roof LAND ROVER FREELANDER 2001 Service Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 805 of 1007

PANEL REPAIRS

77-2-50 REPAIRS

10.Fit rear seat.

+ SEATS, REPAIRS, Rear seat - LH.

+ SEATS, REPAIRS, Rear seat - RH.

11.Fit loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - luggage compartment.

12.Fit rear side seat belt.

+ RESTRAINT SYSTEMS, REPAIRS,

Seat belt - rear - LH.

13.Fit rear quarter upper casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - upper

- 3 door.

14.Fit rear quarter lower casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 3 door.

15.Fit tail lamp.

+ LIGHTING, REPAIRS, Lamp

assembly - tail.

16.Fit rear roof panel finisher.

+ EXTERIOR FITTINGS, REPAIRS,

Moulding - roof - 5 door.

17.Fit tail door aperture seal.

18.Fit soft/hard top.

19.Secure carpet to inner sill and rear heelboard.

20.Fit front door aperture seal.

21.Fit treadplate to front door aperture.

22.Fit door striker to 'B' post.

23.Fit rear wheel arch liner.

24.Fit rear bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper valance - rear - up to 04MY.

25.Fit sill lower finisher.

+ EXTERIOR FITTINGS, REPAIRS,

Finisher - sill - lower.

26.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

27.Connect all ECUs.

28.Connect alternator.

29.Connect battery earth lead.

Complete rear quarter - 5 door

In this procedure, the rear outer body side panel is

replaced in conjunction with the complete rear

quarter.

Remove

1.Disconnect battery earth lead.

2.Disconnect alternator.

3.Disconnect all ECUs.

4.Remove road wheel(s).

5.Remove sill lower finisher.

+ EXTERIOR FITTINGS, REPAIRS,

Finisher - sill - lower.

6.Remove rear bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper valance - rear - up to 04MY.

7.Remove rear wheel arch liner.

8.Remove rear door striker from 'D' post.

9.Remove treadplate from rear door aperture.

10.Remove rear door aperture seal.

11.Release carpet from inner sill and rear

heelboard and position aside.

12.Remove tail door glass upper finisher.

13.Remove tail door glass side finisher.

+ DOORS, REPAIRS, Finisher - rear

screen - side - 5 door.

14.Remove tail door aperture seal.

15.Remove roof panel finisher.

+ EXTERIOR FITTINGS, REPAIRS,

Moulding - roof - 5 door.

16.Remove tail lamp.

+ LIGHTING, REPAIRS, Lamp

assembly - tail.

17.Remove rear quarter lower casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 5 door.

18.Remove rear quarter upper casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - upper

- 5 door.

19.Remove rear side seat belt.

+ RESTRAINT SYSTEMS, REPAIRS,

Seat belt - rear - LH.

20.Remove loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - luggage compartment.

21.Remove rear seat.

+ SEATS, REPAIRS, Rear seat - LH.

+ SEATS, REPAIRS, Rear seat - RH.

22.Remove headlining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining - 5 door.

