oil LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 236 of 1672

ENGINE - TD5

OVERHAUL 12-1-97

8. Remove and discard big-end bearing shell

from connecting rod.

NOTE: Engine Serial No. Prefixes 10P to 14P:–

The 'sputter type' connecting rod bearing shells

fitted to these engines, identified by them

having a slightly darker colour than the bearing

cap shells should be replaced with the 'plain

type' bearing shells fitted to Engine Serial No.

Prefixes 15P to 19P.

9.Repeat above procedures for remaining big-

end bearings. Keep bearing caps in their

fitted order.

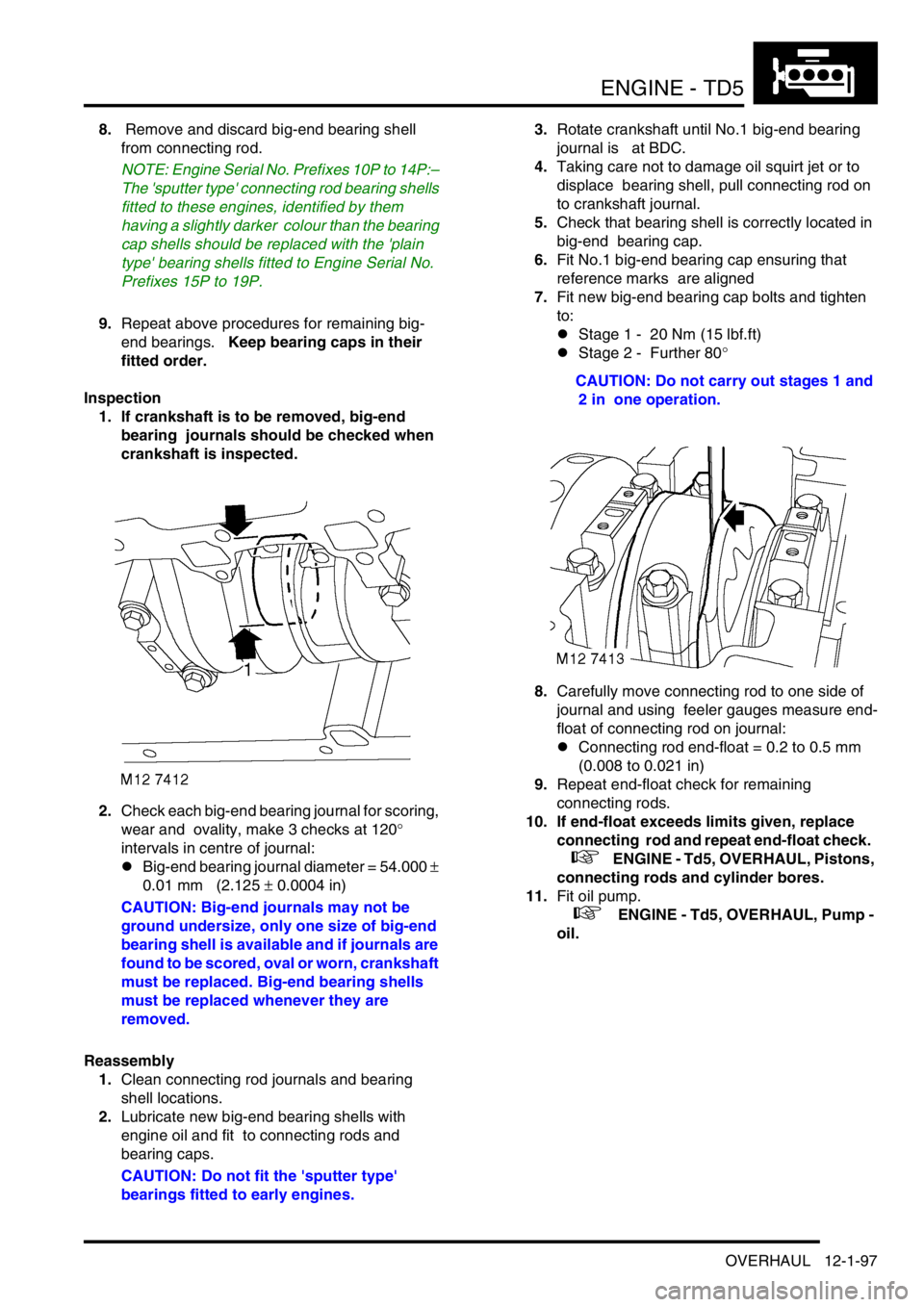

Inspection

1. If crankshaft is to be removed, big-end

bearing journals should be checked when

crankshaft is inspected.

2.Check each big-end bearing journal for scoring,

wear and ovality, make 3 checks at 120

°

intervals in centre of journal:

lBig-end bearing journal diameter = 54.000

±

0.01 mm (2.125

± 0.0004 in)

CAUTION: Big-end journals may not be

ground undersize, only one size of big-end

bearing shell is available and if journals are

found to be scored, oval or worn, crankshaft

must be replaced. Big-end bearing shells

must be replaced whenever they are

removed.

Reassembly

1.Clean connecting rod journals and bearing

shell locations.

2.Lubricate new big-end bearing shells with

engine oil and fit to connecting rods and

bearing caps.

CAUTION: Do not fit the 'sputter type'

bearings fitted to early engines.3.Rotate crankshaft until No.1 big-end bearing

journal is at BDC.

4.Taking care not to damage oil squirt jet or to

displace bearing shell, pull connecting rod on

to crankshaft journal.

5.Check that bearing shell is correctly located in

big-end bearing cap.

6.Fit No.1 big-end bearing cap ensuring that

reference marks are aligned

7.Fit new big-end bearing cap bolts and tighten

