lock LAND ROVER FREELANDER 2001 Manual Online

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 242 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-65

11.With assistance, position tensioner, fit new

Patchlok bolts and tighten to 25 Nm (18 lbf.ft).

CAUTION: Ensure tensioner plunger is

contacting underside of tensioner

backplate.

12.Remove tools LRT-12-175 from rear timing belt

gears.

13.Fit tools LRT-12-196 to both front inlet

camshaft gears and into the end of each

exhaust camshaft.

CAUTION: Special tools must be fitted when

tightening or loosening gear retaining bolts,

otherwise damage to camshafts may occur.

14. Tighten front inlet camshaft gear bolts to:

lStage 1 - 27 Nm (20 lbf.ft)

lStage 2 - Further 90°

15.Remove tools LRT-12-196 from both inlet

camshaft gears and exhaust camshafts.

16.Remove wedge from between drive belt and oil

pump belt guard.

17.Remove 1.5 mm diameter pin from tensioner.

18.Fit rubber blanking plug around tensioner.

19.Remove timing pin LRT-12-232.

20.Clean exhaust camshaft front cap seal

locations and fit new cap seals.

CAUTION: The sealing edge of the cap seal

and mating face must be clean and dry.

21.Position engine front mounting plate and

manoeuvre plate into position. Fit bolts but do

not tighten at this stage.22.Fit bolts securing IRD support bracket to front

mounting plate but do not tighten at this stage.

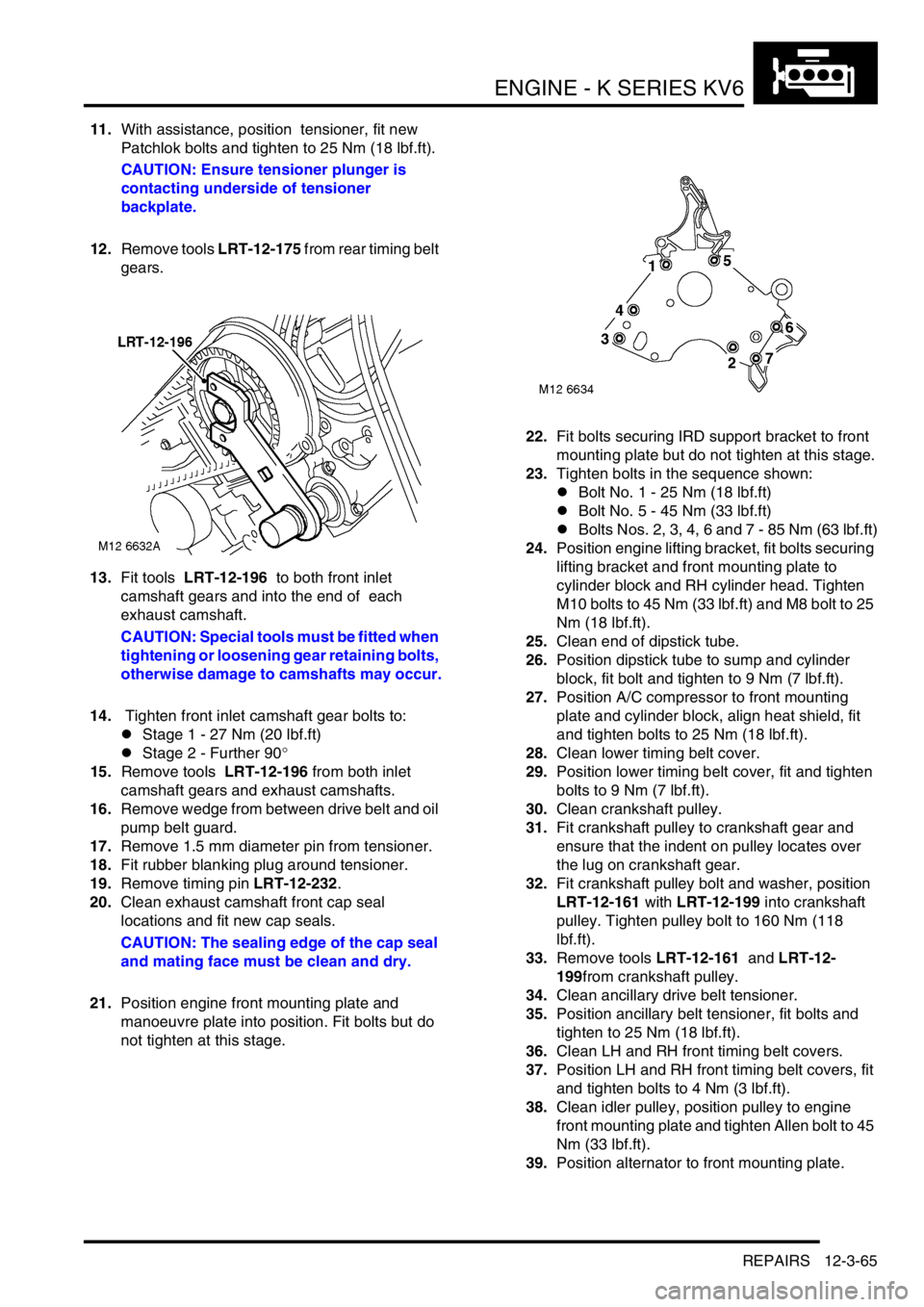

23.Tighten bolts in the sequence shown:

lBolt No. 1 - 25 Nm (18 lbf.ft)

lBolt No. 5 - 45 Nm (33 lbf.ft)

lBolts Nos. 2, 3, 4, 6 and 7 - 85 Nm (63 lbf.ft)

24.Position engine lifting bracket, fit bolts securing

lifting bracket and front mounting plate to

cylinder block and RH cylinder head. Tighten

M10 bolts to 45 Nm (33 lbf.ft) and M8 bolt to 25

Nm (18 lbf.ft).

25.Clean end of dipstick tube.

26.Position dipstick tube to sump and cylinder

block, fit bolt and tighten to 9 Nm (7 lbf.ft).

27.Position A/C compressor to front mounting

plate and cylinder block, align heat shield, fit

and tighten bolts to 25 Nm (18 lbf.ft).

28.Clean lower timing belt cover.

29.Position lower timing belt cover, fit and tighten

bolts to 9 Nm (7 lbf.ft).

30.Clean crankshaft pulley.

31.Fit crankshaft pulley to crankshaft gear and

ensure that the indent on pulley locates over

the lug on crankshaft gear.

32.Fit crankshaft pulley bolt and washer, position

LRT-12-161 with LRT-12-199 into crankshaft

pulley. Tighten pulley bolt to 160 Nm (118

lbf.ft).

33.Remove tools LRT-12-161 and LRT-12-

199from crankshaft pulley.

