fuel LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 458 of 1007

AUTOMATIC GEARBOX - JATCO

REPAIRS 44-23

23.Fit CKP sensor, fit bolt and tighten to 9 Nm (7

lbf.ft).

24.Position fluid cooler, tighten M12 bolts to 85 Nm

(63 lbf.ft) and M8 bolt to 25 Nm (18 lbf.ft).

25.Clean fluid cooler unions.

26.Lubricate new 'O' rings with clean transmission

fluid and fit 'O' rings to fluid cooler hoses.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

27.Connect fluid cooler hoses to gearbox and

tighten unions to 18 Nm (13 lbf.ft).

28.Clean exhaust manifold and mating face on

cylinder head.

29.Fit exhaust manifold gasket.

30.Position exhaust manifold, fit nuts and

progressively tighten, from centre outwards to

45 Nm (33 lbf.ft).

31.Connect HO2S multiplug and secure to support

bracket.

32.Position IRD cooling hose retainer, fit bolt and

tighten to 25 Nm (18 lbf.ft).

33.Align marks on drive plate to torque converter.

34.Fit bolts securing drive plate to torque converter

and tighten bolts to 45 Nm (33 lbf.ft).

35.Clean torque converter access plate.

36.Position access plate, fit bolts and tighten to 9

Nm (7 lbf.ft).

37.Clean end of drive shaft and mating splines in

gearbox.

38.Fit new circlip to LH drive shaft.

39.With assistance pull hub outwards, align drive

shaft and fit to gearbox, taking care not to

damage drive shaft oil seal.

CAUTION: Pull the drive shaft to ensure the

circlip is fully engaged and retains the shaft.

40.Fit splash shield and secure with bolts.

41.Position trunnion to selector lever, locate inner

cable through trunnion, do not tighten nut at this

stage.

42.Position selector cable to gearbox bracket and

secure with clip.

43.Adjust selector cable.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Selector cable - adjust.

44.Fit IRD.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - KV6.

45.Connect battery earth lead.

46.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

47.Untie and close bonnet.

Gearbox - Td4

$% 44.20.02.99

Remove

1.Disconnect battery earth lead.

2.Tie bonnet back in upright position.

3.Remove intake ducting assembly.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Ducting - intake assembly.

4.Remove fluid cooler.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Fluid cooler - Td4.

5.Remove starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - Td4.

6.Remove IRD.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - Td4.

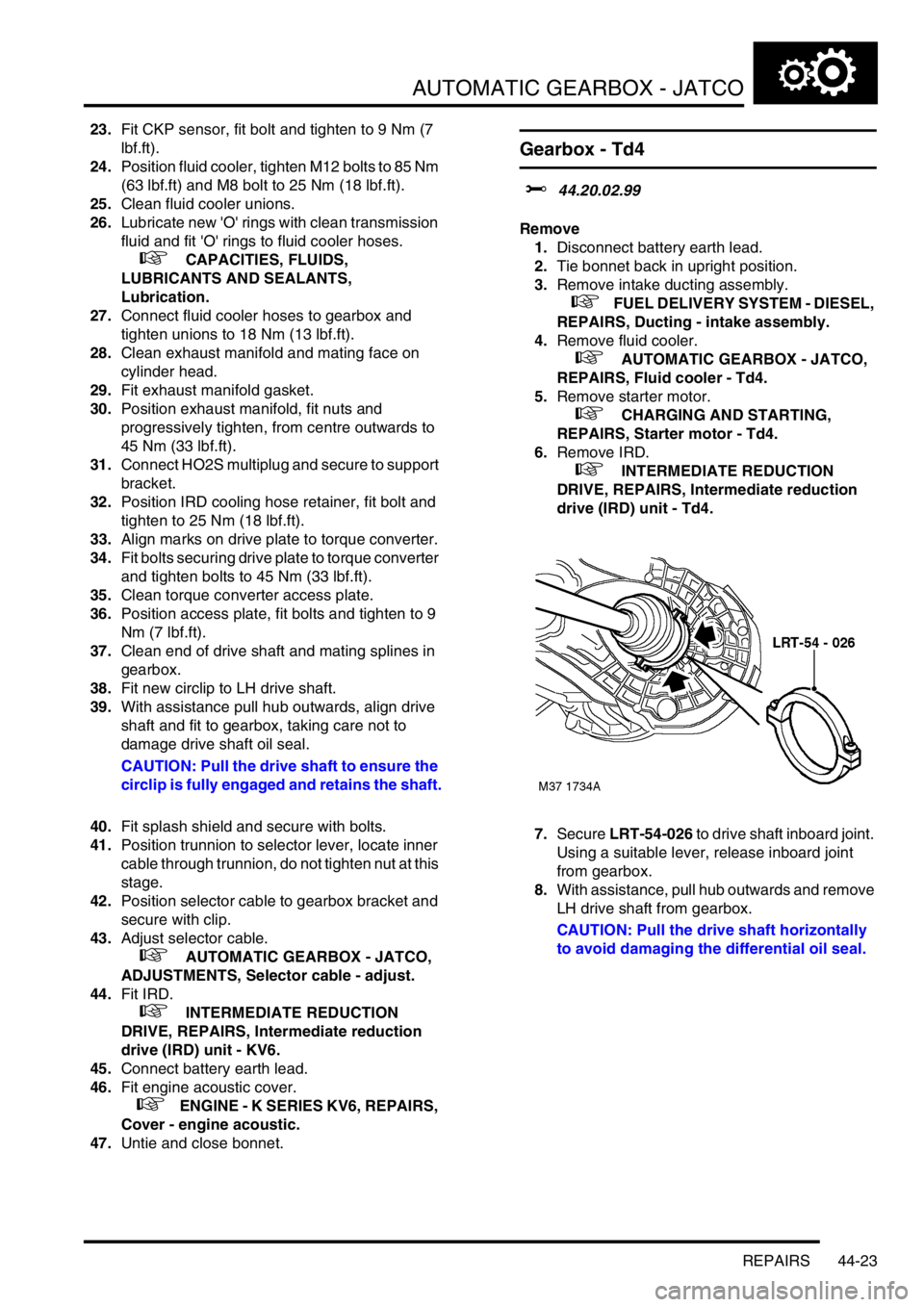

7.Secure LRT-54-026 to drive shaft inboard joint.

Using a suitable lever, release inboard joint

from gearbox.

8.With assistance, pull hub outwards and remove

LH drive shaft from gearbox.

CAUTION: Pull the drive shaft horizontally

to avoid damaging the differential oil seal.

Page 462 of 1007

AUTOMATIC GEARBOX - JATCO

REPAIRS 44-27

21.Fit new circlip to LH drive shaft.