to:

lStage 1 - 20 Nm (15 lbf.ft)

lStage 2 - Further 80

°

CAUTION: Do not carry out stages 1 and

2 in one operation.

8.Carefully move connecting rod to one side of

journal and using feeler gauges measure end-

float of connecting rod on journal:

lConnecting rod end-float = 0.2 to 0.5 mm

(0.008 to 0.021 in)

9.Repeat end-float check for remaining

connecting rods.

10. If end-float exceeds limits given, replace

connecting rod and repeat end-float check.

+ ENGINE - Td5, OVERHAUL, Pistons,

connecting rods and cylinder bores.

11.Fit oil pump.

+ ENGINE - Td5, OVERHAUL, Pump -

oil.

Page 237 of 1672

ENGINE - TD5

12-1-98 OVERHAUL

Pistons, connecting rods and cylinder

bores

$% 12.17.02.03

Disassembly

1.Remove cylinder head gasket.

+ ENGINE - Td5, OVERHAUL, Gasket

- cylinder head.

2.Remove connecting rod bearings.

+ ENGINE - Td5, OVERHAUL,

Bearings - connecting rods.

3.Remove ridge of carbon from top of cylinder

bore.

4.Suitably identify each piston and connecting

rod assembly to its respective cylinder bore.

5.Carefully push connecting rod to top of cylinder

bore taking care that connecting rod does not

contact oil squirt jet or cylinder wall; remove

each piston and connecting rod in turn.

6.Using a suitable expander, remove and discard

piston rings from pistons.

7.Clean carbon from piston crown and skirt. Do

not use abrasives on graphited area of

piston skirt, do not use a wire brush or

scraper on any part of pistons.

8.Secure connecting rod in a soft jawed vice.

9.Suitably identify each piston to its connecting

rod and fitted position of piston on rod.

10.Using suitable circlip pliers, remove and

discard 2 circlips securing gudgeon pin.

11.Push gudgeon pin out of piston and connecting

rod; remove piston.

12.Suitably identify each gudgeon pin to its

respective piston.