34.Clean ancillary drive belt tensioner.

35.Position ancillary belt tensioner, fit bolts and

tighten to 25 Nm (18 lbf.ft).

36.Clean LH and RH front timing belt covers.

37.Position LH and RH front timing belt covers, fit

and tighten bolts to 4 Nm (3 lbf.ft).

38.Clean idler pulley, position pulley to engine

front mounting plate and tighten Allen bolt to 45

Nm (33 lbf.ft).

39.Position alternator to front mounting plate.

Page 244 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-67

Camshaft timing belt cover - LH front

$% 12.65.41

Remove

1.Disconnect battery earth lead.

2.Remove ancillary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Ancillary drive belt - KV6.

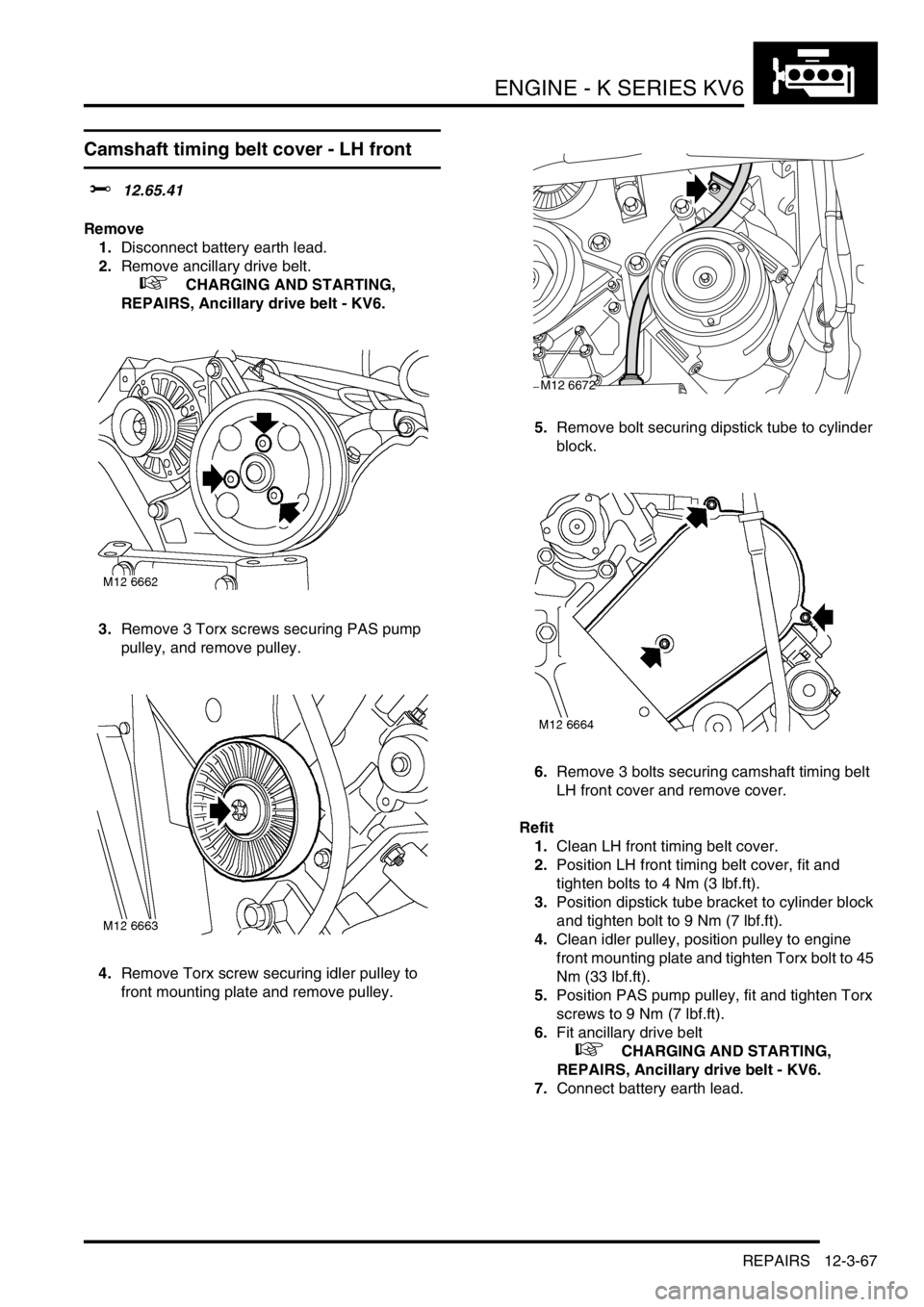

3.Remove 3 Torx screws securing PAS pump

pulley, and remove pulley.

4.Remove Torx screw securing idler pulley to

front mounting plate and remove pulley.5.Remove bolt securing dipstick tube to cylinder

block.

6.Remove 3 bolts securing camshaft timing belt

LH front cover and remove cover.

Refit

1.Clean LH front timing belt cover.

2.Position LH front timing belt cover, fit and

tighten bolts to 4 Nm (3 lbf.ft).

3.Position dipstick tube bracket to cylinder block

and tighten bolt to 9 Nm (7 lbf.ft).

4.Clean idler pulley, position pulley to engine

front mounting plate and tighten Torx bolt to 45

Nm (33 lbf.ft).

5.Position PAS pump pulley, fit and tighten Torx

screws to 9 Nm (7 lbf.ft).

6.Fit ancillary drive belt

+ CHARGING AND STARTING,

REPAIRS, Ancillary drive belt - KV6.

7.Connect battery earth lead.

