light LAND ROVER FREELANDER 2001 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 278 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-101

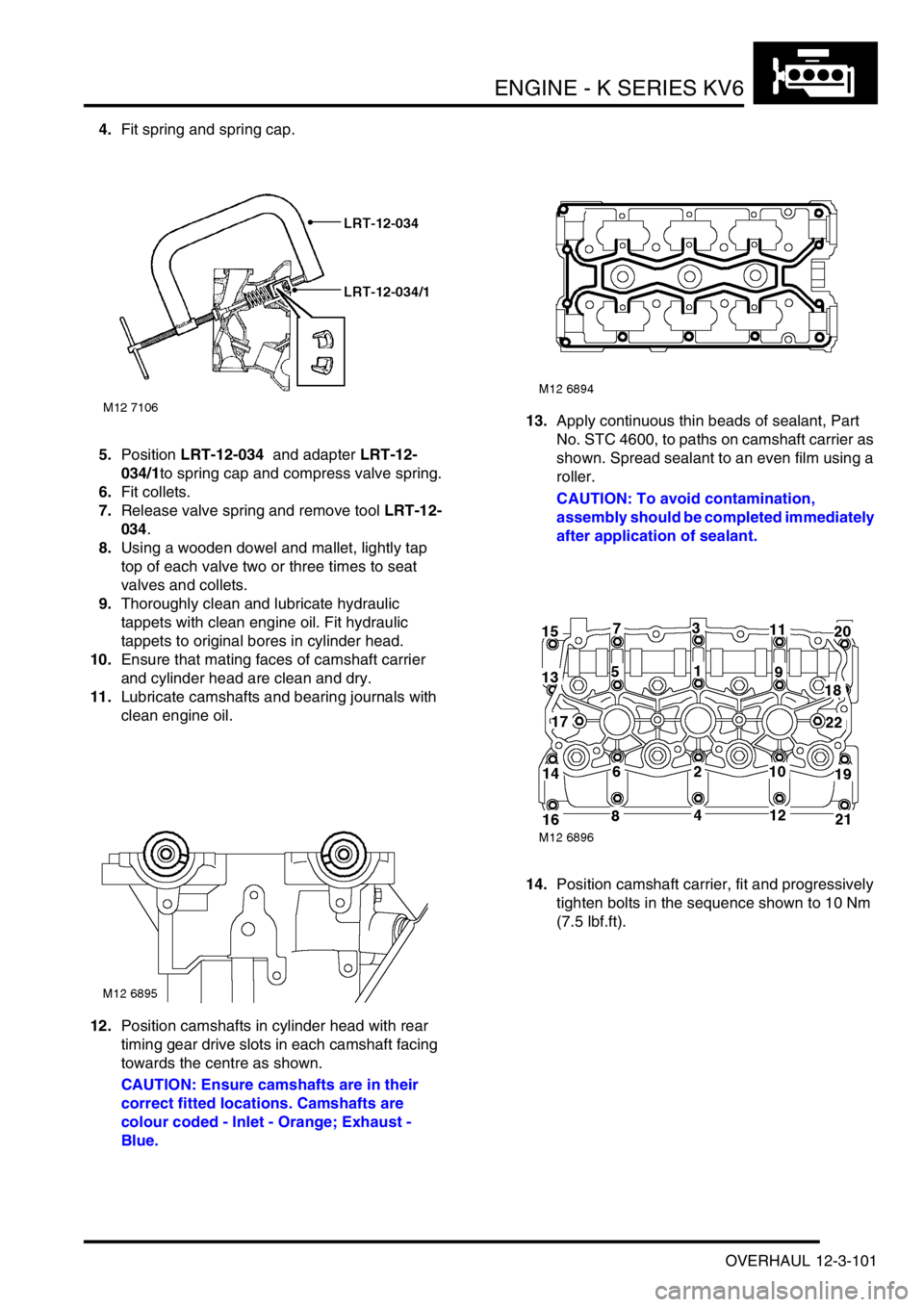

4.Fit spring and spring cap.

5.Position LRT-12-034 and adapter LRT-12-

034/1to spring cap and compress valve spring.

6.Fit collets.

7.Release valve spring and remove tool LRT-12-

034.

8.Using a wooden dowel and mallet, lightly tap

top of each valve two or three times to seat

valves and collets.

9.Thoroughly clean and lubricate hydraulic

tappets with clean engine oil. Fit hydraulic

tappets to original bores in cylinder head.

10.Ensure that mating faces of camshaft carrier

and cylinder head are clean and dry.

11.Lubricate camshafts and bearing journals with

clean engine oil.

12.Position camshafts in cylinder head with rear

timing gear drive slots in each camshaft facing

towards the centre as shown.

