lock LAND ROVER FREELANDER 2001 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 199 of 1007

ENGINE - K SERIES KV6

12-3-22 REPAIRS

5.Remove bolt securing multiplug bracket which

also retains front HO2S multiplug, move

bracket and multiplug aside.

6.Withdraw multiplug lock and disconnect

multiplug from each plug top coil.

7.Remove bolt securing each plug top coil to

camshaft cover and remove 3 plug top coils.

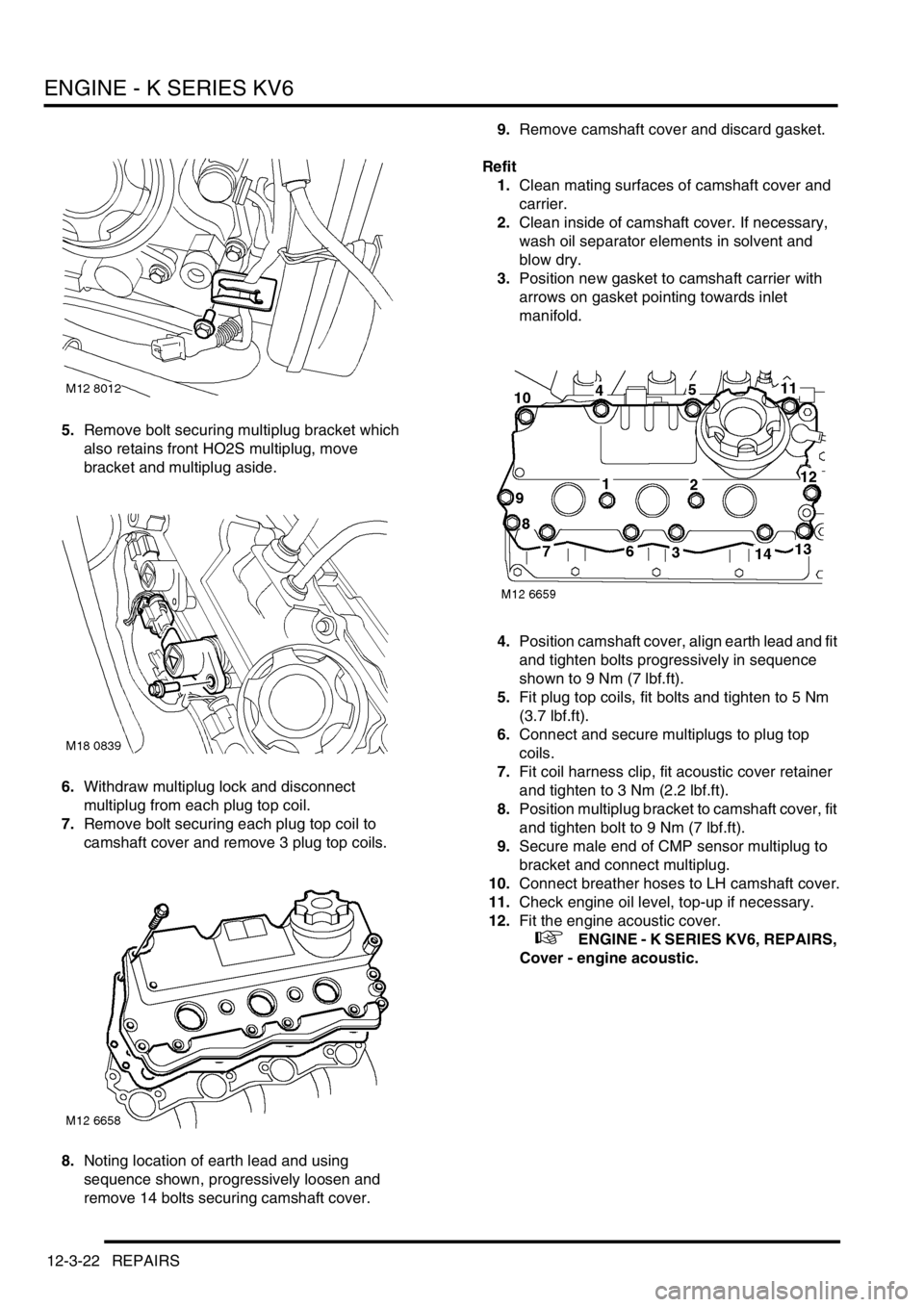

8.Noting location of earth lead and using

sequence shown, progressively loosen and

remove 14 bolts securing camshaft cover.9.Remove camshaft cover and discard gasket.

Refit

1.Clean mating surfaces of camshaft cover and

carrier.

2.Clean inside of camshaft cover. If necessary,

wash oil separator elements in solvent and

blow dry.

3.Position new gasket to camshaft carrier with

arrows on gasket pointing towards inlet

manifold.

4.Position camshaft cover, align earth lead and fit

and tighten bolts progressively in sequence

shown to 9 Nm (7 lbf.ft).

5.Fit plug top coils, fit bolts and tighten to 5 Nm

(3.7 lbf.ft).

6.Connect and secure multiplugs to plug top

coils.

7.Fit coil harness clip, fit acoustic cover retainer

and tighten to 3 Nm (2.2 lbf.ft).

8.Position multiplug bracket to camshaft cover, fit

and tighten bolt to 9 Nm (7 lbf.ft).

9.Secure male end of CMP sensor multiplug to

bracket and connect multiplug.

10.Connect breather hoses to LH camshaft cover.

11.Check engine oil level, top-up if necessary.

12.Fit the engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

Page 200 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-23

Camshaft cover gasket - RH

$% 12.29.41

Remove

1.Remove inlet manifold chamber.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Seals - inlet

manifold chamber - up to 03MY.

