LAND ROVER DISCOVERY 2002 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 651 of 1672

MANIFOLDS AND EXHAUST SYSTEMS - V8

30-2-22 REPAIRS

Page 652 of 1672

CLUTCH - TD5

DESCRIPTION AND OPERATION 33-1-1

Deze pagina werd opzettelijk niet gebruikt

Cette page est intentionnellement vierge

Questa pagina è stata lasciata in bianco di proposito Diese Seite ist leer

Esta página foi deixada intencionalmente em branco

Esta página fue dejada en blanco intencionalmente This page is intentionally left blank

CLUTCH - Td5 DESCRIPTION AND OPERAT ION

Page 653 of 1672

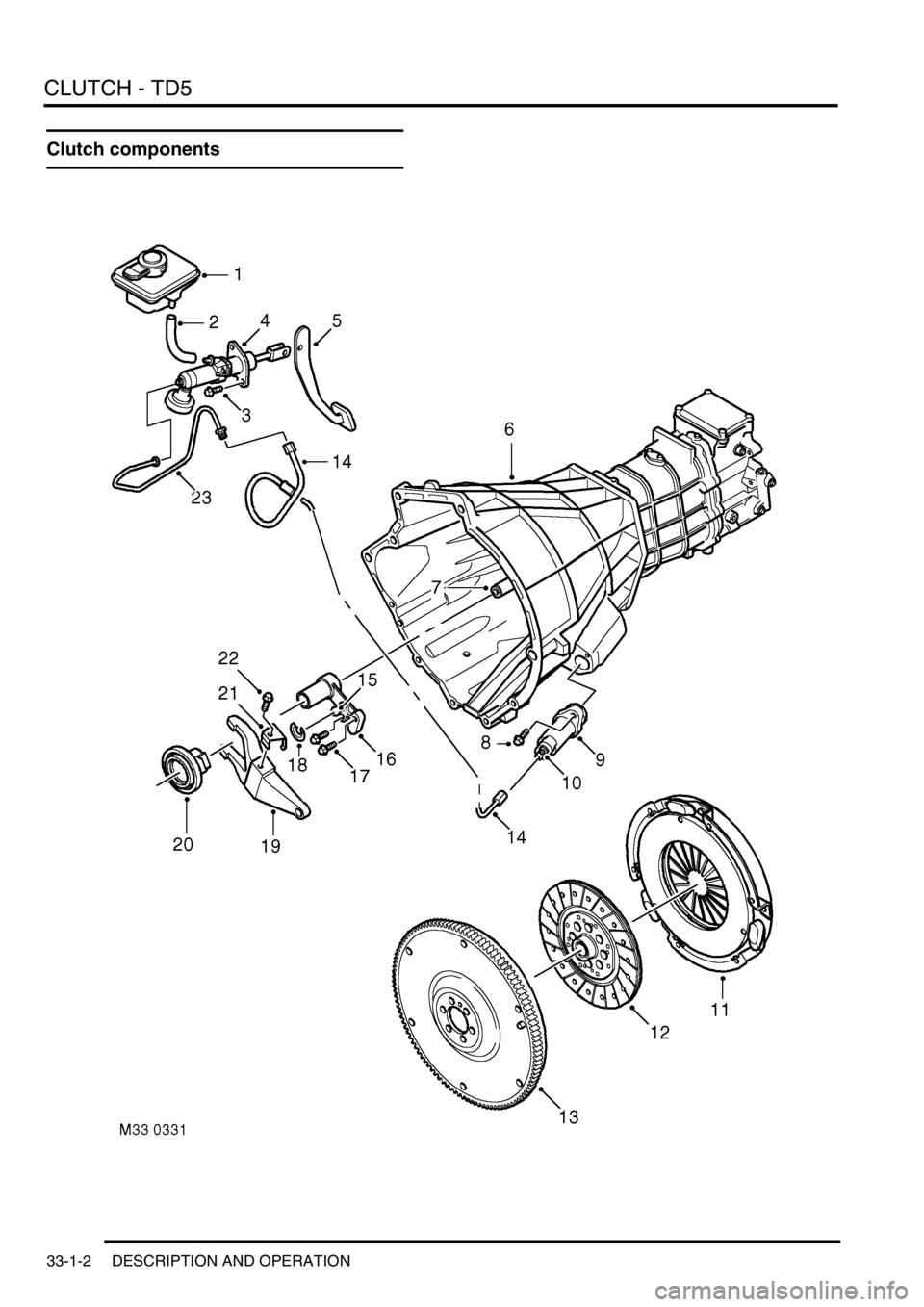

CLUTCH - TD5

33-1-2 DESCRIPTION AND OPERATION

Clutch components

Page 654 of 1672

CLUTCH - TD5

DESCRIPTION AND OPERATION 33-1-3

1Brake/clutch reservoir

2Connecting hose

3Bolt 2 off

4Master cylinder

5Clutch pedal

6Gearbox housing

7Primary driveshaft

8Bolt 2 off

9Slave cylinder

10Bleed nipple

11Pressure plate

12Drive plate

13Dual mass flywheel

14Metal hydraulic pipe

15Ball spigot

16Clutch release bearing sleeve

17Bolt 2 off

18Pivot washer

19Release lever

20Release bearing

21Retaining clip

22Bolt

23Plastic hydraulic pipe

Page 655 of 1672

CLUTCH - TD5

33-1-4 DESCRIPTION AND OPERATION