CAUTION: Ensure camshafts are in their

correct fitted locations. Camshafts are

colour coded - Inlet - Orange; Exhaust -

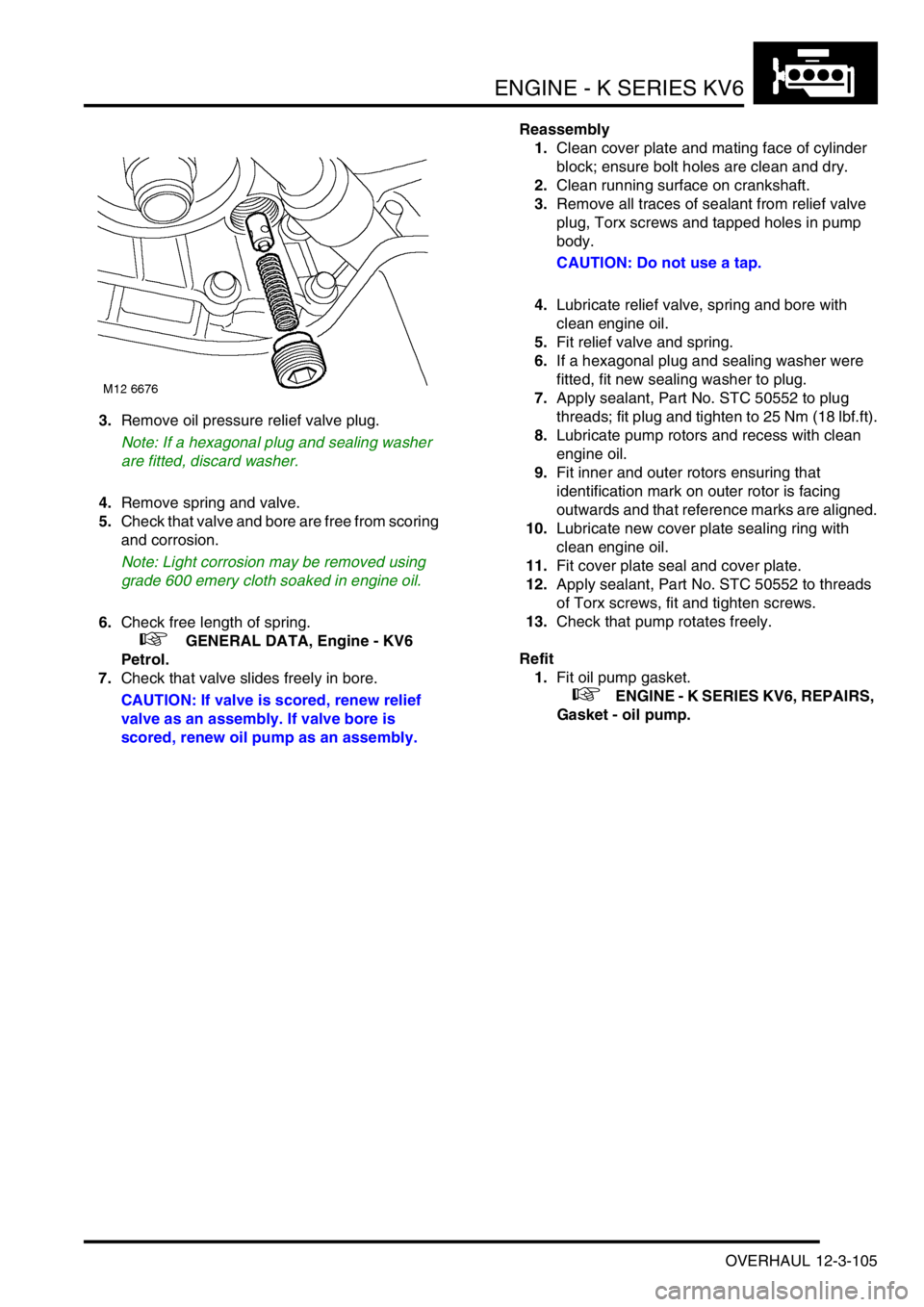

Blue.13.Apply continuous thin beads of sealant, Part

No. STC 4600, to paths on camshaft carrier as

shown. Spread sealant to an even film using a

roller.

CAUTION: To avoid contamination,

assembly should be completed immediately

after application of sealant.

14.Position camshaft carrier, fit and progressively

tighten bolts in the sequence shown to 10 Nm

(7.5 lbf.ft).

Page 282 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-105

3.Remove oil pressure relief valve plug.

Note: If a hexagonal plug and sealing washer

are fitted, discard washer.

4.Remove spring and valve.

5.Check that valve and bore are free from scoring

and corrosion.

Note: Light corrosion may be removed using

grade 600 emery cloth soaked in engine oil.

6.Check free length of spring.

+ GENERAL DATA, Engine - KV6

Petrol.

7.Check that valve slides freely in bore.

CAUTION: If valve is scored, renew relief

valve as an assembly. If valve bore is

scored, renew oil pump as an assembly.Reassembly

1.Clean cover plate and mating face of cylinder

block; ensure bolt holes are clean and dry.

2.Clean running surface on crankshaft.

3.Remove all traces of sealant from relief valve

plug, Torx screws and tapped holes in pump

body.

CAUTION: Do not use a tap.

4.Lubricate relief valve, spring and bore with

clean engine oil.

5.Fit relief valve and spring.

6.If a hexagonal plug and sealing washer were

fitted, fit new sealing washer to plug.

7.Apply sealant, Part No. STC 50552 to plug

threads; fit plug and tighten to 25 Nm (18 lbf.ft).

8.Lubricate pump rotors and recess with clean

engine oil.

9.Fit inner and outer rotors ensuring that

identification mark on outer rotor is facing

outwards and that reference marks are aligned.

10.Lubricate new cover plate sealing ring with

clean engine oil.

11.Fit cover plate seal and cover plate.

12.Apply sealant, Part No. STC 50552 to threads

of Torx screws, fit and tighten screws.

13.Check that pump rotates freely.

Refit

1.Fit oil pump gasket.

+ ENGINE - K SERIES KV6, REPAIRS,

Gasket - oil pump.

