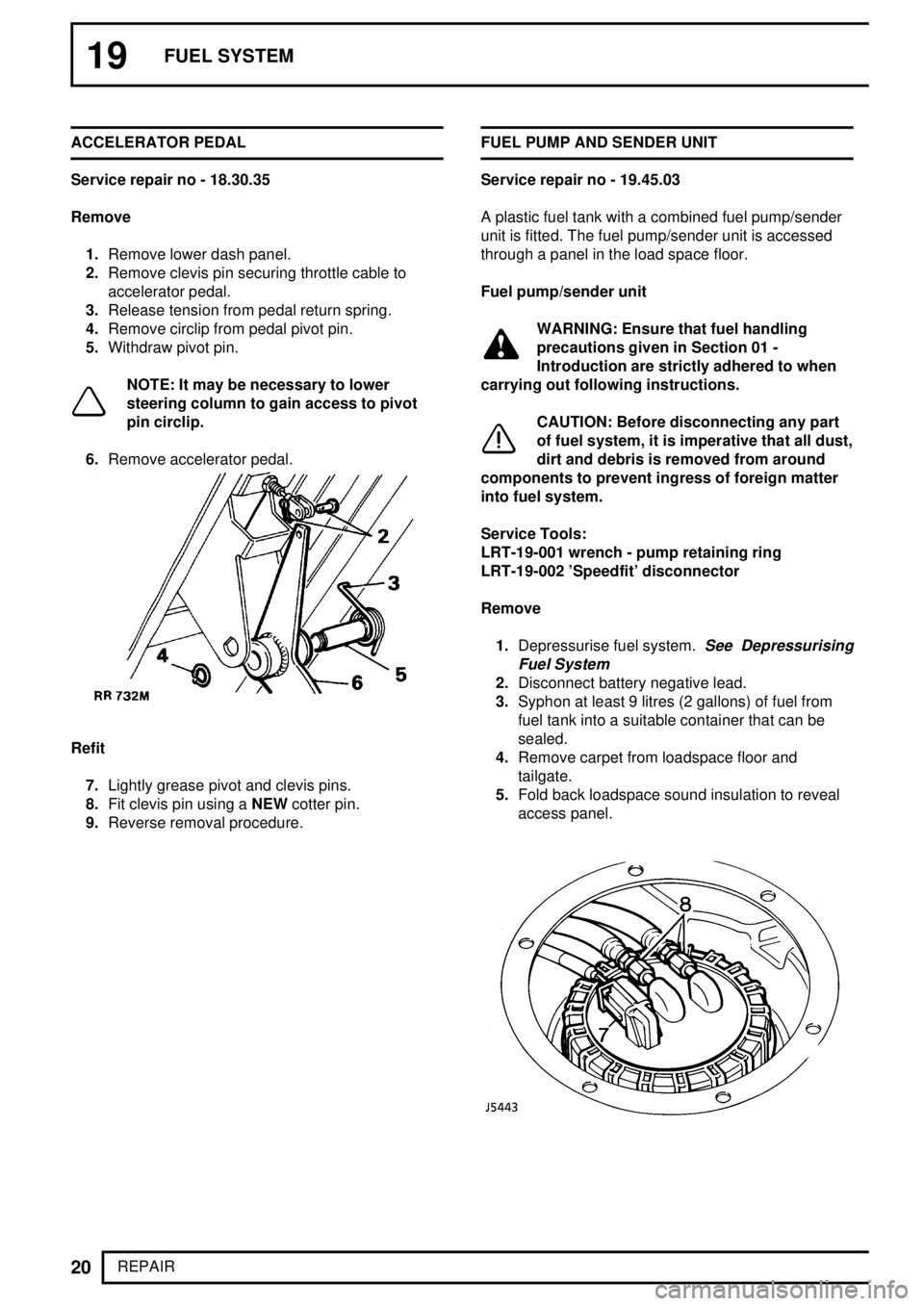

REPAIR ACCELERATOR PEDAL

Service repair no - 18.30.35

Remove

1.Remove lower dash panel.

2.Remove clevis pin securing throttle cable to

accelerator pedal.

3.Release tension from pedal return spring.

4.Remove circlip from pedal pivot pin.

5.Withdraw pivot pin.

