LAND ROVER DISCOVERY 1995 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 661 of 873

75SUPPLEMENTARY RESTRAINT SYSTEM

16

REPAIR

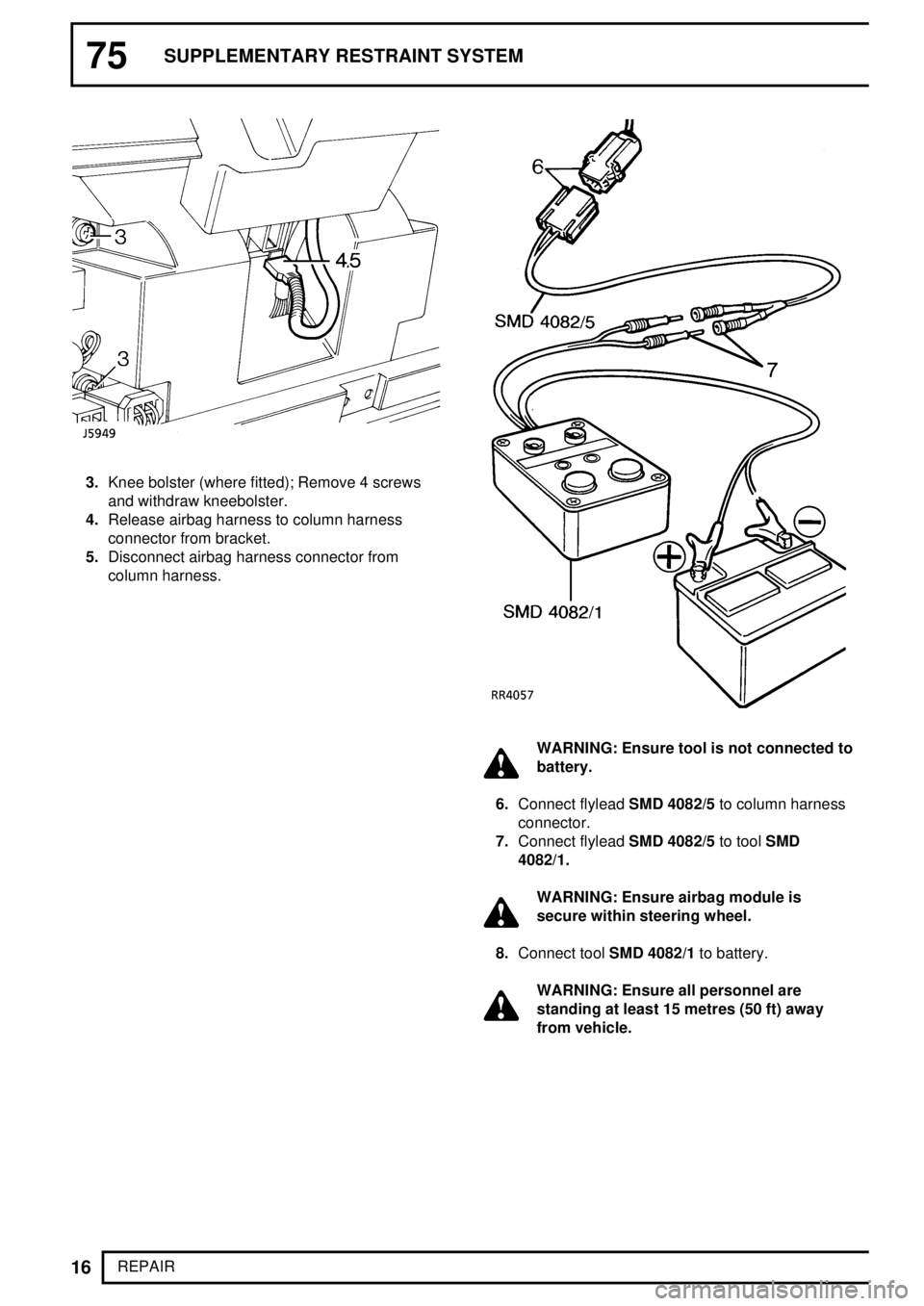

3.Knee bolster (where fitted); Remove 4 screws

and withdraw kneebolster.

4.Release airbag harness to column harness

connector from bracket.

5.Disconnect airbag harness connector from

column harness.

WARNING: Ensure tool is not connected to

battery.

