sensor LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 579 of 1672

FUEL DELIVERY SYSTEM - V8

19-2-14 REPAIRS

8.Remove 2 trim clips securing RH side trim

casing to body.

9.Remove rear lamp access panel from RH side

trim casing.

10.Remove trim clip securing RH side trim casing

to lower 'E' post.

11. Models with third row seats: Remove bolt

securing lower mounting of third row seat belt to

body.

12.Remove RH side trim casing.

13.Pull back loadspace carpet from fuel pump

access panel.

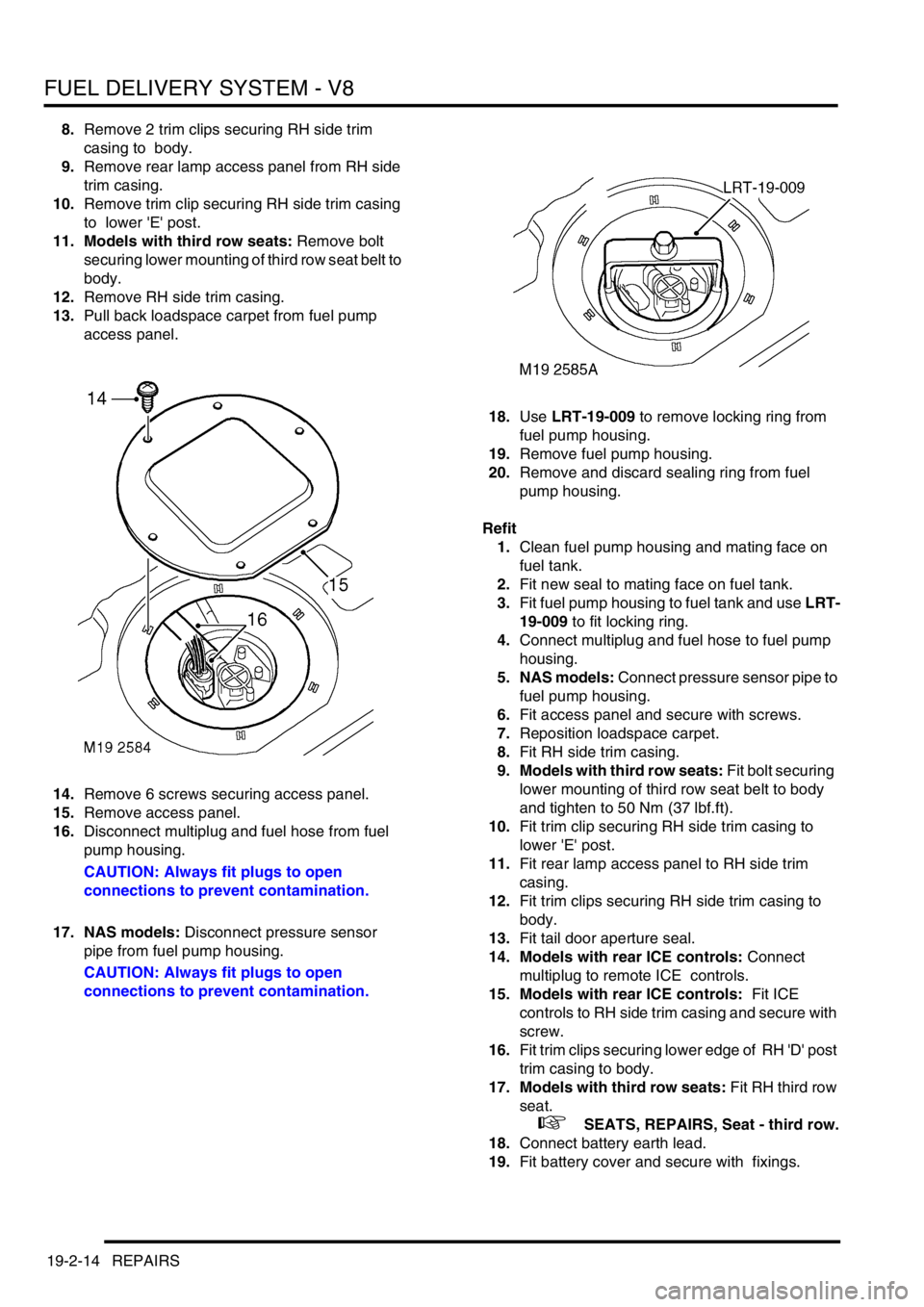

14.Remove 6 screws securing access panel.