22.With assistance, fit LH drive shaft to gearbox,

keep shaft square to prevent damage to oil seal

in gearbox.

23.Fit IRD.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - Td4.

24.Fit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - Td4.

25.Fit fluid cooler.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Fluid cooler - Td4.

26.Fit intake ducting assembly.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Ducting - intake assembly.

27.Connect battery earth lead.

28.Untie and close bonnet.

Fluid pan - reseal

$% 44.24.05

Remove

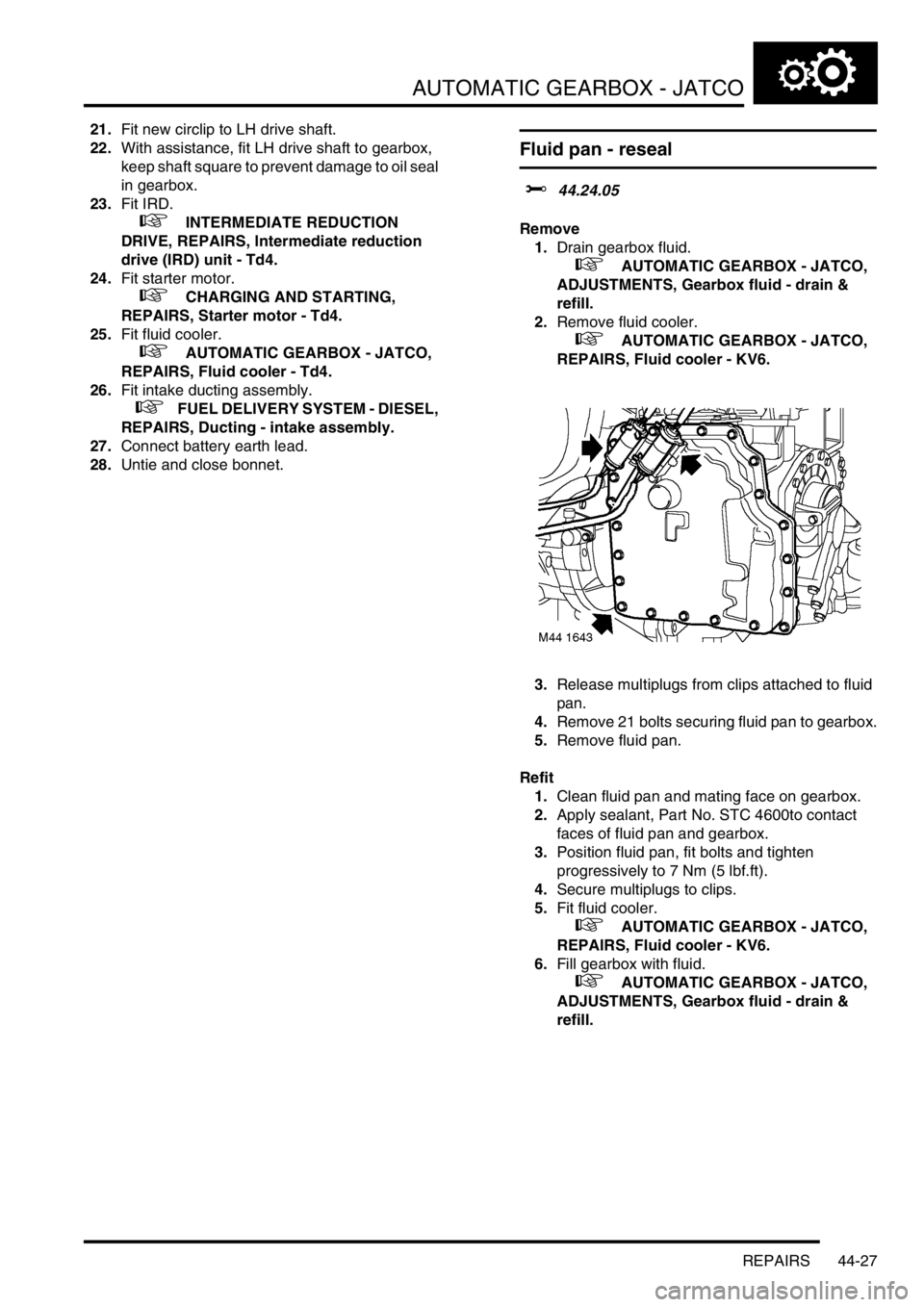

1.Drain gearbox fluid.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Gearbox fluid - drain &

refill.

2.Remove fluid cooler.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Fluid cooler - KV6.

3.Release multiplugs from clips attached to fluid

pan.

4.Remove 21 bolts securing fluid pan to gearbox.

5.Remove fluid pan.

Refit

1.Clean fluid pan and mating face on gearbox.

2.Apply sealant, Part No. STC 4600to contact

faces of fluid pan and gearbox.

3.Position fluid pan, fit bolts and tighten

progressively to 7 Nm (5 lbf.ft).

4.Secure multiplugs to clips.

5.Fit fluid cooler.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Fluid cooler - KV6.

6.Fill gearbox with fluid.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Gearbox fluid - drain &

refill.

Page 502 of 1007

STEERING

REPAIRS 57-9

Oil cooler - Td4 & K1.8 models

$% 57.15.11

Remove

1.Disconnect battery earth lead.

2.Remove engine acoustic cover if fitted.

+ ENGINE - Td4, REPAIRS, Cover -

engine acoustic - Up to 02.5 Model Year.

3. Td4 models: Release and remove air intake

duct.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Ducting - intake assembly.

4. Td4 models: Loosen 2 clips and remove

intercooler outlet hose.

5. Td4 models: Remove dipstick for access.

CAUTION: Always fit plugs to open

connections to prevent contamination.

