ignition LAND ROVER DISCOVERY 2002 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 555 of 1672

FUEL DELIVERY SYSTEM - TD5

19-1-10 DESCRIPTION AND OPERATION

Water sensor

The water sensor has a three pin electrical connector. When the sensor detects water in the filter it illuminates a

warning lamp in the instrument pack .

+ INSTRUMENTS, DESCRIPTION AND OPERATION, Description.

The water sensor attachment thread has a slot machined down one side. The filter can be purged of water by partially

unscrewing the sensor which aligns the slot in the threads with a corresponding hole in the sensor. When aligned,

water and fuel can flow down the slot and flows from a small cast tube on the side of the sensor. Re-tightening the

sensor misaligns the slot and stops the flow of fuel.

The water sensor receives a battery supply from the fuel pump relay in the engine compartment fusebox on one of

the electrical connector pins. The two remaining pins are connected to the instrument pack and an earth header joint.

The sensor operation uses the measurement of resistance between two electrodes submerged in the fuel and

activated by the presence of water.

When the ignition is moved to position II the warning lamp will illuminate for approximately two seconds to check

warning lamp functionality. TestBook can also illuminate the warning lamp to check its functionality.

When the filter is full with fuel and no water is present the resistance of the Diesel fuel will show a reading of 15 mA

maximum on the feed wire to the instrument pack. This current will not illuminate the water sensor warning lamp in

the instrument pack. When sufficient water surrounds both electrodes the resistance of the water will show a reading

of 130 mA maximum. This will supply sufficient voltage to the instrument pack to illuminate the warning lamp to alert

the driver to the presence of water in the fuel system.

Page 556 of 1672

FUEL DELIVERY SYSTEM - TD5

DESCRIPTION AND OPERATION 19-1-11

Operation

When the ignition switch is moved to position II, the fuel pump relay in the engine compartment fusebox is energised

by the ECM. Battery voltage is supplied from the fuel pump relay to the fuel pump which operates. If engine cranking

is not detected by the ECM within a three minute period, the ECM will 'time-out', de-energising the fuel pump relay.

When the ignition is turned off the ECM timer will reset.

The low pressure stage of the fuel pump draws fuel from the swirl pot and pumps it into the fuel filter. The high

pressure stage of the fuel pump draws the fuel from the fuel filter and pumps it along the fuel feed pipe to the cylinder

head.

The fuel enters the cylinder head through a connection on the fuel pressure regulator housing and supplies each

injector with pressurised fuel. The fuel pressure regulator maintains the fuel pressure at the injectors at 4 bar (58

lbf.in

2) by returning excess fuel back to the fuel filter. The returned fuel passes through the fuel cooler in the engine

compartment before it passes to the fuel filter.

When the engine is running, each injector is operated by an overhead camshaft which depresses a push rod in each

injector at a timed interval. When the cam has depressed the push rod and the push rod is returning to its extended

position, fuel is drawn from the fuel supply drilling into the injector.

When the ECM determines that injection is required, the ECM transmits an electrical pulse which energises the fast

acting solenoid, closing the spill valve on the injector and locking fuel in the injector body. As the cam begins to

depress the push rod, the fuel in the injector is rapidly pressurised. When the pressure exceeds the nozzle spring

pressure, the nozzle opens and injects fuel at very high pressure into the cylinder.

When the ECM determines that the injection period should end, the solenoid is rapidly de-energised, opening the spill

valve on the injector and allowing fuel to pass into the return circuit.

The ECM controls the injection timing by altering the time at which the solenoid is energised and the injection period

by controlling the period for which the solenoid is energised.

Page 558 of 1672

FUEL DELIVERY SYSTEM - TD5

ADJUSTMENTS 19-1-13

ADJUST ME NTS

Fuel system purging

$% 19.50.07

If the vehicle runs out of fuel, or the fuel level is so

low that the fuel system draws air into the fuel rail,

the fuel rail will need to be purged before the engine

will start. This can be achieved by following the

procedure below.

