light LAND ROVER FREELANDER 2001 Service Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 562 of 1007

BRAKES

REPAIRS 70-13

Switch - stop light

$% 70.35.42

Remove

1.Disconnect brake light switch multiplug.

2.Release bayonet fitting on brake light switch

and remove switch.

Refit

1.Position switch and secure bayonet fitting.

2.Connect brake light switch multiplug.

3.Depress and hold brake pedal.

4.Reset switch by pulling plunger fully out.

5.Release brake pedal slowly to set switch

adjustment.

Sensor - brake pedal position

$% 70.35.44

Remove

1.Release bayonet fitting on brake light switch

and remove switch.

2.Release sensor from mounting bracket.

3.Disconnect sensor multiplug and remove

sensor.

4.Remove sensor mounting from bracket.

Refit

1.Position sensor to mounting bracket and

connect multiplug.

2.Position switch and secure bayonet fitting.

3.Hold brake pedal depressed and push sensor

fully into bracket, release pedal slowly to set

sensor position.

Page 612 of 1007

DOORS

REPAIRS 76-1-7

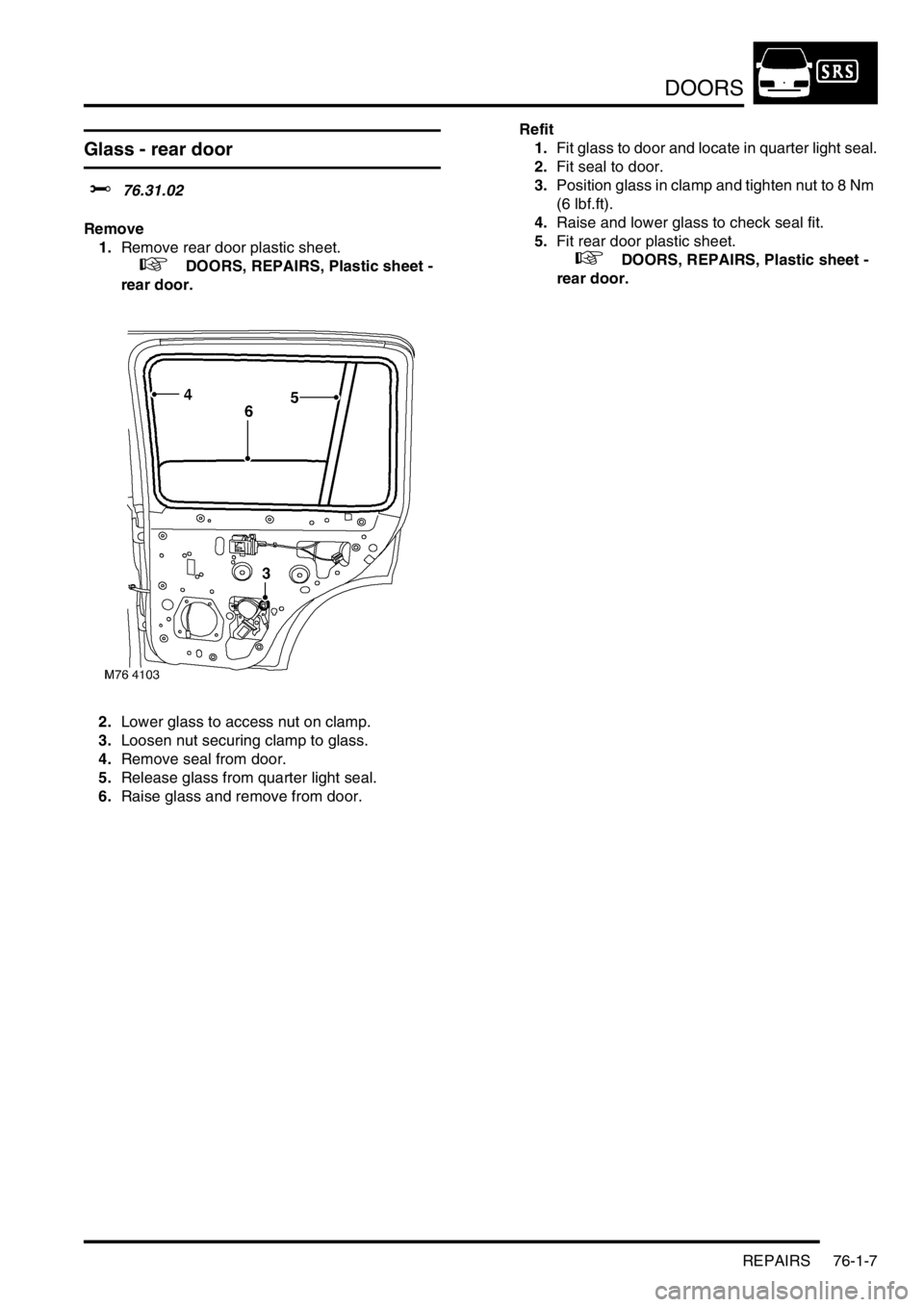

Glass - rear door

$% 76.31.02

Remove

1.Remove rear door plastic sheet.

