fuel LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 811 of 1007

PANEL REPAIRS

77-2-56 REPAIRS

Refit

1. LH side: Fit tail door striker.

2. RH side: Fit fuel tank.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Tank - Non NAS.

3. RH side: Fit fuel filler neck.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Filler neck.

4. RH side: Fit tail door.

+ DOORS, REPAIRS, Door - tail

assembly - remove for access & refit.

5.Secure vehicle harness to 'E' post.

6.Fit loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - luggage compartment.

7.Fit rear quarter lower casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 3 door.

8.Fit tail door aperture seal.

9.Fit soft/hard top.

10.Fit tail lamp.

+ LIGHTING, REPAIRS, Lamp

assembly - tail.

11.Fit rear wheel arch liner.

12.Fit rear bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper valance - rear - up to 04MY.

13.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

14.Connect all ECUs.

15.Connect alternator.

16.Connect battery earth lead.

Inner 'e' post - 5 door

In this procedure, the rear outer body side panel and

the rear body side reinforcement assembly is

replaced in conjunction with the inner 'E' post

assembly.

Remove

1.Disconnect battery earth lead.

2.Disconnect alternator.

3.Disconnect all ECUs.

4.Remove road wheel(s).

5.Remove rear bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper valance - rear - up to 04MY.

6.Remove rear wheel arch liner.

7.Remove tail lamp.

+ LIGHTING, REPAIRS, Lamp

assembly - tail.

8.Remove roof panel finisher.

+ DOORS, REPAIRS, Finisher - rear

screen - side - 5 door.

9.Remove tail door glass upper finisher.

10.Remove tail door glass side finisher.

+ DOORS, REPAIRS, Finisher - rear

screen - side - 5 door.

11.Remove tail door aperture seal.

12.Remove rear quarter lower casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 5 door.

13.Remove rear quarter upper casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - upper

- 5 door.

14.Remove loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - luggage compartment.

15.Remove rear body side glass.

+ SCREENS, REPAIRS, Glass - body

side - rear.

16.Release vehicle harness from 'E' post and

position aside.

17. LH side: Remove tail door striker.

18. RH side: Remove tail door.

+ DOORS, REPAIRS, Door - tail

assembly - remove for access & refit.