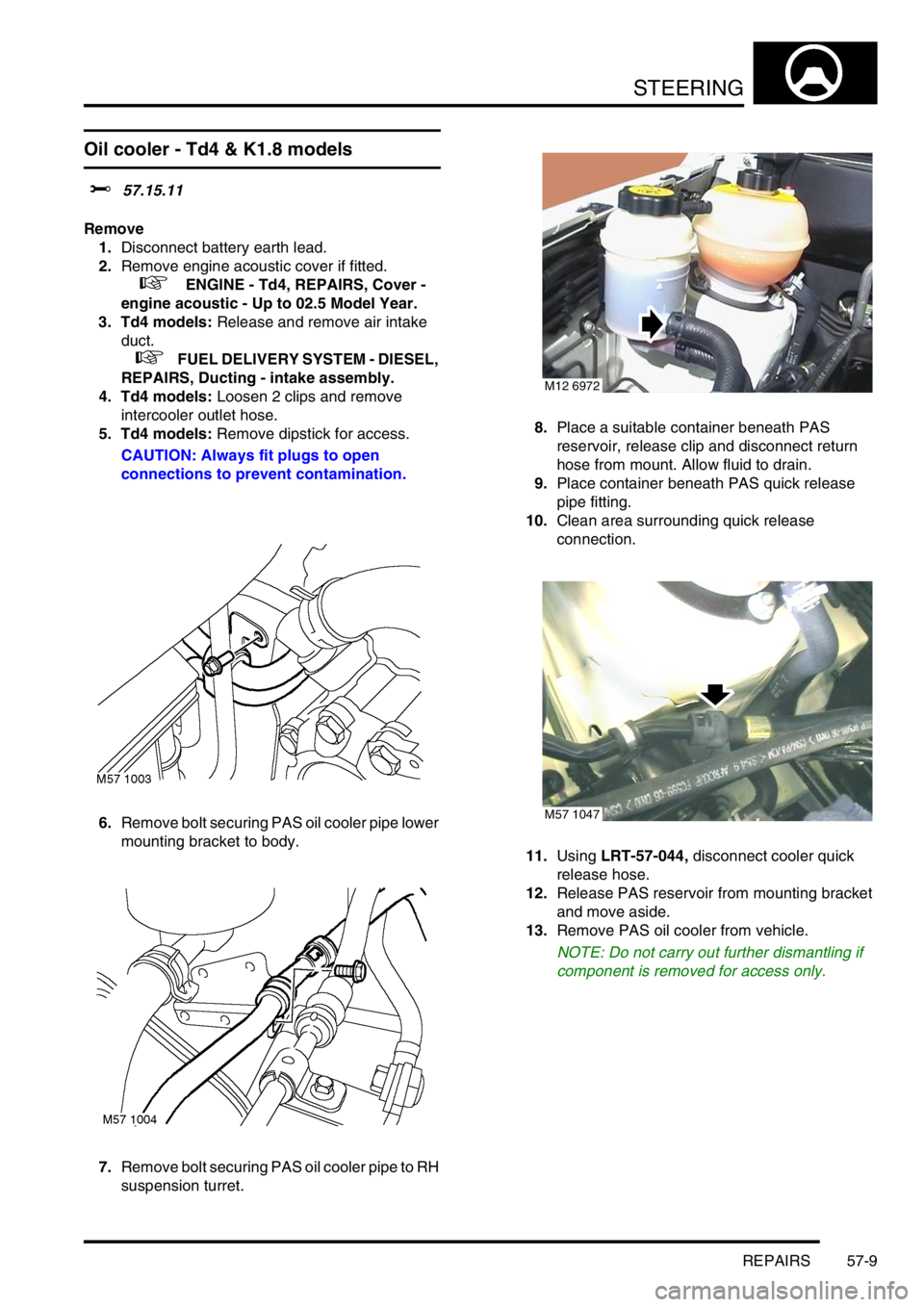

6.Remove bolt securing PAS oil cooler pipe lower

mounting bracket to body.

7.Remove bolt securing PAS oil cooler pipe to RH

suspension turret.8.Place a suitable container beneath PAS

reservoir, release clip and disconnect return

hose from mount. Allow fluid to drain.

9.Place container beneath PAS quick release

pipe fitting.

10.Clean area surrounding quick release

connection.

11.Using LRT-57-044, disconnect cooler quick

release hose.

12.Release PAS reservoir from mounting bracket

and move aside.

13.Remove PAS oil cooler from vehicle.

NOTE: Do not carry out further dismantling if

component is removed for access only.

M12 6972

M57 1047

Page 503 of 1007

STEERING

57-10 REPAIRS

14.Remove clips from PAS oil cooler.

Refit

1.Clean cooler mounting points.

2.Fit clips to PAS cooler.

3.Fit PAS oil cooler to vehicle.

4.Connect quick release pipe fitting.

5.Align PAS pipe bracket, fit bolt and tighten to 10

Nm (7 lbf.ft).

6.Fit bolt to clip securing PAS pipe to RH turret,

tighten to 10 Nm (7 lbf.ft).

7.Fit PAS reservoir to mounting bracket.

8.Clean PAS fluid reservoir around filler cap and

fluid level indicators.

9.Fit PAS return hose to reservoir and secure

clip.

10. Td4 models: Fit intercooler outlet hose and

tighten clips.

11. Td4 models: Fit intake duct to body and duct

assembly.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Ducting - intake assembly.

12. Td4 models: Fit engine oil dipstick.

13. Fit engine acoustic cover if fitted.

+ ENGINE - Td4, REPAIRS, Cover -

engine acoustic - Up to 02.5 Model Year.

14.Connect battery earth lead.

15.Bleed PAS system.

+ STEERING, ADJUSTMENTS, Power

assisted steering (PAS) system - bleed.