M12 6672

Page 246 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-69

Camshaft rear timing belt - LH cylinder

head

$% 12.65.56

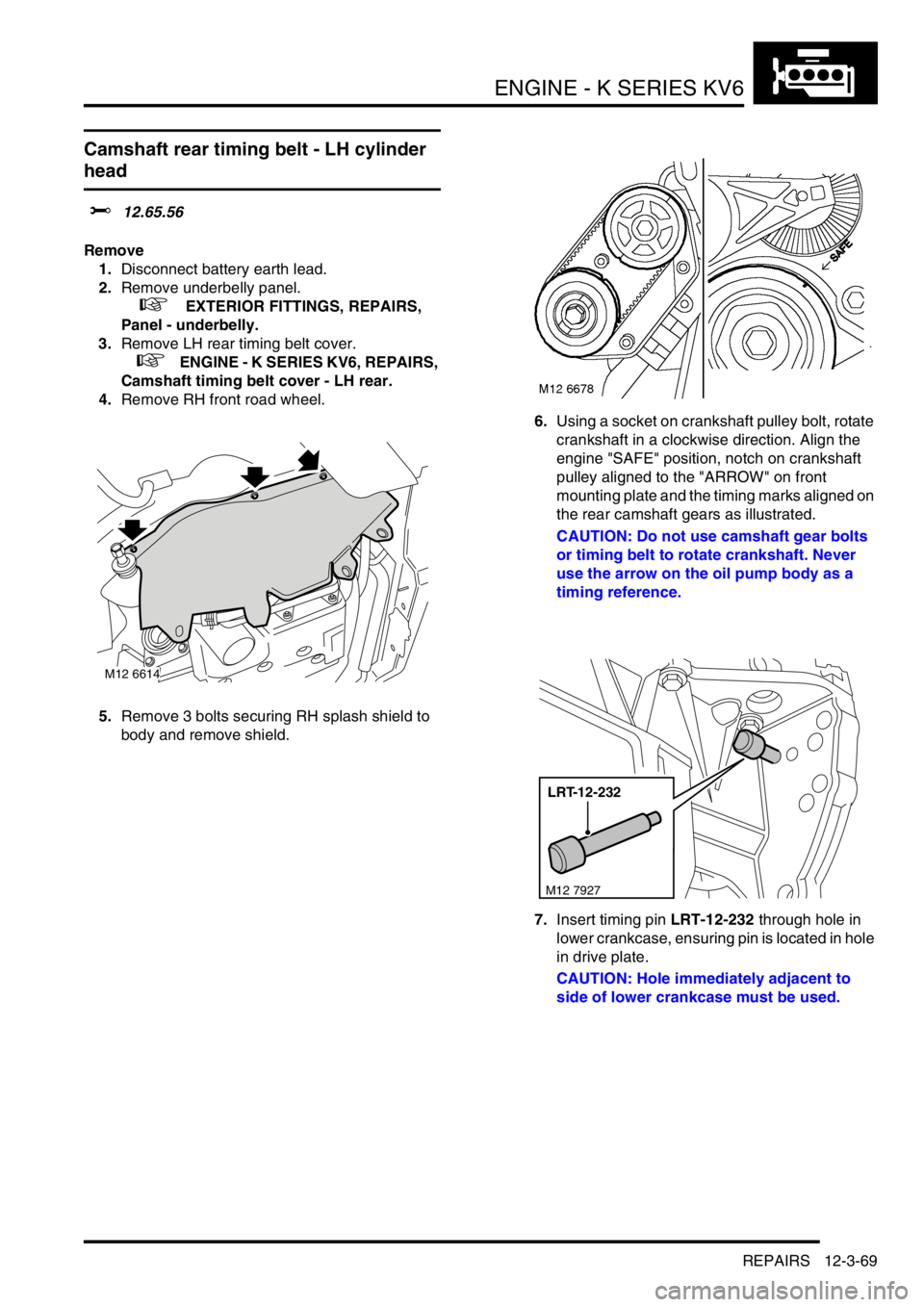

Remove

1.Disconnect battery earth lead.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Remove LH rear timing belt cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft timing belt cover - LH rear.

4.Remove RH front road wheel.

5.Remove 3 bolts securing RH splash shield to

body and remove shield.6.Using a socket on crankshaft pulley bolt, rotate

crankshaft in a clockwise direction. Align the

engine "SAFE" position, notch on crankshaft

pulley aligned to the "ARROW" on front

mounting plate and the timing marks aligned on

the rear camshaft gears as illustrated.

CAUTION: Do not use camshaft gear bolts

or timing belt to rotate crankshaft. Never

use the arrow on the oil pump body as a

timing reference.

7.Insert timing pin LRT-12-232 through hole in

lower crankcase, ensuring pin is located in hole

in drive plate.

CAUTION: Hole immediately adjacent to

side of lower crankcase must be used.

M12 6614

LRT-12-232

M12 7927

Page 250 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-73

Camshaft rear timing belt - RH cylinder

head

$% 12.65.57

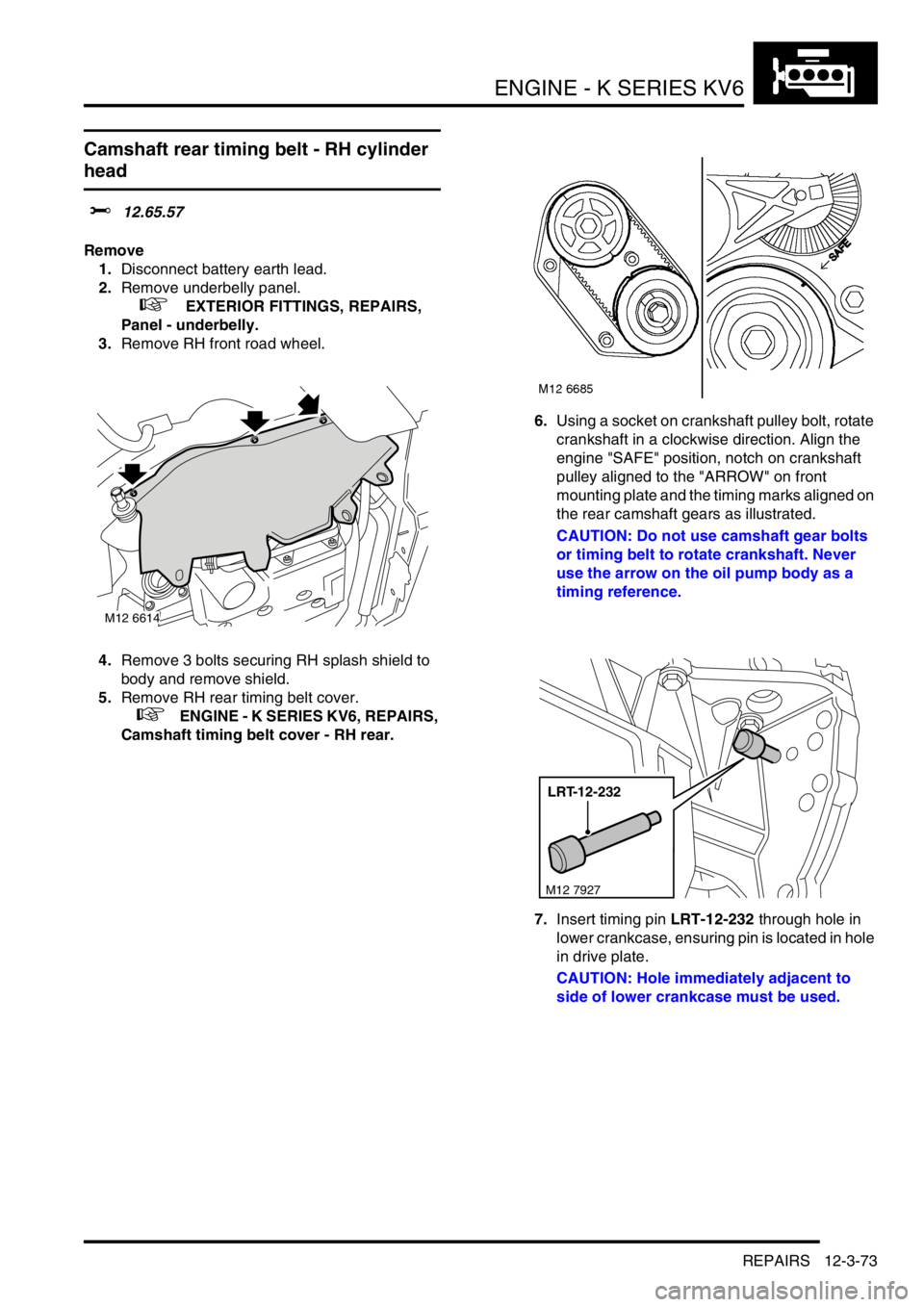

Remove

1.Disconnect battery earth lead.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Remove RH front road wheel.

