LAND ROVER DISCOVERY 1999 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 141 of 1529

MAINTENANCE

10-18 PROCEDURES

Automatic gearbox

WARNING: Avoid excessive skin contact with

mineral oil. Mineral oils remove the natural fats

from the skin, leading to dryness, irritation and

dermatitis.

Replace oil filter

1.Replace oil filter.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Filter - oil.

Replace oil

1. Ensure that gearbox is cool. Apply

handbrake and securely chock front and rear

wheels.

2.Place a suitable container beneath gearbox.

3.Clean area around oil filler/level and drain

plugs.

4.Remove oil drain plug, remove and discard

sealing washer.

5.Allow oil to drain.

6.Fit new sealing washer to oil drain plug.

7.Fit automatic gearbox drain plug and tighten to

15 Nm (11 lbf.ft).

8.Remove oil filler/level plug, remove and discard

sealing washer.

9.Fill gearbox with recommended oil to bottom of

oil level/filler plug hole.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

10.Select 'P' (Park).

11.Ensure handbrake is applied.

12.Start engine and allow it to idle.

13.Apply footbrake. 14.Move selector lever through all gear positions,

while continuing to fill the gearbox. Select 'P'

(Park).

15.With engine idling, continue filling gearbox until

a 2 mm bead of oil runs from oil filler/level plug

hole.

16.Fit new sealing washer to automatic gearbox

filler/level plug, fit plug and tighten to 30 Nm (22

l b f . f t ) .

17.Stop engine.

18.Remove all traces of oil from gearbox casing.

Page 142 of 1529

MAINTENANCE

PROCEDURES 10-19

Transfer box

WARNING: Avoid excessive skin contact with

mineral oil. Mineral oils remove the natural fats

from the skin, leading to dryness, irritation and

dermatitis.

Check/top-up oil level

1.Release fixings, remove rear underbelly panel.

2.Clean area around oil filler/level plug.

3.Remove oil filler/level plug.

4.Check that oil level is to bottom of filler/level

plug hole.

5.Top-up level (if required) with recommended oil

to bottom of oil filler/level plug hole.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

6. Fit transfer box filler/level plug and tighten to 25

Nm (18 lbf.ft).

7.Remove all traces of oil from main casing.

8.Fit rear underbelly panel (if fitted), secure

fixings.Replace oil

1. Release fixings, remove rear underbelly panel.

2.Place a suitable container beneath transfer box

drain plug.

3.Clean area around oil filler/level and drain

plugs.

4.Remove oil filler/level plug.

5.Remove oil drain plug.

6.Allow oil to drain.

7. Fit transfer box drain plug and tighten to 30

Nm (22 lbf.ft).

8.Fill transfer box with recommended oil to

bottom of oil filler/level plug hole.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

9. Fit transfer box filler/level plug and tighten to 25

Nm (18 lbf.ft).

10. Remove all traces of oil from transfer box.

11.Fit rear underbelly panel (if fitted), secure

fixings.