NOTE: It may be necessary to lower

steering column to gain access to pivot

pin circlip.

6.Remove accelerator pedal.

Refit

7.Lightly grease pivot and clevis pins.

8.Fit clevis pin using aNEWcotter pin.

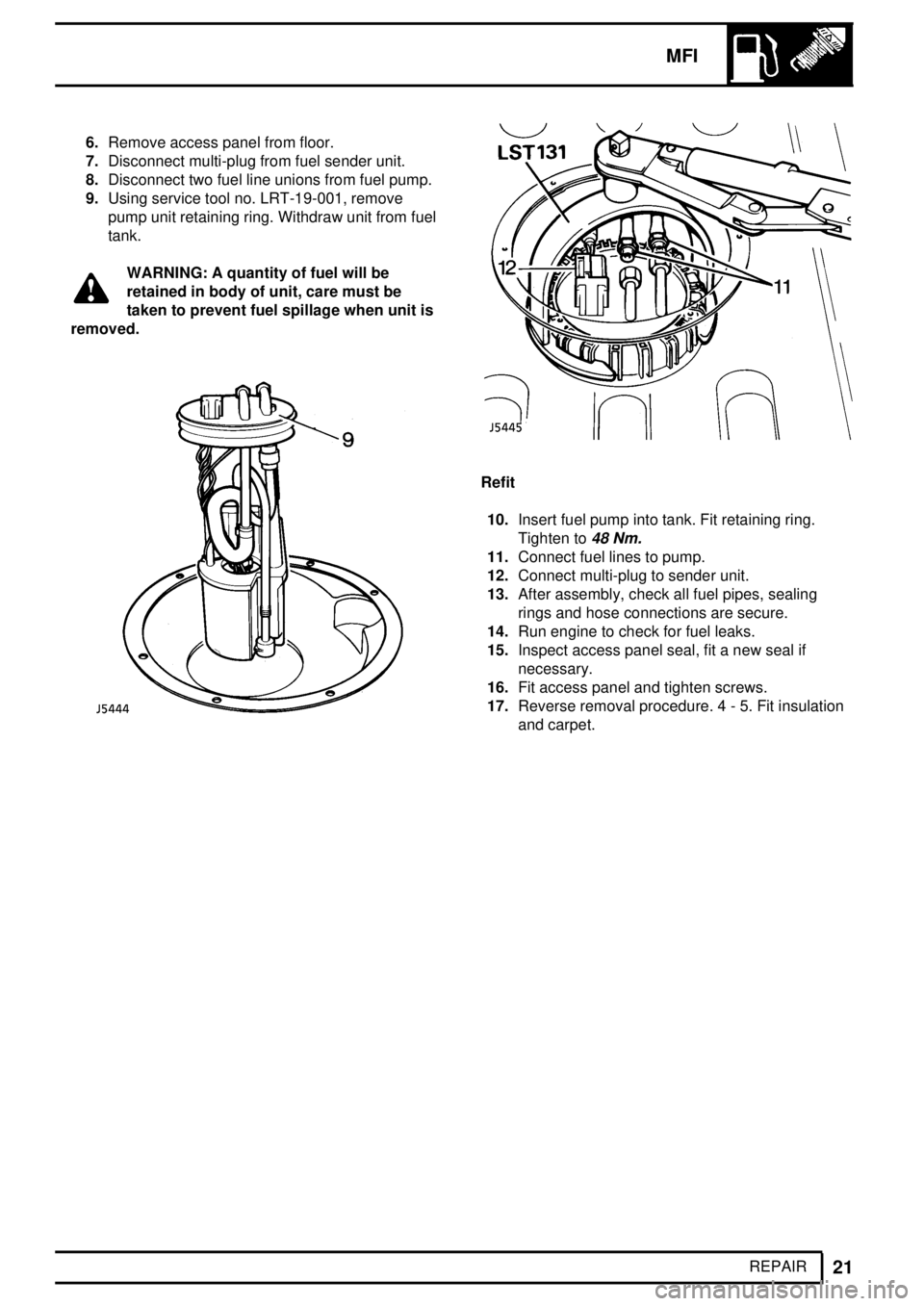

9.Reverse removal procedure.FUEL PUMP AND SENDER UNIT

Service repair no - 19.45.03

A plastic fuel tank with a combined fuel pump/sender

unit is fitted. The fuel pump/sender unit is accessed

through a panel in the load space floor.