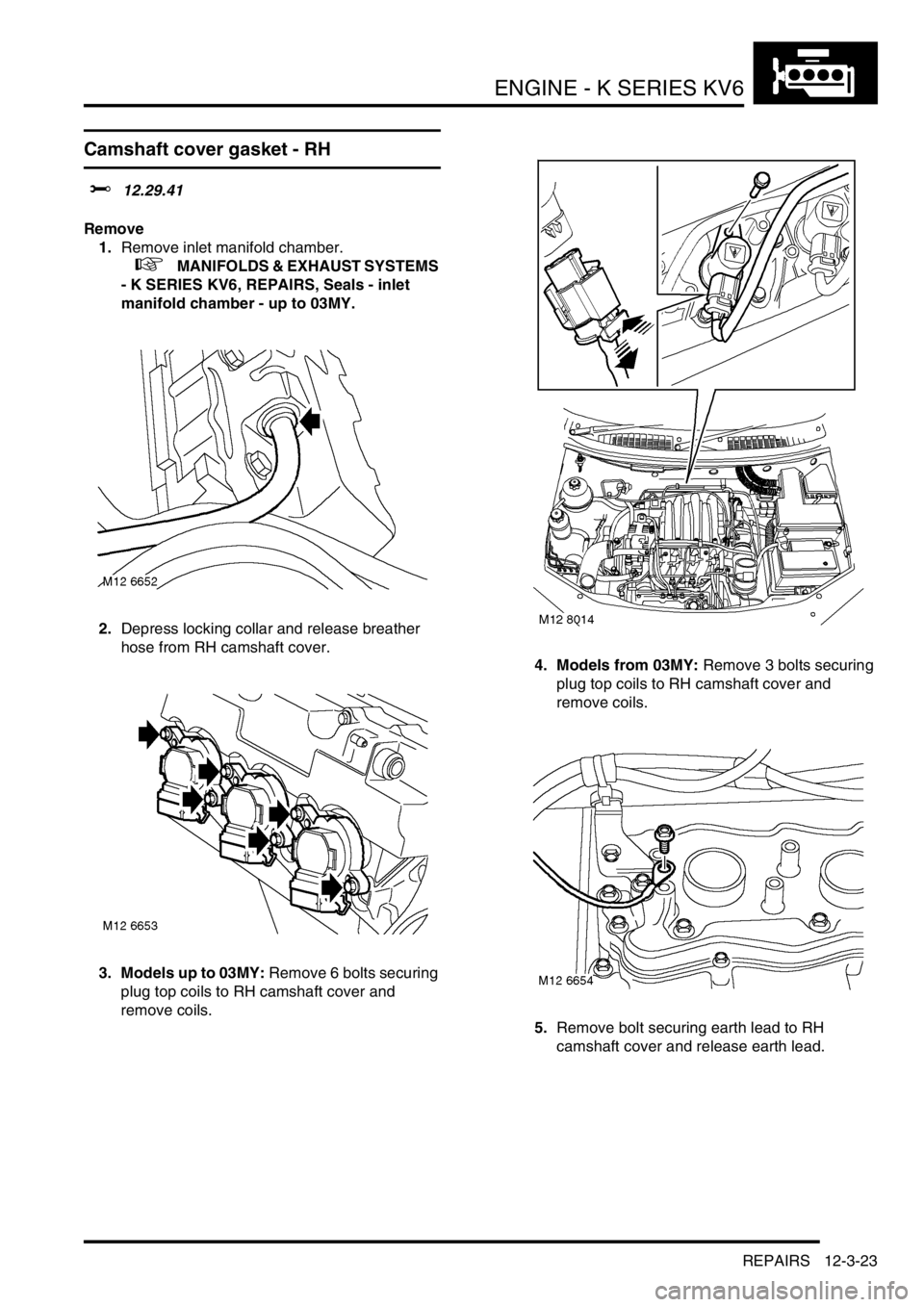

2.Depress locking collar and release breather

hose from RH camshaft cover.

3. Models up to 03MY: Remove 6 bolts securing

plug top coils to RH camshaft cover and

remove coils.4. Models from 03MY: Remove 3 bolts securing

plug top coils to RH camshaft cover and

remove coils.

5.Remove bolt securing earth lead to RH

camshaft cover and release earth lead.

