LAND ROVER DISCOVERY 2002 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 661 of 1672

CLUTCH - TD5

33-1-10 DESCRIPTION AND OPERATION

Operation

Hydraulic operation

Refer to illustration.

+ CLUTCH - Td5, DESCRIPTION AND OPERATION, Hydraulic operation.

When the clutch pedal is depressed, the master cylinder piston is pushed into the master cylinder. The movement of

the piston pressurises the fluid in the master cylinder, forcing the pressurised fluid into the hydraulic feed pipe to the

slave cylinder. The hydraulic pressure is felt at the slave cylinder piston which moves under the hydraulic force

applied, pushing the clutch release lever via the piston rod.

When the clutch pedal is released, the force applied to the release lever by the fingers of the diaphragm, moves the

release lever, which pushes the slave cylinder piston into the cylinder. The displaced hydraulic fluid is pushed up the

hydraulic feed pipe and returns to the master cylinder.

Mechanism operation

When the clutch pedal is depressed, hydraulic pressure extends the piston and rod in the slave cylinder. The

extension of the piston pushes the rod against the outer end of the release lever which pivots around the ball spigot.

The inner end of the release lever pivots towards the engine applying pressure to the release bearing. The release

bearing slides along the release bearing sleeve and pushes on the fingers of the diaphragm. The diaphragm pivots

around the chamfered rivets in the cover. As the diaphragm is deflected, it removes pressure from the pressure plate.

The pressure plate moves away from the drive plate assisted by the three leaf springs.

The removal of force from the pressure plate on the drive plate reduces the friction between the dual mass flywheel,

drive plate and pressure plate. The drive plate slips between the flywheel and the pressure plate preventing rotary

movement being transferred from the flywheel and pressure plate to the primary driveshaft.

When the clutch pedal is released, hydraulic force is removed from the piston in the slave cylinder. This allows the

fingers of the diaphragm to push the release bearing along the release bearing sleeve. The movement of the release

bearing moves the release lever which pivots on the ball spigot, pushing the piston and rod back into the slave

cylinder.

The removal of pressure from the release bearing on the diaphragm, causes the diaphragm to pivot around the

chamfered rivets in the cover. The force applied to the pressure plate from the diaphragm overcomes the force of the

leaf springs and the pressure plate moves towards the drive plate and flywheel.

The pressure plate applies pressure to the drive plate which is pushed against the flywheel. As the clutch pedal is

progressively released, the friction between the drive plate, flywheel and pressure plate increases. The increase in

friction transfers the rotary movement of the flywheel and pressure plate to the drive plate, which in turn starts to rotate

the primary drive shaft. When the clutch pedal is released fully, the force applied by the diaphragm to the pressure

plate forces the drive plate onto the flywheel with no slippage.