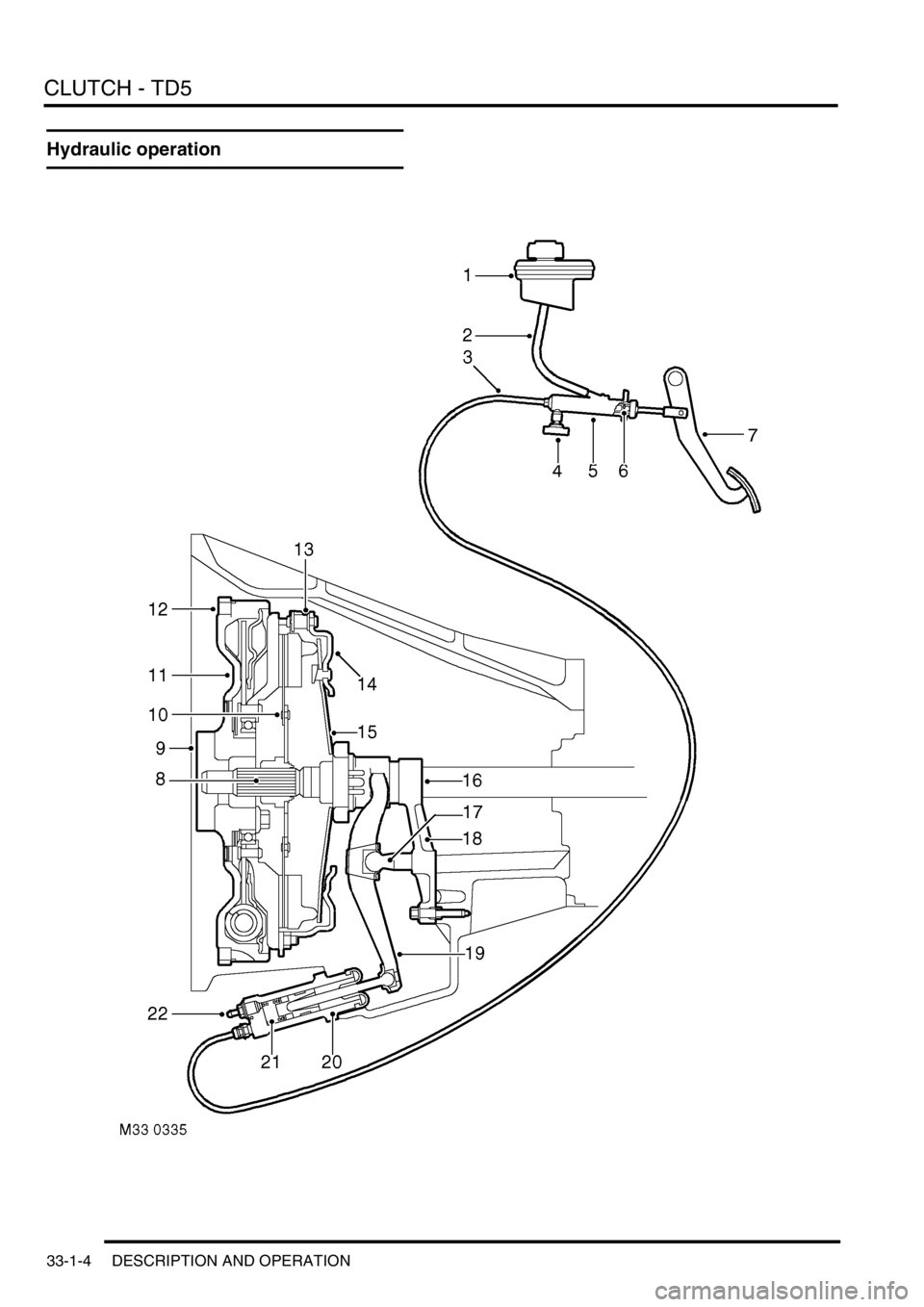

Hydraulic operation

Page 656 of 1672

CLUTCH - TD5

DESCRIPTION AND OPERATION 33-1-5

1Brake/clutch reservoir

2Fluid supply pipe

3Hydraulic feed pipe

4Damper

5Master cylinder

6Piston

7Clutch pedal

8Primary driveshaft

9Engine crankshaft

10Drive plate

11Dual mass flywheel

12Ring gear

13Leaf spring

14Cover - pressure plate

15Diaphragm

16Release bearing

17Ball spigot

18Release bearing sleeve

19Release lever

20Slave cylinder

21Piston

22Bleed nipple

Page 657 of 1672

CLUTCH - TD5

33-1-6 DESCRIPTION AND OPERATION

Description

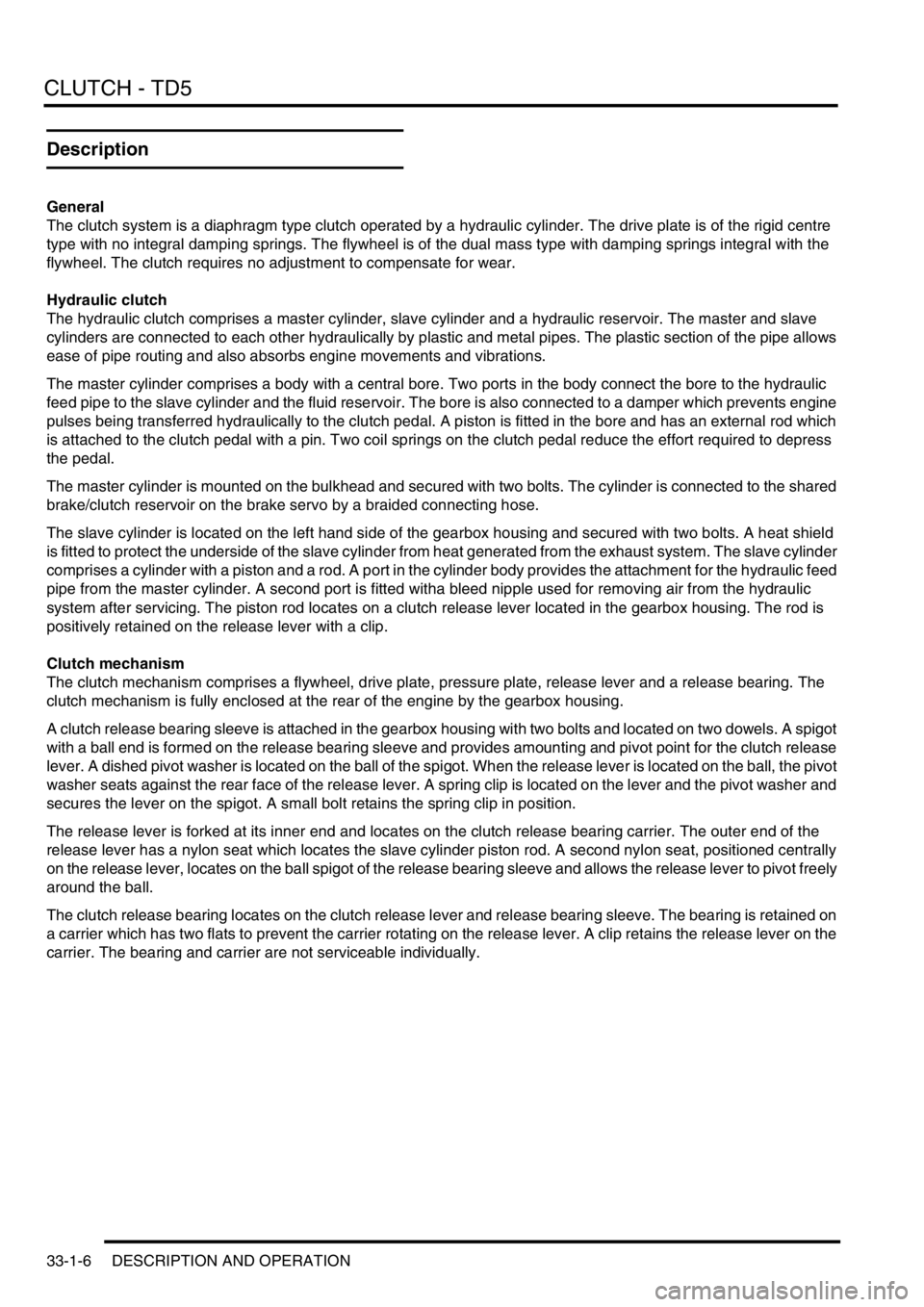

General

The clutch system is a diaphragm type clutch operated by a hydraulic cylinder. The drive plate is of the rigid centre

type with no integral damping springs. The flywheel is of the dual mass type with damping springs integral with the

flywheel. The clutch requires no adjustment to compensate for wear.

Hydraulic clutch

The hydraulic clutch comprises a master cylinder, slave cylinder and a hydraulic reservoir. The master and slave

cylinders are connected to each other hydraulically by plastic and metal pipes. The plastic section of the pipe allows

ease of pipe routing and also absorbs engine movements and vibrations.

