LAND ROVER DISCOVERY 1999 Workshop Manual

DISCOVERY 1999

LAND ROVER

LAND ROVER

https://www.carmanualsonline.info/img/64/57247/w960_57247-0.png

LAND ROVER DISCOVERY 1999 Workshop Manual

Trending: set clock, coolant, change time, brake pads replacement, change language, dashboard, radiator cap

Page 151 of 1529

MAINTENANCE

10-28 PROCEDURES

Check – Height sensors

SLS height sensors

1.Check height sensors for condition and

security.

2.Check electrical harness for chafing and

damage.

Front and rear axle suspension links

Check

Rear suspension

Front suspension

1.Check condition of front and rear axle

suspension link mounting rubbers.

2.Check security of fixings.

+ TORQUE WRENCH SETTINGS,

Front suspension.

+ TORQUE WRENCH SETTINGS, Rear

suspension.

Page 152 of 1529

MAINTENANCE

PROCEDURES 10-29

Towing bracket

Check

1.Check security of towing bracket.

Page 153 of 1529

MAINTENANCE

10-30 PROCEDURES

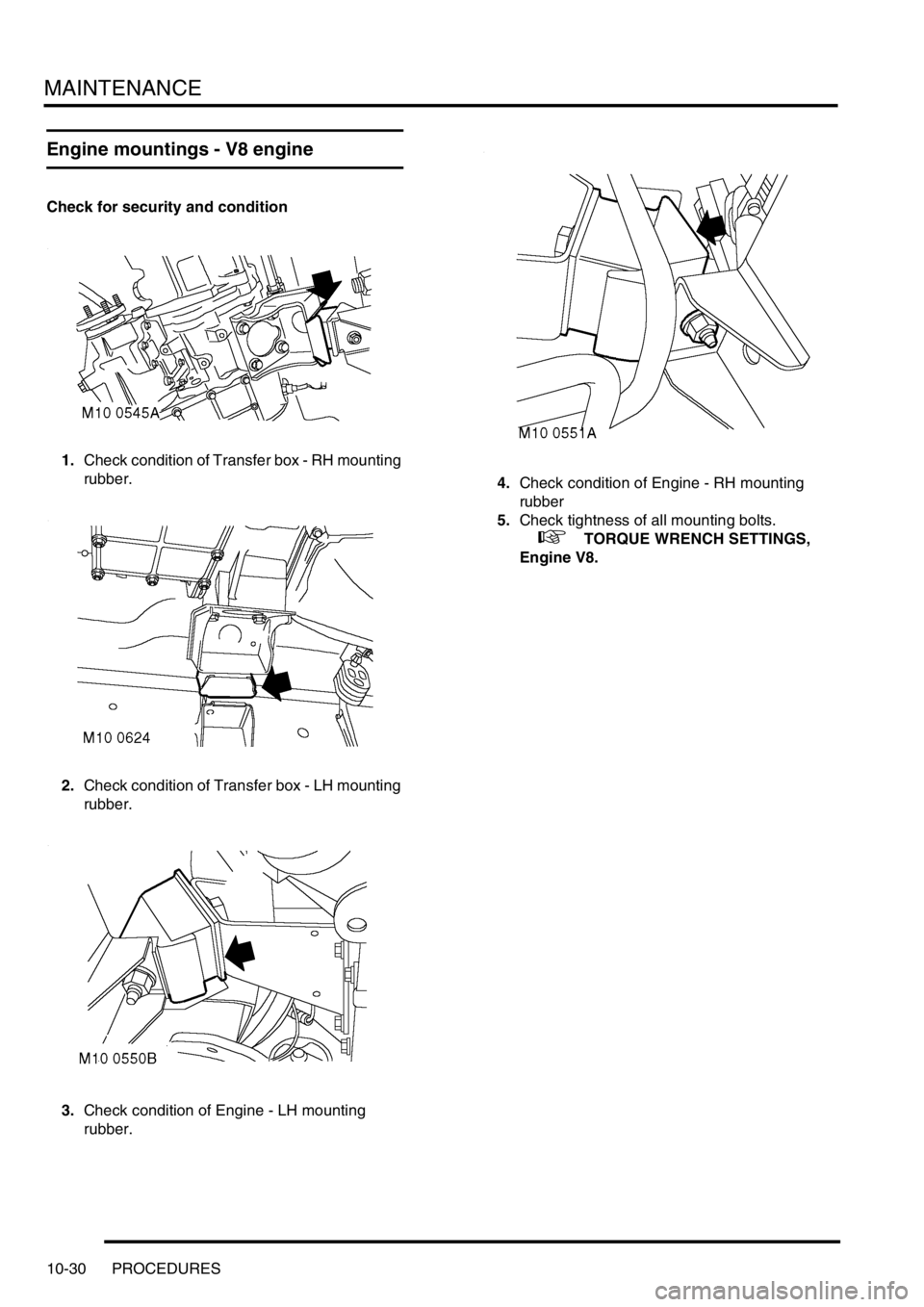

Engine mountings - V8 engine

Check for security and condition

1.Check condition of Transfer box - RH mounting

rubber.

