LAND ROVER DISCOVERY 1995 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 651 of 873

75SUPPLEMENTARY RESTRAINT SYSTEM

6

REPAIR

11.If rotary coupler is being re-used, place a piece

of adhesive tape around moulding in positionA

to prevent rotation.

Refit

12.Reverse removal procedure.

CAUTION: Ensure indicator cancellation

pegs correctly engage into back of

steering wheel.13.Align direction indicator cancellation bush. If

original rotary coupler is being fitted remove

adhesive tape and then fit rotary coupler to

column switch assembly.

NOTE: If original rotary coupler is to be

fitted and there is evidence of tampering, it

is imperative that the coupler is

centralised.

See rotary coupler centralise.

14.If a new rotary coupler is being fitted and the

sealing tape at positionBis broken it MUST

NOT be used.

15.Refit steering wheel.

See steering wheel.

16.Turn steering wheel to both LH and RH lock 5

times. If adverse noises can be heard, check

alignment of indicator cancellation pegs.

17.Refit driver's airbag module.

See driver's

airbag module.

Page 652 of 873

SUPPLEMENTARY RESTRAINT SYSTEM

7

REPAIR ROTARY COUPLER CENTRALISE

Fitting a rotary coupler which has not been centralised

could result in tape breakage. If the tape is broken, a

new rotary coupler must be fitted.

Providing the removal procedure has been correctly

followed this operation should not be necessary. If

however there is evidence of tampering, it is

imperative that the coupler is centralised.

CAUTION: Ensure wheels are positioned

straight ahead before fitting the rotary

coupler.

1.Correctly fit rotary coupler to column switch

assembly but do not fit steering wheel or make

any electrical connections.

See rotary coupler.

2.Depress rotary coupler locking peg and without

using undue force, rotate coupler anti-clockwise

as far as inner tape will allow. Releasing peg will

lock coupler in its current position.

NOTE: Do not apply excessive force when

limit is reached as this may result in tape

breakage. If no limit can be found, tape

has already broken and rotary coupler must be

replaced.

3.Having turned rotary coupler fully anti-clockwise

to limit position, proceed to turn coupler 2.5 turns

clockwise to obtain central position. (Coupler will

normally rotate a full five turns from

anti-clockwise limit to clockwise limit).

4.Make necessary electrical connections and refit

steering wheel.

See steering wheel.

5.Refit driver's airbag module.See driver's

airbag module.