19. RH side: Remove fuel filler neck.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Filler neck.

20. RH side: Remove fuel tank.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Tank - Non NAS.

Page 812 of 1007

PANEL REPAIRS

REPAIRS 77-2-57

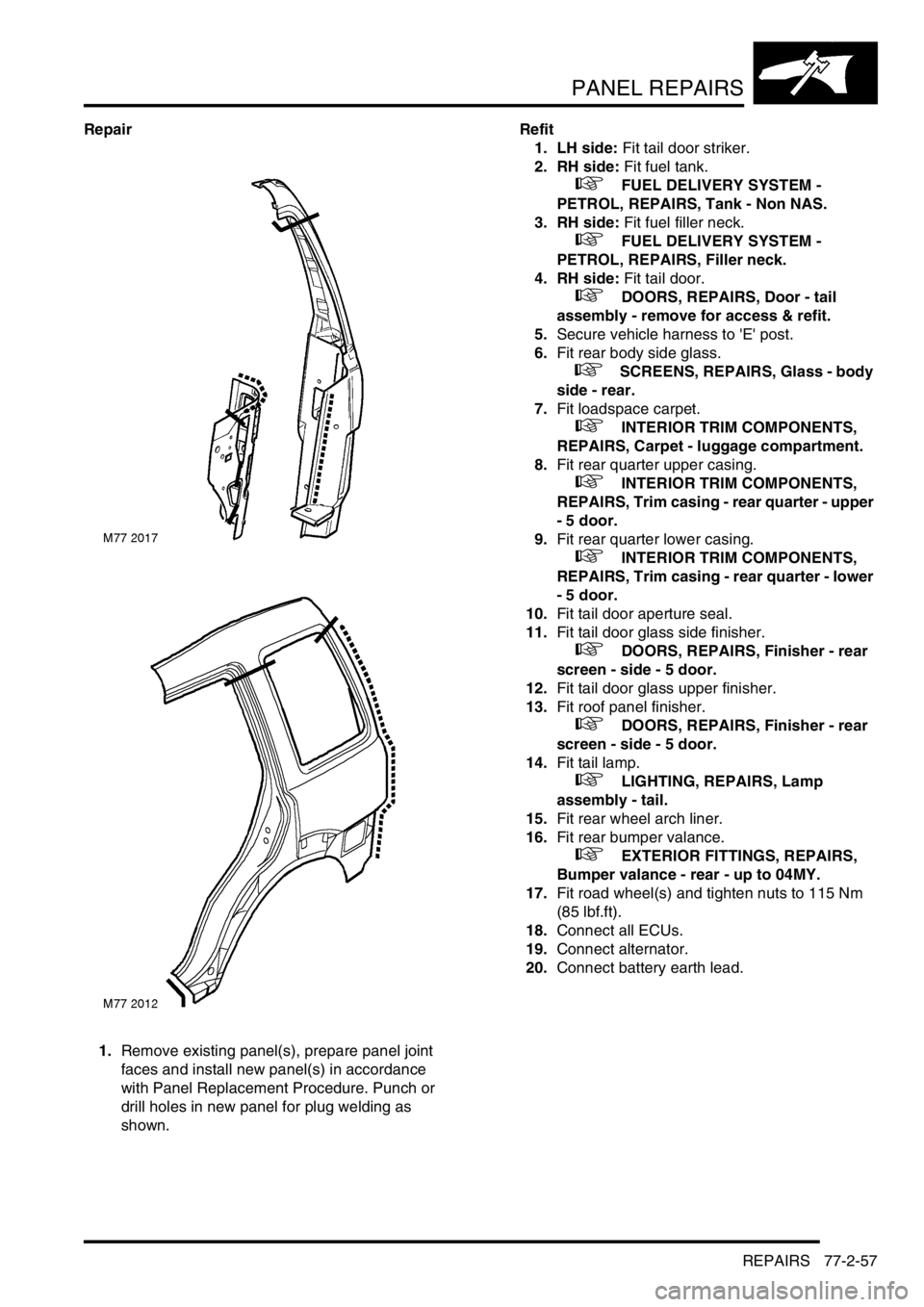

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown. Refit

1. LH side: Fit tail door striker.

2. RH side: Fit fuel tank.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Tank - Non NAS.

3. RH side: Fit fuel filler neck.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Filler neck.

4. RH side: Fit tail door.

+ DOORS, REPAIRS, Door - tail

assembly - remove for access & refit.

5.Secure vehicle harness to 'E' post.

6.Fit rear body side glass.

+ SCREENS, REPAIRS, Glass - body

side - rear.

7.Fit loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - luggage compartment.

8.Fit rear quarter upper casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - upper

- 5 door.

9.Fit rear quarter lower casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 5 door.

10.Fit tail door aperture seal.

11.Fit tail door glass side finisher.

+ DOORS, REPAIRS, Finisher - rear

screen - side - 5 door.

12.Fit tail door glass upper finisher.

13.Fit roof panel finisher.

+ DOORS, REPAIRS, Finisher - rear

screen - side - 5 door.

14.Fit tail lamp.

+ LIGHTING, REPAIRS, Lamp

assembly - tail.

15.Fit rear wheel arch liner.

16.Fit rear bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper valance - rear - up to 04MY.

17.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

18.Connect all ECUs.

19.Connect alternator.

20.Connect battery earth lead.

Page 814 of 1007

PANEL REPAIRS

REPAIRS 77-2-59

Rear floor

In this procedure, the inner quarter to rear floor

gussets are replaced in conjunction with the rear

floor. If required, the safe well can be replaced

separately.

Remove

1.Disconnect battery earth lead.

2.Disconnect alternator.

3.Disconnect all ECUs.

4.Remove tail exhaust pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- Td4, REPAIRS, Exhaust pipe - tail.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES 1.8, REPAIRS, Exhaust pipe -

tail.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Tail pipe &

silencer.

5.Remove tail door.

+ DOORS, REPAIRS, Door - tail

assembly - remove for access & refit.

6.Remove tail door aperture seal.

7.Remove LH and RH rear quarter lower casings.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 5 door.

8.Remove loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - luggage compartment.

9.Remove fuel tank.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Tank - Non NAS.