Page 807 of 1007

PANEL REPAIRS

77-2-52 REPAIRS

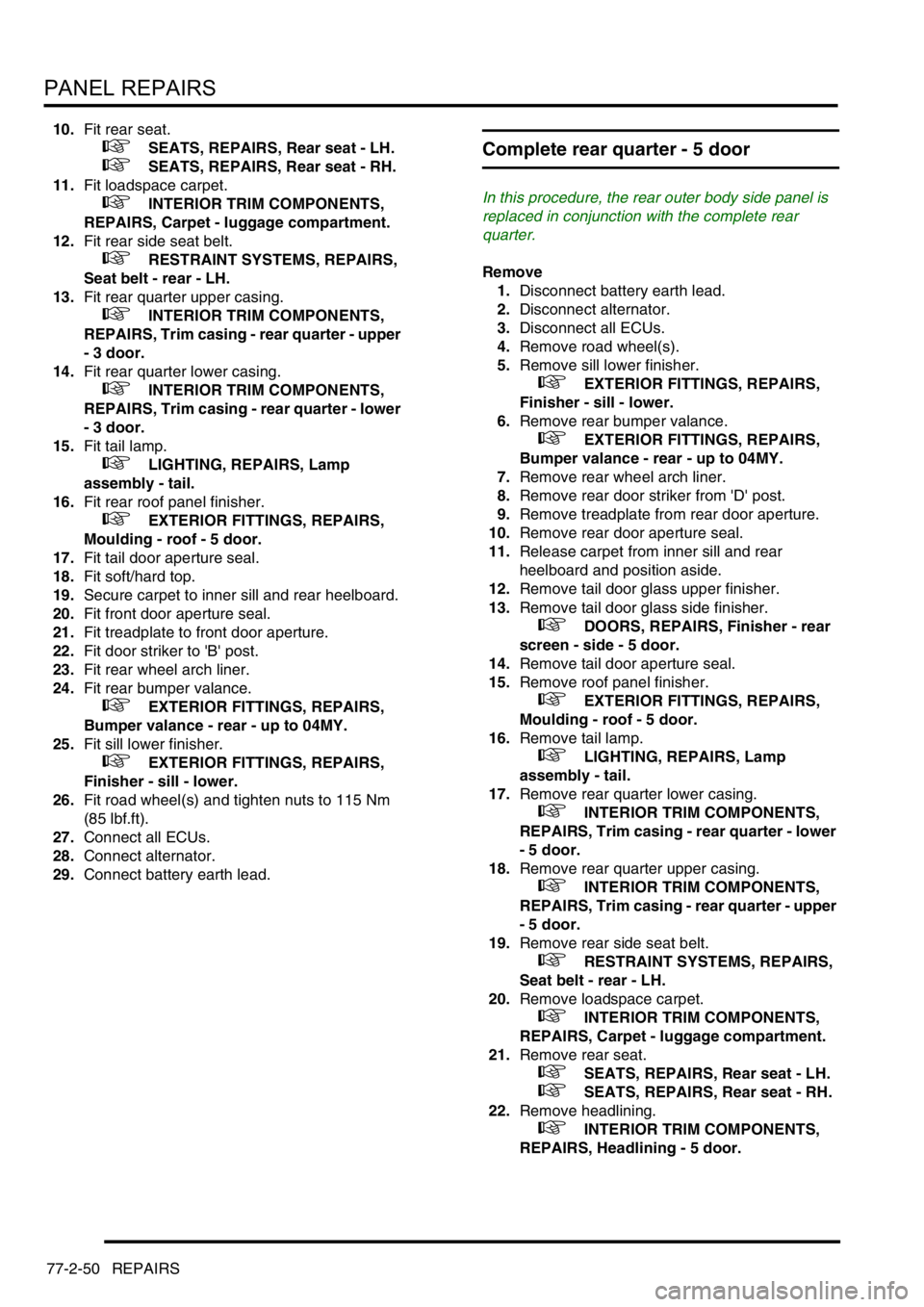

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

2.Arrow A is shown to highlight the fact that there

are plug welds on the other side of the inner

wheel arch as well. These are to weld the rear

longitudinal to the inner wheel arch.

Refit

1. LH side: Fit tail door striker to 'E' post.

2. RH side: Fit fuel tank.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Tank - Non NAS.

3. RH side: Fit fuel filler neck.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Filler neck.

4. RH side: Fit tail door.

+ DOORS, REPAIRS, Door - tail

assembly - remove for access & refit.

5.Secure vehicle harness to rear quarter.

6.Fit rear damper.

+ REAR SUSPENSION, REPAIRS,

Damper.

7.Fit rear body side glass.

+ SCREENS, REPAIRS, Glass - body

side - rear.

8.Fit headlining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining - 5 door.9.Fit rear seat.

+ SEATS, REPAIRS, Rear seat - LH.

+ SEATS, REPAIRS, Rear seat - RH.

10.Fit loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - luggage compartment.

11.Fit rear side seat belt.

+ RESTRAINT SYSTEMS, REPAIRS,

Seat belt - rear - LH.

12.Fit rear quarter upper casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - upper

- 5 door.

13.Fit rear quarter lower casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 5 door.

14.Fit tail lamp.

+ LIGHTING, REPAIRS, Lamp

assembly - tail.

15.Fit roof panel finisher.

