turbo LAND ROVER DISCOVERY 2002 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 178 of 1672

ENGINE - TD5

REPAIRS 12-1-39

Gasket - cylinder head

$% 12.29.02

Remove

Note: The following procedures cover engines

fitted with or without an EGR cooler. The EGR

cooler is bolted to the front of the cylinder head.

1.Remove bonnet.

+ EXTERIOR FITTINGS, REPAIRS,

Bonnet.

2.Release turnbuckles and remove battery cover.

3.Disconnect battery earth lead.

4.Drain cooling system.

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

5.Remove camshaft cover gasket.

+ ENGINE - Td5, REPAIRS, Gasket -

cover - camshaft.

6.Remove cooling fan coupling.

+ COOLING SYSTEM - Td5, REPAIRS,

Fan - viscous.

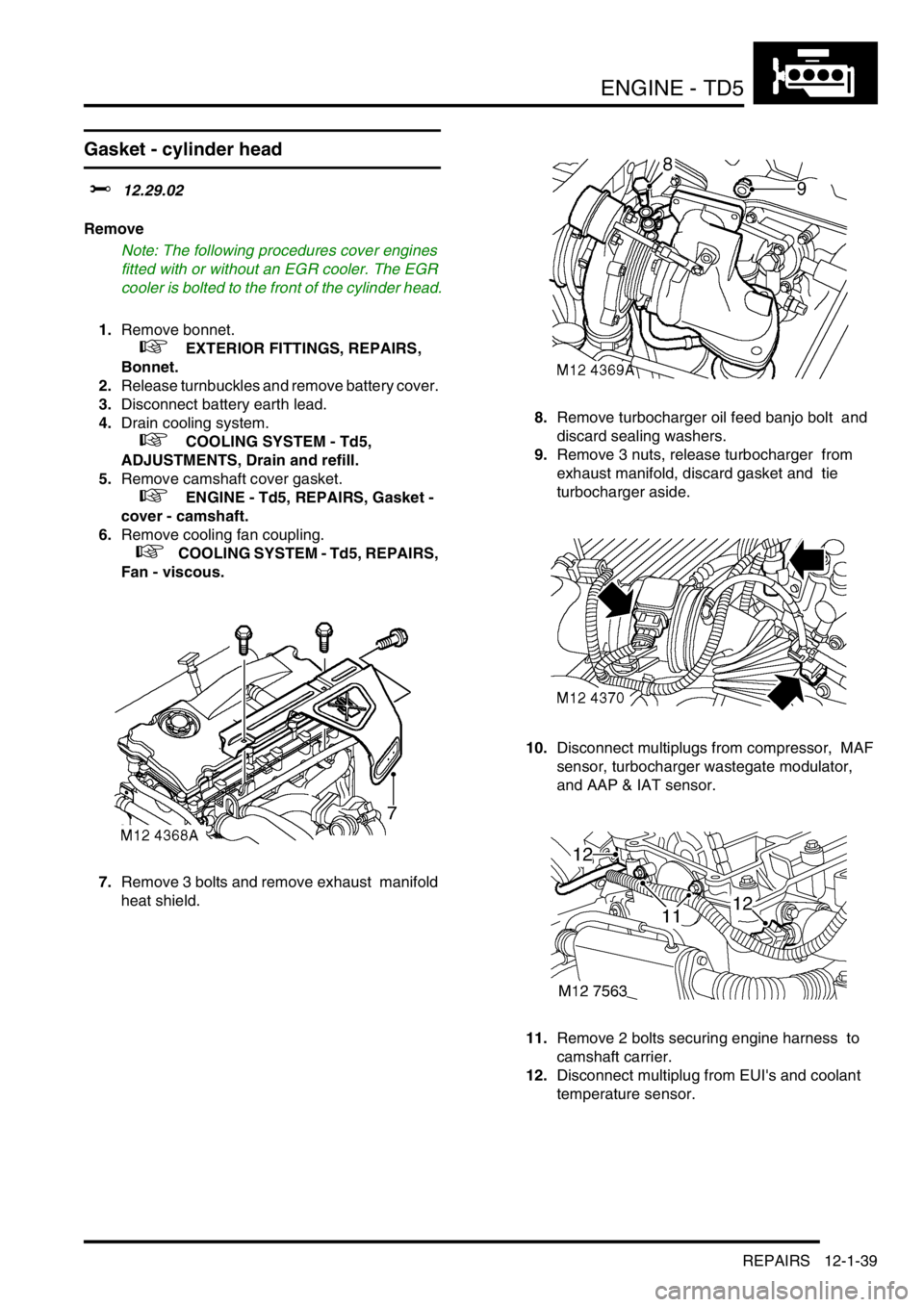

7.Remove 3 bolts and remove exhaust manifold

heat shield. 8.Remove turbocharger oil feed banjo bolt and

discard sealing washers.

9.Remove 3 nuts, release turbocharger from

exhaust manifold, discard gasket and tie

turbocharger aside.

