LAND ROVER DISCOVERY 1999 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 111 of 1529

TORQUE WRENCH SETTINGS

06-20

Heating and air conditioning

Wipers and washers

TORQUE DESCRIPTION METRIC IMPERIAL

Heater assembly16 Nm (12 lbf.ft)

Compressor bolts22 Nm (16 lbf.ft)

Blower motor19 Nm (14 lbf.ft)

Compressor to mounting bracket bolts 25 Nm (18 lbf.ft)

A/C pipes to compressor bolts 10 Nm (7 lbf.ft)

Condenser pipe bolt 5 Nm (3.7 lbf.ft)

Receiver drier to bracket bolts 5 Nm (3.7 lbf.ft)

Adaptor block to receiver drier bolt 5 Nm (3.7 lbf.ft)

Evaporator pipe bolts 5 Nm (3.7 lbf.ft)

Dual pressure switch to receiver drier 10 Nm (7 lbf.ft)

Air conditioning pipes to receiver drier bolts 5 Nm (3.7 lbf.ft)

TX valve pressure pipe union 22 Nm (16 lbf.ft)

Evaporator pipe to TXV valve 32 Nm (24 lbf.ft)

Evaporator assembly to body bolts 16 Nm (12 lbf.ft)

High and low pressure pipe, bolts 10 Nm (7 lbf.ft)

Fuel burning heater Torx bolts 25 Nm (18 lbf.ft)

TORQUE DESCRIPTION METRIC IMPERIAL

Link to motor spindle 7 Nm (5.2 lbf.ft)

Front motor assembly 2.5 Nm (1.8 lbf.ft)

Spindle nut 3 Nm (2.2 lbf.ft)

Wiper arm nut13 Nm (10 lbf.ft)

Page 112 of 1529

TORQUE WRENCH SETTINGS

06-21

Electrical

TORQUE DESCRIPTION METRIC IMPERIAL

Alternator support stay 25 Nm (18 lbf.ft)

Alternator lead - Td5 6 Nm (4.4 lbf.ft)

Auxiliary drive belt tensioner bolt 50 Nm (37 lbf.ft)

Alternator pulley80 Nm (59 lbf.ft)

Alternator B+ nut - V8 18 Nm (13 lbf.ft)

Alternator B+ nut - V8 5 Nm (3.7 lbf.ft)

Starter motor - Td5 27 Nm (20 lbf.ft)

Starter motor solenoid 10 Nm (7 lbf.ft)

Starter motor - V8 44 Nm (32 lbf.ft)

Alternator45 Nm (33 lbf.ft)

Starter motor heat shield - V8 10 Nm (7 lbf.ft)

Horn13 Nm (10 lbf.ft)

Battery carrier bolts 28 Nm (21 lbf.ft)

Page 113 of 1529

Page 114 of 1529

LIFTING AND TOWING

08-1

LIFTING AND TOWING

LIFTING

The following instructions must be carried out before

raising the vehicle off the ground.

lUse a solid level ground surface.

lApply hand brake.

lSelect 'P' (Automatic gearbox) or 1st gear

(Manual gearbox) in main gearbox.

lSelect Low range in transfer gearbox.

To avoid damage occurring to the under body

components of the vehicle the following jacking

procedures must be adhered to.

DO NOT POSITION JACKS OR AXLE STANDS

UNDER THE FOLLOWING COMPONENTS:

lBody structure

lBumpers

lFuel lines

lBrake lines

lFront radius arms

lPanhard rod

lSteering linkage

lRear trailing arms

lFuel tank

lEngine sump

lGearbox bell housing

Vehicle jack

The jack provided with the vehicle is only intended for

use in an emergency, for changing a tyre. DO NOT

use the jack for any other purpose. Refer to Owner's

Handbook for vehicle jack location points and

procedure. Never work under a vehicle supported

solely by the vehicle jack.

Hydraulic jack

A hydraulic jack with a minimum 1500 kg, 3,300 lbs

load capacity must be used. Do not commence

work on the underside of the vehicle until

suitable axle stands have been positioned under

the axle.

