LAND ROVER DISCOVERY 1995 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 551 of 873

STEERING

9

REPAIR LOWER STEERING SHAFT AND UNIVERSAL

JOINTS

Service repair no - 57.40.25

CAUTION: Before removing any parts of

steering linkage, it is imperative that road

wheels are positioned straight ahead.

Then steering wheel removed to prevent rotary

coupler being wound up or damaged.

CAUTION: After refitting steering linkage

parts follow correct procedure to ensure

that road wheels, steering box and

steering wheel are correctly positioned relative to

each other when in straight ahead condition. If

steering wheel requires repositioning, ensure that

drive pegs on rotary coupler are correctly

positioned before steering wheel is replaced.

This ensures drive pegs locate in their holes in

rear of steering wheel.

After final alignment connect rotary coupler,

tighten steering wheel securing nut and fit air bag

module - if fitted or steering wheel trim pad.

Remove

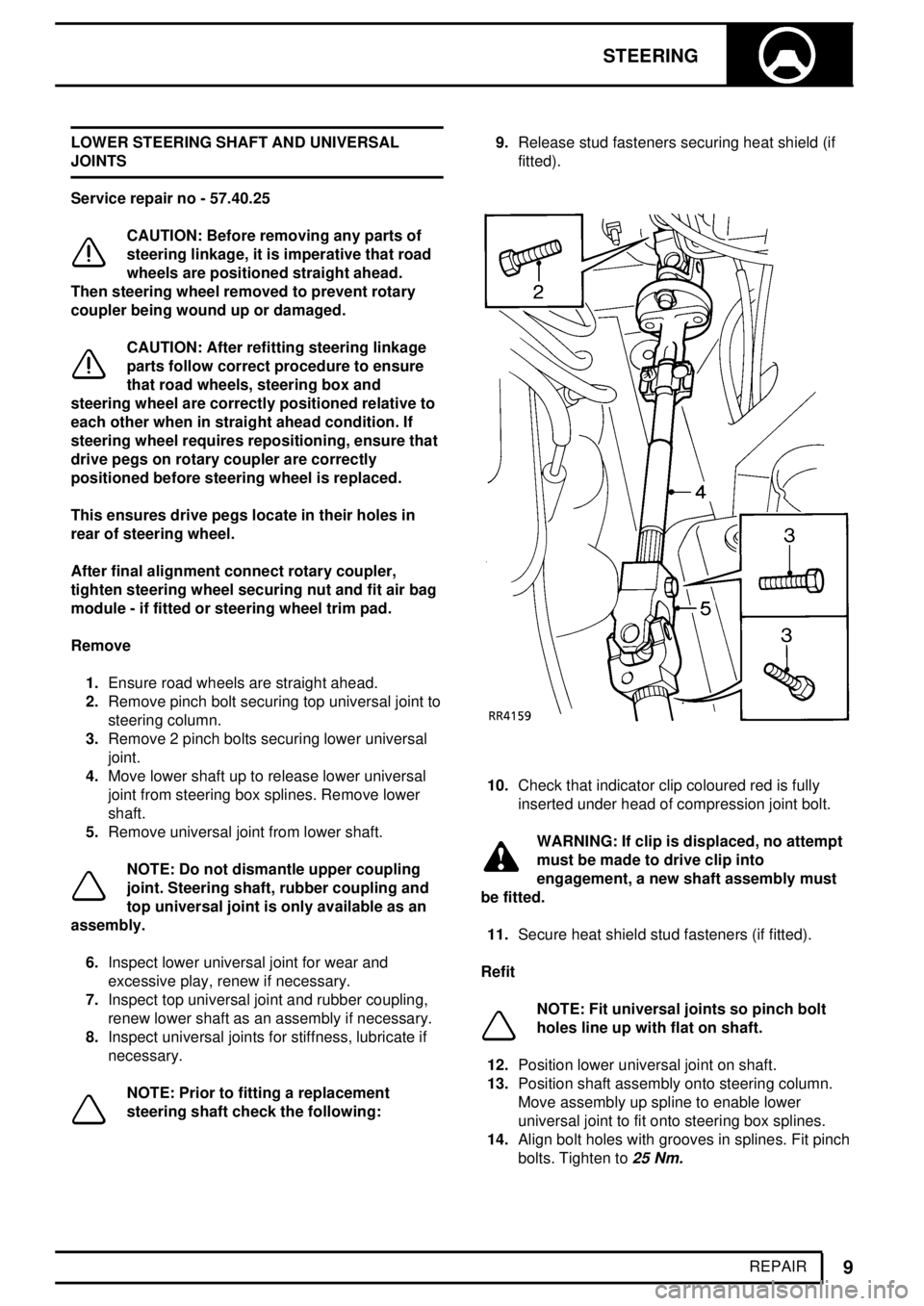

1.Ensure road wheels are straight ahead.