If this procedure is carried out on a vehicle that

has not run out of fuel or otherwise drawn air into

the fuel rail, it can lead to the engine flooding and

failing to start.

Purge

1.Turn the ignition switch off and wait 15

seconds.

2.Turn the ignition switch to position II and wait 3

minutes (this ensures that the fuel system

purges all the air from the fuel rail within the

cylinder head).

3.Fully depress the throttle pedal.

4.Keeping the throttle pedal fully depressed,

crank the engine.

5.As soon as engine speed exceeds 600 rev/min,

release the throttle pedal and the ignition

switch.The engine must not be cranked

continuously for more than 30 seconds at

any one time.

6.If the engine fails to start, repeat the above

procedure.

Fuel tank - drain

$% 19.55.02

Drain

1.Disconnect both leads from battery.

WARNING: Always disconnect the negative

lead first. Disconnection of the positive lead

while the negative lead is connected could

result in a short circuit through accidental

grounding and cause personal injury.

2.Remove fuel pump.

+ FUEL DELIVERY SYSTEM - Td5,

REPAIRS, Pump - fuel.

3.Using a fuel recovery appliance, drain the fuel

from the tank into a sealed container. Follow

the manufacturers instructions for the

connection and safe use of the appliance.

Refill

1.Fit fuel pump.

+ FUEL DELIVERY SYSTEM - Td5,

REPAIRS, Pump - fuel.

2.Connect battery leads, positive terminal first.

Page 572 of 1672

FUEL DELIVERY SYSTEM - V8

DESCRIPTION AND OPERATION 19-2-7

The fuel pump is a 'self priming' wet type pump which is immersed in fuel in the tank. The fuel pump operates at all

times when the ignition switch is in position II. If the engine is not started, the ECU will 'time-out' after 2 seconds and

de-energise the fuel pump relay to protect the pump. The pump receives a feed from the battery via fuse 10 in the

engine compartment fusebox and the fuel pump relay. The relay is energised by the ECM when the ignition switch is

moved to position II.

The fuel pump is retained with a locking ring and sealed with a rubber seal. The locking ring requires a special tool

for removal and fitment. An access panel for the fuel pump is located in the loadspace floor below the loadspace

carpet. The access panel is sealed to the floor with a rubber seal and retained by six self-tapping screws.

The fuel gauge sender is integral with the fuel pump. The sender is submerged in the fuel and is operated by a float

which moves with the fuel level in the tank.

Fuel pump

The fuel pump assembly comprises a top cover which locates the fuel pressure regulator, electrical connector and

fuel pipe coupling. The top cover is attached to a plastic cup shaped housing by two metal springs. The housing

locates the pump and the fuel gauge sender unit.

The lower part of the housing is the swirl pot, which maintains a constant fuel level at the fuel pick-up. A feed pipe

from the pump to the coupling connection and a return pipe from the regulator connect between the top cover and the

housing.

A coarse filter is attached to the base of the housing and prevents the ingress of large contaminants into the swirl pot.

A gauze filter prevents particles entering the fuel pump.

Surrounding the pump is a large fine paper filter element which further protects the fuel pressure regulator, engine

and injectors from particulate contamination. The paper filter is not a serviceable item and removes the requirement

for an external in-line filter.

A non-return valve is located in the base of the housing. When the fuel tank is full, fuel pressure keeps the valve lifted

from its seat allowing fuel to flow into the swirl pot. As the tank level reduces, the fuel pressure in the tank reduces

causing the valve to close. When the valve is closed fuel is retained in the swirl pot, ensuring that the swirl pot remains

full and maintains a constant supply to the fuel pump.

A four pin electrical connector is located on the top cover of the pump and provides power feed and return for fuel

pump and fuel gauge rotary potentiometer operation. A single quick release coupling connects the fuel feed pipe to

the outer top surface of the pump.

