LAND ROVER DISCOVERY 1995 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 541 of 873

57STEERING

2

ADJUSTMENT STEERING LOCK STOPS

Service repair no - 57.65.03

Check

1.Measure clearance between tyre wall and radius

arm at full lock. This must be 20 mm.

Adjust

2.Loosen stop bolt locknut.

3.Turn stop bolt as required.

4.Tighten locknut.

5.Check clearance between tyre wall and radius

arm on each lock.

NOTE: Alternatively lock stop adjustment

may be carried out using following

procedure.

Check

1.Measure stop bolt protrusion as shown in

RR1697M. This must be 40.5 mm.

Adjust

2.Loosen stop bolt locknut.

3.Turn stop bolt as required.

4.Tighten locknut.

5.Check wheel position at full lock.

Page 542 of 873

STEERING

3

ADJUSTMENT FRONT WHEEL ALIGNMENT

Service repair no - 57.65.01

Checking Toe-out dimensions

NOTE: No Adjustment is provided for

castor, camber or swivel pin inclinations.

1.Set vehicle on level ground with road wheels

positioned straight ahead.

2.Push vehicle back and forwards to settle linkage.

3.Measure toe-out at horizontal centre-line of

wheels.

4.Check tightness of clamp bolt fixings. Tighten to

14 Nm.

Adjust

5.Loosen adjuster sleeve clamp.

6.Rotate adjuster to lengthen or shorten track rod.

7.Check toe-out setting as instructions 1 to 4.

When toe-out is correct, tap steering linkage ball

joint, in directions of arrows shown, to maximum

of their travel. This ensures full unrestricted

working travel.

8.Tighten clamp bolts to

14 Nm.

POWER STEERING PUMP DRIVE BELT

Service repair no - 57.20.01

Adjust

NOTE: For details of drive belt adjust

procedure

See ENGINE, Repair, Drive

Belt

Page 543 of 873

STEERING

1

REPAIR POWER STEERING FLUID PIPES

Service repair no - 57.15.21

CAUTION: If any joints are disconnected, it

is essential that open pipe and ports are

plugged to prevent ingress of dirt.

The following procedures must be followed when

refitting fluid pipes:

Power steering pump

1.Remove plugs, place clamp on feed hose.

V8i Steering pump illustrated

2.Push hose onto pump.

3.Hold clamp in position, Tighten to

3 Nm.

4.Fit high pressure union into pump.

5.Hold pipe in correct position. Tighten to

20 Nm.

6.Remove plugs and refit pipes to steering box,

leave fingertight.

7.Tighten to torque: 16mm thread

20 Nm.

14mm thread15 Nm.

Power steering reservoir

1.Remove plugs and refit pipes and clamps.

2.Tighten clamps to3 Nm.

Page 544 of 873

57STEERING

2

REPAIR POWER STEERING BOX

Service repair no - 57.10.01

General precautions

1.Whenever any part of system, is removed or

disconnected, utmost cleanliness must be

observed.

2.Disconnected ports and hoses must be plugged

to prevent ingress of dirt. If metal sediment is

found in system, establish cause rectify and

flush system.

3.Do not start engine until reservoir is full as pump

will be damaged.

4.Metric pipe fittings are used with 'O' ring pipe

ends on fittings to steering box.

5.Follow normal 'O' ring replacement procedure

whenever pipes are disconnected.

6.Ensure compatible metric components when

fitting replacement pipes.

CAUTION: Before removing any parts of

steering linkage, it is imperative that road

wheels are positioned straight ahead.

Then steering wheel removed to prevent rotary

coupler being wound up or damaged.

CAUTION: After refitting steering linkage

parts follow correct procedure to ensure

that road wheels, steering box and

steering wheel are correctly positioned relative to

each other when in straight ahead condition. If

steering wheel requires repositioning, ensure that

drive pegs on rotary coupler are correctly

positioned before steering wheel is replaced.

This ensures drive pegs locate in their holes in

rear of steering wheel.

After final alignment connect rotary coupler

multiplug, tighten steering wheel securing nut and

fit air bag - if fitted or steering wheel trim pad.

NOTE: When drag link is disconnected

from steering box, travel available at

steering wheel to each full lock is not

equal.

