light LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 1311 of 1672

BODY SEALING MATERIALS

77-3-4 MATERIALS AND APPLICATIONS

Application equipment

Manufacturers and suppliers

Suitable application equipment is available from the following manufacturers and suppliers:

3M

Automotive Trades Group

3M UK Plc

3M House

PO Box 1

Market Place

Bracknell

Berks

RG 12 1JU

( (01344) 858611

Cooper Pegler

Burgess Hill

Sussex

RH15 9LA

( (014 446) 42526

SATA Spray Equipment

Minden Industrial Ltd

16 Greyfriars Road

Moreton Hall

Bury St. Edmunds

Suffolk

IP32 7DX

( (01284) 760791

3M Body Schutz Pistol Spraygun 08996

A pistol type spraygun constructed from case and machined light alloy and designed for use with 3M screw fit Body

Schutz containers.

3M Caulking Gun MKIII 8002

A lightweight, robust metal skeleton gun designed to accept 325 mm (13 in) cartridge for dispensing sealants etc. This

gun provides rapid cartridge insertion and loading, with a quick-release lever for accurate control of material ejection

and shut-off.

3M Pneumatic Cartridge Gun 08012

Air line-fed gun for applying 3M cartridge products. Excellent for ease of application to obtain a smooth bead.

Regulator valve for additional control.

3M Pneumatic Applicator Guns

Air line-fed gun for application of 3M sachet sealers (Part Number 08006 for 200 ml and 310 ml sachet applications,

and Part Number 08007 for all size sachets including 600 ml).

Also available: Heavy Duty Manual Gun 08013.

3M Applicator Gun 08190.

For the application of 3M Structural Adhesive 08120.

3M Inner Cavity Wax Applicator Gun 08997

This equipment accepts 1-litre canisters and has a 750 mm (29.572 in) flexible tube.

The approved system is available from all 3M refinishing factors.

Page 1375 of 1672

AIR CONDITIONING

82-2DESCRIPTION AND OPERATION

A/C control system component layout

RH drive shown, LH drive similar

1Air temperature control ECU

2Heater coolant temperature sensor

3Evaporator temperature sensor

4Dual pressure switch

5Ambient temperature sensor

6Sunlight sensor

7In-car temperature sensor

Page 1385 of 1672

AIR CONDITIONING

82-12DESCRIPTION AND OPERATION

Control system

The control system operates the refrigerant system and the control flaps in the heater assembly to control the

temperature and distribution of air in the vehicle interior. It also outputs signals to the fresh/recirculated air servo motor

and the blower to control the volume and source of inlet air. The control system consists of:

lAn Air Temperature Control (ATC) ECU.

lA dual pressure switch.

lAn evaporator temperature sensor.

lAn in-car temperature sensor.

lA sunlight sensor.

lA heater coolant temperature sensor.

lAn ambient temperature sensor.

ATC ECU

The ATC ECU is installed in the centre of the fascia, below the radio. An integral control panel on the ATC ECU

contains switches for system control inputs and a LCD to provide system status information.

Inputs from sensors and the control panel switches are processed by the ATC ECU, which then outputs the

appropriate control signals.

