LAND ROVER DISCOVERY 1995 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 501 of 873

FRONT AXLE AND FINAL DRIVE

3

REPAIR FRONT HUB ASSEMBLY

Service repair no - 60.25.01.

Remove

1.Loosen front wheel nuts, jack up vehicle and

lower onto axle stands and remove road wheel.

2.Release brake hose clips and remove brake

caliper. Secure to one side.

3.Lever off dust cap.

4.Remove circlip and drive shaft shim from

driveshaft.

5.Remove five bolts and withdraw driving member

and joint washer.

6.Bend back lock washer tabs.

7.Remove locknut and lock washer.

8.Remove hub adjusting nut.

9.Remove spacing washer.

10.Remove hub and brake disc assembly complete

with bearings.HUB COMPONENTS

1. Dust cap.

2. Drive shaft circlip.

3. Drive shaft shim.

4. Drive member.

5. Drive member joint washer.

6. Drive member retaining bolt.

7. Lock nut.

8. Lock washer.

9. Hub adjusting nut.

10. Spacing washer.

11. Outer bearing.

12. Hub.

13. Inner bearing.

14. Grease seal.

15. Brake disc

16. Disc retaining bolt.

Page 502 of 873

54FRONT AXLE AND FINAL DRIVE

4

REPAIR Refit

11.Clean stub axle and drive shaft and fit hub

assembly to axle.

12.Fit spacing washer.

13.Fit hub adjusting nut. Tighten to

61 Nm.

14.Back off adjusting nut 90°. Tighten to4 Nm.

This will give the required hub end float of

0,010mm

15.Fit a new lock washer.

16.Fit locknut. Tighten to61 Nm.

17.Tab over lock washer to secure adjusting nut

and locknut.

18.Fit a new joint washer to driving member and fit

member to hub and secure with five bolts.

Tighten to

65 Nm.

19.Fit original drive shaft shim and secure with a

circlip.

20.To check drive shaft end play mount a dial

gauge using bracket LRT-99-503 and rest pin in

a loaded condition on end of drive shaft.

21.Fit a suitable bolt to threaded end of drive shaft.

Move drive shaft in and out noting dial gauge

reading. End play should be between0,08 to

0,25 mm.

22.If end play requires adjustment, remove circlip,

measure shim thickness and fit an appropriate

shim to give required end-play.

23.Remove bolt from drive shaft, fit circlip and dust

cap.

24.Fit brake caliper. Tighten to

82 Nm.

25.Bleed brake system.See BRAKES, Repair,

Brake System Bleed

26.Fit road wheel, remove axle stands and tighten

road wheel nuts to

126 Nm.

27.Operate footbrake to locate brake pads before

taking vehicle on road.

Page 503 of 873

FRONT AXLE AND FINAL DRIVE

1

OVERHAUL FRONT DIFFERENTIAL

Service repair no - 54.10.07.

Overhaul

The front and rear differentials are the same. When

overhauling front differential.

See REAR AXLE AND

FINAL DRIVE, Overhaul, Axle Differential

Assembly

FRONT HUB

Service repair no - 60.26.14.

Overhaul

1.Remove front hub assembly.

See Repair,

Front Hub Assembly

2.Remove outer bearing.

3.Mark, for reassembly, relationship between hub

and brake disc, if original hub is to be refitted.

4.Remove five bolts and separate hub from brake

disc.5.Drift out grease seal and inner bearing from hub

and discard seal.

6.Drift out inner and outer bearing tracks.

7.Clean hub and drift in inner and outer bearing

tracks.

8.Pack hub inner bearing with recommended

grease and fit to hub.

HUB COMPONENTS

1. Dust cap.

2. Drive shaft circlip.

3. Drive shaft shim.

4. Drive member.

5. Drive member joint

washer.

6. Drive member

retaining bolt.

7. Lock nut.8. Lock washer.

9. Hub adjusting nut.

10. Spacing washer.

11. Outer bearing.

12. Hub.

13. Inner bearing.

14. Grease seal.

15. Brake disc.

16. Disc retaining bolt.

Page 504 of 873

54FRONT AXLE AND FINAL DRIVE

2

OVERHAUL 9.With lip side leading fit new seal to hub using

special tool LST 137 seal replacer and drift 18G

134. Drive in seal flush with rear face of hub.

Apply grease between seal lips.

