drain bolt LAND ROVER FREELANDER 2001 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 228 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-51

Gasket - oil pump

$% 12.60.25

Remove

1.Disconnect battery earth lead.

2.Drain engine oil.

+ MAINTENANCE, MAINTENANCE,

Engine Oil and Filter – KV6.

3.Remove camshaft timing belt.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft timing belt.

4.Remove crankshaft gear.

5.Disconnect multiplug from oil pressure switch.

6.Loosen and remove oil cooler pipe unions from

oil filter housing, remove and discard 2 'O'

rings.

7.Using strap wrench, remove and discard oil

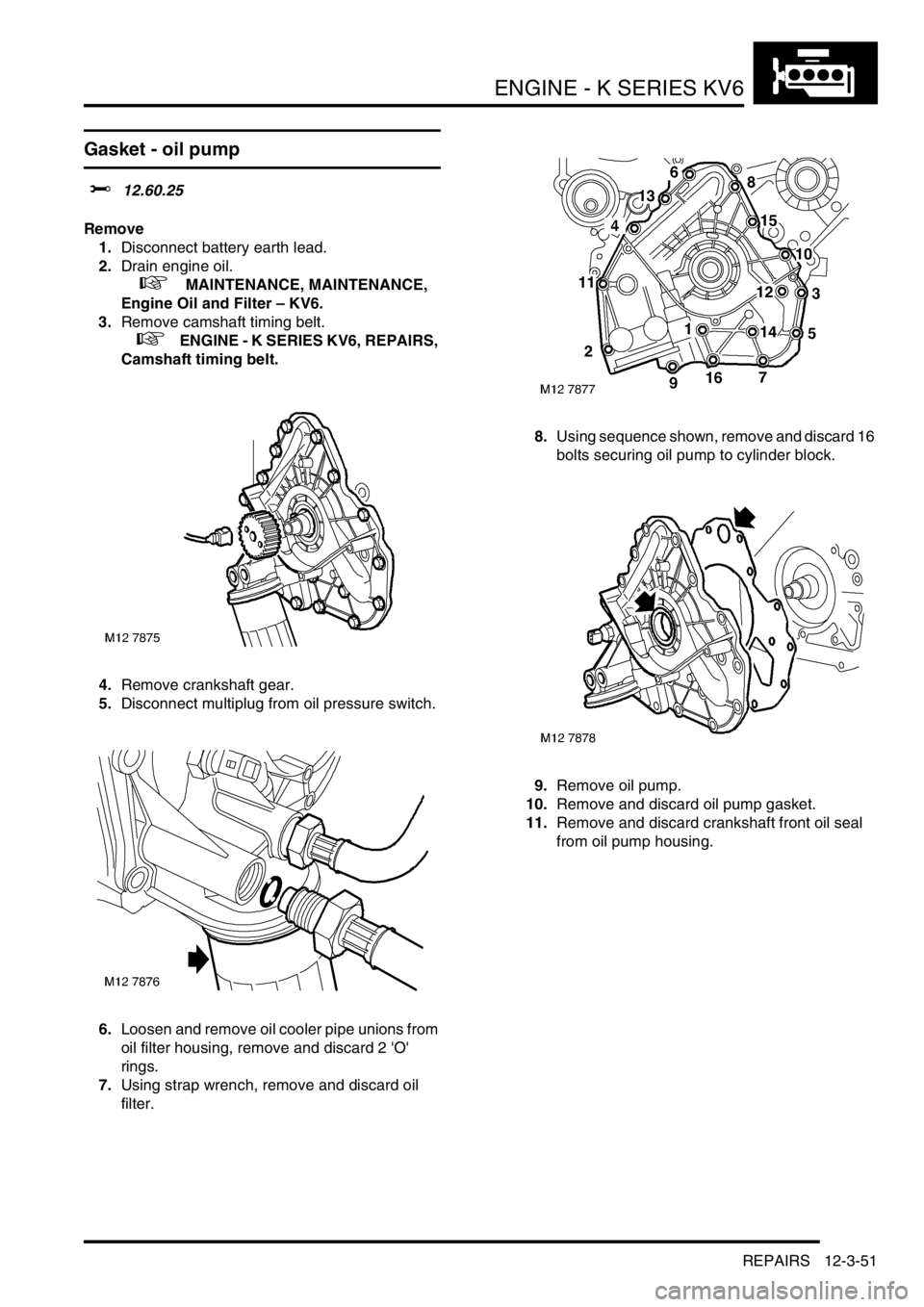

filter.8.Using sequence shown, remove and discard 16

bolts securing oil pump to cylinder block.

9.Remove oil pump.

10.Remove and discard oil pump gasket.

11.Remove and discard crankshaft front oil seal

from oil pump housing.

Page 230 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-53

Sump - reseal

$% 12.60.38

Remove

1.Disconnect battery earth lead.

2.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Drain engine oil.

+ MAINTENANCE, MAINTENANCE,

Engine Oil and Filter – KV6.

4.Remove 3 bolts securing RH splash shield to

body and remove shield.