WARNING: Always chock the wheels when

jacking. The hand brake acts on the

transmission, not the rear wheels, and may be

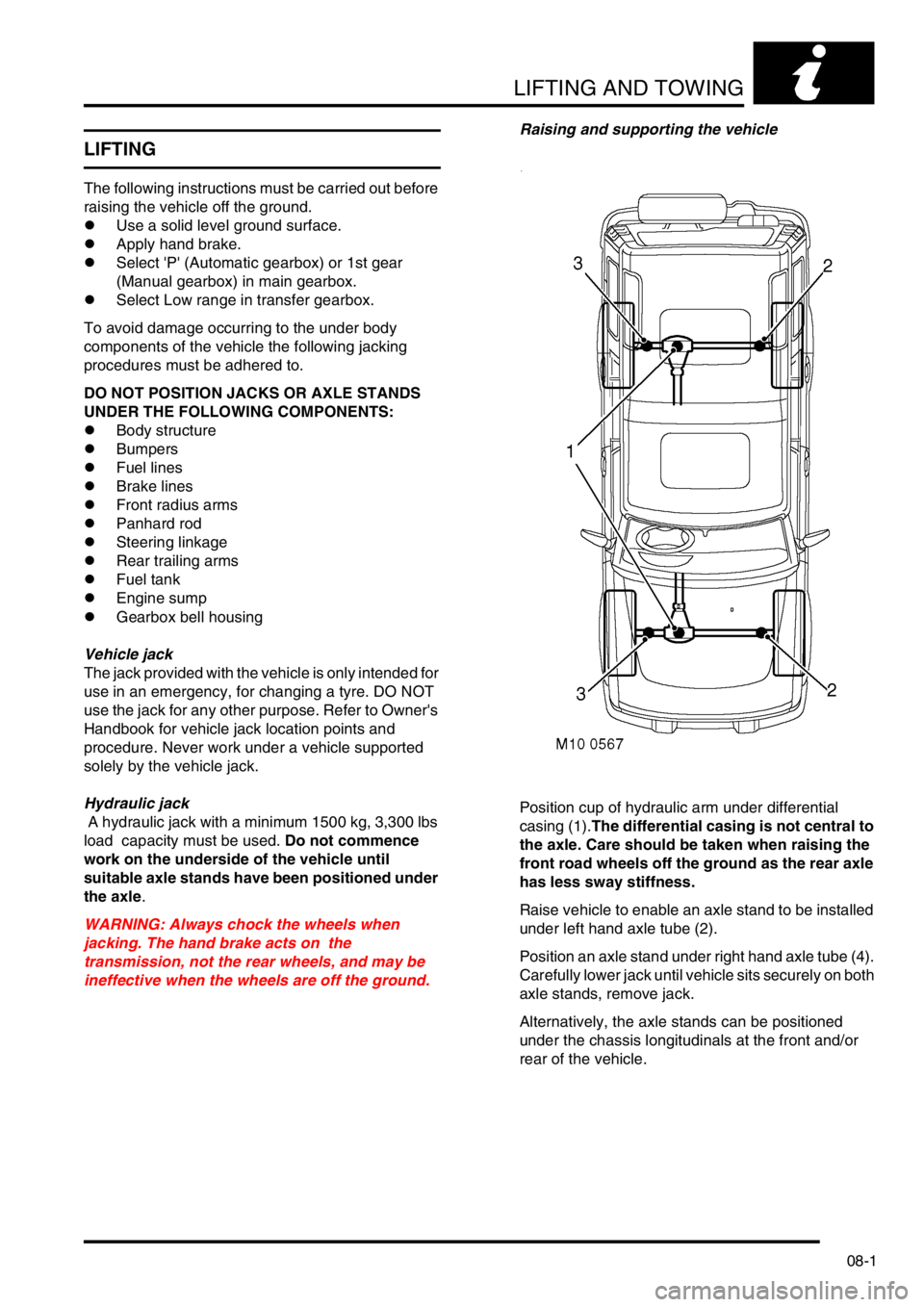

ineffective when the wheels are off the ground.Raising and supporting the vehicle

Position cup of hydraulic arm under differential

casing (1).The differential casing is not central to

the axle. Care should be taken when raising the

front road wheels off the ground as the rear axle

has less sway stiffness.