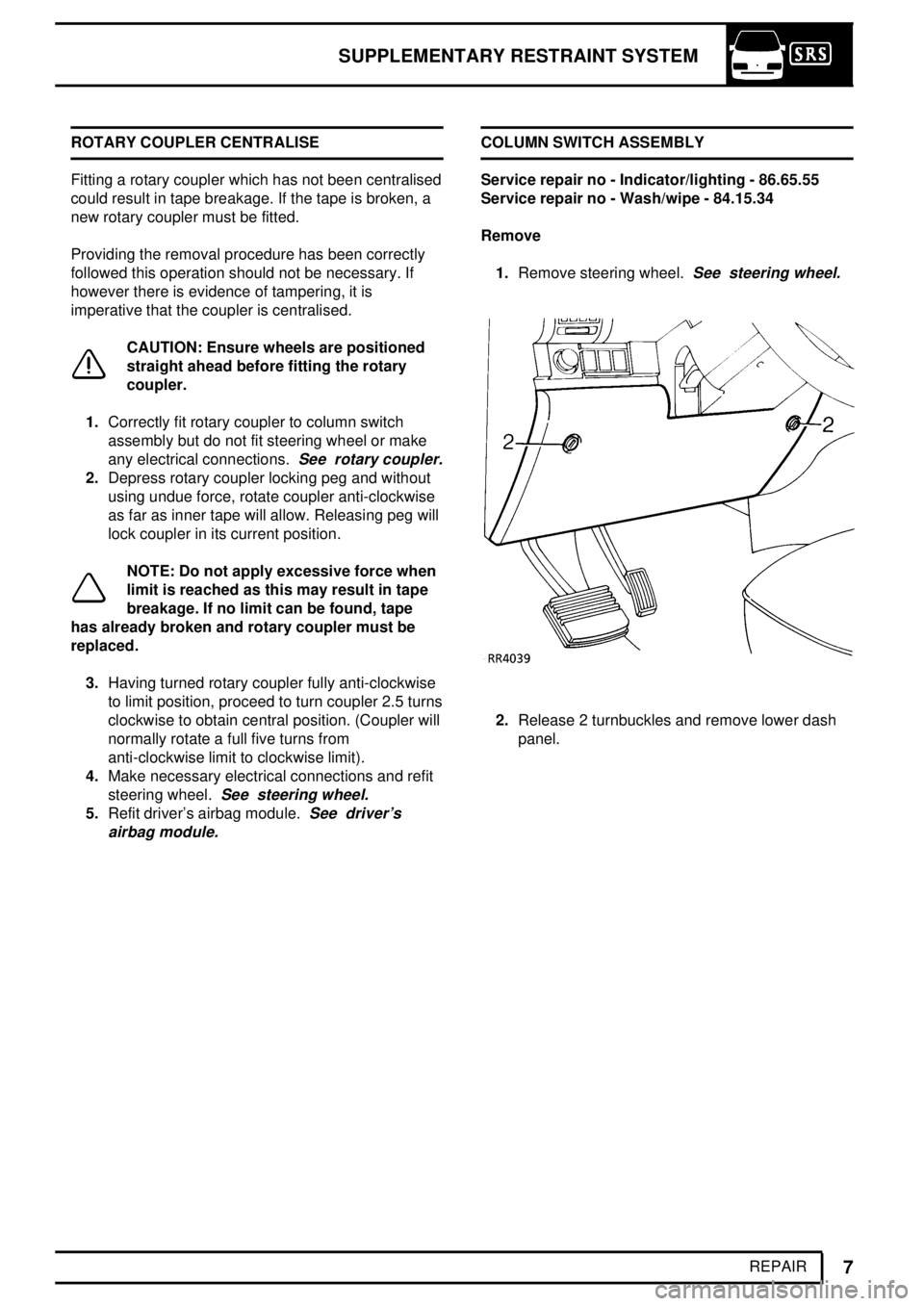

COLUMN SWITCH ASSEMBLY

Service repair no - Indicator/lighting - 86.65.55

Service repair no - Wash/wipe - 84.15.34

Remove

1.Remove steering wheel.

See steering wheel.

2.Release 2 turnbuckles and remove lower dash

panel.

Page 653 of 873

75SUPPLEMENTARY RESTRAINT SYSTEM

8

REPAIR

3.Remove 3 screws securing lower half of nacelle

to steering column.

4.Separate the halves of the nacelle and remove

from steering column.

5.Release 2 clips securing rotary coupler to

column switch assembly.

6.Release rotary coupler.

CAUTION: Do not allow rotary coupler to

hang on its harness.

7.Disconnect 4 connectors from column switch

assembly.

8.Remove column switch assembly from steering

column.

Refit

9.Reverse removal procedure.

Page 654 of 873

SUPPLEMENTARY RESTRAINT SYSTEM

9

REPAIR PASSENGER'S AIRBAG MODULE

Service repair no - 76.74.02

WARNING: All the airbag system

components, including the wiring harness,

MUST be renewed after the airbags have

deployed.

Remove

1.Switch off ignition.

2.Disconnect battery negative lead and then

positive lead.

3.Open glovebox and disconnect harness

connector from airbag module.

4.Use special socket and long extension, remove

2 torx head screws securing front of airbag

module to fascia panel.

5.Use special socket, remove 2 torx head screws

securing rear of airbag module to fascia panel.

6.Release airbag module from fascia panel.

CAUTION: Do not allow the airbag module

to hang by the airbag harness.

7.Carefully and without pulling on connector

remove airbag module.

CAUTION: Store the airbag module in

accordance with the storage procedures

described in Description and Operation.

NOTE: If airbag module is to be replaced

the serial number must be recorded in the

vehicle service record.

Refit

8.Reverse removal procedure.

9.Tighten airbag module securing screws to

8Nm

(6 lbf ft).

CAUTION: Take care not to cross thread

screws.

10.Check Supplementary Restraint System using

Testbook.

Page 655 of 873

75SUPPLEMENTARY RESTRAINT SYSTEM

10

REPAIR CRASH SENSOR - DISTRIBUTED SRS

Service repair no - 76.74.04

Remove

1.Disconnect battery negative lead.

2. LH sensor only:Slacken power steering

reservoir clamp and lift reservoir to provide

access.

Diesel model only:Remove jack and mounting

bracket.

3.Disconnect multiplug from sensor

CAUTION: Ensure airbag harness

connector seal and anti-backout DO NOT

come adrift when disconnecting sensor.

4.Use special socket, remove 2 screws securing

crash sensor to body.

5.Remove crash sensor.Refit

6.Reverse removal procedure.

7.Tighten crash sensor securing screws to

10 Nm

(7 lbf ft).

Ensure multiplug is fully engaged on

sensor and retained by its latch.