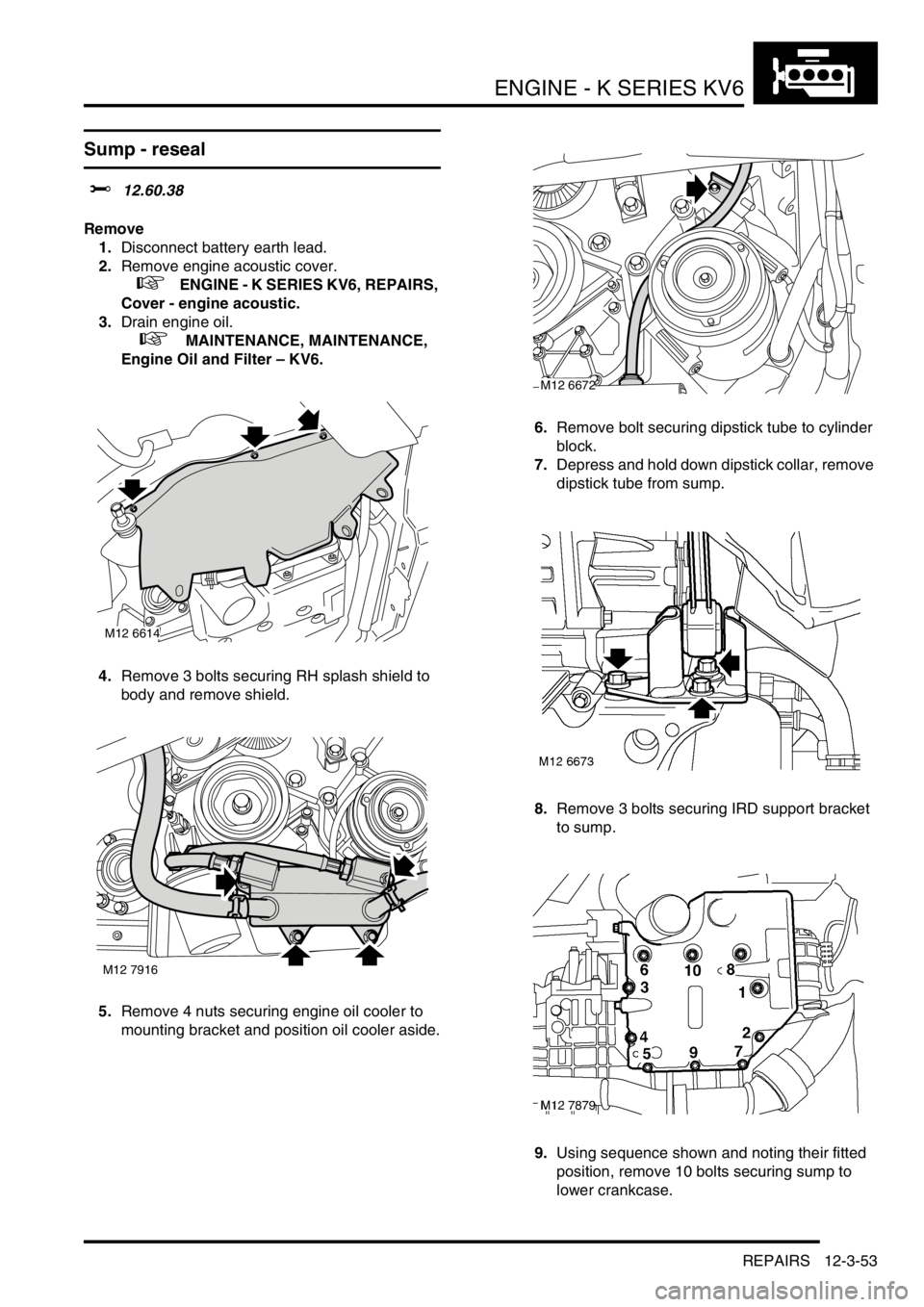

5.Remove 4 nuts securing engine oil cooler to

mounting bracket and position oil cooler aside.6.Remove bolt securing dipstick tube to cylinder

block.

7.Depress and hold down dipstick collar, remove

dipstick tube from sump.

8.Remove 3 bolts securing IRD support bracket

to sump.

9.Using sequence shown and noting their fitted

position, remove 10 bolts securing sump to

lower crankcase.

M12 6614

M12 7916

M12 6672

Page 234 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-57

Oil cooler - engine

$% 12.60.68

Remove

1.Disconnect battery earth lead.

2.Drain cooling system.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

3.Remove RH front road wheel.

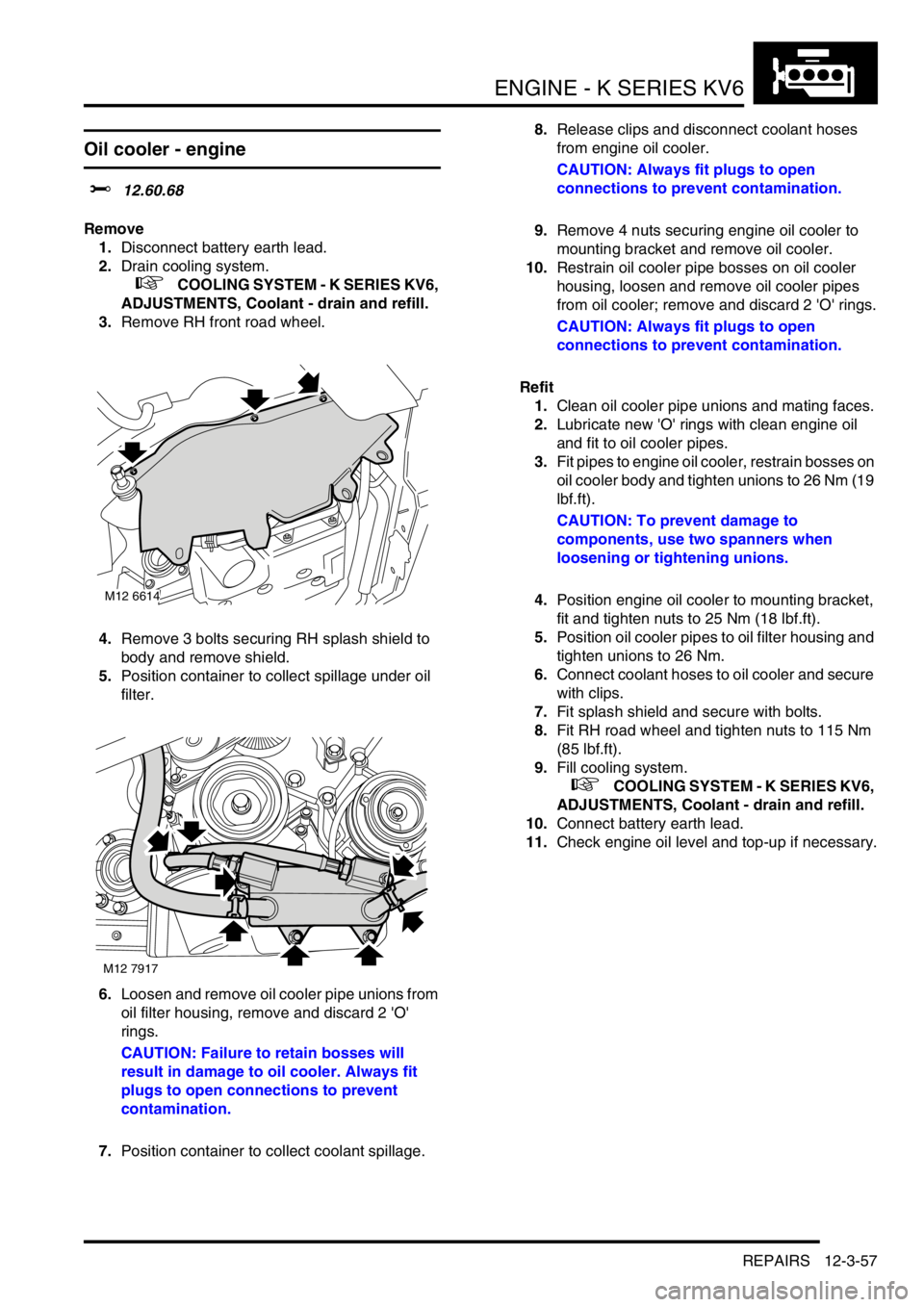

4.Remove 3 bolts securing RH splash shield to

body and remove shield.