Raise vehicle to enable an axle stand to be installed

under left hand axle tube (2).

Position an axle stand under right hand axle tube (4).

Carefully lower jack until vehicle sits securely on both

axle stands, remove jack.

Alternatively, the axle stands can be positioned

under the chassis longitudinals at the front and/or

rear of the vehicle.

Page 115 of 1529

LIFTING AND TOWING

08-2

Before commencing work on underside of vehicle re-

check security of vehicle on stands.

WARNING: Always chock the wheels when

jacking. The hand brake acts on the the

transmission, not the rear wheels, and may be

ineffective when the wheels are off the ground.

Reverse procedure when removing vehicle from

stands.

Hydraulic ramps

Use only a 'drive on' type ramp which supports a

vehicle by it's own road wheels. If a 'wheel free'

condition is required, use a 'drive on' ramp

incorporating a 'wheel free' system that supports

under axle casings. Alternatively, place vehicle on a

firm, flat floor and support on axle stands.

TOWING

Towing

The vehicle has permanent four wheel drive. The

following towing instructions must be adhered

to:

Towing on 4 wheels with driver

Turn ignition key to position '1' to release steering

lock.

Select neutral in main gearbox and transfer gearbox.

Secure tow rope, chain or cable to towing eye.

Release the handbrake.

The brake servo and power assisted steering

system will not be functional without the engine

running. Greater pedal pressure will be required

to apply the brakes, the steering system will

require greater effort to turn the front road

wheels. The vehicle tow connection should be

used only in normal road conditions, 'snatch'

recovery should be avoided.

Suspended tow

To prevent vehicle damage, front or rear

propeller shaft MUST BE removed, dependent

upon which axle is being trailed.

Mark propeller shaft drive flanges at transfer box and

axles with identification lines to enable the propeller

shaft to be refitted in its original position.

Page 116 of 1529

LIFTING AND TOWING

08-3

Remove the propeller shaft fixings, remove the shaft

from the vehicle.

If the front axle is to be trailed turn ignition key to

position '1' to release steering lock.

The steering wheel and/or linkage must be

secured in a straight ahead position. DO NOT use

the steering lock mechanism for this purpose.

Towing eyes

The towing eyes at the front and rear of the vehicle

are designed for vehicle recovery purposes only and

must NOT be used to tow a trailer or caravan.

Front:A single towing eye, set behind a removable

panel in the front spoiler. DO NOT use the front

lashing rings for towing.Rear: A pair of towing eyes at the rear of the vehicle

can be used as lashing rings and for towing another

light vehicle.