Remove

1.Site vehicle on level surface.

2.Open bonnet[hood].

3.Remove filler cap from power steering fluid

reservoir.

4.Clean steering box.

5.Disconnect feed and return pipes from steering

box.

6.Plug open pipes and steering box ports to

prevent ingress of dirt.

7.Support chassis front on axle stands. Or raise

vehicle on a hoist.

WARNING: Ensure wheels are chocked,

parking brake is applied, and low range

selected.

Page 545 of 873

STEERING

3

REPAIR 8.Remove undertray

9.Disconnect drag link from drop arm using a

suitable extractor.

10.Remove pinch bolt securing lower shaft

universal joint to power steering box.

11.Loosen but do not remove nut securing tie bar to

mounting.

12.Remove bolts securing tie bar, move tie bar

aside.

13.Remove bolts securing power steering box to

chassis side member.

14.Withdraw power steering box.

Page 546 of 873

57STEERING

4

REPAIR

Refit

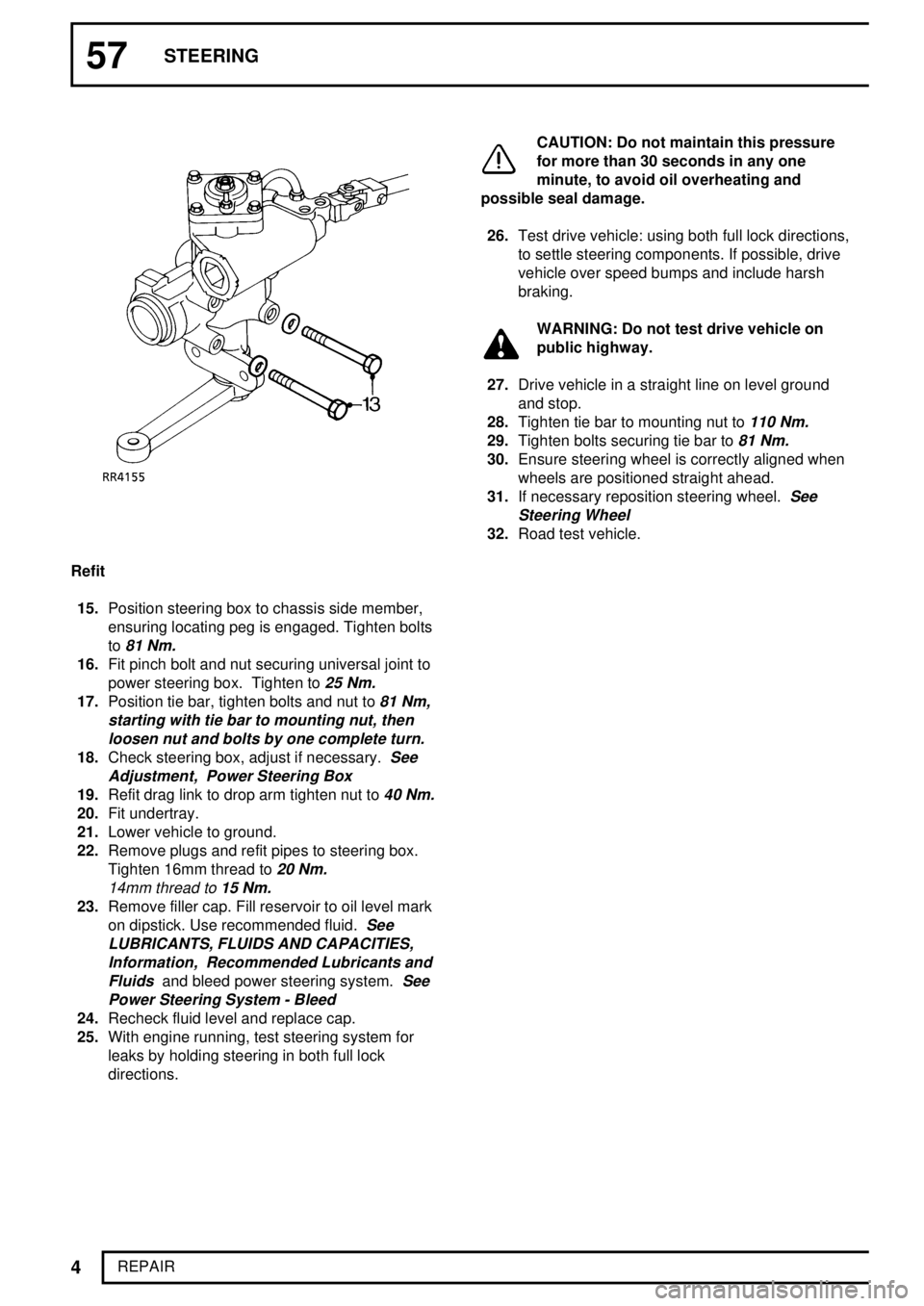

15.Position steering box to chassis side member,

ensuring locating peg is engaged. Tighten bolts

to

81 Nm.

16.Fit pinch bolt and nut securing universal joint to

power steering box. Tighten to

25 Nm.

17.Position tie bar, tighten bolts and nut to81 Nm,

starting with tie bar to mounting nut, then

loosen nut and bolts by one complete turn.

18.Check steering box, adjust if necessary.See

Adjustment, Power Steering Box

19.Refit drag link to drop arm tighten nut to40 Nm.

20.Fit undertray.

21.Lower vehicle to ground.

22.Remove plugs and refit pipes to steering box.

Tighten 16mm thread to

20 Nm.

14mm thread to15 Nm.

23.Remove filler cap. Fill reservoir to oil level mark

on dipstick. Use recommended fluid.

See

LUBRICANTS, FLUIDS AND CAPACITIES,

Information, Recommended Lubricants and

Fluids

and bleed power steering system.See

Power Steering System - Bleed

24.Recheck fluid level and replace cap.

25.With engine running, test steering system for

leaks by holding steering in both full lock

directions.

CAUTION: Do not maintain this pressure

for more than 30 seconds in any one

minute, to avoid oil overheating and

possible seal damage.

26.Test drive vehicle: using both full lock directions,