5.Position container to collect spillage under oil

filter.

6.Loosen and remove oil cooler pipe unions from

oil filter housing, remove and discard 2 'O'

rings.

CAUTION: Failure to retain bosses will

result in damage to oil cooler. Always fit

plugs to open connections to prevent

contamination.

7.Position container to collect coolant spillage.8.Release clips and disconnect coolant hoses

from engine oil cooler.

CAUTION: Always fit plugs to open

connections to prevent contamination.

9.Remove 4 nuts securing engine oil cooler to

mounting bracket and remove oil cooler.

10.Restrain oil cooler pipe bosses on oil cooler

housing, loosen and remove oil cooler pipes

from oil cooler; remove and discard 2 'O' rings.

CAUTION: Always fit plugs to open

connections to prevent contamination.

Refit

1.Clean oil cooler pipe unions and mating faces.

2.Lubricate new 'O' rings with clean engine oil

and fit to oil cooler pipes.

3.Fit pipes to engine oil cooler, restrain bosses on

oil cooler body and tighten unions to 26 Nm (19

lbf.ft).

CAUTION: To prevent damage to

components, use two spanners when

loosening or tightening unions.

4.Position engine oil cooler to mounting bracket,

fit and tighten nuts to 25 Nm (18 lbf.ft).

5.Position oil cooler pipes to oil filter housing and

tighten unions to 26 Nm.

6.Connect coolant hoses to oil cooler and secure

with clips.

7.Fit splash shield and secure with bolts.

8.Fit RH road wheel and tighten nuts to 115 Nm

(85 lbf.ft).

9.Fill cooling system.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

10.Connect battery earth lead.

11.Check engine oil level and top-up if necessary.

M12 6614

M12 7917

Page 283 of 1007

ENGINE - K SERIES KV6

12-3-106 OVERHAUL

Sump - engine oil

$% 12.60.38.01

Remove

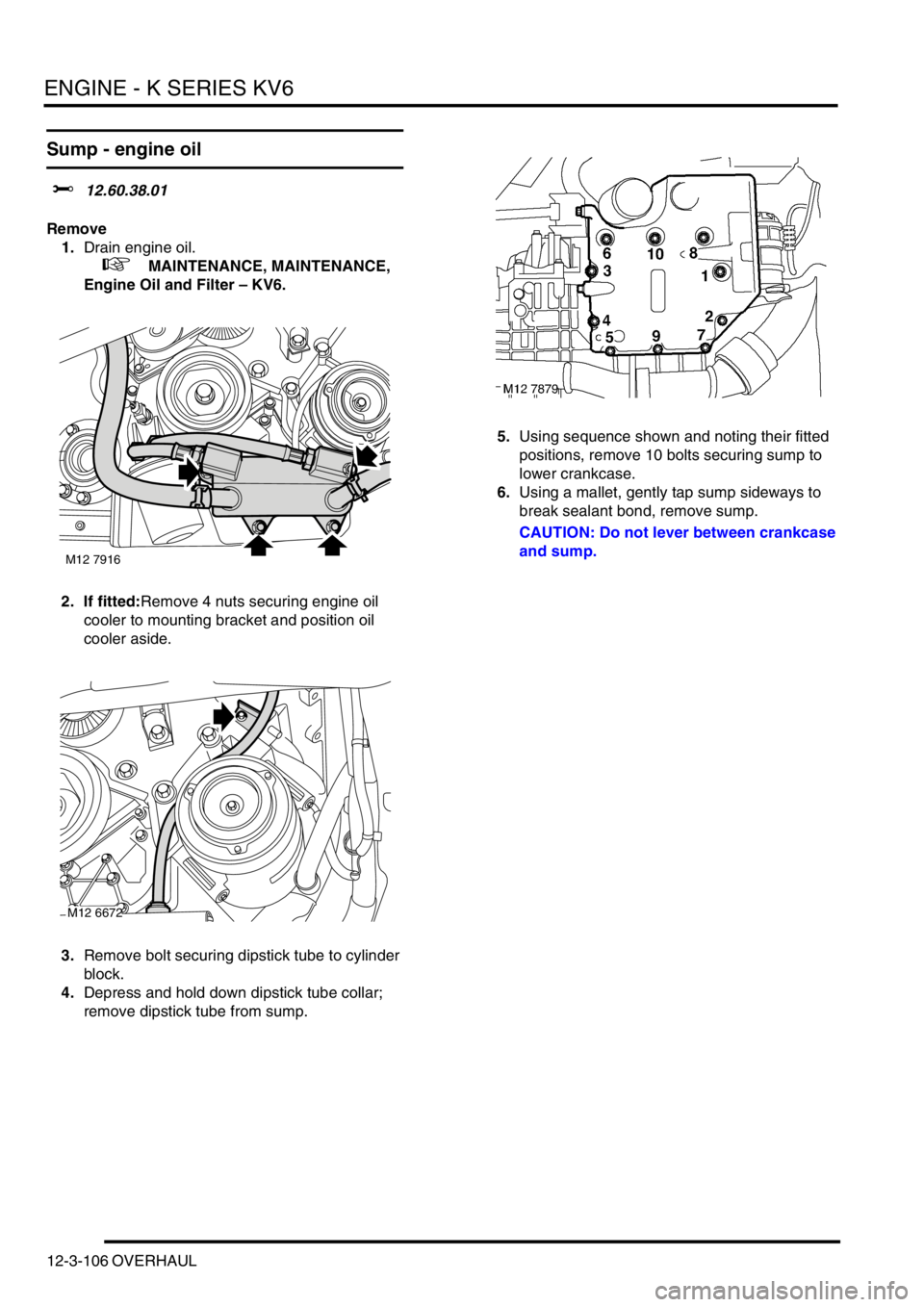

1.Drain engine oil.

+ MAINTENANCE, MAINTENANCE,

Engine Oil and Filter – KV6.

2. If fitted:Remove 4 nuts securing engine oil

cooler to mounting bracket and position oil

cooler aside.

3.Remove bolt securing dipstick tube to cylinder

block.

4.Depress and hold down dipstick tube collar;

remove dipstick tube from sump.5.Using sequence shown and noting their fitted

positions, remove 10 bolts securing sump to

lower crankcase.