Page 117 of 1529

LIFTING AND TOWING

08-4

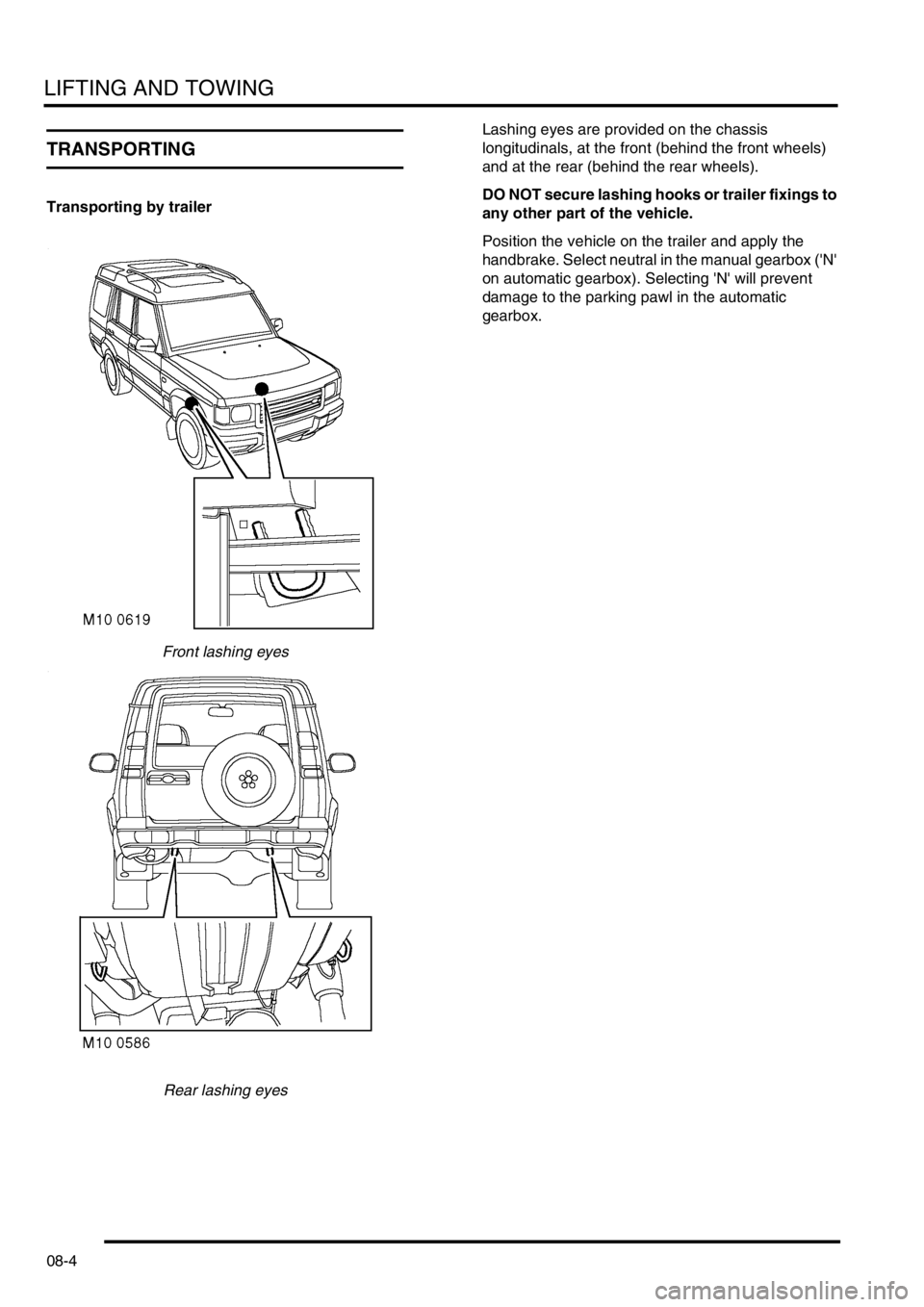

TRANSPORTING

Transporting by trailer

Front lashing eyes

Rear lashing eyesLashing eyes are provided on the chassis

longitudinals, at the front (behind the front wheels)

and at the rear (behind the rear wheels).

DO NOT secure lashing hooks or trailer fixings to

any other part of the vehicle.

Position the vehicle on the trailer and apply the

handbrake. Select neutral in the manual gearbox ('N'

on automatic gearbox). Selecting 'N' will prevent

damage to the parking pawl in the automatic

gearbox.