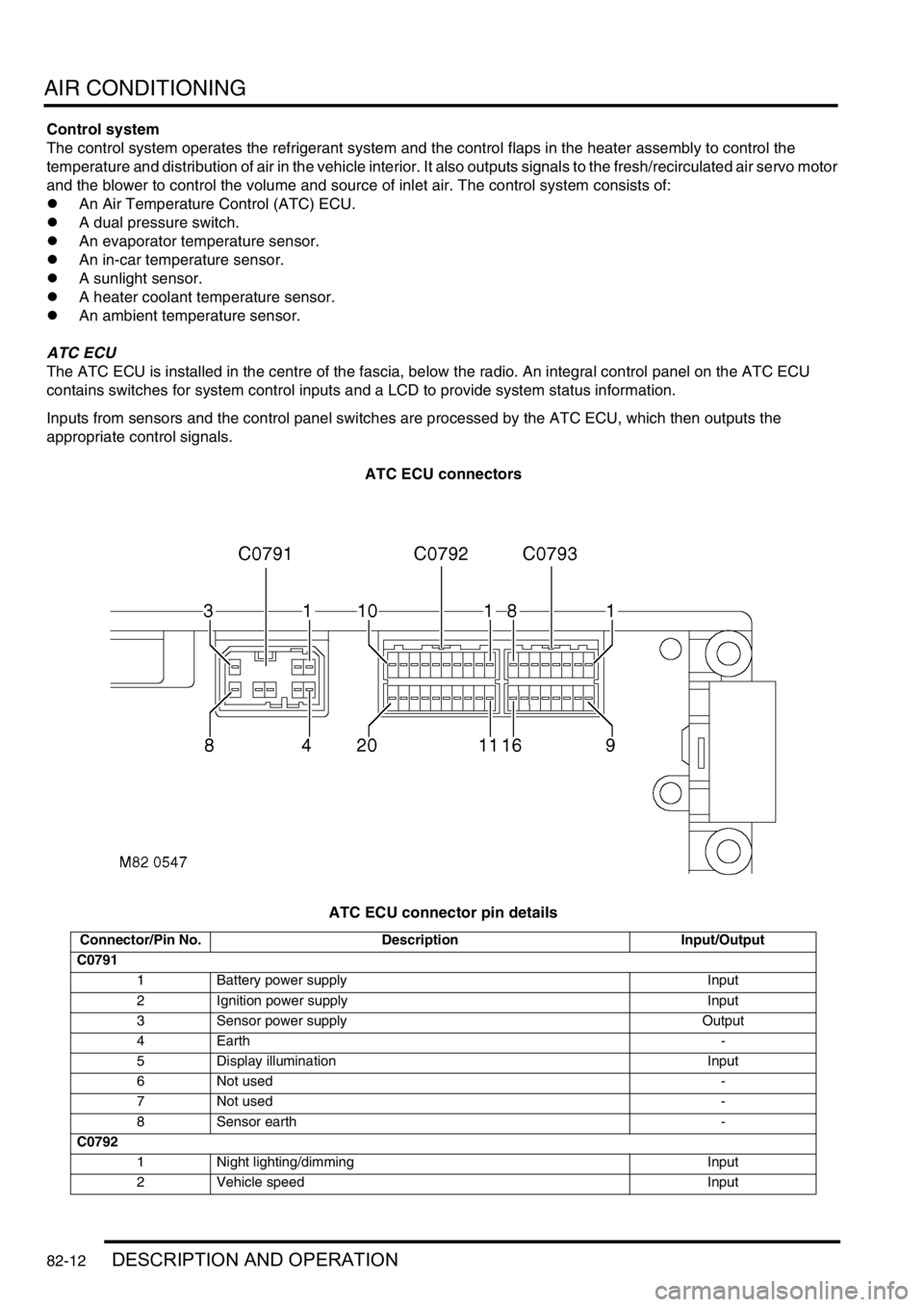

ATC ECU connectors

ATC ECU connector pin details

Connector/Pin No. Description Input/Output

C0791

1 Battery power supply Input

2 Ignition power supply Input

3 Sensor power supply Output

4Earth-

5 Display illumination Input

6 Not used-

7 Not used-

8 Sensor earth -

C0792

1 Night lighting/dimming Input

2 Vehicle speed Input

Page 1389 of 1672

AIR CONDITIONING

82-16DESCRIPTION AND OPERATION

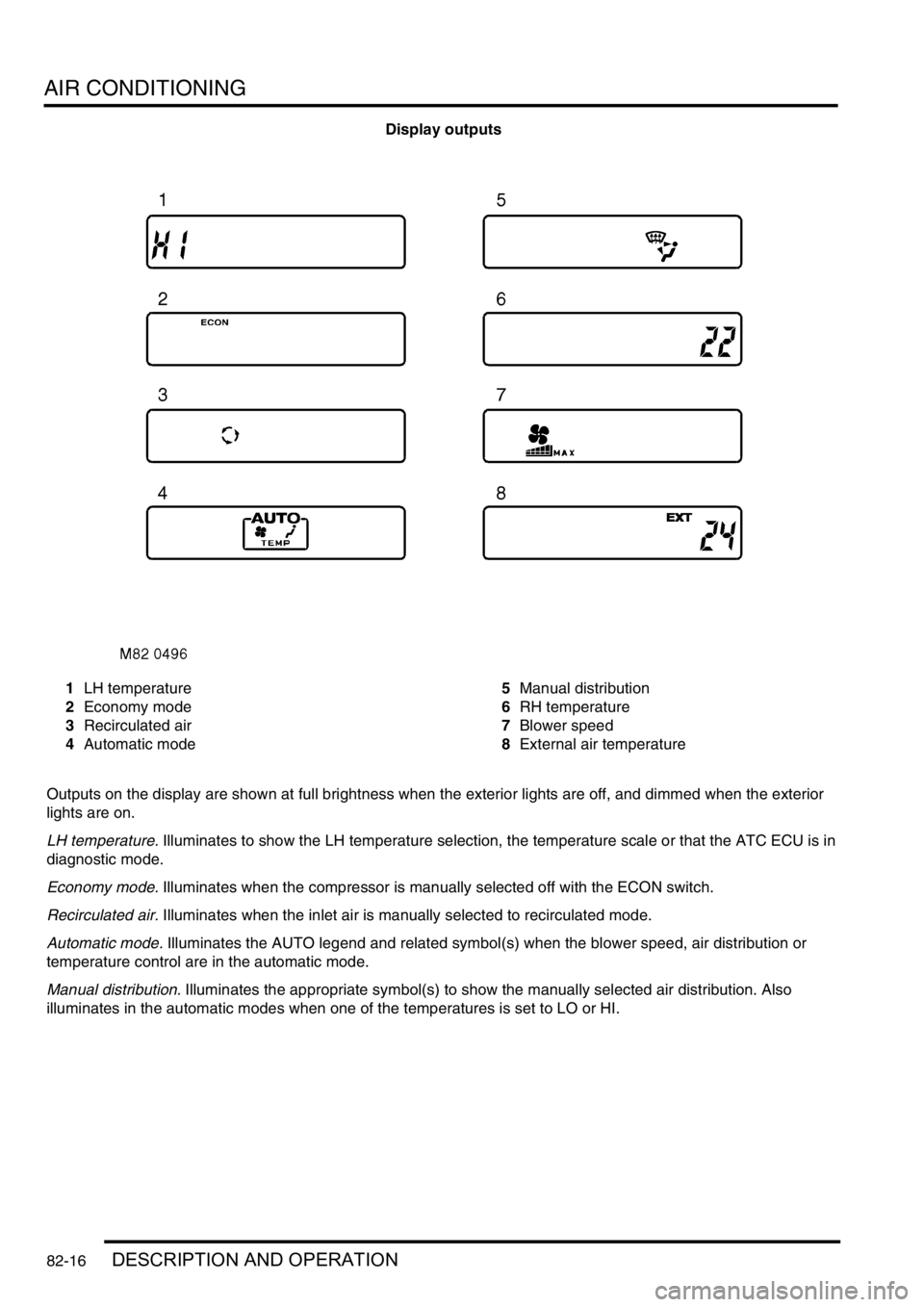

Display outputs

1LH temperature

2Economy mode

3Recirculated air

4Automatic mode5Manual distribution

6RH temperature

7Blower speed

8External air temperature

Outputs on the display are shown at full brightness when the exterior lights are off, and dimmed when the exterior

lights are on.

LH temperature. Illuminates to show the LH temperature selection, the temperature scale or that the ATC ECU is in

diagnostic mode.

Economy mode. Illuminates when the compressor is manually selected off with the ECON switch.

Recirculated air. Illuminates when the inlet air is manually selected to recirculated mode.

Automatic mode. Illuminates the AUTO legend and related symbol(s) when the blower speed, air distribution or

temperature control are in the automatic mode.

Manual distribution. Illuminates the appropriate symbol(s) to show the manually selected air distribution. Also

illuminates in the automatic modes when one of the temperatures is set to LO or HI.

Page 1390 of 1672

AIR CONDITIONING

DESCRIPTION AND OPERATION 82-17

RH temperature. Illuminates to show the RH temperature selection, external air temperature or diagnostic fault code.

Blower speed. Illuminates when the blower speed is manually selected. Also illuminates in the automatic modes when

one of the temperatures is set to LO or HI.

External air temperature. EXT illuminates to show that external air temperature is selected on.

All temperature indications on the display are in either

°C or °F. For 1 second after the system is first switched on, the

display shows only

°C or °F, in the LH temperature window, to indicate which temperature scale is in use. After 1

second, the

°C or °F indication goes off and the display shows all relevant outputs.

Temperature conversion: While the system is on, the temperature indications on the display can be switched between

the two scales by pressing and holding the fresh/recirculated air switch, then pressing and holding the A/C on/off

switch until the audible warning sounds (approximately 3 seconds).