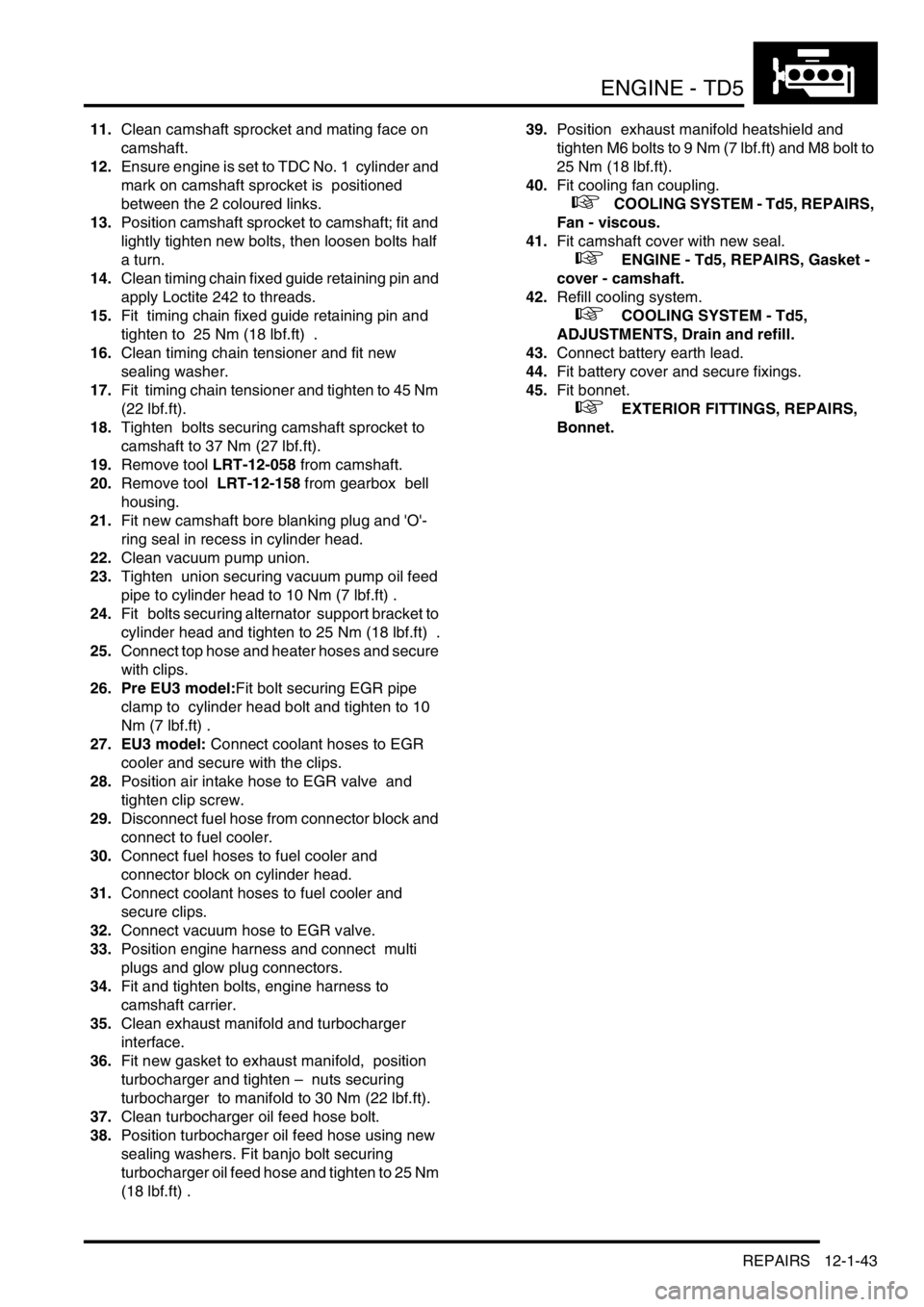

10.Disconnect multiplugs from compressor, MAF

sensor, turbocharger wastegate modulator,

and AAP & IAT sensor.

11.Remove 2 bolts securing engine harness to

camshaft carrier.

12.Disconnect multiplug from EUI's and coolant

temperature sensor.

Page 182 of 1672

ENGINE - TD5

REPAIRS 12-1-43

11.Clean camshaft sprocket and mating face on

camshaft.

12.Ensure engine is set to TDC No. 1 cylinder and

mark on camshaft sprocket is positioned

between the 2 coloured links.

13.Position camshaft sprocket to camshaft; fit and

lightly tighten new bolts, then loosen bolts half

a turn.

14.Clean timing chain fixed guide retaining pin and

apply Loctite 242 to threads.

15.Fit timing chain fixed guide retaining pin and

tighten to 25 Nm (18 lbf.ft) .

16.Clean timing chain tensioner and fit new

sealing washer.

17.Fit timing chain tensioner and tighten to 45 Nm

(22 lbf.ft).

18.Tighten bolts securing camshaft sprocket to

camshaft to 37 Nm (27 lbf.ft).

19.Remove tool LRT-12-058 from camshaft.

20.Remove tool LRT-12-158 from gearbox bell

housing.

21.Fit new camshaft bore blanking plug and 'O'-

ring seal in recess in cylinder head.

22.Clean vacuum pump union.

23.Tighten union securing vacuum pump oil feed

pipe to cylinder head to 10 Nm (7 lbf.ft) .

24.Fit bolts securing alternator support bracket to

cylinder head and tighten to 25 Nm (18 lbf.ft) .

25.Connect top hose and heater hoses and secure

with clips.

26. Pre EU3 model:Fit bolt securing EGR pipe

clamp to cylinder head bolt and tighten to 10

Nm (7 lbf.ft) .

27. EU3 model: Connect coolant hoses to EGR

cooler and secure with the clips.

28.Position air intake hose to EGR valve and

tighten clip screw.

29.Disconnect fuel hose from connector block and

connect to fuel cooler.

30.Connect fuel hoses to fuel cooler and

connector block on cylinder head.

31.Connect coolant hoses to fuel cooler and

secure clips.

32.Connect vacuum hose to EGR valve.

33.Position engine harness and connect multi

plugs and glow plug connectors.

34.Fit and tighten bolts, engine harness to

camshaft carrier.

35.Clean exhaust manifold and turbocharger

interface.