The master cylinder comprises a body with a central bore. Two ports in the body connect the bore to the hydraulic

feed pipe to the slave cylinder and the fluid reservoir. The bore is also connected to a damper which prevents engine

pulses being transferred hydraulically to the clutch pedal. A piston is fitted in the bore and has an external rod which

is attached to the clutch pedal with a pin. Two coil springs on the clutch pedal reduce the effort required to depress

the pedal.

The master cylinder is mounted on the bulkhead and secured with two bolts. The cylinder is connected to the shared

brake/clutch reservoir on the brake servo by a braided connecting hose.

The slave cylinder is located on the left hand side of the gearbox housing and secured with two bolts. A heat shield

is fitted to protect the underside of the slave cylinder from heat generated from the exhaust system. The slave cylinder

comprises a cylinder with a piston and a rod. A port in the cylinder body provides the attachment for the hydraulic feed

pipe from the master cylinder. A second port is fitted witha bleed nipple used for removing air from the hydraulic

system after servicing. The piston rod locates on a clutch release lever located in the gearbox housing. The rod is

positively retained on the release lever with a clip.

Clutch mechanism

The clutch mechanism comprises a flywheel, drive plate, pressure plate, release lever and a release bearing. The

clutch mechanism is fully enclosed at the rear of the engine by the gearbox housing.

A clutch release bearing sleeve is attached in the gearbox housing with two bolts and located on two dowels. A spigot

with a ball end is formed on the release bearing sleeve and provides amounting and pivot point for the clutch release

lever. A dished pivot washer is located on the ball of the spigot. When the release lever is located on the ball, the pivot

washer seats against the rear face of the release lever. A spring clip is located on the lever and the pivot washer and

secures the lever on the spigot. A small bolt retains the spring clip in position.

The release lever is forked at its inner end and locates on the clutch release bearing carrier. The outer end of the

release lever has a nylon seat which locates the slave cylinder piston rod. A second nylon seat, positioned centrally

on the release lever, locates on the ball spigot of the release bearing sleeve and allows the release lever to pivot freely

around the ball.