15.Remove access panel.

16.Disconnect multiplug and fuel hose from fuel

pump housing.

CAUTION: Always fit plugs to open

connections to prevent contamination.

17. NAS models: Disconnect pressure sensor

pipe from fuel pump housing.

CAUTION: Always fit plugs to open

connections to prevent contamination.18.Use LRT-19-009 to remove locking ring from

fuel pump housing.

19.Remove fuel pump housing.

20.Remove and discard sealing ring from fuel

pump housing.

Refit

1.Clean fuel pump housing and mating face on

fuel tank.

2.Fit new seal to mating face on fuel tank.

3.Fit fuel pump housing to fuel tank and use LRT-

19-009 to fit locking ring.

4.Connect multiplug and fuel hose to fuel pump

housing.

5. NAS models: Connect pressure sensor pipe to

fuel pump housing.

6.Fit access panel and secure with screws.

7.Reposition loadspace carpet.

8.Fit RH side trim casing.

9. Models with third row seats: Fit bolt securing

lower mounting of third row seat belt to body

and tighten to 50 Nm (37 lbf.ft).

10.Fit trim clip securing RH side trim casing to

lower 'E' post.

11.Fit rear lamp access panel to RH side trim

casing.

12.Fit trim clips securing RH side trim casing to

body.

13.Fit tail door aperture seal.

14. Models with rear ICE controls: Connect

multiplug to remote ICE controls.

15. Models with rear ICE controls: Fit ICE

controls to RH side trim casing and secure with

screw.

16.Fit trim clips securing lower edge of RH 'D' post

trim casing to body.

17. Models with third row seats: Fit RH third row

seat.

+ SEATS, REPAIRS, Seat - third row.

18.Connect battery earth lead.

19.Fit battery cover and secure with fixings.

Page 581 of 1672

FUEL DELIVERY SYSTEM - V8

19-2-16 REPAIRS

Filler tube - fuel

$% 19.55.07

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Ensure fuel tank is less than half full. If not,

drain fuel tank to less than half full.

+ FUEL DELIVERY SYSTEM - V8,

ADJUSTMENTS, Fuel tank - drain.

3.Remove filler cap.

Non NAS installation

4.Drill out rivet securing lower part of mud flap

support bracket and release bracket .

5. All except NAS models: Disconnect filler

hose, breather hose and vent pipe from filler

tube.

NAS installation

6. NAS models: Loosen securing clip and

release filler tube from fuel tank.7. NAS models: Disconnect vent pipes from filler

tube.

8. Release filler tube from grommet in body and

remove from under rear wing. Collect grommet.

9. NAS models: Remove cable tie securing

pressure sensor pipe to filler tube and remove

filler tube.

Refit

1. NAS models: Position filler tube to pressure

sensor pipe and secure with new cable tie.

2. Fit grommet to body, position filler tube under

rear wing and secure in grommet.

3. NAS models: Connect filler tube to fuel tank

and secure with clip. Connect vent pipes to filler

tube.

4. All except NAS models: Connect filler hose

and breather hose to filler tube and secure with

clips. Connect vent pipe to filler tube.

5. Position support bracket to mud flap and

secure with new rivet.

6.If applicable, refill fuel tank with extracted fuel.

7.Fit filler cap.

8.Remove stand(s) and lower vehicle.