+ EXTERIOR FITTINGS, REPAIRS,

Moulding - roof - 5 door.

16.Fit tail door aperture seal.

17.Fit tail door glass side finisher.

+ DOORS, REPAIRS, Finisher - rear

screen - side - 5 door.

18.Fit tail door glass upper finisher.

19.Secure carpet to inner sill and rear heelboard.

20.Fit rear door aperture seal.

21.Fit treadplate to rear door aperture.

22.Fit rear door striker to 'D' post.

23.Fit rear wheel arch liner.

24.Fit rear bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper valance - rear - up to 04MY.

25.Fit sill lower finisher.

+ EXTERIOR FITTINGS, REPAIRS,

Finisher - sill - lower.

26.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

27.Connect all ECUs.

28.Connect alternator.

29.Connect battery earth lead.

Page 811 of 1007

PANEL REPAIRS

77-2-56 REPAIRS

Refit

1. LH side: Fit tail door striker.

2. RH side: Fit fuel tank.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Tank - Non NAS.

3. RH side: Fit fuel filler neck.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Filler neck.

4. RH side: Fit tail door.

+ DOORS, REPAIRS, Door - tail

assembly - remove for access & refit.

5.Secure vehicle harness to 'E' post.

6.Fit loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - luggage compartment.

7.Fit rear quarter lower casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 3 door.

8.Fit tail door aperture seal.

9.Fit soft/hard top.

10.Fit tail lamp.

+ LIGHTING, REPAIRS, Lamp

assembly - tail.

11.Fit rear wheel arch liner.

12.Fit rear bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper valance - rear - up to 04MY.

13.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

14.Connect all ECUs.

15.Connect alternator.

16.Connect battery earth lead.

Inner 'e' post - 5 door

In this procedure, the rear outer body side panel and

the rear body side reinforcement assembly is

replaced in conjunction with the inner 'E' post

assembly.

Remove

1.Disconnect battery earth lead.

2.Disconnect alternator.

3.Disconnect all ECUs.

4.Remove road wheel(s).

5.Remove rear bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper valance - rear - up to 04MY.

6.Remove rear wheel arch liner.

7.Remove tail lamp.

+ LIGHTING, REPAIRS, Lamp

assembly - tail.

8.Remove roof panel finisher.

+ DOORS, REPAIRS, Finisher - rear

screen - side - 5 door.

9.Remove tail door glass upper finisher.

10.Remove tail door glass side finisher.

+ DOORS, REPAIRS, Finisher - rear

screen - side - 5 door.

11.Remove tail door aperture seal.

12.Remove rear quarter lower casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 5 door.

13.Remove rear quarter upper casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - upper

- 5 door.

14.Remove loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - luggage compartment.

15.Remove rear body side glass.

+ SCREENS, REPAIRS, Glass - body

side - rear.

16.Release vehicle harness from 'E' post and

position aside.

17. LH side: Remove tail door striker.

18. RH side: Remove tail door.

+ DOORS, REPAIRS, Door - tail

assembly - remove for access & refit.

