light LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 1272 of 1672

PANEL REPAIRS

REPAIRS 77-2-23

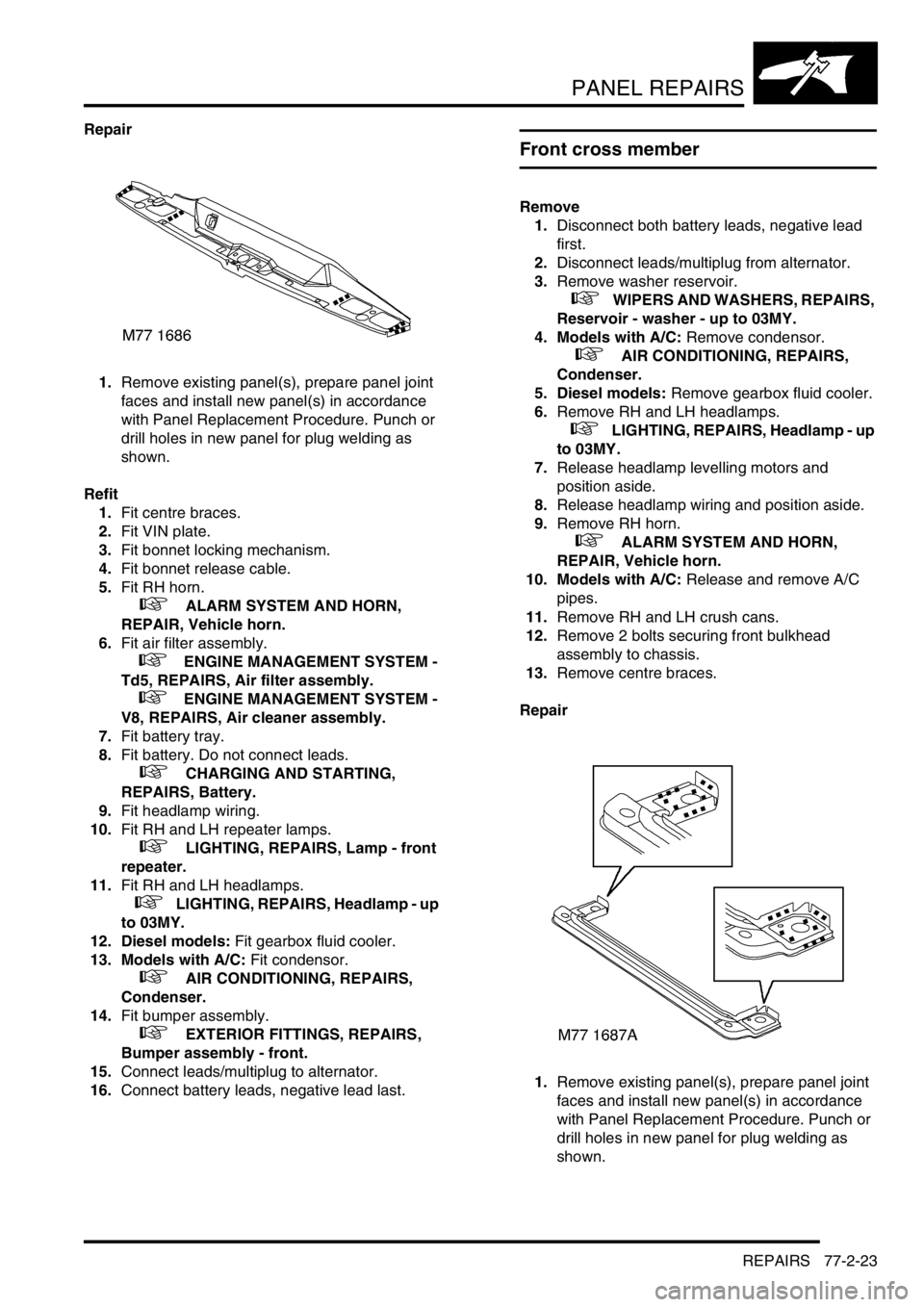

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Fit centre braces.

2.Fit VIN plate.

3.Fit bonnet locking mechanism.

4.Fit bonnet release cable.

5.Fit RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

6.Fit air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

7.Fit battery tray.

8.Fit battery. Do not connect leads.

+ CHARGING AND STARTING,

REPAIRS, Battery.

9.Fit headlamp wiring.

10.Fit RH and LH repeater lamps.

+ LIGHTING, REPAIRS, Lamp - front

repeater.