Page 586 of 1672

COOLING SYSTEM - TD5

DESCRIPTION AND OPERATION 26-1-3

1Pressure cap

2Overflow pipe

3Heater return hose

4Heater matrix

5Heater inlet hose

6Oil cooler return pipe — EU3 models

7Connecting hose

8Oil cooler housing assembly

9Heater inlet pipe

10Connecting hose

11Outlet housing

12Engine Coolant Temperature (ECT) sensor

13Bleed screw

14Radiator top hose

15Radiator - upper

16Intercooler

17Gearbox oil cooler

18Radiator - lower

19Viscous fan

20Drain plug21Connecting hose

22Fuel cooler feed hose

23Radiator bottom hose

24Thermostat housing

25Connecting hose

26Coolant pump feed pipe

27Coolant by-pass pipe

28Radiator bleed pipe

29Connecting hose

30Coolant pump

31Fuel cooler

32Heater/expansion tank return hose

33Expansion tank

34EGR Cooler - EU3 models

35Connecting hose - EU3 models

36Connecting hose - EU3 models

37Hose - EGR Cooler to oil cooler return pipe -

EU3 models

38Radiator lower feed hose - Pre EU3 models

39Oil cooler return pipe - Pre EU3 models

Page 589 of 1672

COOLING SYSTEM - TD5

26-1-6 DESCRIPTION AND OPERATION

Outlet housing

A cast aluminium outlet housing is attached to the cylinder head with three bolts and sealed with a gasket. Coolant

leaves the engine through the outlet housing and is directed through a hose to the heater matrix, the radiator or the

by-pass circuit.

An Engine Coolant Temperature (ECT) sensor is installed in a threaded port on the side of the outlet housing. The

sensor monitors coolant temperature emerging from the engine and sends signals to the Engine Control Module

(ECM) for engine management and temperature gauge operation.

+ ENGINE MANAGEMENT SYSTEM - Td5, DESCRIPTION AND OPERATION, Description.

Expansion tank

The expansion tank is located in the engine compartment. The tank is made from moulded plastic and attached to

brackets on the right hand inner wing. A maximum coolant when cold level is moulded onto the tank.

Excess coolant created by heat expansion is returned to the expansion tank from the radiator bleed pipe at the top of

the radiator. An outlet pipe is connected into the coolant pump feed hose and replaces the coolant displaced by heat

expansion into the system when the engine is cool.

The expansion tank is fitted with a sealed pressure cap. The cap contains a pressure relief valve which opens to allow

excessive pressure and coolant to vent through the overflow pipe. The relief valve is open at a pressure of 1.4 bar (20

lbf.in

2) and above.

Heater matrix

The heater matrix is fitted in the heater assembly inside the passenger compartment. Two pipes pass through the

bulkhead into the engine compartment and provide coolant flow to and from the matrix. The pipes from the bulkhead

are connected to the matrix, sealed with 'O' rings and clamped with circular rings.

The matrix is constructed from aluminium with two end tanks interconnected with tubes. Aluminium fins are located

between the tubes and conduct heat from the hot coolant flowing through the tubes. Air from the heater assembly is

warmed as it passes through the matrix fins. The warm air is then distributed in to the passenger compartment as

required.

+ HEATING AND VENTILATION, DESCRIPTION AND OPERATION, Description.

When the engine is running, coolant from the engine is constantly circulated through the heater matrix.

Radiator

The 44 row radiator is located at the front of the vehicle in the engine compartment. The cross flow type radiator is

manufactured from aluminium with moulded plastic end tanks interconnected with tubes. The bottom four rows are

separate from the upper radiator and form the lower radiator for the fuel cooler. Aluminium fins are located between

the tubes and conduct heat from the hot coolant flowing through the tubes, reducing the coolant temperature as it

flows through the radiator. Air intake from the front of the vehicle when moving carries the heat away from the fins.

When the vehicle is stationary, the viscous fan draws air through the radiator fins to prevent the engine from

overheating.

Two connections at the top of the radiator provide for the attachment of the top hose from the outlet housing and bleed

pipe to the expansion tank. Three connections at the bottom of the radiator allow for the attachment of the bottom

hose to the thermostat housing and the return hose from the oil cooler and the feed hose to the fuel cooler.

The bottom four rows of the lower radiator are dedicated to the fuel cooler. The upper of the two connections at the

bottom of the radiator receives coolant from the oil cooler. This is fed through the four rows of the lower radiator in a

dual pass and emerges at the lower connection. The dual pass lowers the coolant temperature by up to 24

°C before

being passed to the fuel cooler.