Oil cooler - KV6 models

$% 57.15.11

Remove

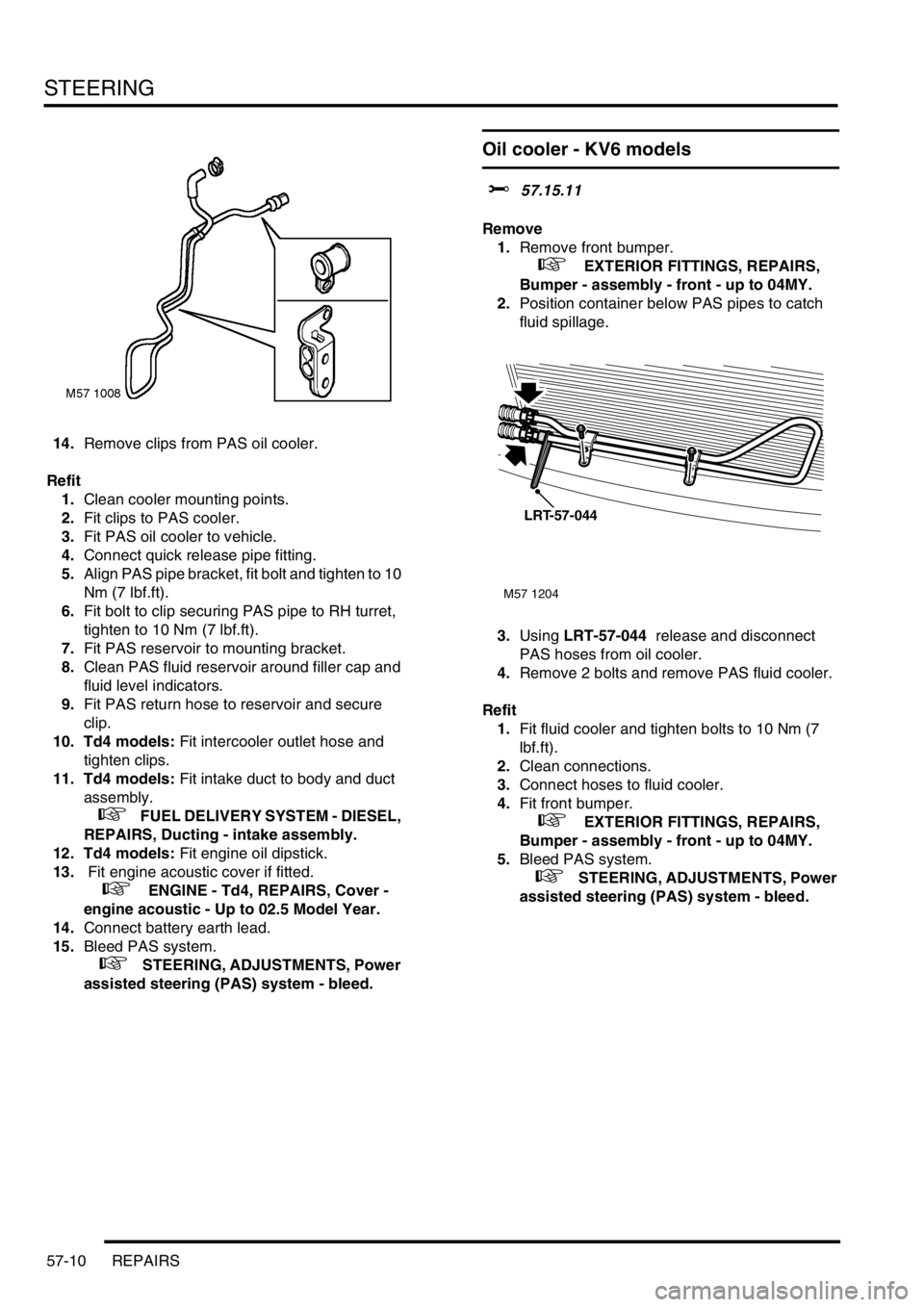

1.Remove front bumper.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

2.Position container below PAS pipes to catch

fluid spillage.

3.Using LRT-57-044 release and disconnect

PAS hoses from oil cooler.

4.Remove 2 bolts and remove PAS fluid cooler.

Refit

1.Fit fluid cooler and tighten bolts to 10 Nm (7

lbf.ft).

2.Clean connections.

3.Connect hoses to fluid cooler.

4.Fit front bumper.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

5.Bleed PAS system.

+ STEERING, ADJUSTMENTS, Power

assisted steering (PAS) system - bleed.

M57 1204

LRT-57-044

Page 566 of 1007

BRAKES

REPAIRS 70-17

14.Check wheel cylinder pistons for freedom of

movement.

15.Check brake adjuster threads, nut and

handbrake linkage for wear. Renew if

necessary.

16.Check condition of return springs and renew if

necessary.

17.Ensure brake adjuster is fully off.

Refit

1.Position adjuster and expander to brake shoes

and fit return springs.

2.Smear brake shoe contact points with Molykote

111 grease.

3.Remove elastic band from wheel cylinder.

4.Manoeuvre brake shoes around rear hub and

locate to abutment and wheel cylinder.

5.Fit brake shoe retaining pins and secure with

clips.

6.Connect hand brake cable to brake shoe lever.

7.Fit brake drum.

+ BRAKES, REPAIRS, Drum - rear.

8.Apply brake pedal a min. of 30 times to ensure

full adjustment of rear brake shoes after

refitting.

9.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

10.Remove stands and lower vehicle.

Servo assembly - LHD

$% 70.50.01

Remove

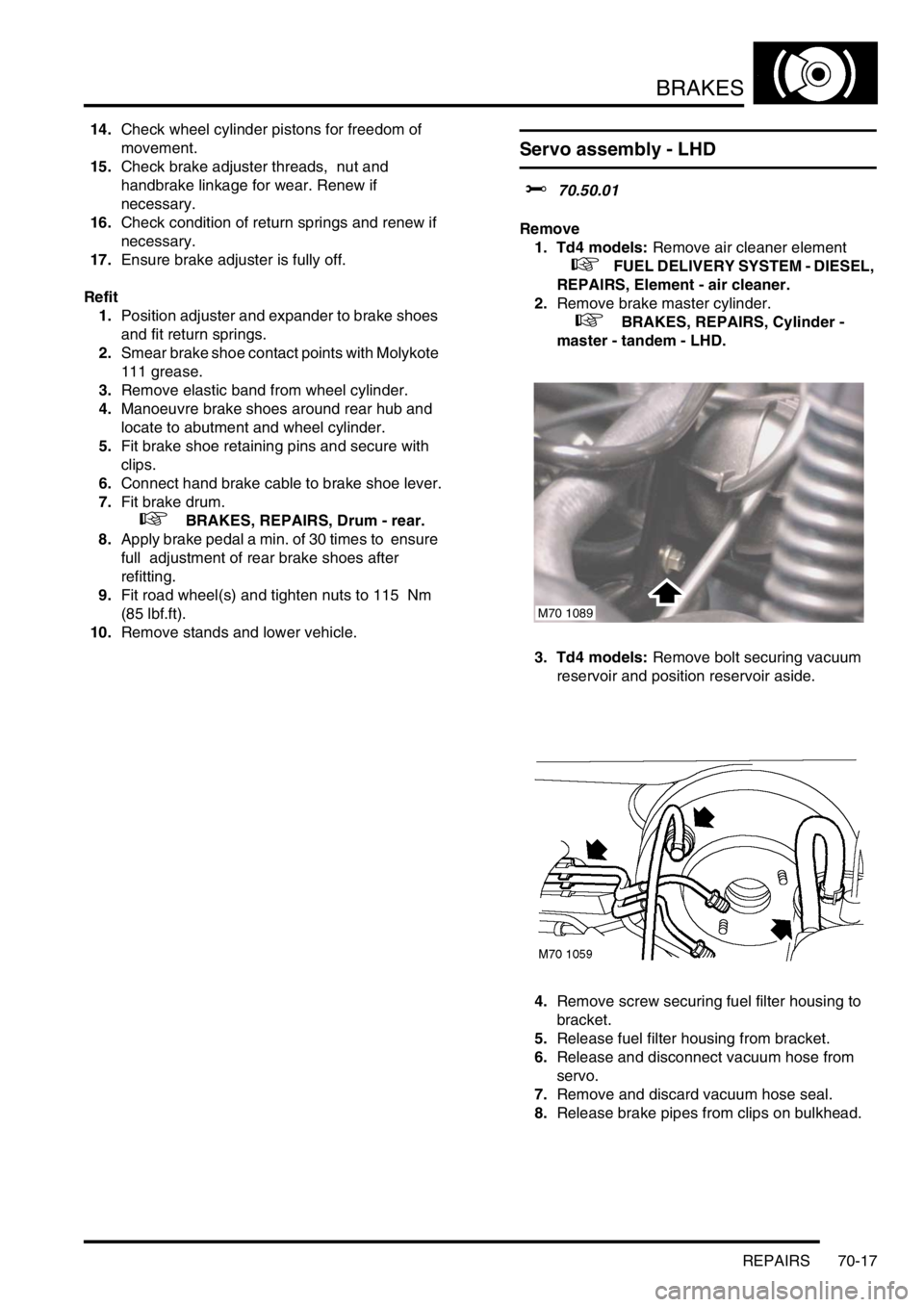

1. Td4 models: Remove air cleaner element

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Element - air cleaner.