10.Release vehicle harness from rear body lower

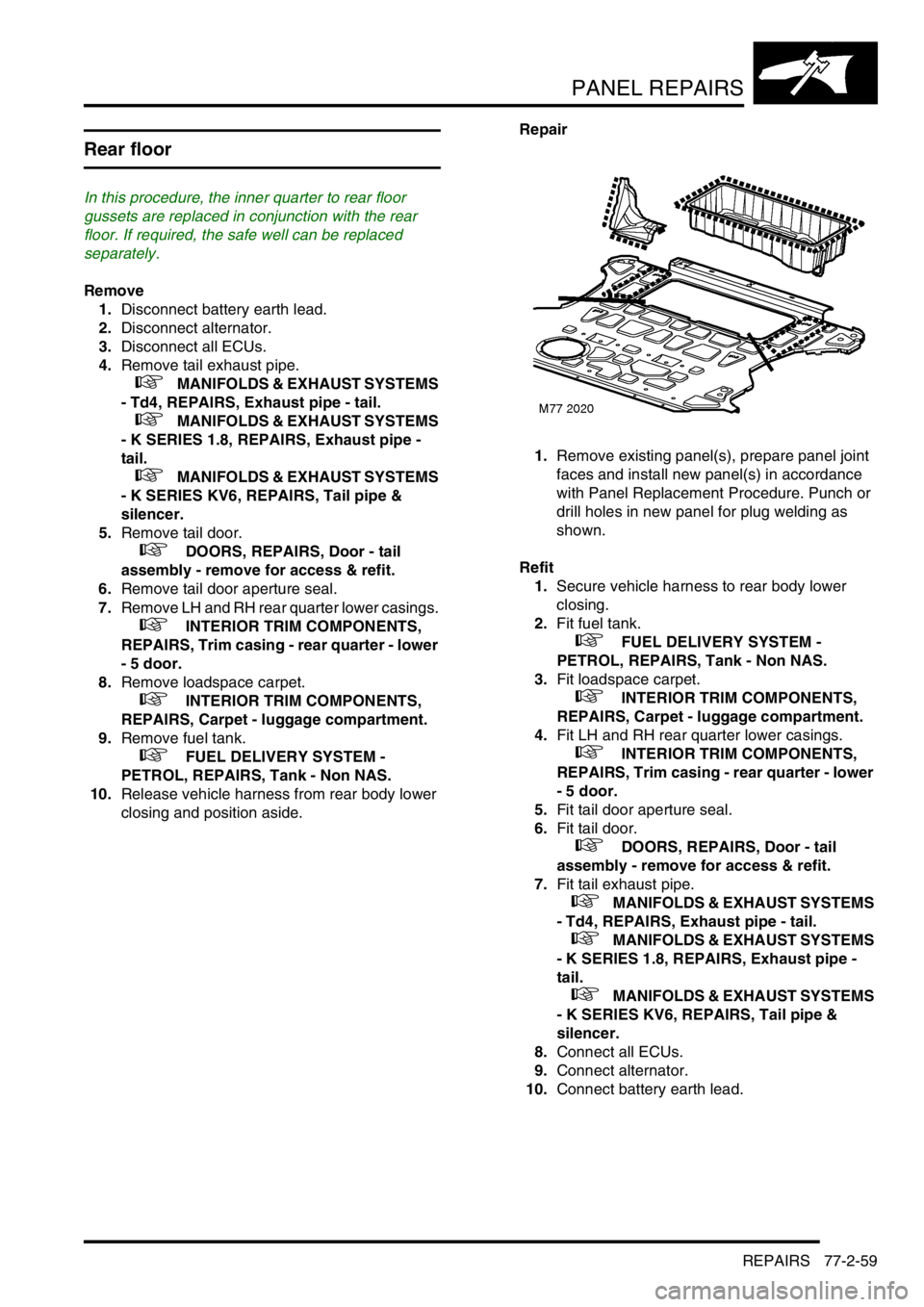

closing and position aside. Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Secure vehicle harness to rear body lower

closing.

2.Fit fuel tank.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Tank - Non NAS.

3.Fit loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - luggage compartment.

4.Fit LH and RH rear quarter lower casings.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 5 door.

5.Fit tail door aperture seal.

6.Fit tail door.

+ DOORS, REPAIRS, Door - tail

assembly - remove for access & refit.

7.Fit tail exhaust pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- Td4, REPAIRS, Exhaust pipe - tail.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES 1.8, REPAIRS, Exhaust pipe -

tail.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Tail pipe &

silencer.

8.Connect all ECUs.

9.Connect alternator.

10.Connect battery earth lead.

Page 815 of 1007

PANEL REPAIRS

77-2-60 REPAIRS

Floor longitudinal

Remove

1.Disconnect battery earth lead.

2.Disconnect alternator.

3.Disconnect all ECUs.

4.Remove tail exhaust pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- Td4, REPAIRS, Exhaust pipe - tail.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES 1.8, REPAIRS, Exhaust pipe -

tail.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Tail pipe &

silencer.

5.Remove tail door.

+ DOORS, REPAIRS, Door - tail

assembly - remove for access & refit.

6.Remove tail door aperture seal.

7.Remove LH and RH rear quarter lower casings.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 5 door.

8.Remove loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - luggage compartment.

9.Remove fuel tank.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Tank - Non NAS.