8.Check Supplementary Restraint System using

Testbook.

Page 656 of 873

SUPPLEMENTARY RESTRAINT SYSTEM

11

REPAIR AIRBAG DIAGNOSTIC CONTROL UNIT -

DISTRIBUTED SRS

Service repair no - 76.74.03

Remove

1.Disconnect battery negative lead.

2.Remove centre console assembly.

See

CHASSIS AND BODY, Repair, centre

console.

3.Remove 4 screws and release the 2 rear

passenger air ducts from their fitted position and

remove centre console mounting bracket.

4.Use flat ended screwdriver and release

YELLOW retainer, pull retainer 30mm (1 1/8 in)

from multiplug and disconnect airbag harness

multiplug from airbag control unit.

5.Use special socket, remove 2 screws securing

airbag control unit to body bracket.

6.Remove airbag diagnostic control unit.

Refit

7.Reverse removal procedure.

8.Tighten control unit securing screws to

10Nm (7

lbf ft).

9.Check Supplementary Restraint System using

Testbook.

Page 657 of 873

75SUPPLEMENTARY RESTRAINT SYSTEM

12

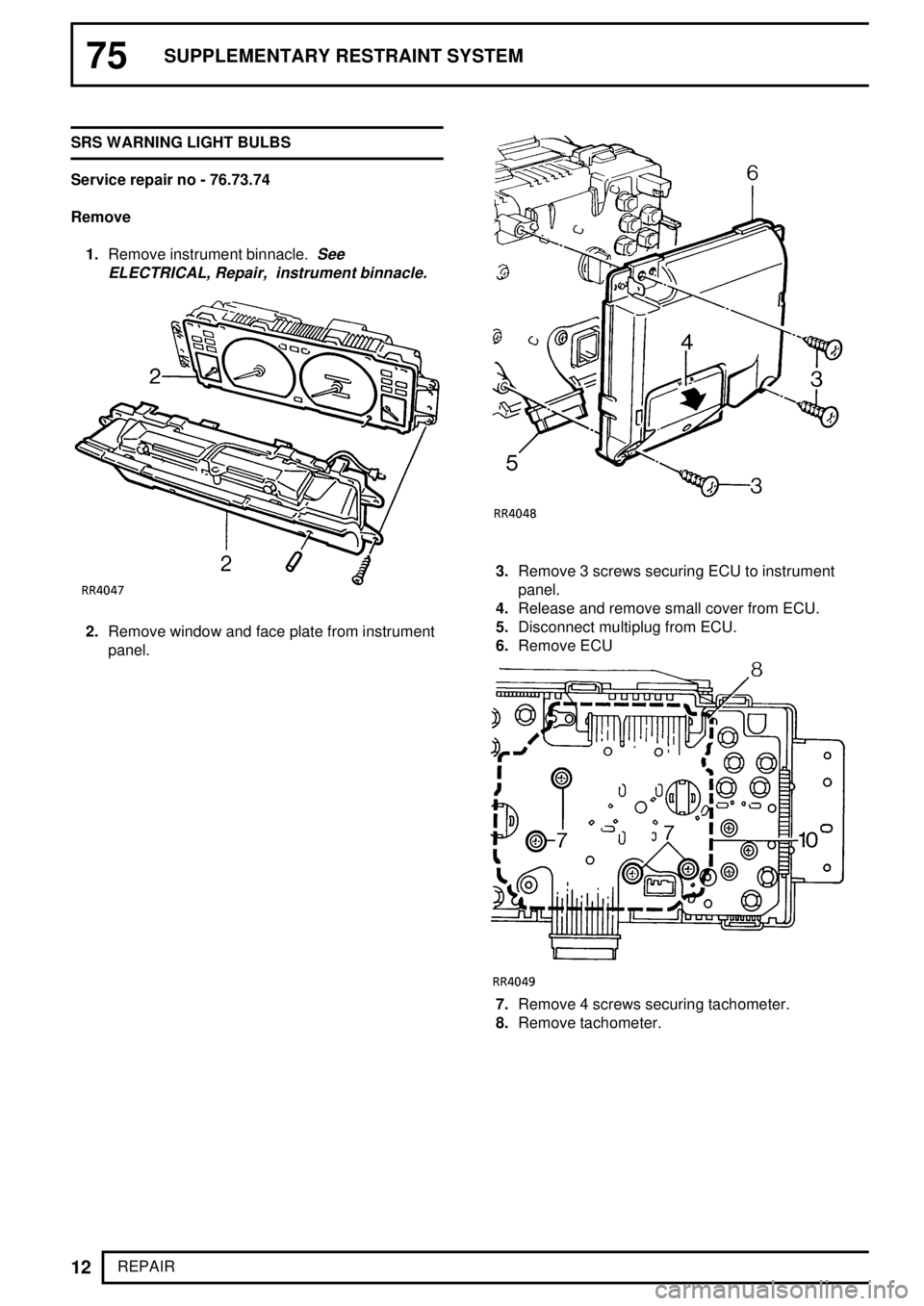

REPAIR SRS WARNING LIGHT BULBS

Service repair no - 76.73.74

Remove

1.Remove instrument binnacle.