11.Fit RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

12. Diesel models: Fit gearbox fluid cooler.

13. Models with A/C: Fit condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

14.Fit bumper assembly.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - front.

15.Connect leads/multiplug to alternator.

16.Connect battery leads, negative lead last.

Front cross member

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

4. Models with A/C: Remove condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

5. Diesel models: Remove gearbox fluid cooler.

6.Remove RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

7.Release headlamp levelling motors and

position aside.

8.Release headlamp wiring and position aside.

9.Remove RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

10. Models with A/C: Release and remove A/C

pipes.

11.Remove RH and LH crush cans.

12.Remove 2 bolts securing front bulkhead

assembly to chassis.

13.Remove centre braces.

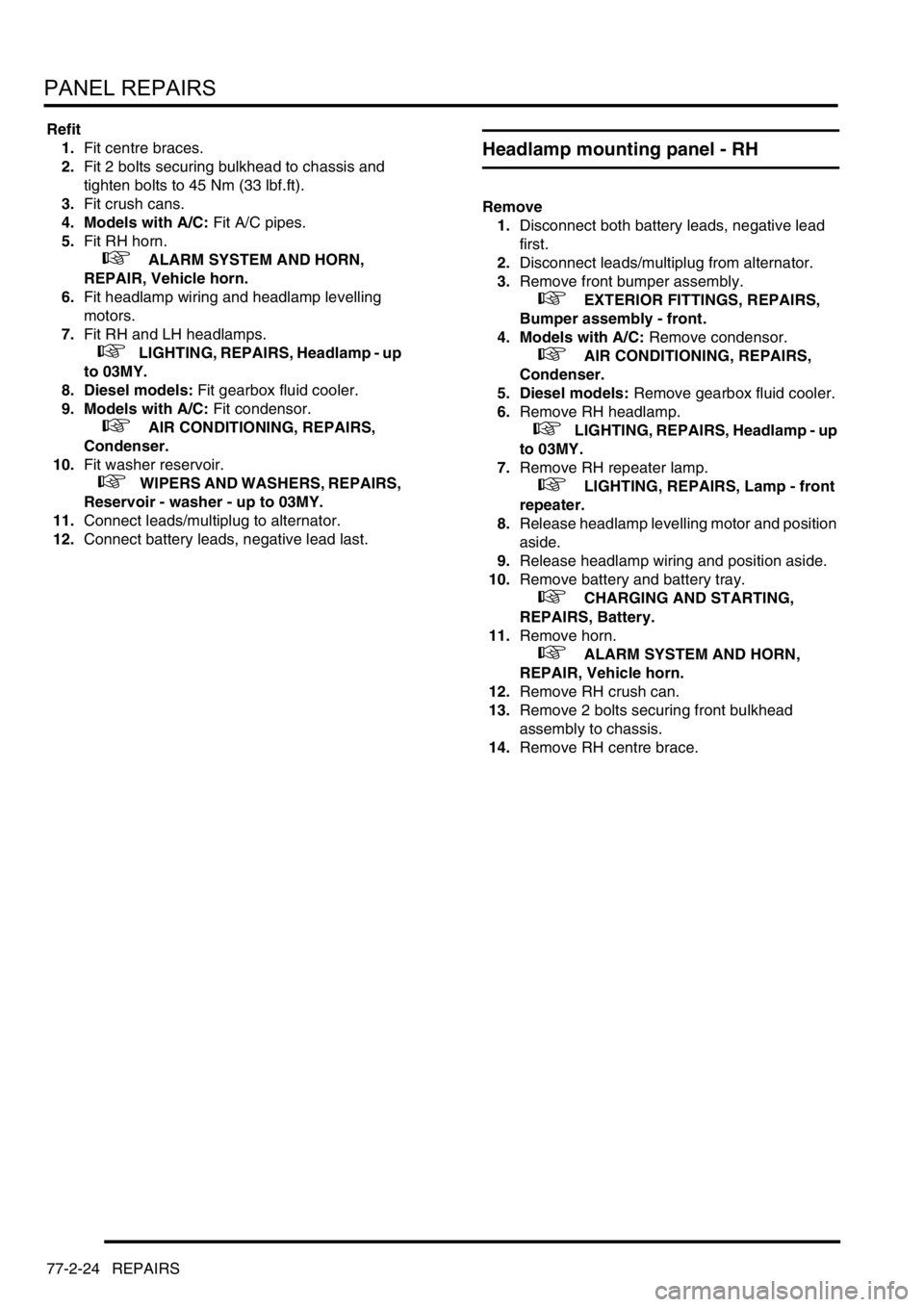

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Page 1273 of 1672

PANEL REPAIRS

77-2-24 REPAIRS

Refit

1.Fit centre braces.