13.Repeat above procedures for remaining

pistons. Inspect

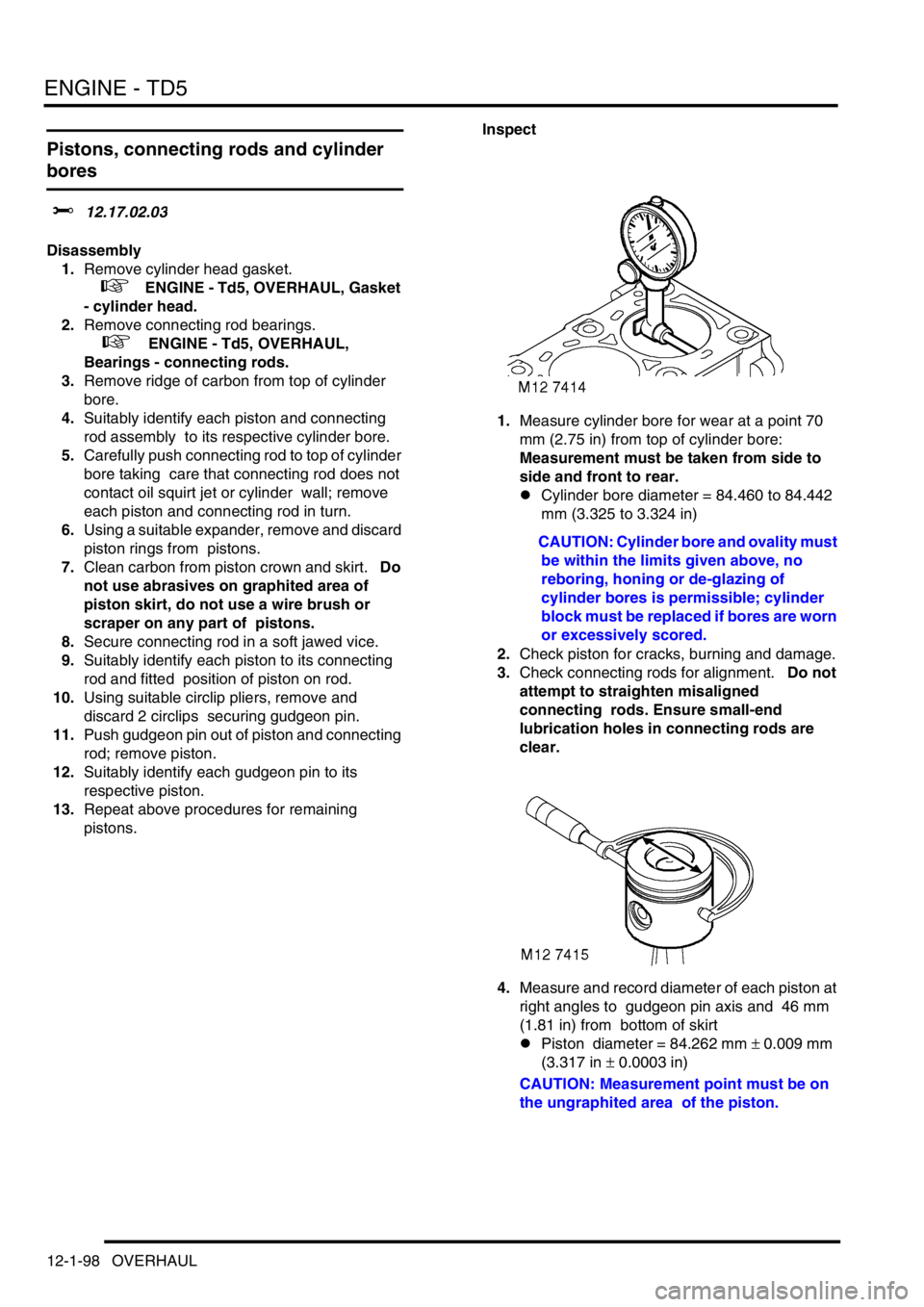

1.Measure cylinder bore for wear at a point 70

mm (2.75 in) from top of cylinder bore:

Measurement must be taken from side to

side and front to rear.

lCylinder bore diameter = 84.460 to 84.442

mm (3.325 to 3.324 in)

CAUTION: Cylinder bore and ovality must

be within the limits given above, no

reboring, honing or de-glazing of

cylinder bores is permissible; cylinder

block must be replaced if bores are worn

or excessively scored.