Page 205 of 1007

ENGINE - K SERIES KV6

12-3-28 REPAIRS

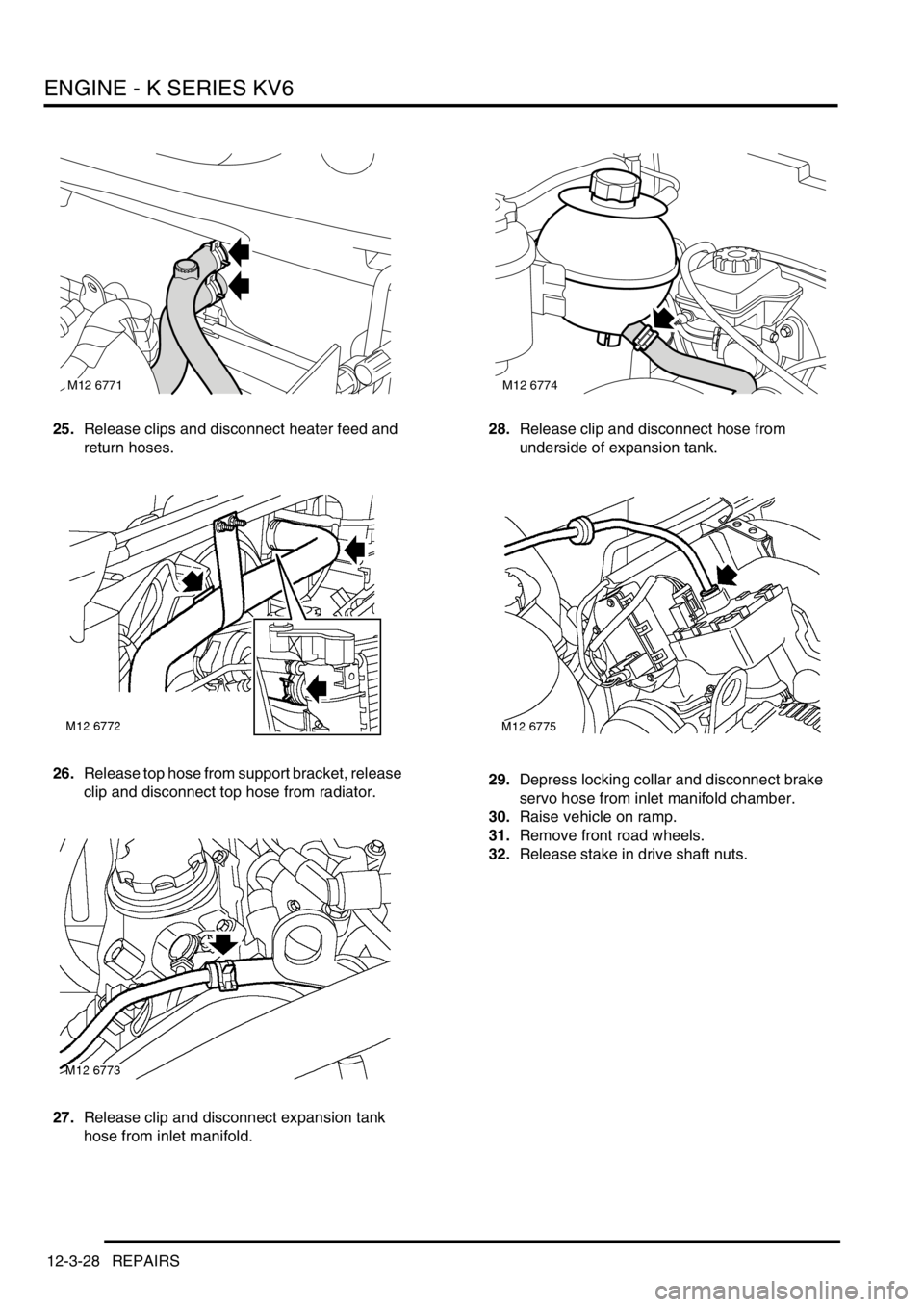

25.Release clips and disconnect heater feed and

return hoses.

26.Release top hose from support bracket, release

clip and disconnect top hose from radiator.

27.Release clip and disconnect expansion tank

hose from inlet manifold.28.Release clip and disconnect hose from

underside of expansion tank.

29.Depress locking collar and disconnect brake

servo hose from inlet manifold chamber.

30.Raise vehicle on ramp.

31.Remove front road wheels.

32.Release stake in drive shaft nuts.

M12 6771M12 6774

Page 208 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-31

55.Note fitted position of heat shield on A/C

compressor and remove 3 bolts securing A/C

compressor to front mounting plate and

cylinder block. Release A/C compressor and

heat shield and position aside.

56.Lower vehicle on ramp.

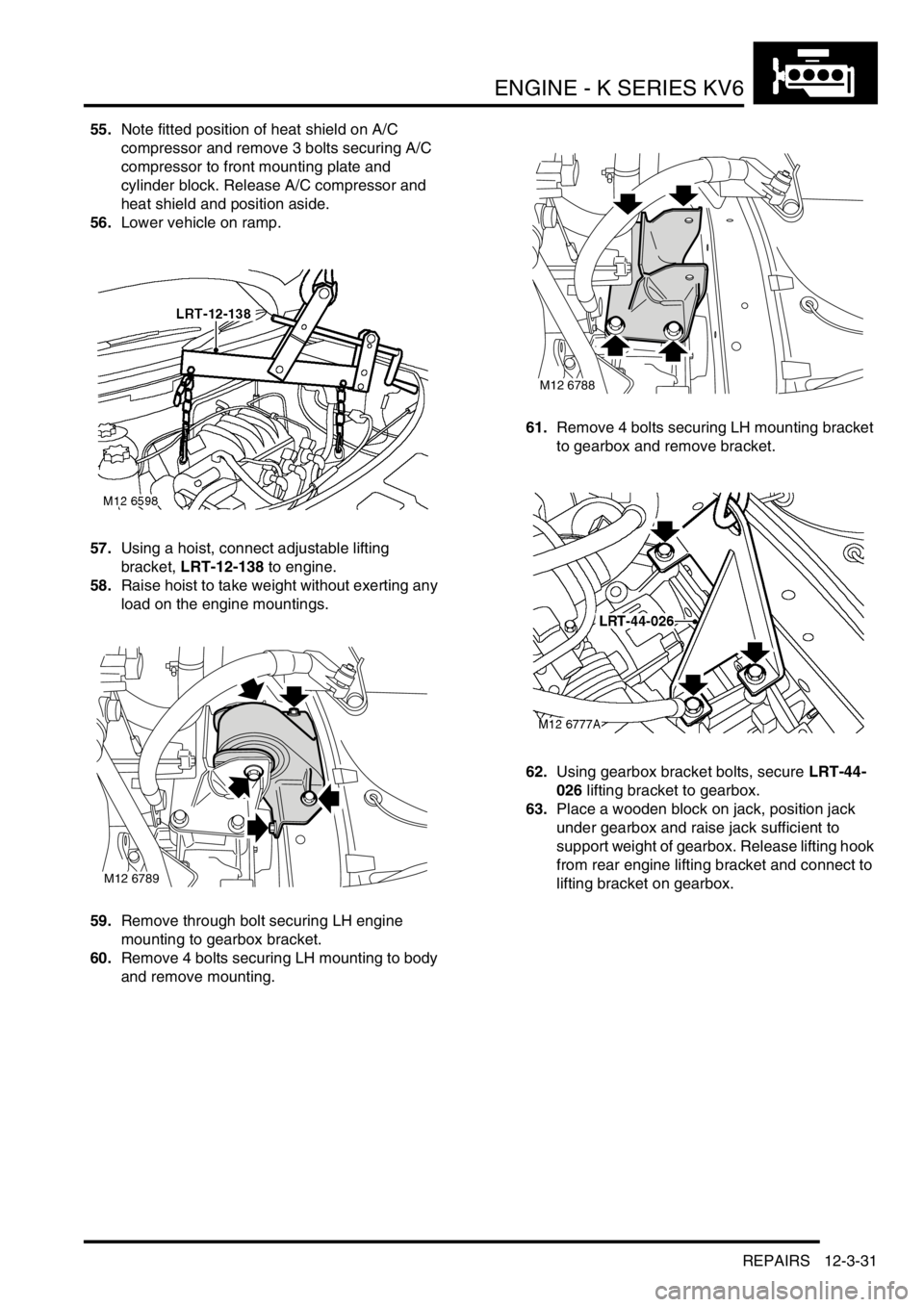

57.Using a hoist, connect adjustable lifting

bracket, LRT-12-138 to engine.

