LAND ROVER DISCOVERY 1995 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 421 of 873

TRANSFER GEARBOX

1

SERVICE TOOLS LT230T TRANSFER GEARBOX

LRT-51-003 Drive flange wrench

18G 1205

18G 1271 Oil seal remover

18G 1271

LRT-37-014 Mainshaft rear oil seal replacer

18G 1422

LRT-99-003 Oil seal replacer handle

MS 550 or 18G 134

Page 422 of 873

ZF

1

DESCRIPTION AND OPERATION DESCRIPTION

The automatic transmission is specially tailored version of the ZF4 HP22, used by many manufacturer's of high

performance vehicles.

A three element torque converter delivers the power to a four speed epicyclic transmission. First, second and third

gears are reduction ratios but fourth is an overdrive gear for high speed cruising. A direct drive clutch, integral with

the torque converter operates to engage fourth gear.

The gear selector has seven positions as follows:

P = Park provides a mechanical lock on the output shaft.

R = Reverse gear.

N = Neutral.

D = Provides a 1st gear start and automatic shifts 1-2-3-4-3-2-1.

3 = Provides a 1st gear start and automatic shifts 1-2-3-2-1.

2 = Provides a 1st gear start and automatic shifts 1-2-1 or 3-2-1.

1 = Provides a 1st gear start with no up shifts, or 3-2-1.

All automatic shifts are automatically controlled by the valve block and an hydraulic governor driven by the output

shaft.

Page 423 of 873

44AUTOMATIC GEARBOX

2

DESCRIPTION AND OPERATION Power flow

1st gear D selected

With D selected 1st gear engaged, clutches 4 and 11 are operative. The front planet gear carrier of gear set 9 is

locked against the housing through freewheel 15 when the engine is pulling but freewheels when the vehicle is

coasting. Epicyclic gear set 10 rotates as a solid unit with the front planet gear carrier. In selector position 1 with

1st gear engaged, clutch 8 operates to prevent the loss of drive on the overrun through freewheel 15, to provide

engine braking.

2nd gear D selected

Clutches 4, 6, 7 and 11 are engaged. Freewheel 15 overruns, the hollow shaft with the sun wheel of epicyclic gear

set 9 is locked. Epicyclic gear set 10 also rotates as a solid unit.

Page 424 of 873

ZF

3

DESCRIPTION AND OPERATION 3rd gear D selected

Clutches 4, 5, 7 and 11 are engaged. Freewheel 15 and 16 are overrun. Epicyclic gear set 9 and 10 rotate as a

solid unit at a ratio of 1:1.

4th gear D selected

Clutches 4, 5, 7 and 12 are engaged. Freewheel 14, 15 and 16 are overrun. Epicyclic gear set 9 rotates as a solid

unit. The hollow shaft with the sun wheel of epicyclic gear set 10 is locked.

Above a predetermined road speed, clutch 2 locks the gearbox power input direct to the engine, by-passing the

torque converter.

Page 425 of 873

44AUTOMATIC GEARBOX

4

DESCRIPTION AND OPERATION Reverse gear

Clutches 5, 8 and 11 are engaged. Since the front planet gear carrier of epicyclic gear set 9 is locked, the direction

of output-shaft rotation is reversed. Epicyclic gear set 10 also rotates as a solid block.

Page 426 of 873

ZF

1

FAULT DIAGNOSIS ZF AUTOMATIC GEARBOX

Before referring to fault symptoms, carry out initial

static checks first:

INITIAL STATIC CHECKS

Check start positions 'P' & 'N' only........................................................

Reverse lights 'R' only..................................................................

Gear engagements N-D,N-3,N-2,N-1,N-R..........................................................

Full throttle Engine switched off, check full travel at engine and at.......................................................................

pedal.

Oil level 'N' selected, engine running at normal running............................................................................

temperature.

Pressure test

2000 rev/min 10±0.3 bar, 150±5 lbf/in

2....................................................................

Idle pressure 6.9±0.3 bar, 100±5 lbf/in2at 665 to 735 rev/min. ....................................................................