6.Using a mallet, gently tap sump sideways to

break sealant bond, remove sump.

CAUTION: Do not lever between crankcase

and sump.

M12 7916

M12 6672

Page 300 of 1007

EMISSION CONTROL

REPAIRS 17-1-9

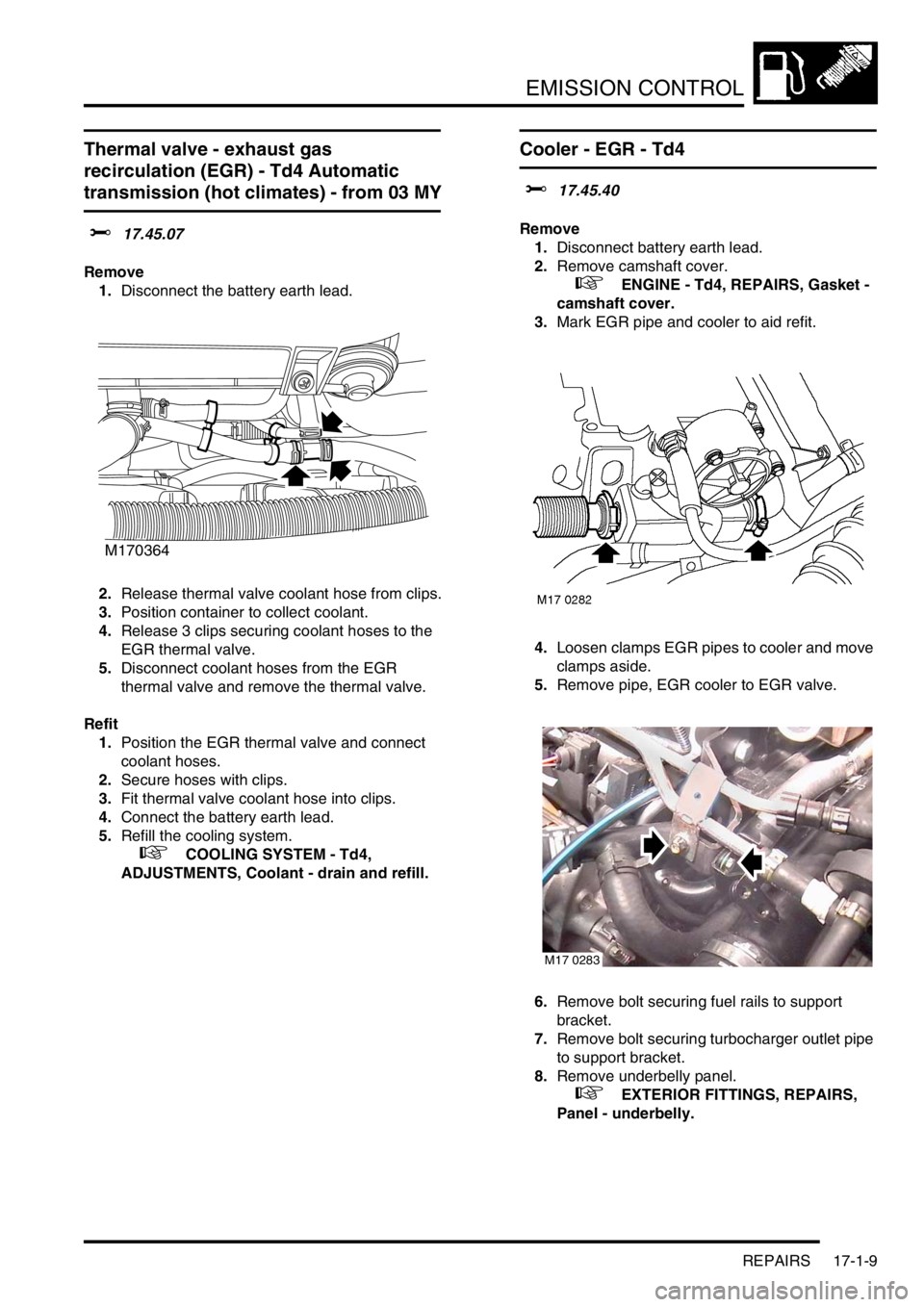

Thermal valve - exhaust gas

recirculation (EGR) - Td4 Automatic

transmission (hot climates) - from 03 MY

$% 17.45.07

Remove

1.Disconnect the battery earth lead.

2.Release thermal valve coolant hose from clips.

3.Position container to collect coolant.

4.Release 3 clips securing coolant hoses to the

EGR thermal valve.

5.Disconnect coolant hoses from the EGR

thermal valve and remove the thermal valve.

Refit

1.Position the EGR thermal valve and connect

coolant hoses.

2.Secure hoses with clips.

3.Fit thermal valve coolant hose into clips.

4.Connect the battery earth lead.

5.Refill the cooling system.

+ COOLING SYSTEM - Td4,

ADJUSTMENTS, Coolant - drain and refill.