58.Raise hoist to take weight without exerting any

load on the engine mountings.

59.Remove through bolt securing LH engine

mounting to gearbox bracket.

60.Remove 4 bolts securing LH mounting to body

and remove mounting.61.Remove 4 bolts securing LH mounting bracket

to gearbox and remove bracket.

62.Using gearbox bracket bolts, secure LRT-44-

026 lifting bracket to gearbox.

63.Place a wooden block on jack, position jack

under gearbox and raise jack sufficient to

support weight of gearbox. Release lifting hook

from rear engine lifting bracket and connect to

lifting bracket on gearbox.

M12 6789

M12 6788

Page 210 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-33

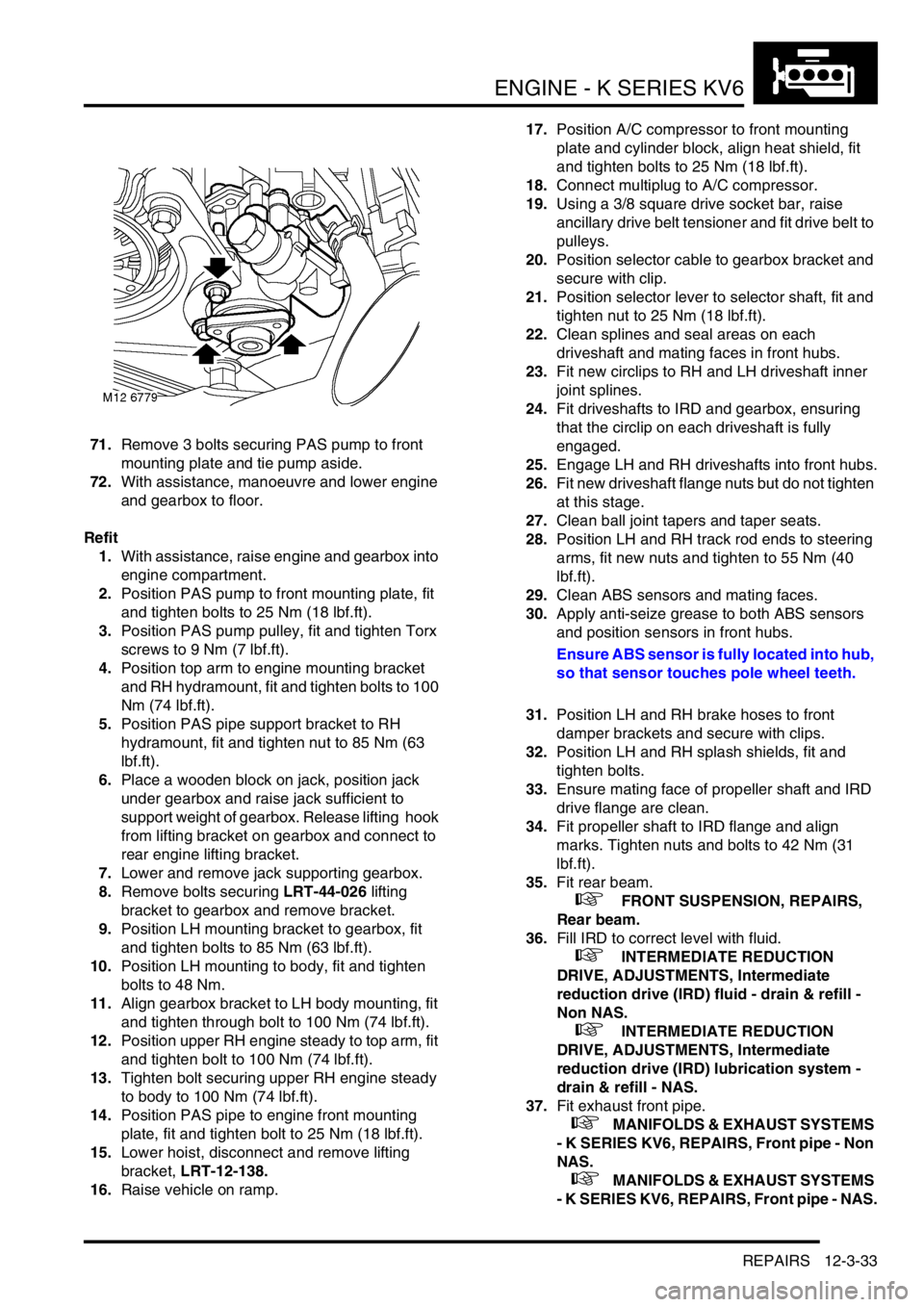

71.Remove 3 bolts securing PAS pump to front

mounting plate and tie pump aside.

72.With assistance, manoeuvre and lower engine

and gearbox to floor.

Refit

1.With assistance, raise engine and gearbox into

engine compartment.

2.Position PAS pump to front mounting plate, fit

and tighten bolts to 25 Nm (18 lbf.ft).

3.Position PAS pump pulley, fit and tighten Torx

screws to 9 Nm (7 lbf.ft).

4.Position top arm to engine mounting bracket

and RH hydramount, fit and tighten bolts to 100

Nm (74 lbf.ft).

5.Position PAS pipe support bracket to RH

hydramount, fit and tighten nut to 85 Nm (63

lbf.ft).

6.Place a wooden block on jack, position jack

under gearbox and raise jack sufficient to

support weight of gearbox. Release lifting hook

from lifting bracket on gearbox and connect to

rear engine lifting bracket.

7.Lower and remove jack supporting gearbox.

8.Remove bolts securing LRT-44-026 lifting

bracket to gearbox and remove bracket.