+ DOORS, REPAIRS, Plastic sheet -

rear door.

2.Lower glass to access nut on clamp.

3.Loosen nut securing clamp to glass.

4.Remove seal from door.

5.Release glass from quarter light seal.

6.Raise glass and remove from door.Refit

1.Fit glass to door and locate in quarter light seal.

2.Fit seal to door.

3.Position glass in clamp and tighten nut to 8 Nm

(6 lbf.ft).

4.Raise and lower glass to check seal fit.

5.Fit rear door plastic sheet.

+ DOORS, REPAIRS, Plastic sheet -

rear door.

Page 614 of 1007

DOORS

REPAIRS 76-1-9

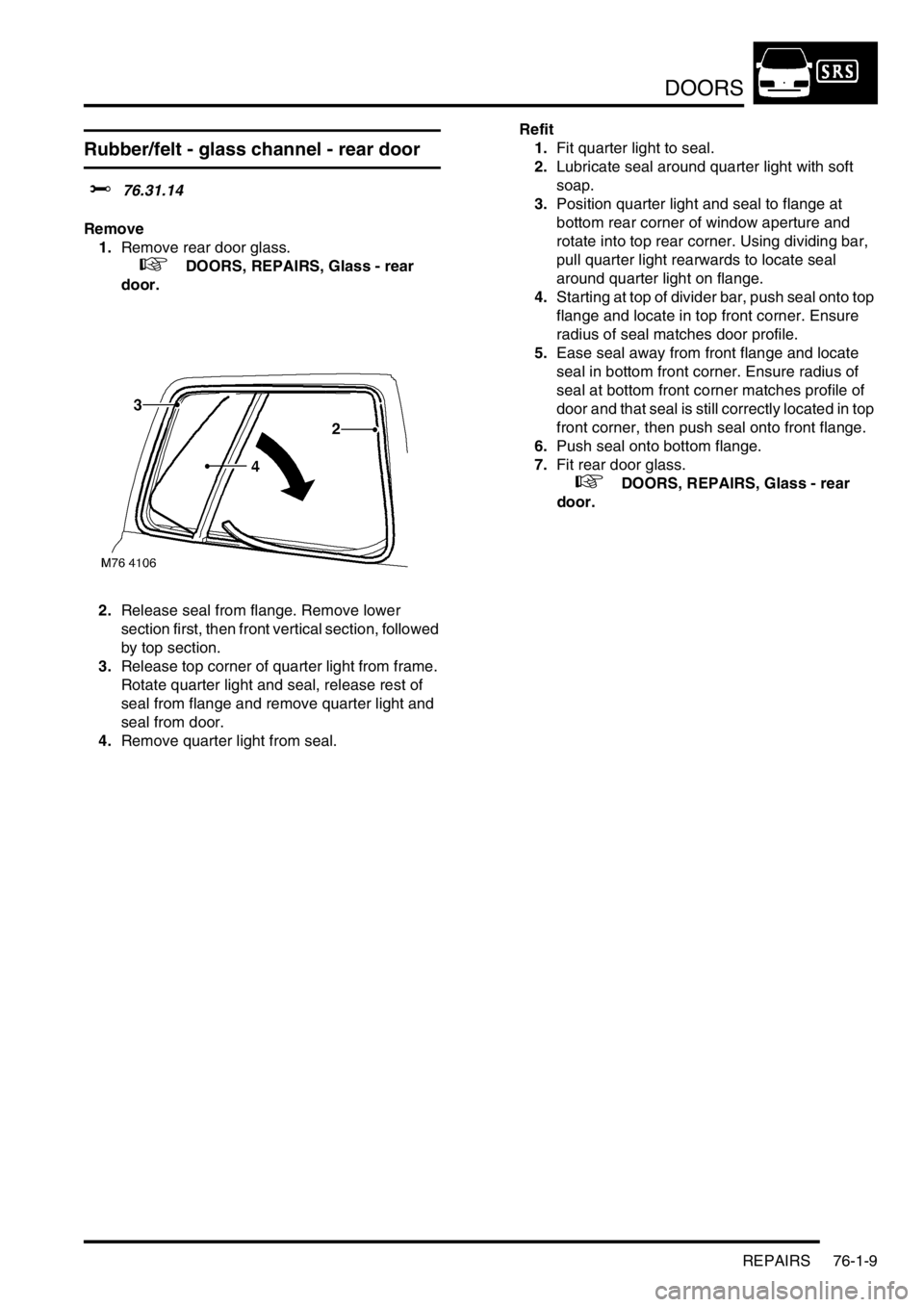

Rubber/felt - glass channel - rear door

$% 76.31.14

Remove

1.Remove rear door glass.