Two metal springs are attached to the top cover and the housing of the pump. When the pump is installed it seats on

the lower surface inside the tank. The springs exert a downward pressure on the pump and ensure that the pump is

located positively at the bottom of the fuel tank.

The fuel pump has a maximum current draw of 6.5 A at 12.5 V.

On NAS vehicles with vacuum type EVAP system leak detection capability only, the fuel pump top cover is fitted with

an On Board Diagnostics (OBD) pressure sensor. This sensor has a three pin electrical connector which provides a

connection between the sensor and the ECM. The sensor is sealed in the top cover with an 'O' ring and secured with

a clip. The sensor monitors tank pressure during OBD tests of the fuel evaporation system integrity. A hose is

connected to the sensor and is routed across the top of the fuel tank and terminates at the top of the fuel filler tube.

The pipe is open to atmosphere and provides atmospheric pressure for the sensor operation.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

Page 575 of 1672

FUEL DELIVERY SYSTEM - V8

19-2-10 DESCRIPTION AND OPERATION

Operation

When the ignition switch is moved to position II, the fuel pump relay in the engine compartment fusebox is energised

by the ECM. Battery voltage is supplied from the fuel pump relay to the fuel pump which operates. If engine cranking

is not detected by the ECU within a thirty second period, the ECU will 'time-out', de-energising the fuel pump relay.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

The fuel pump draws fuel from the swirl pot and pumps it along the fuel feed pipe to the injector fuel rail on the engine.

When the pressure in the fuel feed line reaches 3.5 bar (50 lbf.in

2) the fuel pressure regulator opens and relieves

pressure by directing fuel back into the swirl pot. The pressure regulator is constantly opening and closing to maintain

the pressure in the fuel feed pipe and the fuel rail at 3.5 bar (50 lbf.in

2).

The pressure is felt at each of the eight injectors connected to the fuel rail. The ECM controls the injection timing and

energises each injector to allow a metered amount of fuel at pump pressure to be injected into the inlet tract of the

inlet manifold. The atomised fuel from the injector is mixed with air from the inlet manifold before passing into the

cylinder.

Page 634 of 1672

MANIFOLDS AND EXHAUST SYSTEMS - V8

DESCRIPTION AND OPERATION 30-2-5

Description

General

The inlet manifold on the V8 engine is located on the top of the engine, between the cylinders. The manifold directs

intake air into the cylinders. The intake air is mixed with fuel delivered by the injectors prior to ignition in the cylinders.

The inlet manifold comprises three separate aluminium castings.

Two exhaust manifolds are used, one for each bank of four cylinders. Each exhaust manifold allows combustion

gases from the cylinders to leave the engine and directs them into the exhaust system.

The exhaust system is connected to each exhaust manifold and merges into one pipe midway along the underside of

the vehicle. A catalytic converter (where fitted) is located in the front pipe from each manifold. A silencer is installed

midway along the system and a second tail silencer is located at the rear of the vehicle.

Inlet manifold

The inlet manifold comprises three aluminium castings; a lower manifold, an upper manifold and a plenum. The inlet

manifold is located on the top of the engine and feeds air into the cylinders.

Lower manifold

The lower manifold is a one piece machined aluminium casting which locates in the vee on the top of the engine and

is secured to each cylinder head with six bolts per head. A one piece coated metal gasket seals the lower manifold to

each cylinder head and also serves as a cover for the cylinder block.

Eight injectors are fitted into the lower manifold, four on each side. Each injector is sealed in the manifold with O-ring

seals and retained in position by the fuel rails. A fuel rail is attached to each side of the manifold and secured with two

bolts.

Eight air intake ports are cast and machined on the top of the manifold, each port directing intake air into one cylinder.

These ports mate with matching ports in the upper manifold and are sealed with a coated metal gasket between the

two manifolds.

A cavity at the front of the manifold collects coolant flow from the engine. A coolant outlet pipe is sealed and attached

to the front of the manifold and provides for coolant to flow through the cavity in the casting to the radiator top hose.