Dual pressure switch

The dual pressure switch protects the refrigerant system from extremes of pressure. The normally closed switch is

installed in the top of the receiver drier. If minimum or maximum pressure limits are exceeded the switch contacts

open, causing the compressor clutch to be disengaged. The minimum pressure limit protects the compressor, by

preventing operation of the system unless there is a minimum refrigerant pressure (and thus refrigerant and

lubricating oil) in the system. The maximum pressure limit keeps the refrigerant system within a safe operating

pressure.

Dual pressure switch nominal operating pressures

Evaporator temperature sensor

The evaporator temperature sensor is an encapsulated thermistor that provides the ATC ECU with an input of the

evaporator air outlet temperature. The evaporator temperature sensor is installed in a clip which locates in the

evaporator matrix in the heater assembly. The ATC ECU uses the input to prevent the formation of ice on the

evaporator.

In-car temperature sensor

The in-car temperature sensor is an encapsulated thermistor that provides the ATC ECU with an input of cabin air

temperature. The sensor is integrated into the inlet of an electric fan, which is installed behind a grille in the fascia

outboard of the steering column. The fan runs continuously, while the ignition is on, to draw air through the grille and

across the sensor.

Sunlight sensor

The sunlight sensor consists of two diodes that provide the ATC ECU with inputs of light intensity, one as sensed

coming from the left of the vehicle and one as sensed coming from the right. The inputs are used as a measure of the

solar heating effect on vehicle occupants. The sensor is installed in the centre of the fascia upper surface.

Heater coolant temperature sensor

The heater coolant temperature sensor is an encapsulated thermistor that provides the ATC ECU with an input related

to heater matrix coolant temperature. The sensor is installed in the casing of the heater assembly and presses against

the end tank of the heater matrix.

Ambient temperature sensor

The ambient temperature sensor is an encapsulated thermistor that provides the ATC ECU with an input of external

air temperature. The sensor is attached to the cooling fan mounting bracket in front of the condenser.

Limit Opening pressure, bar (lbf.in2) Closing pressure, bar (lbf.in2)

Minimum 2.0 (29.0), pressure decreasing 2.3 (33.4), pressure increasing

Maximum 32 (464), pressure increasing 26 (377), pressure decreasing

Page 1394 of 1672

AIR CONDITIONING

DESCRIPTION AND OPERATION 82-21

Diagnostics

The ATC ECU performs a diagnostic check each time the ignition is switched on. To avoid nuisance fault indications

at low light levels, the sunlight sensor is omitted from the diagnostic check. If a fault is detected, the audible warning

sounds three times and the AUTO window on the control panel display flashes for 20 seconds. The ATC ECU then

reverts to normal control but uses a default value or strategy for the detected fault. Faults are identified by performing

a manual diagnostic check of the system.

A manual diagnostic check includes a check of the sunlight sensor, and is initiated by pressing and holding the AUTO

switch and the air distribution switch, then turning the ignition switch from off to on. The audible warning sounds once

and the indications on the control panel display illuminate. FC is shown in the LH temperature window and the results

of the check are shown as a two digit fault code in the RH temperature window. If a fault is detected, the audible

warning sounds three times and the AUTO window on the display flashes on and off for 20 seconds. If more than one

fault is detected, the fault codes cycle in numerical order, at 1 Hz. The audible warning sounds as each fault code is

shown. In low light conditions, to avoid false sunlight sensor fault indications, the sunlight sensor should be illuminated

with a strong light source.

Diagnostic fault codes and fault descriptions

Code Component Fault Default value/strategy

00 - No fault found -

11 In-car temperature sensor Open or short circuit 25°C (77°F)

12 Ambient temperature sensor Open or short circuit 10°C (50°F)

Cooling fan permanently on

Display shows "- -" if external

air temperature selected

13 Thermistor Open or short circuit 0°C (32°F)

14 Heater coolant temperature sensor Open or short circuit 70°C (158°F)

21 Sunlight sensor, left output Open or short circuit No solar heating correction

22 Sunlight sensor, right output Open or short circuit No solar heating correction

31 LH temperature servo motor Open or short circuit

Motor or flap mechanism seizedServo motor locked in position

32 RH temperature servo motor Open or short circuit

Motor or flap mechanism seizedServo motor locked in position

33 Distribution servo motor Open or short circuit

Motor or flap mechanism seizedServo motor locked in position

Page 1411 of 1672

AIR CONDITIONING

82-38REPAIRS

Sensor - ambient air temperature

$% 82.20.91

Remove

1.Remove front grille.