The clutch release bearing locates on the clutch release lever and release bearing sleeve. The bearing is retained on

a carrier which has two flats to prevent the carrier rotating on the release lever. A clip retains the release lever on the

carrier. The bearing and carrier are not serviceable individually.

Page 658 of 1672

CLUTCH - TD5

DESCRIPTION AND OPERATION 33-1-7

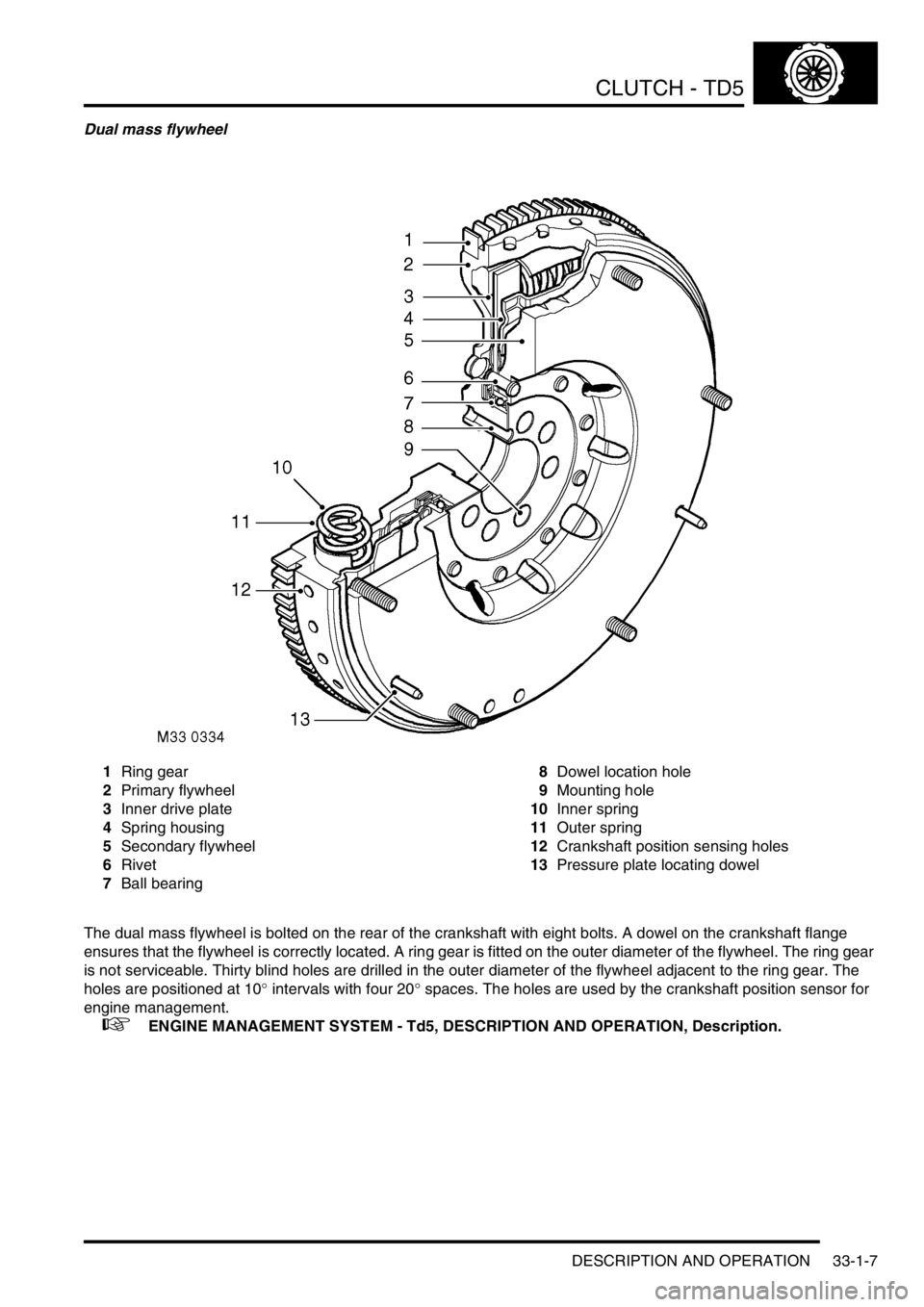

Dual mass flywheel

1Ring gear

2Primary flywheel

3Inner drive plate

4Spring housing

5Secondary flywheel

6Rivet

7Ball bearing8Dowel location hole

9Mounting hole

10Inner spring

11Outer spring

12Crankshaft position sensing holes

13Pressure plate locating dowel

The dual mass flywheel is bolted on the rear of the crankshaft with eight bolts. A dowel on the crankshaft flange