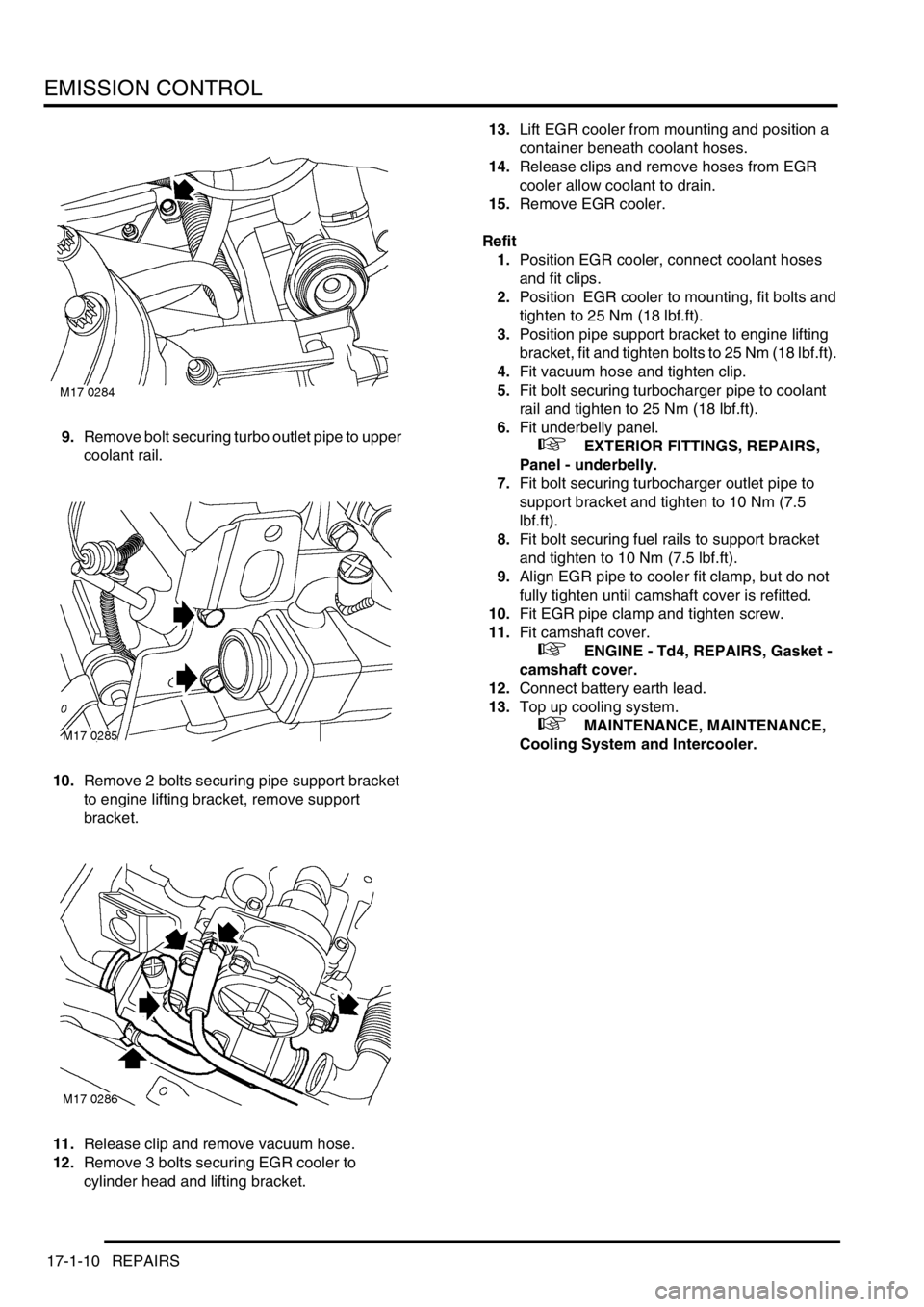

Cooler - EGR - Td4

$% 17.45.40

Remove

1.Disconnect battery earth lead.

2.Remove camshaft cover.

+ ENGINE - Td4, REPAIRS, Gasket -

camshaft cover.

3.Mark EGR pipe and cooler to aid refit.

4.Loosen clamps EGR pipes to cooler and move

clamps aside.

5.Remove pipe, EGR cooler to EGR valve.

6.Remove bolt securing fuel rails to support

bracket.

7.Remove bolt securing turbocharger outlet pipe

to support bracket.

8.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

M170364

M17 0283

Page 301 of 1007

EMISSION CONTROL

17-1-10 REPAIRS

9.Remove bolt securing turbo outlet pipe to upper

coolant rail.

10.Remove 2 bolts securing pipe support bracket

to engine lifting bracket, remove support

bracket.

11.Release clip and remove vacuum hose.

12.Remove 3 bolts securing EGR cooler to

cylinder head and lifting bracket.13.Lift EGR cooler from mounting and position a

container beneath coolant hoses.

14.Release clips and remove hoses from EGR

cooler allow coolant to drain.

15.Remove EGR cooler.

Refit

1.Position EGR cooler, connect coolant hoses

and fit clips.

2.Position EGR cooler to mounting, fit bolts and

tighten to 25 Nm (18 lbf.ft).

3.Position pipe support bracket to engine lifting

bracket, fit and tighten bolts to 25 Nm (18 lbf.ft).

4.Fit vacuum hose and tighten clip.

5.Fit bolt securing turbocharger pipe to coolant

rail and tighten to 25 Nm (18 lbf.ft).

6.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

7.Fit bolt securing turbocharger outlet pipe to

support bracket and tighten to 10 Nm (7.5

lbf.ft).

8.Fit bolt securing fuel rails to support bracket

and tighten to 10 Nm (7.5 lbf.ft).

9.Align EGR pipe to cooler fit clamp, but do not

fully tighten until camshaft cover is refitted.

10.Fit EGR pipe clamp and tighten screw.

11.Fit camshaft cover.

+ ENGINE - Td4, REPAIRS, Gasket -

camshaft cover.

12.Connect battery earth lead.

13.Top up cooling system.

+ MAINTENANCE, MAINTENANCE,

Cooling System and Intercooler.