2.Fit 2 bolts securing bulkhead to chassis and

tighten bolts to 45 Nm (33 lbf.ft).

3.Fit crush cans.

4. Models with A/C: Fit A/C pipes.

5.Fit RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

6.Fit headlamp wiring and headlamp levelling

motors.

7.Fit RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

8. Diesel models: Fit gearbox fluid cooler.

9. Models with A/C: Fit condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

10.Fit washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

11.Connect leads/multiplug to alternator.

12.Connect battery leads, negative lead last.

Headlamp mounting panel - RH

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove front bumper assembly.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - front.

4. Models with A/C: Remove condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

5. Diesel models: Remove gearbox fluid cooler.

6.Remove RH headlamp.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

7.Remove RH repeater lamp.

+ LIGHTING, REPAIRS, Lamp - front

repeater.

8.Release headlamp levelling motor and position

aside.

9.Release headlamp wiring and position aside.

10.Remove battery and battery tray.

+ CHARGING AND STARTING,

REPAIRS, Battery.

11.Remove horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

12.Remove RH crush can.

13.Remove 2 bolts securing front bulkhead

assembly to chassis.

14.Remove RH centre brace.

Page 1274 of 1672

PANEL REPAIRS

REPAIRS 77-2-25

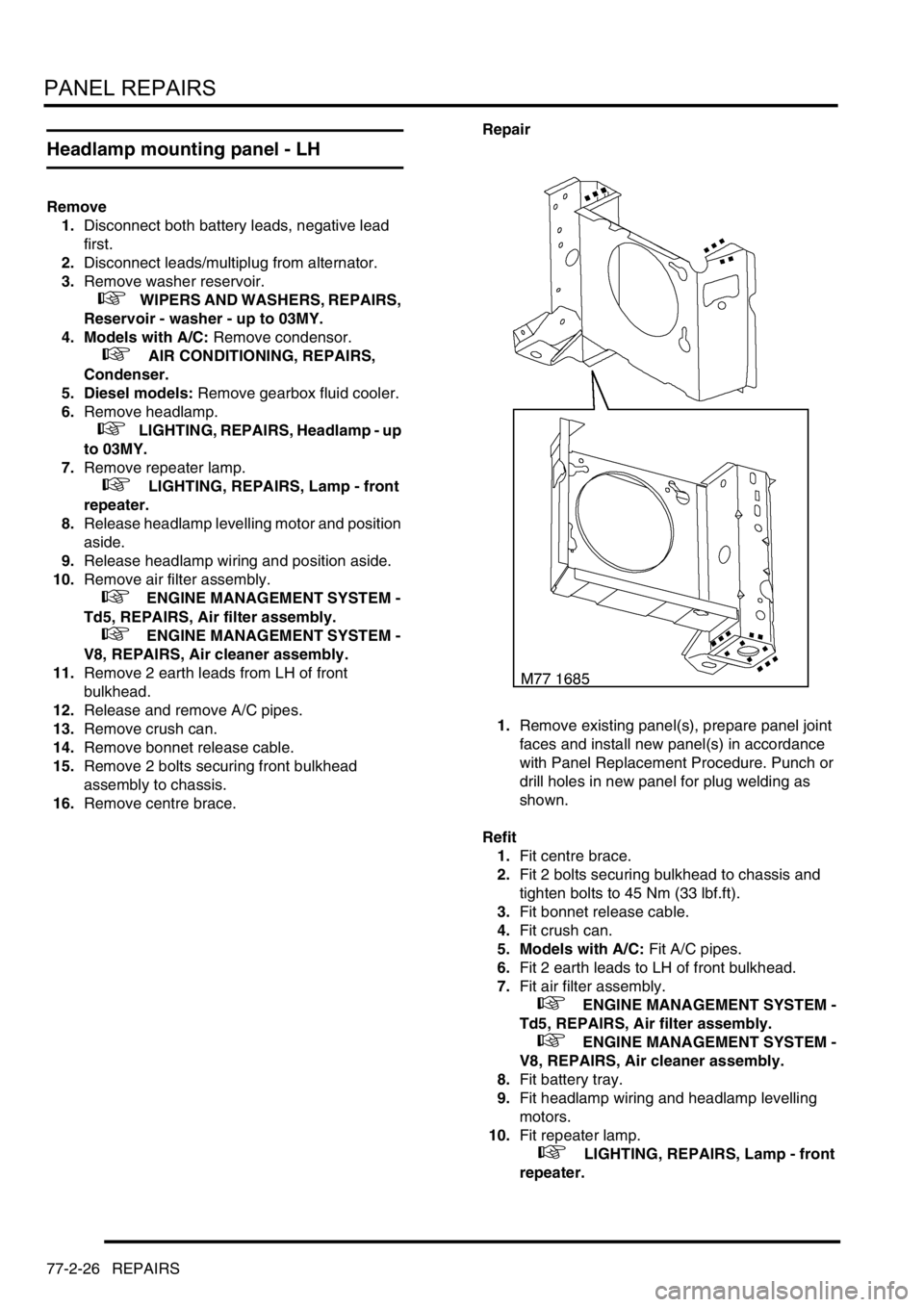

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Fit centre brace.

2.Fit 2 bolts securing bulkhead to chassis and

tighten bolts to 45 Nm (33 lbf.ft).

3.Fit crush can.

4. Models with A/C: Fit A/C pipes.

5.Fit horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

6.Fit battery and battery tray. Do not connect

leads.

+ CHARGING AND STARTING,

REPAIRS, Battery.

7.Fit headlamp wiring and headlamp levelling

motors.

8.Fit repeater lamp.

+ LIGHTING, REPAIRS, Lamp - front

repeater.9.Fit headlamp.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

10. Diesel models: Fit gearbox fluid cooler.

11. Models with A/C: Fit condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

12.Fit bumper assembly.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - front.

13.Connect leads/multiplug to alternator.

14.Connect battery leads, negative lead last.

M77 1741A

Page 1275 of 1672

PANEL REPAIRS

77-2-26 REPAIRS

Headlamp mounting panel - LH

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

4. Models with A/C: Remove condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

5. Diesel models: Remove gearbox fluid cooler.

6.Remove headlamp.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