Two smaller radiators are located in front of the cooling radiator. The upper radiator is the intercooler for the air intake

system and the lower radiator provides cooling of the gearbox oil.

+ EMISSION CONTROL - Td5, DESCRIPTION AND OPERATION, Emission Control Systems.

+ MANUAL GEARBOX - R380, DESCRIPTION AND OPERATION, Description.

+ AUTOMATIC GEARBOX - ZF4HP22 - 24, DESCRIPTION AND OPERATION, Description.

Page 608 of 1672

COOLING SYSTEM - V8

DESCRIPTION AND OPERATION 26-2-7

Inlet manifold - Cooling connections

Coolant leaves the cylinder block via an outlet pipe attached to the front of the air intake manifold. The pipe is

connected to the thermostat housing and the radiator by a branch hose off the radiator top hose.

Hot coolant from the engine is also directed from the inlet manifold via pipes and hoses into the heater matrix. Coolant

is circulated through the heater matrix at all times when the engine is running.

A further tapping from the inlet manifold supplies coolant to the throttle housing via a hose. The coolant circulates

through a plate attached to the bottom of the housing and is returned through a plastic bleed pipe to an expansion

tank. The hot coolant heats the air intake of the throttle housing preventing ice from forming.

An Engine Coolant Temperature (ECT) sensor is fitted in the inlet manifold adjacent to the manifold outlet pipe. The

sensor monitors coolant temperature emerging from the engine and sends signals to the ECM for engine

management and temperature gauge operation.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

Expansion tank

The expansion tank is located in the engine compartment. The tank is made from moulded plastic and attached to

brackets on the right hand inner wing. A maximum coolant when cold level is moulded onto the tank.

Excess coolant created by heat expansion is returned to the expansion tank from the radiator bleed pipe at the top of

the radiator. An outlet pipe is connected into the pump feed hose and replaces the coolant displaced by heat

expansion into the system when the engine is cool.

The expansion tank is fitted with a sealed pressure cap. The cap contains a pressure relief valve which opens to allow

excessive pressure and coolant to vent through the overflow pipe. The relief valve opens at a pressure of 1.4 bar (20

lbf.in

2) and above.

Heater matrix

The heater matrix is fitted in the heater assembly inside the passenger compartment. Two pipes pass through the

bulkhead into the engine compartment and provide coolant flow to and from the matrix. The pipes from the bulkhead

are connected to the matrix, sealed with 'O' rings and clamped with circular rings.

The matrix is constructed from aluminium with two end tanks interconnected with tubes. Aluminium fins are located

between the tubes and conduct heat away from the hot coolant flowing through the tubes. Air from the heater

assembly is warmed as it passes through the matrix fins. The warm air is then distributed into the passenger

compartment as required.

+ HEATING AND VENTILATION, DESCRIPTION AND OPERATION, Description.When the engine is

running, coolant from the engine is constantly circulated through the heater matrix.

Radiator

The 45 row radiator is located at the front of the vehicle. The cross-flow type radiator is manufactured from aluminium

with moulded plastic end tanks interconnected with tubes. Aluminium fins are located between the tubes and conduct

heat from the hot coolant flowing through the tubes, reducing the cooling temperature as it flows through the radiator.

Air intake from the front of the vehicle when moving carries heat away from the fins. When the vehicle is stationary,

the viscous fan draws air through the radiator fins to prevent the engine from overheating.

Two connections at the top of the radiator provide for the attachment of the top hose and bleed pipe. A connection at

the bottom of the radiator allows for the attachment of the bottom hose to the thermostat housing.

Two smaller radiators are located in front of the cooling radiator. The lower radiator provides cooling of the gearbox

oil and the upper radiator provides cooling for the engine oil.

+ MANUAL GEARBOX - R380, DESCRIPTION AND OPERATION, Description.

+ AUTOMATIC GEARBOX - ZF4HP22 - 24, DESCRIPTION AND OPERATION, Description.