Page 326 of 1007

FUEL DELIVERY SYSTEM - PETROL

ADJUSTMENTS 19-2-5

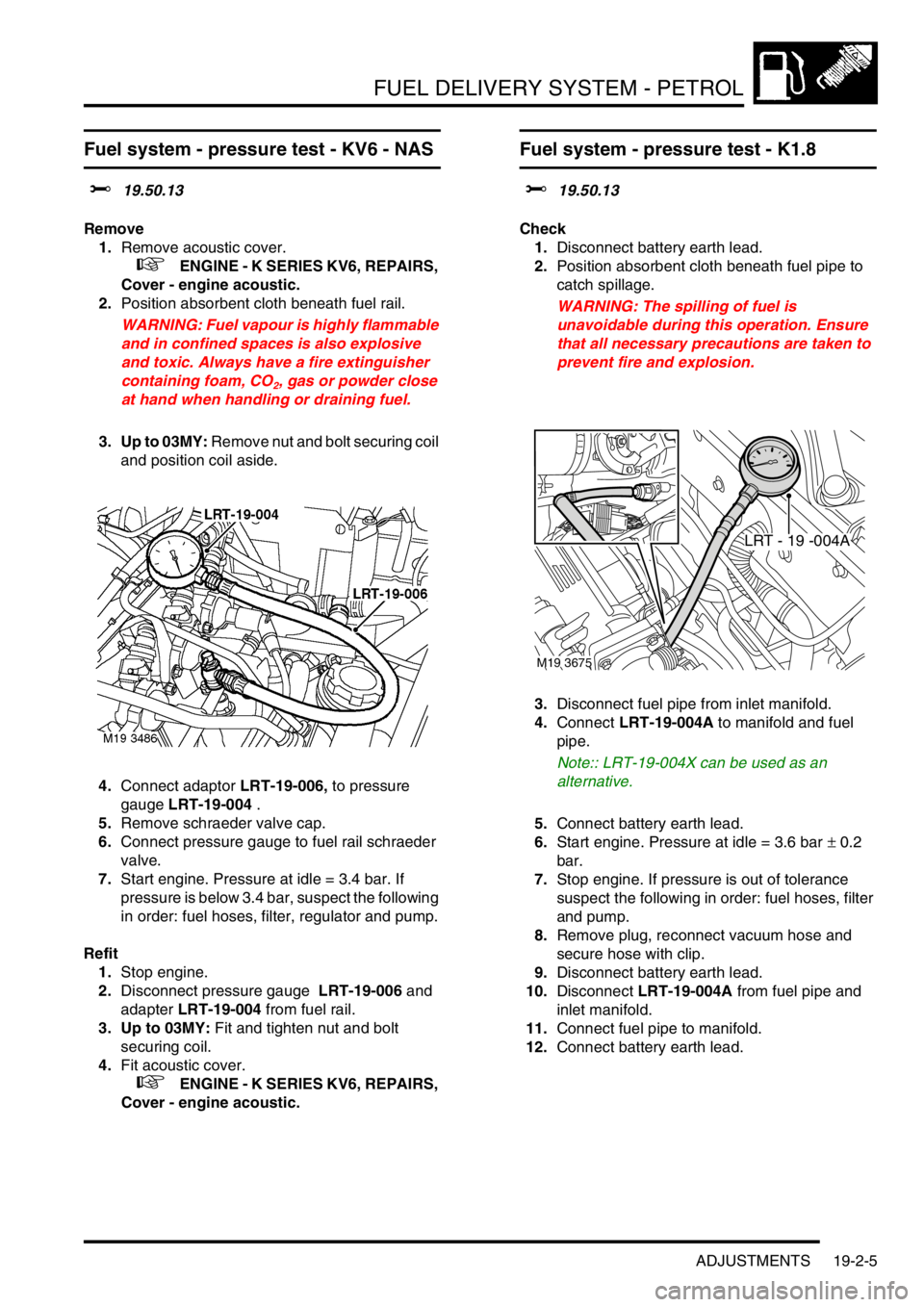

Fuel system - pressure test - KV6 - NAS

$% 19.50.13

Remove

1.Remove acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Position absorbent cloth beneath fuel rail.

WARNING: Fuel vapour is highly flammable

and in confined spaces is also explosive

and toxic. Always have a fire extinguisher

containing foam, CO

2, gas or powder close

at hand when handling or draining fuel.

3. Up to 03MY: Remove nut and bolt securing coil

and position coil aside.

4.Connect adaptor LRT-19-006, to pressure

gauge LRT-19-004 .

5.Remove schraeder valve cap.

6.Connect pressure gauge to fuel rail schraeder

valve.

7.Start engine. Pressure at idle = 3.4 bar. If

pressure is below 3.4 bar, suspect the following

in order: fuel hoses, filter, regulator and pump.

Refit

1.Stop engine.

2.Disconnect pressure gauge LRT-19-006 and

adapter LRT-19-004 from fuel rail.

3. Up to 03MY: Fit and tighten nut and bolt

securing coil.

4.Fit acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

Fuel system - pressure test - K1.8

$% 19.50.13

Check

1.Disconnect battery earth lead.

2.Position absorbent cloth beneath fuel pipe to

catch spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

3.Disconnect fuel pipe from inlet manifold.

4.Connect LRT-19-004A to manifold and fuel

pipe.

Note:: LRT-19-004X can be used as an

alternative.

5.Connect battery earth lead.

6.Start engine. Pressure at idle = 3.6 bar ± 0.2

bar.

7.Stop engine. If pressure is out of tolerance

suspect the following in order: fuel hoses, filter

and pump.

8.Remove plug, reconnect vacuum hose and

secure hose with clip.

9.Disconnect battery earth lead.

10.Disconnect LRT-19-004A from fuel pipe and

inlet manifold.

11.Connect fuel pipe to manifold.

12.Connect battery earth lead.