+ DOORS, REPAIRS, Glass - rear

door.

2.Release seal from flange. Remove lower

section first, then front vertical section, followed

by top section.

3.Release top corner of quarter light from frame.

Rotate quarter light and seal, release rest of

seal from flange and remove quarter light and

seal from door.

4.Remove quarter light from seal.Refit

1.Fit quarter light to seal.

2.Lubricate seal around quarter light with soft

soap.

3.Position quarter light and seal to flange at

bottom rear corner of window aperture and

rotate into top rear corner. Using dividing bar,

pull quarter light rearwards to locate seal

around quarter light on flange.

4.Starting at top of divider bar, push seal onto top

flange and locate in top front corner. Ensure

radius of seal matches door profile.

5.Ease seal away from front flange and locate

seal in bottom front corner. Ensure radius of

seal at bottom front corner matches profile of

door and that seal is still correctly located in top

front corner, then push seal onto front flange.

6.Push seal onto bottom flange.

7.Fit rear door glass.

+ DOORS, REPAIRS, Glass - rear

door.

Page 616 of 1007

DOORS

REPAIRS 76-1-11

Quarter light - rear door

$% 76.31.31

Remove

1.The procedure for renewing the quarter light is

identical to renewing the rear door glass

channel seal.

+ DOORS, REPAIRS, Rubber/felt -

glass channel - rear door.