10.Release vehicle harness from rear body lower

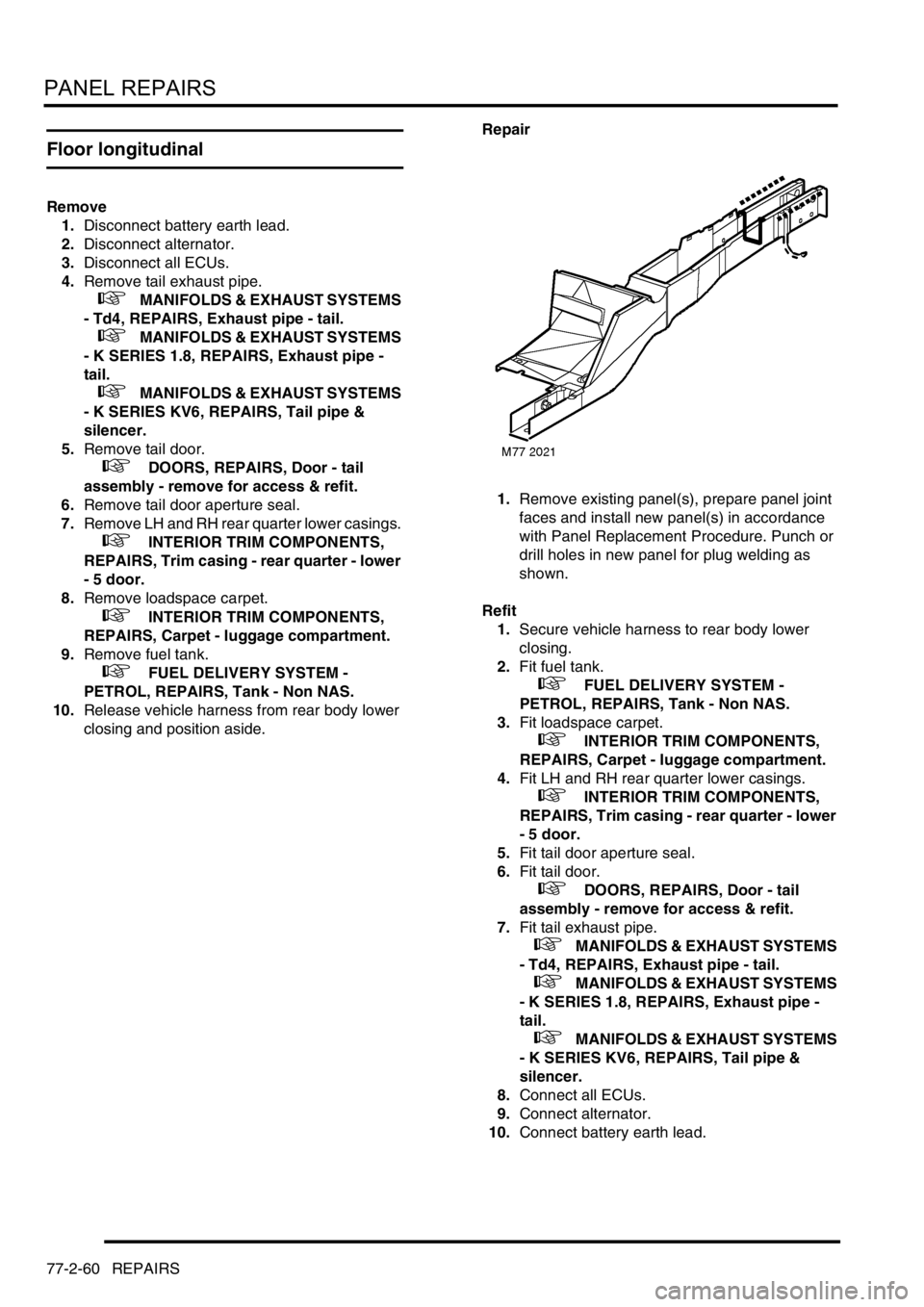

closing and position aside. Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Secure vehicle harness to rear body lower

closing.

2.Fit fuel tank.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Tank - Non NAS.

3.Fit loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - luggage compartment.

4.Fit LH and RH rear quarter lower casings.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 5 door.

5.Fit tail door aperture seal.

6.Fit tail door.

+ DOORS, REPAIRS, Door - tail

assembly - remove for access & refit.

7.Fit tail exhaust pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- Td4, REPAIRS, Exhaust pipe - tail.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES 1.8, REPAIRS, Exhaust pipe -

tail.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Tail pipe &

silencer.

8.Connect all ECUs.

9.Connect alternator.

10.Connect battery earth lead.

Page 840 of 1007

CORROSION PREVENTION AND SEALING

SEALING 77-4-9

Inspections during maintenance servicing

It is a requirement of the Corrosion Warranty that the vehicle body is checked for corrosion by an authorised Land

Rover Dealer at least once a year, to ensure that the factory-applied protection remains effective.

Service Job Sheets include the following operations to check bodywork for corrosion:

lWith the vehicle on a lift, carry out visual check of underbody sealer for damage.

lWith the vehicle lowered, inspect exterior paintwork for damage and body panels for corrosion.

The vehicle must be washed and free from deposits prior to inspection. It is part of the owner's responsibility to ensure

that the vehicle is kept free of accumulations of mud which could accelerate the onset of corrosion. It will be necessary

for the vehicle to be washed by the Dealer prior to inspection of bodywork if the customer has offered the vehicle in

a dirty condition. Particular attention should be paid to areas where access is difficult.

The checks described above are intended to be visual only. It is not intended that the operator should remove trim

panels, finishers, rubbing strips or sound-deadening materials when checking the vehicle for corrosion and paint

damage.

With the vehicle on a lift, and using an inspection or spot lamp, visually check for the following:

lCorrosion damage and damaged paintwork, condition of underbody sealer on front and rear lower panels, sills

and wheel arches.

lDamage to underbody sealer. Corrosion in areas adjacent to suspension mountings and fuel tank fixings.

The presence of small blisters in underbody sealer is acceptable, providing they do not expose bare metal.

Pay special attention to signs of damage caused to panels or corrosion protection material by incorrect jack

positioning.

caut : It is essential to follow the correct jacking and lifting procedures.

With the vehicle lowered, visually check for evidence of damage and corrosion on all visible painted areas, in

particular the following:

lFront edge of bonnet.

lVisible flanges in engine compartment.

lLower body and door panels.

Rectify any bodywork damage or evidence of corrosion found during inspection as soon as is practicable, both to

minimise the extent of the damage and to ensure the long term effectiveness of the factory-applied corrosion

prevention treatment. Where the cost of rectification work is the owner's responsibility, the Dealer must advise the

owner and endorse the relevant documentation accordingly.

Where corrosion has become evident and is emanating from beneath a removable component (e.g. trim panel,

window glass, seat etc.), remove the component as required to permit effective rectification.