19. RH side: Remove fuel filler neck.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Filler neck.

20. RH side: Remove fuel tank.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Tank - Non NAS.

Page 812 of 1007

PANEL REPAIRS

REPAIRS 77-2-57

Repair

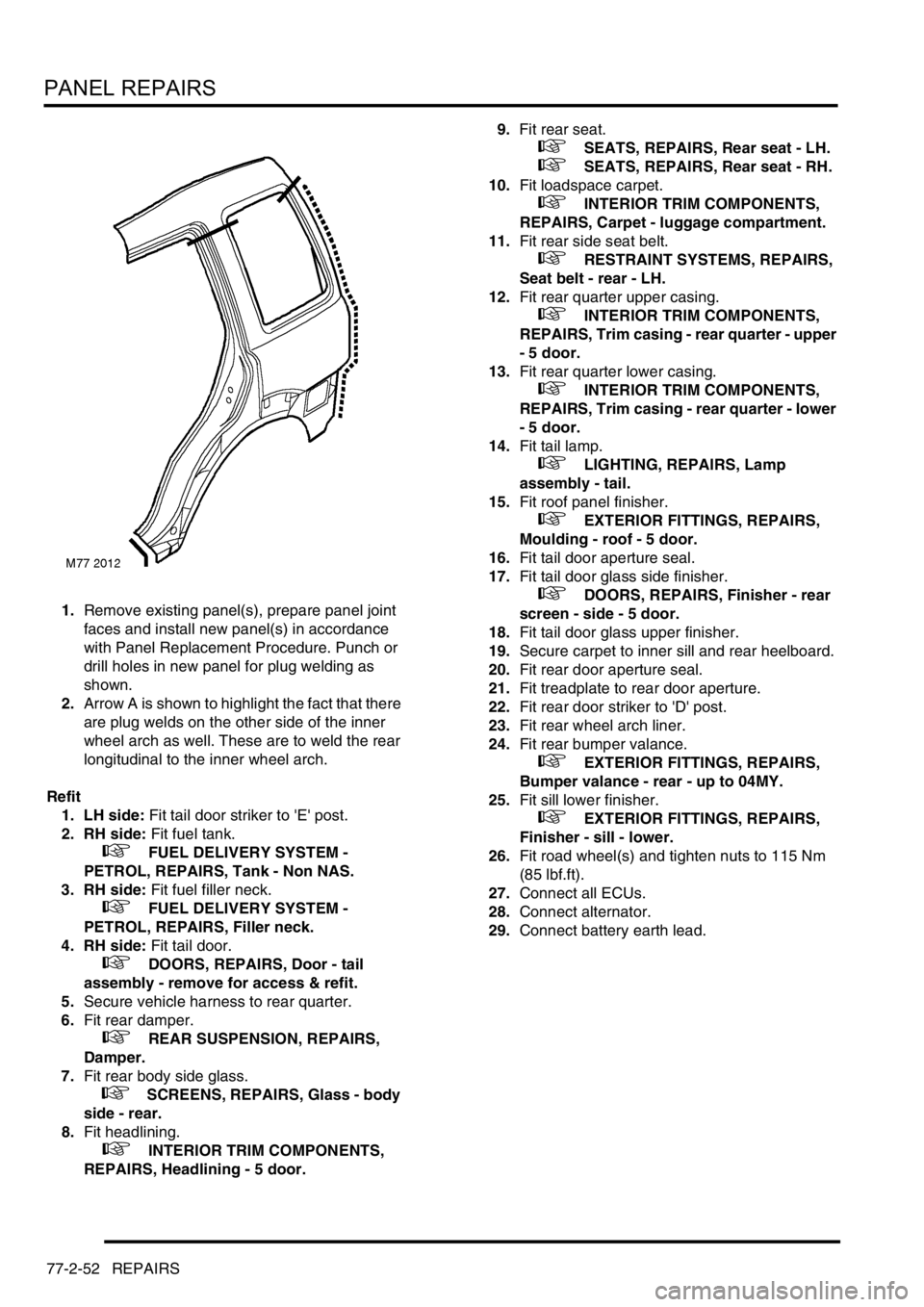

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown. Refit

1. LH side: Fit tail door striker.

2. RH side: Fit fuel tank.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Tank - Non NAS.

3. RH side: Fit fuel filler neck.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Filler neck.

4. RH side: Fit tail door.

+ DOORS, REPAIRS, Door - tail

assembly - remove for access & refit.

5.Secure vehicle harness to 'E' post.

6.Fit rear body side glass.

+ SCREENS, REPAIRS, Glass - body

side - rear.

7.Fit loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - luggage compartment.

8.Fit rear quarter upper casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - upper

- 5 door.

9.Fit rear quarter lower casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 5 door.

10.Fit tail door aperture seal.

11.Fit tail door glass side finisher.

+ DOORS, REPAIRS, Finisher - rear

screen - side - 5 door.

12.Fit tail door glass upper finisher.

13.Fit roof panel finisher.

+ DOORS, REPAIRS, Finisher - rear

screen - side - 5 door.

14.Fit tail lamp.

+ LIGHTING, REPAIRS, Lamp

assembly - tail.

15.Fit rear wheel arch liner.

16.Fit rear bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper valance - rear - up to 04MY.

17.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

18.Connect all ECUs.

19.Connect alternator.