Page 118 of 1529

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

09-1

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

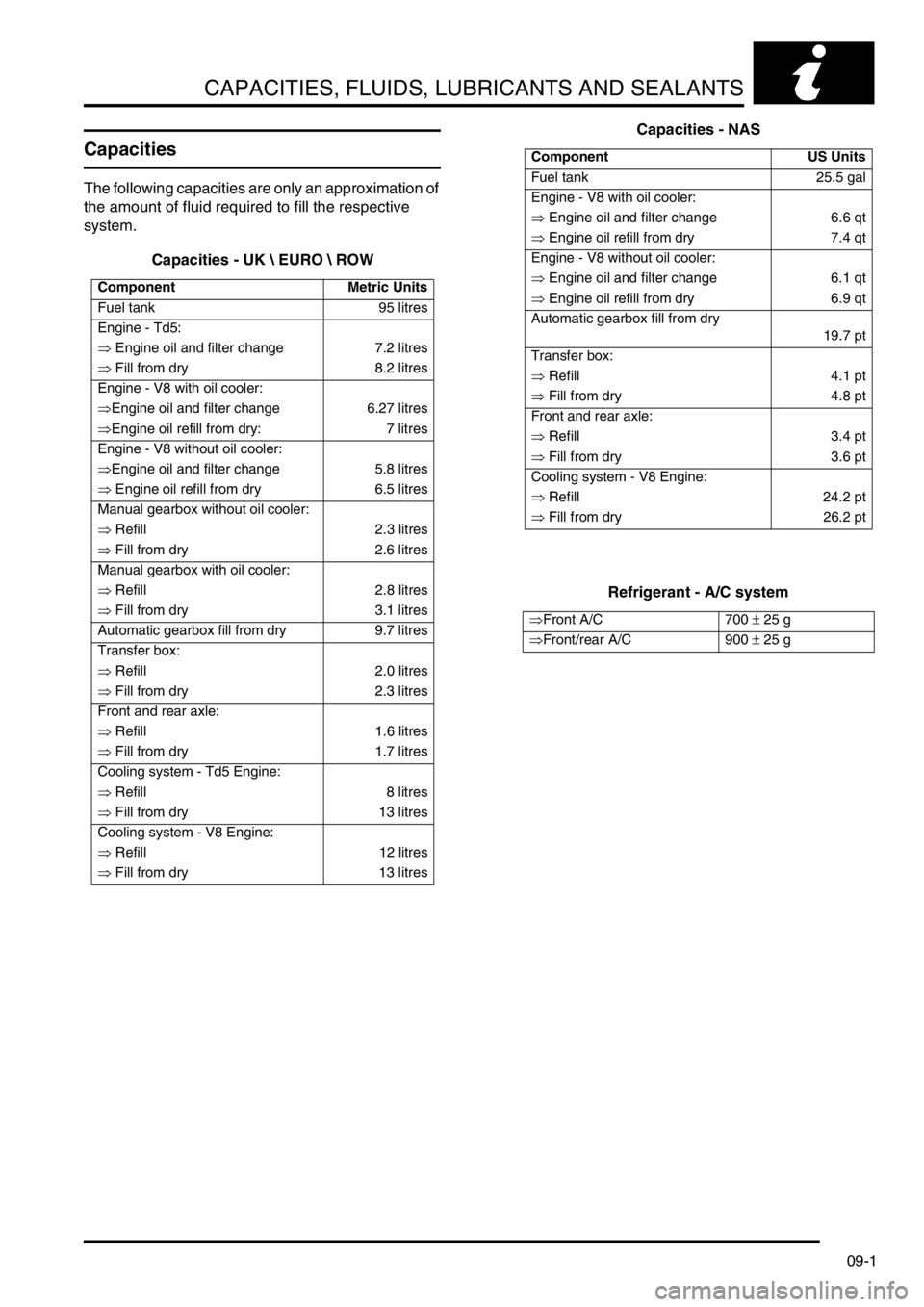

Capacities

The following capacities are only an approximation of

the amount of fluid required to fill the respective

system.

Capacities - UK EURO ROWCapacities - NAS

Refrigerant - A/C system

Component Metric Units

Fuel tank 95 litres

Engine - Td5:

⇒ Engine oil and filter change 7.2 litres

⇒ Fill from dry 8.2 litres

Engine - V8 with oil cooler:

⇒Engine oil and filter change 6.27 litres

⇒Engine oil refill from dry: 7 litres

Engine - V8 without oil cooler:

⇒Engine oil and filter change 5.8 litres

⇒ Engine oil refill from dry 6.5 litres

Manual gearbox without oil cooler:

⇒ Refill 2.3 litres

⇒ Fill from dry 2.6 litres

Manual gearbox with oil cooler:

⇒ Refill 2.8 litres

⇒ Fill from dry 3.1 litres

Automatic gearbox fill from dry 9.7 litres

Transfer box:

⇒ Refill 2.0 litres

⇒ Fill from dry 2.3 litres

Front and rear axle:

⇒ Refill 1.6 litres

⇒ Fill from dry 1.7 litres

Cooling system - Td5 Engine:

⇒ Refill 8 litres

⇒ Fill from dry 13 litres

Cooling system - V8 Engine:

⇒ Refill 12 litres

⇒ Fill from dry 13 litres

Component US Units

Fuel tank 25.5 gal

Engine - V8 with oil cooler:

⇒ Engine oil and filter change 6.6 qt

⇒ Engine oil refill from dry 7.4 qt

Engine - V8 without oil cooler:

⇒ Engine oil and filter change 6.1 qt

⇒ Engine oil refill from dry 6.9 qt

Automatic gearbox fill from dry

19.7 pt

Transfer box:

⇒ Refill 4.1 pt

⇒ Fill from dry 4.8 pt

Front and rear axle:

⇒ Refill 3.4 pt

⇒ Fill from dry 3.6 pt

Cooling system - V8 Engine:

⇒ Refill 24.2 pt

⇒ Fill from dry 26.2 pt

⇒Front A/C 700 ± 25 g

⇒Front/rear A/C 900 ± 25 g

Page 119 of 1529

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

09-2

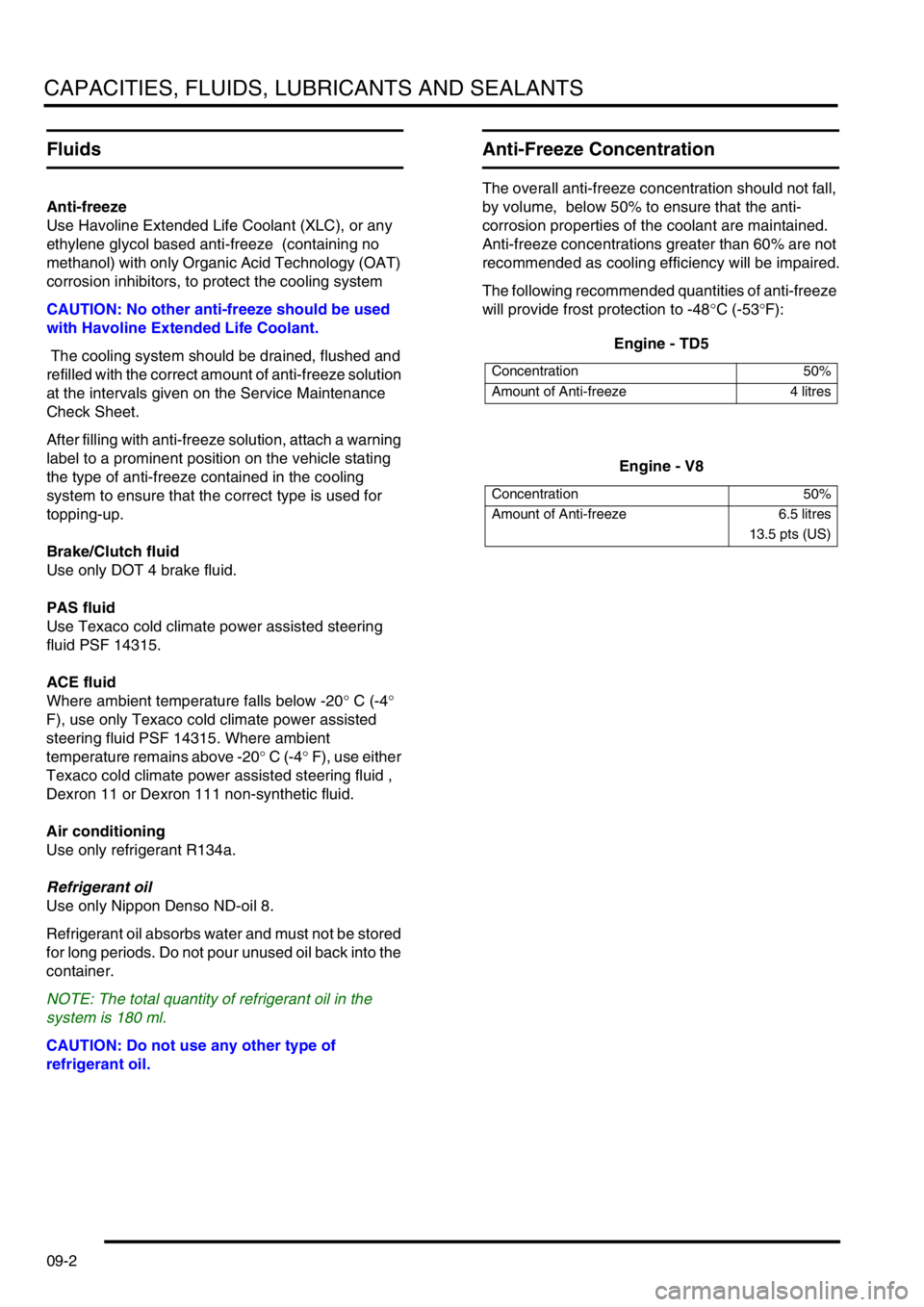

Fluids

Anti-freeze

Use Havoline Extended Life Coolant (XLC), or any

ethylene glycol based anti-freeze (containing no

methanol) with only Organic Acid Technology (OAT)

corrosion inhibitors, to protect the cooling system

CAUTION: No other anti-freeze should be used

with Havoline Extended Life Coolant.

The cooling system should be drained, flushed and

refilled with the correct amount of anti-freeze solution

at the intervals given on the Service Maintenance

Check Sheet.

After filling with anti-freeze solution, attach a warning

label to a prominent position on the vehicle stating

the type of anti-freeze contained in the cooling

system to ensure that the correct type is used for

topping-up.

Brake/Clutch fluid

Use only DOT 4 brake fluid.

PAS fluid

Use Texaco cold climate power assisted steering

fluid PSF 14315.

ACE fluid

Where ambient temperature falls below -20° C (-4°

F), use only Texaco cold climate power assisted

steering fluid PSF 14315. Where ambient