+ ENGINE - V8, DESCRIPTION AND OPERATION, Description.

Page 617 of 1672

COOLING SYSTEM - V8

26-2-16 REPAIRS

8.Remove 6 scrivets and remove LH and RH air

deflectors from front panel. Disconnect

multiplug of gearbox oil temperature sensor

(arrowed).

9.Remove nut and move horn aside. 10.Remove 2 bolts securing radiator LH and RH

upper mounting brackets to body panel and

remove brackets.

11.Remove 4 screws securing air conditioning

condenser LH and RH upper mounting

brackets to condenser.

12.Remove brackets with rubber mounts from

radiator extension brackets.

13.Position absorbent cloth under each cooler

hose to collect oil spillage.

14.Push against coupling release rings and

disconnect hoses from gearbox oil cooler.

CAUTION: Always fit plugs to open

connections to prevent contamination.

15. If fitted: Push against coupling release rings

and disconnect hoses from engine oil cooler.

Page 618 of 1672

COOLING SYSTEM - V8

REPAIRS 26-2-17

16.Remove radiator assembly.

17.Release clip and remove bottom hose from

radiator.

18.Remove 2 bolts and remove extension

brackets from radiator.

19.Remove 2 captive nuts from radiator.

20.Remove 2 screws and remove gearbox oil

cooler from radiator.

21. If fitted: Remove 2 screws and remove engine

oil cooler from radiator.

22.Remove 2 rubber mountings from radiator.

23.Remove sealing strip from bottom of radiator.

24.Remove 2 cowl retaining clips from radiator. Refit

1.Fit cowl retaining clips to radiator.

2.Fit sealing strip to radiator.

3.Fit rubber mountings to radiator.

4.Fit gearbox oil cooler to radiator and secure

with screws.

5. If fitted: Fit engine oil cooler to radiator and

secure with screws.

6.Fit captive nuts to radiator.

7.Fit extension brackets to radiator and secure

with bolts.

8.Fit bottom hose to radiator and secure with clip.

9.Fit radiator and engage lower mountings in

chassis.

10.Ensure connections are clean, then secure

hoses to oil coolers.

11.Fit air conditioning condenser brackets and

secure with screws.

12.Fit radiator upper mounting brackets and

secure with bolts.

13.Fit LH horn and secure with nut.

14.Fit air deflectors and secure with scrivets.

15.Connect multiplug of gearbox oil temperature

sensor.

16.Fit front grille.

+ EXTERIOR FITTINGS, REPAIRS,

Grille - front - up to 03MY.

17.Connect bottom hose to thermostat housing

and secure with clip.

18.Connect top hose to radiator and secure with

clip.

19.Connect bleed hose to radiator and fit clip.

20.Fit lower fan cowl and secure with screws.

21.Fit viscous fan.

+ COOLING SYSTEM - V8, REPAIRS,

Fan - viscous.

22.Top up gearbox oil.

23.Top up engine oil.

24.Refill cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

Page 624 of 1672

MANIFOLDS AND EXHAUST SYSTEMS - TD5

DESCRIPTION AND OPERATION 30-1-3

Description

General

The diesel engine has the inlet manifold attached to the right hand side of the engine and the exhaust manifold

attached to the left hand side of the engine. The inlet manifold directs cooled compressed air from the turbocharger

and intercooler into the cylinders, where it is mixed with fuel from the injectors. Exhaust gases from the exhaust

manifold can also be directed into the inlet manifold via a pipe from the exhaust manifold and an Exhaust Gas

Recirculation (EGR) valve on the inlet manifold. The exhaust manifold allows combustion gases from the cylinders to

leave the engine where they are directed into the exhaust system and turbocharger.

The exhaust system is attached to the turbocharger and is directed along the underside of the vehicle to emit exhaust

gases from a tail pipe at the rear of the vehicle. A silencer is installed midway along the system and a second tail

silencer is located at the rear of the vehicle.

Inlet manifold

The inlet manifold is a one piece aluminium casting. The manifold is secured to the cylinder head with two studs and

flanged nuts and eight flanged bolts. A one piece laminated gasket seals the manifold to the cylinder head.