20.Connect battery earth lead.

Page 816 of 1007

PANEL REPAIRS

REPAIRS 77-2-61

Front roof assembly - 3 door

Remove

1.Disconnect battery earth lead.

2.Disconnect alternator.

3.Disconnect all ECUs.

4.Remove LH and RH front roof panel finishers.

5.Remove headlining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining - 3 door.

6.Remove sunroof assembly.

+ SUNROOF, REPAIRS, Sun/sliding

roof - complete - front - 3 door.

7.Remove windscreen.

+ SCREENS, REPAIRS, Windscreen.

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. There are

no plug welds used in this procedure, spot

welds only.

Refit

1.Fit windscreen.

+ SCREENS, REPAIRS, Windscreen.

2.Fit sunroof.

+ SUNROOF, REPAIRS, Sun/sliding

roof - complete - front - 3 door.

3.Fit headlining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining - 3 door.

4.Fit LH and RH front roof panel finishers.

5.Connect all ECUs.

6.Connect alternator.

7.Connect battery earth lead.

Rear roof assembly - 3 door

Remove

1.Disconnect battery earth lead.

2.Disconnect alternator.

3.Disconnect all ECUs.

4.Remove soft/hard top.

5.Remove LH and RH rear roof panel finishers.

6.Remove headlining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining - 3 door.

7.Remove sunroof.

+ SUNROOF, REPAIRS, Sun/sliding

roof - complete - front - 3 door.

8.Remove aerial.

+ IN CAR ENTERTAINMENT,

REPAIRS, Aerial - manual - 3 door.

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. There are

no plug welds used in this procedure, spot

welds only.

Refit

1.Fit aerial.

+ IN CAR ENTERTAINMENT,

REPAIRS, Aerial - manual - 3 door.

2.Fit sunroof.

+ SUNROOF, REPAIRS, Sun/sliding

roof - complete - front - 3 door.

3.Fit headlining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining - 3 door.

4.Fit LH and RH rear roof panel finishers.

5.Fit soft/hard top.

6.Connect all ECUs.

7.Connect alternator.

8.Connect battery earth lead.