4.Remove 3 bolts securing RH splash shield to

body and remove shield.

5.Remove RH rear timing belt cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft timing belt cover - RH rear.6.Using a socket on crankshaft pulley bolt, rotate

crankshaft in a clockwise direction. Align the

engine "SAFE" position, notch on crankshaft

pulley aligned to the "ARROW" on front

mounting plate and the timing marks aligned on

the rear camshaft gears as illustrated.

CAUTION: Do not use camshaft gear bolts

or timing belt to rotate crankshaft. Never

use the arrow on the oil pump body as a

timing reference.

7.Insert timing pin LRT-12-232 through hole in

lower crankcase, ensuring pin is located in hole

in drive plate.

CAUTION: Hole immediately adjacent to

side of lower crankcase must be used.

M12 6614

LRT-12-232

M12 7927

Page 254 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-77

OVERHAUL

Piston assemblies - engine set

$% 12.17.03.01

Disassembly

1.Remove crankshaft.

+ ENGINE - K SERIES KV6,

OVERHAUL, Crankshaft.

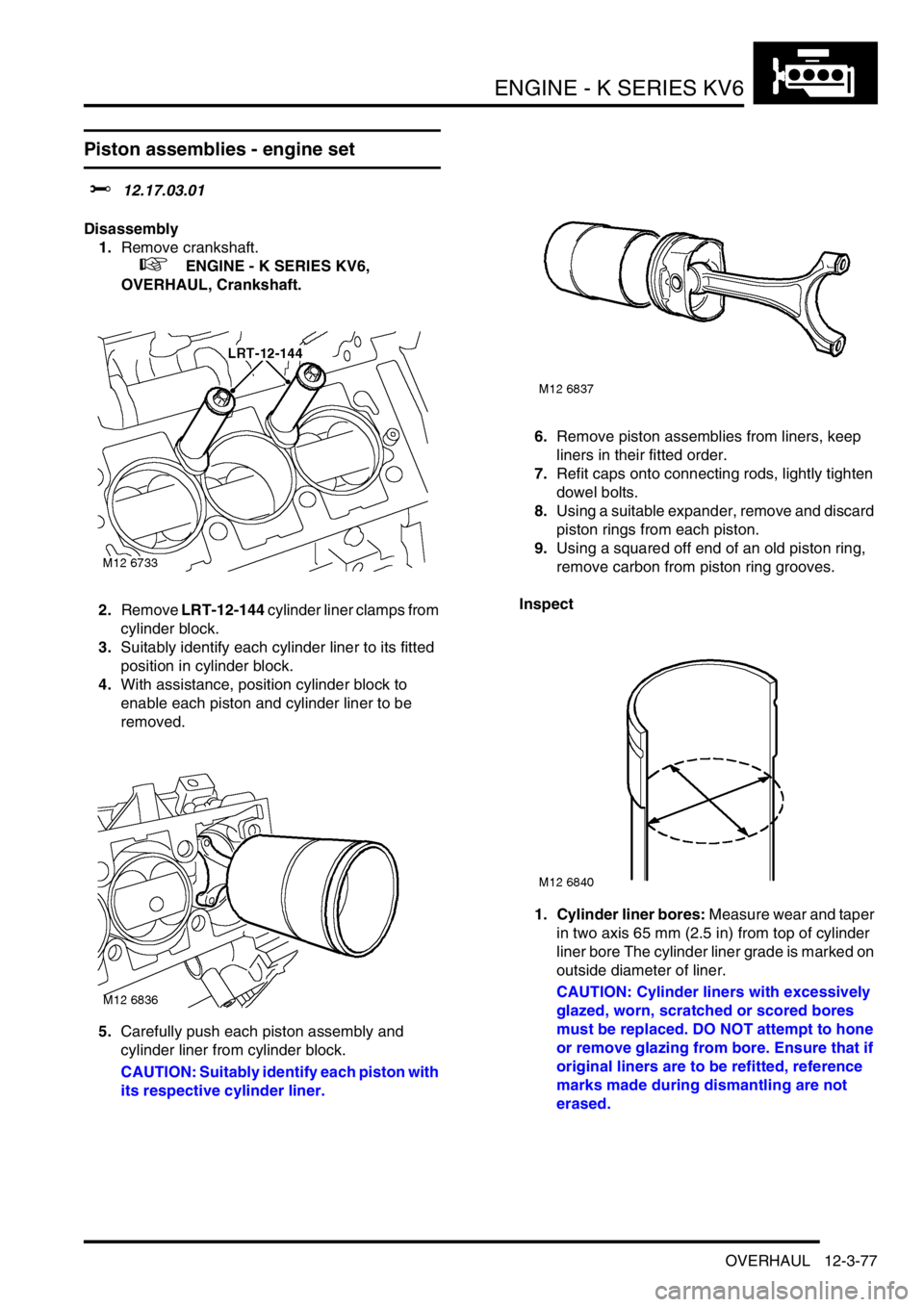

2.Remove LRT-12-144 cylinder liner clamps from

cylinder block.

3.Suitably identify each cylinder liner to its fitted

position in cylinder block.

4.With assistance, position cylinder block to

enable each piston and cylinder liner to be

removed.

5.Carefully push each piston assembly and

cylinder liner from cylinder block.

CAUTION: Suitably identify each piston with

its respective cylinder liner.6.Remove piston assemblies from liners, keep

liners in their fitted order.

7.Refit caps onto connecting rods, lightly tighten

dowel bolts.

8.Using a suitable expander, remove and discard

piston rings from each piston.

9.Using a squared off end of an old piston ring,

remove carbon from piston ring grooves.

Inspect

1. Cylinder liner bores: Measure wear and taper

in two axis 65 mm (2.5 in) from top of cylinder

liner bore The cylinder liner grade is marked on

outside diameter of liner.