Page 662 of 1672

CLUTCH - TD5

ADJUSTMENTS 33-1-11

ADJUST ME NTS

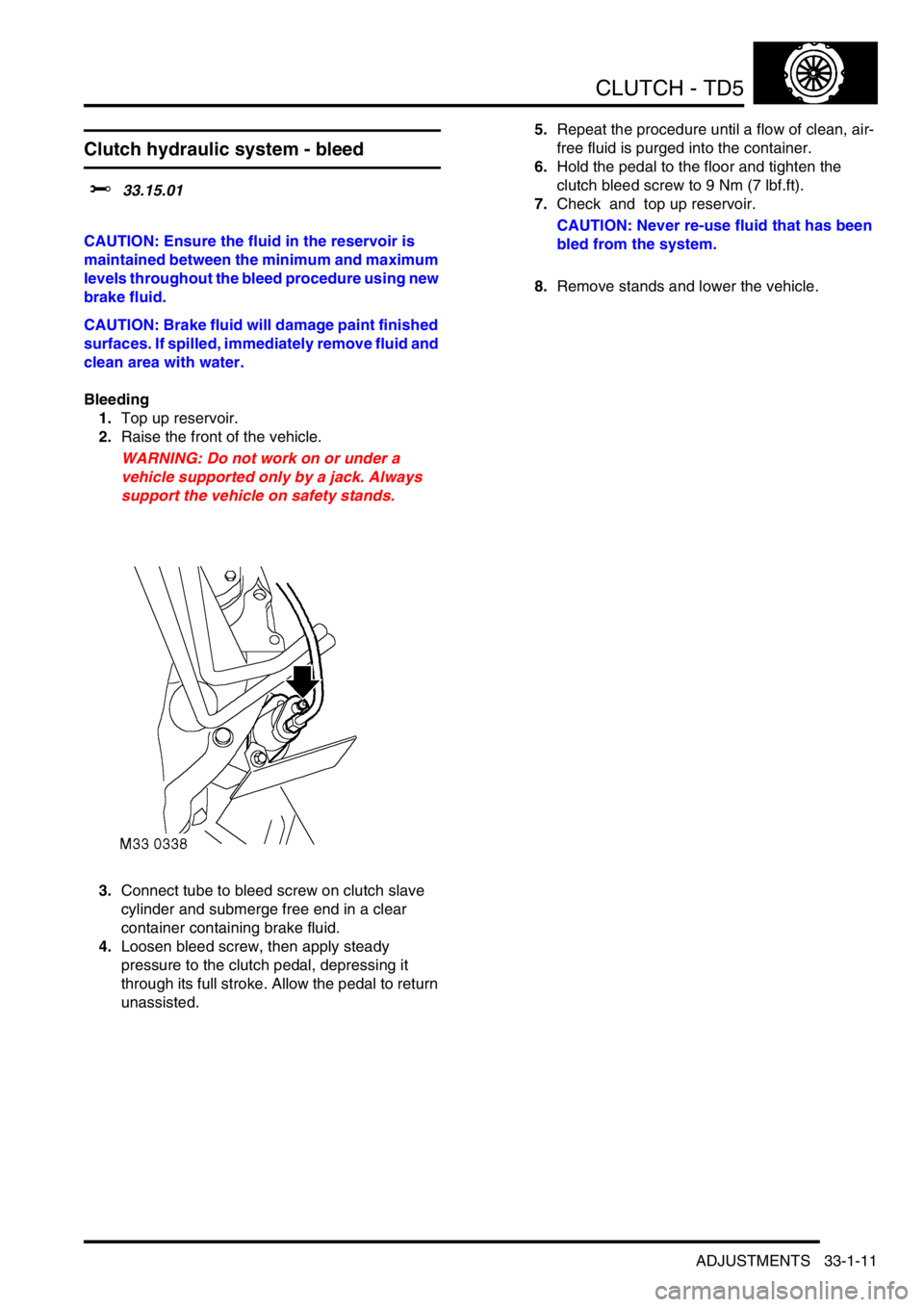

Clutch hydraulic system - bleed

$% 33.15.01

CAUTION: Ensure the fluid in the reservoir is

maintained between the minimum and maximum

levels throughout the bleed procedure using new

brake fluid.

CAUTION: Brake fluid will damage paint finished

surfaces. If spilled, immediately remove fluid and

clean area with water.

Bleeding

1.Top up reservoir.

2.Raise the front of the vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Connect tube to bleed screw on clutch slave

cylinder and submerge free end in a clear

container containing brake fluid.

4.Loosen bleed screw, then apply steady

pressure to the clutch pedal, depressing it

through its full stroke. Allow the pedal to return

unassisted.5.Repeat the procedure until a flow of clean, air-

free fluid is purged into the container.

6.Hold the pedal to the floor and tighten the

clutch bleed screw to 9 Nm (7 lbf.ft).

7.Check and top up reservoir.

CAUTION: Never re-use fluid that has been

bled from the system.

8.Remove stands and lower the vehicle.