6.Connect flyleadSMD 4082/5to column harness

connector.

7.Connect flyleadSMD 4082/5to toolSMD

4082/1.

WARNING: Ensure airbag module is

secure within steering wheel.

8.Connect toolSMD 4082/1to battery.

WARNING: Ensure all personnel are

standing at least 15 metres (50 ft) away

from vehicle.

Page 662 of 873

SUPPLEMENTARY RESTRAINT SYSTEM

17

REPAIR

9.Press both operating buttons to deploy airbag

module.

10. DO NOTreturn to airbag module for 30 minutes.

11.Using gloves and face mask, remove airbag

module from steering wheel, place airbag

module in plastic bag and seal bag.

12.Transport deployed airbag module to designated

area for incineration.

NOTE: DO NOT transport airbag module in

the vehicle passenger compartment.

13.Scrap all remaining parts of airbag system.

DO NOTre-use or salvage any parts of the

airbag system including steering wheel.Deployment with module removed from vehicle.

Driver's Airbag Module

These guidelines are written to aid authorised

personnel to carry out the safe disposal of airbag

modules when removed from the vehicle.

WARNING: Only use the LAND ROVER

approved deployment equipment.

Deploy airbag modules in a well ventilated

designated area.

Ensure airbag module is not damaged or ruptured

before deploying.

1.Carry out deployment tool self test.

2.Remove airbag module from steering wheel.

See driver's airbag module.

3.Position toolSMD 4082/2in vice, ensuring that

vice jaws grip tool above bottom flange to

prevent possibility of tool being forced upwards

from vice. Tighten vice.

Page 663 of 873

75SUPPLEMENTARY RESTRAINT SYSTEM

18

REPAIR

WARNING: Ensure tool SMD 4082/1 is not

connected to battery.

4.Secure airbag module to toolSMD 4082/2.

Ensure module is correctly secured using both

fixings.

5.Ensure airbag module mounting brackets are

secure.

6.Connect flyleadSMD 4082/4to airbag module.

7.Connect flyleadSMD 4082/4to toolSMD

4082/1.

WARNING: Do not lean over module whilst

connecting.

8.Connect toolSMD 4082/1to battery.

WARNING: Ensure all personnel are

standing at least 15 metres (50 ft) away

from module.

Page 664 of 873

SUPPLEMENTARY RESTRAINT SYSTEM

19

REPAIR

9.Press both operating buttons to deploy airbag

module.

10. DO NOTreturn to airbag module for 30 minutes.

11.Using gloves and face mask, remove airbag

module from tool, place airbag module in plastic

bag and seal bag.

12.Wipe down tool with damp cloth.

13.Transport deployed airbag module to designated

area for incineration.

NOTE: DO NOT transport airbag module in

the vehicle passenger compartment. DO

NOT re-use or salvage any parts of the

airbag system including steering wheel or

steering column.Passenger's Airbag Module

1.Carry out deployment tool self test.

2.Remove airbag module from fascia.

See

passenger's airbag module.

3.Position toolSMD 4082/6in vice, ensuring that

vice jaws grip tool above bottom flange to

prevent possibility of tool being forced upwards

from vice. Tighten vice.

4.Position bracketsSMD 4082/7to tool; lightly

tighten bolts.

Page 665 of 873

75SUPPLEMENTARY RESTRAINT SYSTEM

20

REPAIR

5.Position airbag module to toolSMD 4082/6.

Ensure module is correctly secured using all

fixings.

6.Ensure airbag module mounting brackets are

secure.

WARNING: Ensure tool SMD 4082/1 is not

connected to battery.

7.Connect flyleadSMD 4082/5to airbag module.

8.Connect flyleadSmd 4082/5to toolSMD 4082/1

WARNING: Do not lean over module whilst

connecting.

9.Connect toolSMD 4082/1to battery.

WARNING: Ensure all personnel are

standing at least 15 metres (50 ft) away

from module.

Page 666 of 873

SUPPLEMENTARY RESTRAINT SYSTEM

21

REPAIR

10.Press both operating buttons to deploy airbag

module.

11. DO NOTreturn to airbag module for 30 minutes.

12.Using gloves and face mask, remove airbag

module from tool, place airbag module in plastic

bag and seal bag.

13.Wipe down tool with damp cloth.