CAUTION: Cylinder liners with excessively

glazed, worn, scratched or scored bores

must be replaced. DO NOT attempt to hone

or remove glazing from bore. Ensure that if

original liners are to be refitted, reference

marks made during dismantling are not

erased.

Page 256 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-79

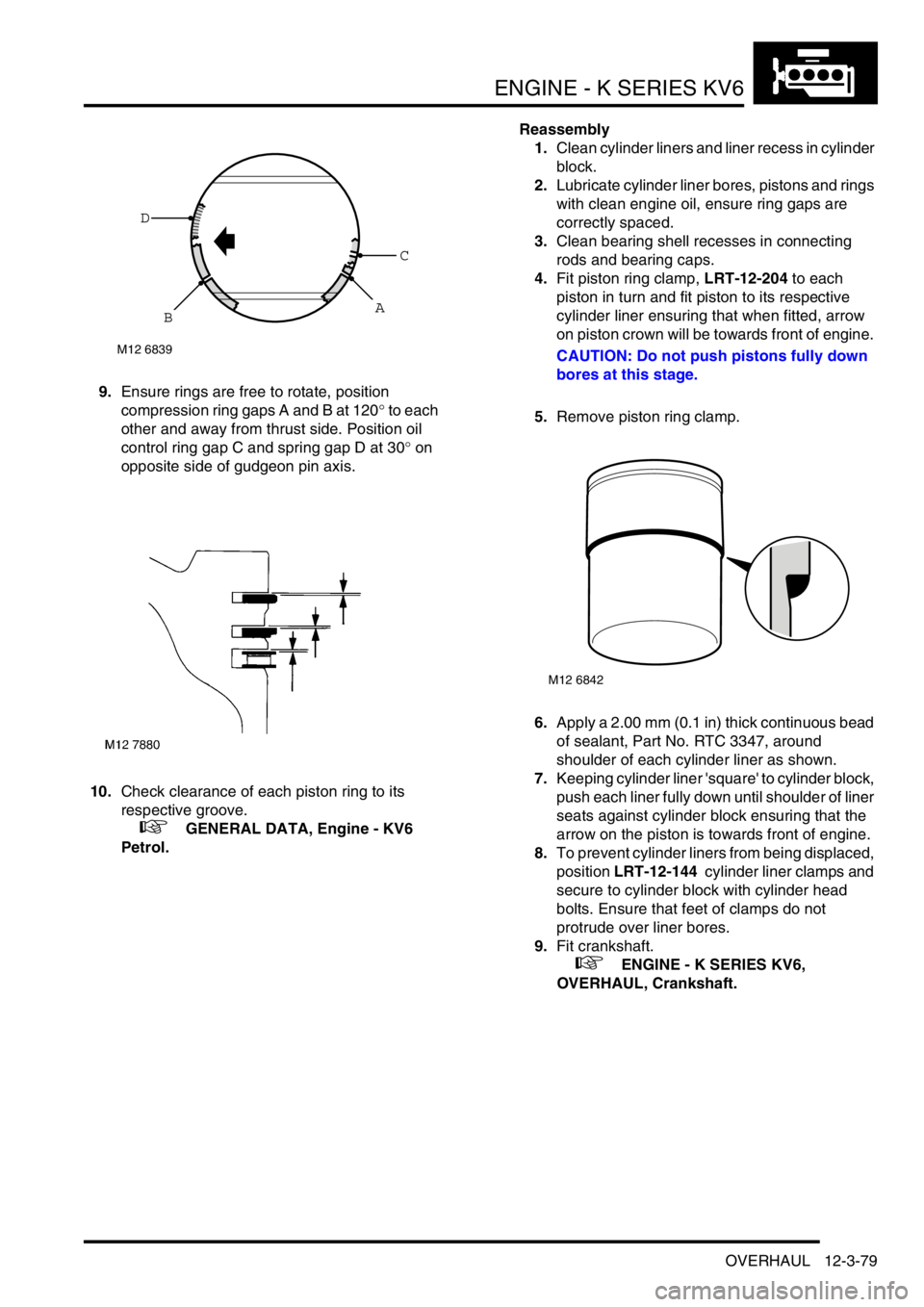

9.Ensure rings are free to rotate, position

compression ring gaps A and B at 120° to each

other and away from thrust side. Position oil

control ring gap C and spring gap D at 30° on

opposite side of gudgeon pin axis.

10.Check clearance of each piston ring to its

respective groove.

+ GENERAL DATA, Engine - KV6

Petrol.Reassembly

1.Clean cylinder liners and liner recess in cylinder

block.

2.Lubricate cylinder liner bores, pistons and rings

with clean engine oil, ensure ring gaps are

correctly spaced.

3.Clean bearing shell recesses in connecting

rods and bearing caps.

4.Fit piston ring clamp, LRT-12-204 to each

piston in turn and fit piston to its respective

cylinder liner ensuring that when fitted, arrow

on piston crown will be towards front of engine.

CAUTION: Do not push pistons fully down

bores at this stage.

5.Remove piston ring clamp.

6.Apply a 2.00 mm (0.1 in) thick continuous bead

of sealant, Part No. RTC 3347, around

shoulder of each cylinder liner as shown.

7.Keeping cylinder liner 'square' to cylinder block,

push each liner fully down until shoulder of liner

seats against cylinder block ensuring that the

arrow on the piston is towards front of engine.

8.To prevent cylinder liners from being displaced,

position LRT-12-144 cylinder liner clamps and

secure to cylinder block with cylinder head

bolts. Ensure that feet of clamps do not

protrude over liner bores.

9.Fit crankshaft.

+ ENGINE - K SERIES KV6,

OVERHAUL, Crankshaft.