to settle steering components. If possible, drive

vehicle over speed bumps and include harsh

braking.

WARNING: Do not test drive vehicle on

public highway.

27.Drive vehicle in a straight line on level ground

and stop.

28.Tighten tie bar to mounting nut to

110 Nm.

29.Tighten bolts securing tie bar to81 Nm.

30.Ensure steering wheel is correctly aligned when

wheels are positioned straight ahead.

31.If necessary reposition steering wheel.

See

Steering Wheel

32.Road test vehicle.

Page 547 of 873

STEERING

5

REPAIR POWER STEERING SYSTEM - BLEED

Service repair no - 57.15.02

1.Ensure fluid in reservoir reaches dipstick

maximum.

2.Run engine to normal operating temperature.

3.Recheck and correct reservoir fluid level.

NOTE: During instructions 4 to 6, maintain

maximum fluid level in reservoir. Do not

increase engine speed or move steering

wheel.

4.With engine at idle speed, loosen bleed screw.

When fluid seeps past bleed screw retighten

screw.

5.Check fluid level.

6.Clean away fluid around bleed screw.

7.Check hose connections, pump and steering box

for fluid leaks by holding steering on full lock in

both directions.

CAUTION: Do not maintain this pressure

for more than 30 seconds in any one

minute to avoid overheating fluid and

possibly damaging seals.

8.Carry out road test.POWER STEERING FLUID RESERVOIR

Service repair no - 57.15.08

Remove

1.Remove undertray.

2.Position drain tin beneath reservoir.

3.Loosen mounting bracket clamp bolt, raise

reservoir to gain access to pipe clamps.

4.Loosen clamps, disconnect feed and return

hoses from reservoir, allow fluid to drain.

CAUTION: Plug the connections.

5.Remove reservoir.

CAUTION: Discard fluid drained from

system. Do not allow fluid to contact

paintwork, if spilled, remove fluid and

clean area with warm water.

Page 548 of 873

57STEERING

6

REPAIR Refit

6.Position reservoir, connect feed and return

hoses and tighten clamps to

3 Nm.

7.Fit reservoir in clamp, tighten clamp bolt.

8.Fill reservoir to 'MAX' mark on dipstick with

power steering fluid.

See LUBRICANTS,

FLUIDS AND CAPACITIES, Information,

Recommended Lubricants and Fluids

9.Fit undertray.

