lock LAND ROVER FREELANDER 2001 Owners Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 262 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-85

9. Big-end bearings selection: Select the

required bearing shells from general data.

+ GENERAL DATA, Engine - KV6

Petrol.

10.Ensure all bolt holes are clean and dry.

Remove all traces of thread locking material

from oil pick-up strainer bolt hole and threads of

retaining bolt.

CAUTION: Do not use a tap.

11.Ensure bearing ladder locating dowels are

fitted and dowel holes in bearing ladder are

clean and dry.

12.Check coolant stub pipe in cylinder block for

signs of leakage and corrosion, replace as

necessary. Apply sealant, Part No. STC 50554

to seal replacement pipe to cylinder block.

13.Clean main bearing shell recesses in cylinder

block.

14.Clean crankshaft main bearing and big end

bearing journals. Clean bearing shell locations

in connecting rods and caps.

15.Fit selected main bearing shells, grooved into

cylinder block and plain into bearing ladder.

16.Fit new thrust washers to cylinder block.

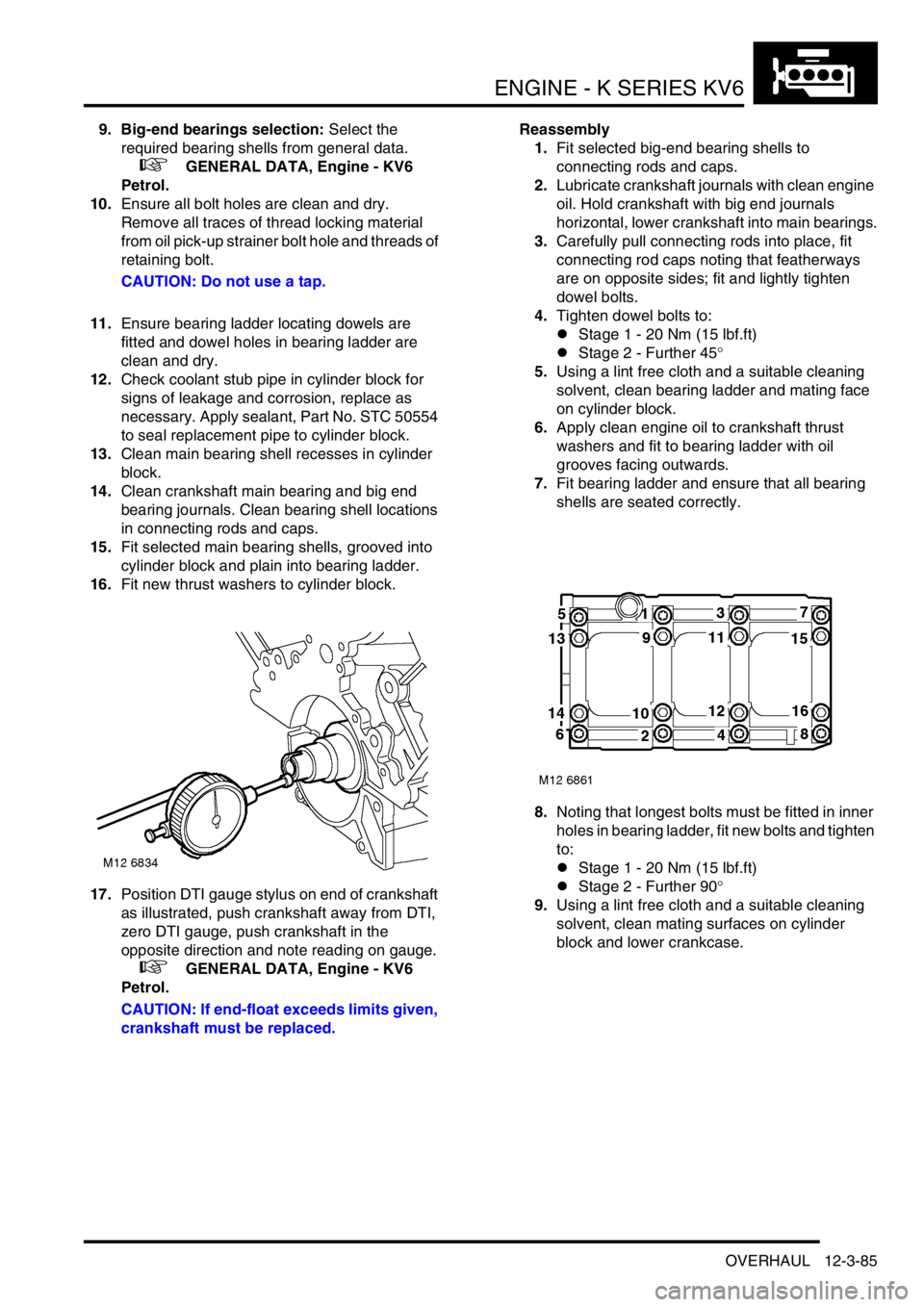

17.Position DTI gauge stylus on end of crankshaft

as illustrated, push crankshaft away from DTI,

zero DTI gauge, push crankshaft in the

opposite direction and note reading on gauge.

+ GENERAL DATA, Engine - KV6

Petrol.

CAUTION: If end-float exceeds limits given,

crankshaft must be replaced.Reassembly

1.Fit selected big-end bearing shells to

connecting rods and caps.

2.Lubricate crankshaft journals with clean engine

oil. Hold crankshaft with big end journals

horizontal, lower crankshaft into main bearings.

3.Carefully pull connecting rods into place, fit

connecting rod caps noting that featherways

are on opposite sides; fit and lightly tighten

dowel bolts.

4.Tighten dowel bolts to:

lStage 1 - 20 Nm (15 lbf.ft)

lStage 2 - Further 45°

5.Using a lint free cloth and a suitable cleaning

solvent, clean bearing ladder and mating face

on cylinder block.

6.Apply clean engine oil to crankshaft thrust

washers and fit to bearing ladder with oil

grooves facing outwards.

7.Fit bearing ladder and ensure that all bearing

shells are seated correctly.

8.Noting that longest bolts must be fitted in inner

holes in bearing ladder, fit new bolts and tighten

to:

lStage 1 - 20 Nm (15 lbf.ft)

lStage 2 - Further 90°

9.Using a lint free cloth and a suitable cleaning

solvent, clean mating surfaces on cylinder

block and lower crankcase.