temperature remains above -20° C (-4° F), use either

Texaco cold climate power assisted steering fluid ,

Dexron 11 or Dexron 111 non-synthetic fluid.

Air conditioning

Use only refrigerant R134a.

Refrigerant oil

Use only Nippon Denso ND-oil 8.

Refrigerant oil absorbs water and must not be stored

for long periods. Do not pour unused oil back into the

container.

NOTE: The total quantity of refrigerant oil in the

system is 180 ml.

CAUTION: Do not use any other type of

refrigerant oil.

Anti-Freeze Concentration

The overall anti-freeze concentration should not fall,

by volume, below 50% to ensure that the anti-

corrosion properties of the coolant are maintained.

Anti-freeze concentrations greater than 60% are not

recommended as cooling efficiency will be impaired.

The following recommended quantities of anti-freeze

will provide frost protection to -48°C (-53°F):

Engine - TD5

Engine - V8

Concentration 50%

Amount of Anti-freeze 4 litres

Concentration 50%

Amount of Anti-freeze 6.5 litres

13.5 pts (US)

Page 120 of 1529

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

09-3

Lubrication

General

The engine and other lubricating systems are filled

with high-performance lubricants giving prolonged

life.

CAUTION: Always use a high quality oil of the

correct viscosity range in the engine. The use of

oil of the incorrect specification can lead to high

oil and fuel consumption and ultimately to

damaged components.

Oil to the correct specification contains additives

which disperse the corrosive acids formed by

combustion and prevent the formation of sludge

which can block the oil ways. Additional oil additives

should not be used.