Page 663 of 1672

CLUTCH - TD5

33-1-12 ADJUSTMENTS

Page 664 of 1672

CLUTCH - TD5

REPAIRS 33-1-13

REPAIRS

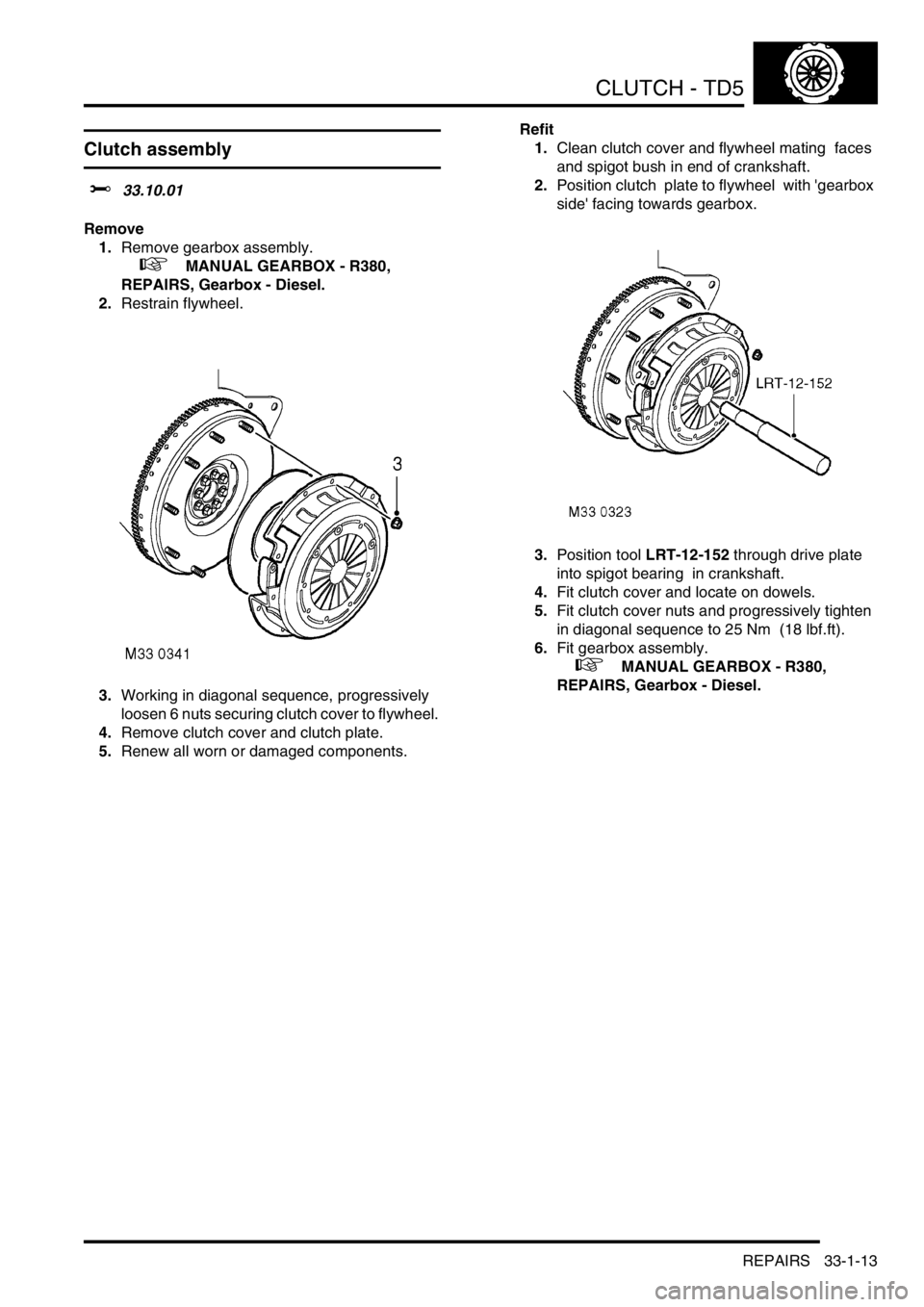

Clutch assembly

$% 33.10.01

Remove

1.Remove gearbox assembly.

+ MANUAL GEARBOX - R380,

REPAIRS, Gearbox - Diesel.

2.Restrain flywheel.

3.Working in diagonal sequence, progressively

loosen 6 nuts securing clutch cover to flywheel.

4.Remove clutch cover and clutch plate.

5.Renew all worn or damaged components.Refit

1.Clean clutch cover and flywheel mating faces

and spigot bush in end of crankshaft.