Page 263 of 1007

ENGINE - K SERIES KV6

12-3-86 OVERHAUL

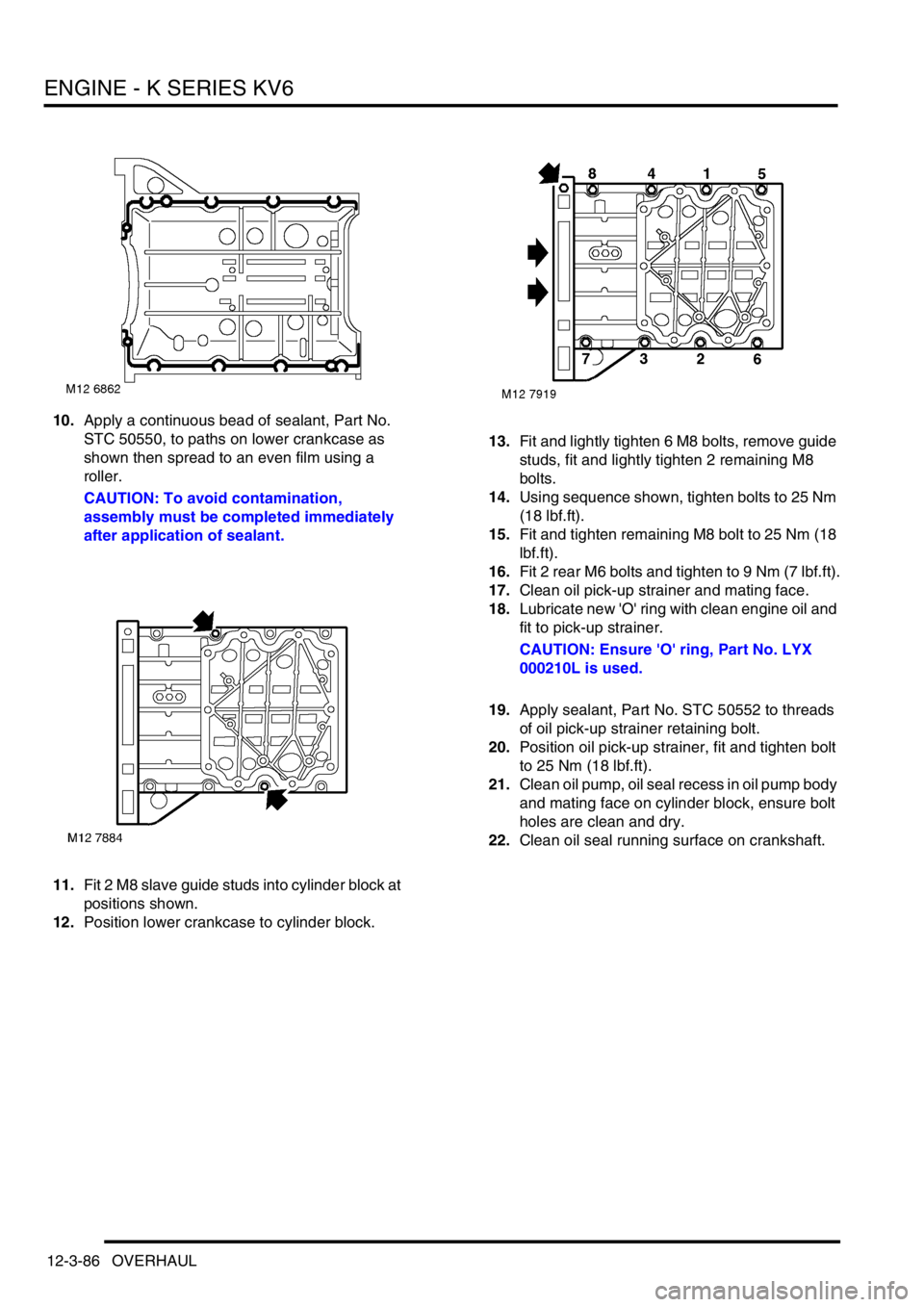

10.Apply a continuous bead of sealant, Part No.

STC 50550, to paths on lower crankcase as

shown then spread to an even film using a

roller.

CAUTION: To avoid contamination,

assembly must be completed immediately

after application of sealant.

11.Fit 2 M8 slave guide studs into cylinder block at

positions shown.

12.Position lower crankcase to cylinder block.13.Fit and lightly tighten 6 M8 bolts, remove guide

studs, fit and lightly tighten 2 remaining M8

bolts.

14.Using sequence shown, tighten bolts to 25 Nm

(18 lbf.ft).

15.Fit and tighten remaining M8 bolt to 25 Nm (18

lbf.ft).

16.Fit 2 rear M6 bolts and tighten to 9 Nm (7 lbf.ft).

17.Clean oil pick-up strainer and mating face.

18.Lubricate new 'O' ring with clean engine oil and

fit to pick-up strainer.

CAUTION: Ensure 'O' ring, Part No. LYX

000210L is used.

19.Apply sealant, Part No. STC 50552 to threads

of oil pick-up strainer retaining bolt.

20.Position oil pick-up strainer, fit and tighten bolt

to 25 Nm (18 lbf.ft).

21.Clean oil pump, oil seal recess in oil pump body

and mating face on cylinder block, ensure bolt

holes are clean and dry.

22.Clean oil seal running surface on crankshaft.

Page 264 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-87

Refit

1.Fit oil pump gasket.

+ ENGINE - K SERIES KV6,

OVERHAUL, Oil pump - Overhaul.

2.Fit engine sump.

+ ENGINE - K SERIES KV6,

OVERHAUL, Sump - engine oil.

3.Fit crankshaft rear oil seal.

+ ENGINE - K SERIES KV6,

OVERHAUL, Crankshaft rear oil seal.