Page 289 of 1007

ENGINE - K SERIES KV6

12-3-112 OVERHAUL

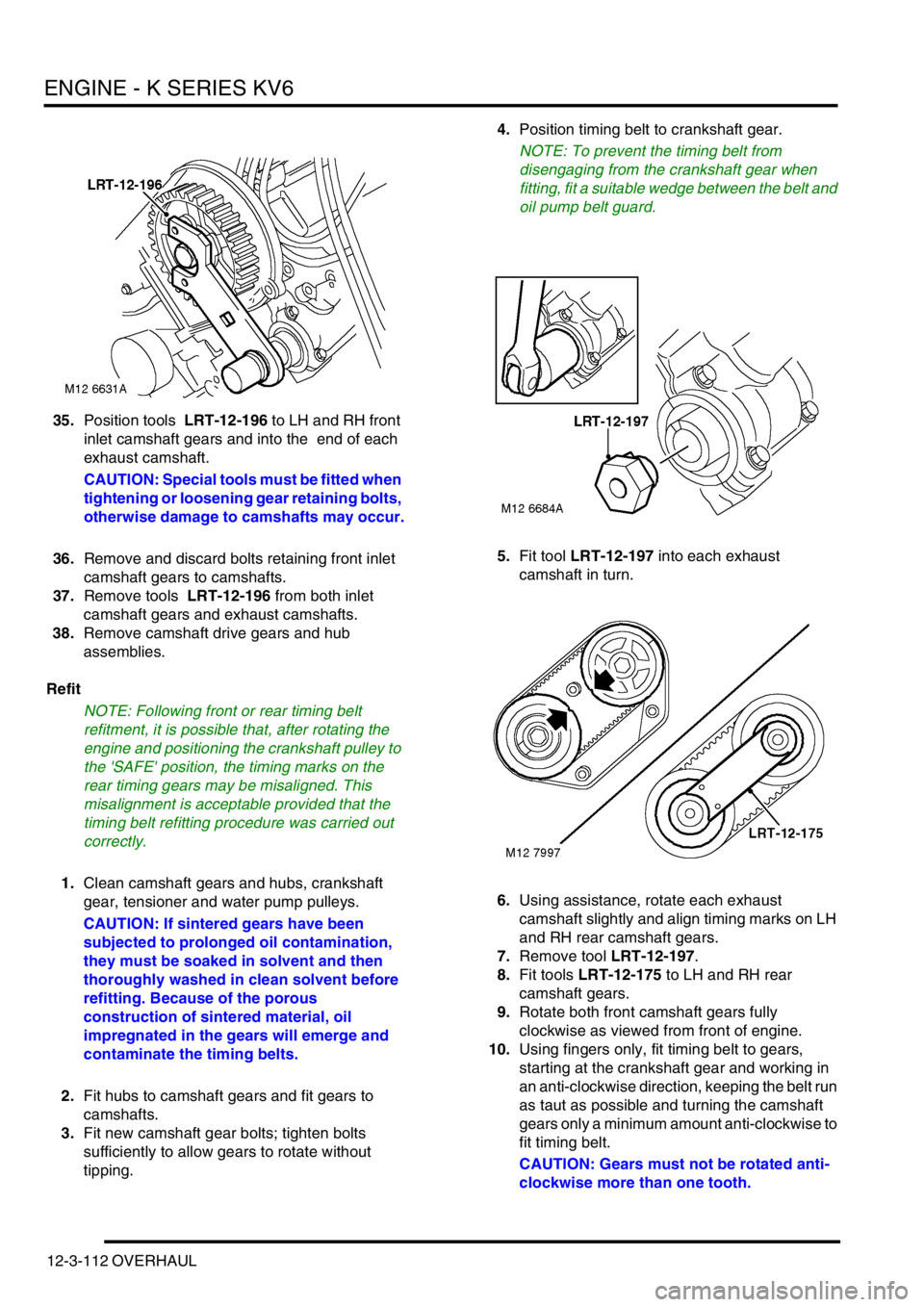

35.Position tools LRT-12-196 to LH and RH front

inlet camshaft gears and into the end of each

exhaust camshaft.

CAUTION: Special tools must be fitted when

tightening or loosening gear retaining bolts,

otherwise damage to camshafts may occur.

36.Remove and discard bolts retaining front inlet

camshaft gears to camshafts.

37.Remove tools LRT-12-196 from both inlet

camshaft gears and exhaust camshafts.

38.Remove camshaft drive gears and hub

assemblies.

Refit

NOTE: Following front or rear timing belt

refitment, it is possible that, after rotating the

engine and positioning the crankshaft pulley to

the 'SAFE' position, the timing marks on the

rear timing gears may be misaligned. This

misalignment is acceptable provided that the

timing belt refitting procedure was carried out

correctly.

1.Clean camshaft gears and hubs, crankshaft

gear, tensioner and water pump pulleys.

CAUTION: If sintered gears have been

subjected to prolonged oil contamination,

they must be soaked in solvent and then

thoroughly washed in clean solvent before

refitting. Because of the porous

construction of sintered material, oil

impregnated in the gears will emerge and

contaminate the timing belts.

2.Fit hubs to camshaft gears and fit gears to

camshafts.

3.Fit new camshaft gear bolts; tighten bolts

sufficiently to allow gears to rotate without

tipping.4.Position timing belt to crankshaft gear.

NOTE: To prevent the timing belt from

disengaging from the crankshaft gear when

fitting, fit a suitable wedge between the belt and

oil pump belt guard.

5.Fit tool LRT-12-197 into each exhaust

camshaft in turn.

6.Using assistance, rotate each exhaust

camshaft slightly and align timing marks on LH

and RH rear camshaft gears.

7.Remove tool LRT-12-197.

8.Fit tools LRT-12-175 to LH and RH rear

camshaft gears.

9.Rotate both front camshaft gears fully

clockwise as viewed from front of engine.

10.Using fingers only, fit timing belt to gears,

starting at the crankshaft gear and working in

an anti-clockwise direction, keeping the belt run

as taut as possible and turning the camshaft

gears only a minimum amount anti-clockwise to

fit timing belt.

CAUTION: Gears must not be rotated anti-

clockwise more than one tooth.

Page 425 of 1007

INTERMEDIATE REDUCTION DRIVE

41-22 REPAIRS

Refit

1.Clean pinion shaft, drive flange and housing.

2.Clean oil seal recess.

3.Lubricate and fit bearing to pinion housing.

4.Lubricate new seal.

5.Using a suitable adapter, press seal into

housing.

CAUTION: Oil seal must be flush with end of

pinion housing.

6.Assemble pinion to housing using new

collapsible spacer.

7.Lightly lubricate drive flange splines with

Molybdenum Disulphide grease.

8.Align pinion to drive flange reference marks

and press flange onto pinion shaft until a 2 mm

clearance exists in bearings.

9.Fit pinion assembly to mounting plate and

secure in vice.

10.Fit new pinion nut, hold pinion drive flange

using LRT-51-003 and tighten pinion nut to 150

Nm (111 lbf.ft).

11.Check pinion torque to turn figure.

NOTE: Figure for new bearings is 180 to 200

Ncm.