Page 143 of 1529

MAINTENANCE

10-20 PROCEDURES

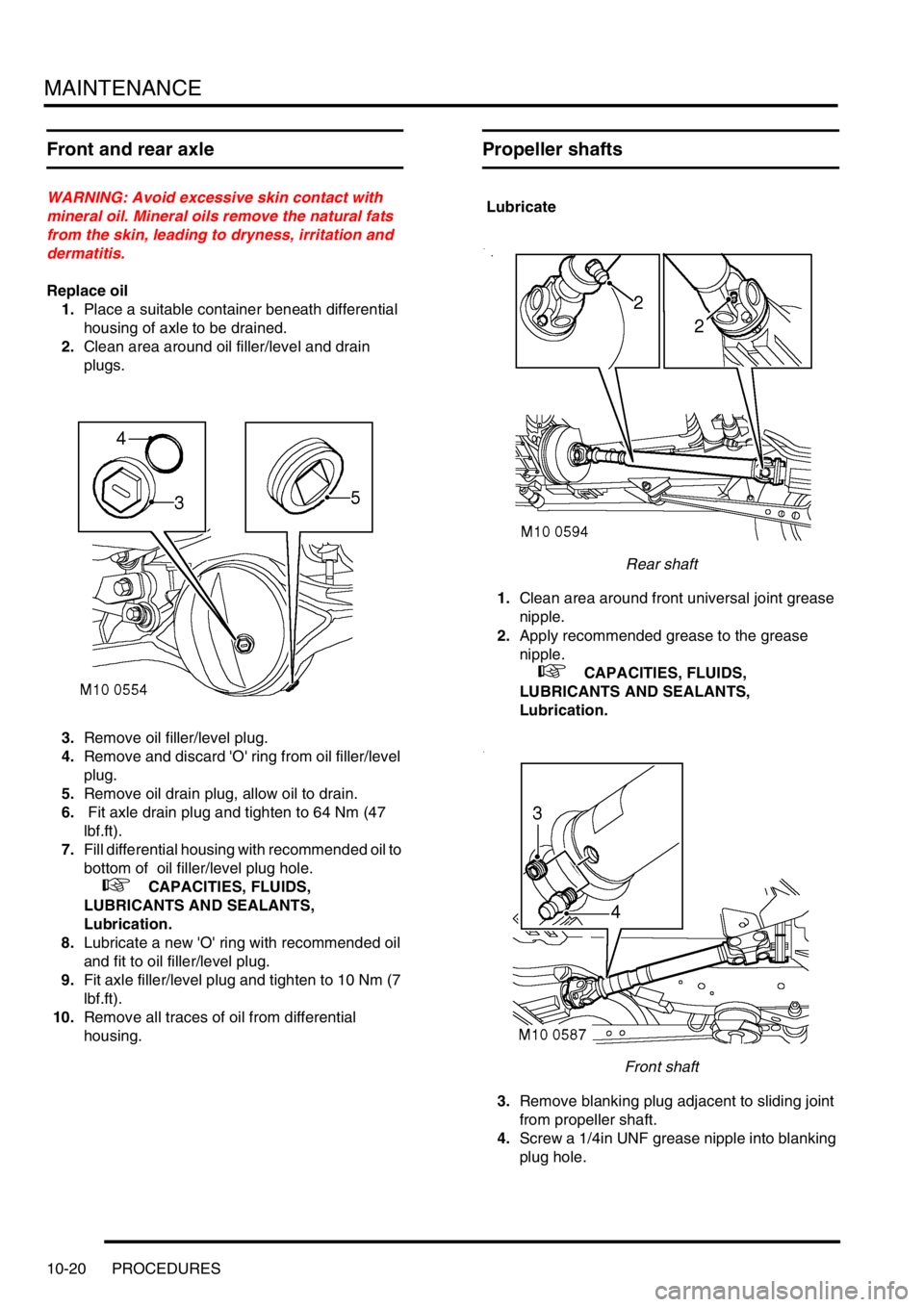

Front and rear axle

WARNING: Avoid excessive skin contact with

mineral oil. Mineral oils remove the natural fats

from the skin, leading to dryness, irritation and

dermatitis.

Replace oil

1.Place a suitable container beneath differential

housing of axle to be drained.

2.Clean area around oil filler/level and drain

plugs.

3.Remove oil filler/level plug.

4.Remove and discard 'O' ring from oil filler/level

plug.

5.Remove oil drain plug, allow oil to drain.

6. Fit axle drain plug and tighten to 64 Nm (47

lbf.ft).

7.Fill differential housing with recommended oil to

bottom of oil filler/level plug hole.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

8.Lubricate a new 'O' ring with recommended oil

and fit to oil filler/level plug.

9.Fit axle filler/level plug and tighten to 10 Nm (7

lbf.ft).

10.Remove all traces of oil from differential

housing.