Fuel pump/sender unit

WARNING: Ensure that fuel handling

precautions given in Section 01 -

Introduction are strictly adhered to when

carrying out following instructions.

CAUTION: Before disconnecting any part

of fuel system, it is imperative that all dust,

dirt and debris is removed from around

components to prevent ingress of foreign matter

into fuel system.

Service Tools:

LRT-19-001 wrench - pump retaining ring

LRT-19-002 'Speedfit' disconnector

Remove

1.Depressurise fuel system.

See Depressurising

Fuel System

2.Disconnect battery negative lead.

3.Syphon at least 9 litres (2 gallons) of fuel from

fuel tank into a suitable container that can be

sealed.

4.Remove carpet from loadspace floor and

tailgate.

5.Fold back loadspace sound insulation to reveal

access panel.

Page 267 of 873

MFI

21

REPAIR 6.Remove access panel from floor.

7.Disconnect multi-plug from fuel sender unit.

8.Disconnect two fuel line unions from fuel pump.

9.Using service tool no. LRT-19-001, remove

pump unit retaining ring. Withdraw unit from fuel

tank.

WARNING: A quantity of fuel will be

retained in body of unit, care must be

taken to prevent fuel spillage when unit is

removed.

Refit

10.Insert fuel pump into tank. Fit retaining ring.

Tighten to

48 Nm.

11.Connect fuel lines to pump.

12.Connect multi-plug to sender unit.

13.After assembly, check all fuel pipes, sealing

rings and hose connections are secure.

14.Run engine to check for fuel leaks.

15.Inspect access panel seal, fit a new seal if

necessary.

16.Fit access panel and tighten screws.

17.Reverse removal procedure. 4 - 5. Fit insulation

and carpet.