2.Position clutch plate to flywheel with 'gearbox

side' facing towards gearbox.

3.Position tool LRT-12-152 through drive plate

into spigot bearing in crankshaft.

4.Fit clutch cover and locate on dowels.

5.Fit clutch cover nuts and progressively tighten

in diagonal sequence to 25 Nm (18 lbf.ft).

6.Fit gearbox assembly.

+ MANUAL GEARBOX - R380,

REPAIRS, Gearbox - Diesel.

Page 665 of 1672

CLUTCH - TD5

33-1-14 REPAIRS

Master cylinder

$% 33.20.01

CAUTION: Brake fluid will damage paint finished

surfaces. If spilled, immediately remove fluid and

clean area with water.

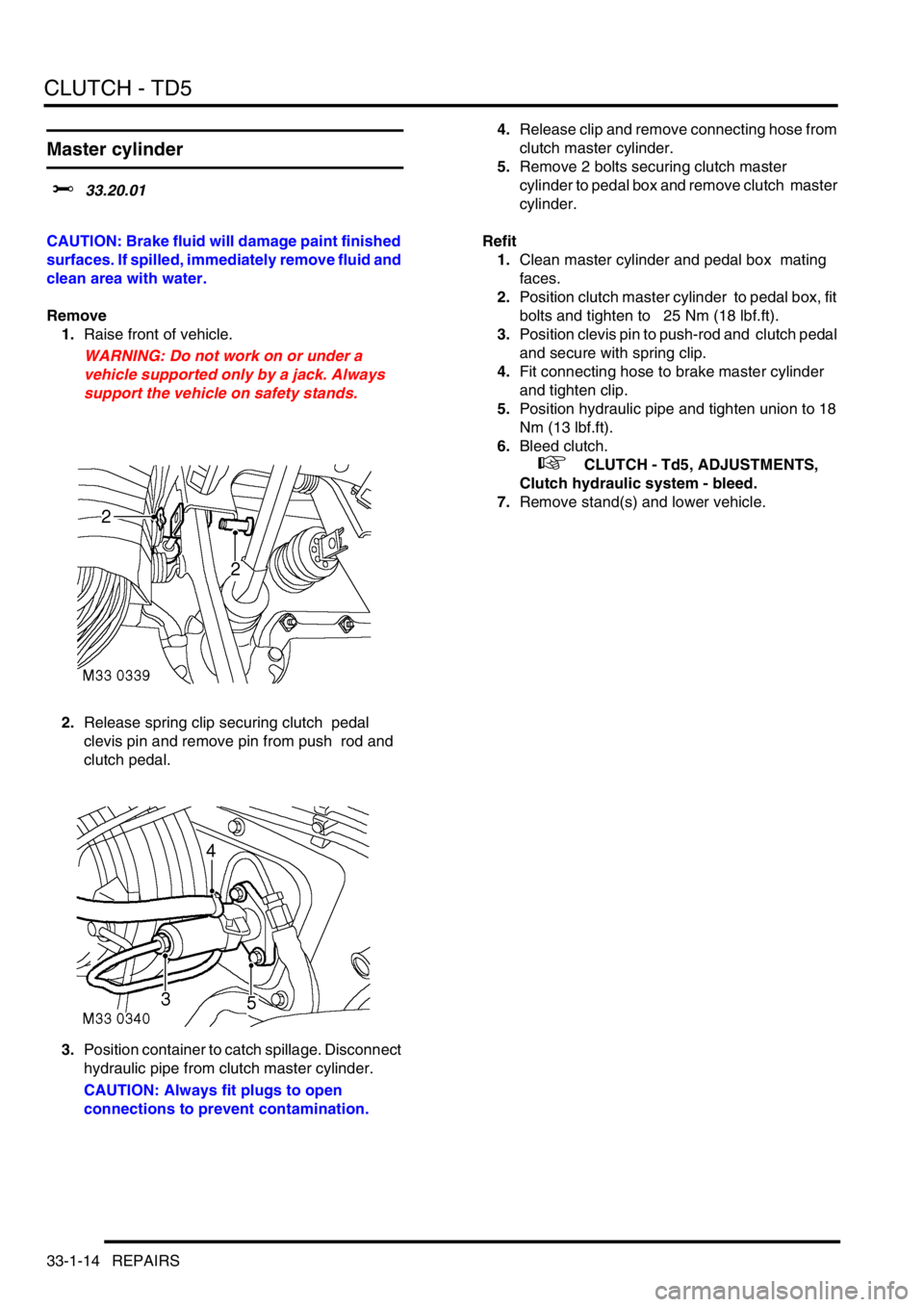

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

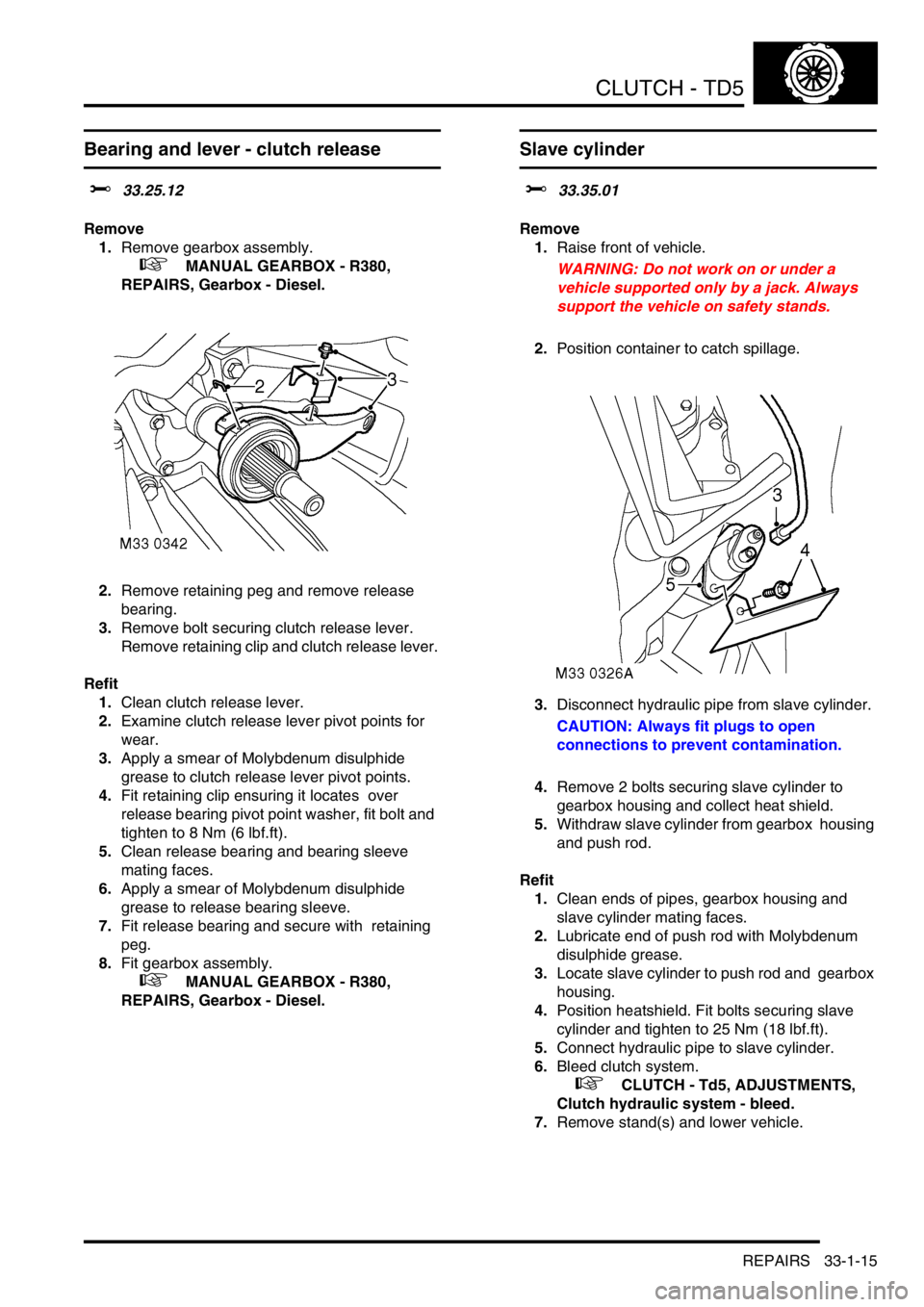

2.Release spring clip securing clutch pedal

clevis pin and remove pin from push rod and

clutch pedal.