2.Check piston for cracks, burning and damage.

3.Check connecting rods for alignment. Do not

attempt to straighten misaligned

connecting rods. Ensure small-end

lubrication holes in connecting rods are

clear.

4.Measure and record diameter of each piston at

right angles to gudgeon pin axis and 46 mm

(1.81 in) from bottom of skirt

lPiston diameter = 84.262 mm

± 0.009 mm

(3.317 in

± 0.0003 in)

CAUTION: Measurement point must be on

the ungraphited area of the piston.

Page 239 of 1672

ENGINE - TD5

12-1-100 OVERHAUL

12.Insert new compression and oil control rings in

turn into No.1 cylinder bore 30 mm (1.25 in)

from top of bore and check ring fitted gaps;

ensure rings are kept square to bore when

checking gaps:

l1st compression ring fitted gap = 0.30 to

0.40 mm (0.012 to 0.016 in).

l2nd compression ring fitted gap = 0.40 to

0.60 mm (0.016 to 0.024 in).

lOil control ring fitted gap = 0.25 to 0.50 mm

0.01 to 0.02 in).

CAUTION: 1st compression rings fitted to

Engine Serial No. Prefixes 10P to 14P are

not interchangeable with those fitted to

Engine Serial No. Prefixes 15P to 19P. The

later rings may, however, be fitted to early

engines together with the later type pistons

in engine sets only.

13.Repeat for each cylinder bore in turn.

CAUTION: Ensure rings are suitably

identified with the cylinder bore in which

they were checked and are fitted to the

piston for that bore.