2.Remove pinch bolt securing top universal joint to

steering column.

3.Remove 2 pinch bolts securing lower universal

joint.

4.Move lower shaft up to release lower universal

joint from steering box splines. Remove lower

shaft.

5.Remove universal joint from lower shaft.

NOTE: Do not dismantle upper coupling

joint. Steering shaft, rubber coupling and

top universal joint is only available as an

assembly.

6.Inspect lower universal joint for wear and

excessive play, renew if necessary.

7.Inspect top universal joint and rubber coupling,

renew lower shaft as an assembly if necessary.

8.Inspect universal joints for stiffness, lubricate if

necessary.

NOTE: Prior to fitting a replacement

steering shaft check the following:9.Release stud fasteners securing heat shield (if

fitted).

10.Check that indicator clip coloured red is fully

inserted under head of compression joint bolt.

WARNING: If clip is displaced, no attempt

must be made to drive clip into

engagement, a new shaft assembly must

be fitted.

11.Secure heat shield stud fasteners (if fitted).

Refit

NOTE: Fit universal joints so pinch bolt

holes line up with flat on shaft.

12.Position lower universal joint on shaft.

13.Position shaft assembly onto steering column.

Move assembly up spline to enable lower

universal joint to fit onto steering box splines.

14.Align bolt holes with grooves in splines. Fit pinch

bolts. Tighten to

25 Nm.

Page 552 of 873

57STEERING

10

REPAIR STEERING COLUMN SHROUD

Service repair no - 57.40.29

Remove

1.Disconnect battery negative lead.

2.Remove 3 screws securing shroud.

3.Carefully release upper shroud from lower.

4.Manoeuvre lower shroud clear of steering

column.

Refit

5.Position upper and lower shrouds to steering

column ensuring plastic tags on lower shroud

are correctly located. Clip both halves of shroud

together.

6.Fit and tighten 3 screws.STEERING WHEEL

Service repair no - 57.60.01

CAUTION: Prior to commencing work on

vehicles fitted with an air bag,

See

SUPPLEMENTARY RESTRAINT SYSTEM,

Description and operation,

CAUTION: Before removing any parts of

steering linkage, it is imperative that road

wheels are positioned straight ahead.

Then remove steering wheel to prevent rotary

coupler being wound up or damaged.

CAUTION: After refitting steering linkage

parts follow correct procedure to ensure

that road wheels, steering box and

steering wheel are correctly positioned relative to

each other when in straight ahead condition. If

steering wheel requires repositioning, ensure that

drive pegs on rotary coupler are correctly

positioned before steering wheel is replaced.

This ensures drive pegs locate in their holes in

rear of steering wheel.

After final alignment connect rotary coupler

multiplug, tighten steering wheel securing nut and

fit air bag - if fitted or steering wheel trim pad.

Page 553 of 873

STEERING

11

REPAIR Remove

1.Disconnect battery negative lead.

2.Position road wheels straight ahead so steering

wheel can be correctly re-assembled.

3. Airbag fitted:Remove air bag.

See

SUPPLEMENTARY RESTRAINT SYSTEM,

Repair, Driver's Airbag Module

4.Remove trim pad from steering wheel,

disconnect Lucars from horn button.

5.Disconnect rotary coupler multiplug.

6.Loosen but do not remove retaining nut.

7.Release steering wheel from taper, remove

retaining nut and washer.

8.Release harness from retaining clip.

9.Withdraw steering wheel whilst at the same time

feeding harness through wheel hub.

CAUTION: Prevent rotation of rotary

coupler once steering wheel is removed.

Secure in position with adhesive tape.

NOTE:Do not carry out further

dismantling if component is removed for

access only.

Refit

10.Recheck road wheels are positioned straight

ahead.

11.Position steering wheel to column, feed harness

through wheel hub.

12.Remove adhesive tape securing rotary coupler.

13.Locate rotary coupler drive pegs and indicator

switch self-cancel pegs in steering wheel hub,

push wheel fully onto taper.

14.Fit steering wheel nut. Tighten to

50 Nm.

15.Connect rotary coupler multiplug.