2.Check condition of Transfer box - LH mounting

rubber.

3.Check condition of Engine - LH mounting

rubber.4.Check condition of Engine - RH mounting

rubber

5.Check tightness of all mounting bolts.

+ TORQUE WRENCH SETTINGS,

Engine V8.

Page 154 of 1529

MAINTENANCE

PROCEDURES 10-31

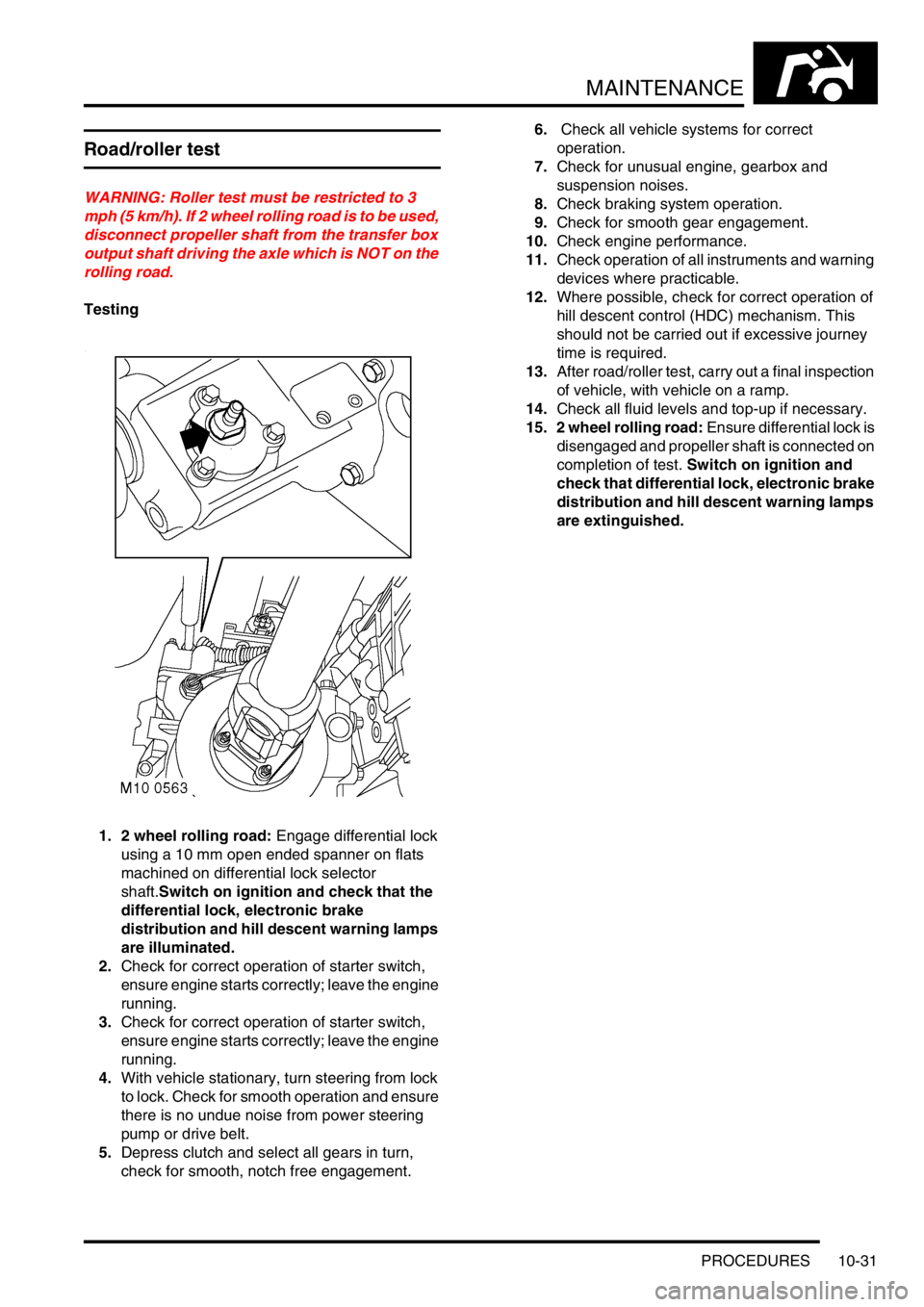

Road/roller test

WARNING: Roller test must be restricted to 3

mph (5 km/h). If 2 wheel rolling road is to be used,

disconnect propeller shaft from the transfer box

output shaft driving the axle which is NOT on the

rolling road.