36.Fit new gasket to exhaust manifold, position

turbocharger and tighten – nuts securing

turbocharger to manifold to 30 Nm (22 lbf.ft).

37.Clean turbocharger oil feed hose bolt.

38.Position turbocharger oil feed hose using new

sealing washers. Fit banjo bolt securing

turbocharger oil feed hose and tighten to 25 Nm

(18 lbf.ft) . 39.Position exhaust manifold heatshield and

tighten M6 bolts to 9 Nm (7 lbf.ft) and M8 bolt to

25 Nm (18 lbf.ft).

40.Fit cooling fan coupling.

+ COOLING SYSTEM - Td5, REPAIRS,

Fan - viscous.

41.Fit camshaft cover with new seal.

+ ENGINE - Td5, REPAIRS, Gasket -

cover - camshaft.

42.Refill cooling system.

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

43.Connect battery earth lead.

44.Fit battery cover and secure fixings.

45.Fit bonnet.

+ EXTERIOR FITTINGS, REPAIRS,

Bonnet.

Page 186 of 1672

ENGINE - TD5

REPAIRS 12-1-47

Engine and ancillaries

$% 12.41.01

Remove

1.Remove bonnet.

+ EXTERIOR FITTINGS, REPAIRS,

Bonnet.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Drain engine oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - diesel engine.

4.Remove radiator.

+ COOLING SYSTEM - Td5, REPAIRS,

Radiator.

5.Remove turbocharger.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Turbocharger.

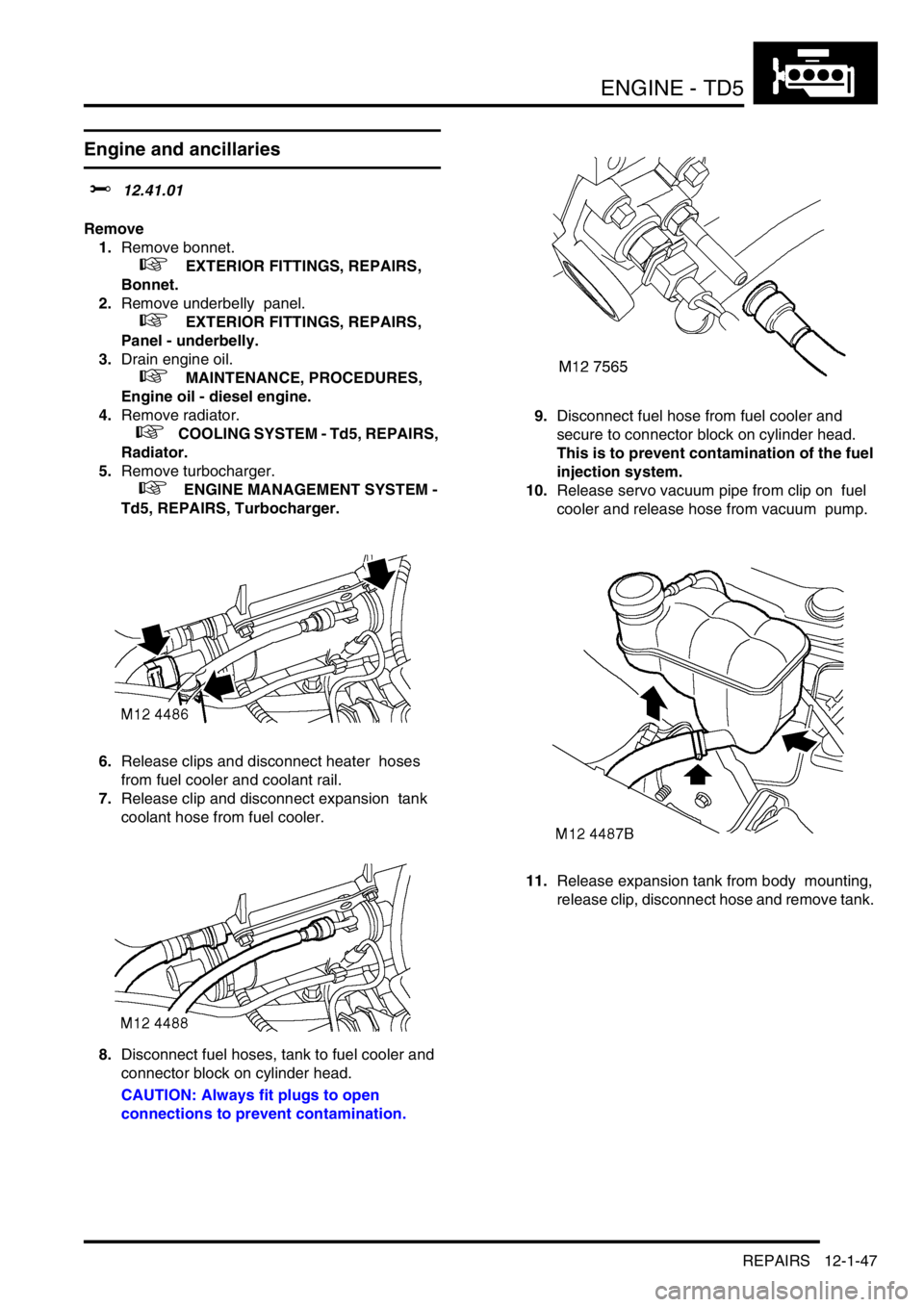

6.Release clips and disconnect heater hoses

from fuel cooler and coolant rail.

7.Release clip and disconnect expansion tank

coolant hose from fuel cooler.

8.Disconnect fuel hoses, tank to fuel cooler and

connector block on cylinder head.

CAUTION: Always fit plugs to open

connections to prevent contamination.9.Disconnect fuel hose from fuel cooler and

secure to connector block on cylinder head.