Page 846 of 1007

CORROSION PREVENTION AND SEALING

SEALING 77-4-15

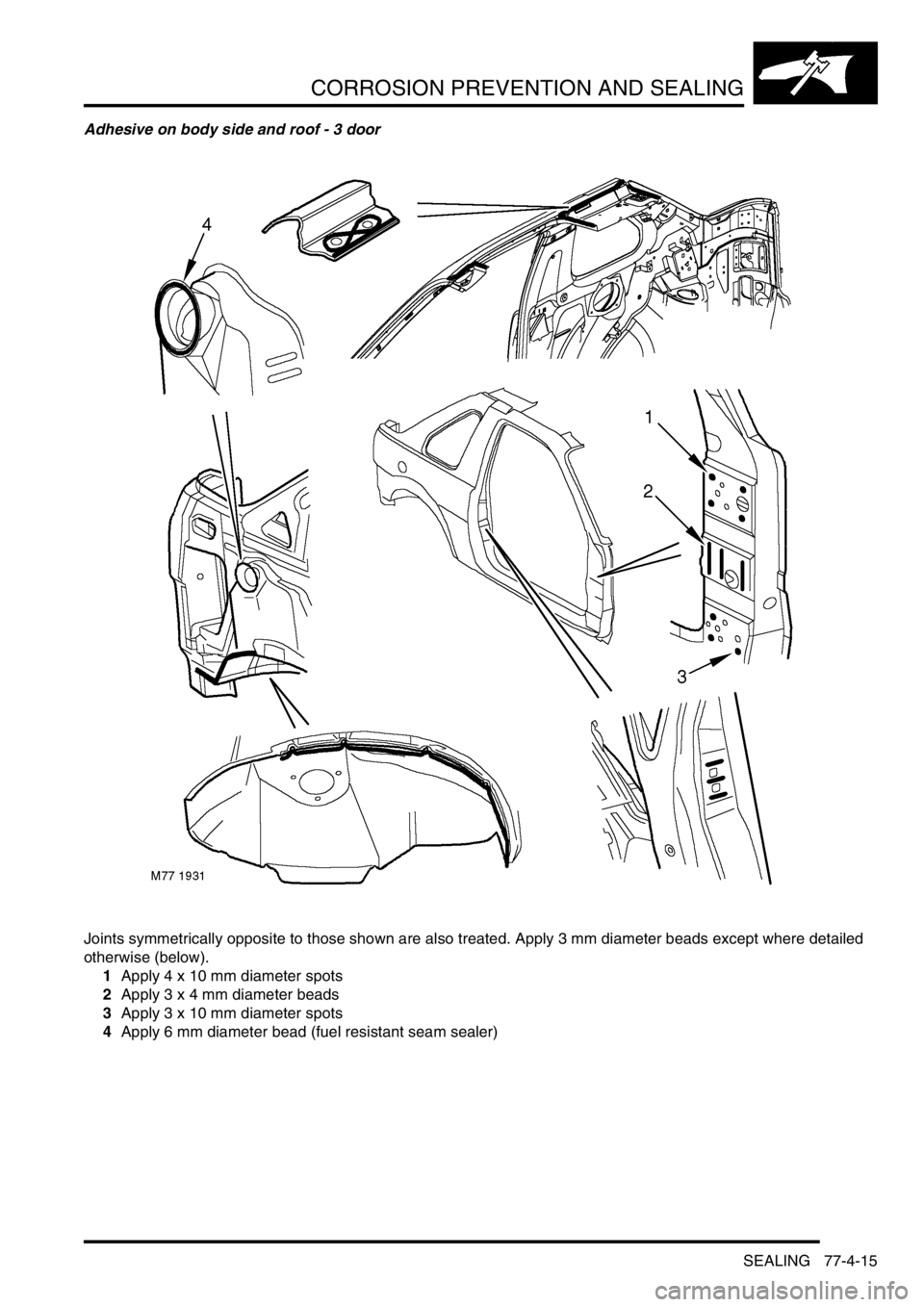

Adhesive on body side and roof - 3 door

Joints symmetrically opposite to those shown are also treated. Apply 3 mm diameter beads except where detailed

otherwise (below).

1Apply 4 x 10 mm diameter spots

2Apply 3 x 4 mm diameter beads

3Apply 3 x 10 mm diameter spots

4Apply 6 mm diameter bead (fuel resistant seam sealer)