Four threaded bosses on the manifold provide for the attachment of the fuel cooler. The fuel cooler is secured to the

manifold with four bolts. A boss with two threaded holes allows for the attachment of the combined intake air

temperature/pressure sensor. The sensor is secured to the manifold with two screws and sealed with a gasket.

At the forward end of the manifold, a machined face and four threaded holes provide for the attachment of the EGR

valve. The valve is sealed to the manifold with a gasket.

+ EMISSION CONTROL - Td5, DESCRIPTION AND OPERATION, Emission Control Systems.

Exhaust manifold

The exhaust manifold is made from cast iron. The manifold has five ports, one from each cylinder, which merge into

one flanged outlet connection positioned centrally on the manifold.

The manifold is attached to the cylinder head with ten studs and flanged nuts. A laminated metal gasket seals the

manifold to the cylinder head. The flanged outlet on the manifold provides the attachment for the turbocharger, which

is attached with three studs and flanged nuts and sealed with a metal laminated gasket.

A second flanged outlet, located at the forward end of the manifold, provides attachment for the EGR pipe. The EGR

pipe is secured to the manifold with two cap screws and connected to the EGR valve mounted on the inlet manifold.

There is no gasket used between the pipe and the exhaust manifold.

+ EMISSION CONTROL - Td5, DESCRIPTION AND OPERATION, Emission Control Systems.

Exhaust system

The exhaust system comprises a front pipe, an intermediate pipe which incorporates a silencer and a tail pipe

assembly which also has a silencer. The exhaust system is constructed mainly of 63 mm (2.48 in) diameter extruded

pipe with a 1.5 mm (0.06 in) wall thickness. All pipes are aluminized to resist corrosion and the silencers are fabricated

from stainless steel sheet.