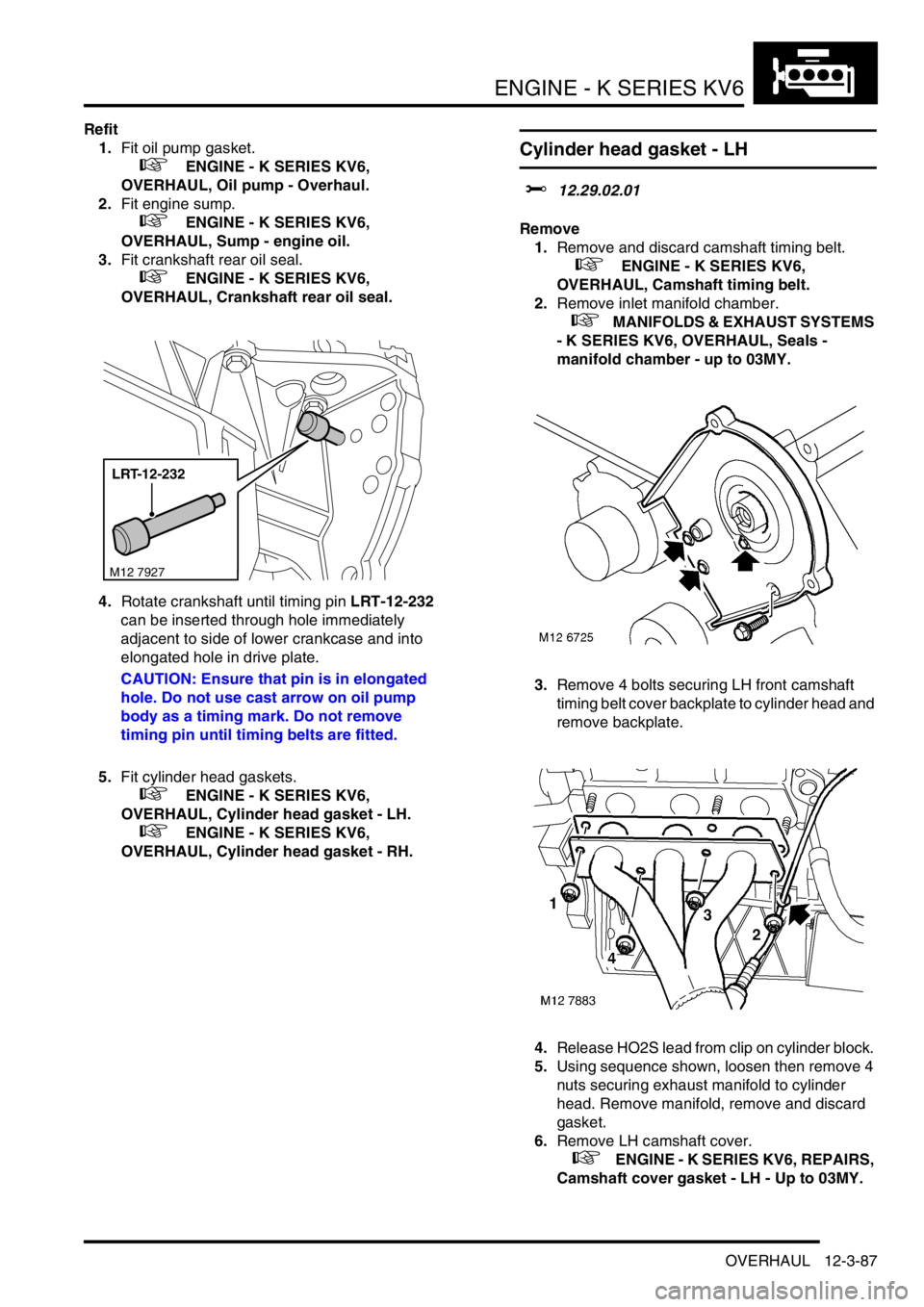

4.Rotate crankshaft until timing pin LRT-12-232

can be inserted through hole immediately

adjacent to side of lower crankcase and into

elongated hole in drive plate.

CAUTION: Ensure that pin is in elongated

hole. Do not use cast arrow on oil pump

body as a timing mark. Do not remove

timing pin until timing belts are fitted.

5.Fit cylinder head gaskets.

+ ENGINE - K SERIES KV6,

OVERHAUL, Cylinder head gasket - LH.

+ ENGINE - K SERIES KV6,

OVERHAUL, Cylinder head gasket - RH.

Cylinder head gasket - LH

$% 12.29.02.01

Remove

1.Remove and discard camshaft timing belt.

+ ENGINE - K SERIES KV6,

OVERHAUL, Camshaft timing belt.

2.Remove inlet manifold chamber.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, OVERHAUL, Seals -

manifold chamber - up to 03MY.

3.Remove 4 bolts securing LH front camshaft

timing belt cover backplate to cylinder head and

remove backplate.

4.Release HO2S lead from clip on cylinder block.

5.Using sequence shown, loosen then remove 4

nuts securing exhaust manifold to cylinder

head. Remove manifold, remove and discard

gasket.

6.Remove LH camshaft cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft cover gasket - LH - Up to 03MY.

LRT-12-232

M12 7927

Page 265 of 1007

ENGINE - K SERIES KV6

12-3-88 OVERHAUL

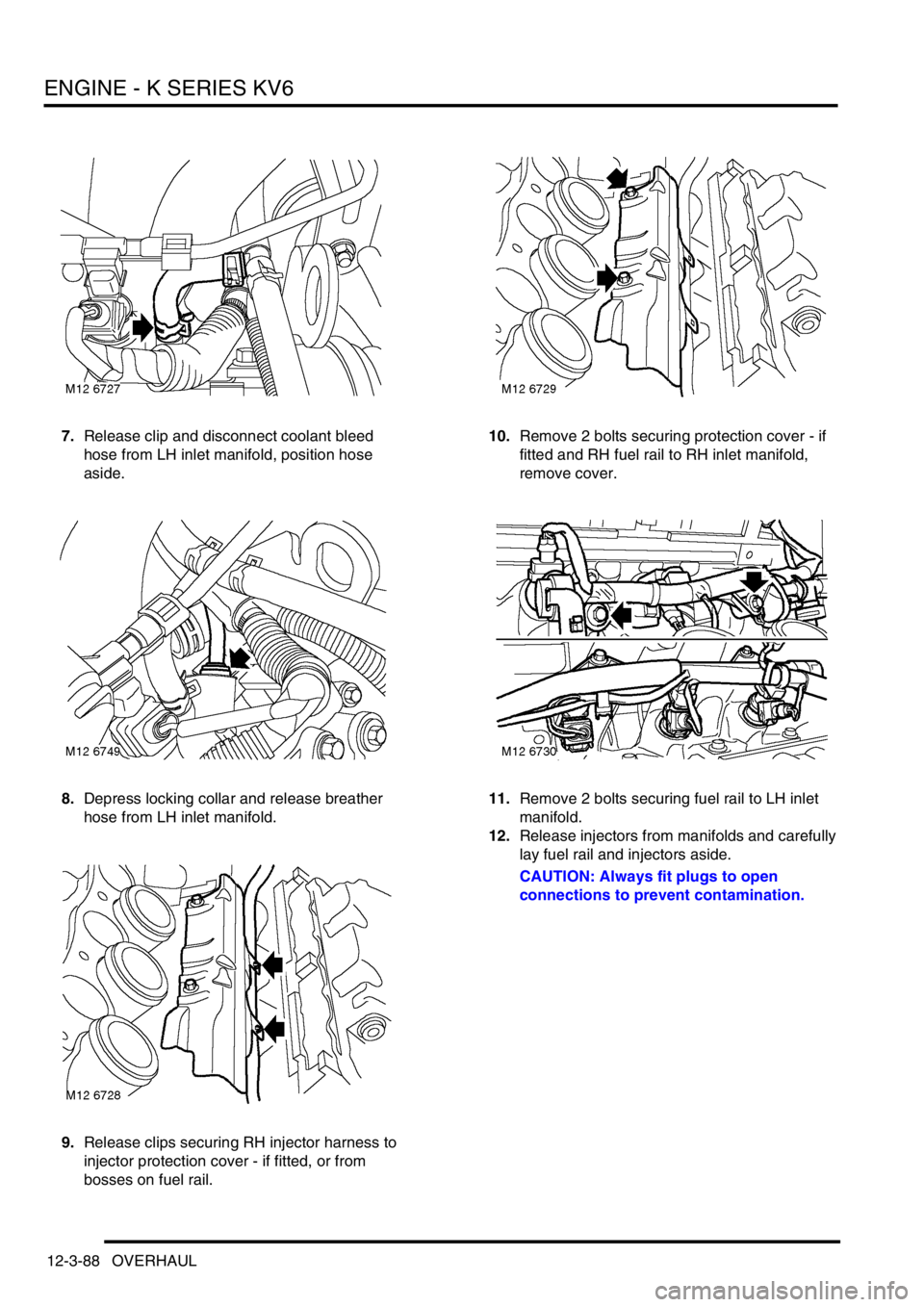

7.Release clip and disconnect coolant bleed

hose from LH inlet manifold, position hose

aside.