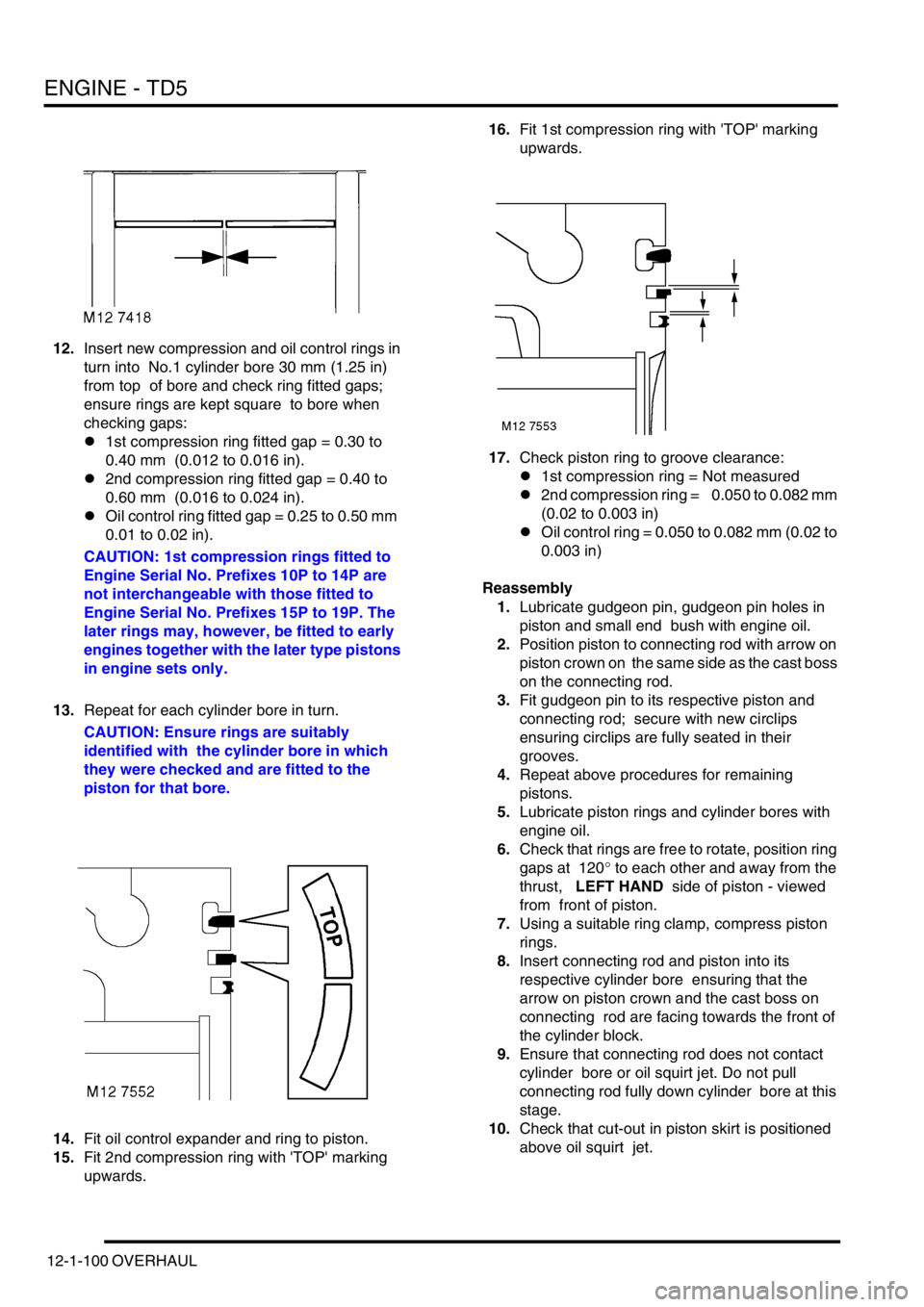

14.Fit oil control expander and ring to piston.

15.Fit 2nd compression ring with 'TOP' marking

upwards. 16.Fit 1st compression ring with 'TOP' marking

upwards.

17.Check piston ring to groove clearance:

l1st compression ring = Not measured

l2nd compression ring = 0.050 to 0.082 mm

(0.02 to 0.003 in)

lOil control ring = 0.050 to 0.082 mm (0.02 to

0.003 in)

Reassembly

1.Lubricate gudgeon pin, gudgeon pin holes in

piston and small end bush with engine oil.

2.Position piston to connecting rod with arrow on

piston crown on the same side as the cast boss

on the connecting rod.

3.Fit gudgeon pin to its respective piston and

connecting rod; secure with new circlips

ensuring circlips are fully seated in their

grooves.

4.Repeat above procedures for remaining

pistons.

5.Lubricate piston rings and cylinder bores with

engine oil.

6.Check that rings are free to rotate, position ring

gaps at 120

° to each other and away from the

thrust, LEFT HAND side of piston - viewed

from front of piston.

7.Using a suitable ring clamp, compress piston

rings.

8.Insert connecting rod and piston into its

respective cylinder bore ensuring that the

arrow on piston crown and the cast boss on

connecting rod are facing towards the front of

the cylinder block.

9.Ensure that connecting rod does not contact

cylinder bore or oil squirt jet. Do not pull

connecting rod fully down cylinder bore at this

stage.

10.Check that cut-out in piston skirt is positioned

above oil squirt jet.

Page 241 of 1672

ENGINE - TD5

12-1-102 OVERHAUL

Crankshaft

$% 12.21.33.01

Disassembly

1.Remove timing chain and sprockets.

+ ENGINE - Td5, OVERHAUL, Timing

chain and sprockets.

2.Remove crankshaft rear oil seal.

+ ENGINE - Td5, OVERHAUL, Seal -

crankshaft - rear - manual models.

3.Remove connecting rod bearings.