+ EXTERIOR FITTINGS, REPAIRS,

Grille - front - up to 03MY.

2.Release ambient air temperature sensor from

support bracket, disconnect multiplug and

remove sensor.

Refit

1.Position sensor, connect multiplug and secure

sensor to support bracket

2.Fit front grille.

+ EXTERIOR FITTINGS, REPAIRS,

Grille - front - up to 03MY.

Sensor - solar light

$% 82.20.92

Remove

1.Carefully remove solar light sensor from fascia.

2.Disconnect multiplug from solar light sensor.

3.Remove solar light sensor.

Refit

1.Connect multiplug to solar light sensor.

2.Position solar light sensor to fascia and push to

secure.

Page 1438 of 1672

WIPERS AND WASHERS

DESCRIPTION AND OPERATION 84-17

Front flick wipe

Flick wipe operation will only activate when the following conditions are met:

lIgnition switch is in position I or II.

lFront flick switch is operated.

Pressing the flick wipe switch operates the front wiper motor at high speed. The front wiper motor operates as long

as the flick switch is activated. Releasing the flick switch causes the front wiper motor to run through the park switch

circuitry. The park switch only permits low speed operation. Thus if the flick switch is pressed and immediately

released, the wipers operate at low speed.

Rear intermittent wipe variable delay

The rear intermittent wipe variable delay operation allows the driver to adjust the interval between wipes to suit local

conditions. Rear variable delay operation only activates if the following conditions are met:

lIgnition switch in position I or II.

lFront wash/ wipe switch on intermittent.

lRear wipe switch is operated.

The BCU determines the desired delay interval based on the setting of the variable delay switch. The rear wash/ wipe

delay is nominally twice as long as that of the front. This information passes from the IDM to the rear wiper relay and

activates the rear wiper motor.

If the delay duration is decreased during operation of the rear wiper, the wipers immediately operate once and the

delay cycle is reset.

If the delay duration is increased during operation of the rear wiper, the delay cycle is automatically increased by the

BCU.

Reverse wiping

Reverse wiping operates the rear wiper motor when reverse gear is selected. The transmission must be in reverse

for longer then 0.5 seconds before reversing wipe activates. Reversing wipe activates if the following conditions are

met:

lIgnition switch is in position II.

lReverse gear is selected.

lRear wiper or front wipers operating.

If the rear wiper is active in any mode when reverse gear is selected, the rear wiper activates for 4 second. After 4

seconds the rear wiper operates in a delay operation at the same delay interval set by the variable delay switch until

reverse gear is deselected.

If the front wipers are operating on either low or high speed when reverse gear is selected, the rear wiper activates

continuously until reverse gear is deselected.

In order to enable reversing wipe functions, the BCU utilises the reversing light switch located within the transmission

to determine when reverse gear has been selected.

If the front intermittent wipe is active when reverse gear is selected, the rear wiper completes 2 cycles before operating

at the same intermittent delay as the front wipers.