Page 648 of 1007

EXTERIOR FITTINGS

REPAIRS 76-2-7

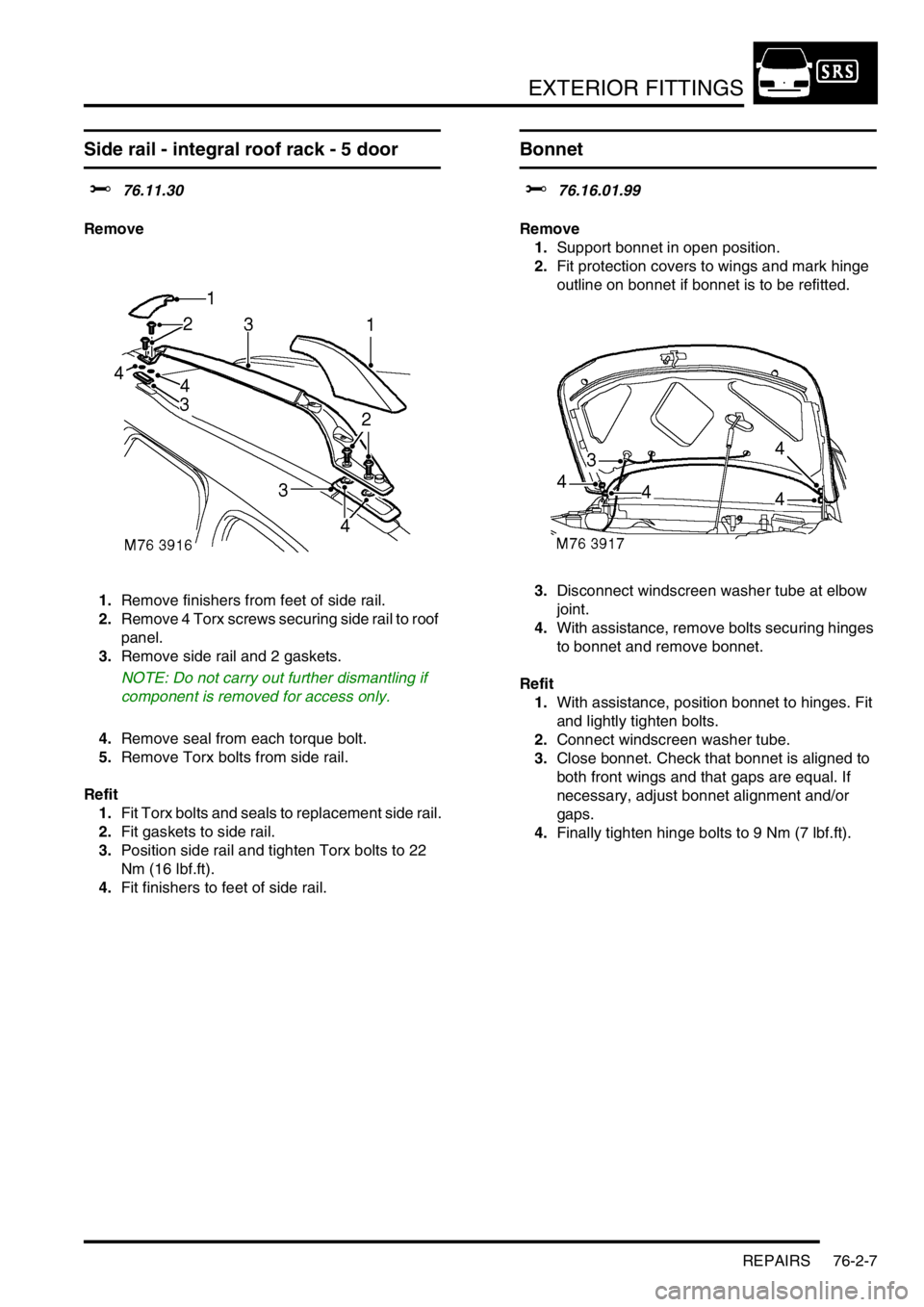

Side rail - integral roof rack - 5 door

$% 76.11.30

Remove

1.Remove finishers from feet of side rail.

2.Remove 4 Torx screws securing side rail to roof

panel.

3.Remove side rail and 2 gaskets.

NOTE: Do not carry out further dismantling if

component is removed for access only.

4.Remove seal from each torque bolt.

5.Remove Torx bolts from side rail.

Refit

1.Fit Torx bolts and seals to replacement side rail.

2.Fit gaskets to side rail.

3.Position side rail and tighten Torx bolts to 22

Nm (16 lbf.ft).

4.Fit finishers to feet of side rail.

Bonnet

$% 76.16.01.99

Remove

1.Support bonnet in open position.

2.Fit protection covers to wings and mark hinge

outline on bonnet if bonnet is to be refitted.

3.Disconnect windscreen washer tube at elbow

joint.

4.With assistance, remove bolts securing hinges

to bonnet and remove bonnet.

Refit

1.With assistance, position bonnet to hinges. Fit

and lightly tighten bolts.

2.Connect windscreen washer tube.

3.Close bonnet. Check that bonnet is aligned to

both front wings and that gaps are equal. If

necessary, adjust bonnet alignment and/or

gaps.

4.Finally tighten hinge bolts to 9 Nm (7 lbf.ft).