Page 627 of 1672

MANIFOLDS AND EXHAUST SYSTEMS - TD5

30-1-6 REPAIRS

Gasket - inlet manifold

$% 30.15.08

Remove

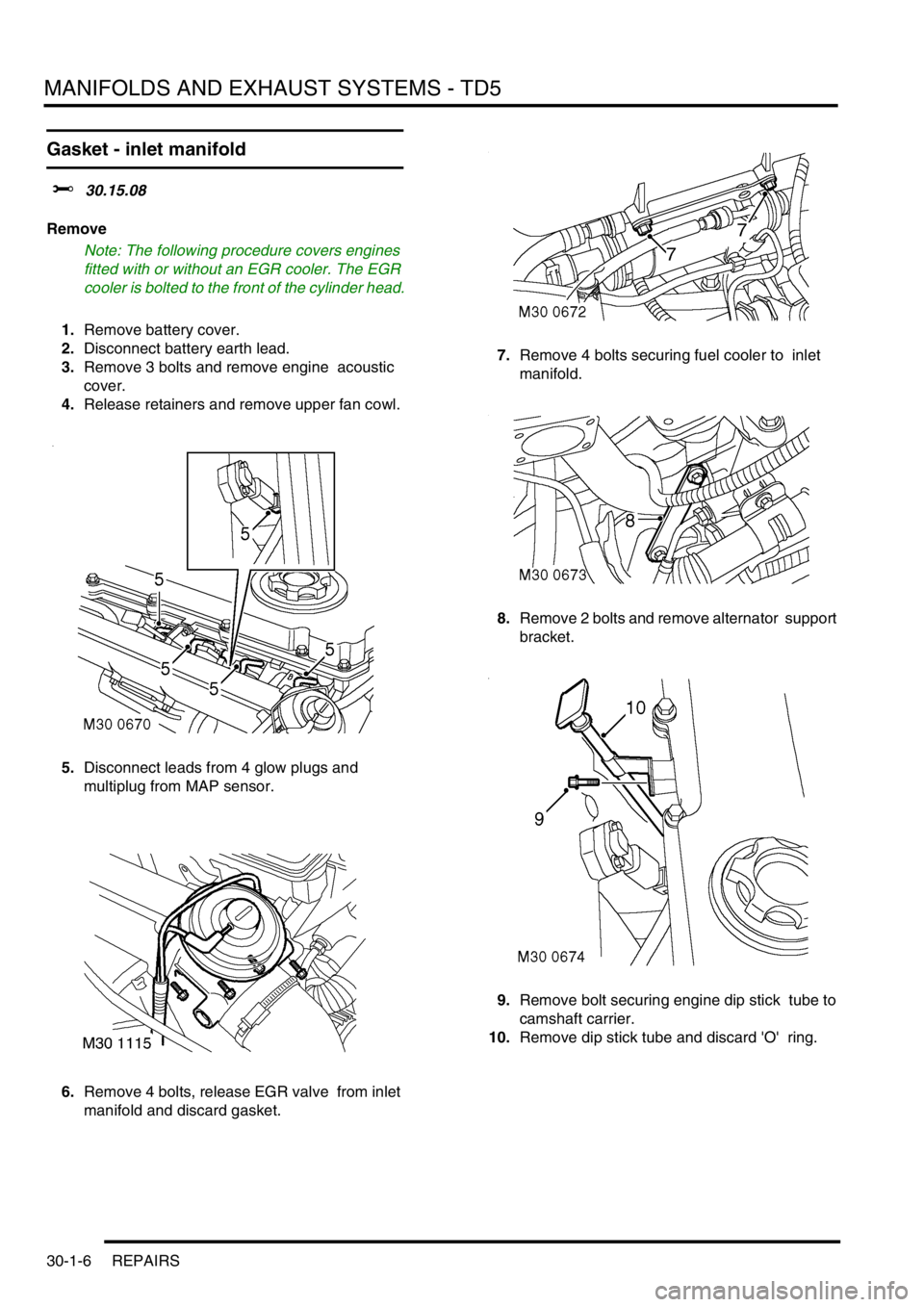

Note: The following procedure covers engines

fitted with or without an EGR cooler. The EGR

cooler is bolted to the front of the cylinder head.

1.Remove battery cover.

2.Disconnect battery earth lead.

3.Remove 3 bolts and remove engine acoustic

cover.

4.Release retainers and remove upper fan cowl.

5.Disconnect leads from 4 glow plugs and

multiplug from MAP sensor.

6.Remove 4 bolts, release EGR valve from inlet

manifold and discard gasket. 7.Remove 4 bolts securing fuel cooler to inlet

manifold.

8.Remove 2 bolts and remove alternator support

bracket.

9.Remove bolt securing engine dip stick tube to

camshaft carrier.

10.Remove dip stick tube and discard 'O' ring.