16.Non airbag module: Fit horn push assembly,

connect Lucars to horn button, secure harness

in clip.

17.Fit airbag module - if fitted.

See

SUPPLEMENTARY RESTRAINT SYSTEM,

Repair, Driver's Airbag Module

18.Reconnect battery negative lead.

Page 554 of 873

57STEERING

12

REPAIR UPPER STEERING COLUMN

Service repair no - 57.40.01

NOTE: Steering column assembly is not a

serviceable component.

CAUTION: Before removing any parts of

steering linkage, it is imperative that road

wheels are positioned straight ahead. then

steering wheel removed to prevent rotary coupler

being wound up or damaged.

CAUTION: After refitting steering linkage

parts follow correct procedure to ensure

that road wheels, steering box and

steering wheel are correctly positioned relative to

each other when in straight ahead condition. if

steering wheel requires repositioning, ensure that

drive pegs on rotary coupler are correctly

positioned before steering wheel is replaced.

This ensures drive pegs locate in their holes in

rear of steering wheel.

After final alignment, connect rotary coupler

multiplug, tighten steering wheel securing nut and

fit airbag - if fitted or steering wheel trim pad and

horn push assembly.

Remove

1.Remove steering wheel.

See Steering Wheel

CAUTION: Prevent rotation of rotary

coupler once steering wheel is removed.

Secure in position with adhesive tape.

2.Remove driver's access panel.

3.Remove steering column shroud.

See Steering

Column Shroud

4.Remove rotary coupler.See

SUPPLEMENTARY RESTRAINT SYSTEM,

Repair, Rotary Coupler

5.If fitted - remove 4 screws securing knee bolster,

remove knee bolster.

6.Disconnect column switch multiplug.

7.Disconnect ignition switch multiplug from fuse

box.

Page 555 of 873

STEERING

13

REPAIR

8.Disconnect ignition switch main feed multiplug.

9.Remove 4 nuts securing upper column to lower

mounting.

10.Remove 2 nuts securing lower mounting steady

bracket, remove bracket.

11.Remove pinch bolt securing upper column to

universal joint.

12.Remove 2 nuts and washes securing upper

column to upper mounting bracket.13.Carefully manoeuvre upper column out of

footwell, recover rubber boot.

NOTE: Do not carry out further

dismantling if upper column is removed

for access only.

14.Loosen but, do not remove screw securing

column switch assembly, withdraw assembly to

gain access to multiplugs.

15.Disconnect column switch multiplugs, remove

column switch assembly.

16.Disconnect ignition switch multiplug.

17.Remove shear bolts securing steering column

lock, remove lock and saddle; discard shear

bolts.

18.Withdraw bulb holder from column lock shroud.

19.Transfer components to new upper column,

connect multiplug.

NOTE: Do not shear column lock bolts at

this stage.

Page 556 of 873

57STEERING

14

REPAIR Refit

20.Manoeuvre upper column to position in footwell,

ensure splines in column and universal joint are

correctly engaged and rubber boot is fitted.

21.Fit but do not tighten universal joint pinch bolt.

22.Position upper column to upper mounting, fit

washers and nuts, do not tighten nuts.

23.Fit but do not tighten nuts and bolts securing

upper column to lower mounting.

24.Fit lower mounting steady bracket, fit but do not

tighten nuts and bolts.

25.Ensure upper column is aligned to mountings.

26.Tighten all nuts and bolts to

22 Nm.

27.Tighten universal joint pinch bolt to25 Nm.

28.Connect column switch multiplug.

29.Connect ignition switch multiplugs.

30.Fit rotary coupler.

See SUPPLEMENTARY

RESTRAINT SYSTEM, Repair, Rotary

Coupler

31.Fit steering wheel.See Steering Wheel

32.Reconnect battery negative lead.

33.Check steering column lock for correct

operation, tighten shear bolts until heads shear

off.

34.If fitted - position knee bolster, fit and tighten

screws.

35.Fit steering column shroud.

See Steering

Column Shroud

36.Fit driver's access panel.

Page 557 of 873

STEERING

15

REPAIR STEERING COLUMN LOCK ASSEMBLY

Service repair no - 57.40.31

Remove

CAUTION: Before removing any parts of

steering linkage, it is imperative that road

wheels are positioned straight ahead.

Then steering wheel removed to prevent rotary

coupler being wound up or damaged.