9.Position LH mounting bracket to gearbox, fit

and tighten bolts to 85 Nm (63 lbf.ft).

10.Position LH mounting to body, fit and tighten

bolts to 48 Nm.

11.Align gearbox bracket to LH body mounting, fit

and tighten through bolt to 100 Nm (74 lbf.ft).

12.Position upper RH engine steady to top arm, fit

and tighten bolt to 100 Nm (74 lbf.ft).

13.Tighten bolt securing upper RH engine steady

to body to 100 Nm (74 lbf.ft).

14.Position PAS pipe to engine front mounting

plate, fit and tighten bolt to 25 Nm (18 lbf.ft).

15.Lower hoist, disconnect and remove lifting

bracket, LRT-12-138.

16.Raise vehicle on ramp.17.Position A/C compressor to front mounting

plate and cylinder block, align heat shield, fit

and tighten bolts to 25 Nm (18 lbf.ft).

18.Connect multiplug to A/C compressor.

19.Using a 3/8 square drive socket bar, raise

ancillary drive belt tensioner and fit drive belt to

pulleys.

20.Position selector cable to gearbox bracket and

secure with clip.

21.Position selector lever to selector shaft, fit and

tighten nut to 25 Nm (18 lbf.ft).

22.Clean splines and seal areas on each

driveshaft and mating faces in front hubs.

23.Fit new circlips to RH and LH driveshaft inner

joint splines.

24.Fit driveshafts to IRD and gearbox, ensuring

that the circlip on each driveshaft is fully

engaged.

25.Engage LH and RH driveshafts into front hubs.

26.Fit new driveshaft flange nuts but do not tighten

at this stage.

27.Clean ball joint tapers and taper seats.

28.Position LH and RH track rod ends to steering

arms, fit new nuts and tighten to 55 Nm (40

lbf.ft).

29.Clean ABS sensors and mating faces.

30.Apply anti-seize grease to both ABS sensors

and position sensors in front hubs.

Ensure ABS sensor is fully located into hub,

so that sensor touches pole wheel teeth.

31.Position LH and RH brake hoses to front

damper brackets and secure with clips.

32.Position LH and RH splash shields, fit and

tighten bolts.

33.Ensure mating face of propeller shaft and IRD

drive flange are clean.

34.Fit propeller shaft to IRD flange and align

marks. Tighten nuts and bolts to 42 Nm (31

lbf.ft).

35.Fit rear beam.

+ FRONT SUSPENSION, REPAIRS,

Rear beam.

36.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) lubrication system -

drain & refill - NAS.

37.Fit exhaust front pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - Non

NAS.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - NAS.

Page 213 of 1007

ENGINE - K SERIES KV6

12-3-36 REPAIRS

17.Rotate heated front screen relay anti-clockwise

and release it from 'E' box bracket.

18.Release 4 clips and remove carrier from 'E' box.

19.Remove nut, release retainer and remove 'E'

box.20.Remove engine compartment fuse box cover.

21.Remove 2 bolts securing battery and starter

lead to fuse box.

22.Disconnect multiplug from fuse box.

23.Disconnect earth header multiplug.

24.Release 3 clips securing engine harness to 'E'

box mounting bracket, lay harness over engine.