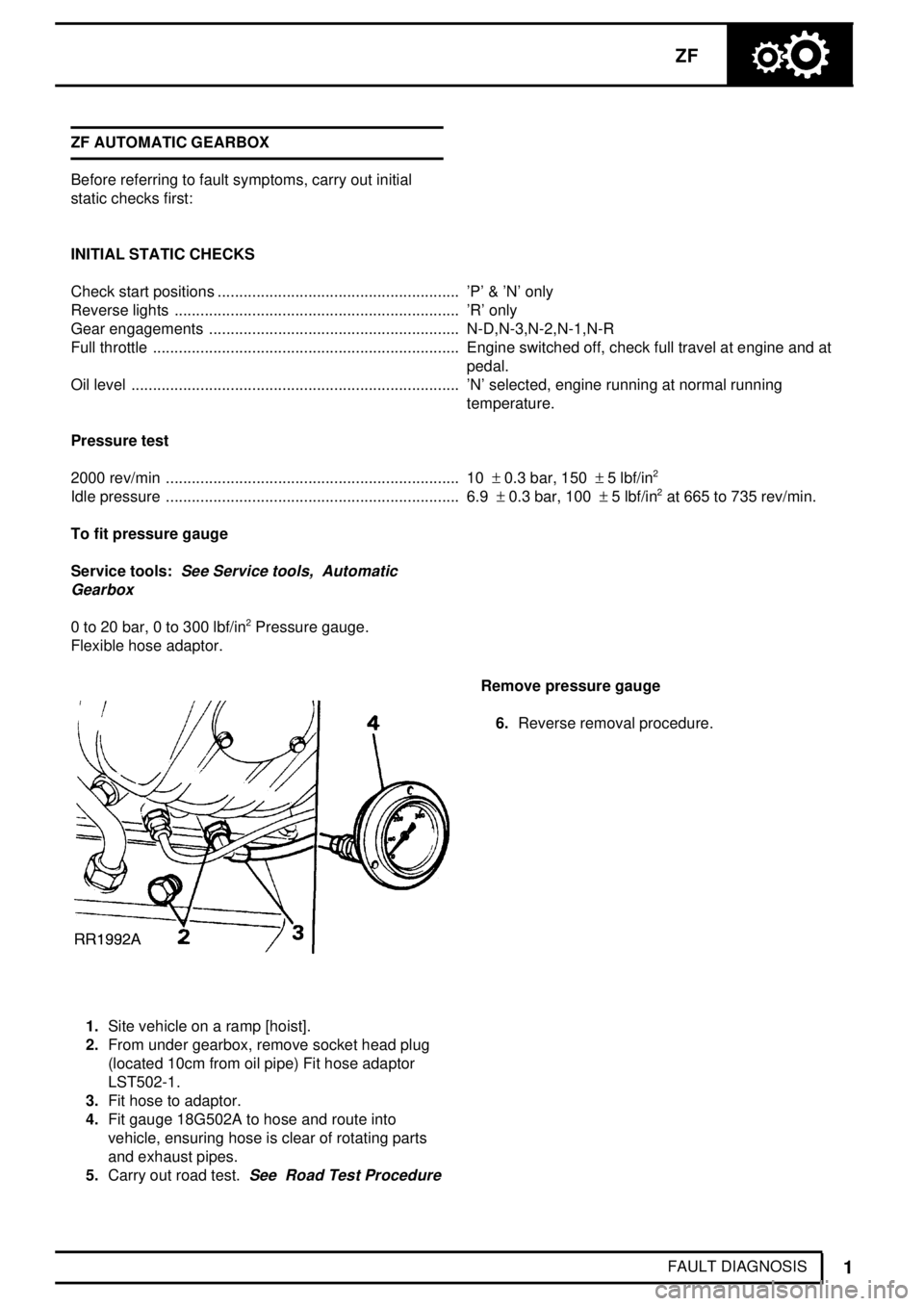

To fit pressure gauge

Service tools:

See Service tools, Automatic

Gearbox

0 to 20 bar, 0 to 300 lbf/in2Pressure gauge.

Flexible hose adaptor.

1.Site vehicle on a ramp [hoist].

2.From under gearbox, remove socket head plug

(located 10cm from oil pipe) Fit hose adaptor

LST502-1.

3.Fit hose to adaptor.

4.Fit gauge 18G502A to hose and route into

vehicle, ensuring hose is clear of rotating parts

and exhaust pipes.

5.Carry out road test.

See Road Test Procedure

Remove pressure gauge

6.Reverse removal procedure.