8.Depress locking collar and release breather

hose from LH inlet manifold.

9.Release clips securing RH injector harness to

injector protection cover - if fitted, or from

bosses on fuel rail.10.Remove 2 bolts securing protection cover - if

fitted and RH fuel rail to RH inlet manifold,

remove cover.

11.Remove 2 bolts securing fuel rail to LH inlet

manifold.

12.Release injectors from manifolds and carefully

lay fuel rail and injectors aside.

CAUTION: Always fit plugs to open

connections to prevent contamination.

Page 266 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-89

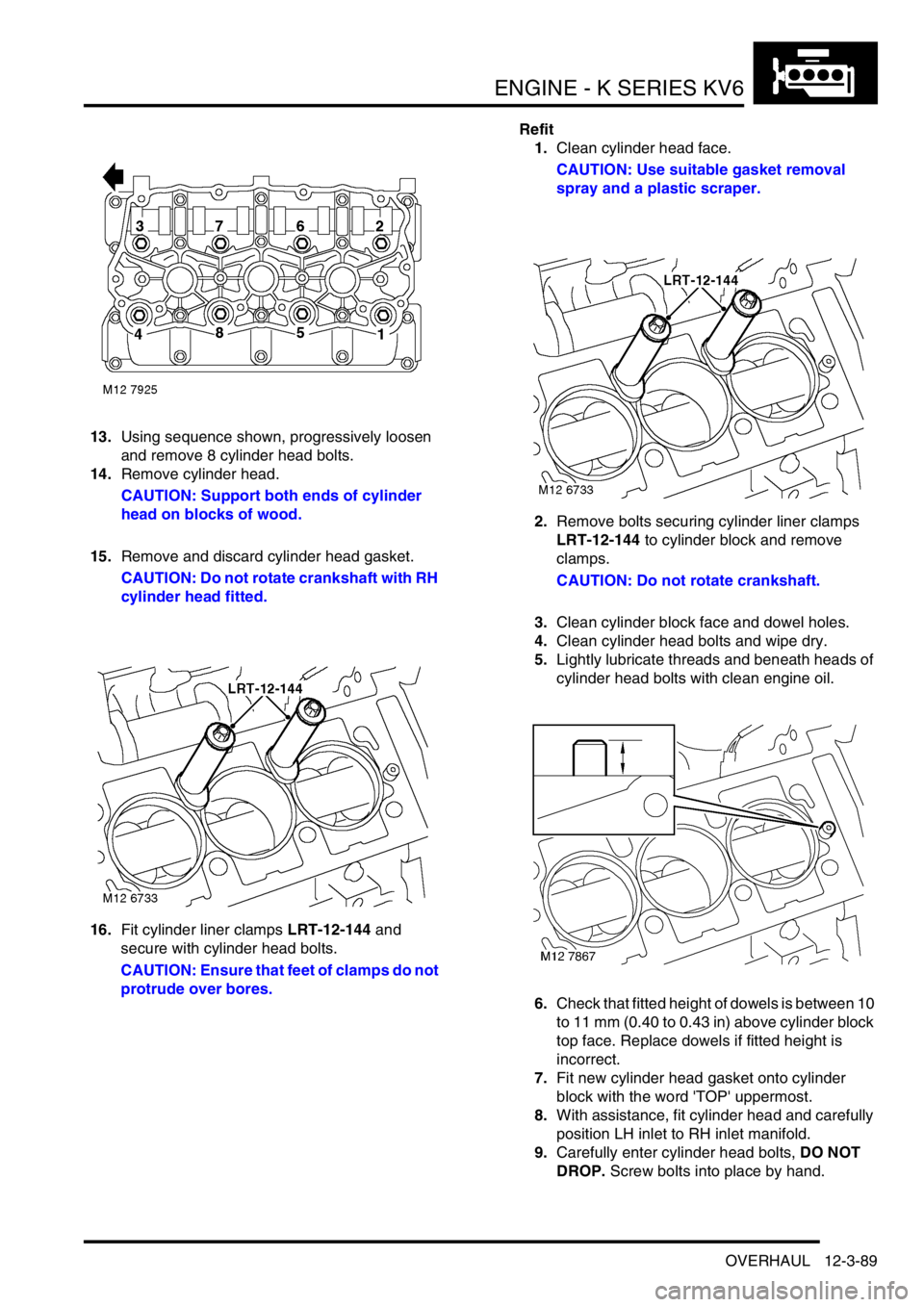

13.Using sequence shown, progressively loosen

and remove 8 cylinder head bolts.

14.Remove cylinder head.

CAUTION: Support both ends of cylinder

head on blocks of wood.

15.Remove and discard cylinder head gasket.

CAUTION: Do not rotate crankshaft with RH

cylinder head fitted.

16.Fit cylinder liner clamps LRT-12-144 and

secure with cylinder head bolts.

CAUTION: Ensure that feet of clamps do not

protrude over bores.Refit

1.Clean cylinder head face.

CAUTION: Use suitable gasket removal

spray and a plastic scraper.

2.Remove bolts securing cylinder liner clamps

LRT-12-144 to cylinder block and remove

clamps.

CAUTION: Do not rotate crankshaft.

3.Clean cylinder block face and dowel holes.

4.Clean cylinder head bolts and wipe dry.

5.Lightly lubricate threads and beneath heads of

cylinder head bolts with clean engine oil.

6.Check that fitted height of dowels is between 10

to 11 mm (0.40 to 0.43 in) above cylinder block

top face. Replace dowels if fitted height is

incorrect.

7.Fit new cylinder head gasket onto cylinder

block with the word 'TOP' uppermost.

8.With assistance, fit cylinder head and carefully

position LH inlet to RH inlet manifold.

9.Carefully enter cylinder head bolts, DO NOT

DROP. Screw bolts into place by hand.