2.Remove brake master cylinder.

+ BRAKES, REPAIRS, Cylinder -

master - tandem - LHD.

3. Td4 models: Remove bolt securing vacuum

reservoir and position reservoir aside.

4.Remove screw securing fuel filter housing to

bracket.

5.Release fuel filter housing from bracket.

6.Release and disconnect vacuum hose from

servo.

7.Remove and discard vacuum hose seal.

8.Release brake pipes from clips on bulkhead.

M70 1089

Page 567 of 1007

BRAKES

70-18 REPAIRS

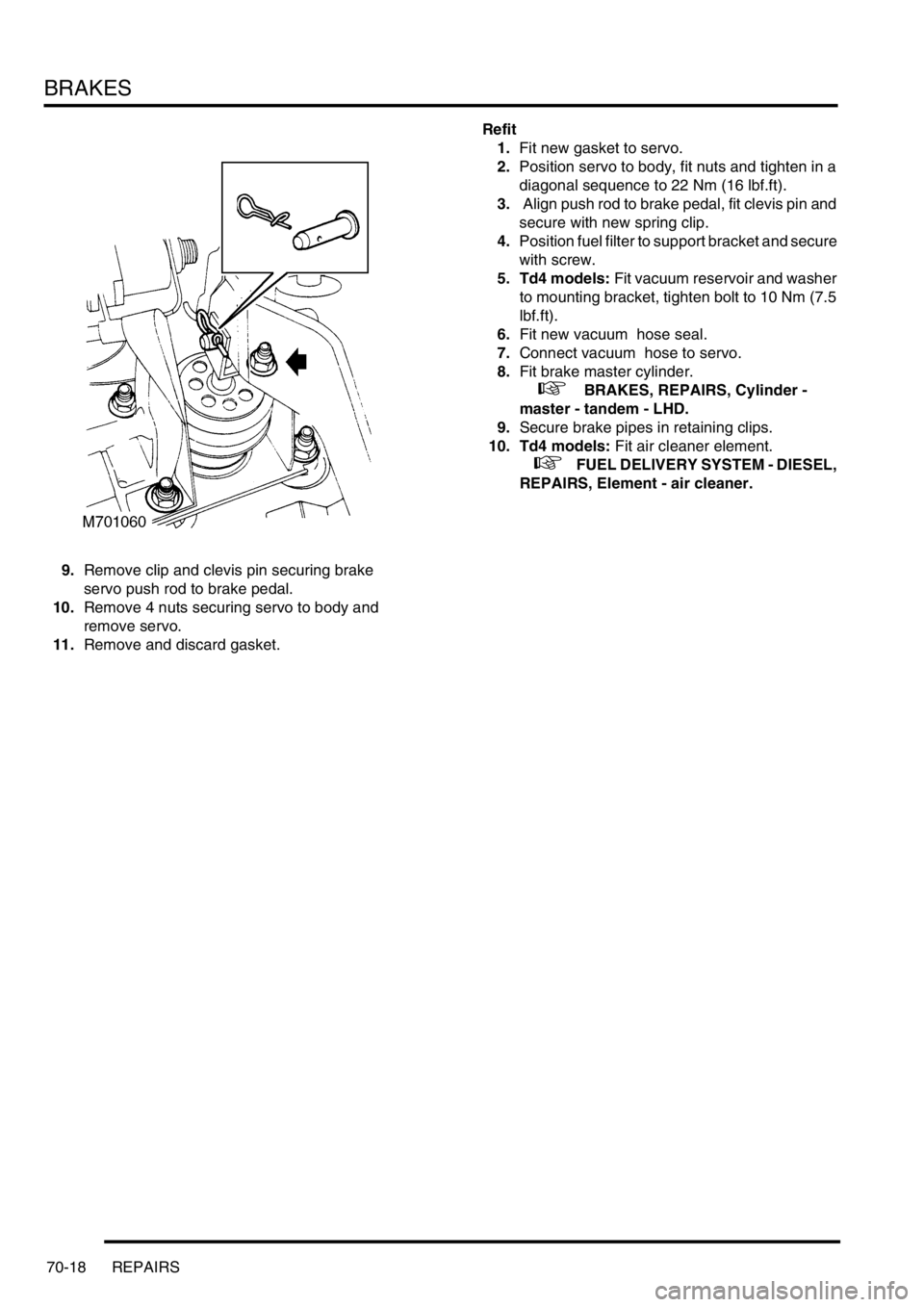

9.Remove clip and clevis pin securing brake

servo push rod to brake pedal.

10.Remove 4 nuts securing servo to body and

remove servo.

11.Remove and discard gasket.Refit

1.Fit new gasket to servo.

2.Position servo to body, fit nuts and tighten in a

diagonal sequence to 22 Nm (16 lbf.ft).

3. Align push rod to brake pedal, fit clevis pin and

secure with new spring clip.

4.Position fuel filter to support bracket and secure

with screw.

5. Td4 models: Fit vacuum reservoir and washer

to mounting bracket, tighten bolt to 10 Nm (7.5

lbf.ft).

6.Fit new vacuum hose seal.

7.Connect vacuum hose to servo.

8.Fit brake master cylinder.

+ BRAKES, REPAIRS, Cylinder -

master - tandem - LHD.

9.Secure brake pipes in retaining clips.