A smaller port in the manifold also allows coolant to flow from the cavity to the heater matrix. The lower manifold also

locates the Engine Coolant Temperature (ECT) sensor in a port in the front of the manifold.

Upper manifold

The upper manifold is a one piece machined aluminium casting. The manifold has eight ports on its lower face which

mate with the eight ports on the lower manifold. The joint between the upper and lower manifolds is sealed with a

coated metal gasket and secured with six bolts.

The manifold divides from the eight ports into eight branches, four on each side. Each set of four branches merge into

one gallery on each side of the manifold. Each gallery has an opening at its forward end which mates with the intake

plenum.

The upper manifold provides attachment for the Idle Air Control (IAC) valve and for brackets which retain pipes, plug

leads and throttle cables.

Page 647 of 1672

MANIFOLDS AND EXHAUST SYSTEMS - V8

30-2-18 REPAIRS

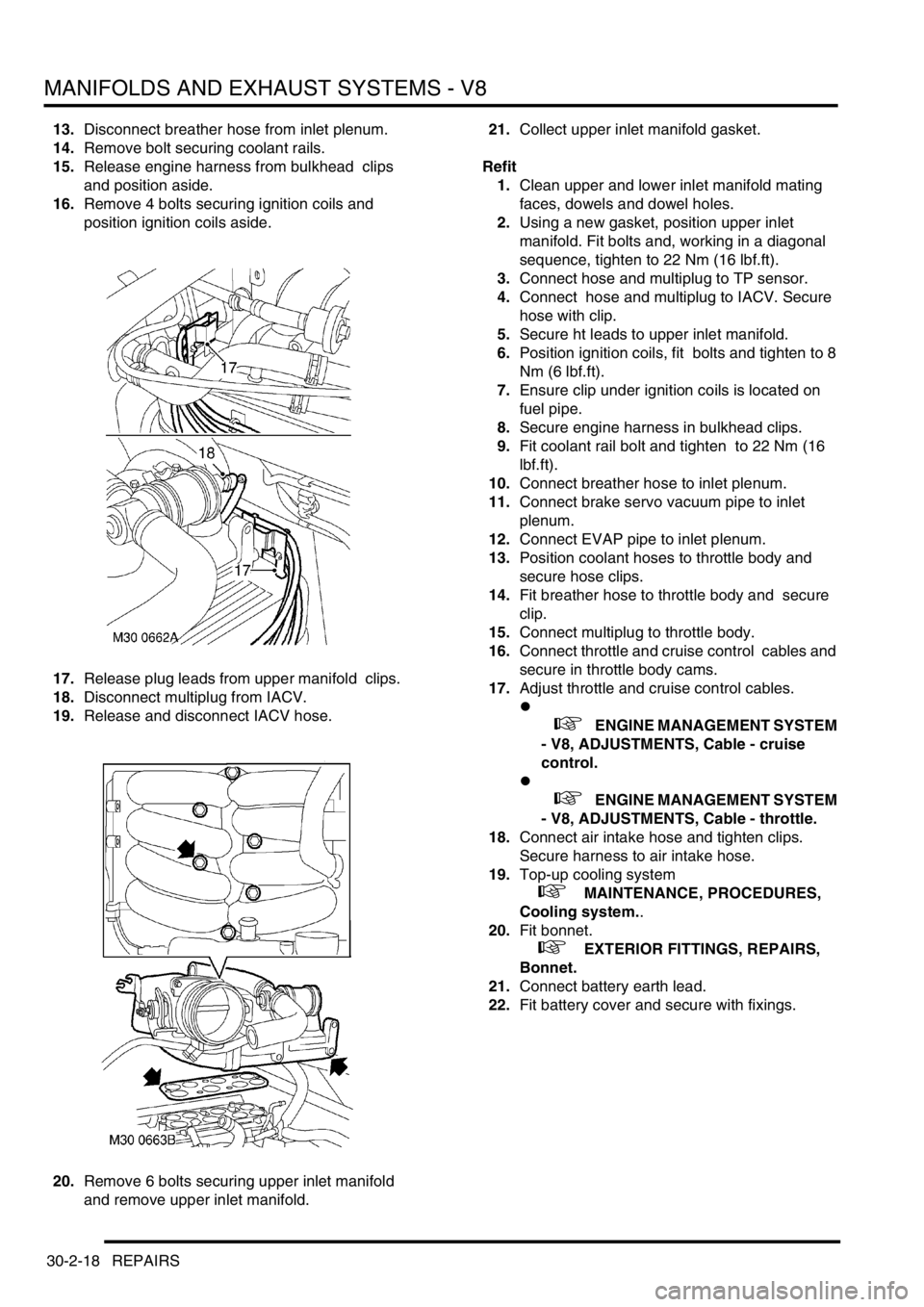

13.Disconnect breather hose from inlet plenum.

14.Remove bolt securing coolant rails.

15.Release engine harness from bulkhead clips

and position aside.

16.Remove 4 bolts securing ignition coils and

position ignition coils aside.

17.Release plug leads from upper manifold clips.

18.Disconnect multiplug from IACV.

19.Release and disconnect IACV hose.

20.Remove 6 bolts securing upper inlet manifold

and remove upper inlet manifold. 21.Collect upper inlet manifold gasket.

Refit

1.Clean upper and lower inlet manifold mating

faces, dowels and dowel holes.

2.Using a new gasket, position upper inlet

manifold. Fit bolts and, working in a diagonal

sequence, tighten to 22 Nm (16 lbf.ft).

3.Connect hose and multiplug to TP sensor.