Page 267 of 1007

ENGINE - K SERIES KV6

12-3-90 OVERHAUL

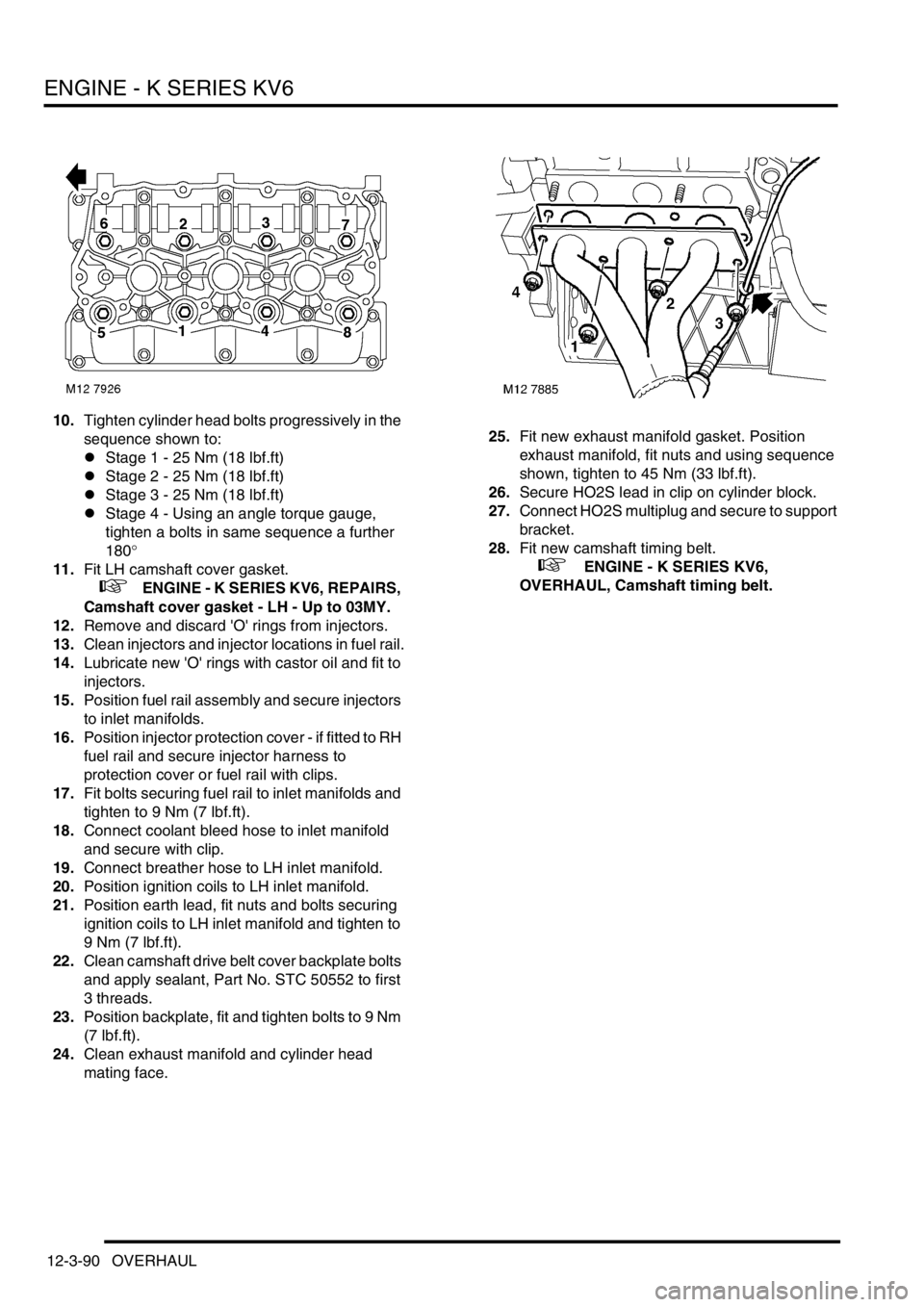

10.Tighten cylinder head bolts progressively in the

sequence shown to:

lStage 1 - 25 Nm (18 lbf.ft)

lStage 2 - 25 Nm (18 lbf.ft)

lStage 3 - 25 Nm (18 lbf.ft)

lStage 4 - Using an angle torque gauge,

tighten a bolts in same sequence a further

180°

11.Fit LH camshaft cover gasket.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft cover gasket - LH - Up to 03MY.

12.Remove and discard 'O' rings from injectors.

13.Clean injectors and injector locations in fuel rail.

14.Lubricate new 'O' rings with castor oil and fit to

injectors.

15.Position fuel rail assembly and secure injectors

to inlet manifolds.

16.Position injector protection cover - if fitted to RH

fuel rail and secure injector harness to

protection cover or fuel rail with clips.

17.Fit bolts securing fuel rail to inlet manifolds and

tighten to 9 Nm (7 lbf.ft).

18.Connect coolant bleed hose to inlet manifold

and secure with clip.

19.Connect breather hose to LH inlet manifold.

20.Position ignition coils to LH inlet manifold.

21.Position earth lead, fit nuts and bolts securing

ignition coils to LH inlet manifold and tighten to

9 Nm (7 lbf.ft).

22.Clean camshaft drive belt cover backplate bolts

and apply sealant, Part No. STC 50552 to first

3 threads.

23.Position backplate, fit and tighten bolts to 9 Nm

(7 lbf.ft).

24.Clean exhaust manifold and cylinder head

mating face.25.Fit new exhaust manifold gasket. Position

exhaust manifold, fit nuts and using sequence

shown, tighten to 45 Nm (33 lbf.ft).

26.Secure HO2S lead in clip on cylinder block.

27.Connect HO2S multiplug and secure to support

bracket.

28.Fit new camshaft timing belt.

+ ENGINE - K SERIES KV6,

OVERHAUL, Camshaft timing belt.