This is to prevent contamination of the fuel

injection system.

10.Release servo vacuum pipe from clip on fuel

cooler and release hose from vacuum pump.

11.Release expansion tank from body mounting,

release clip, disconnect hose and remove tank.

Page 188 of 1672

ENGINE - TD5

REPAIRS 12-1-49

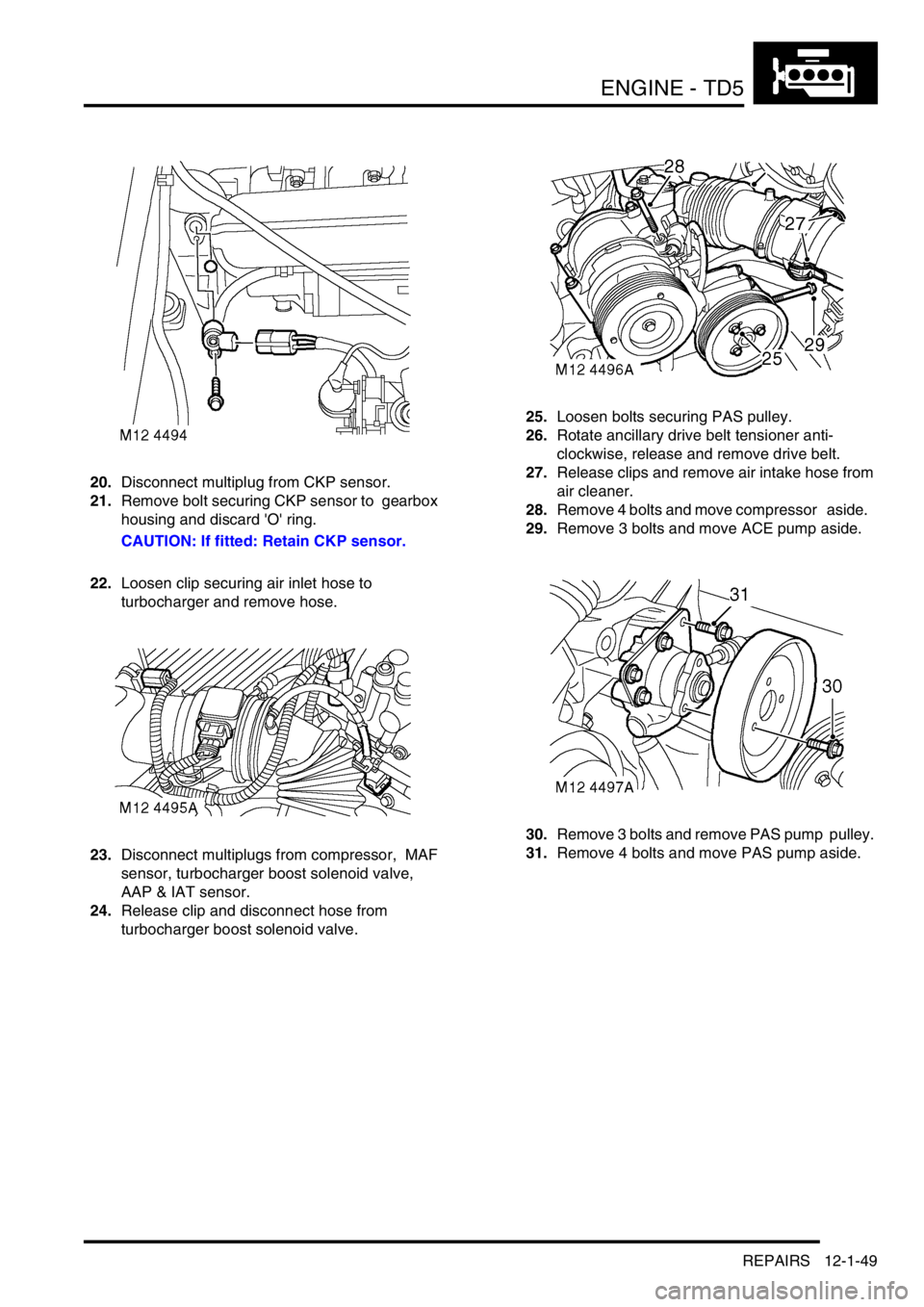

20.Disconnect multiplug from CKP sensor.

21.Remove bolt securing CKP sensor to gearbox

housing and discard 'O' ring.

CAUTION: If fitted: Retain CKP sensor.

22.Loosen clip securing air inlet hose to

turbocharger and remove hose.

23.Disconnect multiplugs from compressor, MAF

sensor, turbocharger boost solenoid valve,

AAP & IAT sensor.

24.Release clip and disconnect hose from

turbocharger boost solenoid valve. 25.Loosen bolts securing PAS pulley.

26.Rotate ancillary drive belt tensioner anti-

clockwise, release and remove drive belt.

27.Release clips and remove air intake hose from

air cleaner.

28.Remove 4 bolts and move compressor aside.

29.Remove 3 bolts and move ACE pump aside.

30.Remove 3 bolts and remove PAS pump pulley.

31.Remove 4 bolts and move PAS pump aside.

Page 191 of 1672

ENGINE - TD5

12-1-52 REPAIRS

5.Fit 2 upper bolts securing engine oil cooler pipe

and gearbox housing to engine and tighten to

50 Nm (37 lbf.ft) .

6.Lower engine onto mountings, and tighten nuts

to 85 Nm (63 lbf.ft) .

7.Remove tool LRT-12-138 from engine.

8.Fit and tighten bolt securing engine closing

panel to gearbox.

9.Raise vehicle on ramp.