Page 268 of 873

19FUEL SYSTEM

22

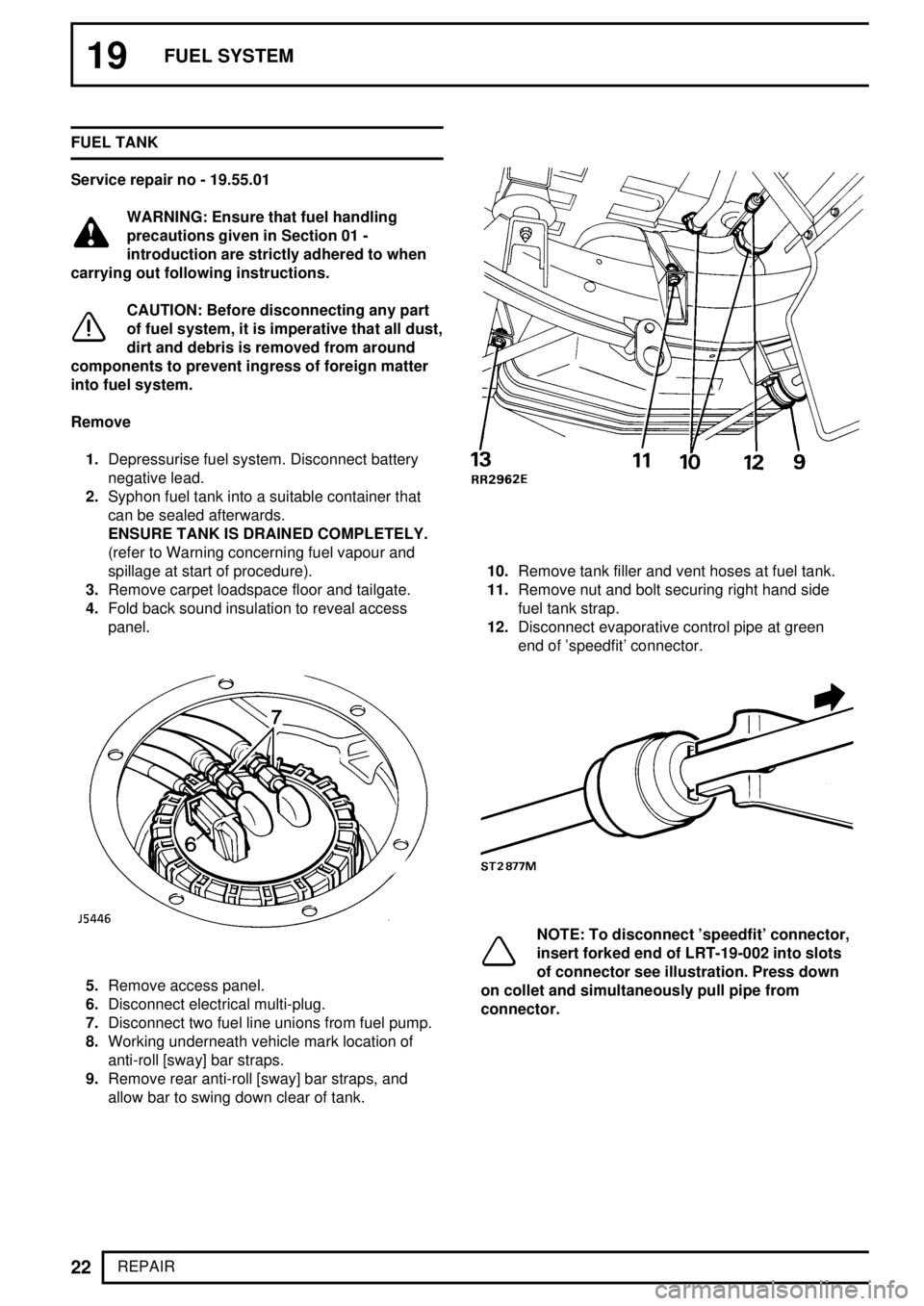

REPAIR FUEL TANK

Service repair no - 19.55.01

WARNING: Ensure that fuel handling

precautions given in Section 01 -

introduction are strictly adhered to when

carrying out following instructions.

CAUTION: Before disconnecting any part

of fuel system, it is imperative that all dust,

dirt and debris is removed from around

components to prevent ingress of foreign matter

into fuel system.

Remove

1.Depressurise fuel system. Disconnect battery

negative lead.

2.Syphon fuel tank into a suitable container that

can be sealed afterwards.

ENSURE TANK IS DRAINED COMPLETELY.

(refer to Warning concerning fuel vapour and

spillage at start of procedure).

3.Remove carpet loadspace floor and tailgate.

4.Fold back sound insulation to reveal access

panel.

5.Remove access panel.

6.Disconnect electrical multi-plug.

7.Disconnect two fuel line unions from fuel pump.

8.Working underneath vehicle mark location of

anti-roll [sway] bar straps.

9.Remove rear anti-roll [sway] bar straps, and

allow bar to swing down clear of tank.

10.Remove tank filler and vent hoses at fuel tank.

11.Remove nut and bolt securing right hand side

fuel tank strap.

12.Disconnect evaporative control pipe at green

end of 'speedfit' connector.

NOTE: To disconnect 'speedfit' connector,

insert forked end of LRT-19-002 into slots

of connector see illustration. Press down

on collet and simultaneously pull pipe from

connector.

Page 269 of 873

MFI

23

REPAIR

13.Remove back two bolts and nut plates securing

fuel tank cradle.

14.Remove front nuts, bolts and washers. Remove

fuel tank cradle.

15.With assistance, tilt right hand side of tank

upwards and manoeuvre tank through chassis to

remove.

Refit

16.Reverse removal procedure. Ensuring sealing

ring, fuel pipe and hose connections are secure.

17.Run engine, check all connections for fuel leaks.

Page 270 of 873

MFI

1

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

Air-Bypass valve (stepper motor) 20...............................................................

All flexible hose securing clamps 1,3...............................................................

Fuel feed pipe - hose to fuel rail 22.................................................................

Fuel filter 31....................................................................................................

EVAPORATIVE LOSS CONTROL SYSTEM

All flexible hose securing clamps 1,7...............................................................

METRIC Nm

M5 6...........................................................................

M6 9...........................................................................

M8 25...........................................................................

M10 45.........................................................................

M12 90.........................................................................

M14 105.........................................................................

M16 180.........................................................................

UNC / UNF

1/4 9...........................................................................

5/16 24.........................................................................

3/8 39...........................................................................

7/16 78.........................................................................

1/2 90...........................................................................

5/8 136...........................................................................

NOTE: Torque values above are for all screws and bolts used except for those specified.