Page 628 of 1672

MANIFOLDS AND EXHAUST SYSTEMS - TD5

REPAIRS 30-1-7

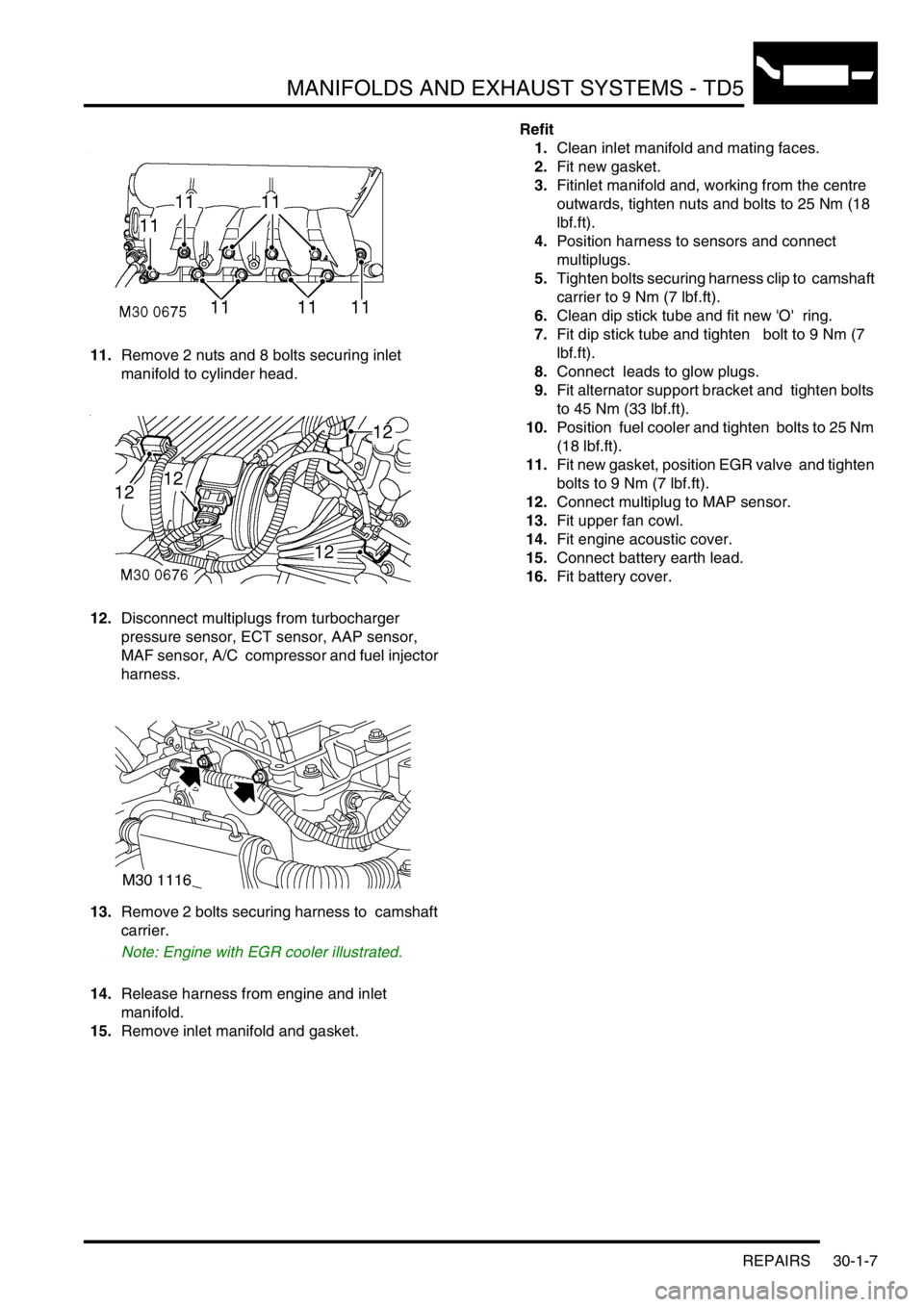

11.Remove 2 nuts and 8 bolts securing inlet

manifold to cylinder head.

12.Disconnect multiplugs from turbocharger

pressure sensor, ECT sensor, AAP sensor,

MAF sensor, A/C compressor and fuel injector

harness.

13.Remove 2 bolts securing harness to camshaft

carrier.

Note: Engine with EGR cooler illustrated.

14.Release harness from engine and inlet

manifold.

15.Remove inlet manifold and gasket. Refit

1.Clean inlet manifold and mating faces.

2.Fit new gasket.

3.Fitinlet manifold and, working from the centre

outwards, tighten nuts and bolts to 25 Nm (18

lbf.ft).

4.Position harness to sensors and connect

multiplugs.

5.Tighten bolts securing harness clip to camshaft

carrier to 9 Nm (7 lbf.ft).

6.Clean dip stick tube and fit new 'O' ring.

7.Fit dip stick tube and tighten bolt to 9 Nm (7

lbf.ft).

8.Connect leads to glow plugs.

9.Fit alternator support bracket and tighten bolts

to 45 Nm (33 lbf.ft).

10.Position fuel cooler and tighten bolts to 25 Nm

(18 lbf.ft).

11.Fit new gasket, position EGR valve and tighten

bolts to 9 Nm (7 lbf.ft).

12.Connect multiplug to MAP sensor.

13.Fit upper fan cowl.

14.Fit engine acoustic cover.

15.Connect battery earth lead.

16.Fit battery cover.