14.Transport deployed airbag module to designated

area for incineration.

NOTE: DO NOT transport airbag module in

the vehicle passenger compartment. DO

NOT re-use or salvage any parts of the

airbag system.AIRBAG DIAGNOSTIC CONTROL UNIT - SPS SRS

Service repair no - 76.74.03

Remove

1.Remove centre console.

See CHASSIS AND

BODY, Repair, centre console.

2.Disconnect connector from control unit.

3.Remove 2 Torx bolts securing control unit to

body.

4.Remove control unit.

Refit

5.Position control unit to body, fit Torx bolts and

tighten to

10 Nm (7 lbf ft).

6.Connect control unit connector and secure.

7.Fit centre console.

See CHASSIS AND BODY,

Repair, centre console.

8.Check supplementary restraint system using

TestBook.

Page 667 of 873

SUPPLEMENTARY RESTRAINT SYSTEM

1

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

Airbag module screws 8 (6 lbf ft)...........................................................................

Steering wheel nut 50 (37 lbf ft)..............................................................................

Crash sensor screws (Distributed SRS) 10 (7 lbf ft)..............................................

Control unit 10 (7 lbf ft)...........................................................................................

Page 668 of 873

CHASSIS AND BODY

1

REPAIR FRONT DOOR

Service repair no - 76.28.01

Remove

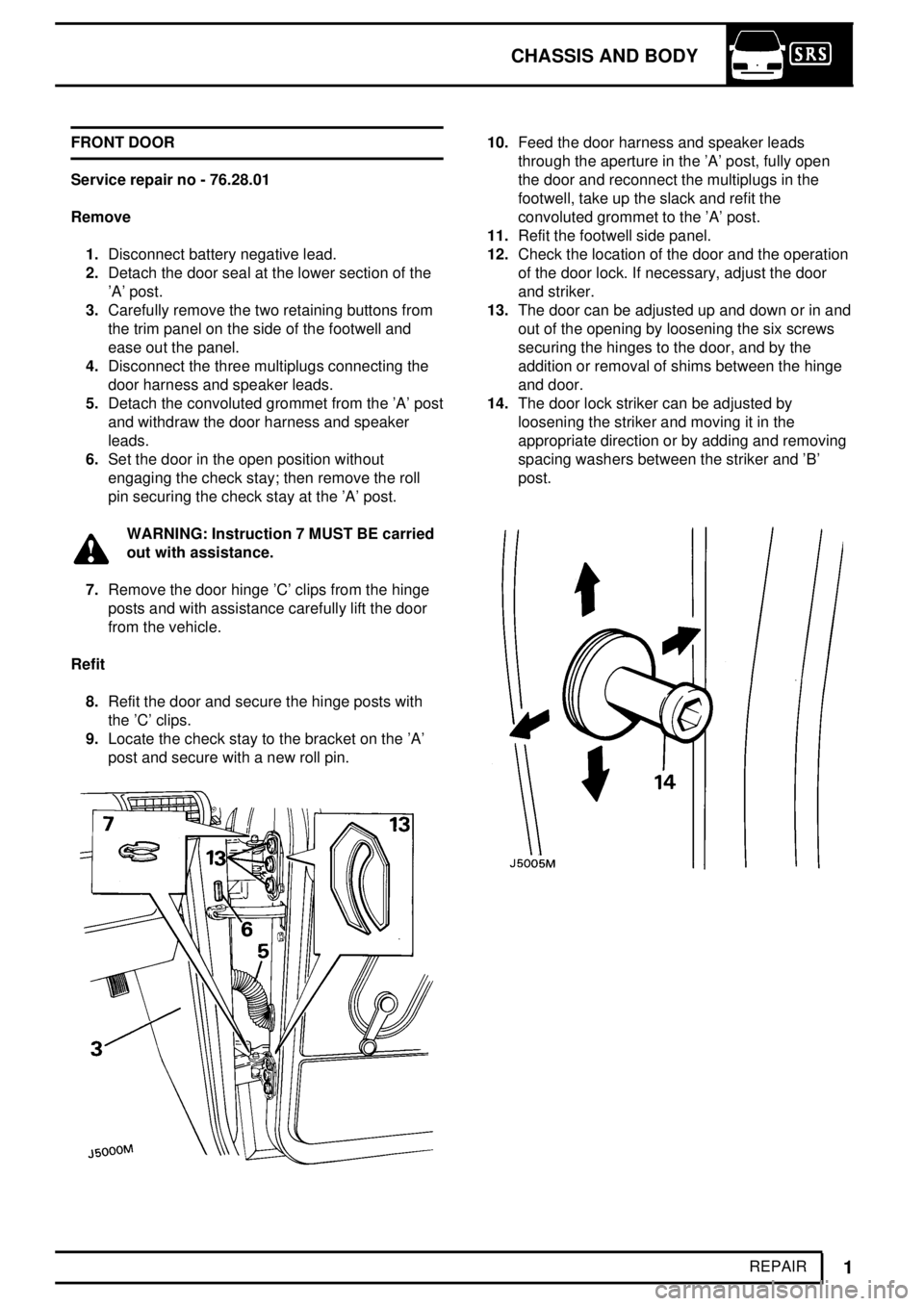

1.Disconnect battery negative lead.

2.Detach the door seal at the lower section of the

'A' post.