M12 6765

M12 6766

Page 215 of 1007

ENGINE - K SERIES KV6

12-3-38 REPAIRS

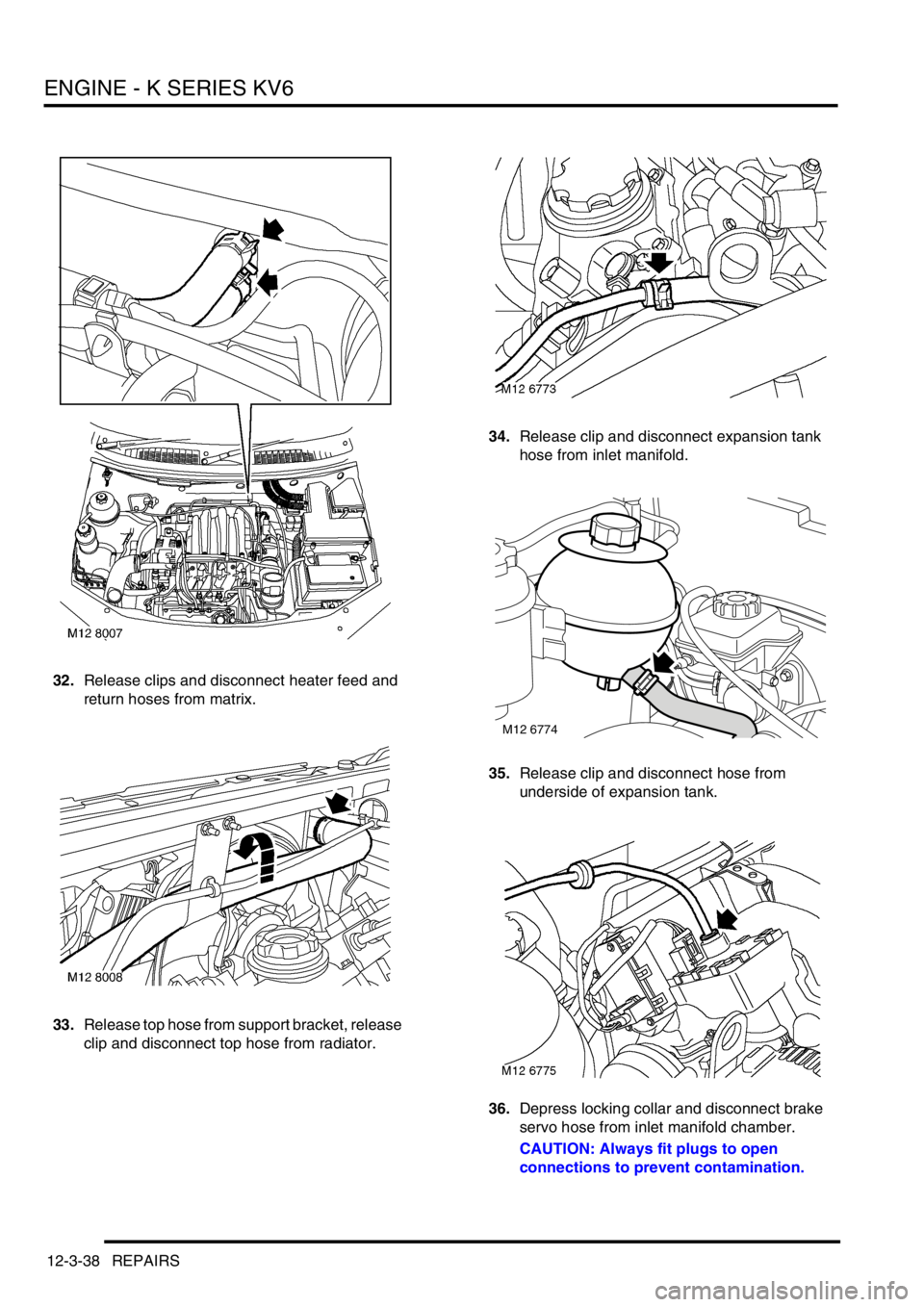

32.Release clips and disconnect heater feed and

return hoses from matrix.

33.Release top hose from support bracket, release

clip and disconnect top hose from radiator.34.Release clip and disconnect expansion tank

hose from inlet manifold.

35.Release clip and disconnect hose from

underside of expansion tank.

36.Depress locking collar and disconnect brake

servo hose from inlet manifold chamber.

CAUTION: Always fit plugs to open

connections to prevent contamination.

M12 6774

Page 218 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-41

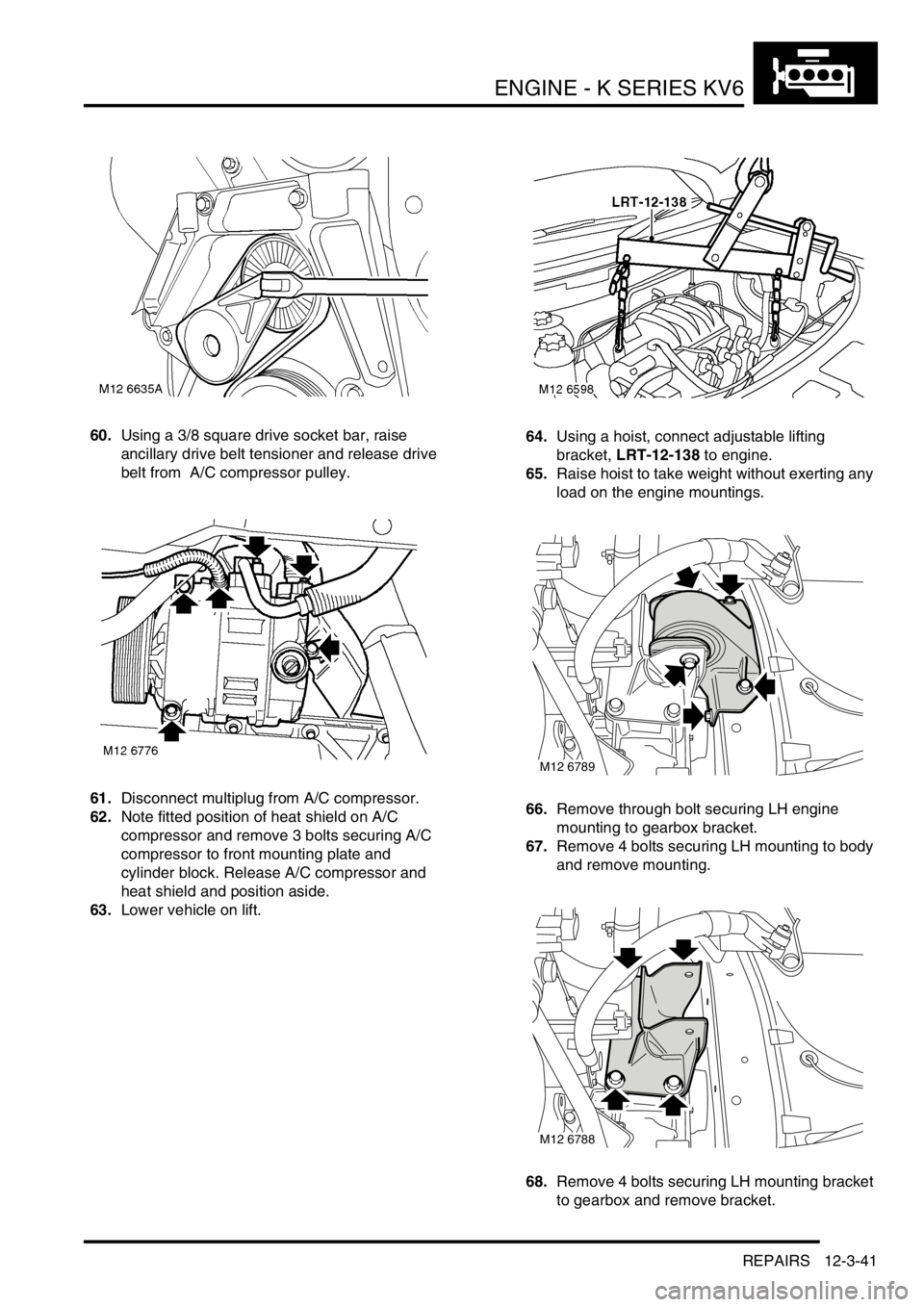

60.Using a 3/8 square drive socket bar, raise

ancillary drive belt tensioner and release drive

belt from A/C compressor pulley.

61.Disconnect multiplug from A/C compressor.

62.Note fitted position of heat shield on A/C

compressor and remove 3 bolts securing A/C

compressor to front mounting plate and

cylinder block. Release A/C compressor and

heat shield and position aside.

63.Lower vehicle on lift.64.Using a hoist, connect adjustable lifting

bracket, LRT-12-138 to engine.

65.Raise hoist to take weight without exerting any

load on the engine mountings.

66.Remove through bolt securing LH engine

mounting to gearbox bracket.