Page 654 of 1007

EXTERIOR FITTINGS

REPAIRS 76-2-13

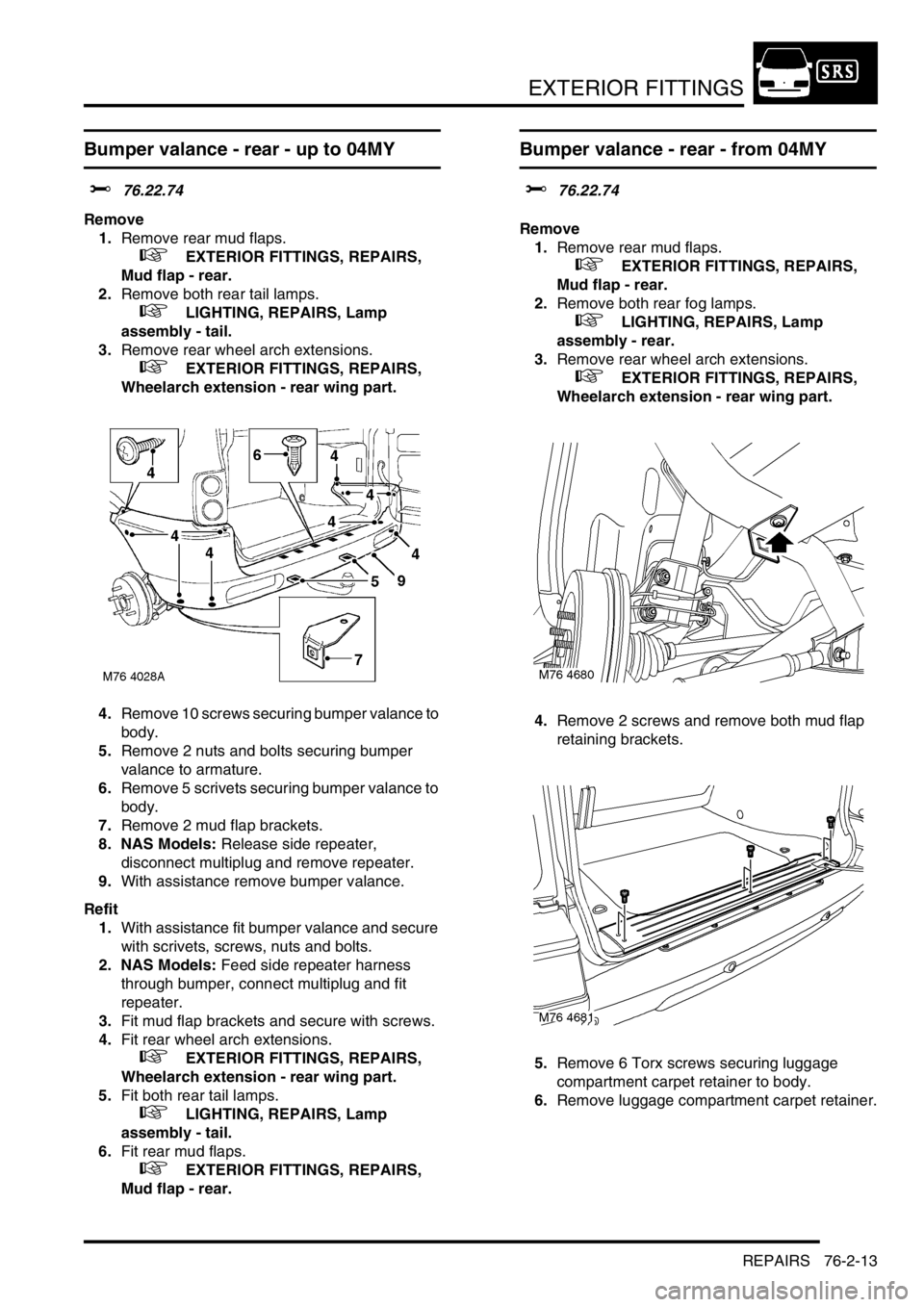

Bumper valance - rear - up to 04MY

$% 76.22.74

Remove

1.Remove rear mud flaps.

+ EXTERIOR FITTINGS, REPAIRS,

Mud flap - rear.

2.Remove both rear tail lamps.

+ LIGHTING, REPAIRS, Lamp

assembly - tail.

3.Remove rear wheel arch extensions.

+ EXTERIOR FITTINGS, REPAIRS,

Wheelarch extension - rear wing part.

4.Remove 10 screws securing bumper valance to

body.

5.Remove 2 nuts and bolts securing bumper

valance to armature.

6.Remove 5 scrivets securing bumper valance to

body.

7.Remove 2 mud flap brackets.

8. NAS Models: Release side repeater,

disconnect multiplug and remove repeater.

9.With assistance remove bumper valance.

Refit

1.With assistance fit bumper valance and secure

with scrivets, screws, nuts and bolts.

2. NAS Models: Feed side repeater harness

through bumper, connect multiplug and fit

repeater.

3.Fit mud flap brackets and secure with screws.

4.Fit rear wheel arch extensions.

+ EXTERIOR FITTINGS, REPAIRS,

Wheelarch extension - rear wing part.

5.Fit both rear tail lamps.

+ LIGHTING, REPAIRS, Lamp

assembly - tail.

6.Fit rear mud flaps.

+ EXTERIOR FITTINGS, REPAIRS,

Mud flap - rear.

Bumper valance - rear - from 04MY

$% 76.22.74

Remove

1.Remove rear mud flaps.

+ EXTERIOR FITTINGS, REPAIRS,

Mud flap - rear.

2.Remove both rear fog lamps.

+ LIGHTING, REPAIRS, Lamp

assembly - rear.

3.Remove rear wheel arch extensions.

+ EXTERIOR FITTINGS, REPAIRS,

Wheelarch extension - rear wing part.

4.Remove 2 screws and remove both mud flap

retaining brackets.

5.Remove 6 Torx screws securing luggage

compartment carpet retainer to body.

6.Remove luggage compartment carpet retainer.

Page 655 of 1007

EXTERIOR FITTINGS

76-2-14 REPAIRS

7.Release tailgate aperture seal to access

bumper valance to body retaining scrivets.

8.Remove 5 scrivets securing bumper valance to

body.