Page 269 of 1007

ENGINE - K SERIES KV6

12-3-92 OVERHAUL

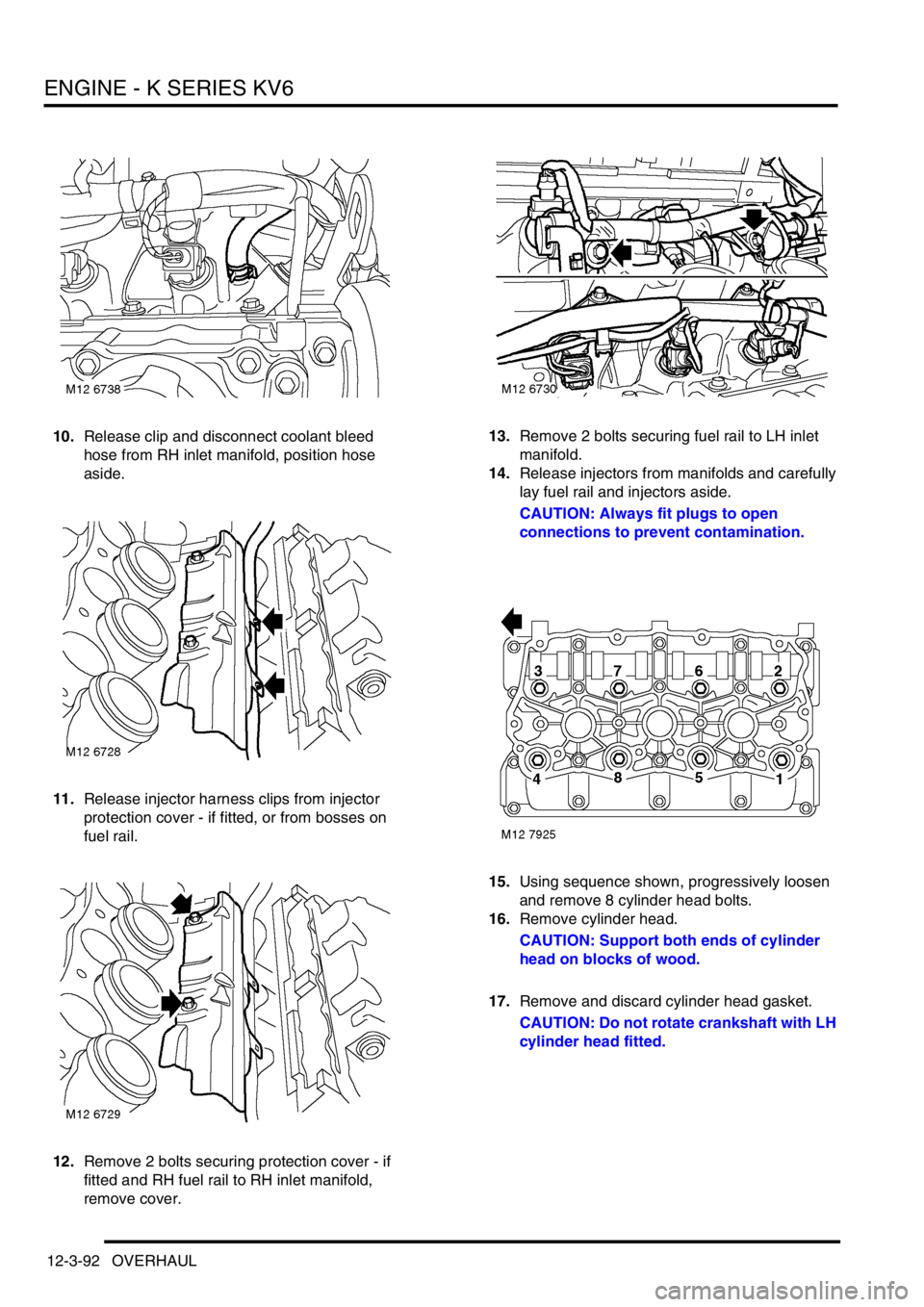

10.Release clip and disconnect coolant bleed

hose from RH inlet manifold, position hose

aside.

11.Release injector harness clips from injector

protection cover - if fitted, or from bosses on

fuel rail.

12.Remove 2 bolts securing protection cover - if

fitted and RH fuel rail to RH inlet manifold,

remove cover.13.Remove 2 bolts securing fuel rail to LH inlet

manifold.

14.Release injectors from manifolds and carefully

lay fuel rail and injectors aside.

CAUTION: Always fit plugs to open

connections to prevent contamination.

15.Using sequence shown, progressively loosen

and remove 8 cylinder head bolts.

16.Remove cylinder head.

CAUTION: Support both ends of cylinder

head on blocks of wood.

17.Remove and discard cylinder head gasket.

CAUTION: Do not rotate crankshaft with LH

cylinder head fitted.

Page 270 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-93

18.Fit cylinder liner clamps LRT-12-144 and

secure with cylinder head bolts.

CAUTION: Ensure that feet of clamps do not

protrude over bores.

Refit

1.Clean cylinder head face.

CAUTION: Use suitable gasket removal

spray and a plastic scraper.

2.Remove bolts securing cylinder liner clamps

LRT-12-144 to cylinder block and remove

clamps.

CAUTION: Do not rotate crankshaft.

3.Clean cylinder block face, dowels and dowel

holes.

4.Clean cylinder head bolts and wipe dry.

5.Lightly lubricate threads and beneath heads of

cylinder head bolts with clean engine oil.6.Check that fitted height of dowels is between 10

to 11 mm (0.40 to 0.43 in) above cylinder block

top face. Replace dowels if fitted height is

incorrect.

7.Fit new cylinder head gasket onto cylinder

block with the word 'TOP' uppermost.

8.With assistance, fit cylinder head and carefully

position RH inlet to LH inlet manifold.

9.Carefully enter cylinder head bolts, DO NOT

DROP. Screw bolts into place by hand.