10.Fit nuts and bolts securing engine LH and RH

mountings to chassis and tighten to 85 Nm (63

lbf.ft).

11.Fit remaining bolts securing gearbox housing to

engine and tighten to 50 Nm (37 lbf.ft).

12.Rotate crankshaft and align drive plate to

torque converter.

13.Using a magnetic socket, fit and tighten new

torque converter drive plate bolts to 50 Nm (37

lbf.ft) .

14.Fit front cross member and tighten bolts to 26

Nm (19 lbf.ft).

15.Align gearbox oil cooler pipes.

16.Fit oil cooler pipe clip and tighten bolts to 9 Nm

(7 lbf.ft).

17.Position gearbox oil cooler pipe clamps and

tighten nuts.

18.Position coolant rail and secure support bracket

in engine LH and RH mounting brackets.

19.Fit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - diesel.

20.Lower ramp.

21.Position coolant rail to front chassis member, fit

and tighten bolt to 10 Nm (7 lbf.ft).

22.Connect heater hose to coolant rail and secure

with clip.

23.Connect hose to coolant pump and secure with

clip.

24.Position PAS pump and tighten bolts to 25 Nm

(18 lbf.ft).

25.Position PAS pump pulley and lightly tighten

bolts.

26.Position ACE pump, fit bolts and tighten to 25

Nm (18 lbf.ft).

27.Position A/C compressor, fit bolts and tighten

to 25 Nm (18 lbf.ft).

28.Position ancillary drive belt, rotate tensioner

anti-clockwise and locate belt to pulleys.

29.Tighten PAS pump pulley bolts to 10 Nm (7

lbf.ft).

30.Position air intake hose to air cleaner and

secure clips.

31.Position engine harness and connect

multiplugs to compressor, MAF sensor,

turbocharger boost solenoid, AAP & IAT

sensor.

32.Position air inlet hose to turbocharger and

tighten clip. 33.Connect hoses to turbocharger boost solenoid

and secure clips.

34.Clean CKP sensor and mating face.

CAUTION: If originally fitted: Fit spacer to

CKP sensor.

35.Using new 'O' ring, fit CKP sensor, tighten CKP

sensor bolt to 9 Nm (7 lbf.ft) and connect

multiplug.

36.Connect multiplug to EGR modulator.

37.Connect engine earth lead to battery earth lead

and tighten bolt.

38.Connect engine harness multiplug to ECM and

main harness.

39.Connect engine harness multiplugs to fuse

box.

40.Position glow plug lead to fusebox and secure

with bolt.

41.Position battery and alternator leads to fusebox

and secure with bolts.

42.Fit engine compartment fuse box cover.

43.Connect vacuum hose to EGR valve.

44.Connect hose to vacuum pump and secure

vacuum pipe to fuel cooler.

45.Disconnect fuel hose from connector block and

connect to fuel cooler.

46.Connect fuel hoses to fuel cooler and

connector block on cylinder head.

47.Position expansion tank, connect hose and

secure with clip. Secure tank to body mounting.

48.Connect coolant hoses to fuel cooler and

coolant rail and secure clips.

49.Fit turbocharger.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Turbocharger.

50. Fit radiator.

+ COOLING SYSTEM - Td5, REPAIRS,

Radiator.

51.Fill engine with oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - diesel engine.

52.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

53.Fit bonnet.

+ EXTERIOR FITTINGS, REPAIRS,

Bonnet.

Page 203 of 1672

ENGINE - TD5

12-1-64 REPAIRS

Refit

1.Clean oil cooler and mating faces.

2.Fit oil pressure switch and tighten to 9 Nm (7

lbf.ft).

3.Position new gasket and fit oil cooler housing,

tighten bolts to 25 Nm (18 lbf.ft).

4.Position and fit oil filter adaptor housing,

tighten bolts to 25 Nm (18 lbf. ft).

5.Fit oil filter, tighten hand tight then a further half

turn.

6.Position coolant hose to oil cooler and secure

clip.

7.Position coolant pipe bolt and tighten to 50 Nm

(37 lbf.ft) .

8.Connect multiplug to oil pressure switch.

9.Fit centrifuge assembly.

+ ENGINE - Td5, REPAIRS, Gasket -

centrifuge oil drain pipe.

10.Refill cooling system.

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

11.Top up engine oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - diesel engine.