Page 847 of 1007

CORROSION PREVENTION AND SEALING

77-4-16 SEALING

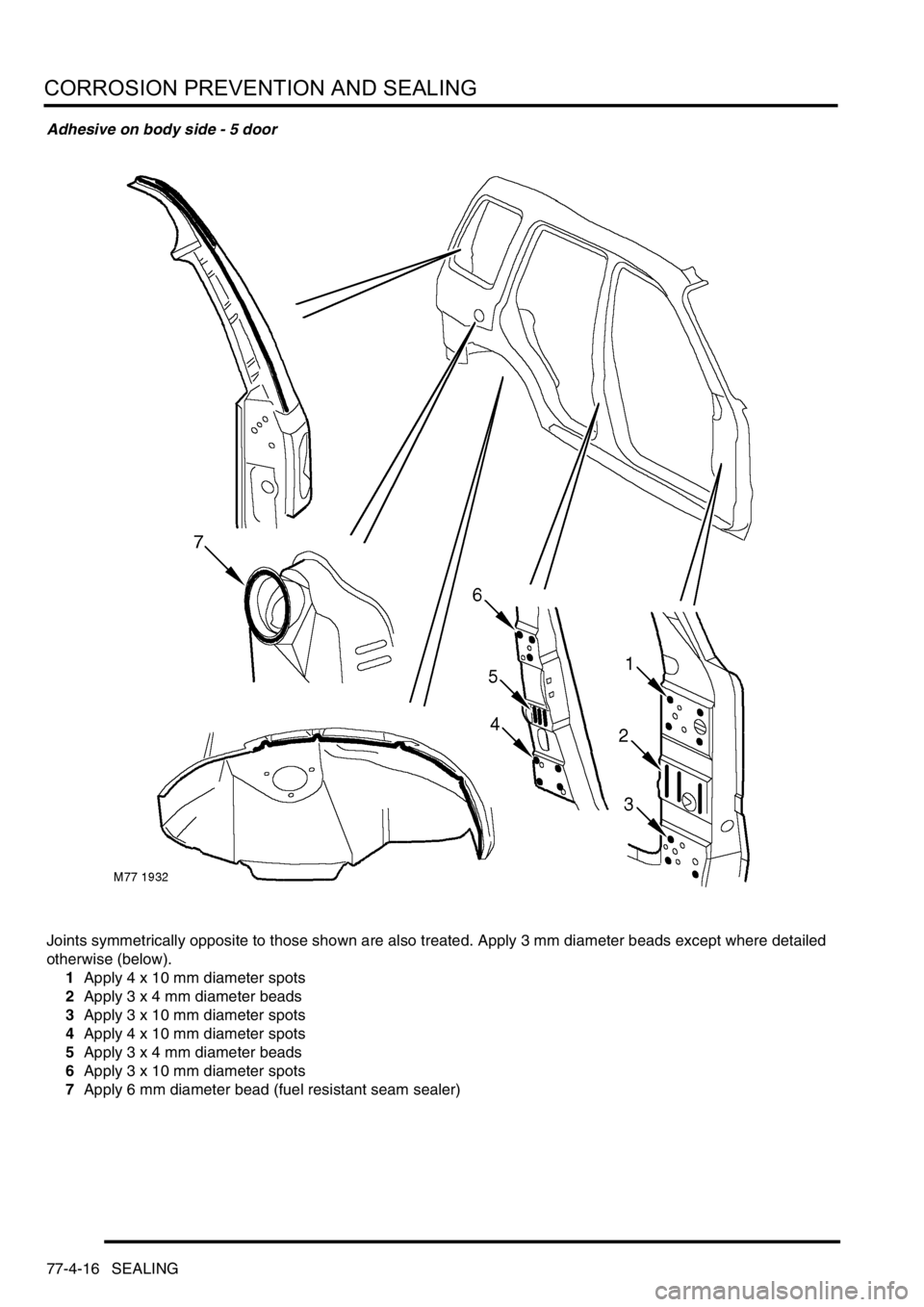

Adhesive on body side - 5 door

Joints symmetrically opposite to those shown are also treated. Apply 3 mm diameter beads except where detailed

otherwise (below).

1Apply 4 x 10 mm diameter spots

2Apply 3 x 4 mm diameter beads

3Apply 3 x 10 mm diameter spots

4Apply 4 x 10 mm diameter spots

5Apply 3 x 4 mm diameter beads

6Apply 3 x 10 mm diameter spots

7Apply 6 mm diameter bead (fuel resistant seam sealer)