Testing

1. 2 wheel rolling road: Engage differential lock

using a 10 mm open ended spanner on flats

machined on differential lock selector

shaft.Switch on ignition and check that the

differential lock, electronic brake

distribution and hill descent warning lamps

are illuminated.

2.Check for correct operation of starter switch,

ensure engine starts correctly; leave the engine

running.

3.Check for correct operation of starter switch,

ensure engine starts correctly; leave the engine

running.

4.With vehicle stationary, turn steering from lock

to lock. Check for smooth operation and ensure

there is no undue noise from power steering

pump or drive belt.

5.Depress clutch and select all gears in turn,

check for smooth, notch free engagement.6. Check all vehicle systems for correct

operation.

7.Check for unusual engine, gearbox and

suspension noises.

8.Check braking system operation.

9.Check for smooth gear engagement.

10.Check engine performance.

11.Check operation of all instruments and warning

devices where practicable.

12.Where possible, check for correct operation of

hill descent control (HDC) mechanism. This

should not be carried out if excessive journey

time is required.

13.After road/roller test, carry out a final inspection

of vehicle, with vehicle on a ramp.

14.Check all fluid levels and top-up if necessary.

15. 2 wheel rolling road: Ensure differential lock is

disengaged and propeller shaft is connected on

completion of test. Switch on ignition and

check that differential lock, electronic brake

distribution and hill descent warning lamps

are extinguished.