9.Remove 4 screws securing bumper valance to

body.

10.Remove 2 Torx bolts securing bumper valance

to bumper armature.11.With assistance, release bumper valance and

parking aid sensor harness from body.

12.Remove parking aid sensor harness retaining

clip and disconnect multiplug.

13.Remove bumper valance.

NOTE: Do not carry out further dismantling if

component is removed for access only.

14.Remove both rear tail lamps.

+ LIGHTING, REPAIRS, Lamp

assembly - tail.

15.Disconnect multiplugs from 4 parking aid

sensors and release harness from 9 retaining

clips.

16.Remove parking aid harness from bumper

valance.

M76 4682

Page 656 of 1007

EXTERIOR FITTINGS

REPAIRS 76-2-15

17.Release 2 retaining clips and remove parking

aid sensor from finisher.

18.Remove parking aid sensor finisher from

bumper valance.

19.Repeat above procedure for remaining 3

parking aid sensors.

20.Remove tail lamp speed nuts from bumper

valance.Refit

1.Fit tail lamp speed nuts to bumper valance.

2.Fit and secure parking aid finishers and

sensors to bumper valance.

3.Fit and secure parking aid harness to sensors

and bumpers valance.

4.Fit both rear tail lamps.

+ LIGHTING, REPAIRS, Lamp

assembly - tail.

5.With assistance, position bumper valance to

body.

6.Connect parking aid harness multiplug, fit

retaining clip and secure to body.

7.Align bumper valance to body and secure with

retaining screws and scrivets.

8.Fit Torx screws securing bumper valance to

bumper armature and tighten to 5 Nm (3.7

lbf.ft).

9.Fit tailgate aperture seal to body.

10.Fit luggage compartment carpet retainer and

secure with Torx screws.

11.Fit both mud flap retaining brackets and secure

with screws.

12.Fit rear wheel arch extensions.

+ EXTERIOR FITTINGS, REPAIRS,

Wheelarch extension - rear wing part.

13.Fit both rear fog lamps.

+ LIGHTING, REPAIRS, Lamp

assembly - rear.

14.Fit rear mud flaps.

+ EXTERIOR FITTINGS, REPAIRS,

Mud flap - rear.