10.Fit brake disc to hub, lining up to marks made

during dismantling. apllying Loctite 270, fit five

retaining bolts. Tighten to

73 Nm.

11.Grease and fit outer bearing to hub.

12.Fit front hub assembly.

See Repair, Front Hub

Assembly

Page 505 of 873

FRONT AXLE AND FINAL DRIVE

3

OVERHAUL FRONT STUB AXLE, CONSTANT VELOCITY JOINT

AND SWIVEL PIN HOUSING NON ABS

Service repair no - 60.15.43.

Remove stub axle, axle shaft and constant

velocity joint.

1.Remove front hub assembly.

See Repair,

Front Hub Assembly

2.Drain swivel pin housing and refit plug.

3.Remove six bolts retaining stub axle to swivel

housing.

4.Remove mud shield.

5.Remove stub axle and joint washer.

6.Pull out axle shaft and constant velocity joint

from axle casing.

Remove constant velocity joint from axle shaft

7.Hold axle shaft firmly in a soft jawed vice.

8.Using a soft mallet drive constant velocity joint

from shaft.

9.Remove circlip and collar from axle shaft.

Constant velocity joint

10.Mark positions of constant velocity joint, inner

and outer race and cage for reassembly.

11.Swivel cage and inner race to remove balls.

Page 506 of 873

54FRONT AXLE AND FINAL DRIVE

4

OVERHAUL 12.Examine all components in particular inner and

outer track, cage balls and bearing surfaces for

damage and excessive wear.

13.Maximum acceptable end-float on assembled

joint 0,64mm. Renew if worn or damaged.

Lubricate with a recommended oil during

assembly.

Fit constant velocity joint to axle

14.Fit collar and a new circlip.

15.Engage constant velocity joint on axle shaft

splines and using a soft mallet, drive joint in fully.

Renew stub axle,thrust ring, oil seal and bearing

16.Drill and chisel off thrust ring taking care to avoid

damaging stub axle.

17.Remove bearing and oil seal using special tool

LRT-37-004 and slide hammer LRT-99-004.

Ensure lip of tool locates behind bearing to to

drive it out.

18.Repeat instruction for removal of oil seal.

19.Lubricate seal and lip with EP90 oil and with

cavity side leading press in a new oil seal using

special tool LRT-54-004.

20.Using special tool LRT-54-005, fit bearing with

its part number visible when fitted, and flush with

end face of stub axle.

21.Press fit a new thrust ring onto stub axle.

Page 507 of 873

FRONT AXLE AND FINAL DRIVE

5

OVERHAUL Swivel pin housing

22.Remove bolts securing oil seal retaining plate

and joint washer. Release assembly from swivel

pin housing.

NOTE: Removal of oil seal and retaining

plate is achieved when swivel bearing

housing is removed.

23.Remove two bolts, retaining lower swivel pin to

housing.

24.Remove brake disc shield bracket.

25.tap lug to remove lower swivel pin and joint

washer.

26.Remove two bolts retainin brake hose bracket

and top swivel pin.

27.Remove bracket, top swivel pin and shims.

28.Remove swivel pin housing while retrieving

lower and upper bearings.

Swivel bearing housing

29.Remove lower bearing track from swivel bearing

housing.

NOTE: Use upper bearing opening to gain

access to lower bearing track.

30.Remove seven bolts retaining swivel bearing

housing to axle case.

31.Remove inner oil seal from back of housing.

32.Remove top bearing track from swivel bearing

housing.

NOTE: Use lower bearing opening to gain

access to upper bearing track.

33.If worn, pitted or damaged, renew housing.

34.Fit upper and lower bearing tracks into swivel

bearing housing.

CAUTION: Ensure bearing tracks are fitted

square or damage could occur.

35.With seal lips trailing, fit swivel housing inner oil

seal into rear of housing. Grease seal lips.Fit swivel pin housing

36.Coat swivel bearing housing to axle casing bolts

with Loctite 270 or equivalent.

37.Coat both sides of joint washer with a sealing

compound. Position swivel bearing housing to

axle mating face.

38.Place retaining plate, joint washer and oil seal

over axle flange ready for assembly.

39.Fit swivel bearing housing to axle flange with

seven bolts. Tighten to

73 Nm.

40.Grease and fit upper and lower swivel pin taper

roller bearings.