3.Carefully remove the two retaining buttons from

the trim panel on the side of the footwell and

ease out the panel.

4.Disconnect the three multiplugs connecting the

door harness and speaker leads.

5.Detach the convoluted grommet from the 'A' post

and withdraw the door harness and speaker

leads.

6.Set the door in the open position without

engaging the check stay; then remove the roll

pin securing the check stay at the 'A' post.

WARNING: Instruction 7 MUST BE carried

out with assistance.

7.Remove the door hinge 'C' clips from the hinge

posts and with assistance carefully lift the door

from the vehicle.

Refit

8.Refit the door and secure the hinge posts with

the 'C' clips.

9.Locate the check stay to the bracket on the 'A'

post and secure with a new roll pin.

10.Feed the door harness and speaker leads

through the aperture in the 'A' post, fully open

the door and reconnect the multiplugs in the

footwell, take up the slack and refit the

convoluted grommet to the 'A' post.

11.Refit the footwell side panel.

12.Check the location of the door and the operation

of the door lock. If necessary, adjust the door

and striker.

13.The door can be adjusted up and down or in and

out of the opening by loosening the six screws

securing the hinges to the door, and by the

addition or removal of shims between the hinge

and door.

14.The door lock striker can be adjusted by

loosening the striker and moving it in the

appropriate direction or by adding and removing

spacing washers between the striker and 'B'

post.