Page 427 of 873

44AUTOMATIC GEARBOX

2

FAULT DIAGNOSIS ROAD TEST PROCEDURE

Follow the procedure given commencing each test,

from a standing start, on a level road, in good weather

conditions.

ROADTEST 1 = CHECKS 1-2-3-4-5-6-7-8

D SELECTED KICKDOWN START FROM REST

CHECK 1

Check for clutch squeal and slip. Check pressure is

150lbf/in

2

CHECK 2

Check 1st to 2nd upshift speed and quality. Pressure

should fall to 120 lbf/in

2.

CHECK 3

Check 2nd-3rd upshift speed and quality. Pressure

should fall to 100 lbf/in

2

CHECK 4

Release throttle to allow simultaneous engagement

4th + DDC. Check shift quality and engine rpm drop of

approximately 500 rpm.

CHECK 5

To proceed to Check 5 release throttle and check

drop out speed of direct drive clutch to 4th.

CHECK 6

Check down shift speed and quality 4th to 3rd.

NOTE: This shift is usually very smooth

and difficult to detect.

CHECK 7

Check downshift speed and quality 3rd to 2nd.

CHECK 8

Check downshift speed and quality 2nd to 1st. Also

difficult to detect.

END OF ROADTEST 1ROADTEST 2 CHECKS = 9-10-11

D SELECTED FROM REST

FULL THROTTLE START

CHECK 9

Check 1st-2nd upshift speed and quality.

CHECK 10

Check 2nd 3rd upshift speed and quality.

CHECK 11

Check 3rd 4th and direct drive clutch upshift speed

and quality.

NOTE: 4th and the direct drive clutch

engage simultaneously.

END OF ROADTEST 2

Page 428 of 873

ZF

3

FAULT DIAGNOSIS ROADTEST 3 = CHECKS

12-13-14-15-16-17-18-19-20-21-22-23

D SELECTED FROM REST

LIGHT THROTTLE START

CHECK 12

Check 1st 2nd upshift speed and quality.

CHECK 13

Check 2nd 3rd upshift speed and quality.

CHECK 14

Check 3rd 4th upshift speed and quality.

NOTE: This shift is usually very difficult to

detect but can be confirmed by a 200 rpm

drop in engine speed.

CHECK 15

Check speed and quality of shift into direct drive

clutch, confirmed by 300 rpm drop in engine speed.

NOTE: An intermediate throttle position

engagement of 4th and the direct drive

clutch, which is indicated by a fall of

500rpm in engine speed.

CHECK 16

At approximately 88 kph (55 mph) depress throttle to

kickdown - gearbox should change down to 2nd -

release throttle to re-engage 4th direct drive clutch

continue to accelerate gently.

CHECK 17

At approximately 128 kph (80 mph) depress throttle to

kickdown - gearbox should change down to 3rd -

release throttle to re-engage 4th direct drive clutch

and continue to accelerate gently.CHECK 18

At approximately 138 kph (85 mph) select 3rd,

gearbox should change immediately down to 3rd.

Release throttle.

CHECK 19

De-accelerate to approximately 47 kph (30 mph)

depress throttle to kickdown - geabox should

downshift to 1st gear, continue accelerating at full

throttle until 3rd gear is attained. To do this you will

have repeated check 2 of Test 1.

CHECK 20

At 128 kph (80 mph) select 2nd no downshift should

occur. Release throttle.

CHECK 21

At 104 kph (65 mph) an automatic downshift into 2nd

gear should occur. Continue to de-accelerate.

CHECK 22

At 88 kph (55 mph) select 1st. No downshift should

occur. Continue to de-accelerate.

CHECK 23

With 1 selected 2nd gear engaged continue to

de-accelerate and at 45 kph (28 mph) the box should

automatically downshift to 1st gear after which no

upshifts will occur in this selector position.

END OF ROADTEST

Page 429 of 873

44AUTOMATIC GEARBOX

4

FAULT DIAGNOSIS AUTOMATIC GEARBOX ASSEMBLY ILLUSTRATED

1. Gearbox assembly

2. Inhibitor switch assembly

3. Control unit assembly

4. Filter and sump assembly

Page 430 of 873

ZF

5

FAULT DIAGNOSIS 1. Torque converter housing assembly

2. Gearbox pump and casing assembly

3. Governor and adaptor housing assembly