67.Remove 4 bolts securing LH mounting to body

and remove mounting.

68.Remove 4 bolts securing LH mounting bracket

to gearbox and remove bracket.

M12 6789

M12 6788

Page 219 of 1007

ENGINE - K SERIES KV6

12-3-42 REPAIRS

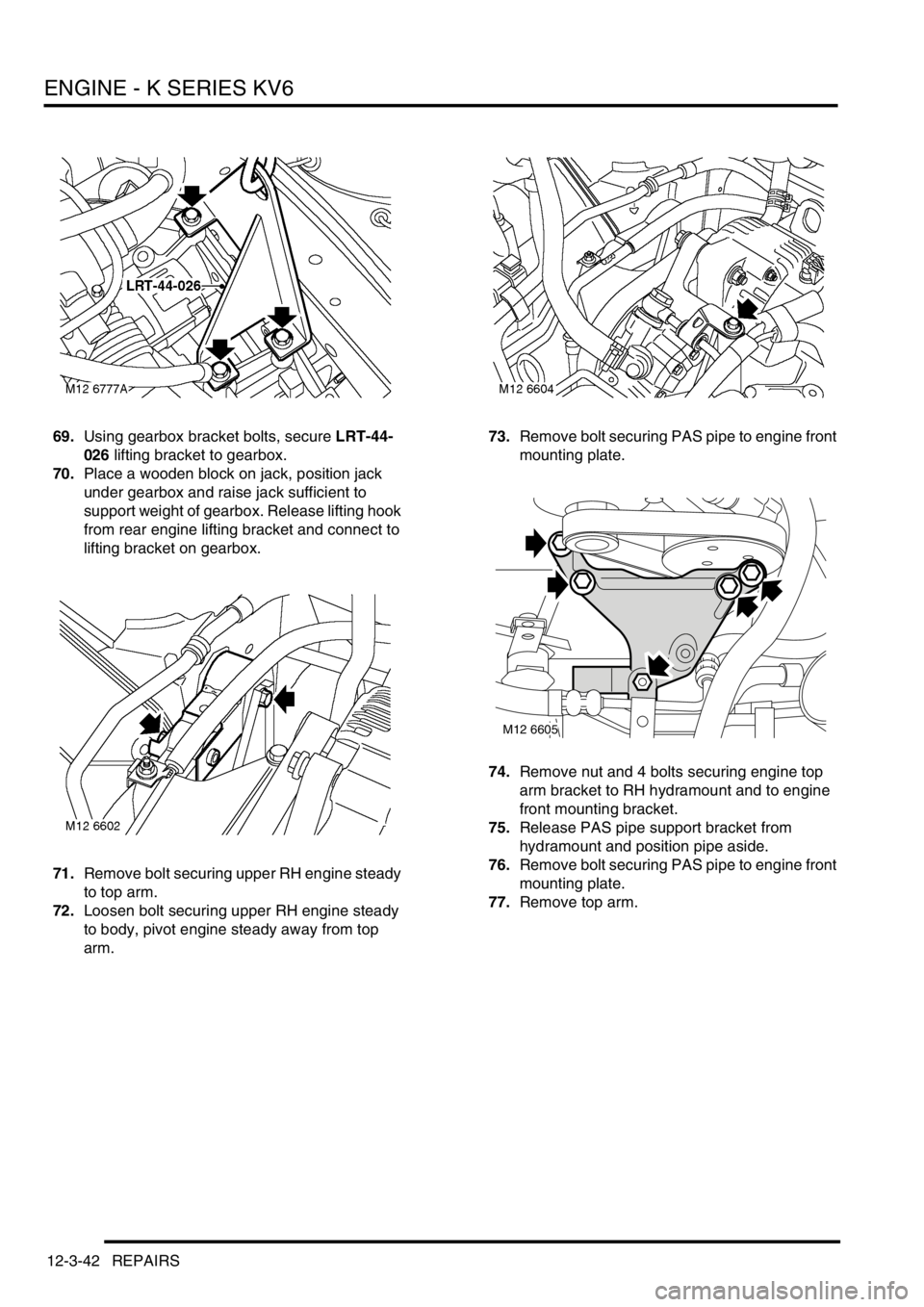

69.Using gearbox bracket bolts, secure LRT-44-

026 lifting bracket to gearbox.

70.Place a wooden block on jack, position jack

under gearbox and raise jack sufficient to

support weight of gearbox. Release lifting hook

from rear engine lifting bracket and connect to

lifting bracket on gearbox.

71.Remove bolt securing upper RH engine steady

to top arm.

72.Loosen bolt securing upper RH engine steady

to body, pivot engine steady away from top

arm.73.Remove bolt securing PAS pipe to engine front

mounting plate.

74.Remove nut and 4 bolts securing engine top

arm bracket to RH hydramount and to engine

front mounting bracket.

75.Release PAS pipe support bracket from

hydramount and position pipe aside.

76.Remove bolt securing PAS pipe to engine front

mounting plate.

77.Remove top arm.