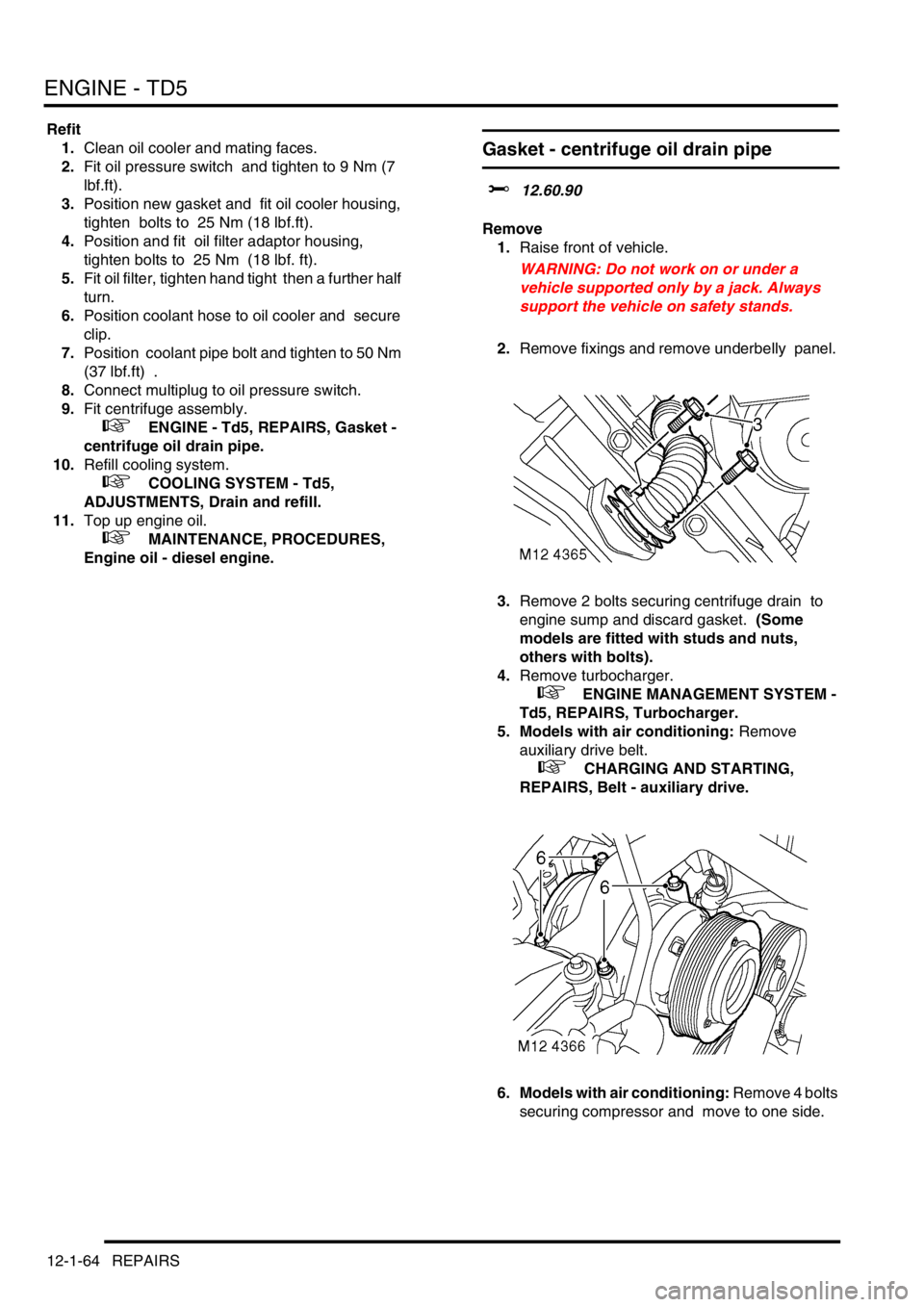

Gasket - centrifuge oil drain pipe

$% 12.60.90

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove fixings and remove underbelly panel.

3.Remove 2 bolts securing centrifuge drain to

engine sump and discard gasket. (Some

models are fitted with studs and nuts,

others with bolts).

4.Remove turbocharger.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Turbocharger.

5. Models with air conditioning: Remove

auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

6. Models with air conditioning: Remove 4 bolts

securing compressor and move to one side.

Page 204 of 1672

ENGINE - TD5

REPAIRS 12-1-65

7.Remove 3 bolts securing centrifuge to engine

oil cooler.

8.Remove centrifuge and discard 'O' ring.

9.Remove 2 bolts, remove drain pipe from

centrifuge and discard gasket. Refit

1.Clean mating faces of centrifuge, oil cooler and

sump.

2.Position new gasket and fit oil drain pipe to

centrifuge, tighten bolts to 10 Nm (7 lbf.ft).

CAUTION: Gasket must be fitted dry.

3.Position new 'O' ring to oil cooler.

4.Position centrifuge to oil cooler housing and

tighten bolts to 25 Nm (18 lbf.ft).

5.Using a new gasket, align the centrifuge oil

drain pipe to sump and tighten bolts to 10 Nm

(7 lbf.ft).

CAUTION: Gasket must be fitted dry.

6. Models with air conditioning: Position A/C

compressor and tighten bolts to 25 Nm (18

lbf.ft).

7.Fit turbocharger.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Turbocharger.

8. Models with air conditioning: Fit auxiliary

drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

9.Fit underbelly panel and secure with fixings.

10.Remove stand(s) and lower vehicle.