10. Td4 models: Fit air cleaner element.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Element - air cleaner.

Page 568 of 1007

BRAKES

REPAIRS 70-19

Servo assembly - RHD

$% 70.50.01

Remove

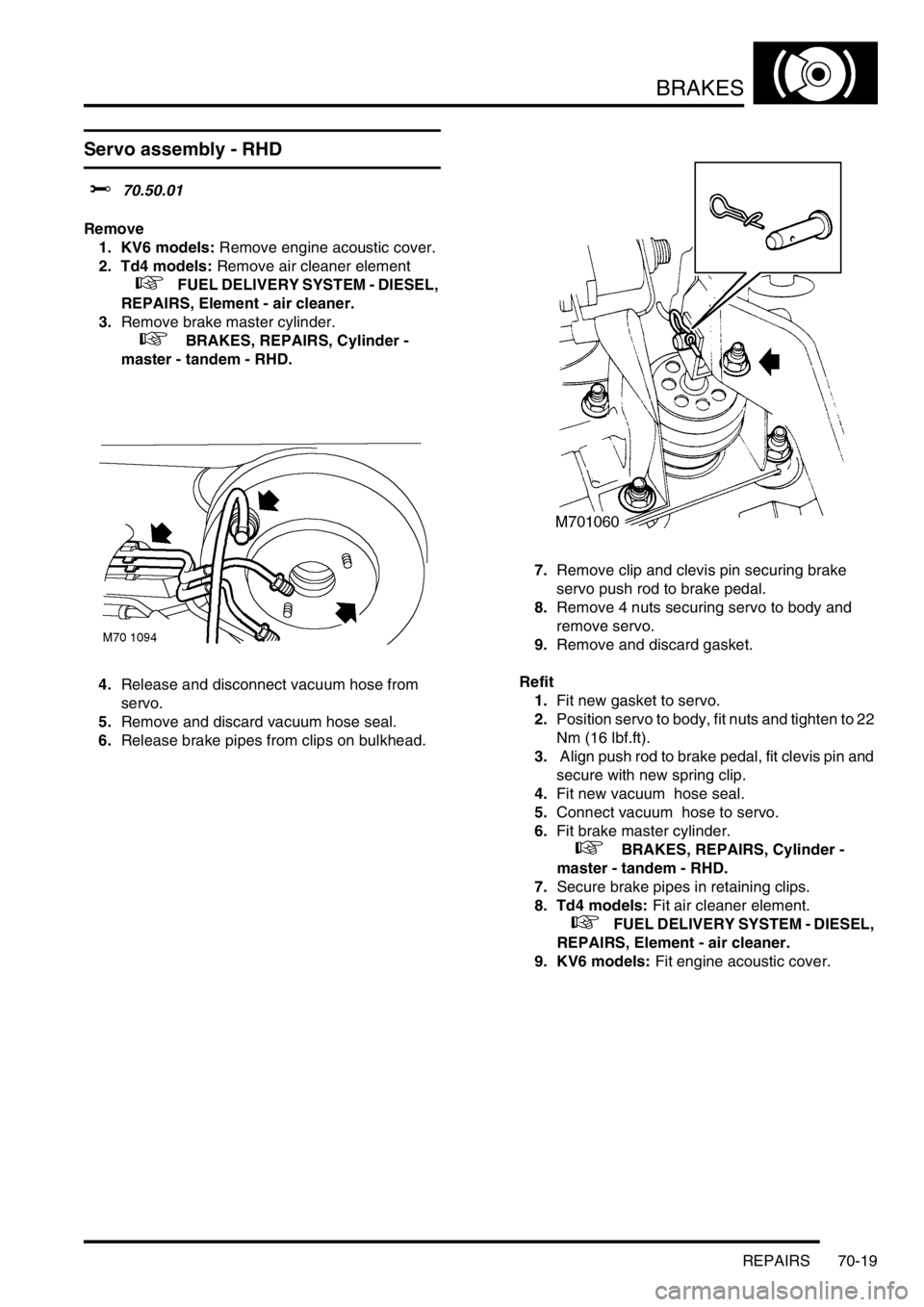

1. KV6 models: Remove engine acoustic cover.

2. Td4 models: Remove air cleaner element

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Element - air cleaner.

3.Remove brake master cylinder.

+ BRAKES, REPAIRS, Cylinder -

master - tandem - RHD.

4.Release and disconnect vacuum hose from

servo.

5.Remove and discard vacuum hose seal.

6.Release brake pipes from clips on bulkhead.7.Remove clip and clevis pin securing brake

servo push rod to brake pedal.

8.Remove 4 nuts securing servo to body and

remove servo.

9.Remove and discard gasket.

Refit

1.Fit new gasket to servo.

2.Position servo to body, fit nuts and tighten to 22

Nm (16 lbf.ft).

3. Align push rod to brake pedal, fit clevis pin and

secure with new spring clip.

4.Fit new vacuum hose seal.

5.Connect vacuum hose to servo.

6.Fit brake master cylinder.

+ BRAKES, REPAIRS, Cylinder -

master - tandem - RHD.

7.Secure brake pipes in retaining clips.