+ ENGINE - Td5, OVERHAUL,

Bearings - connecting rods.

4.Check that cylinder reference number is on

each main bearing cap and make alignment

marks between each main bearing cap and

cylinder block.

5.Starting at No.3 main bearing cap and working

outwards, progressively loosen, then remove 2

bolts securing each cap. Discard main bearing

cap bolts. 6.Fit 2 slave bolts into main bearing cap in turn

and ease bearing caps from cylinder block.

7.Remove and discard plain bearing shells from

each main bearing cap.

8.Using assistance, remove crankshaft.

9.Remove and discard grooved main bearing

shells and 2 thrust washers from cylinder

block.

10.Remove Torx screw securing each oil squirt jet

to cylinder block, remove squirt jets.

11.Clean main bearing shell and thrust washer

locations in cylinder block, ensure bolt holes

are clean and dry.

12.Clean main bearing caps.

13.Clean crankshaft bearing journals, check

oilways are clear.

14.Ensure drillings in oil squirt jets are clear.

Page 242 of 1672

ENGINE - TD5

OVERHAUL 12-1-103

15.Check core plugs in cylinder block for corrosion

or signs of leakage, seal replacement plugs

with Loctite 243.

Crankshaft - Inspection

1.Check crankshaft main and big-end bearings

for scoring, wear and ovality, make 3 checks at

120

° intervals in centre of journals.

lMain bearings = 62.0 mm

± 0.013 mm

(2.441 in

± 0.001 in).

lBig-end bearings = 54.000 mm

± 0.01 mm

(2.125 in

± 0.0004 in).

2. Crankshafts may not be reground, only one

size of main and big-end bearing shell is

available and if journals are found to be

scored, oval or worn, crankshaft must be

replaced. Main and big-end bearing shells

and thrust washers must be replaced

whenever they are removed.

3.Check crankshaft spigot bush for wear, replace

if necessary using the following procedures:

4.Secure crankshaft in a suitably padded vice.

5.Tap a thread in spigot bush to accommodate a

suitable impulse extractor.

6.Fit impulse extractor to spigot bush.

7.Remove spigot bush.

8.Clean spigot bush recess in crankshaft.

9.Fit new spigot bush to crankshaft using a

suitable mandrel. Reassembly

1.Fit oil squirt jets, fit Torx screws and tighten to

8 Nm (6 lbf.ft).

2.Lubricate new, grooved, main bearing shells

with engine oil and fit to cylinder block.

3.Lubricate new thrust washers with engine oil

and fit, grooved side facing outward, to recess

in each side of No.3 main bearing in cylinder

block.

4.Lubricate crankshaft journals with engine oil

and using assistance, position crankshaft in

cylinder block.

5.Lubricate new, plain, main bearing shells with

engine oil and fit to main bearing caps.

6.Fit main bearing caps in their original fitted

positions ensuring reference marks are

aligned.

7.Fit and lightly tighten new main bearing cap

bolts. Do not lubricate bolt threads.

8.Starting with No.3 main bearing cap and

working outwards, tighten main bearing cap

bolts to:

lStage 1 - 33 Nm (24 lbf.ft)

lStage 2 - Further 90

°

CAUTION: Do not carry out stages 1 and

2 in one operation.

9.Check that crankshaft rotates smoothly.

10. Attach a magnetic base DTI to front of cylinder

block with stylus of gauge on end of crankshaft.

Page 243 of 1672

ENGINE - TD5

12-1-104 OVERHAUL

11.Using suitably padded levers, move crankshaft

rearwards and zero DTI.

12.Move crankshaft forwards and note end-float

reading on gauge:

lCrankshaft end-float = 0.02 to 0.025 mm

(0.001 to 0.11 in)

CAUTION: Oversize thrust washers are

not available, if end-float exceeds figure

given, crankshaft must be replaced.

13.Remove DTI.

14.Fit connecting rod bearings.

+ ENGINE - Td5, OVERHAUL,

Bearings - connecting rods.