Page 209 of 1672

ENGINE - TD5

12-1-70 OVERHAUL

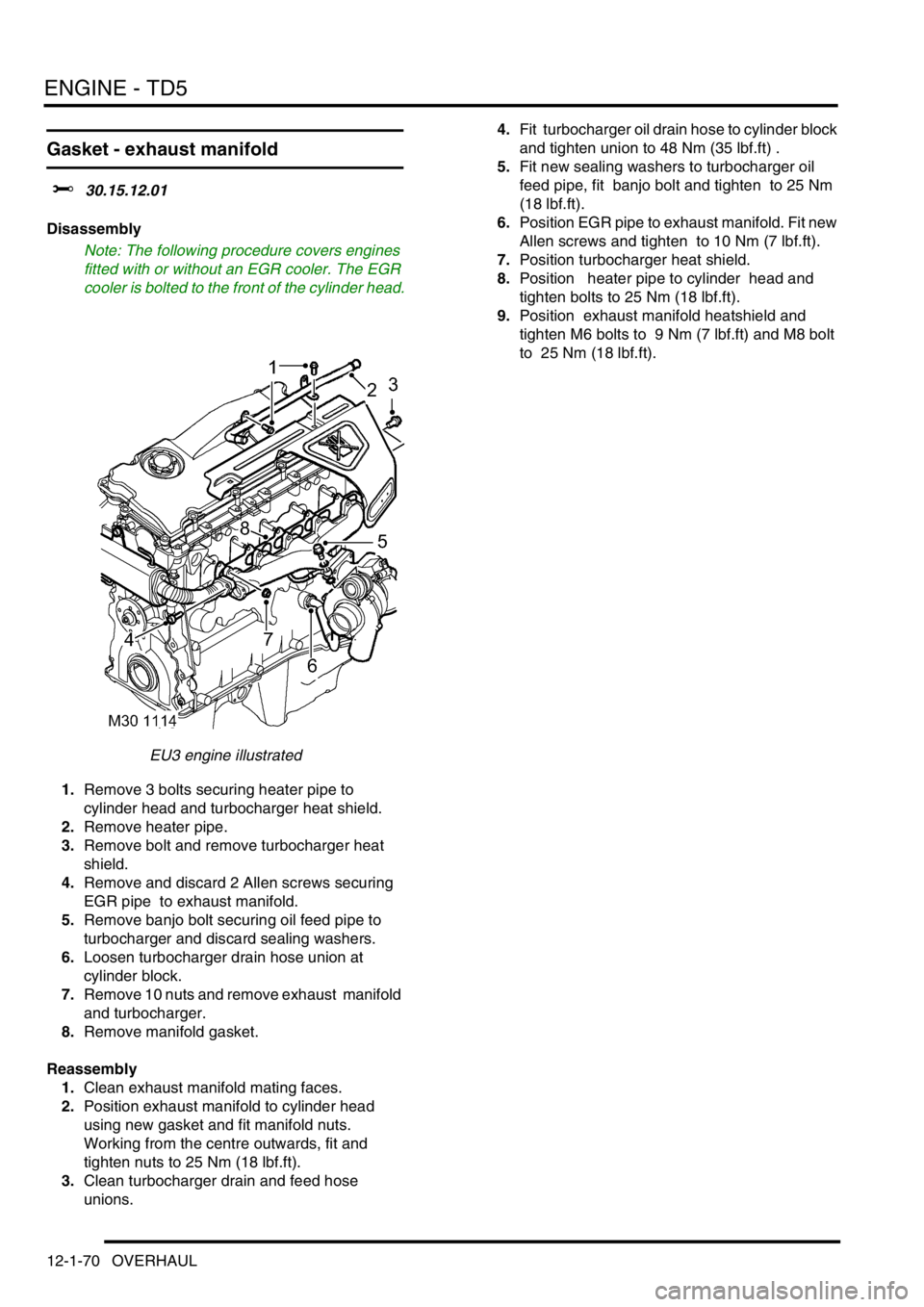

Gasket - exhaust manifold

$% 30.15.12.01

Disassembly

Note: The following procedure covers engines

fitted with or without an EGR cooler. The EGR

cooler is bolted to the front of the cylinder head.

EU3 engine illustrated

1.Remove 3 bolts securing heater pipe to

cylinder head and turbocharger heat shield.

2.Remove heater pipe.

3.Remove bolt and remove turbocharger heat

shield.

4.Remove and discard 2 Allen screws securing

EGR pipe to exhaust manifold.

5.Remove banjo bolt securing oil feed pipe to

turbocharger and discard sealing washers.

6.Loosen turbocharger drain hose union at

cylinder block.

7.Remove 10 nuts and remove exhaust manifold

and turbocharger.

8.Remove manifold gasket.

Reassembly

1.Clean exhaust manifold mating faces.

2.Position exhaust manifold to cylinder head

using new gasket and fit manifold nuts.

Working from the centre outwards, fit and

tighten nuts to 25 Nm (18 lbf.ft).

3.Clean turbocharger drain and feed hose

unions. 4.Fit turbocharger oil drain hose to cylinder block

and tighten union to 48 Nm (35 lbf.ft) .

5.Fit new sealing washers to turbocharger oil

feed pipe, fit banjo bolt and tighten to 25 Nm

(18 lbf.ft).

6.Position EGR pipe to exhaust manifold. Fit new

Allen screws and tighten to 10 Nm (7 lbf.ft).

7.Position turbocharger heat shield.

8.Position heater pipe to cylinder head and

tighten bolts to 25 Nm (18 lbf.ft).

9.Position exhaust manifold heatshield and

tighten M6 bolts to 9 Nm (7 lbf.ft) and M8 bolt

to 25 Nm (18 lbf.ft).

Page 325 of 1672

EMISSION CONTROL - TD5

17-1-4 DESCRIPTION AND OPERATION

Emission Control Systems

Engine design has evolved in order to minimise the emission of harmful by-products. Emission control systems fitted

to Land Rover vehicles are designed to maintain the emission levels within the legal limits pertaining for the specified

market.

Despite the utilisation of specialised emission control equipment, it is still necessary to ensure that the engine is

correctly maintained and is in good mechanical order, so that it operates at its optimum condition.

In addition to emissions improvements through engine design and the application of electronic engine management

systems, special emission control systems are used to limit the pollutant levels developed under certain conditions.

Two main types of additional emission control system are utilised with the Td5 engine to reduce the levels of harmful

emissions released into the atmosphere. These are as follows:

1Crankcase emission control – also known as blow-by gas emissions from the engine crankcase.

2Exhaust gas recirculation – to reduce NO

2 emissions.

Crankcase emission control

All internal combustion engines generate oil vapour and smoke in the crankcase as a result of high crankcase

temperatures and piston ring and valve stem blow-by, a closed crankcase ventilation system is used to vent

crankcase gases back to the air induction system and so reduce the emission of hydrocarbons.

Gases from the crankcase are drawn into the inlet manifold to be burnt in the combustion chambers with the fresh air/

fuel mixture. The system provides effective emission control under all engine operating conditions.

Crankcase gases are drawn through the breather port in the top of the camshaft cover and routed through the breather

hose and breather valve on the flexible air intake duct to be drawn into the turbocharger intake for delivery to the air

inlet manifold via an intercooler.