If original bearing figure is above 20 to 30 Ncm

and below new bearing figure, set to figure

recorded.

If original bearing is below 20 Ncm set to 20 to

30 Ncm.12.If turning torque is too low, carefully tighten nut

and recheck reading. If turning torque is too

high, pinion assembly will have to be

dismantled and a new collapsible spacer fitted.

Reassemble using new nut and recheck turning

torque.

13.Check drive flange run-out using a Dial Test

Indicator (DTI).

CAUTION: The drive flange run-out should

not exceed 0.05 mm.

14.Remove pinion housing from vice and

mounting plate.

15.Fit pinion housing.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Seal - pinion gear

housing - Td4.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Seal - pinion gear

housing - K1.8.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Seal - pinion gear

housing - KV6 - Non NAS.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Seal - pinion gear

housing - KV6 - NAS.

Page 497 of 1007

STEERING

57-4 ADJUSTMENTS

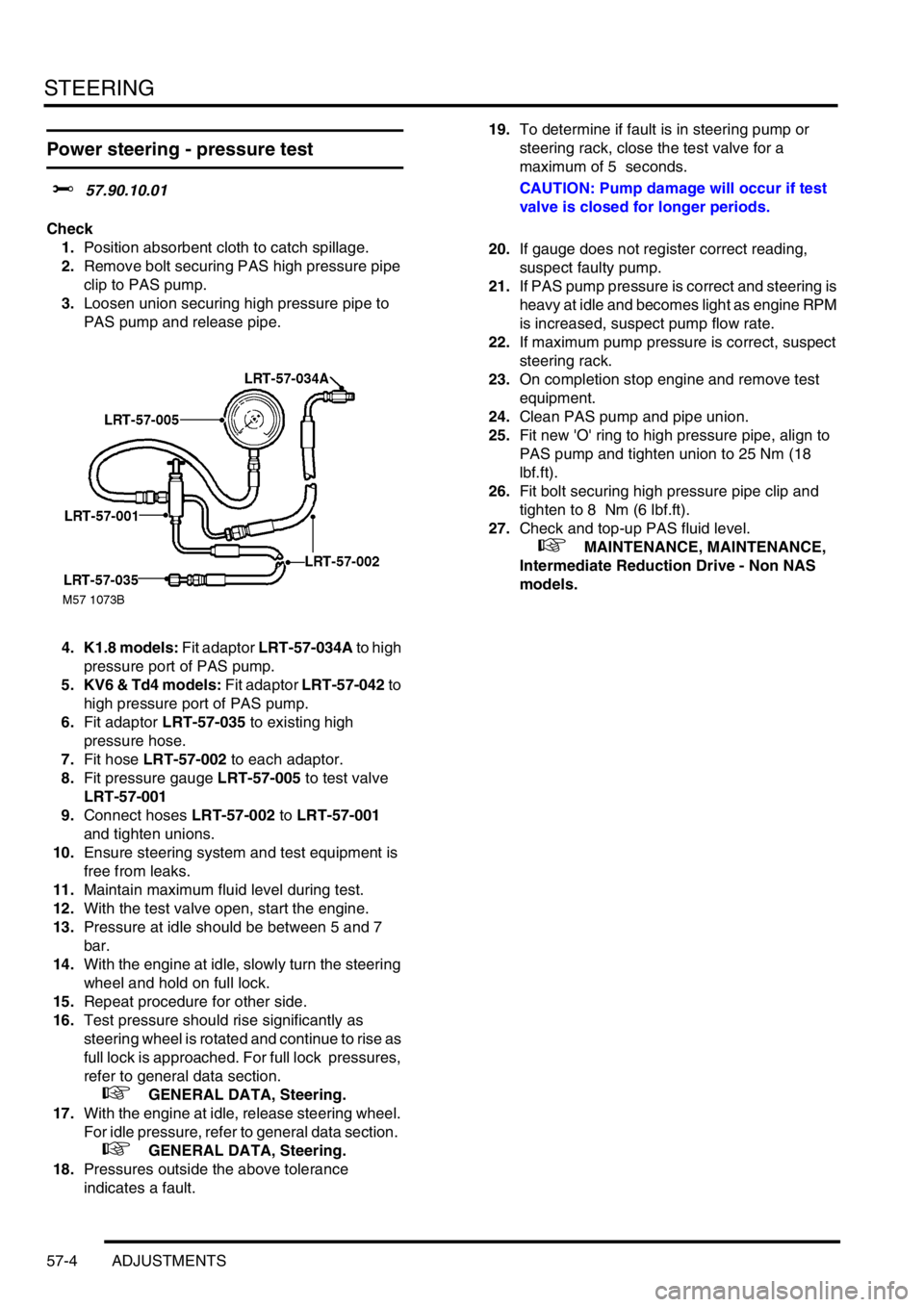

Power steering - pressure test

$% 57.90.10.01

Check

1.Position absorbent cloth to catch spillage.

2.Remove bolt securing PAS high pressure pipe

clip to PAS pump.

3.Loosen union securing high pressure pipe to

PAS pump and release pipe.

4. K1.8 models: Fit adaptor LRT-57-034A to high

pressure port of PAS pump.

5. KV6 & Td4 models: Fit adaptor LRT-57-042 to

high pressure port of PAS pump.

6.Fit adaptor LRT-57-035 to existing high

pressure hose.

7.Fit hose LRT-57-002 to each adaptor.

8.Fit pressure gauge LRT-57-005 to test valve

LRT-57-001

9.Connect hoses LRT-57-002 to LRT-57-001

and tighten unions.

10.Ensure steering system and test equipment is

free from leaks.

11.Maintain maximum fluid level during test.

12.With the test valve open, start the engine.

13.Pressure at idle should be between 5 and 7

bar.

14.With the engine at idle, slowly turn the steering

wheel and hold on full lock.

15.Repeat procedure for other side.

16.Test pressure should rise significantly as

steering wheel is rotated and continue to rise as

full lock is approached. For full lock pressures,

refer to general data section.

+ GENERAL DATA, Steering.