7.Remove repeater lamp.

+ LIGHTING, REPAIRS, Lamp - front

repeater.

8.Release headlamp levelling motor and position

aside.

9.Release headlamp wiring and position aside.

10.Remove air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

11.Remove 2 earth leads from LH of front

bulkhead.

12.Release and remove A/C pipes.

13.Remove crush can.

14.Remove bonnet release cable.

15.Remove 2 bolts securing front bulkhead

assembly to chassis.

16.Remove centre brace.Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Fit centre brace.

2.Fit 2 bolts securing bulkhead to chassis and

tighten bolts to 45 Nm (33 lbf.ft).

3.Fit bonnet release cable.

4.Fit crush can.

5. Models with A/C: Fit A/C pipes.

6.Fit 2 earth leads to LH of front bulkhead.

7.Fit air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

8.Fit battery tray.

9.Fit headlamp wiring and headlamp levelling

motors.

10.Fit repeater lamp.

+ LIGHTING, REPAIRS, Lamp - front

repeater.

Page 1276 of 1672

PANEL REPAIRS

REPAIRS 77-2-27

11.Fit headlamp.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

12. Diesel models: Fit gearbox fluid cooler.

13. Models with A/C: Fit condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

14.Fit washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

15.Connect leads/multiplug to alternator.

16.Connect battery leads, negative lead last.

Valance upper assembly - LH

In this procedure, the front wing, the valance outer

reinforcement and the bonnet alarm switch mounting

bracket are replaced in conjunction with the LH

valance upper assembly.

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - up to 03MY.

4.Remove air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

5.Remove PAS/ACE reservoir.

6.Remove ABS modulator.

+ BRAKES, REPAIRS, Modulator unit

- ABS.

7.Remove brake pipes from valance.

8.Release harness from valance and position

aside.

9. Models with A/C: Depressurise A/C system

and remove pipes from valance.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery,

recycling and recharging.

Page 1289 of 1672

PANEL REPAIRS

77-2-40 REPAIRS

13.Fit front door striker to B/C post, fit Torx bolts

and tighten to 26 Nm (19 lbf.ft).

14.Fit rear door.

+ DOORS, REPAIRS, Door - rear.

15.Connect leads/multiplug to alternator.

16.Connect battery leads, negative lead last.

Panel body side assembly

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove loadspace side trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - side - loadspace.

4.Remove head lining rear trim finisher.

5.Remove rear head rests, if fitted.

6.Remove body side rear glass.

+ SCREENS, REPAIRS, Glass - body

side - rear.