An oil separator plate is included in the camshaft cover which removes the heavy particles of oil before the crankcase

gas leaves via the camshaft cover port. The rocker cover features circular chambers which promote swirl in the oil

mist emanating from the cylinder head and camshaft carrier. As the mist passes through the series of chambers

between the rocker cover and oil separator plate, oil particles are thrown against the separator walls where they

condense and fall back into the cylinder head via two air inlet holes located at each end of the rocker cover.

The breather valve is a depression limiting valve which progressively closes as engine speed increases, thereby

limiting the depression in the crankcase. The valve is of moulded plastic construction and has a port on the underside

which plugs into a port in the flexible air intake duct. A port on the side of the breather valve connects to the camshaft

cover port by means of a breather hose which is constructed from a heavy-duty braided rubber hose which is held in

place by hose clips. A corrugated plastic sleeve is used to give further protection to the breather hose. The breather

valve is orientation sensitive, and “TOP” is marked on the upper surface to ensure it is mounted correctly.

It is important that the system is airtight so hose connections to ports should be checked and the condition of the

breather hose should be periodically inspected to ensure it is in good condition.

Page 396 of 1672

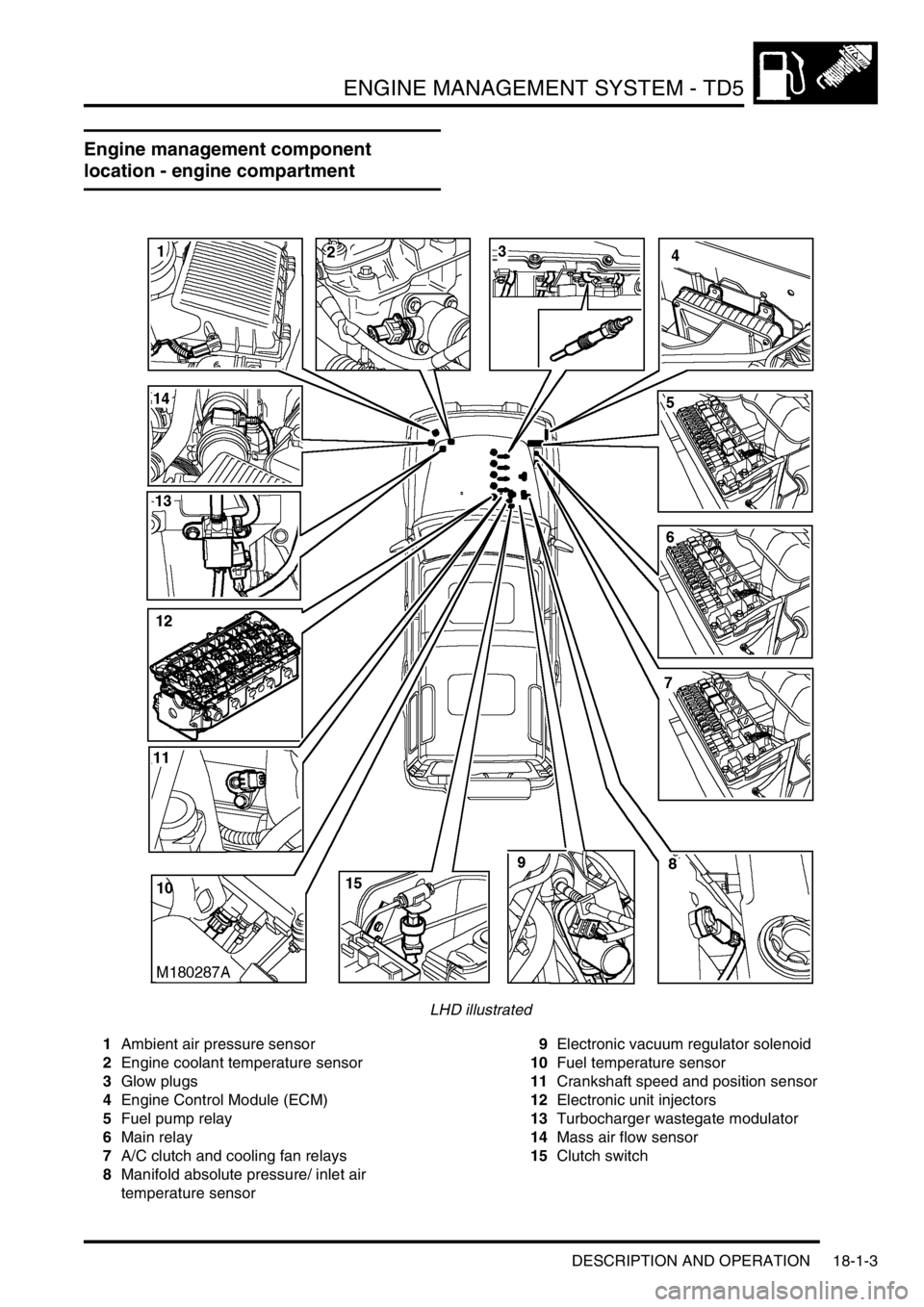

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-3

Engine management component

location - engine compartment

LHD illustrated

1Ambient air pressure sensor

2Engine coolant temperature sensor

3Glow plugs

4Engine Control Module (ECM)

5Fuel pump relay

6Main relay

7A/C clutch and cooling fan relays

8Manifold absolute pressure/ inlet air

temperature sensor9Electronic vacuum regulator solenoid

10Fuel temperature sensor

11Crankshaft speed and position sensor

12Electronic unit injectors

13Turbocharger wastegate modulator

14Mass air flow sensor

15Clutch switch