LRT - 19 -004A

M19 3675

Page 351 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-30 REPAIRS

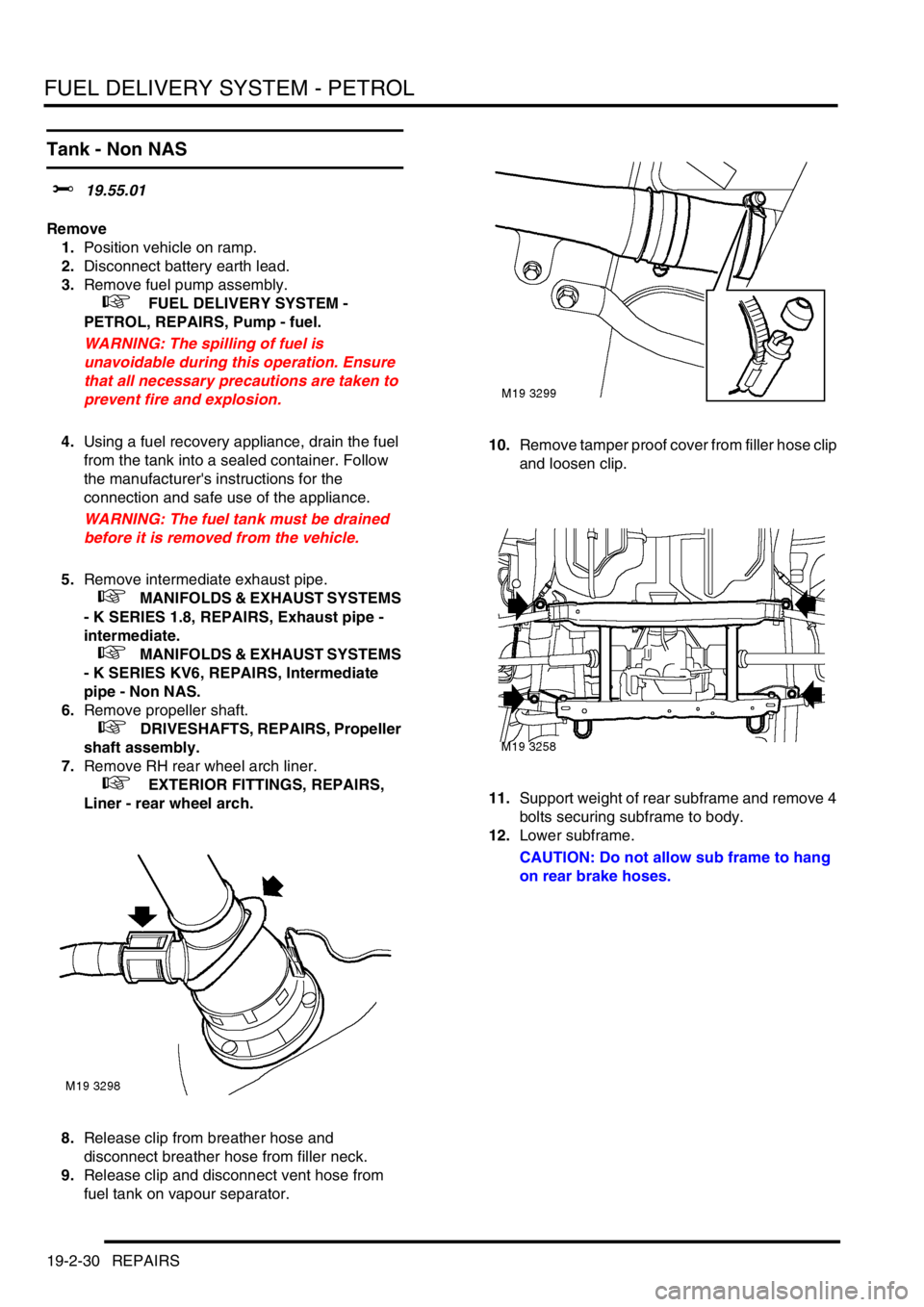

Tank - Non NAS

$% 19.55.01

Remove

1.Position vehicle on ramp.

2.Disconnect battery earth lead.

3.Remove fuel pump assembly.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Pump - fuel.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

4.Using a fuel recovery appliance, drain the fuel

from the tank into a sealed container. Follow

the manufacturer's instructions for the

connection and safe use of the appliance.

WARNING: The fuel tank must be drained

before it is removed from the vehicle.

5.Remove intermediate exhaust pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES 1.8, REPAIRS, Exhaust pipe -

intermediate.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Intermediate

pipe - Non NAS.

6.Remove propeller shaft.

+ DRIVESHAFTS, REPAIRS, Propeller

shaft assembly.

7.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

8.Release clip from breather hose and

disconnect breather hose from filler neck.

9.Release clip and disconnect vent hose from

fuel tank on vapour separator.10.Remove tamper proof cover from filler hose clip

and loosen clip.

11.Support weight of rear subframe and remove 4

bolts securing subframe to body.

12.Lower subframe.

CAUTION: Do not allow sub frame to hang

on rear brake hoses.

Page 353 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-32 REPAIRS

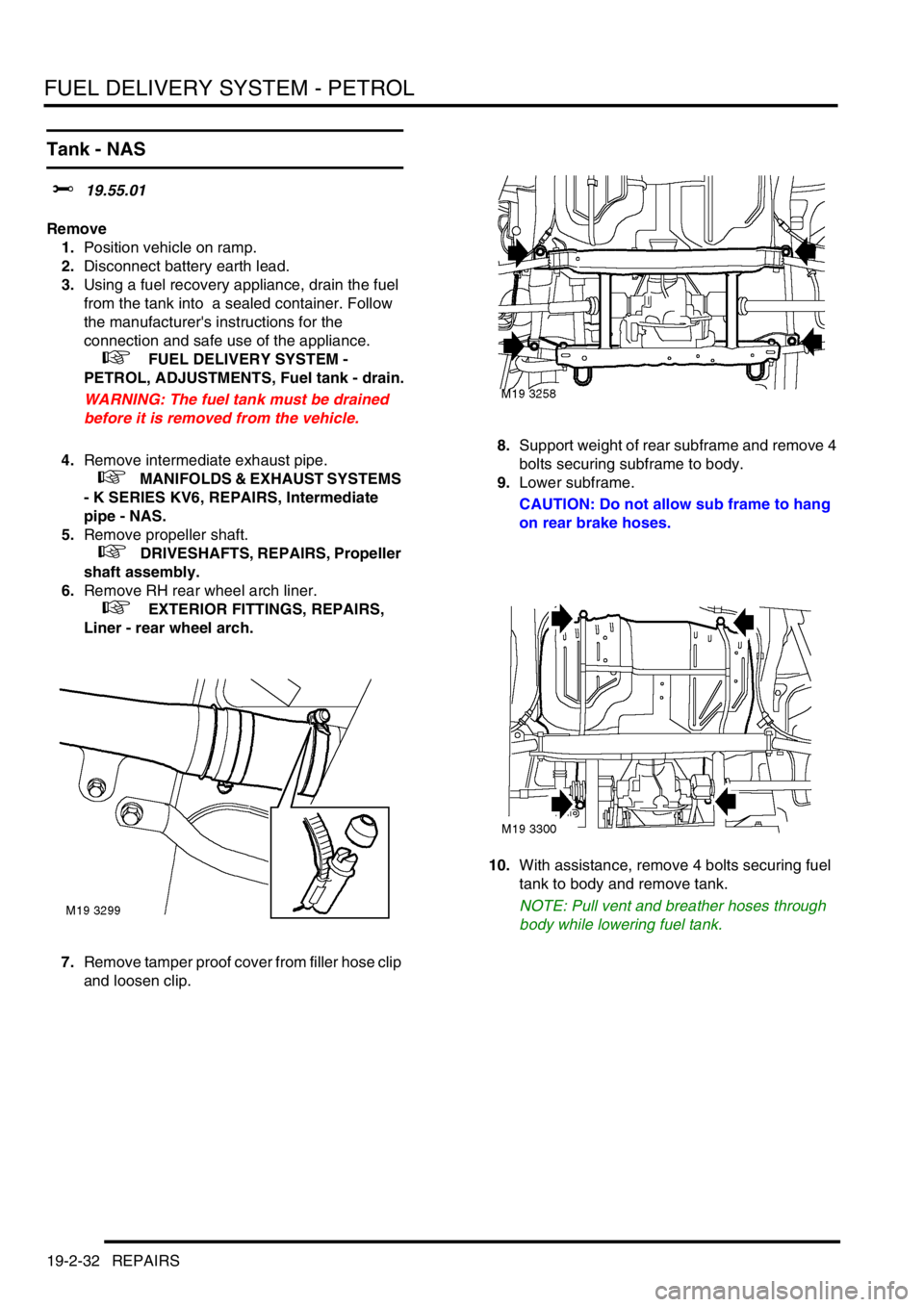

Tank - NAS

$% 19.55.01

Remove

1.Position vehicle on ramp.

2.Disconnect battery earth lead.

3.Using a fuel recovery appliance, drain the fuel

from the tank into a sealed container. Follow

the manufacturer's instructions for the

connection and safe use of the appliance.