ensures that the flywheel is correctly located. A ring gear is fitted on the outer diameter of the flywheel. The ring gear

is not serviceable. Thirty blind holes are drilled in the outer diameter of the flywheel adjacent to the ring gear. The

holes are positioned at 10

° intervals with four 20° spaces. The holes are used by the crankshaft position sensor for

engine management.

+ ENGINE MANAGEMENT SYSTEM - Td5, DESCRIPTION AND OPERATION, Description.

Page 659 of 1672

CLUTCH - TD5

33-1-8 DESCRIPTION AND OPERATION

The dual mass flywheel is used to insulate the gearbox from torsional and transient vibrations produced by the engine.

The flywheel comprises primary and secondary flywheels with the drive between the two transferred by a torsional

damper which comprises four coil springs. The springs are located in the inside diameter of the primary flywheel. Two

of the springs are of smaller diameter and fit inside the larger diameter springs.

The primary flywheel locates the ring gear and is attached to the crankshaft flange with eight bolts. The two pairs of

coil springs are located in a recess in the flywheel between two riveted retainers. A roller bearing is pressed onto the

central boss of the primary flywheel and retained with a riveted plate. The bearing provides the mounting for the

secondary flywheel.

The secondary flywheel comprises two parts; an outer flywheel which provides the friction surface for the clutch drive

plate and an inner drive plate which transfers the drive from the primary flywheel, via the coil springs, to the outer

flywheel. The two components of the secondary flywheel are secured to each other with rivets. The inner drive plate

is located between the two pairs of coil springs and can rotate on the ball bearing in either direction against the

combined compression force of the four coil springs. Under high torque loading conditions the secondary flywheel can

rotate in either direction up to 70

° in relation to the primary flywheel.

The operating face of the secondary flywheel is machined to provide a smooth surface for the drive plate to engage

on. Three dowels and six studs and nuts provide for the location and attachment of the pressure plate.