8. Td4 models: Fit air cleaner element.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Element - air cleaner.

9. KV6 models: Fit engine acoustic cover.

Page 569 of 1007

BRAKES

70-20 REPAIRS

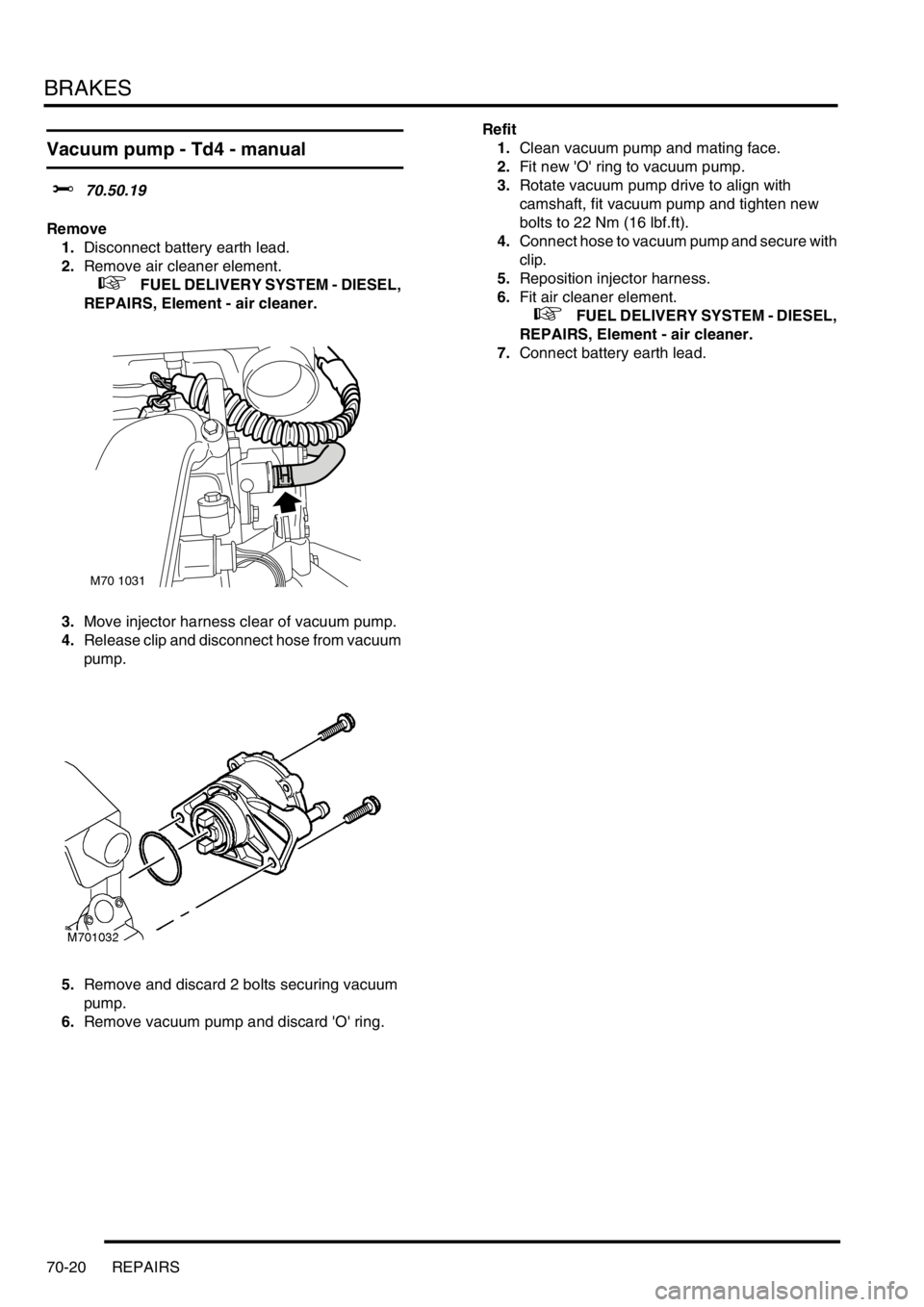

Vacuum pump - Td4 - manual

$% 70.50.19

Remove

1.Disconnect battery earth lead.

2.Remove air cleaner element.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Element - air cleaner.

3.Move injector harness clear of vacuum pump.

4.Release clip and disconnect hose from vacuum

pump.

5.Remove and discard 2 bolts securing vacuum

pump.

6.Remove vacuum pump and discard 'O' ring.Refit

1.Clean vacuum pump and mating face.

2.Fit new 'O' ring to vacuum pump.

3.Rotate vacuum pump drive to align with

camshaft, fit vacuum pump and tighten new

bolts to 22 Nm (16 lbf.ft).

4.Connect hose to vacuum pump and secure with

clip.

5.Reposition injector harness.

6.Fit air cleaner element.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Element - air cleaner.

7.Connect battery earth lead.

M70 1031

Page 570 of 1007

BRAKES

REPAIRS 70-21

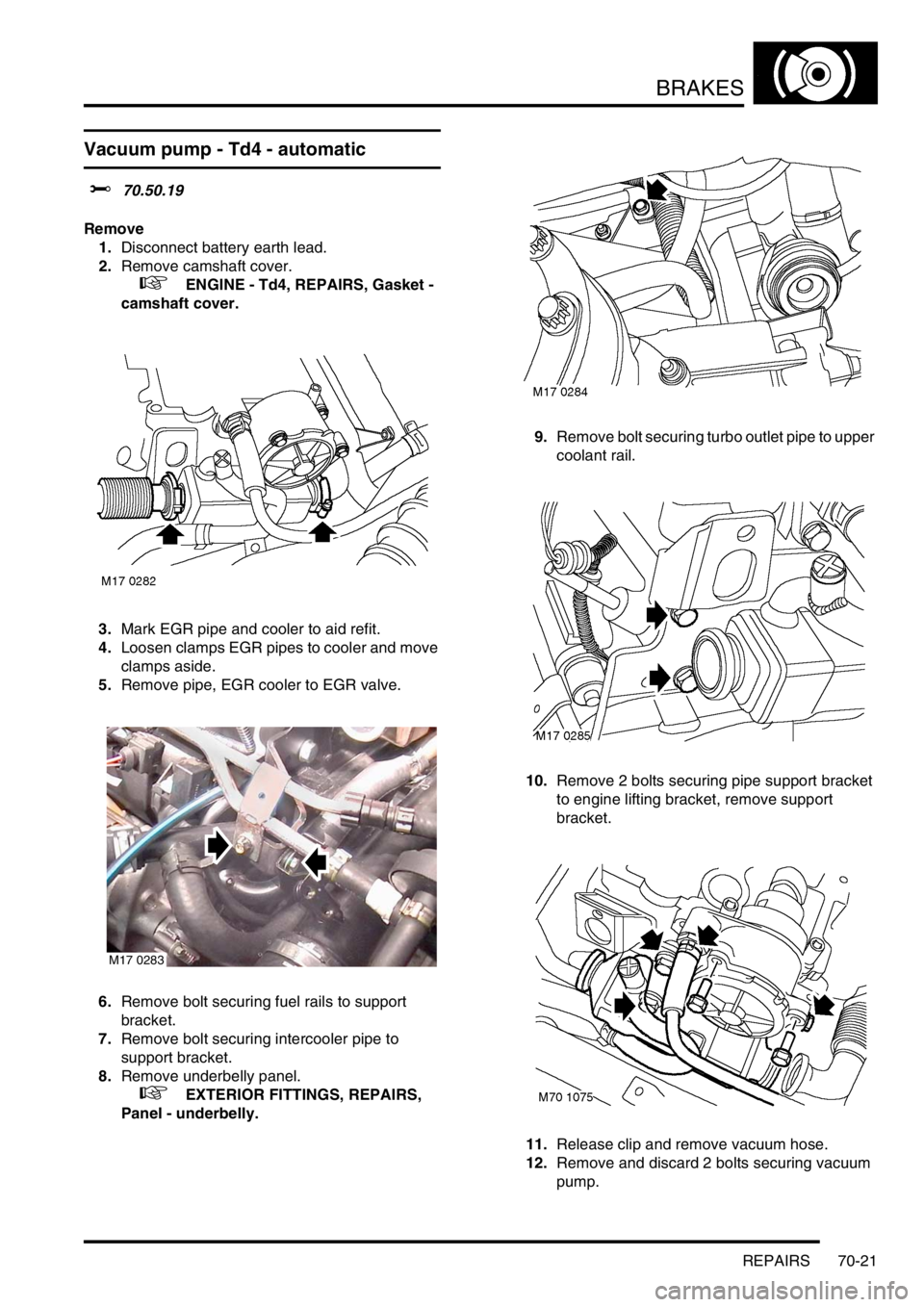

Vacuum pump - Td4 - automatic

$% 70.50.19

Remove

1.Disconnect battery earth lead.