7.Remove rear bumper assembly.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - rear - up to 03MY.

8.Remove rear bumper finisher.

9.Remove rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - wheel arch - rear.

10.Remove mud flap.

11.Remove tread plate from rear door aperture.

12.Remove rear door aperture seal.

13.Remove rear door striker from 'D' post.

14.Remove 'D' post outer trim finisher.

15.Remove wheel arch trim finisher.

16.Remove side drip rail finisher.

17. RH side: Remove tail door.

18. LH side: Remove tail door striker and setting

block from 'E' post.

19.Remove tail door tread plate.

20.Remove loadspace carpet retainer.

21.Remove tail door aperture seal.

22.Remove tail lamp.

+ LIGHTING, REPAIRS, Lamp - tail.

23. RH side: Remove fuel filler flap.

24. RH side: Remove fuel filler tube.

+ FUEL DELIVERY SYSTEM - V8,

REPAIRS, Filler tube - fuel.

25.Remove aerial amplifier.

26.Remove relevant wiring from body side area.

Page 1290 of 1672

PANEL REPAIRS

REPAIRS 77-2-41

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. The panel

body side assembly does not require any

welding, as it is bolted into position.

Refit

1.Position and secure wiring.

2.Fit aerial amplifier.

3. RH side: Fit fuel filler tube.

+ FUEL DELIVERY SYSTEM - V8,

REPAIRS, Filler tube - fuel.

4. RH side: Fit fuel filler flap.

5.Fit tail lamp.

+ LIGHTING, REPAIRS, Lamp - tail.

6.Fit tail door aperture seal.

7.Fit loadspace carpet retainer.

8.Fit tail door tread plate.

9. LH side: Fit tail door striker and setting block to

'E' post, fit Torx bolts and tighten to 26 Nm (19

lbf.ft).

10. RH side: Fit tail door.

11.Fit side drip rail finisher.

12.Fit wheel arch trim finisher.

13.Fit 'D' post outer trim finisher.

14.Fit rear door striker.

15.Fit rear door aperture seal.

16.Fit tread plate to rear door aperture.

17.Fit mud flap.18.Fit rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - wheel arch - rear.

19.Fit rear bumper finisher.

20.Fit rear bumper assembly.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - rear - up to 03MY.

21.Fit body side rear glass.

+ SCREENS, REPAIRS, Glass - body

side - rear.

22.Fit rear head rests, if fitted.

23.Fit head lining rear trim finisher.

24.Fit loadspace side trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - side - loadspace.

25.Connect leads/multiplug to alternator.

26.Connect battery leads, negative lead last.

M77 0000

Page 1301 of 1672

PANEL REPAIRS

77-2-52 REPAIRS

Rear floor (RH/LH section)

In this procedure, the cross member rear assembly,

cross member outer rear panel (RH/LH section),

cross member closing rear panel, 'E' post assembly,

'E' post closing assembly and the panel body side

assembly are replaced in conjunction with the rear

floor (RH/LH section).

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove cross member rear assembly.

+ PANEL REPAIRS, REPAIRS, Cross

member rear assembly.

4.Remove mud flap mounting brackets.

5. LH side: Remove exhaust heatshield from rear

floor.

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1. LH side: Fit exhaust heatshield to rear floor.

2.Fit mud flap mounting brackets.

3.Fit cross member rear assembly.

+ PANEL REPAIRS, REPAIRS, Cross

member rear assembly.

4.Connect leads/multiplug to alternator.

5.Connect battery leads, negative lead last.

Roof assembly

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3. Models with sunroof: Remove front sunroof.

+ SUNROOF, REPAIRS, Sunroof -

front.

4. Models with sunroof: Remove rear sunroof.

+ SUNROOF, REPAIRS, Sunroof -

rear.

5. Models with sunroof: Release sunroof drain

tubes and position aside.

6. Models with fixed roof: Remove head lining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining.

7.Remove front seats.

+ SEATS, REPAIRS, Seat - front.

8.Remove rear seats.

+ SEATS, REPAIRS, Seat - rear.

9.Remove rear headrests, if fitted.

10.Remove roof bars, if fitted.

+ EXTERIOR FITTINGS, REPAIRS,

Roof bars.

11.Remove tread plates from front door apertures.

12.Remove 'A' post lower trim panels.

13.Remove front door aperture seals.

14.Remove tread plates from rear door apertures.

15.Remove rear door aperture seals.

16.Remove 'D' post outer trim finisher.

17.Remove windscreen.

+ SCREENS, REPAIRS, Windscreen.