17.With the engine at idle, release steering wheel.

For idle pressure, refer to general data section.

+ GENERAL DATA, Steering.

18.Pressures outside the above tolerance

indicates a fault.19.To determine if fault is in steering pump or

steering rack, close the test valve for a

maximum of 5 seconds.

CAUTION: Pump damage will occur if test

valve is closed for longer periods.

20.If gauge does not register correct reading,

suspect faulty pump.

21.If PAS pump pressure is correct and steering is

heavy at idle and becomes light as engine RPM

is increased, suspect pump flow rate.

22.If maximum pump pressure is correct, suspect

steering rack.

23.On completion stop engine and remove test

equipment.

24.Clean PAS pump and pipe union.

25.Fit new 'O' ring to high pressure pipe, align to

PAS pump and tighten union to 25 Nm (18

lbf.ft).

26.Fit bolt securing high pressure pipe clip and

tighten to 8 Nm (6 lbf.ft).

27.Check and top-up PAS fluid level.

+ MAINTENANCE, MAINTENANCE,

Intermediate Reduction Drive - Non NAS

models.

Page 512 of 1007

STEERING

REPAIRS 57-19

Refit

1.Position cable, align to heater and steering

column bracket and secure in retaining clips.

2.Align key interlock cable to column lock and

tighten union to 4 Nm (3 lbf.ft).

3.Fit height adjuster clamp bolt and tighten nut to

10 Nm (7.5 lbf.ft). Ensure bolt and plastic stop

are correctly located in slot in column bracket.

4.Fit height adjuster lever and tighten bolt 12 Nm

(9 lbf.ft). Ensure lever is in the fully up position

before tightening bolt. Hold clamp bolt nut to

prevent nut rotation.

5.Connect cable to interlock mechanism.

6.Check key interlock cable adjustment.

+ STEERING, ADJUSTMENTS, Cable

- key interlock - adjust.

7.Fit steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

column.

8.Fit front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

9.Connect battery earth lead.

Column assembly - inner & outer

$% 57.41.01

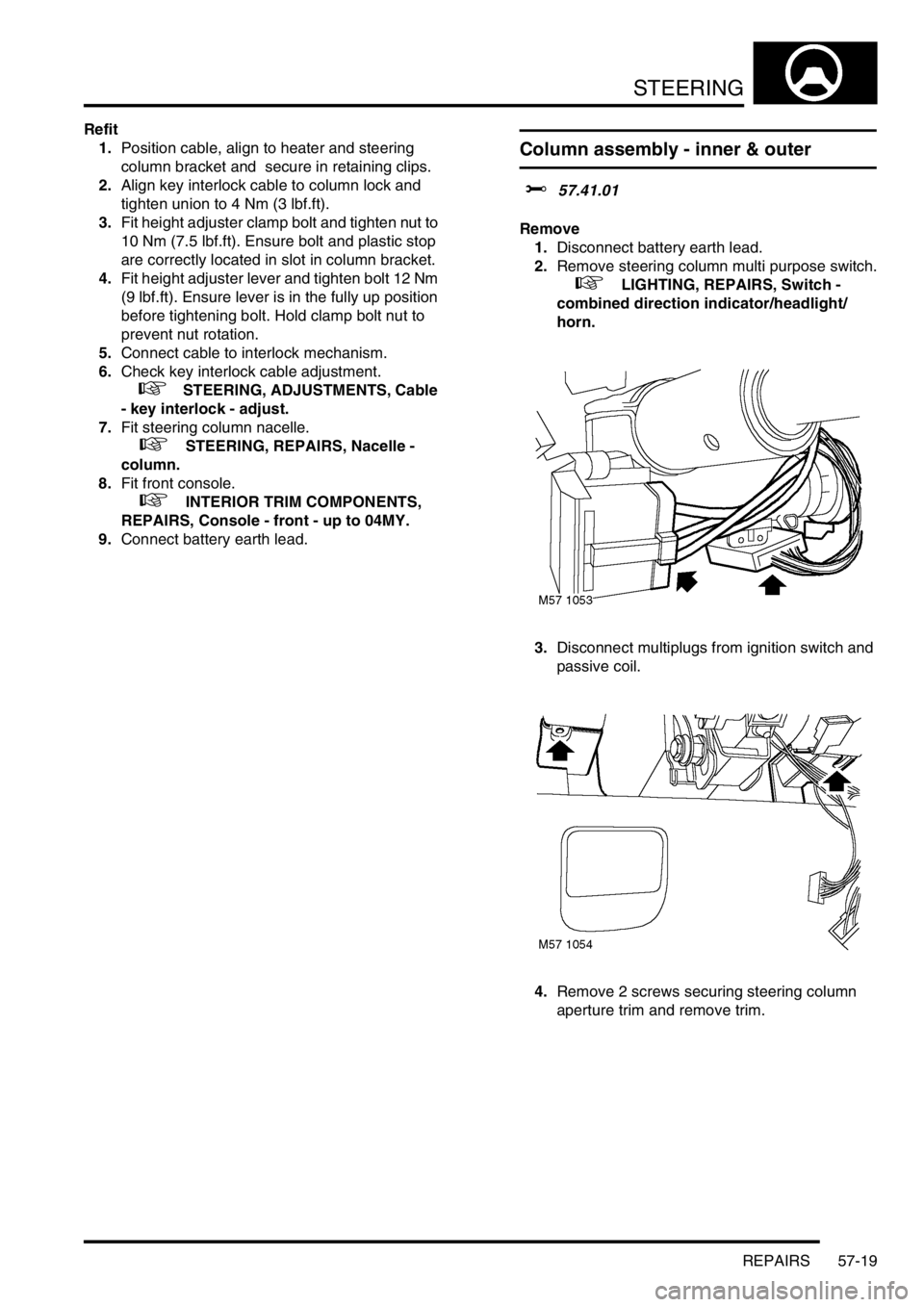

Remove

1.Disconnect battery earth lead.

2.Remove steering column multi purpose switch.