15.Fit timing chain and sprockets.

+ ENGINE - Td5, OVERHAUL, Timing

chain and sprockets.

16.Fit crankshaft rear oil seal.

+ ENGINE - Td5, OVERHAUL, Seal -

crankshaft - rear - manual models.

Page 246 of 1672

ENGINE - V8

DESCRIPTION AND OPERATION 12-2-3

1Split pin

2Washers

3Spring

4Rocker arm

5Pedestal bolt

6Pedestal

7Push rod

8Hydraulic tappet

9Rocker shaft

10Cylinder head - left hand

11Gasket - rocker cover

12Rocker cover - left hand

13Bolt - rocker cover

14Valve spring cap

15Valve stem oil seals

16Collets

17Valve spring18Bolt - engine lifting bracket

19Engine lifting bracket

20Valve seat insert

21Exhaust valve

22Clamp - inlet manifold gasket

23Seal - inlet manifold gasket

24Bolt - inlet manifold gasket clamp

25Gasket - inlet manifold

26Inlet valve

27Gasket - cylinder head

28Gasket - exhaust manifold

29Cylinder head - right hand

30Spark plug

31Bolt - cylinder head

32Valve guide

33Rocker cover - right hand

34Engine oil filler cap

Page 248 of 1672

ENGINE - V8

DESCRIPTION AND OPERATION 12-2-5

1Core plugs

2Cylinder block

3Camshaft

4Dipstick tube, clamp and bolt

5Woodruff key

6Timing chain

7Camshaft timing gear

8Washer

9Bolt - camshaft timing gear

10Thrust plate - camshaft end-float

11Bolt - camshaft thrust plate

12Gasket - timing cover

13Timing cover

14Oil pressure switch

15Bolt

16Crankshaft front oil seal

17Oil filter element

18Crankshaft front pulley

19Washer

20Bolt - crankshaft front pulley

21Upper main bearing shell

22Upper centre main bearing shell and thrust

washer

23Crankshaft

24Woodruff key

25Crankshaft timing gear

26Lower main bearing shells

27Numbers 1, 2 and 3 main bearing caps

28Bolt - main bearing caps

29Oil pick-up pipe and strainer

30'O' ring31Bolt - oil pick-up pipe

32Gasket - sump

33Sump

34Bolt - sump

35Sump oil drain plug

36Sealing washer

37Spacer, washers and nut - oil pick-up pipe

38Number 4 main bearing cap

39Bolt - connecting rod big-end bearing cap

40Connecting rod big-end bearing shell - lower

41Connecting rod big-end bearing cap

42Number 5 - rear main bearing cap

43Cruciform seal - rear main bearing cap

44Number 5 - rear main bearing shell

45Crankshaft rear oil seal

46Crankshaft knock sensor

47Side bolt - main bearing cap

48Side Allen bolt - main bearing cap

49Dowty washers

50Connecting rod big-end bearing shell - upper

51Connecting rod

52Piston

53Gudgeon pin

54Oil control ring

55Top compression ring

562nd compression ring

57Flywheel/drive plate and starter ring gear

58Bolt - flywheel/drive plate

Page 249 of 1672

ENGINE - V8

12-2-6 DESCRIPTION AND OPERATION

Description

General

The V8 petrol engine is an eight cylinder, water cooled unit having two banks of four cylinders positioned at 90 degrees

to each other. The engine comprises five main castings - two cylinder heads, cylinder block, timing cover and the oil

sump, all of which are manufactured from aluminium alloy.

NAS market vehicles from 03 model year receive a 4.6 litre version of the V8 engine to replace the previous 4.0 litre

version.

Cylinder heads

The cylinder heads are fitted with replaceable valve guides and valve seat inserts with the combustion chambers

formed in the head. Each cylinder head is sealed to the cylinder block with a gasket. The exhaust manifolds are bolted

to the outside of each cylinder head whilst the inlet manifolds are located in the centre of the 'Vee' and are bolted to

the inside face of each head. Inlet and exhaust manifolds are sealed to the cylinder heads by means of gaskets.