10.Bleed power steering system.

See Power

Steering System - Bleed

POWER STEERING PUMP DRIVE BELT

Service repair no - 57.20.02

NOTE: For details of drive belt remove and

refit.

See ENGINE, Repair, Drive Belt

POWER STEERING PUMP - V8i

Service repair no - 57.20.14

NOTE: The power steering pump is not

serviceable. Fit new pump if worn or

damaged.

Remove

1.Disconnect battery negative lead.

2.Remove drive belt from steering pump.

See

ENGINE, Repair, Drive Belt

3.Remove undertray.

4.Remove fan blades and viscous coupling.

See

COOLING SYSTEM, Repair, Viscous

Coupling, Fan Blades, Pulley and Fan Cowl

5.Position drain tin beneath steering pump.

6.Using a 9 mm Allen key to restrain steering

pump pulley, remove 3 bolts securing pulley to

pump; remove pulley.

Page 549 of 873

STEERING

7

REPAIR 7.Loosen clamp securing reservoir hose to

steering pump; disconnect hose.

8.Disconnect high pressure pipe from steering

pump.

CAUTION: Plug the connections.

9.Release ht lead from clip

10.Remove 3 bolts securing steering pump.

Remove pump and recover engine lifting

bracket.

NOTE:Do not carry out further

dismantling if component is removed for

access only.

11.Remove 5 bolts securing front mounting plate.

12.Fit front mounting plate to replacement steering

pump. Tighten bolts to

9 Nm.

Refit

13.Position steering pump and engine lifting plate,

fit bolts. Tighten to

35 Nm.Secure ht lead in

clip.

14.Connect high pressure pipe to steering pump,

tighten union to

20 Nm.

15.Connect reservoir hose to steering pump.

Tighten clamp to

3 Nm.

16.Position pulley to pump, coat threads of bolts

with Loctite 242.

17.Restrain pulley using a 9 mm Allen key, fit bolts.

Tighten to

10 Nm.

18.Fit drive belt.See ENGINE, Repair, Drive Belt

19.Fit fan blades and viscous coupling.See

COOLING SYSTEM, Repair, Viscous

Coupling, Fan Blades, Pulley and Fan Cowl

20.Fit undertray.

21.Reconnect battery negative lead.

22.Bleed power steering system.

See Power

Steering System - Bleed

POWER STEERING PUMP - Tdi

Service repair no - 57.20.14

Remove

1.Remove fan blades and viscous coupling.

See

COOLING SYSTEM, Repair, Viscous

Coupling, Fan Blades, Pulley and Fan Cowl

2.Restrain steering pump pulley, loosen but do not

remove 3 bolts securing pulley.

3.Remove drive belt.

See ENGINE, Repair,

Drive Belt

4.Remove 3 bolts securing steering pump pulley,

remove pulley.

5.Remove undertray.

6.Position drain tin beneath steering pump.

Page 550 of 873

57STEERING

8

REPAIR 7.Loosen clamp securing reservoir hose to

steering pump, disconnect hose.

8.Disconnect high pressure pipe from steering

pump.

CAUTION: Plug the connections.

9.Remove 4 bolts securing steering pump to

mounting bracket, remove pump.

NOTE:Do not carry out further

dismantling if component is removed for

access only.

10.Remove 3 bolts securing mounting plate to

pump, remove plate.

11.Fit mounting plate to replacement steering

pump. Tighten bolts to

9 Nm.

Refit

12.Position steering pump, fit 3 bolts. Tighten to

35

Nm.

13.Connect high pressure pipe to steering pump.

Tighten to

20 Nm.

14.Connect reservoir hose to steering pump.

Tighten clamp to

3 Nm.

15.Position pulley to steering pump, coat threads of

bolts with Loctite 242; fit but do not fully tighten 3

bolts.

16.Fit drive belt.

See ENGINE, Repair, Drive Belt

17.Restrain steering pump pulley, tighten bolts to10

Nm.

18.Fit fan blades and viscous coupling.See

COOLING SYSTEM, Repair, Viscous

Coupling, Fan Blades, Pulley and Fan Cowl

19.Fit undertray.

20.Bleed power steering system.

See Power

Steering System - Bleed