+ LIGHTING, REPAIRS, Switch -

combined direction indicator/headlight/

horn.

3.Disconnect multiplugs from ignition switch and

passive coil.

4.Remove 2 screws securing steering column

aperture trim and remove trim.

Page 515 of 1007

STEERING

57-22 REPAIRS

Refit

1.Remove column from vice.

2.Fit new cable ties to steering column.

3. Models with automatic transmission: Fit key

interlock cable clip.

4.Position steering column to vehicle, locate

steering column on PAS rack, aligning column

coupling with PAS rack input flag.

5.Locate steering column on studs fit nuts but do

not tighten at this stage.

6.Fit bolts and snubber to pivot mountings and

tighten bolts to 14 Nm (10 lbf.ft).

7.Tighten nuts to 14 Nm (10 lbf.ft).

8.Fit and tighten PAS rack pinion clamp bolt to 32

Nm (24 lbf.ft).

CAUTION: Nuts and bolts must be tightened

with weight of vehicle on suspension.

9. Models with automatic transmission:

Remove clamp bolt from height adjuster and

position key interlock cable.

10. Models with automatic transmission: Fit

height adjuster clamp bolt and tighten nut to 10

Nm (7.5 lbf.ft). Ensure bolt and plastic stop are

correctly located in slot in column bracket.

11. Models with automatic transmission: Fit

height adjuster lever and tighten bolt 12 Nm (9

lbf.ft). Ensure lever is in the fully up position

before tightening bolt. Hold clamp bolt nut to

prevent nut rotation.

12. Models with automatic transmission:

Remove starter key from column lock.

13. Models with automatic transmission: Align

key interlock cable to column lock and tighten

union to 4 Nm (3 lbf.ft).

14. Models with automatic

transmission:Position lock to steering column

assembly and fit shear bolts. Do not tighten

shear bolts at this stage.

15. Models with automatic transmission: Insert

starter key, check operation of steering lock

and that key turns freely.

16. Models with automatic transmission:

Ensure correct operation of key interlock cable.

17. Models with automatic transmission:

Remove starter key from column lock.

18. Models with automatic transmission:

Tighten shear bolts fully and shear heads off.

19. Models with automatic transmission: Fit

passive coil.

20. Models with automatic transmission:

Position ignition switch to column, fit and

tighten screws.

21. Models with automatic transmission:

Secure key interlock cable in clip.

22. Models with automatic transmission:

Ensure key interlock cable is correctly fitted.23.Fit side support bolt and tighten to 10 Nm (7.5

lbf.ft).

24.Position harness and secure cable ties.

25.Fit fusebox cover and close glove box lid.

26.Connect multiplugs to column switch and

passive coil.

27.Fit aperture trim and secure with screws.

28. Fit steering column multi purpose switch.

+ LIGHTING, REPAIRS, Switch -

combined direction indicator/headlight/

horn.

29.Connect battery earth lead.