2.Remove camshaft cover.

+ ENGINE - Td4, REPAIRS, Gasket -

camshaft cover.

3.Mark EGR pipe and cooler to aid refit.

4.Loosen clamps EGR pipes to cooler and move

clamps aside.

5.Remove pipe, EGR cooler to EGR valve.

6.Remove bolt securing fuel rails to support

bracket.

7.Remove bolt securing intercooler pipe to

support bracket.

8.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.9.Remove bolt securing turbo outlet pipe to upper

coolant rail.

10.Remove 2 bolts securing pipe support bracket

to engine lifting bracket, remove support

bracket.

11.Release clip and remove vacuum hose.

12.Remove and discard 2 bolts securing vacuum

pump.

M17 0283

Page 571 of 1007

BRAKES

70-22 REPAIRS

13.Remove 3 bolts securing EGR cooler to

cylinder head and lifting bracket.

14.Move EGR cooler aside for access to vacuum

pump.

15.Remove vacuum pump and discard 'O' ring.

Refit

1.Clean vacuum pump and mating face.

2.Fit new seal to vacuum pump, fit vacuum pump

and tighten new bolts to 22 Nm (16 lbf.ft).

3.Position EGR cooler to mounting, fit bolts and

tighten to 25 Nm (18 lbf.ft).

4.Position pipe support bracket to engine lifting

bracket, fit and tighten bolts to 25 Nm (18 lbf.ft).

5.Fit vacuum hose and tighten clip.

6.Fit bolt securing turbocharger pipe to coolant

rail and tighten to 25 Nm (18 lbf.ft).

7.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

8.Fit bolt securing turbocharger intercooler pipe

to support bracket and tighten to 10 Nm (7.5

lbf.ft).

9.Fit bolt securing fuel rails to support bracket

and tighten to 10 Nm (7.5 lbf.ft).

10.Align EGR pipe to cooler, fit clamp but do not

fully tighten until camshaft cover is refitted.

11.Fit EGR pipe clamp and tighten screw.

12.Fit camshaft cover.

+ ENGINE - Td4, REPAIRS, Gasket -

camshaft cover.

13.Connect battery earth lead.

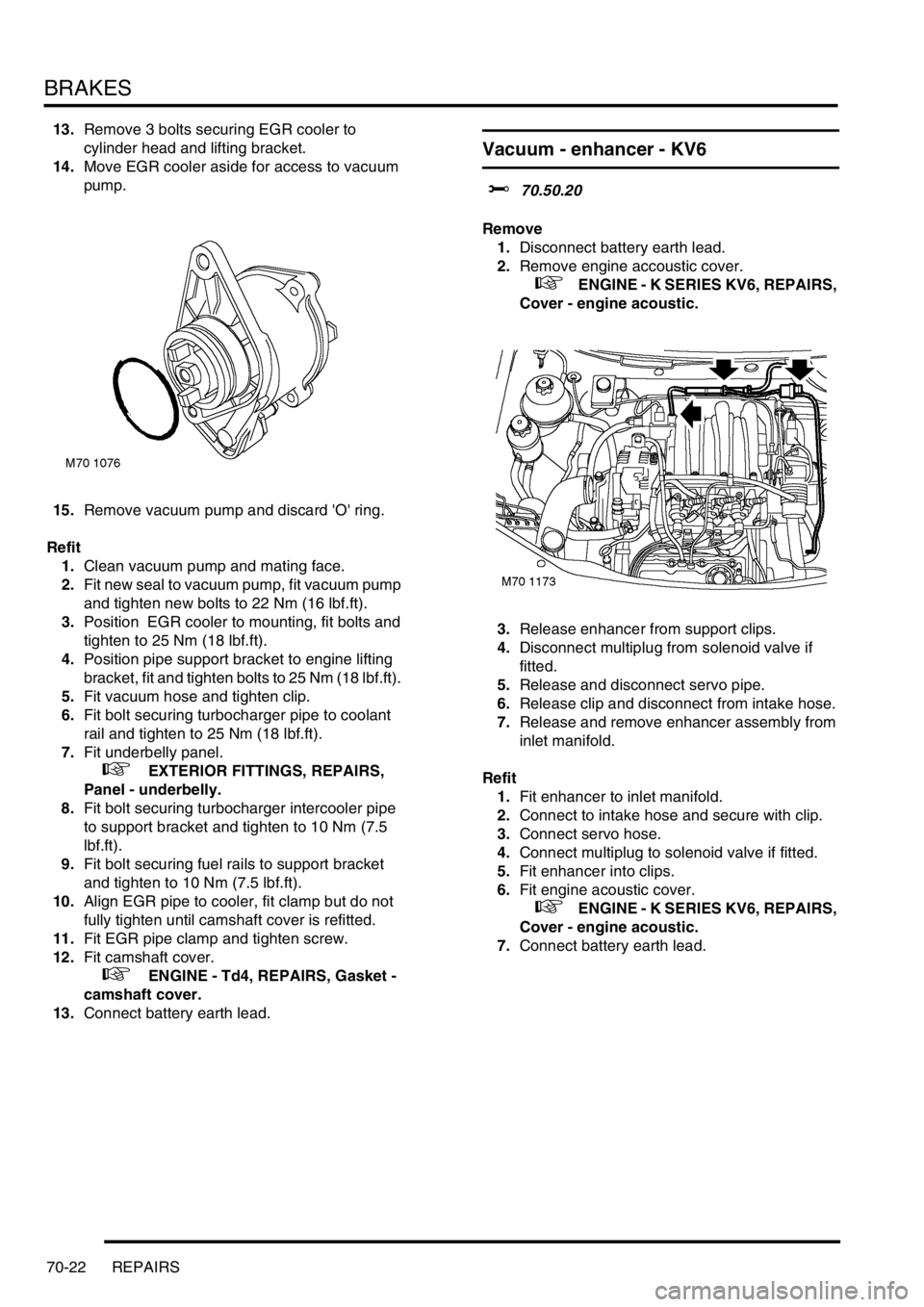

Vacuum - enhancer - KV6

$% 70.50.20

Remove

1.Disconnect battery earth lead.

2.Remove engine accoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Release enhancer from support clips.

4.Disconnect multiplug from solenoid valve if

fitted.

5.Release and disconnect servo pipe.

6.Release clip and disconnect from intake hose.

7.Release and remove enhancer assembly from

inlet manifold.

Refit

1.Fit enhancer to inlet manifold.

2.Connect to intake hose and secure with clip.

3.Connect servo hose.

4.Connect multiplug to solenoid valve if fitted.

5.Fit enhancer into clips.

6.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

7.Connect battery earth lead.