M12 6839

D

BA

C

M12 6842

Page 258 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-81

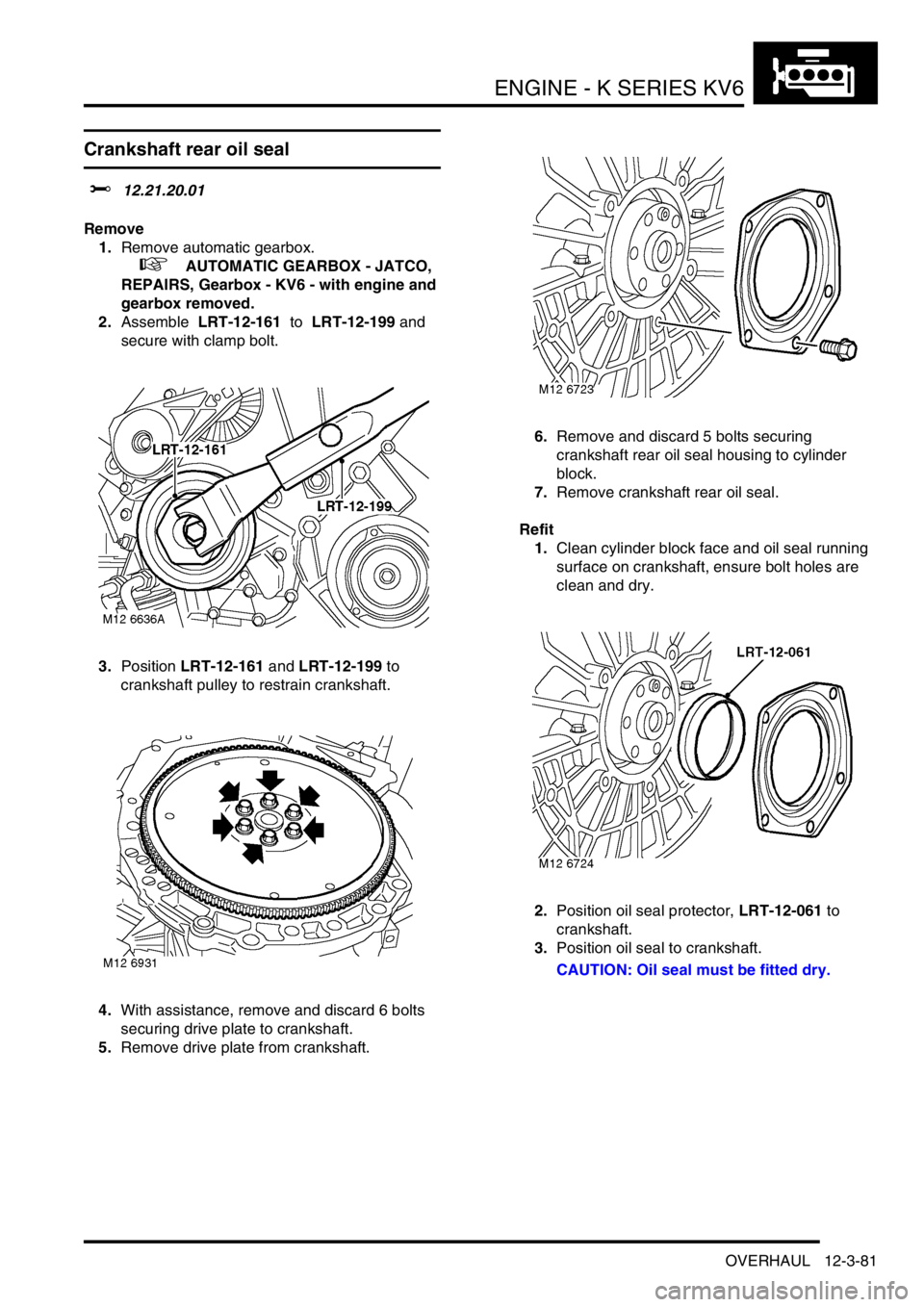

Crankshaft rear oil seal

$% 12.21.20.01

Remove

1.Remove automatic gearbox.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Gearbox - KV6 - with engine and

gearbox removed.

2.Assemble LRT-12-161 to LRT-12-199 and

secure with clamp bolt.

3.Position LRT-12-161 and LRT-12-199 to

crankshaft pulley to restrain crankshaft.

4.With assistance, remove and discard 6 bolts

securing drive plate to crankshaft.

5.Remove drive plate from crankshaft.6.Remove and discard 5 bolts securing

crankshaft rear oil seal housing to cylinder

block.

7.Remove crankshaft rear oil seal.

Refit

1.Clean cylinder block face and oil seal running

surface on crankshaft, ensure bolt holes are

clean and dry.

2.Position oil seal protector, LRT-12-061 to

crankshaft.

3.Position oil seal to crankshaft.

CAUTION: Oil seal must be fitted dry.