Page 551 of 1007

BRAKES

70-2 ADJUSTMENTS

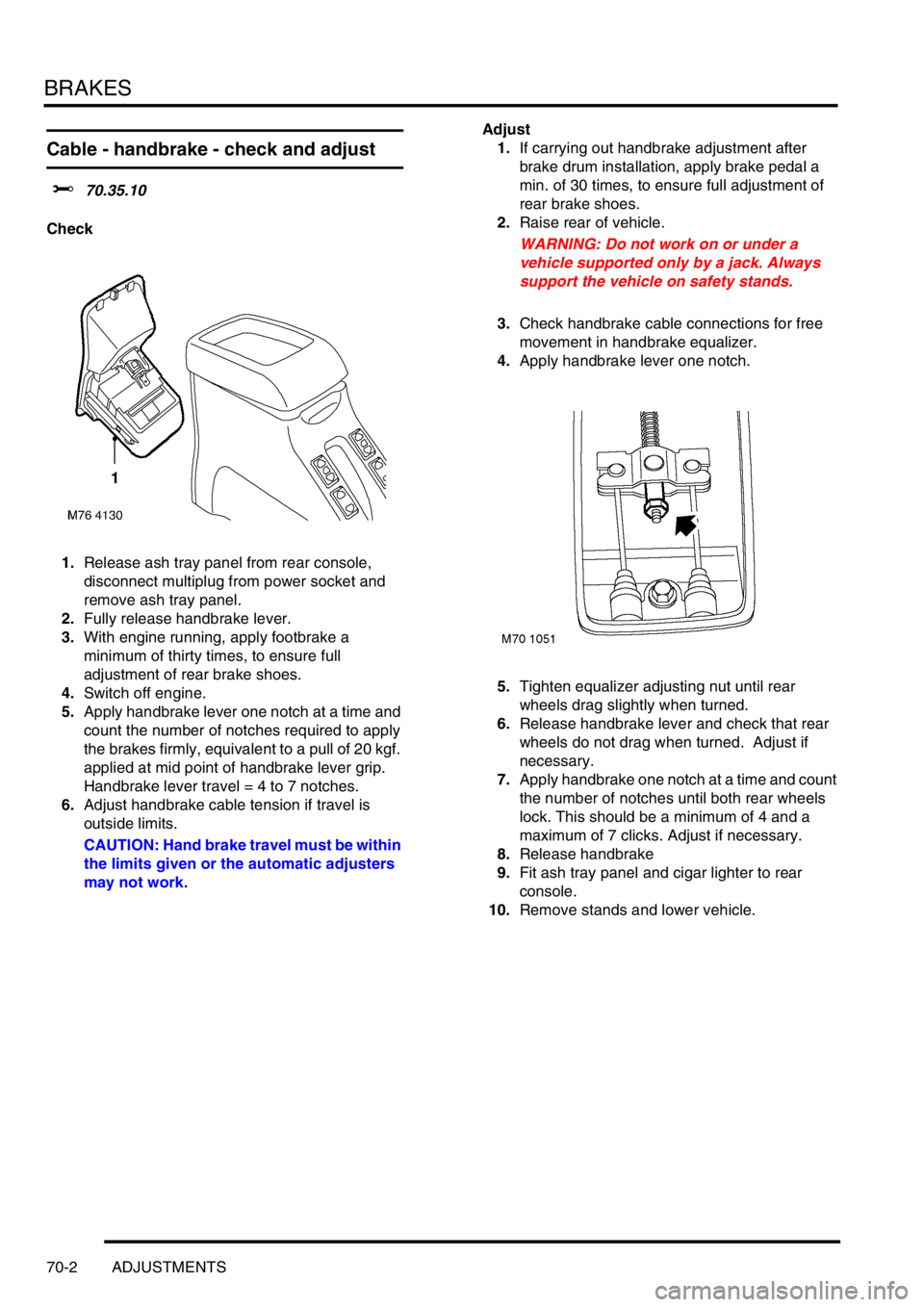

Cable - handbrake - check and adjust

$% 70.35.10

Check

1.Release ash tray panel from rear console,

disconnect multiplug from power socket and

remove ash tray panel.

2.Fully release handbrake lever.

3.With engine running, apply footbrake a

minimum of thirty times, to ensure full

adjustment of rear brake shoes.

4.Switch off engine.

5.Apply handbrake lever one notch at a time and

count the number of notches required to apply

the brakes firmly, equivalent to a pull of 20 kgf.

applied at mid point of handbrake lever grip.

Handbrake lever travel = 4 to 7 notches.

6.Adjust handbrake cable tension if travel is

outside limits.

CAUTION: Hand brake travel must be within

the limits given or the automatic adjusters

may not work.Adjust

1.If carrying out handbrake adjustment after

brake drum installation, apply brake pedal a

min. of 30 times, to ensure full adjustment of

rear brake shoes.

2.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Check handbrake cable connections for free

movement in handbrake equalizer.

4.Apply handbrake lever one notch.

5.Tighten equalizer adjusting nut until rear

wheels drag slightly when turned.

6.Release handbrake lever and check that rear

wheels do not drag when turned. Adjust if

necessary.

7.Apply handbrake one notch at a time and count

the number of notches until both rear wheels

lock. This should be a minimum of 4 and a

maximum of 7 clicks. Adjust if necessary.

8.Release handbrake

9.Fit ash tray panel and cigar lighter to rear

console.

10.Remove stands and lower vehicle.

Page 560 of 1007

BRAKES

REPAIRS 70-11

Cable - handbrake

$% 70.35.25

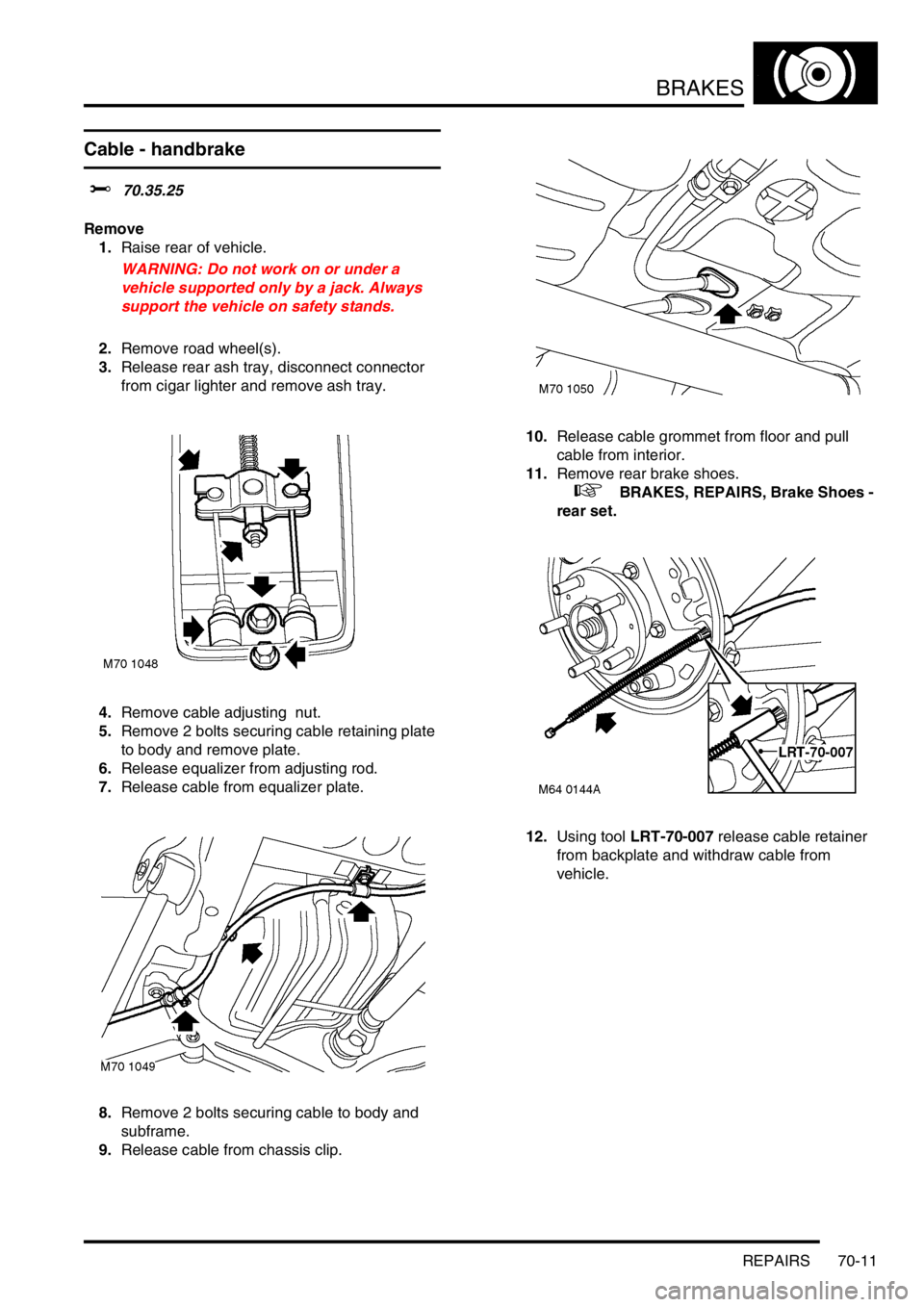

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel(s).