3.Position container to catch spillage. Disconnect

hydraulic pipe from clutch master cylinder.

CAUTION: Always fit plugs to open

connections to prevent contamination.4.Release clip and remove connecting hose from

clutch master cylinder.

5.Remove 2 bolts securing clutch master

cylinder to pedal box and remove clutch master

cylinder.

Refit

1.Clean master cylinder and pedal box mating

faces.

2.Position clutch master cylinder to pedal box, fit

bolts and tighten to 25 Nm (18 lbf.ft).

3.Position clevis pin to push-rod and clutch pedal

and secure with spring clip.

4.Fit connecting hose to brake master cylinder

and tighten clip.

5.Position hydraulic pipe and tighten union to 18

Nm (13 lbf.ft).

6.Bleed clutch.

+ CLUTCH - Td5, ADJUSTMENTS,

Clutch hydraulic system - bleed.

7.Remove stand(s) and lower vehicle.

Page 666 of 1672

CLUTCH - TD5

REPAIRS 33-1-15

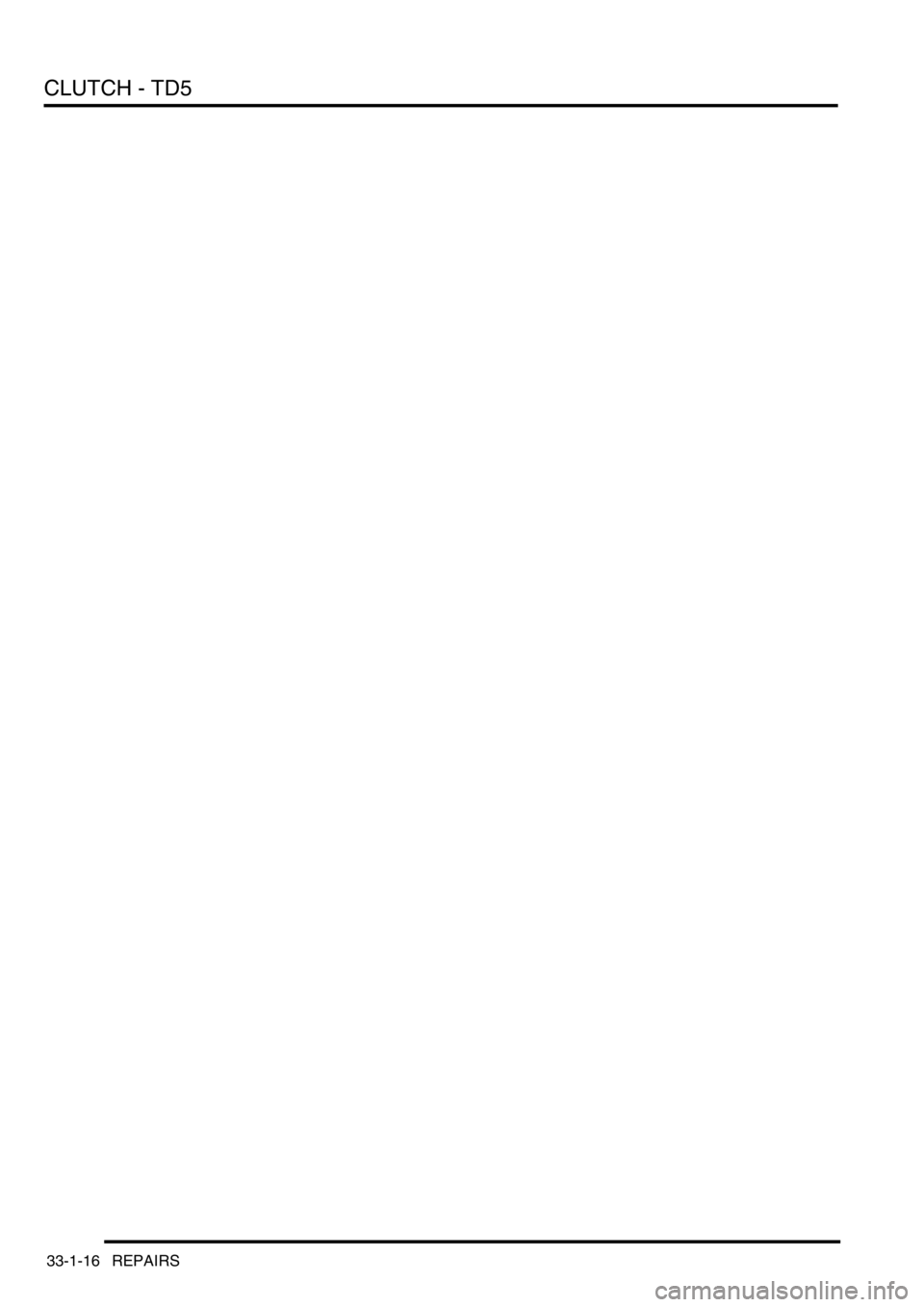

Bearing and lever - clutch release

$% 33.25.12

Remove

1.Remove gearbox assembly.

+ MANUAL GEARBOX - R380,

REPAIRS, Gearbox - Diesel.

2.Remove retaining peg and remove release

bearing.

3.Remove bolt securing clutch release lever.

Remove retaining clip and clutch release lever.

Refit

1.Clean clutch release lever.

2.Examine clutch release lever pivot points for

wear.

3.Apply a smear of Molybdenum disulphide

grease to clutch release lever pivot points.

4.Fit retaining clip ensuring it locates over

release bearing pivot point washer, fit bolt and

tighten to 8 Nm (6 lbf.ft).