Page 1456 of 1672

LIGHTING

ADJUSTMENTS 86-2-1

LIGHTING ADJUST ME NTS

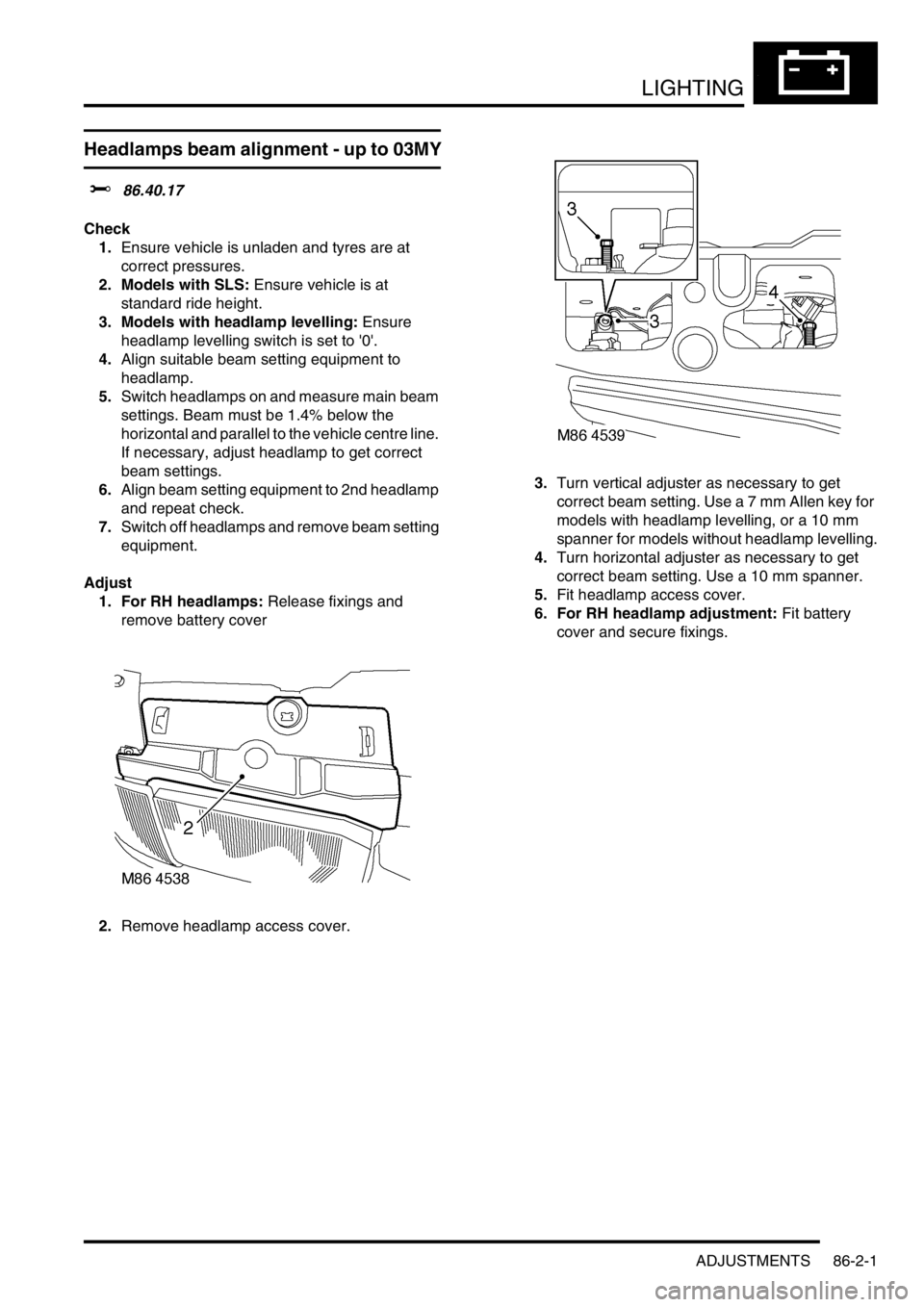

Headlamps beam alignment - up to 03MY

$% 86.40.17

Check

1.Ensure vehicle is unladen and tyres are at

correct pressures.

2. Models with SLS: Ensure vehicle is at

standard ride height.

3. Models with headlamp levelling: Ensure

headlamp levelling switch is set to '0'.

4.Align suitable beam setting equipment to

headlamp.

5.Switch headlamps on and measure main beam

settings. Beam must be 1.4% below the

horizontal and parallel to the vehicle centre line.

If necessary, adjust headlamp to get correct

beam settings.

6.Align beam setting equipment to 2nd headlamp

and repeat check.

7.Switch off headlamps and remove beam setting

equipment.

Adjust

1. For RH headlamps: Release fixings and

remove battery cover

2.Remove headlamp access cover.3.Turn vertical adjuster as necessary to get

correct beam setting. Use a 7 mm Allen key for

models with headlamp levelling, or a 10 mm

spanner for models without headlamp levelling.

4.Turn horizontal adjuster as necessary to get

correct beam setting. Use a 10 mm spanner.

5.Fit headlamp access cover.

6. For RH headlamp adjustment: Fit battery

cover and secure fixings.