Page 817 of 1007

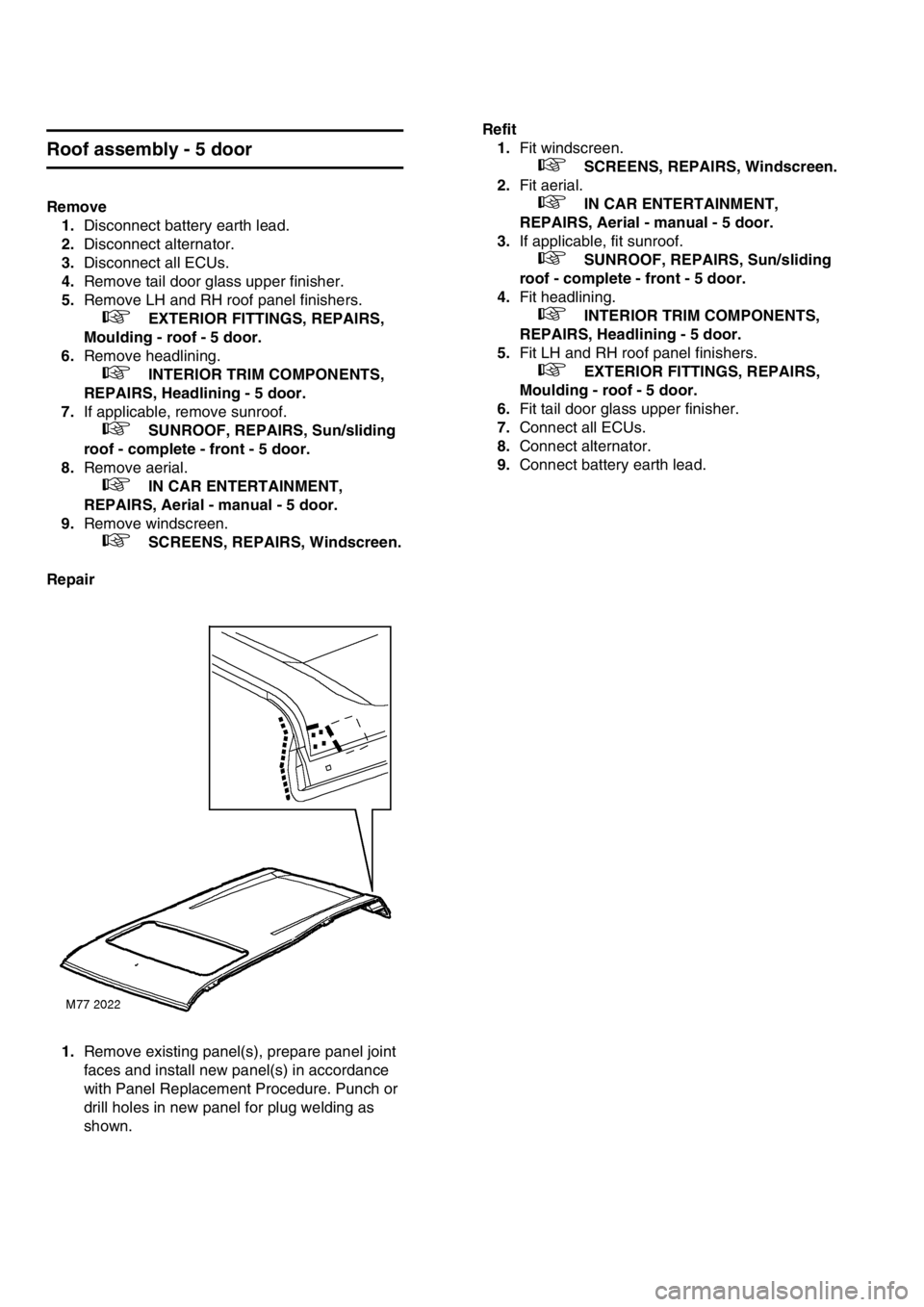

Roof assembly - 5 door

Remove

1.Disconnect battery earth lead.

2.Disconnect alternator.

3.Disconnect all ECUs.

4.Remove tail door glass upper finisher.

5.Remove LH and RH roof panel finishers.

+ EXTERIOR FITTINGS, REPAIRS,

Moulding - roof - 5 door.

6.Remove headlining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining - 5 door.

7.If applicable, remove sunroof.

+ SUNROOF, REPAIRS, Sun/sliding

roof - complete - front - 5 door.

8.Remove aerial.

+ IN CAR ENTERTAINMENT,

REPAIRS, Aerial - manual - 5 door.

9.Remove windscreen.

+ SCREENS, REPAIRS, Windscreen.

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown. Refit

1.Fit windscreen.

+ SCREENS, REPAIRS, Windscreen.

2.Fit aerial.

+ IN CAR ENTERTAINMENT,

REPAIRS, Aerial - manual - 5 door.

3.If applicable, fit sunroof.

+ SUNROOF, REPAIRS, Sun/sliding

roof - complete - front - 5 door.

4.Fit headlining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining - 5 door.

5.Fit LH and RH roof panel finishers.

+ EXTERIOR FITTINGS, REPAIRS,

Moulding - roof - 5 door.

6.Fit tail door glass upper finisher.

7.Connect all ECUs.

8.Connect alternator.

9.Connect battery earth lead.