Page 853 of 1007

CORROSION PREVENTION AND SEALING

77-4-22 SEALING

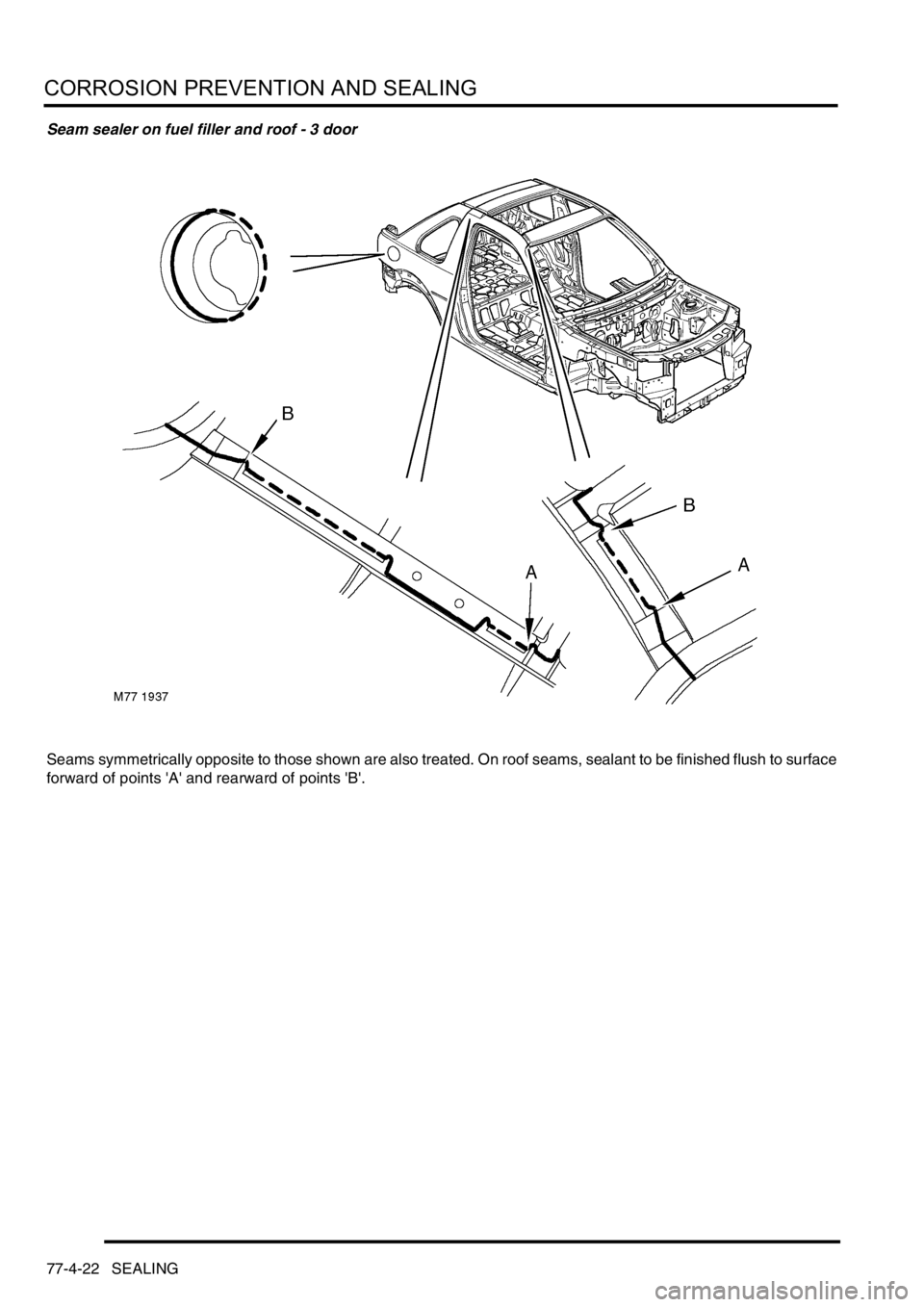

Seam sealer on fuel filler and roof - 3 door

Seams symmetrically opposite to those shown are also treated. On roof seams, sealant to be finished flush to surface

forward of points 'A' and rearward of points 'B'.

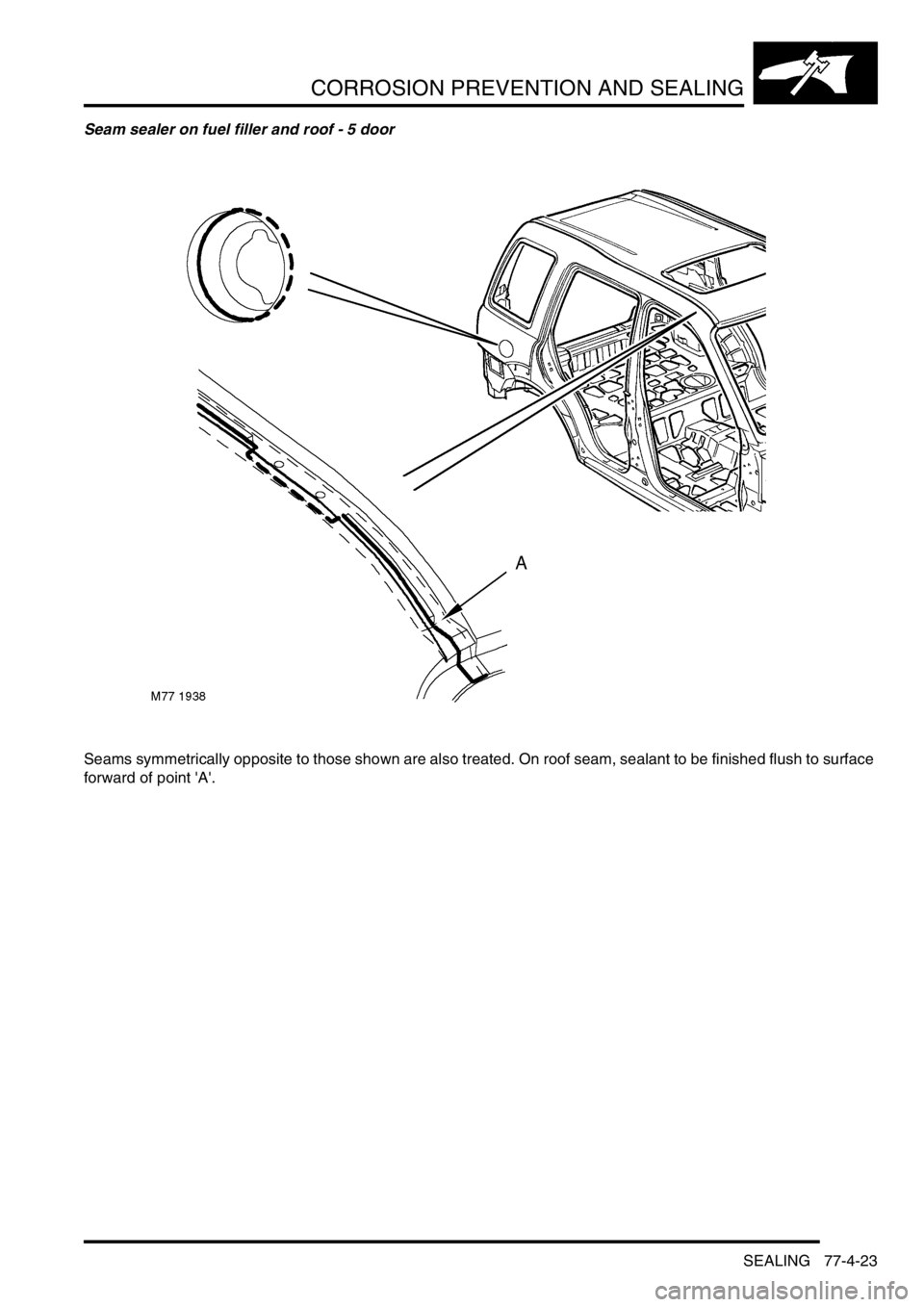

Page 854 of 1007

CORROSION PREVENTION AND SEALING

SEALING 77-4-23

Seam sealer on fuel filler and roof - 5 door

Seams symmetrically opposite to those shown are also treated. On roof seam, sealant to be finished flush to surface

forward of point 'A'.