5.Clean release bearing and bearing sleeve

mating faces.

6.Apply a smear of Molybdenum disulphide

grease to release bearing sleeve.

7.Fit release bearing and secure with retaining

peg.

8.Fit gearbox assembly.

+ MANUAL GEARBOX - R380,

REPAIRS, Gearbox - Diesel.

Slave cylinder

$% 33.35.01

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Position container to catch spillage.

3.Disconnect hydraulic pipe from slave cylinder.

CAUTION: Always fit plugs to open

connections to prevent contamination.

4.Remove 2 bolts securing slave cylinder to

gearbox housing and collect heat shield.

5.Withdraw slave cylinder from gearbox housing

and push rod.

Refit

1.Clean ends of pipes, gearbox housing and

slave cylinder mating faces.

2.Lubricate end of push rod with Molybdenum

disulphide grease.

3.Locate slave cylinder to push rod and gearbox

housing.

4.Position heatshield. Fit bolts securing slave

cylinder and tighten to 25 Nm (18 lbf.ft).

5.Connect hydraulic pipe to slave cylinder.

6.Bleed clutch system.

+ CLUTCH - Td5, ADJUSTMENTS,

Clutch hydraulic system - bleed.

7.Remove stand(s) and lower vehicle.

Page 667 of 1672

CLUTCH - TD5

33-1-16 REPAIRS

Page 668 of 1672

CLUTCH - V8

DESCRIPTION AND OPERATION 33-2-1

Deze pagina werd opzettelijk niet gebruikt

Cette page est intentionnellement vierge

Questa pagina è stata lasciata in bianco di proposito Diese Seite ist leer

Esta página foi deixada intencionalmente em branco

Esta página fue dejada en blanco intencionalmente This page is intentionally left blank