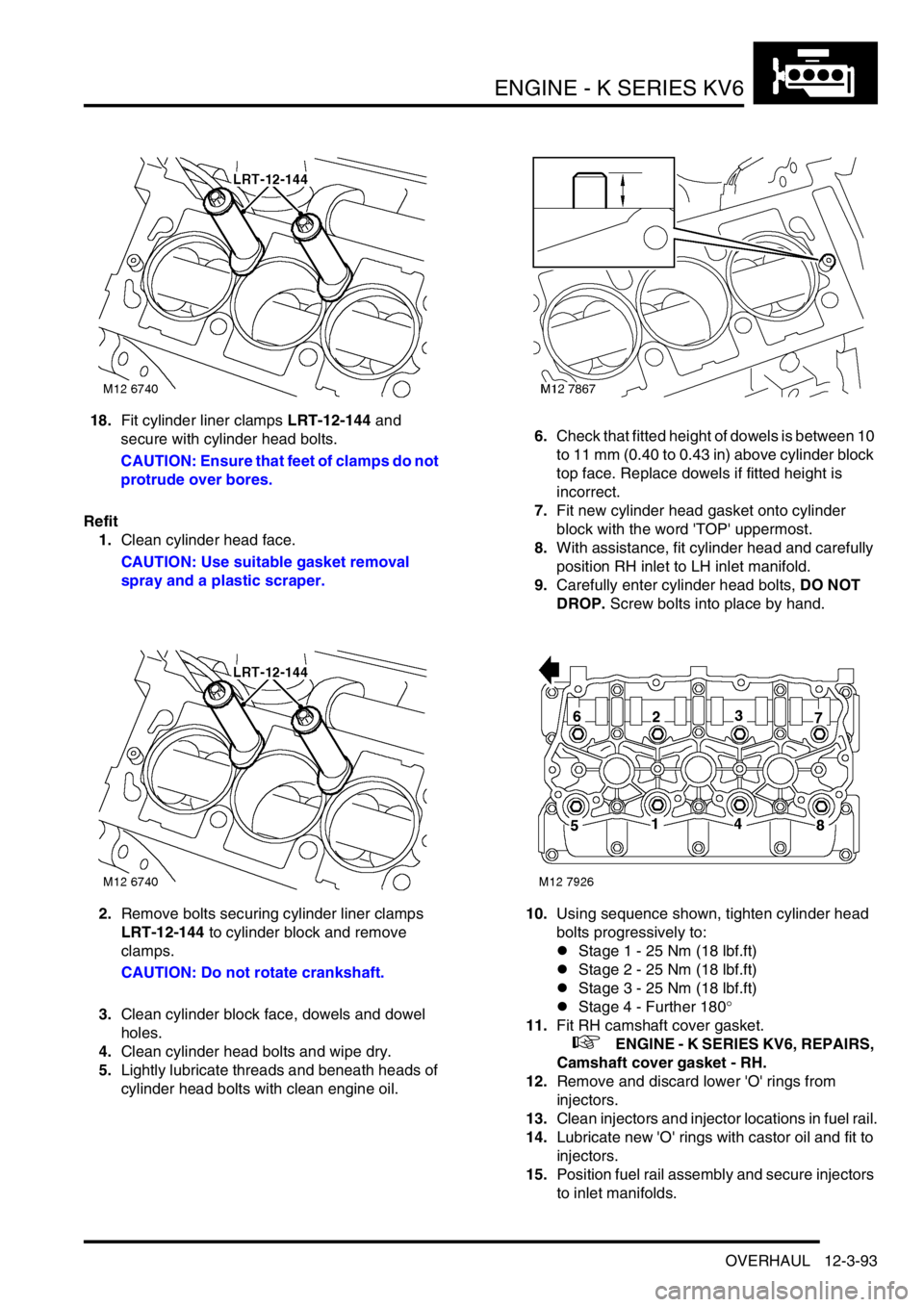

10.Using sequence shown, tighten cylinder head

bolts progressively to:

lStage 1 - 25 Nm (18 lbf.ft)

lStage 2 - 25 Nm (18 lbf.ft)

lStage 3 - 25 Nm (18 lbf.ft)

lStage 4 - Further 180°

11.Fit RH camshaft cover gasket.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft cover gasket - RH.

12.Remove and discard lower 'O' rings from

injectors.

13.Clean injectors and injector locations in fuel rail.

14.Lubricate new 'O' rings with castor oil and fit to

injectors.

15.Position fuel rail assembly and secure injectors

to inlet manifolds.

Page 276 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-99

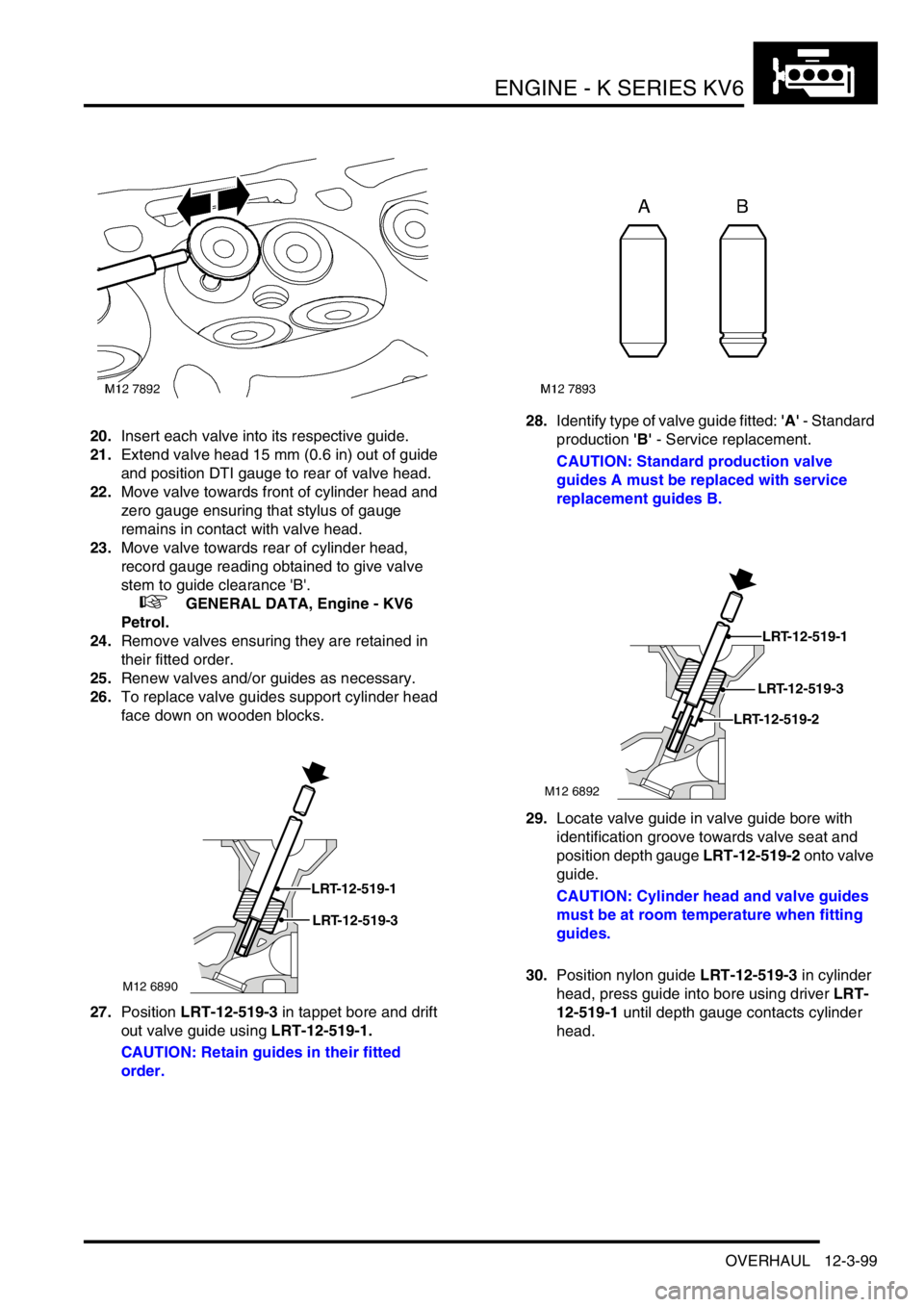

20.Insert each valve into its respective guide.

21.Extend valve head 15 mm (0.6 in) out of guide

and position DTI gauge to rear of valve head.

22.Move valve towards front of cylinder head and

zero gauge ensuring that stylus of gauge

remains in contact with valve head.