41.Position swivel pin housing over swivel bearing

housing.

42.Coat joint washer both sides with sealing

compound and position on lower swivel pin.

43.Loosely fit brake shield bracket plus lower swivel

pin with lug outboard to swivel pin housing.

44.Loosely fit top swivel pin plus existing shims and

brake hose bracket to swivel pin housing.

45.Apply Loctite 270 or equivalent to lower swivel

pin bolts. Tighten to

78 Nmbend over lock

tabs.

46.Tighten top swivel pin bolts to

78 Nm.

Page 508 of 873

54FRONT AXLE AND FINAL DRIVE

6

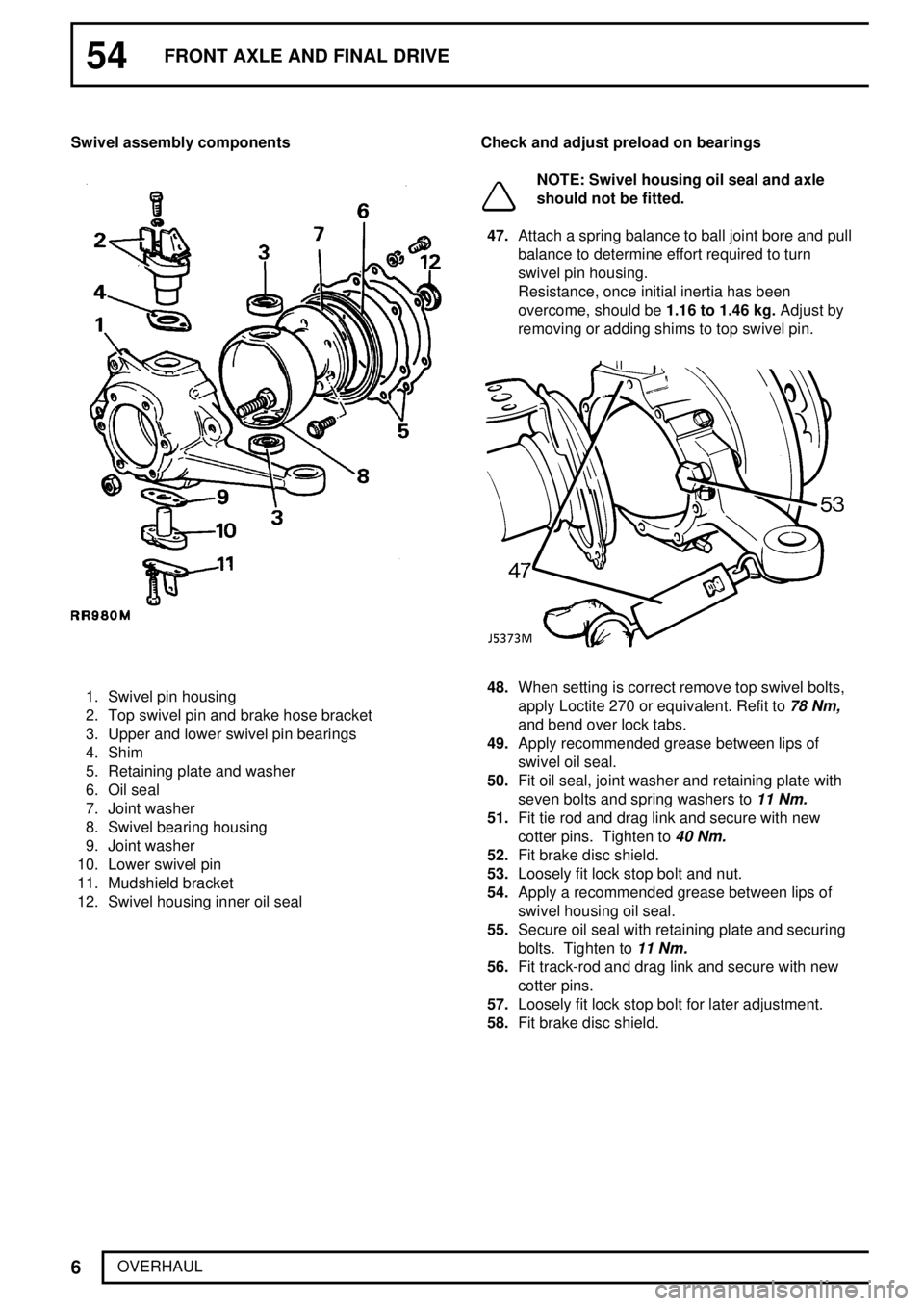

OVERHAUL Swivel assembly components

1. Swivel pin housing

2. Top swivel pin and brake hose bracket

3. Upper and lower swivel pin bearings

4. Shim

5. Retaining plate and washer

6. Oil seal

7. Joint washer

8. Swivel bearing housing

9. Joint washer

10. Lower swivel pin

11. Mudshield bracket

12. Swivel housing inner oil sealCheck and adjust preload on bearings

NOTE: Swivel housing oil seal and axle

should not be fitted.

47.Attach a spring balance to ball joint bore and pull

balance to determine effort required to turn

swivel pin housing.

Resistance, once initial inertia has been

overcome, should be1.16 to 1.46 kg.Adjust by

removing or adding shims to top swivel pin.

48.When setting is correct remove top swivel bolts,

apply Loctite 270 or equivalent. Refit to

78 Nm,

and bend over lock tabs.

49.Apply recommended grease between lips of

swivel oil seal.

50.Fit oil seal, joint washer and retaining plate with