Page 883 of 1007

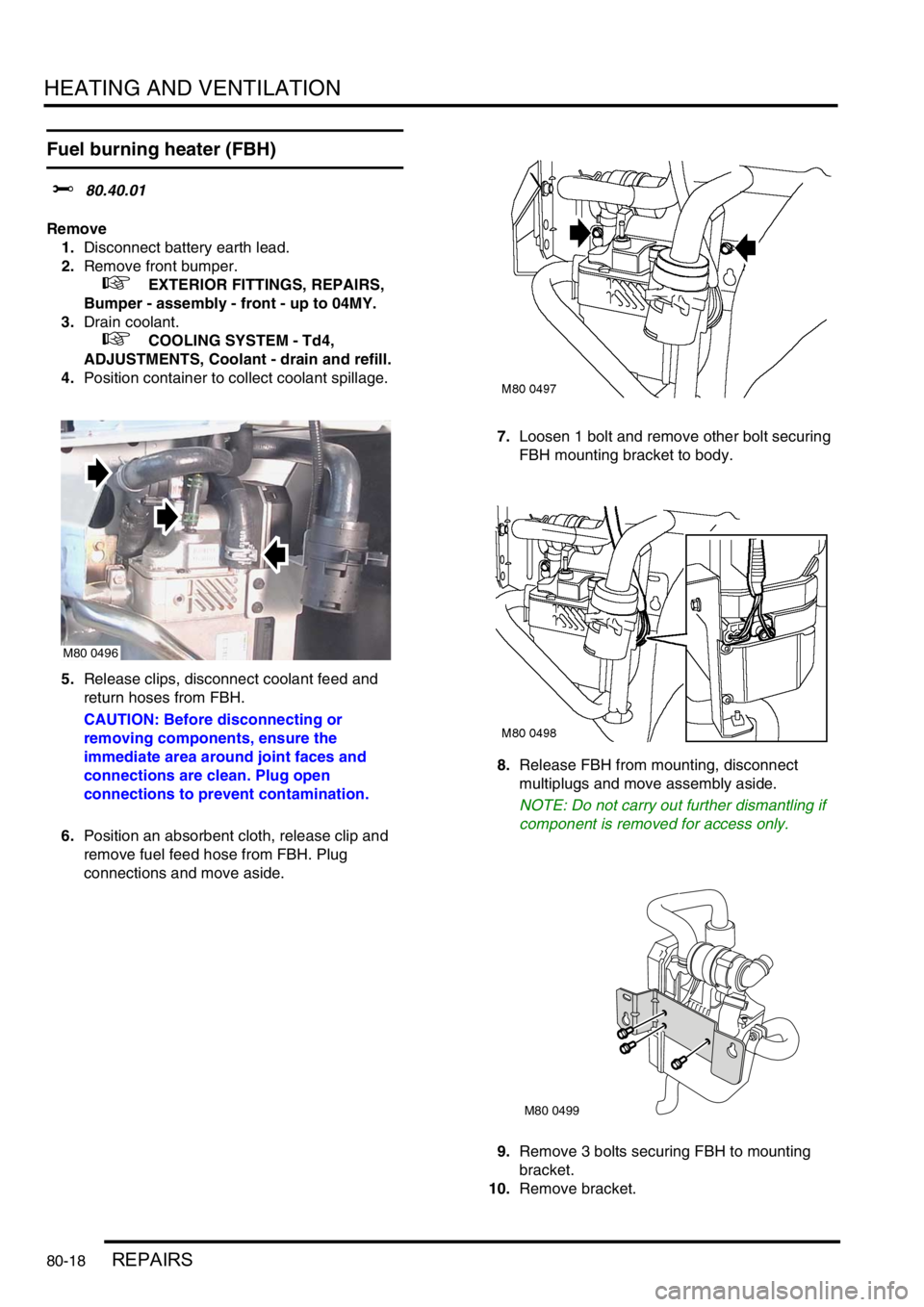

HEATING AND VENTILATION

80-18REPAIRS

Fuel burning heater (FBH)

$% 80.40.01

Remove

1.Disconnect battery earth lead.

2.Remove front bumper.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

3.Drain coolant.

+ COOLING SYSTEM - Td4,

ADJUSTMENTS, Coolant - drain and refill.

4.Position container to collect coolant spillage.

5.Release clips, disconnect coolant feed and

return hoses from FBH.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

6.Position an absorbent cloth, release clip and

remove fuel feed hose from FBH. Plug

connections and move aside.7.Loosen 1 bolt and remove other bolt securing

FBH mounting bracket to body.

8.Release FBH from mounting, disconnect

multiplugs and move assembly aside.

NOTE: Do not carry out further dismantling if

component is removed for access only.

9.Remove 3 bolts securing FBH to mounting

bracket.

10.Remove bracket.

M80 0496

M80 0499