4.Connect hose and multiplug to IACV. Secure

hose with clip.

5.Secure ht leads to upper inlet manifold.

6.Position ignition coils, fit bolts and tighten to 8

Nm (6 lbf.ft).

7.Ensure clip under ignition coils is located on

fuel pipe.

8.Secure engine harness in bulkhead clips.

9.Fit coolant rail bolt and tighten to 22 Nm (16

lbf.ft).

10.Connect breather hose to inlet plenum.

11.Connect brake servo vacuum pipe to inlet

plenum.

12.Connect EVAP pipe to inlet plenum.

13.Position coolant hoses to throttle body and

secure hose clips.

14.Fit breather hose to throttle body and secure

clip.

15.Connect multiplug to throttle body.

16.Connect throttle and cruise control cables and

secure in throttle body cams.

17.Adjust throttle and cruise control cables.

l

+ ENGINE MANAGEMENT SYSTEM

- V8, ADJUSTMENTS, Cable - cruise

control.

l

+ ENGINE MANAGEMENT SYSTEM

- V8, ADJUSTMENTS, Cable - throttle.

18.Connect air intake hose and tighten clips.

Secure harness to air intake hose.

19.Top-up cooling system

+ MAINTENANCE, PROCEDURES,

Cooling system..

20.Fit bonnet.

+ EXTERIOR FITTINGS, REPAIRS,

Bonnet.

21.Connect battery earth lead.

22.Fit battery cover and secure with fixings.

Page 746 of 1672

TRANSFER BOX - LT230SE

DESCRIPTION AND OPERATION 41-13

Description

General

The LT 230SE transfer box is mounted at the rear of the gearbox and transmits drive via high or low reduction ratios

to the front and rear axles via the propeller shafts. The high/low ratios are 1.211:1 and 3.32:1 respectively.

Transfer boxes fitted to this model have the prefixes 41D and 42D to the unit serial number. Prefix 41D denotes that

the unit is not fitted with interlock whilst 42D denotes that interlock is fitted.