seven bolts and spring washers to

11 Nm.

51.Fit tie rod and drag link and secure with new

cotter pins. Tighten to

40 Nm.

52.Fit brake disc shield.

53.Loosely fit lock stop bolt and nut.

54.Apply a recommended grease between lips of

swivel housing oil seal.

55.Secure oil seal with retaining plate and securing

bolts. Tighten to

11 Nm.

56.Fit track-rod and drag link and secure with new

cotter pins.

57.Loosely fit lock stop bolt for later adjustment.

58.Fit brake disc shield.

Page 509 of 873

FRONT AXLE AND FINAL DRIVE

7

OVERHAUL Fit driveshaft and stub axle

59.Insert axle shaft, and when differential splines

are engaged, push assembly in fully.

CAUTION: Take care not to damage axle

shaft oil seals.

60.Place a new joint washer in position on swivelpin

housing to stub axle mating face. Coat threads

of stub axle bolts with Loctite 270.

61.Fit stub axle with flat at 12 o'clock position.

CAUTION: Ensure that constant velocity

joint bearing journal is butted against

thrust ring on stub axle. Before stub axle

is secured.

62.Place mud shield in position and secure stub

axle to swivel pin housing with six bolts and

tighten evenly to

65 Nm.

63.Fit brake jump hoses to brake jump hose

bracket.

64.Fit front hub complete assembly.

See Repair,

Front Hub Assembly

65.Check swivel pin housing oil drain plug is fitted.

66.Fill swivel assembly to correct level, with new oil.

See SECTION 10, Maintenance, Under

Vehicle Maintenance

67.Set steering lock stop bolts to provide a

clearance of 20mm.