Page 259 of 1007

ENGINE - K SERIES KV6

12-3-82 OVERHAUL

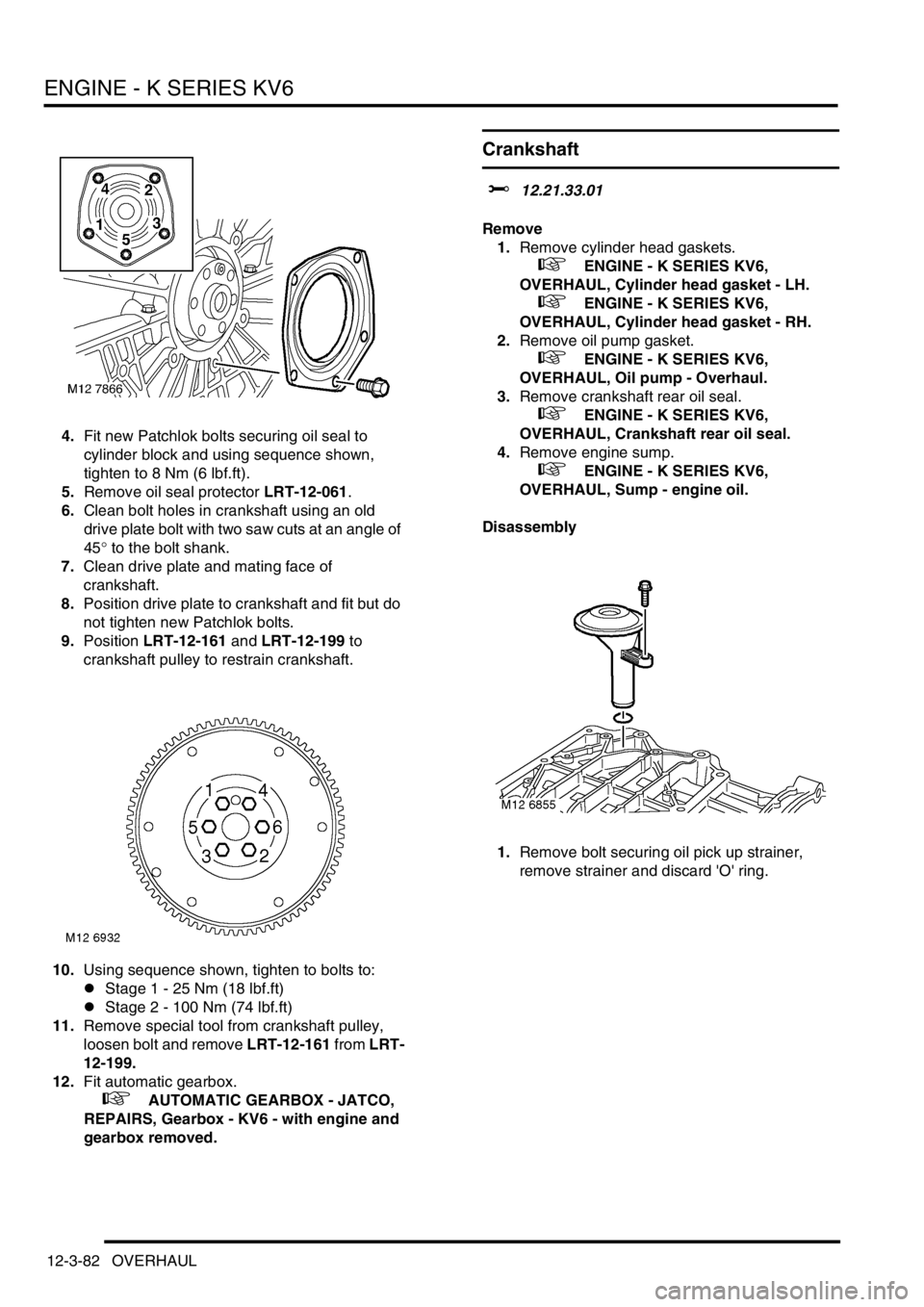

4.Fit new Patchlok bolts securing oil seal to

cylinder block and using sequence shown,

tighten to 8 Nm (6 lbf.ft).

5.Remove oil seal protector LRT-12-061.

6.Clean bolt holes in crankshaft using an old

drive plate bolt with two saw cuts at an angle of

45° to the bolt shank.

7.Clean drive plate and mating face of

crankshaft.

8.Position drive plate to crankshaft and fit but do

not tighten new Patchlok bolts.

9.Position LRT-12-161 and LRT-12-199 to

crankshaft pulley to restrain crankshaft.

10.Using sequence shown, tighten to bolts to:

lStage 1 - 25 Nm (18 lbf.ft)

lStage 2 - 100 Nm (74 lbf.ft)

11.Remove special tool from crankshaft pulley,

loosen bolt and remove LRT-12-161 from LRT-

12-199.

12.Fit automatic gearbox.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Gearbox - KV6 - with engine and

gearbox removed.

Crankshaft

$% 12.21.33.01

Remove

1.Remove cylinder head gaskets.

+ ENGINE - K SERIES KV6,

OVERHAUL, Cylinder head gasket - LH.

+ ENGINE - K SERIES KV6,

OVERHAUL, Cylinder head gasket - RH.

2.Remove oil pump gasket.

+ ENGINE - K SERIES KV6,

OVERHAUL, Oil pump - Overhaul.

3.Remove crankshaft rear oil seal.

+ ENGINE - K SERIES KV6,

OVERHAUL, Crankshaft rear oil seal.

4.Remove engine sump.

+ ENGINE - K SERIES KV6,

OVERHAUL, Sump - engine oil.

Disassembly

1.Remove bolt securing oil pick up strainer,

remove strainer and discard 'O' ring.

Page 260 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-83

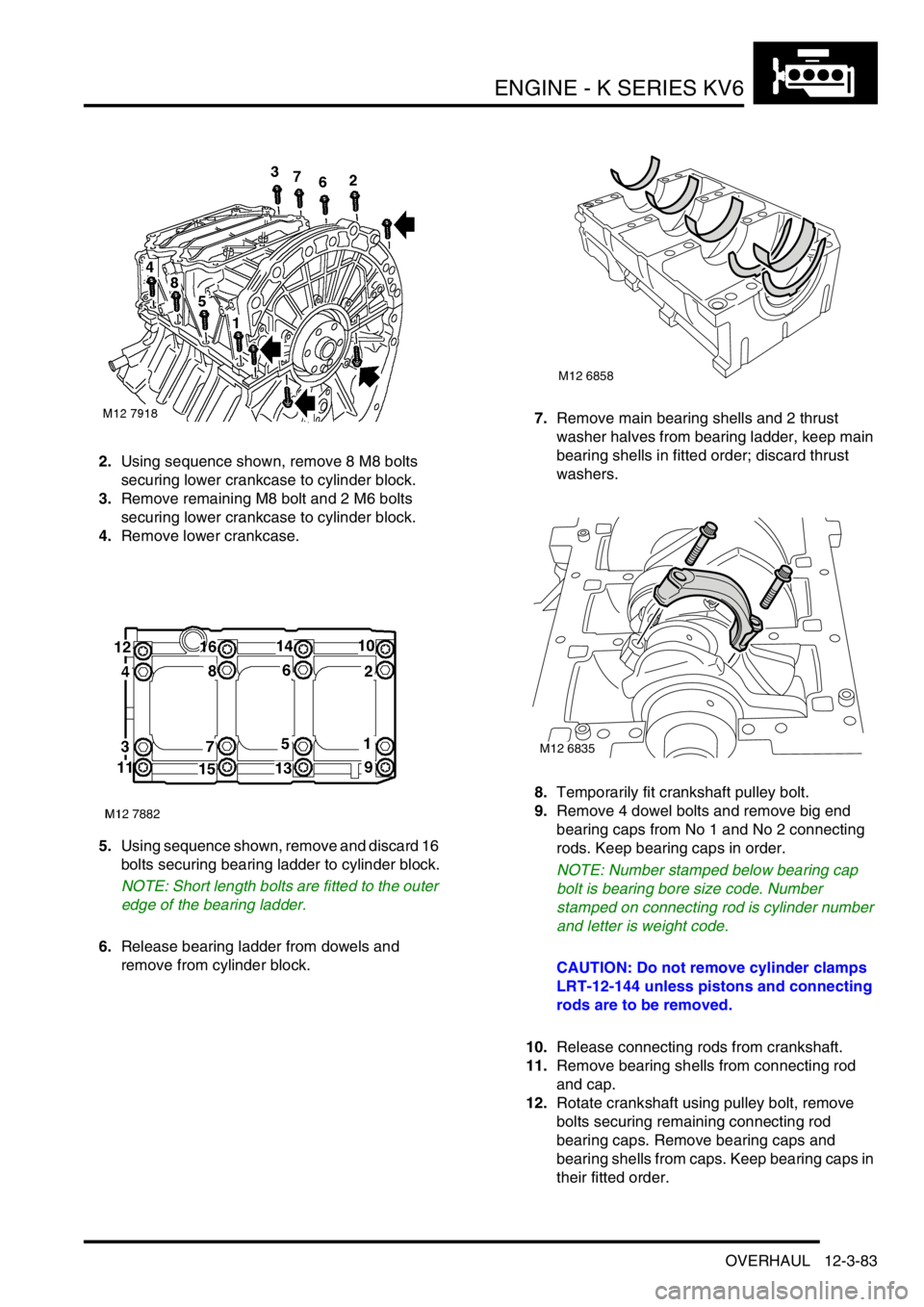

2.Using sequence shown, remove 8 M8 bolts

securing lower crankcase to cylinder block.