M12 6605

Page 220 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-43

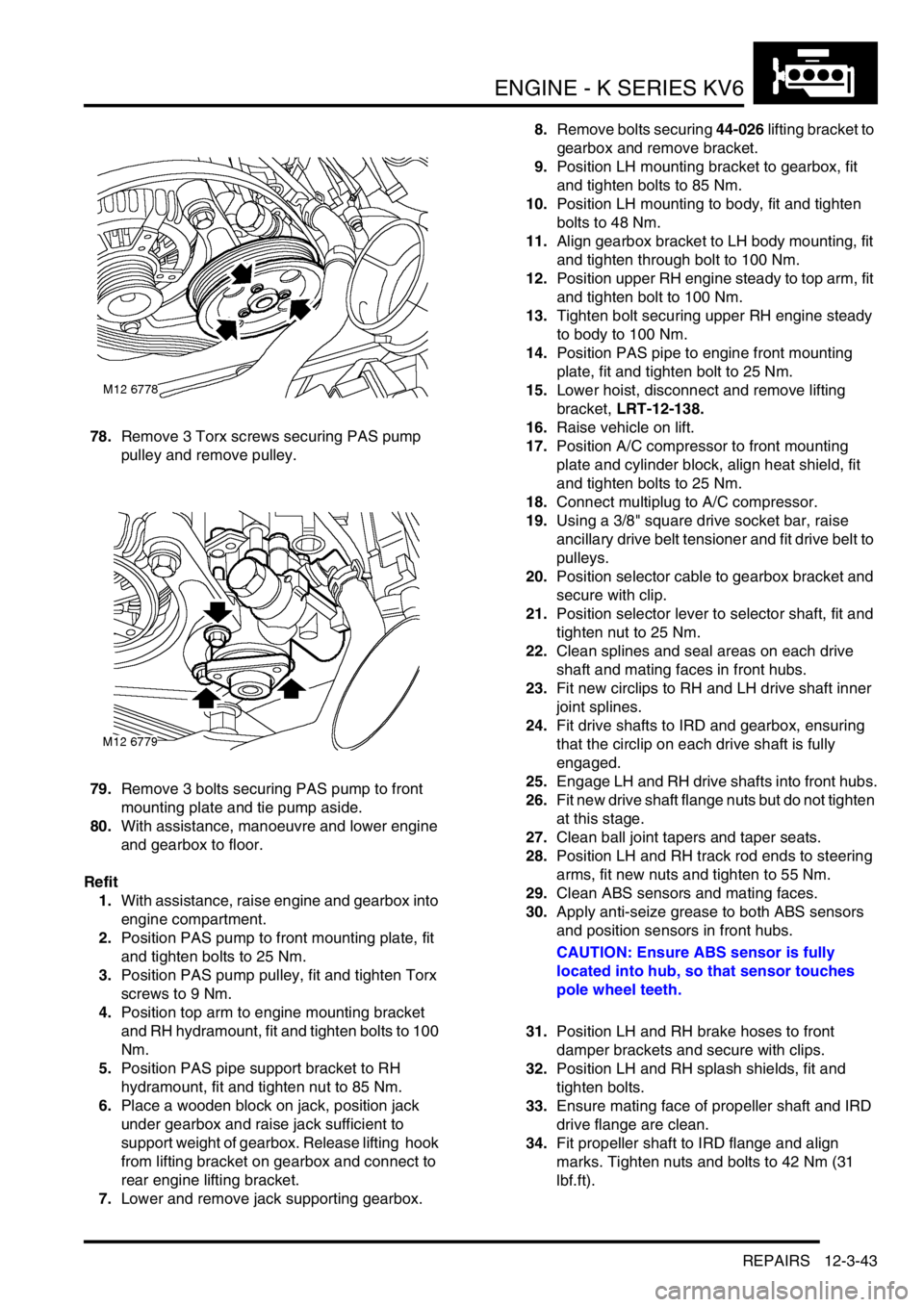

78.Remove 3 Torx screws securing PAS pump

pulley and remove pulley.

79.Remove 3 bolts securing PAS pump to front

mounting plate and tie pump aside.

80.With assistance, manoeuvre and lower engine

and gearbox to floor.

Refit

1.With assistance, raise engine and gearbox into

engine compartment.

2.Position PAS pump to front mounting plate, fit

and tighten bolts to 25 Nm.

3.Position PAS pump pulley, fit and tighten Torx

screws to 9 Nm.

4.Position top arm to engine mounting bracket

and RH hydramount, fit and tighten bolts to 100

Nm.

5.Position PAS pipe support bracket to RH

hydramount, fit and tighten nut to 85 Nm.

6.Place a wooden block on jack, position jack

under gearbox and raise jack sufficient to

support weight of gearbox. Release lifting hook

from lifting bracket on gearbox and connect to

rear engine lifting bracket.

7.Lower and remove jack supporting gearbox.8.Remove bolts securing 44-026 lifting bracket to

gearbox and remove bracket.

9.Position LH mounting bracket to gearbox, fit

and tighten bolts to 85 Nm.

10.Position LH mounting to body, fit and tighten

bolts to 48 Nm.

11.Align gearbox bracket to LH body mounting, fit

and tighten through bolt to 100 Nm.

12.Position upper RH engine steady to top arm, fit

and tighten bolt to 100 Nm.

13.Tighten bolt securing upper RH engine steady

to body to 100 Nm.

14.Position PAS pipe to engine front mounting

plate, fit and tighten bolt to 25 Nm.

15.Lower hoist, disconnect and remove lifting

bracket, LRT-12-138.

16.Raise vehicle on lift.

17.Position A/C compressor to front mounting

plate and cylinder block, align heat shield, fit

and tighten bolts to 25 Nm.

18.Connect multiplug to A/C compressor.

19.Using a 3/8" square drive socket bar, raise

ancillary drive belt tensioner and fit drive belt to

pulleys.

20.Position selector cable to gearbox bracket and

secure with clip.

21.Position selector lever to selector shaft, fit and

tighten nut to 25 Nm.

22.Clean splines and seal areas on each drive

shaft and mating faces in front hubs.

23.Fit new circlips to RH and LH drive shaft inner

joint splines.

24.Fit drive shafts to IRD and gearbox, ensuring

that the circlip on each drive shaft is fully

engaged.

25.Engage LH and RH drive shafts into front hubs.

26.Fit new drive shaft flange nuts but do not tighten

at this stage.

27.Clean ball joint tapers and taper seats.

28.Position LH and RH track rod ends to steering

arms, fit new nuts and tighten to 55 Nm.

29.Clean ABS sensors and mating faces.

30.Apply anti-seize grease to both ABS sensors

and position sensors in front hubs.

CAUTION: Ensure ABS sensor is fully

located into hub, so that sensor touches

pole wheel teeth.

31.Position LH and RH brake hoses to front

damper brackets and secure with clips.

32.Position LH and RH splash shields, fit and

tighten bolts.

33.Ensure mating face of propeller shaft and IRD

drive flange are clean.

34.Fit propeller shaft to IRD flange and align

marks. Tighten nuts and bolts to 42 Nm (31

lbf.ft).