See STEERING,

Adjustment, Steering Lock Stops

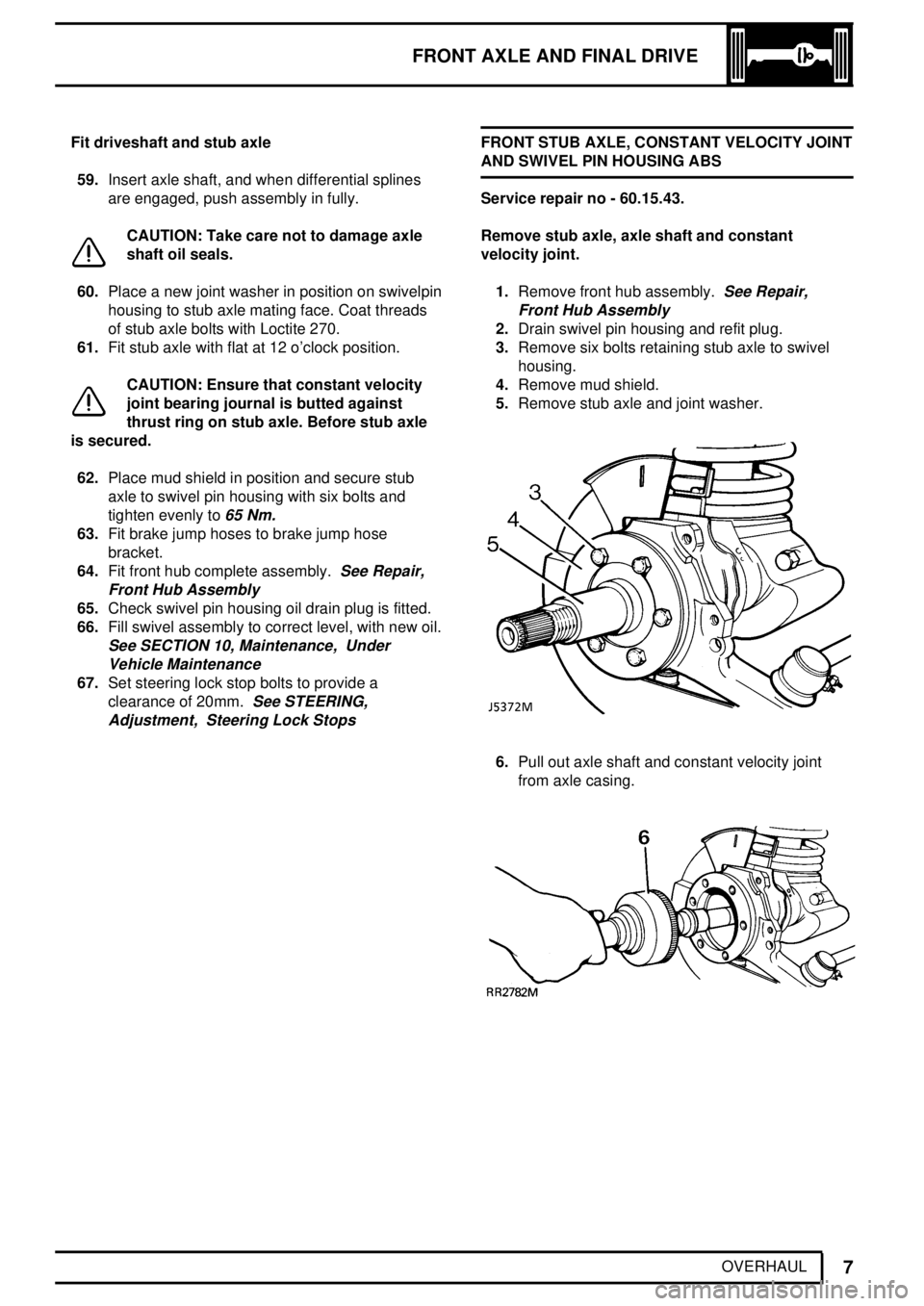

FRONT STUB AXLE, CONSTANT VELOCITY JOINT

AND SWIVEL PIN HOUSING ABS

Service repair no - 60.15.43.

Remove stub axle, axle shaft and constant

velocity joint.

1.Remove front hub assembly.

See Repair,

Front Hub Assembly

2.Drain swivel pin housing and refit plug.

3.Remove six bolts retaining stub axle to swivel

housing.

4.Remove mud shield.

5.Remove stub axle and joint washer.

6.Pull out axle shaft and constant velocity joint

from axle casing.

Page 510 of 873

54FRONT AXLE AND FINAL DRIVE

8

OVERHAUL Remove constant velocity joint from axle shaft

7.Hold axle shaft firmly in a soft jawed vice.

8.Using a soft mallet drive constant velocity joint

from shaft.

9.Remove circlip and collar from axle shaft.

Constant velocity joint

10.Mark positions of constant velocity joint, inner

and outer race and cage for reassembly.

11.Swivel cage and inner race to remove balls.

12.Examine all components in particular inner and

outer track, cage balls and bearing surfaces for

damage and excessive wear.

13.Maximum acceptable end-float on assembled

joint 0,64mm. Renew if worn or damaged.

Lubricate with a recommended oil during

assembly.

Fit constant velocity joint to axle

14.Fit collar and a new circlip.

15.Engage constant velocity joint on axle shaft

splines and using a soft mallet, drive joint in fully.

Renew stub axle,thrust ring, oil seal and bearing

16.Drill and chisel off thrust ring taking care to avoid

damaging stub axle.

17.Remove bearing and oil seal using special tool

LRT-37-004 and slide hammer LRT-99-004.

Ensure lip of tool locates behind bearing to to

drive it out.

18.Repeat instruction for removal of oil seal.