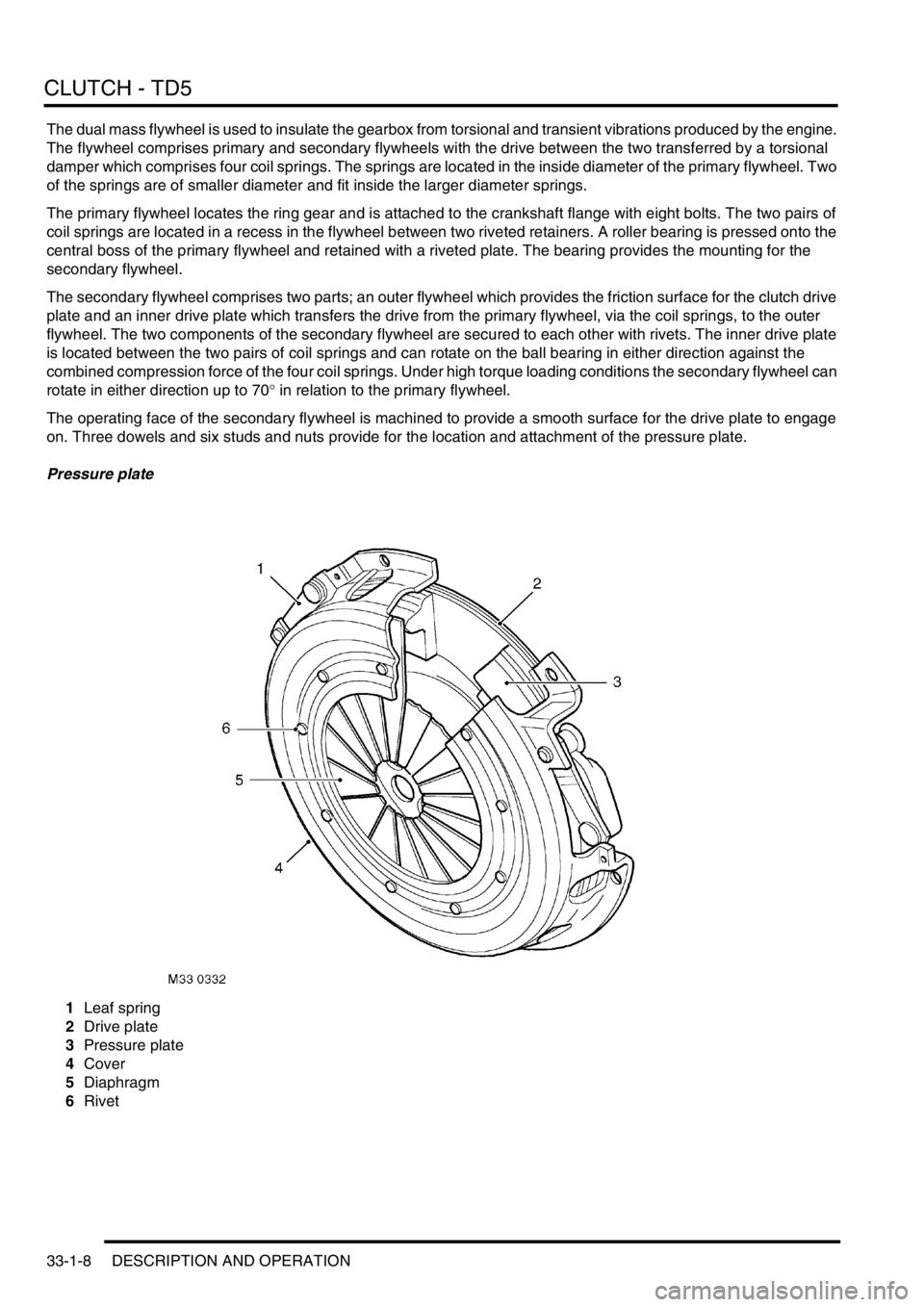

Pressure plate

1Leaf spring

2Drive plate

3Pressure plate

4Cover

5Diaphragm

6Rivet

Page 660 of 1672

CLUTCH - TD5

DESCRIPTION AND OPERATION 33-1-9

The pressure plate assembly comprises a pressure plate, cover and diaphragm and is mounted on and rotates with

the dual mass flywheel.

The pressure plate is forged from cast iron and machined to provide a smooth surface for the drive plate to engage

on. Three lugs on the outer diameter of the pressure plate connect it via three leaf spring to the cover. The leaf springs

have three tempered steel leaves which assist in pulling the pressure plate away from the drive plate when the clutch

pedal is depressed.

The cover is made from pressed steel and houses all pressure plate components. Shouldered rivets support the

diaphragm inside the cover. The rivets heads are chamfered to allow the diaphragm to pivot when pressure is applied

to it by the release bearing. Three holes in the cover locate on the dowels on the flywheel and six further holes provide

for the attachment of the cover to the flywheel with six nuts. Larger holes in the cover provide ventilation for the drive

plate and pressure plate and flywheel contact surfaces.

The diaphragm comprises a cast ring with eighteen fingers. The diaphragm is attached to the cover with nine

shouldered rivets. The inner head of each rivet is chamfered to allow the diaphragm to pivot when the clutch is

depressed or released. When pressure is applied to the fingers of the diaphragm by the release bearing, the

diaphragm pivots on the rivets and moves away from the pressure plate, releasing the force applied to the pressure

plate and allowing the drive plate to slip between the pressure plate and the flywheel.