Propeller shafts

Lubricate

Rear shaft

1.Clean area around front universal joint grease

nipple.

2.Apply recommended grease to the grease

nipple.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

Front shaft

3.Remove blanking plug adjacent to sliding joint

from propeller shaft.

4.Screw a 1/4in UNF grease nipple into blanking

plug hole.

Page 144 of 1529

MAINTENANCE

PROCEDURES 10-21

5.Apply recommended grease to the grease

nipple.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

6.Remove grease nipple.

7.Fit blanking plug.

Page 145 of 1529

MAINTENANCE

10-22 PROCEDURES

Anti-roll bar links

Check rear links

Rubber boots

Fixings

1.Check anti-roll bar links for free play.

2.Check rubber boots for splits, damage and

security.Anti-roll bar mountings - front

1.Check condition of mounting rubbers and

security of fixings.

+ TORQUE WRENCH SETTINGS,

Front suspension.

Anti-roll bar mountings - rear

Fixings

Rubber mountings

1.Check condition of mounting rubbers and

security of fixings.

+ TORQUE WRENCH SETTINGS, Rear

suspension.

Page 146 of 1529

MAINTENANCE

PROCEDURES 10-23

ACE actuators

Check

Actuator boots

1.Check ACE actuator gaiters for splits, damage

and clips for security.

ACE filter

Replace

1.Replace ACE filter.

+ FRONT SUSPENSION, REPAIRS,

Filter - high pressure - ACE.