Each cylinder has a single inlet and exhaust valve. The exhaust valves are of the 'carbon break' type, a recess on the

valve stem prevents a build-up of carbon in the valve guide by dislodging particles of carbon as the valve stem moves

up and down the guide. Inlet and exhaust valve stem oil seals are fitted at the top of each valve guide. Valve operation

is by means of rocker arms, push rods and hydraulic tappets. Each of the rocker arms is located on a rocker shaft

which is supported by means of pedestals bolted to the cylinder heads. A spring, positioned on either side of each

rocker arm, maintains the correct relative position of the arm to its valve stem. The rocker arms are operated directly

by the push rods which pass through drillings in the cylinder heads and cylinder block. The bottom end of each push

rod locates in a hydraulic tappet operated by the single, chain driven camshaft.

The rocker covers are bolted to the cylinder heads and are sealed to the heads by a rubber gasket. Stub pipes for

crankcase ventilation hose connections are fitted to each rocker cover, the pipe in the right hand cover incorporates

an oil separator. The engine oil filler cap is situated in the right hand cover.

Cylinder block and camshaft

The cylinder block is fitted with cast iron cylinder liners which are shrink fitted and locate on stops in the block. The

camshaft is positioned in the centre of the cylinder block and runs in one piece bearing shells which are line bored

after fitting. Camshaft end-float is controlled by a thrust plate bolted to the front of the cylinder block. A timing gear,

chain driven by the crankshaft timing gear is bolted to the front of the camshaft.

Crankshaft and main bearings

The crankshaft is carried in five main bearings. The upper main bearing shell locations are an integral part of the

cylinder block casting. The lower main bearing caps are bolted to the cylinder block on either side of the upper bearing

shell locations with an additional bolt being inserted into each cap from either side of the cylinder block. The rear

main bearing cap carries the crankshaft rear oil seal and is sealed to the cylinder block by means of cruciform shaped

seals in each side of the cap. Number four main bearing cap carries the stud fixing for the oil pick-up pipe. Lower

main bearing shells are plain whilst the upper shells have an oil feed hole and are grooved. Crankshaft end-float is

controlled by the thrust faces of the upper centre shell. The crankshaft timing gear is located on the front of the

crankshaft by means of a Woodruff key which is also used to drive the gear type oil pump. The flywheel/drive plate

carries the crankshaft position sensor reluctor ring and is dowel located and bolted to the flywheel.

Timing cover

The timing cover is bolted to the front of the cylinder block and is sealed to the block with a gasket. The disposable,

full flow oil filter canister is screwed on to the timing cover which also carries the oil pressure switch, oil pressure relief

valve and crankshaft front oil seal. The gear type oil pump is integral with the cover which also has an internal oilway

to direct oil from the oil cooler to the filter.

NOTE: Oil coolers are only fitted to vehicles up to VIN 756821.

Page 250 of 1672

ENGINE - V8

DESCRIPTION AND OPERATION 12-2-7

Oil sump

The oil sump is bolted to the bottom of the cylinder block and the timing cover and is sealed to both components with

a one piece gasket. A removable baffle to prevent oil surge is fitted in the sump. The oil pick-up pipe and strainer

assembly is positioned within the sump and is attached at the pick-up end to a stud screwed into number four main

bearing cap and at the delivery end to the oil pump. The oil drain plug is located in the bottom of the sump and is

sealed with a washer.

Pistons and connecting rods

Each of the aluminium alloy pistons has two compression rings and an oil control ring. The pistons are secured to the

connecting rods by semi-floating gudgeon pins. Each gudgeon pin is offset by 0.5 mm (0.02 in). The top of each piston

is recessed, the depth of recess determining the compression ratio of the engine. Plain, big-end bearing shells are

fitted to each connecting rod and cap.