23.Move valve towards rear of cylinder head,

record gauge reading obtained to give valve

stem to guide clearance 'B'.

+ GENERAL DATA, Engine - KV6

Petrol.

24.Remove valves ensuring they are retained in

their fitted order.

25.Renew valves and/or guides as necessary.

26.To replace valve guides support cylinder head

face down on wooden blocks.

27.Position LRT-12-519-3 in tappet bore and drift

out valve guide using LRT-12-519-1.

CAUTION: Retain guides in their fitted

order.28.Identify type of valve guide fitted: 'A' - Standard

production 'B' - Service replacement.

CAUTION: Standard production valve

guides A must be replaced with service

replacement guides B.

29.Locate valve guide in valve guide bore with

identification groove towards valve seat and

position depth gauge LRT-12-519-2 onto valve

guide.

CAUTION: Cylinder head and valve guides

must be at room temperature when fitting

guides.

30.Position nylon guide LRT-12-519-3 in cylinder

head, press guide into bore using driver LRT-

12-519-1 until depth gauge contacts cylinder

head.

M12 6890

LRT-12-519-1

LRT-12-519-3

M12 6892

LRT-12-519-2

LRT-12-519-1

LRT-12-519-3

Page 282 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-105

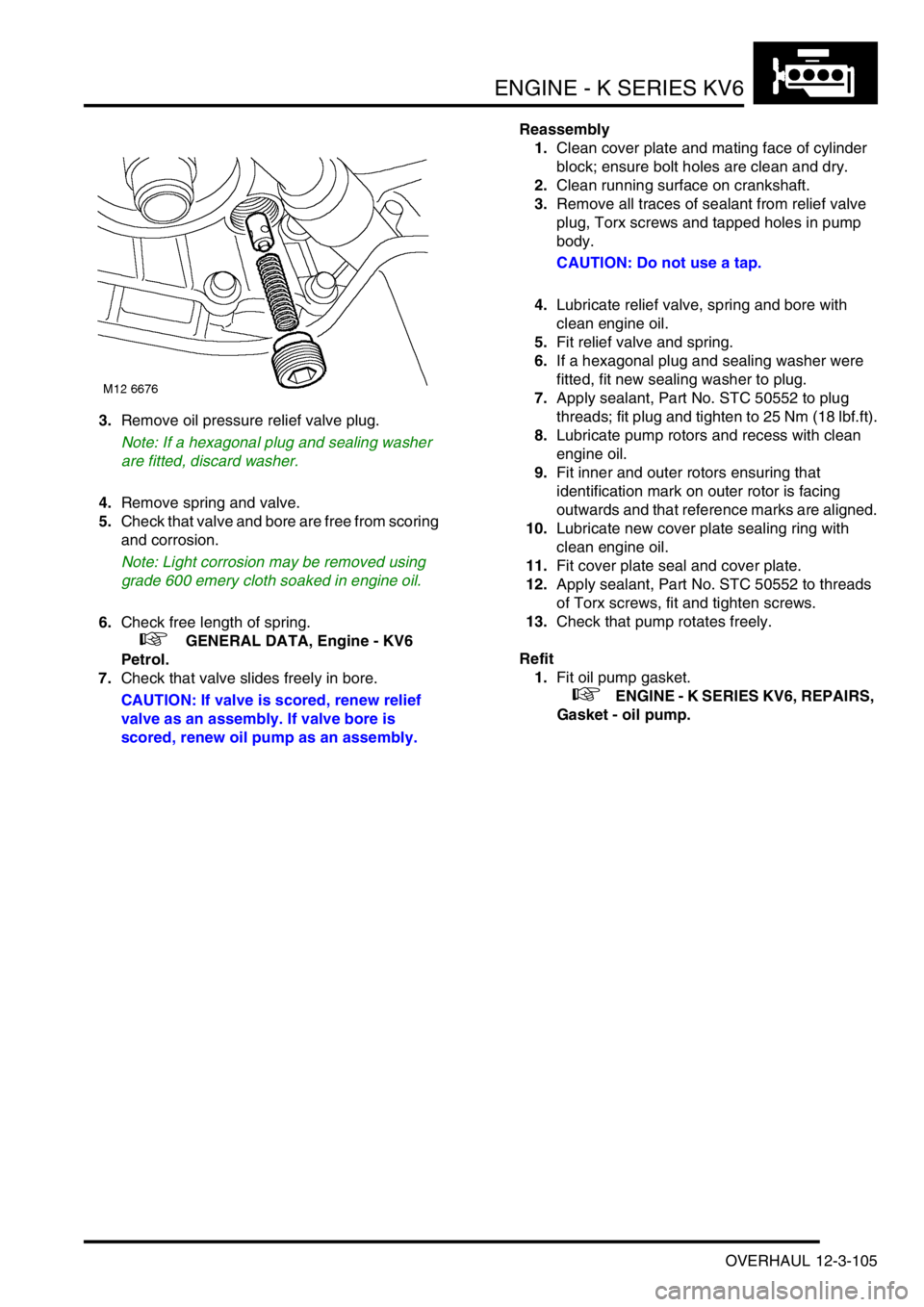

3.Remove oil pressure relief valve plug.

Note: If a hexagonal plug and sealing washer

are fitted, discard washer.

4.Remove spring and valve.

5.Check that valve and bore are free from scoring

and corrosion.

Note: Light corrosion may be removed using

grade 600 emery cloth soaked in engine oil.

6.Check free length of spring.

+ GENERAL DATA, Engine - KV6

Petrol.

7.Check that valve slides freely in bore.

CAUTION: If valve is scored, renew relief

valve as an assembly. If valve bore is

scored, renew oil pump as an assembly.Reassembly

1.Clean cover plate and mating face of cylinder

block; ensure bolt holes are clean and dry.

2.Clean running surface on crankshaft.

3.Remove all traces of sealant from relief valve

plug, Torx screws and tapped holes in pump

body.

CAUTION: Do not use a tap.

4.Lubricate relief valve, spring and bore with

clean engine oil.

5.Fit relief valve and spring.

6.If a hexagonal plug and sealing washer were

fitted, fit new sealing washer to plug.

7.Apply sealant, Part No. STC 50552 to plug

threads; fit plug and tighten to 25 Nm (18 lbf.ft).

8.Lubricate pump rotors and recess with clean

engine oil.

9.Fit inner and outer rotors ensuring that

identification mark on outer rotor is facing

outwards and that reference marks are aligned.

10.Lubricate new cover plate sealing ring with

clean engine oil.

11.Fit cover plate seal and cover plate.

12.Apply sealant, Part No. STC 50552 to threads

of Torx screws, fit and tighten screws.

13.Check that pump rotates freely.

Refit

1.Fit oil pump gasket.

+ ENGINE - K SERIES KV6, REPAIRS,

Gasket - oil pump.