Always adhere to the recommended servicing

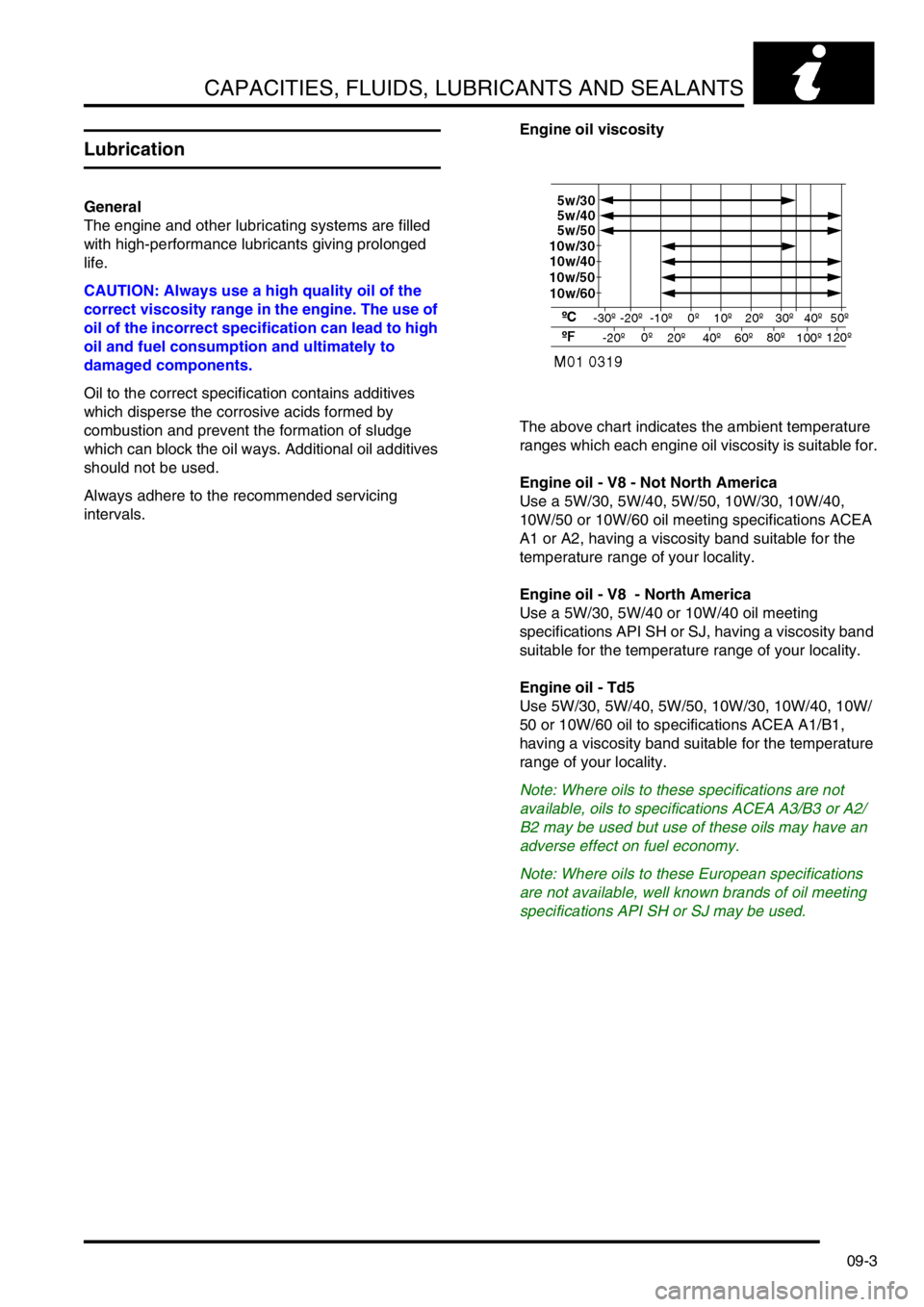

intervals.Engine oil viscosity

The above chart indicates the ambient temperature

ranges which each engine oil viscosity is suitable for.

Engine oil - V8 - Not North America

Use a 5W/30, 5W/40, 5W/50, 10W/30, 10W/40,

10W/50 or 10W/60 oil meeting specifications ACEA

A1 or A2, having a viscosity band suitable for the

temperature range of your locality.

Engine oil - V8 - North America

Use a 5W/30, 5W/40 or 10W/40 oil meeting

specifications API SH or SJ, having a viscosity band

suitable for the temperature range of your locality.

Engine oil - Td5

Use 5W/30, 5W/40, 5W/50, 10W/30, 10W/40, 10W/

50 or 10W/60 oil to specifications ACEA A1/B1,

having a viscosity band suitable for the temperature

range of your locality.

Note: Where oils to these specifications are not

available, oils to specifications ACEA A3/B3 or A2/

B2 may be used but use of these oils may have an

adverse effect on fuel economy.

Note: Where oils to these European specifications

are not available, well known brands of oil meeting

specifications API SH or SJ may be used.