CLUTCH - V8 DESCRIPTION AND OPERAT ION

Page 669 of 1672

CLUTCH - V8

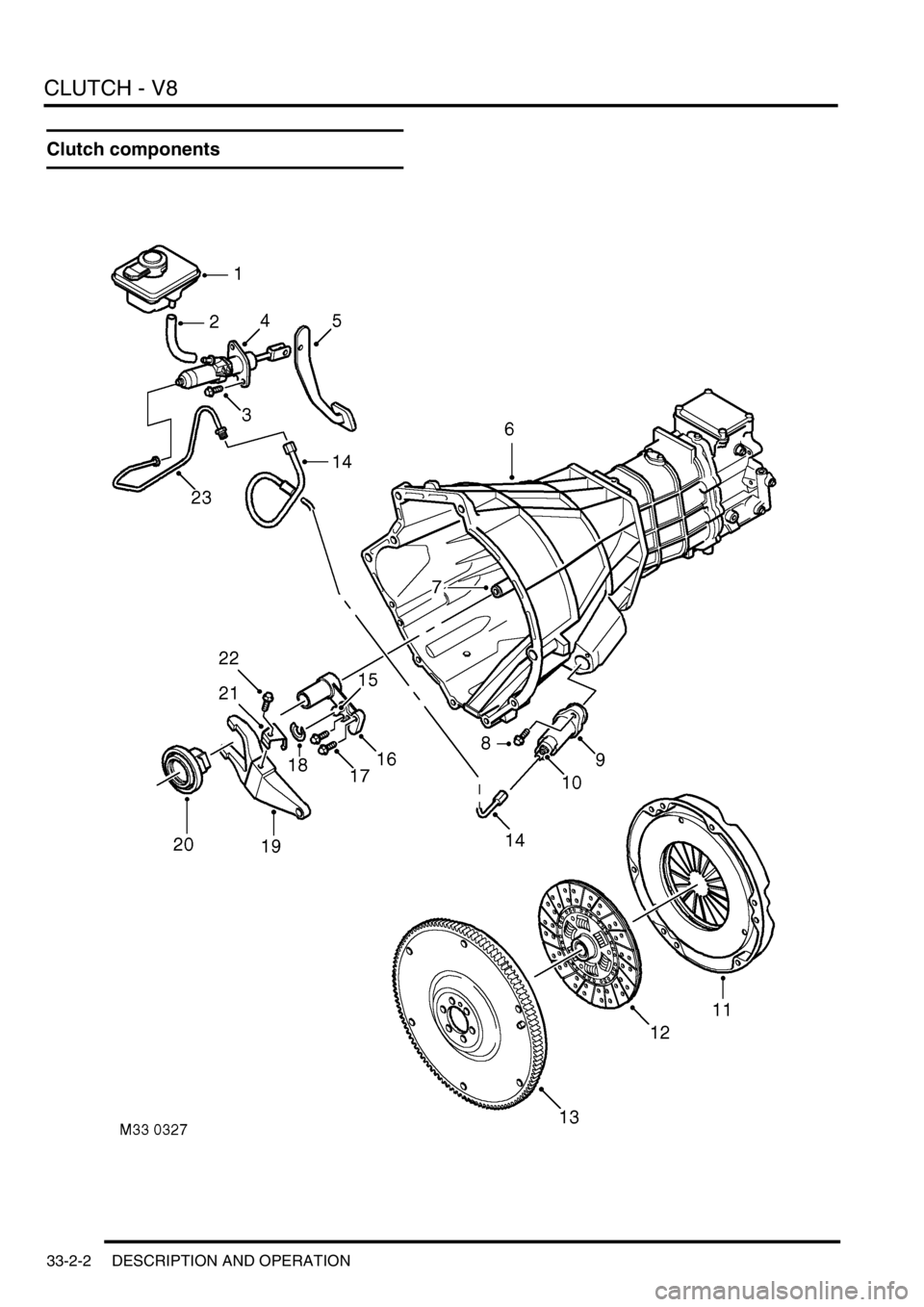

33-2-2 DESCRIPTION AND OPERATION

Clutch components

Page 670 of 1672

CLUTCH - V8

DESCRIPTION AND OPERATION 33-2-3

1Brake/clutch reservoir

2Connecting hose

3Bolt 2 off

4Master cylinder

5Clutch pedal

6Gearbox housing

7Primary driveshaft

8Bolt 2 off

9Slave cylinder

10Bleed nipple

11Pressure plate

12Drive plate

13Flywheel

14Metal hydraulic pipes

15Ball spigot

16Clutch release bearing sleeve

17Bolt 2 off

18Pivot washer

19Release lever

20Release bearing

21Retaining clip

22Bolt

23Bolt