Vehicles up to 03 model year – Whilst similar to LT230Q transfer boxes fitted to other models, the LT230SE transfer

box has certain engineering modifications incorporated which are as follows:

lUprated torque capacity

lModified front and rear output and cross shaft housings

lIntermediate gear bearing pre-load now controlled by a selective, non-collapsible spacer

lSpeedometer drive and driven gears not fitted for this application

lModified high/low sleeve

lModified front output flange and mud shield

lDifferential lock fitted to certain vehicles, but no longer driver operated

lFixed setting of differential lock warning lamp switch on vehicles fitted with differential lock

Vehicles from 03 model year – The LT230SE transfer box is as described above for vehicles up to 03 model year

with the following modifications:

The following items are introduced on vehicles from 03 model year

lRibs added to main casing to reduce operating noise

lBearing retaining nut on the differential carrier has patchlock added to the threads

lInterlock solenoid moved from main casing to selector lever assembly

lIntermediate gears modified with machined internal shoulder and bearing circlips deleted

The following items are introduced later in the 03 model year build programme and therefore may not appear on all

03 model year vehicles

lDriver operated differential lock (if fitted)

lHigh/Low selector shaft fitted with spring assist

lExisting differential lock switch replaced by new design switch.

lNew secondary differential lock switch installed in the front output housing

Construction

The transfer box comprises three main assemblies; the main casing, the front output housing and the rear output

housing. Both output housings and all cover plates are sealed to the main casing by sealant; mud and water ingress

being prevented by mud shields located on the output flanges.

Main casing

The main casing carries the mainshaft input gear, the intermediate gears and the differential, together with the high/

low range gears, selector shaft and fork. The front and rear output housings are bolted to either side of the main

casing.

Transmission neutral sensor

A transmission neutral sensor is fitted on automatic gearbox vehicles for North America and Japan. The sensor is

connected to the BCU and is normally in the open position. The sensor provides an earth path for the BCU which then

interprets the signal and activates an audible warning generated by the IDM if neutral is selected on the transfer box

when the ignition is on.

Page 747 of 1672

TRANSFER BOX - LT230SE

41-14 DESCRIPTION AND OPERATION

Transfer box interlock solenoid - Automatic gearbox vehicles

An interlock solenoid is fitted for North America and Japan. The solenoid is located on the top of the transfer box main

casing on vehicles up to 03 model year or on the selector lever assembly on vehicles from 03 model year. The

solenoid is connected to the transfer box relay which, in turn, is controlled by the IDM. The purpose of the solenoid is

to prevent neutral being selected on the transfer box when the ignition key is removed, thereby locking the box in

either high or low ratio.

Mainshaft input gear

The gearbox output shaft is splined into the mainshaft input gear which is supported by taper roller bearings.

Input gear bearing pre-load is achieved by the use of a selective shim located in the bearing housing.

Intermediate gears

The intermediate gear cluster is supported by the taper roller bearings located at each end of the cluster and runs on

the intermediate shaft which, in turn, is supported at the front and rear by the main casing.

A selective spacer, positioned between the gears, pre-loads the intermediate gear bearings when the intermediate

shaft nut is tightened sufficiently to achieve the correct 'torque to turn' of the intermediate gears.

On vehicles from 03 model year, the circlips used to retain the bearings in the intermediate gear are deleted. The bore

of the intermediate gear is machined with a shoulder at each end to locate the bearings.

Differential assembly

The differential assembly is supported at the front and rear by taper roller bearings, the front bearing outer track is

located in the front output housing and the rear bearing outer track is located in the main casing by the rear output

housing. Bearing pre-load is achieved by means of a selective shim located in the front output housing.

The differential rear shaft carries the low range gear, high/low selector sleeve and hub, high range gear and bush and

the differential rear bearing; these components being secured to the shaft by a special staked nut.

The differential assembly comprises front and rear half carriers with integral shafts and with sun and planet gears

mounted on cross shafts within the half carriers. Dished, non-selective thrust washers control the engagement of the

planet gears with the sun gears, whilst selective thrust washers are used to control engagement of the sun gears and

'torque to turn' of the differential. The differential carrier halves are bolted together, a retaining ring providing positive

location of the cross shafts.