Page 155 of 1529

Page 156 of 1529

ENGINE - V8

DESCRIPTION AND OPERATION 12-2-1

ENGIN E - V 8 DESCRIPTION AND OPERAT ION

V8 Engine

Page 157 of 1529

ENGINE - V8

12-2-2 DESCRIPTION AND OPERATION

Cylinder head components

Page 158 of 1529

ENGINE - V8

DESCRIPTION AND OPERATION 12-2-3

1Split pin

2Washers

3Spring

4Rocker arm

5Pedestal bolt

6Pedestal

7Push rod

8Hydraulic tappet

9Rocker shaft

10Cylinder head - left hand

11Gasket - rocker cover

12Rocker cover - left hand

13Bolt - rocker cover

14Valve spring cap

15Valve stem oil seals

16Collets

17Valve spring18Bolt - engine lifting bracket

19Engine lifting bracket

20Valve seat insert

21Exhaust valve

22Clamp - inlet manifold gasket

23Seal - inlet manifold gasket

24Bolt - inlet manifold gasket clamp

25Gasket - inlet manifold

26Inlet valve

27Gasket - cylinder head

28Gasket - exhaust manifold

29Cylinder head - right hand

30Spark plug

31Bolt - cylinder head

32Valve guide

33Rocker cover - right hand

34Engine oil filler cap

Page 159 of 1529

ENGINE - V8

12-2-4 DESCRIPTION AND OPERATION

Cylinder block components

Page 160 of 1529

ENGINE - V8

DESCRIPTION AND OPERATION 12-2-5

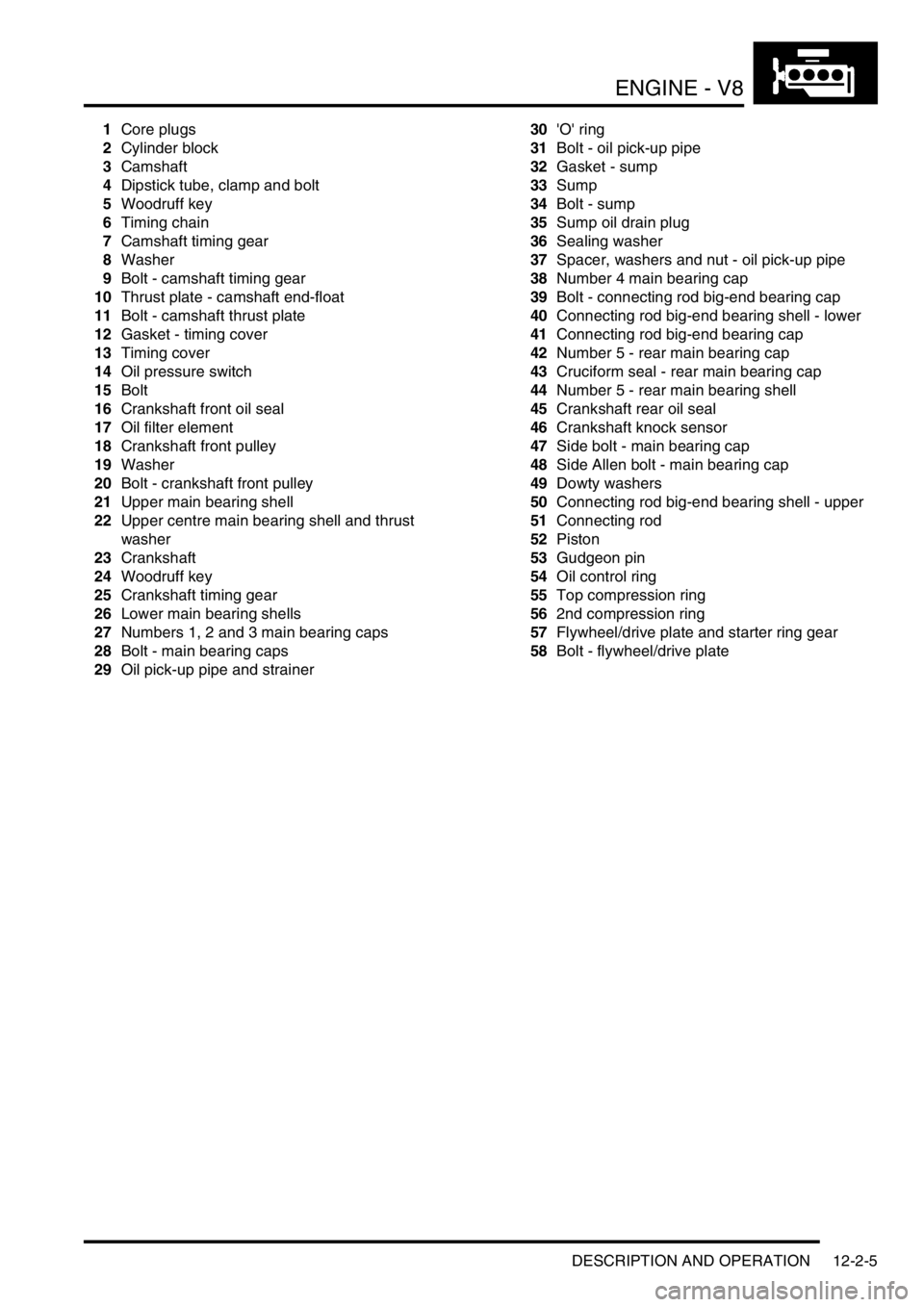

1Core plugs

2Cylinder block

3Camshaft

4Dipstick tube, clamp and bolt

5Woodruff key

6Timing chain

7Camshaft timing gear

8Washer

9Bolt - camshaft timing gear

10Thrust plate - camshaft end-float

11Bolt - camshaft thrust plate

12Gasket - timing cover

13Timing cover

14Oil pressure switch

15Bolt

16Crankshaft front oil seal

17Oil filter element

18Crankshaft front pulley

19Washer

20Bolt - crankshaft front pulley

21Upper main bearing shell

22Upper centre main bearing shell and thrust

washer

23Crankshaft

24Woodruff key

25Crankshaft timing gear

26Lower main bearing shells

27Numbers 1, 2 and 3 main bearing caps

28Bolt - main bearing caps

29Oil pick-up pipe and strainer30'O' ring

31Bolt - oil pick-up pipe

32Gasket - sump

33Sump

34Bolt - sump

35Sump oil drain plug

36Sealing washer

37Spacer, washers and nut - oil pick-up pipe

38Number 4 main bearing cap

39Bolt - connecting rod big-end bearing cap

40Connecting rod big-end bearing shell - lower

41Connecting rod big-end bearing cap

42Number 5 - rear main bearing cap

43Cruciform seal - rear main bearing cap

44Number 5 - rear main bearing shell

45Crankshaft rear oil seal

46Crankshaft knock sensor

47Side bolt - main bearing cap

48Side Allen bolt - main bearing cap

49Dowty washers

50Connecting rod big-end bearing shell - upper

51Connecting rod

52Piston

53Gudgeon pin

54Oil control ring

55Top compression ring

562nd compression ring

57Flywheel/drive plate and starter ring gear

58Bolt - flywheel/drive plate

Trending: automatic transmission fluid, light, jacking points, language, battery capacity, ESP inoperative, air bleeding