18.Remove alpine light glass.

+ SCREENS, REPAIRS, Glass - alpine

light.

19.Remove side and rear drip rail finishers.

20.Release relevant wiring and position aside.

Page 1302 of 1672

PANEL REPAIRS

REPAIRS 77-2-53

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

2. During welding operations, apply 'Heat

shrink paste' to roof and body side panel to

avoid heat damage to paintwork.Refit

1.Fit and secure wiring.

2.Fit side and rear drip rail finishers.

3.Fit alpine light glass.

+ SCREENS, REPAIRS, Glass - alpine

light.

4.Fit windscreen.

+ SCREENS, REPAIRS, Windscreen.

5.Fit 'D' post outer trim finishers.

6.Fit rear door aperture seals.

7.Fit tread plates to rear door apertures.

8.Fit front door aperture seals.

9.Fit 'A' post lower trim panels.

10.Fit tread plates to front door apertures.

11.Fit roof bars.

+ EXTERIOR FITTINGS, REPAIRS,

Roof bars.

12.Fit rear headrests.

13.Fit rear seats.

+ SEATS, REPAIRS, Seat - rear.

14.Fit front seats.

+ SEATS, REPAIRS, Seat - front.

15. Models with fixed roof: Fit head lining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining.

16. Models with sunroof: Fit sunroof drain tubes.

17. Models with sunroof: Fit rear sunroof.

+ SUNROOF, REPAIRS, Sunroof -

rear.

18. Models with sunroof: Fit front sunroof.

+ SUNROOF, REPAIRS, Sunroof -

front.

19.Connect leads/multiplug to alternator.

20.Connect battery leads, negative lead last.

M77 1715A

Page 1309 of 1672

BODY SEALING MATERIALS

77-3-2 MATERIALS AND APPLICATIONS

Approved materials

The following is a table of materials approved by Land Rover for use during body repairs.

Description - Usage Supplier Part Number

Cavity waxes

Inner Cavity Wax (Amber) 3M 08901/11/21

Inner Cavity Wax (Transparent) 3M 08909/19/29

Cavity Wax Croda PW57

Engine bay waxes/lacquers

Astrolan Engine Bay Wax and Cosmetic Wax Astors DA3243/1

Engine Bay Cosmetic Wax/Lacquer Croda PW197

Engine Bay Cosmetic Wax/Lacquer Dinol 4010

Miscellaneous materials

Aerosol Auto Adhesive (Trim) - impact adhesive for trim parts 3M 08080

Flexible Parts Repair Material - rubber modified polypropylene parts 3M 05900

Waterproof Cloth Tape - sealing panel apertures 3M Y387/Y3998

Sound Dampening Foam Gurit-Essex Betacore 7999

Water Shedder Repair (Aerosol) Teroson

Seam sealers

Body Caulking - type (b) gaps between panels 3M 08568

Bolted Panel Sealer - between bolted panels 3M 08572

Drip Chek Clear - bolted, spot welded and bonded panel edges; type (a) and

(b) gaps between panels; type (c) clinch joints 3M 08401

Drip Chek Heavy - type (b) gaps between panels; type (c) clinch joints 3M 08531

Polyurethane Seam Sealer - bolted, spot welded and bonded panel edges;

type (a) and (b) gaps between panels; type (b) clinch joints3M 08684/89/94

Polyurethane Sealer (Sachet) - bolted panel edges; type (b) clinch joints 3M 08703/83/88

Sprayable Sealer - lap joints 3M 08800/23

Super Seam Sealer - lap joints; type (b) clinch joints 3M 08537

Weld Thru' Sealer - between spot welded panels 3M 08626

Betafill Clinch and Brushable Sealer - type (b) clinch joints Gurit-Essex 10211/15/20

Clinch, Joint and Underbody Coating - lap joints Gurit-Essex 10101/10707

Leak Chek Clear - between bolted panels; spot welded and bonded panel

edges; type (c) clinch joints; type (a) gaps between panels Kent Industries 10075

Putty - type (b) gaps between panels Kent Industries

Polyurethane Seam Sealer - bolted, spot welded and bonded panel edges;

between bonded panels; type (a) and (b) gaps between panels PPG 6500

Polyurethane Seam Sealer - bolted, spot welded and bonded panel edges;

between bonded panels; type (b) gaps between panels Teroson 92

Terolan Light Seam Sealer - bolted, spot welded and bonded panel edges;

type (a) and (b) gaps between panels; between bonded panels; type (c)

clinch jointsTeroson