Page 693 of 1007

SCREENS

76-4-2 REPAIRS

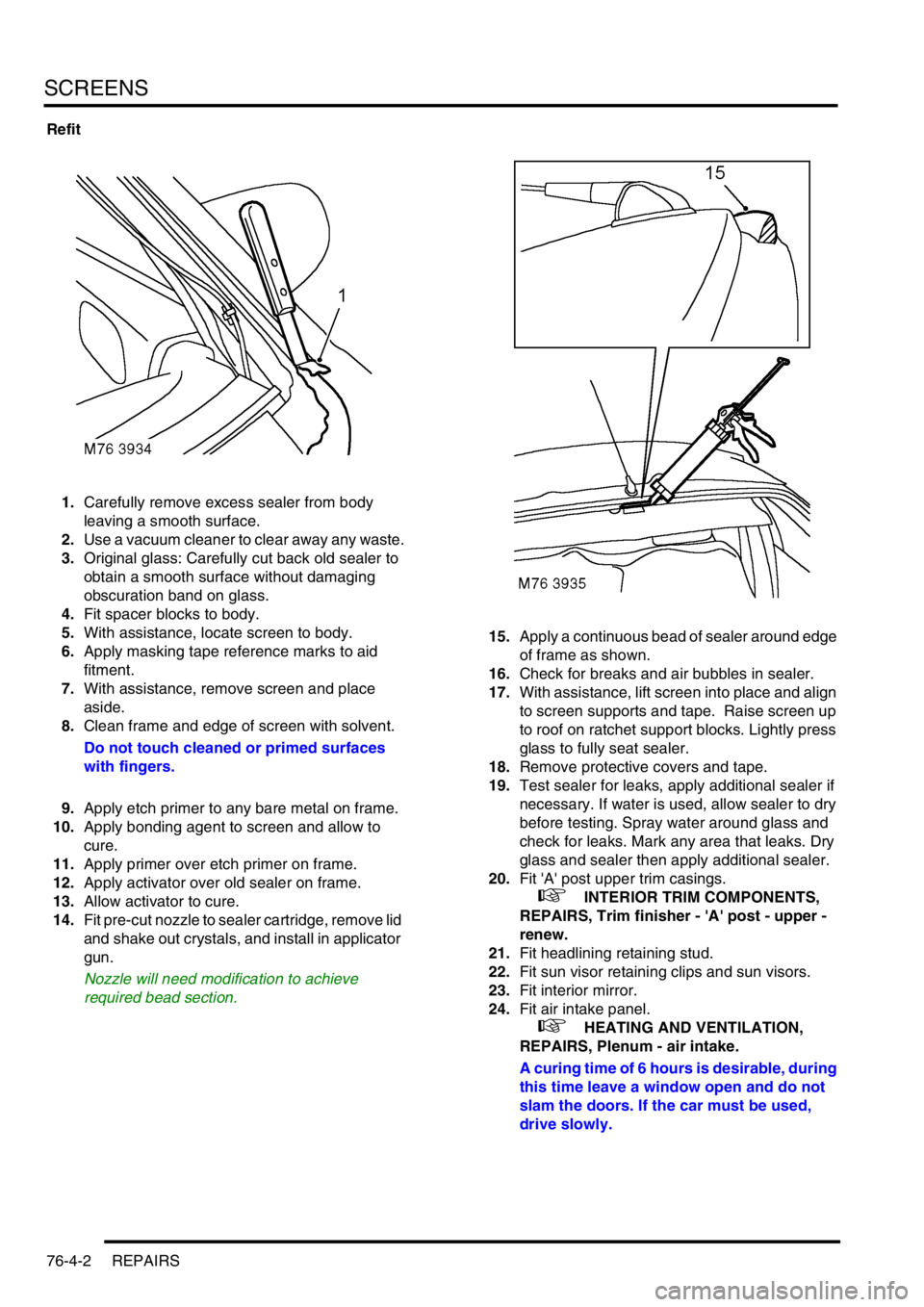

Refit

1.Carefully remove excess sealer from body

leaving a smooth surface.

2.Use a vacuum cleaner to clear away any waste.

3.Original glass: Carefully cut back old sealer to

obtain a smooth surface without damaging

obscuration band on glass.

4.Fit spacer blocks to body.

5.With assistance, locate screen to body.

6.Apply masking tape reference marks to aid

fitment.

7.With assistance, remove screen and place

aside.

8.Clean frame and edge of screen with solvent.

Do not touch cleaned or primed surfaces

with fingers.

9.Apply etch primer to any bare metal on frame.

10.Apply bonding agent to screen and allow to

cure.

11.Apply primer over etch primer on frame.

12.Apply activator over old sealer on frame.

13.Allow activator to cure.

14.Fit pre-cut nozzle to sealer cartridge, remove lid

and shake out crystals, and install in applicator

gun.

Nozzle will need modification to achieve

required bead section.15.Apply a continuous bead of sealer around edge

of frame as shown.

16.Check for breaks and air bubbles in sealer.

17.With assistance, lift screen into place and align

to screen supports and tape. Raise screen up

to roof on ratchet support blocks. Lightly press

glass to fully seat sealer.

18.Remove protective covers and tape.

19.Test sealer for leaks, apply additional sealer if

necessary. If water is used, allow sealer to dry

before testing. Spray water around glass and

check for leaks. Mark any area that leaks. Dry

glass and sealer then apply additional sealer.

20.Fit 'A' post upper trim casings.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim finisher - 'A' post - upper -

renew.

21.Fit headlining retaining stud.

22.Fit sun visor retaining clips and sun visors.

23.Fit interior mirror.

24.Fit air intake panel.

+ HEATING AND VENTILATION,

REPAIRS, Plenum - air intake.

A curing time of 6 hours is desirable, during

this time leave a window open and do not

slam the doors. If the car must be used,

drive slowly.