3.Remove remaining M8 bolt and 2 M6 bolts

securing lower crankcase to cylinder block.

4.Remove lower crankcase.

5.Using sequence shown, remove and discard 16

bolts securing bearing ladder to cylinder block.

NOTE: Short length bolts are fitted to the outer

edge of the bearing ladder.

6.Release bearing ladder from dowels and

remove from cylinder block.7.Remove main bearing shells and 2 thrust

washer halves from bearing ladder, keep main

bearing shells in fitted order; discard thrust

washers.

8.Temporarily fit crankshaft pulley bolt.

9.Remove 4 dowel bolts and remove big end

bearing caps from No 1 and No 2 connecting

rods. Keep bearing caps in order.

NOTE: Number stamped below bearing cap

bolt is bearing bore size code. Number

stamped on connecting rod is cylinder number

and letter is weight code.

CAUTION: Do not remove cylinder clamps

LRT-12-144 unless pistons and connecting

rods are to be removed.

10.Release connecting rods from crankshaft.

11.Remove bearing shells from connecting rod

and cap.

12.Rotate crankshaft using pulley bolt, remove

bolts securing remaining connecting rod

bearing caps. Remove bearing caps and

bearing shells from caps. Keep bearing caps in

their fitted order.

M12 6858

M12 6835

Page 261 of 1007

ENGINE - K SERIES KV6

12-3-84 OVERHAUL

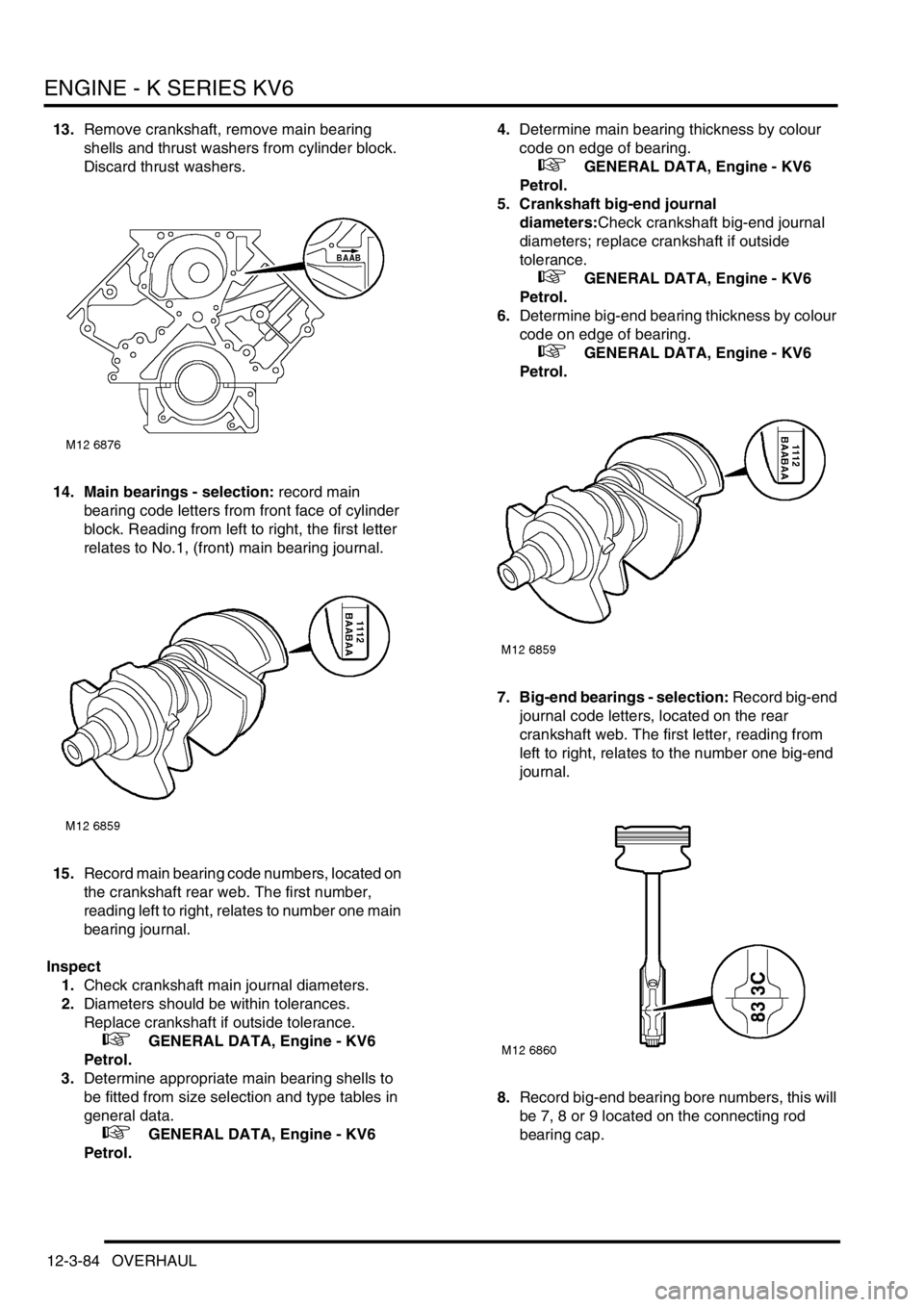

13.Remove crankshaft, remove main bearing

shells and thrust washers from cylinder block.

Discard thrust washers.

14. Main bearings - selection: record main

bearing code letters from front face of cylinder

block. Reading from left to right, the first letter

relates to No.1, (front) main bearing journal.

15.Record main bearing code numbers, located on

the crankshaft rear web. The first number,

reading left to right, relates to number one main

bearing journal.

Inspect

1.Check crankshaft main journal diameters.

2.Diameters should be within tolerances.

Replace crankshaft if outside tolerance.

+ GENERAL DATA, Engine - KV6

Petrol.

3.Determine appropriate main bearing shells to

be fitted from size selection and type tables in

general data.

+ GENERAL DATA, Engine - KV6

Petrol.4.Determine main bearing thickness by colour

code on edge of bearing.

+ GENERAL DATA, Engine - KV6

Petrol.

5. Crankshaft big-end journal

diameters:Check crankshaft big-end journal

diameters; replace crankshaft if outside

tolerance.

+ GENERAL DATA, Engine - KV6

Petrol.

6.Determine big-end bearing thickness by colour

code on edge of bearing.

+ GENERAL DATA, Engine - KV6

Petrol.

7. Big-end bearings - selection: Record big-end

journal code letters, located on the rear

crankshaft web. The first letter, reading from

left to right, relates to the number one big-end

journal.

8.Record big-end bearing bore numbers, this will

be 7, 8 or 9 located on the connecting rod

bearing cap.