Page 1457 of 1672

LIGHTING

86-2-2 ADJUSTMENTS

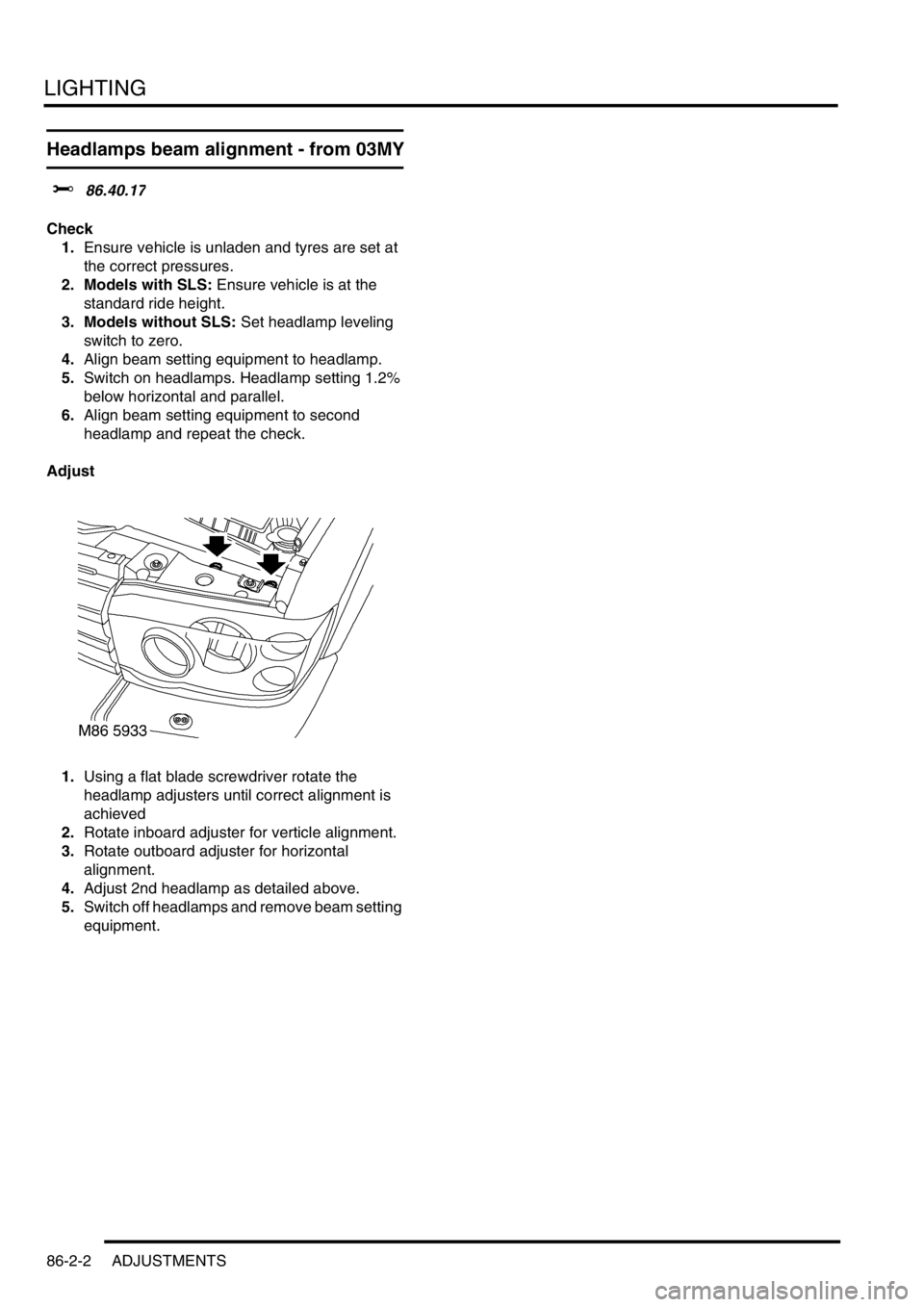

Headlamps beam alignment - from 03MY

$% 86.40.17

Check

1.Ensure vehicle is unladen and tyres are set at

the correct pressures.

2. Models with SLS: Ensure vehicle is at the

standard ride height.

3. Models without SLS: Set headlamp leveling

switch to zero.

4.Align beam setting equipment to headlamp.

5.Switch on headlamps. Headlamp setting 1.2%

below horizontal and parallel.

6.Align beam setting equipment to second

headlamp and repeat the check.

Adjust

1.Using a flat blade screwdriver rotate the

headlamp adjusters until correct alignment is

achieved

2.Rotate inboard adjuster for verticle alignment.

3.Rotate outboard adjuster for horizontal

alignment.

4.Adjust 2nd headlamp as detailed above.

5.Switch off headlamps and remove beam setting

equipment.