See

ELECTRICAL, Repair, instrument binnacle.

2.Remove window and face plate from instrument

panel.

3.Remove 3 screws securing ECU to instrument

panel.

4.Release and remove small cover from ECU.

5.Disconnect multiplug from ECU.

6.Remove ECU

7.Remove 4 screws securing tachometer.

8.Remove tachometer.

Page 658 of 873

SUPPLEMENTARY RESTRAINT SYSTEM

13

REPAIR

9.Carefully remove 2 screws securing face plate to

tachometer.

10.Release warning light housing from tachometer

circuit board.

11.Carefully (to avoid damage to tachometer needle

and spindle), tilt and remove warning light

housing.

12.Remove 2 warning light bulbs.Refit

13.Reverse removal procedure.

14.Fit new warning light bulbs.

15.Carefully fit warning light housing, ensuring that

locating pegs engage correctly and that retaining

clips lock housing into position.

16.Ensure that tachometer needle is on the correct

side of its stop.

17.Fit instrument binnacle.

See ELECTRICAL,

Repair, instrument binnacle.

Page 659 of 873

75SUPPLEMENTARY RESTRAINT SYSTEM

14

REPAIR AIRBAG HARNESS

Service repair no - 86.70.63

Remove

1.Remove driver's airbag.

See driver's airbag

module.

2.Remove passenger's airbag.See passenger's

airbag module.

3.Remove dash panel assembly.See CHASSIS

AND BODY, Repair, dash panel assembly

4.Remove heater blower unit.See HEATING

AND VENTILATION, Repair, blower motor

unit - heater and air conditioning.

5.Remove heater and cooler unit.See AIR

CONDITIONING, Repair, heater and cooler

unit

Pre 97 MY

6.Remove 3 screws securing expansion tank and

position expansion tank aside.

7.Disconnect multiplug from each crash sensor.

8.Release airbag harness from clips and ties along

the bulkhead and each valance.

9.Displace airbag harness grommet to inside of

bulkhead and feed harness through bulkhead.

All Models

10.Disconnect multiplug from airbag control unit.

11.Release airbag harness from under carpet.

12.Release ties securing harness along toeboard.

13.Disconnect steering wheel airbag multiplug.

14.Release airbag harness from driver's side and

remove.

Refit

15.Reverse removal procedure.

CAUTION: Ensure harness is correctly

routed in harness protector and that all

securing clips and ties are correctly

engaged and harness is undamaged. Ensure all

connections are fully engaged and retained by

their latches.

Page 660 of 873

SUPPLEMENTARY RESTRAINT SYSTEM

15

REPAIR AIRBAG MANUAL DEPLOYMENT

CAUTION: Deployment in the vehicle will

damage the steering wheel; if the vehicle

is not being scrapped deploy the module

away from the vehicle in accordance with the

separate procedure.

If a vehicle is to be scrapped and contains an

undeployed airbag module, the module must be

manually deployed. This operation should only be

carried out using the following recommended manual

deployment procedure.

Before deployment is started the deployment tool self

test procedure should be carried out.

Deployment tool SMD 4082/1 self test procedure

1.Insert BLUE and YELLOW connectors of tool

lead into corresponding sockets on face of tool.

2.Connect crocodile clips of second tool lead to

battery, RED to positive and BLACK to negative.

3.RED "READY" light should illuminate.

4.Press and hold both operating buttons.5.GREEN "DEFECTIVE" light should illuminate.

6.Release both operating buttons.

7.RED "READY" light should illuminate.

8.Disconnect tool from battery.

9.Disconnect blue and yellow connectors from tool

face sockets.

10.Self test now complete.

Deployment with module fitted to vehicle

These guidelines are written to aid authorised

personnel to carry out the safe disposal of the airbag

module when fitted to the vehicle.

WARNING: Only use the LAND ROVER

approved deployment equipment. Deploy

airbag module in a well ventilated

designated area. Ensure airbag module is not

damaged or ruptured before deploying.

1.Carry out deployment tool self test.

2.Release 2 turnbuckles securing lower panel to

dash, remove lower panel.