Page 147 of 1529

MAINTENANCE

10-24 PROCEDURES

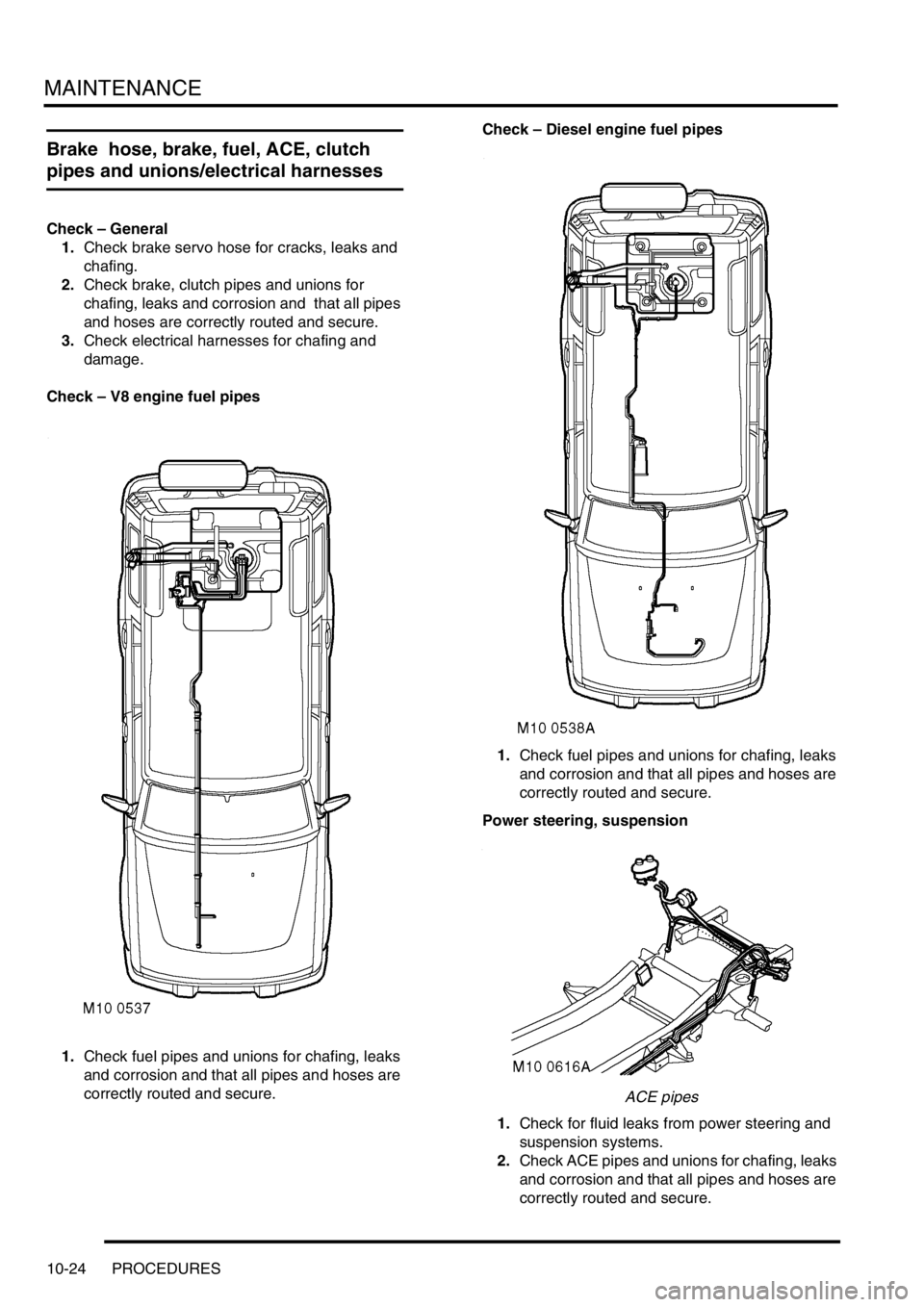

Brake hose, brake, fuel, ACE, clutch

pipes and unions/electrical harnesses

Check – General

1.Check brake servo hose for cracks, leaks and

chafing.

2.Check brake, clutch pipes and unions for

chafing, leaks and corrosion and that all pipes

and hoses are correctly routed and secure.

3.Check electrical harnesses for chafing and

damage.

Check – V8 engine fuel pipes

1.Check fuel pipes and unions for chafing, leaks

and corrosion and that all pipes and hoses are

correctly routed and secure. Check – Diesel engine fuel pipes

1.Check fuel pipes and unions for chafing, leaks

and corrosion and that all pipes and hoses are

correctly routed and secure.

Power steering, suspension

ACE pipes

1.Check for fluid leaks from power steering and

suspension systems.

2.Check ACE pipes and unions for chafing, leaks

and corrosion and that all pipes and hoses are

correctly routed and secure.

Page 148 of 1529

MAINTENANCE

PROCEDURES 10-25

Engine, gearbox, transfer box and axles

Check

1.Check for oil leaks from engine, gearbox

(manual and automatic), transfer box and front

and rear axles; pay particular attention to areas

around oil seals.

Exhaust system

Check

1.Check for signs of exhaust system leaks,

damage and security.