3.Release rear ash tray, disconnect connector

from cigar lighter and remove ash tray.

4.Remove cable adjusting nut.

5.Remove 2 bolts securing cable retaining plate

to body and remove plate.

6.Release equalizer from adjusting rod.

7.Release cable from equalizer plate.

8.Remove 2 bolts securing cable to body and

subframe.

9.Release cable from chassis clip.10.Release cable grommet from floor and pull

cable from interior.

11.Remove rear brake shoes.

+ BRAKES, REPAIRS, Brake Shoes -

rear set.

12.Using tool LRT-70-007 release cable retainer

from backplate and withdraw cable from

vehicle.

Page 561 of 1007

BRAKES

70-12 REPAIRS

Refit

1.Manoeuvre cable into position and secure floor

grommet.

2.Fit and secure handbrake cable to backplate.

3.Fit brake shoes.

+ BRAKES, REPAIRS, Brake Shoes -

rear set.

4.Align cable clips, fit bolts and tighten to 22 Nm

(16 lbf.ft).

5.Secure cable in chassis clip.

6.Connect handbrake cable to equalizer.

7.Ensure spring is in place and fit equalizer to

adjusting rod.

8.Fit cable adjusting nut.

9.Fit cable retaining plate, fit bolts and tighten to

22 Nm (16 lbf.ft).

10.Adjust handbrake cable.

+ BRAKES, ADJUSTMENTS, Cable -

handbrake - check and adjust.

11.Fit ash tray and cigar lighter to rear console.

12.Fit road wheel(s).

13.Remove stands and lower vehicle.

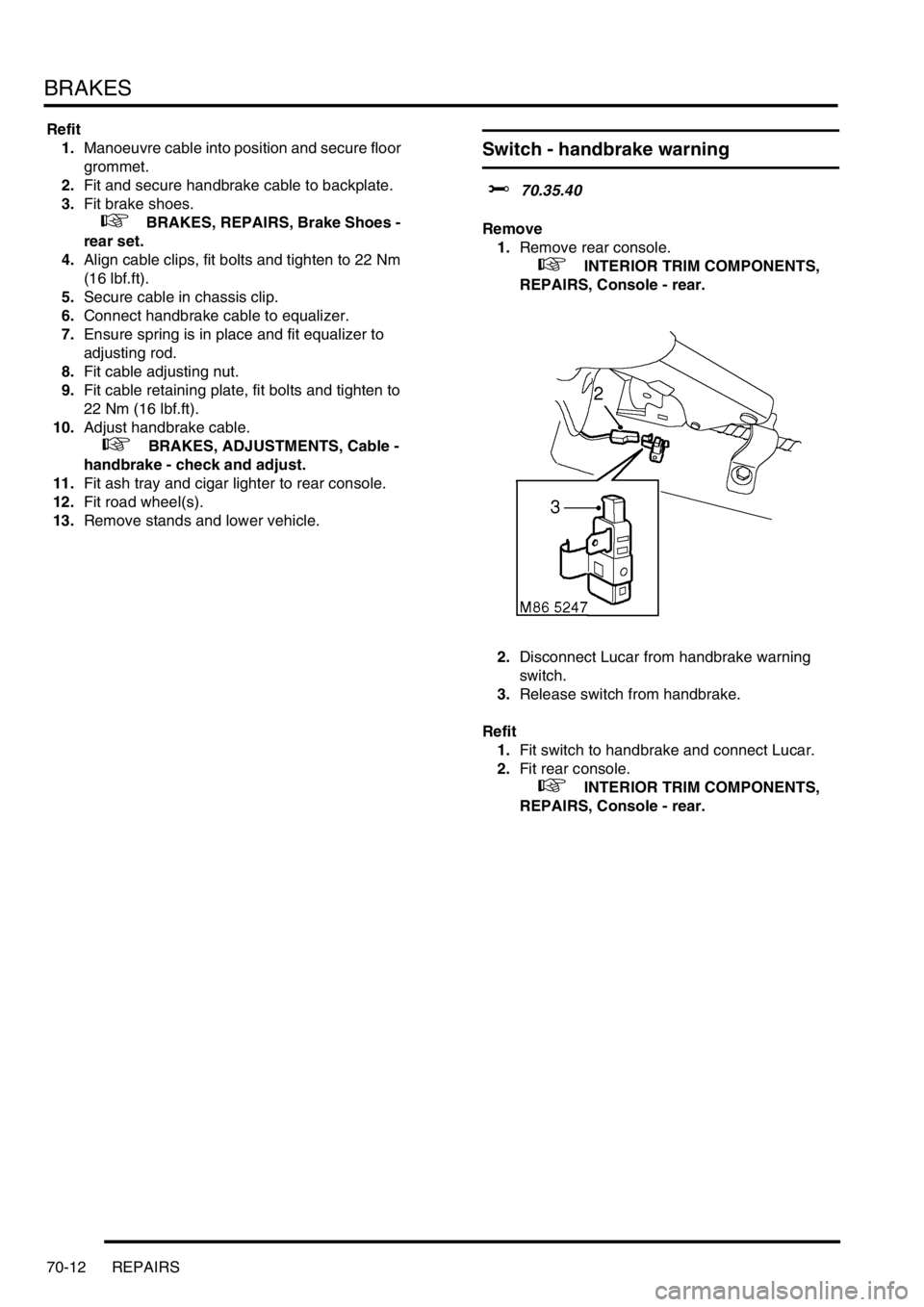

Switch - handbrake warning

$% 70.35.40

Remove

1.Remove rear console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - rear.

2.Disconnect Lucar from handbrake warning

switch.

3.Release switch from handbrake.

Refit

1.Fit switch to handbrake and connect Lucar.

2.Fit rear console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - rear.