+ FUEL DELIVERY SYSTEM -

PETROL, ADJUSTMENTS, Fuel tank - drain.

WARNING: The fuel tank must be drained

before it is removed from the vehicle.

4.Remove intermediate exhaust pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Intermediate

pipe - NAS.

5.Remove propeller shaft.

+ DRIVESHAFTS, REPAIRS, Propeller

shaft assembly.

6.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

7.Remove tamper proof cover from filler hose clip

and loosen clip.8.Support weight of rear subframe and remove 4

bolts securing subframe to body.

9.Lower subframe.

CAUTION: Do not allow sub frame to hang

on rear brake hoses.

10.With assistance, remove 4 bolts securing fuel

tank to body and remove tank.

NOTE: Pull vent and breather hoses through

body while lowering fuel tank.

Page 355 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-34 REPAIRS

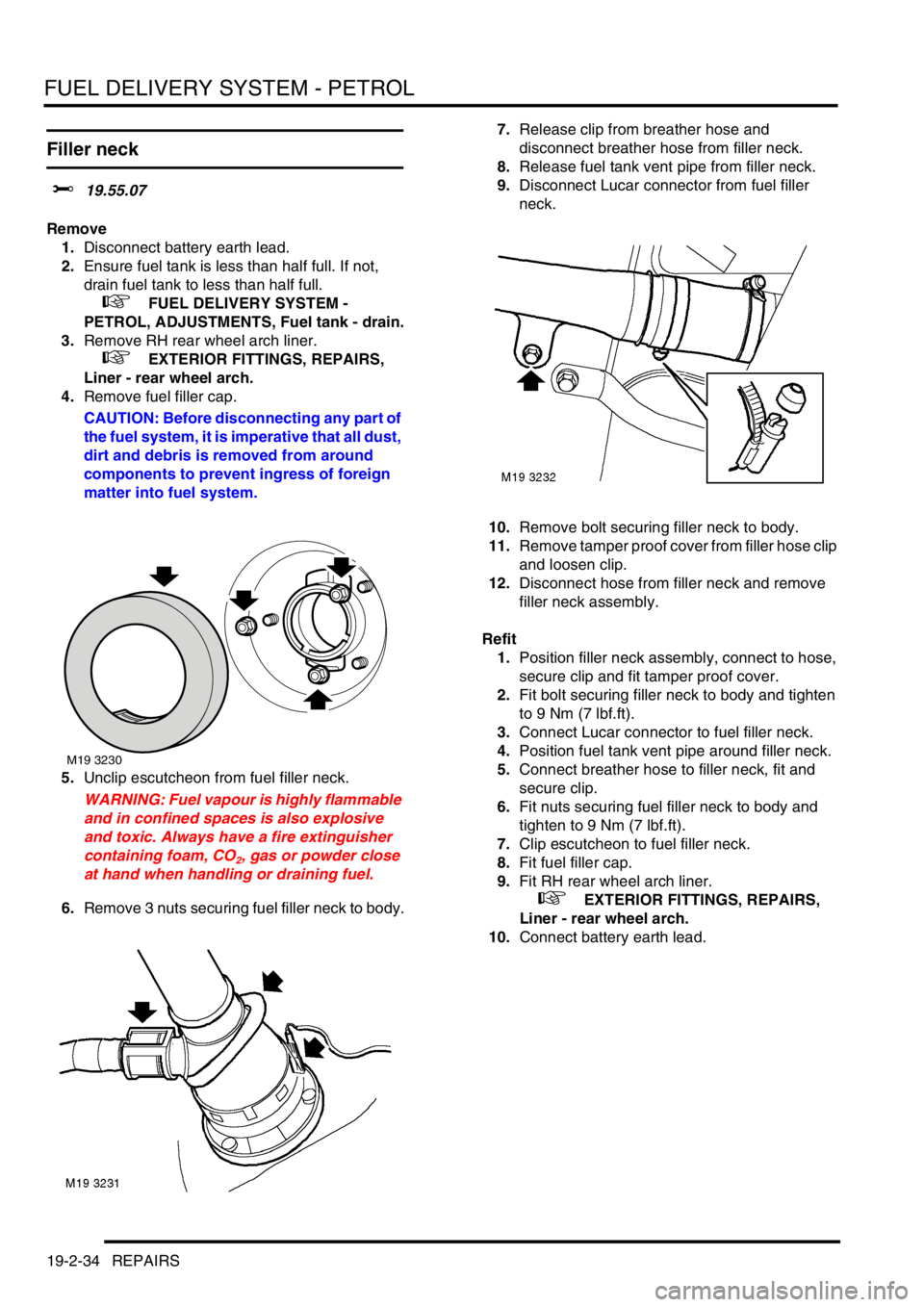

Filler neck

$% 19.55.07

Remove

1.Disconnect battery earth lead.

2.Ensure fuel tank is less than half full. If not,

drain fuel tank to less than half full.

+ FUEL DELIVERY SYSTEM -

PETROL, ADJUSTMENTS, Fuel tank - drain.

3.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

4.Remove fuel filler cap.

CAUTION: Before disconnecting any part of

the fuel system, it is imperative that all dust,

dirt and debris is removed from around

components to prevent ingress of foreign

matter into fuel system.

5.Unclip escutcheon from fuel filler neck.

WARNING: Fuel vapour is highly flammable

and in confined spaces is also explosive

and toxic. Always have a fire extinguisher

containing foam, CO

2, gas or powder close

at hand when handling or draining fuel.

6.Remove 3 nuts securing fuel filler neck to body.7.Release clip from breather hose and

disconnect breather hose from filler neck.

8.Release fuel tank vent pipe from filler neck.

9.Disconnect Lucar connector from fuel filler

neck.

10.Remove bolt securing filler neck to body.

11.Remove tamper proof cover from filler hose clip

and loosen clip.

12.Disconnect hose from filler neck and remove

filler neck assembly.

Refit

1.Position filler neck assembly, connect to hose,

secure clip and fit tamper proof cover.

2.Fit bolt securing filler neck to body and tighten

to 9 Nm (7 lbf.ft).

3.Connect Lucar connector to fuel filler neck.

4.Position fuel tank vent pipe around filler neck.

5.Connect breather hose to filler neck, fit and

secure clip.

6.Fit nuts securing fuel filler neck to body and

tighten to 9 Nm (7 lbf.ft).

7.Clip escutcheon to fuel filler neck.

8.Fit fuel filler cap.

9.Fit RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

10.Connect battery earth lead.

M19 3230