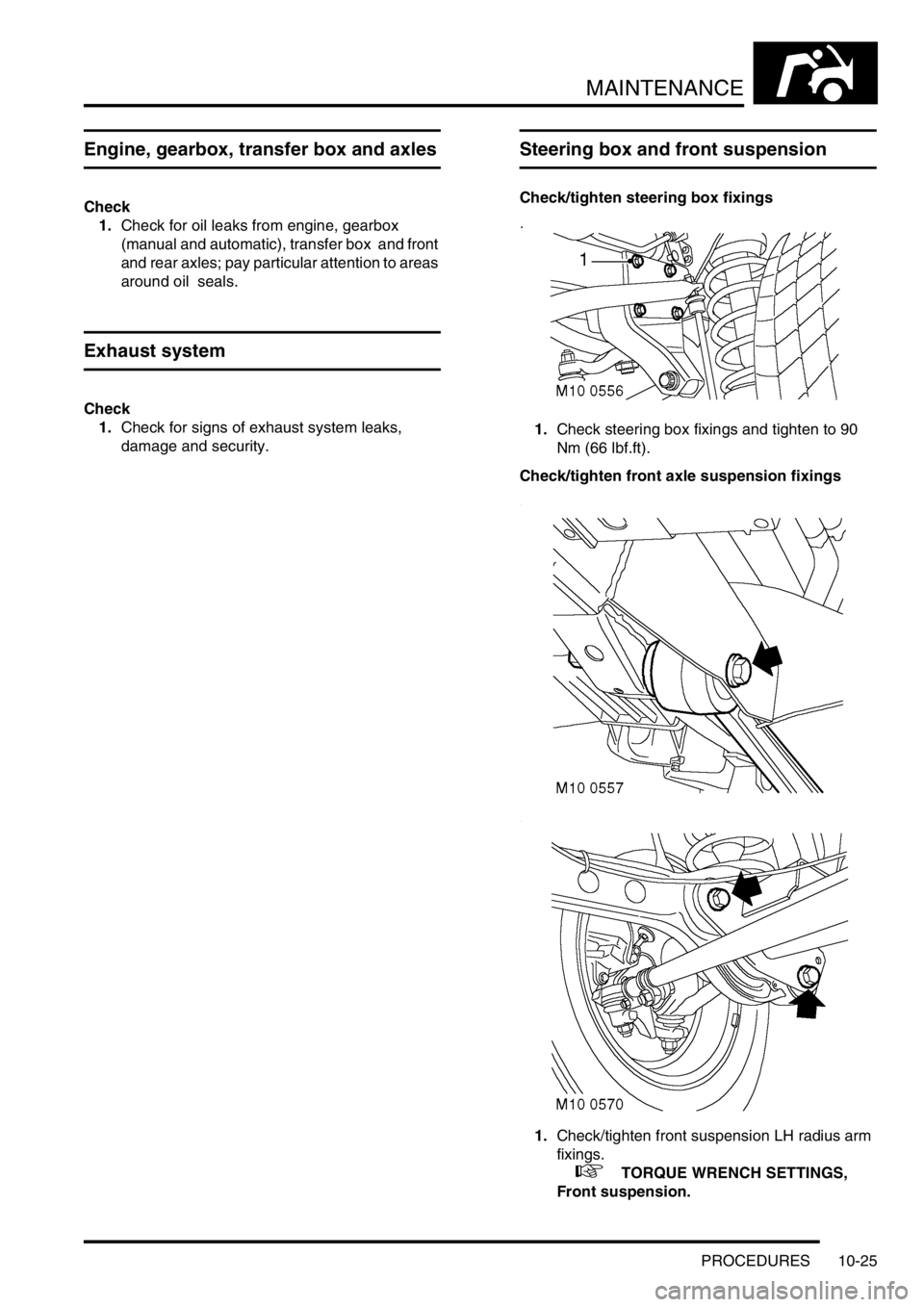

Steering box and front suspension

Check/tighten steering box fixings

1.Check steering box fixings and tighten to 90

Nm (66 lbf.ft).

Check/tighten front axle suspension fixings

1.Check/tighten front suspension LH radius arm

fixings.

+ TORQUE WRENCH SETTINGS,

Front suspension.

Page 149 of 1529

MAINTENANCE

10-26 PROCEDURES

2.Check/tighten front suspension RH radius arm

fixings.

3.Check/tighten front suspension Panhard rod

fixingsCheck rear axle suspension fixings

1.Check and tighten if necessary all rear axle

suspension fixings.

+ TORQUE WRENCH SETTINGS, Rear

suspension.

Page 150 of 1529

MAINTENANCE

PROCEDURES 10-27

Steering rod ball joints

Check

1.Check condition of ball joints and dust covers,

and security of fixings.

+ TORQUE WRENCH SETTINGS,

Steering.

2.Attempt to move the ball joints forwards,

backwards, side to side and up and down. No

end float in any direction should be detected. If

end float is present, the ball joint must be

renewed.

Dampers and SLS height sensors

Check – Dampers

Front dampers

Rear dampers

1.Check dampers for security and signs of

leakage.