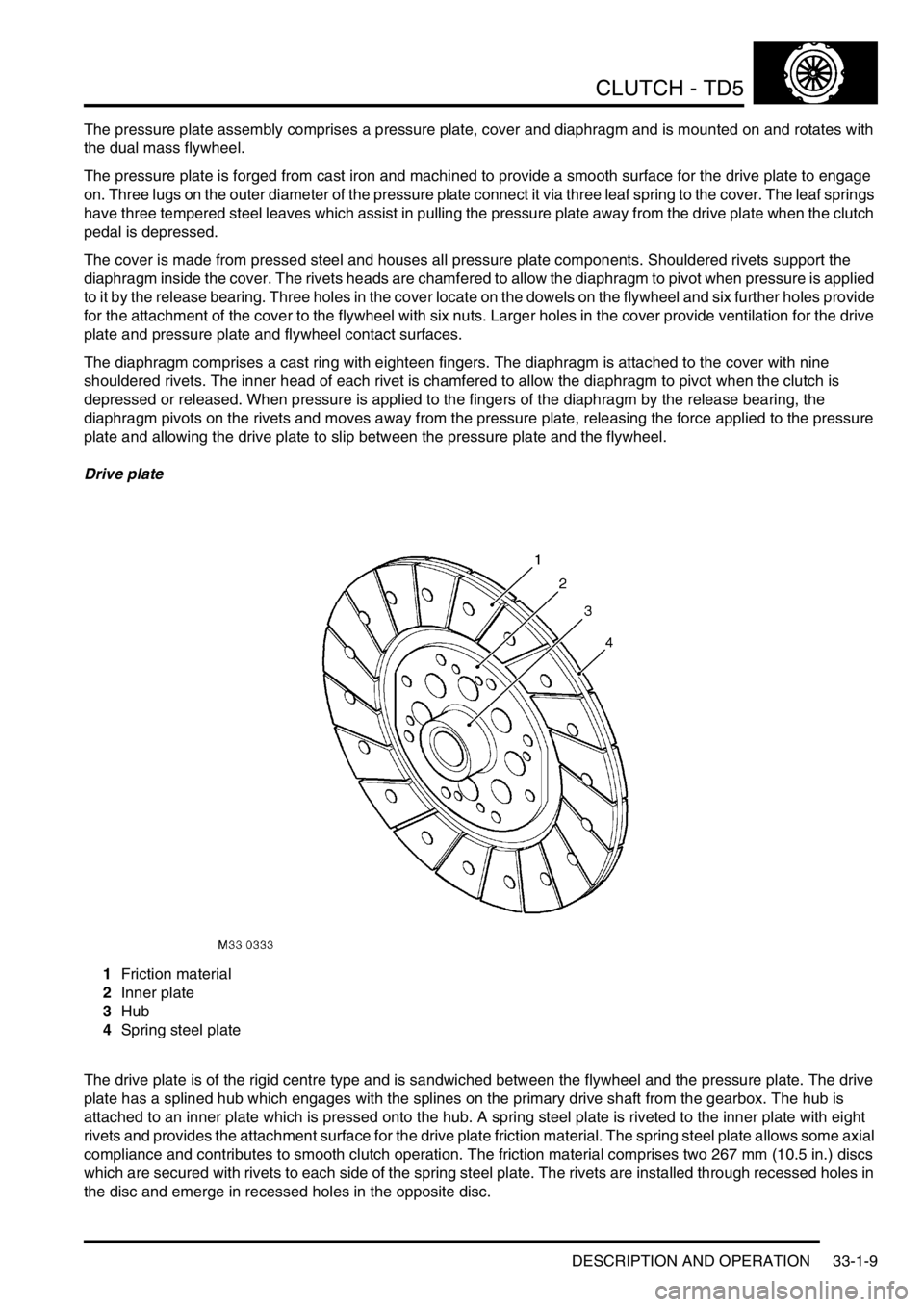

Drive plate

1Friction material

2Inner plate

3Hub

4Spring steel plate

The drive plate is of the rigid centre type and is sandwiched between the flywheel and the pressure plate. The drive

plate has a splined hub which engages with the splines on the primary drive shaft from the gearbox. The hub is

attached to an inner plate which is pressed onto the hub. A spring steel plate is riveted to the inner plate with eight

rivets and provides the attachment surface for the drive plate friction material. The spring steel plate allows some axial

compliance and contributes to smooth clutch operation. The friction material comprises two 267 mm (10.5 in.) discs

which are secured with rivets to each side of the spring steel plate. The rivets are installed through recessed holes in

the disc and emerge in recessed holes in the opposite disc.