CAUTION: After refitting steering linkage

parts follow correct procedure to ensure

that road wheels, steering box and

steering wheel are correctly positioned relative to

each other when in straight ahead condition. If

steering wheel requires repositioning, ensure that

drive pegs on rotary coupler are correctly

positioned before steering wheel is replaced.

This ensures drive pegs locate in their holes in

rear of steering wheel.

After final alignment connect rotary coupler

multiplug, tighten steering wheel securing nut and

fit airbag module - if fitted.

1.Disconnect battery negative lead.

2.Remove steering column shroud.

See Steering

Column Shroud

3.Release turnbuckles, lower driver's access

panel.

4.If fitted, remove 4 screws securing knee pad,

remove bolster.

5.Disconnect ignition switch multiplug from fuse

box.

6.Disconnect ignition switch main feed multiplug.

Page 558 of 873

57STEERING

16

REPAIR

7.Remove bulb holder from steering column lock

shroud.

8.Tap head of shear bolts anti-clockwise to release

them.

9.Remove and discard shear bolts.

10.Detach saddle.

11.Remove steering column lock assembly.

Refit

12.Position steering lock saddle on column, locating

spigot in hole provided.

13.Place lower lock assembly into column.

14.Fit but do not fully tighten new shear bolts.

15.Connect multiplugs.

16.Insert bulb holder into steering column lock

shroud.

17.Reconnect battery negative lead.

18.Check steering column lock for correct

operation, tighten shear bolts until heads shear

off.

19.Fit steering column shroud.

See Steering

Column Shroud

20.If fitted - fit knee bolster, fit and tighten screws.

21.Raise driver's access panel, secure turnbuckles.DROP ARM

Service repair no - 57.50.14

Remove

1.Place vehicle on a hoist, or support front axle on

axle stands.

2.Disconnect drag link ball joint from drop arm,

using extractor LRT-57-018.

Page 559 of 873

STEERING

17

REPAIR 3.Bend back tabs on locking washer and remove

drop arm using extractor LRT-57-012. Loosen

drop arm securing nut, but do not remove before

using extractor.

4.Remove nut, discard locking washer.

Refit

5.Centralise steering box.

See Adjustment,

Centralise Steering Box

6.Fit drop arm, align master splines.

7.Fit a new tab washer and drop arm fixing nut.

Tighten to

176 Nm,bend over tab.

8.Fit drag link. Tighten ball joint nut

40 Nm.

STEERING DAMPER

Service repair no - 57.55.21

Remove

1.Site vehicle on a ramp [hoist].

2.Remove fixings at differential case bracket.

3.Remove fixings at track rod bracket.

4.Remove steering damper.

Refit

5.Reverse removal procedure. 1 to 4.

Page 560 of 873

![LAND ROVER DISCOVERY 1995 Workshop Manual 57STEERING

18

REPAIR TRACK ROD AND LINKAGE

Service repair no - 57.55.09

Remove track rod

1.Site vehicle on a ramp [hoist].

2.Disconnect steering damper at track rod.

3.Disconnect track rod at ball joi LAND ROVER DISCOVERY 1995 Workshop Manual 57STEERING

18

REPAIR TRACK ROD AND LINKAGE

Service repair no - 57.55.09

Remove track rod

1.Site vehicle on a ramp [hoist].

2.Disconnect steering damper at track rod.

3.Disconnect track rod at ball joi](/img/64/57248/w960_57248-559.png)

57STEERING

18

REPAIR TRACK ROD AND LINKAGE

Service repair no - 57.55.09

Remove track rod

1.Site vehicle on a ramp [hoist].

2.Disconnect steering damper at track rod.

3.Disconnect track rod at ball joints, using

extractor LRT-57-018.

4.Remove track rod.

Remove linkage

5.Loosen clamp bolts.

6.Unscrew ball joints.

7.Unscrew track rod adjuster. (left hand thread).

Refit linkage

8.Fit replacement parts. Loosely fit clamp pinch

bolts.

9.Screw in ball joint to full extent of threads.

10.Set adjuster to track rod distance to 9mm as

shown.

11.Set adjuster end ball joint distance to 28.5mm as

shown.

12.Track rod effective length of 1230.0mm is

subject to adjustment during wheel alignment

check.

Refit track rod

CAUTION: Fit a new track rod if existing is

damaged or bent. No attempt should be

made to repair it.

13.Fit track rod and tighten ball joint nuts to

40 Nm.

14.Check front wheel alignment.See Adjustment,

Front Wheel Alignment

15.Connect steering damper to track rod.

16.Remove vehicle from hoist, or axle stands.