Page 669 of 873

76CHASSIS AND BODY

2

REPAIR FRONT DOOR TRIM PANEL

Service repair no - 76.34.01

Remove

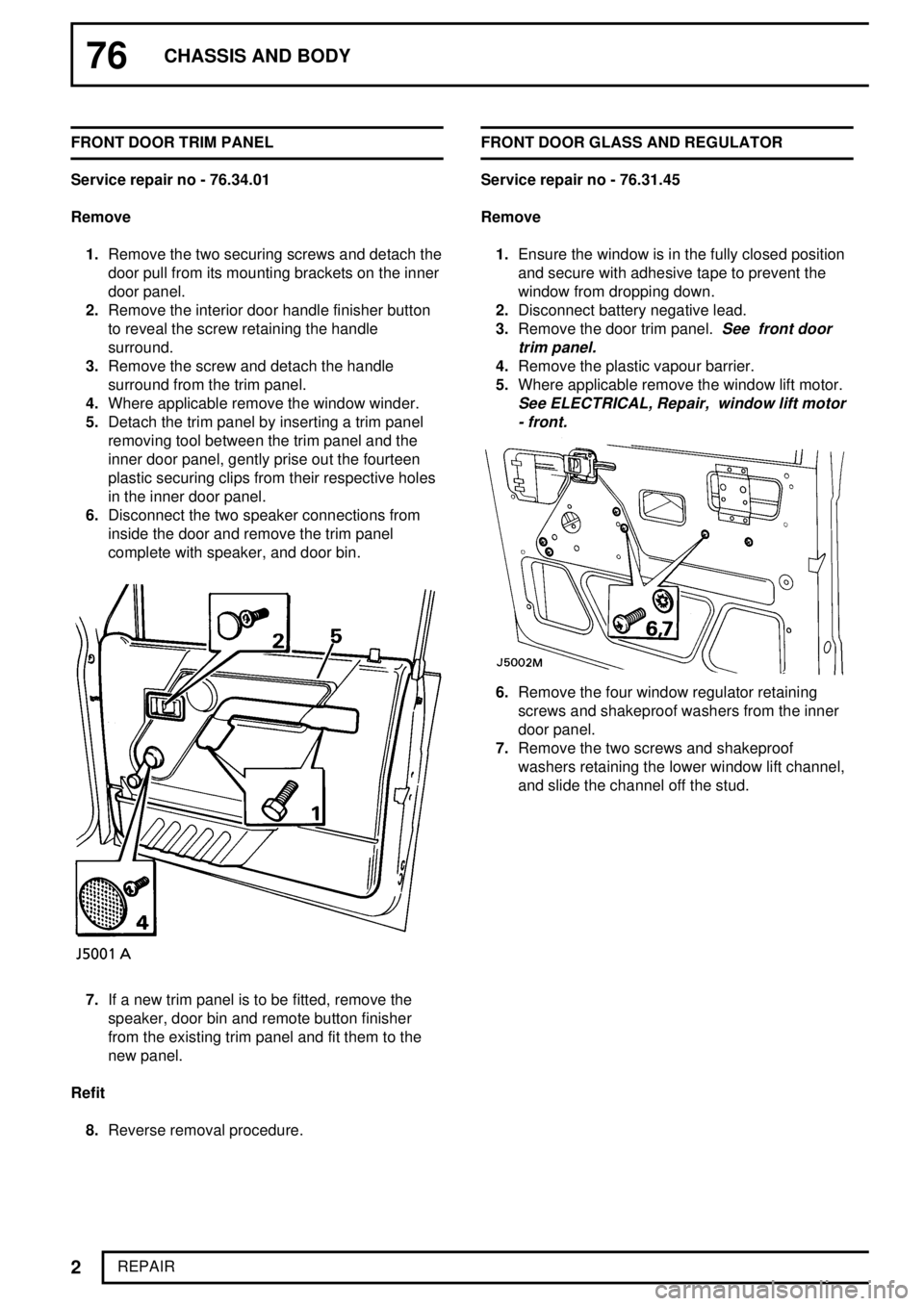

1.Remove the two securing screws and detach the

door pull from its mounting brackets on the inner

door panel.

2.Remove the interior door handle finisher button

to reveal the screw retaining the handle

surround.

3.Remove the screw and detach the handle

surround from the trim panel.

4.Where applicable remove the window winder.

5.Detach the trim panel by inserting a trim panel

removing tool between the trim panel and the

inner door panel, gently prise out the fourteen

plastic securing clips from their respective holes

in the inner door panel.

6.Disconnect the two speaker connections from

inside the door and remove the trim panel

complete with speaker, and door bin.

7.If a new trim panel is to be fitted, remove the

speaker, door bin and remote button finisher

from the existing trim panel and fit them to the

new panel.

Refit

8.Reverse removal procedure.FRONT DOOR GLASS AND REGULATOR

Service repair no - 76.31.45

Remove

1.Ensure the window is in the fully closed position

and secure with adhesive tape to prevent the

window from dropping down.

2.Disconnect battery negative lead.

3.Remove the door trim panel.

See front door

trim panel.

4.Remove the plastic vapour barrier.

5.Where applicable remove the window lift motor.

See ELECTRICAL, Repair, window lift motor

- front.

6.Remove the four window regulator retaining

screws and shakeproof washers from the inner

door panel.

7.Remove the two screws and shakeproof

washers retaining the lower window lift channel,

and slide the channel off the stud.