The high/low selector shaft and fork are located at the side of the differential, movement of the shaft, fork and selector

sleeve being controlled by the high/low selector finger. A spring loaded detent ball fitted in the main casing, locates

in grooves in the shaft.

On vehicles from 03 model year, the selector fork is modified and fitted with a spring assistor and clips to reduce the

effort required to move the selector lever.

Front output housing

The front output housing carries the front output shaft and flange, high/low cross shaft, housing and selector and on

certain vehicles, the differential lock selector shaft and fork.

The front output shaft is supported in the housing by a single bearing and is splined into the differential front sun gear.

High/low selector

The high/low cross shaft is located in a housing bolted to the top of the output housing and is connected to the high/

low selector finger which locates in a slot in the selector shaft.

Page 749 of 1672

TRANSFER BOX - LT230SE

41-16 DESCRIPTION AND OPERATION

Functionality – Vehicles from 03 model year only

The differential lock must be engaged for 2 wheel rolling road testing. It will also be necessary to disconnect the

propeller shaft from the transfer box output shaft driving the axle whose wheels are NOT on the rolling road. In

addition, the ETC system must be deactivated by either, removing a fuse (10A fuse 28 in the passenger compartment

fusebox, labelled ABS) or disconnecting the ABS modulator pump. This must be done with the ignition switched off.

Note that the SLABS ECU may record a system fault.

The lock can be engaged or disengaged using the selector lever. Vehicles not fitted with a differential lock can be

identified by a high/low range selector lever with no differential lock functionality and the cover and selector shaft

(arrowed), not visible on the front output housing.

WARNING: VEHICLES NOT FITTED WITH A DIFFERENTIAL LOCK MUST NOT BE TESTED ON A ROLLING

ROAD WHERE THE ROLLERS ARE DRIVEN BY THE VEHICLE.

Differential lock warning lamp switch - if fitted - Vehicles up to 03 model year

A differential lock warning lamp switch connected to the SLABS ECU and operated by movement of the selector fork

and shaft is screwed into the top of the output housing. The switch connects to earth when the differential lock is

engaged.

Differential lock warning lamp switches - if fitted - Vehicles from 03 model year

Vehicles from 03 model year are fitted with two differential lock warning lamp switches.

One switch is of a new design and is fitted into the top of the front output housing in the same position as on previous

models. The switch is connected to the SLABS ECU and is operated by movement of the selector fork and shaft.

The second switch is located in a threaded hole on the forward face of the front output housing. The switch is also

connected to the SLABS ECU and is operated by movement of the selector shaft.

Both switches have an aluminium washer which seals the switch to the casing and also sets the switch position,

removing the requirement for a setting procedure.

Both switches are connected in parallel to earth when the differential lock is engaged. This earth is sensed by the

SLABS ECU which illuminates the differential lock warning lamp in the instrument pack.

Differential lock warning lamp - Vehicles up to 03 model year – if fitted

The differential lock warning lamp is located in the instrument pack and provides a warning to the driver when the

ignition is switched on that the differential lock is engaged. The warning lamp illuminates in a Red colour.

With the lock engaged, the traction control and electronic brake distribution warning lamps will also be illuminated.

Disengagement of the differential lock should be carried out with the ignition switched off. The warning lamps must

be extinguished when the ignition is switched on again.

Differential lock warning lamp – vehicles from 03 model year – if fitted

The differential lock warning lamp is located in the instrument pack and provides a visual warning to the driver, when

the ignition is on, the differential lock is engaged. The warning lamp illuminates in an amber colour.

When the lock is engaged, the warning lamp is illuminated and the instrument pack sounder emits three audible

chimes. When the lock is disengaged, the warning lamp is extinguished and the instrument pack sounder emits three

audible chimes.

Rear output housing

The rear output housing carries the output shaft and flange. A cable operated transmission brake is attached to the

housing, the brake drum being attached to the output flange.

The rear output shaft is supported in the housing by a single bearing and is splined into the differential rear sun gear.