Page 695 of 1007

SCREENS

76-4-4 REPAIRS

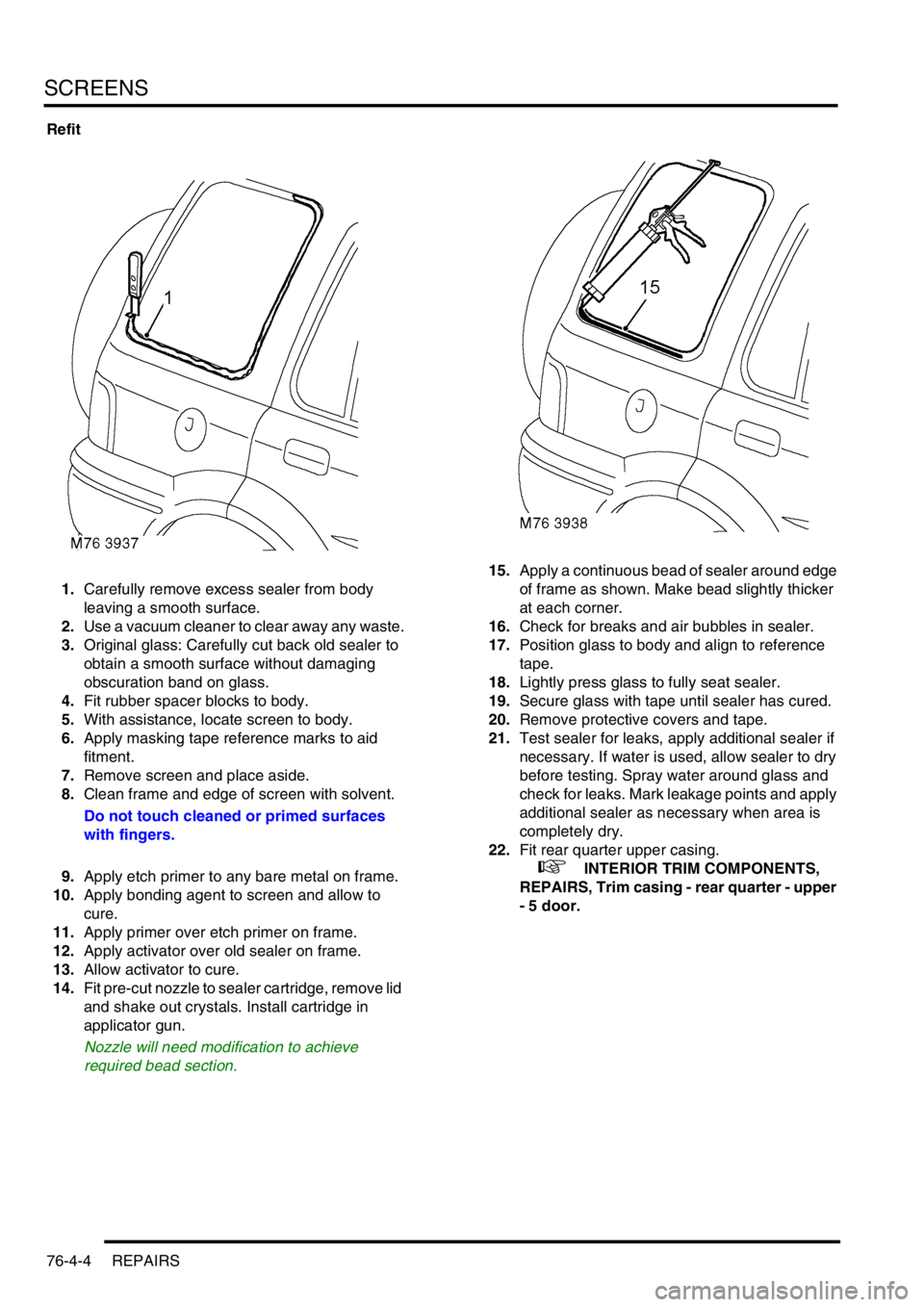

Refit

1.Carefully remove excess sealer from body

leaving a smooth surface.

2.Use a vacuum cleaner to clear away any waste.

3.Original glass: Carefully cut back old sealer to

obtain a smooth surface without damaging

obscuration band on glass.

4.Fit rubber spacer blocks to body.

5.With assistance, locate screen to body.

6.Apply masking tape reference marks to aid

fitment.

7.Remove screen and place aside.

8.Clean frame and edge of screen with solvent.

Do not touch cleaned or primed surfaces

with fingers.

9.Apply etch primer to any bare metal on frame.

10.Apply bonding agent to screen and allow to

cure.

11.Apply primer over etch primer on frame.

12.Apply activator over old sealer on frame.

13.Allow activator to cure.

14.Fit pre-cut nozzle to sealer cartridge, remove lid

and shake out crystals. Install cartridge in

applicator gun.

Nozzle will need modification to achieve

required bead section.15.Apply a continuous bead of sealer around edge

of frame as shown. Make bead slightly thicker

at each corner.

16.Check for breaks and air bubbles in sealer.

17.Position glass to body and align to reference

tape.

18.Lightly press glass to fully seat sealer.

19.Secure glass with tape until sealer has cured.

20.Remove protective covers and tape.

21.Test sealer for leaks, apply additional sealer if

necessary. If water is used, allow sealer to dry

before testing. Spray water around glass and

check for leaks. Mark leakage points and apply

additional sealer as necessary when area is

completely dry.

22.Fit rear quarter upper casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - upper

- 5 door.