Page 670 of 873

CHASSIS AND BODY

3

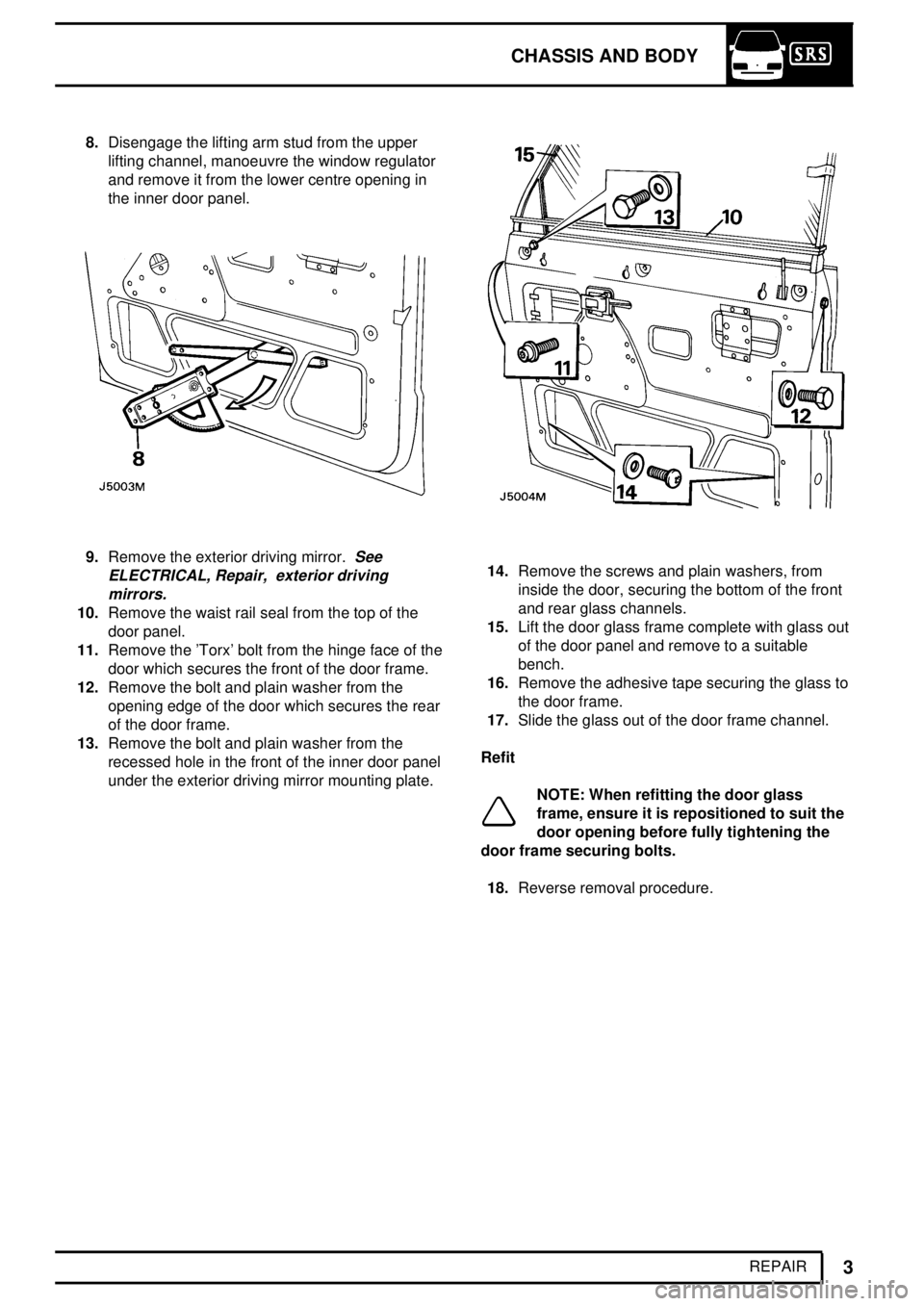

REPAIR 8.Disengage the lifting arm stud from the upper

lifting channel, manoeuvre the window regulator

and remove it from the lower centre opening in

the inner door panel.

9.Remove the exterior driving mirror.See

ELECTRICAL, Repair, exterior driving

mirrors.

10.Remove the waist rail seal from the top of the

door panel.

11.Remove the 'Torx' bolt from the hinge face of the

door which secures the front of the door frame.

12.Remove the bolt and plain washer from the

opening edge of the door which secures the rear

of the door frame.

13.Remove the bolt and plain washer from the

recessed hole in the front of the inner door panel

under the exterior driving mirror mounting plate.

14.Remove the screws and plain washers, from

inside the door, securing the bottom of the front

and rear glass channels.

15.Lift the door glass frame complete with glass out

of the door panel and remove to a suitable

bench.

16.Remove the adhesive tape securing the glass to

the door frame.

17.Slide the glass out of the door frame channel.

Refit

NOTE: When refitting the door glass

frame, ensure it is repositioned to suit the

door opening before fully tightening the

door frame securing bolts.

18.Reverse removal procedure.