Page 818 of 1007

PANEL REPAIRS

TIMES 77-2-63

TIME S

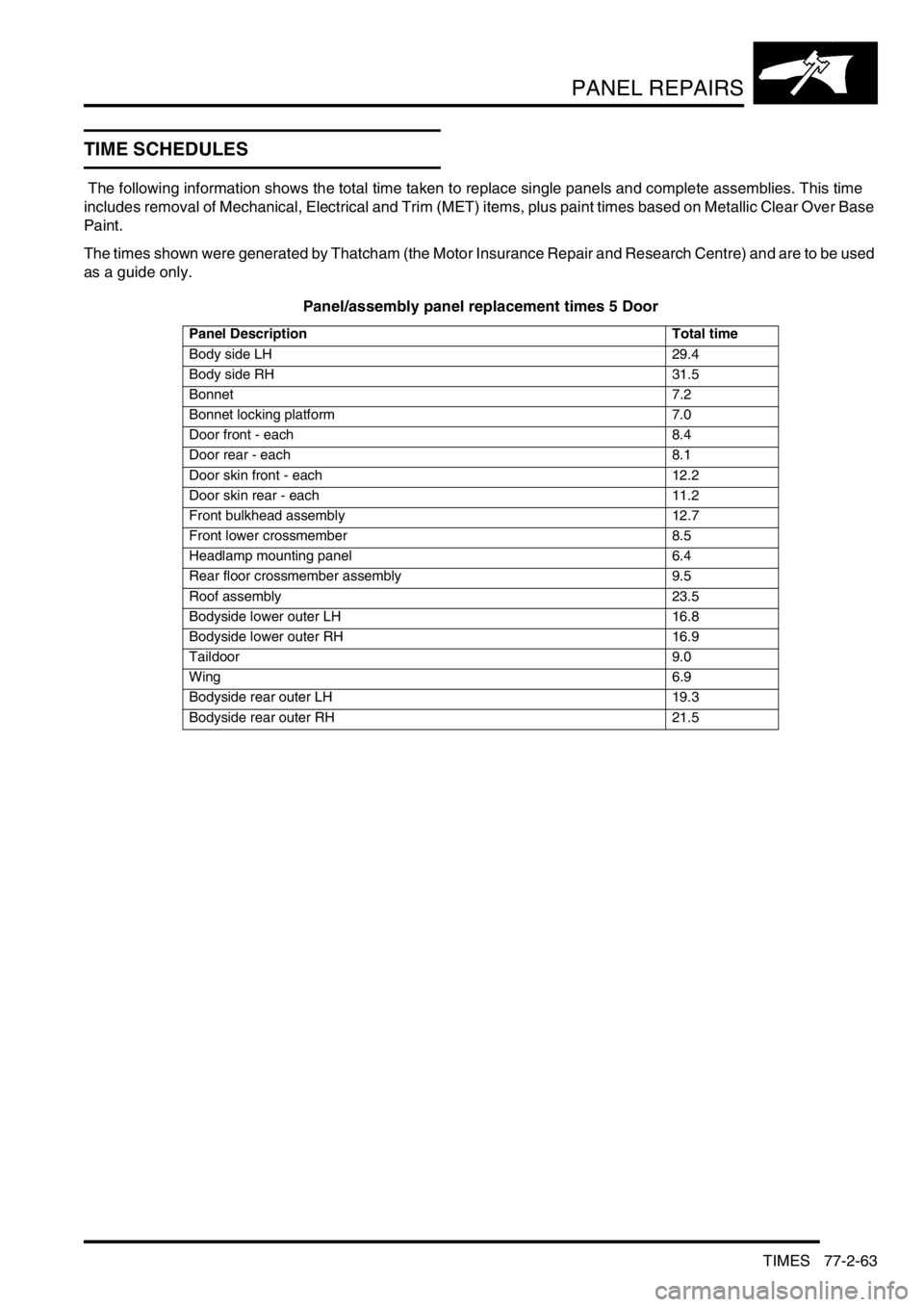

TIME SCHEDULES

The following information shows the total time taken to replace single panels and complete assemblies. This time

includes removal of Mechanical, Electrical and Trim (MET) items, plus paint times based on Metallic Clear Over Base

Paint.

The times shown were generated by Thatcham (the Motor Insurance Repair and Research Centre) and are to be used

as a guide only.

Panel/assembly panel replacement times 5 Door

Panel Description Total time

Body side LH 29.4

Body side RH 31.5

Bonnet 7.2

Bonnet locking platform 7.0

Door front - each 8.4

Door rear - each 8.1

Door skin front - each 12.2

Door skin rear - each 11.2

Front bulkhead assembly 12.7

Front lower crossmember 8.5

Headlamp mounting panel 6.4

Rear floor crossmember assembly 9.5

Roof assembly 23.5

Bodyside lower outer LH 16.8

Bodyside lower outer RH 16.9

Taildoor 9.0

Wing6.9

Bodyside rear outer LH 19.3

Bodyside rear outer RH 21.5

Page 821 of 1007

PANEL REPAIRS

77-2-66 TIMES

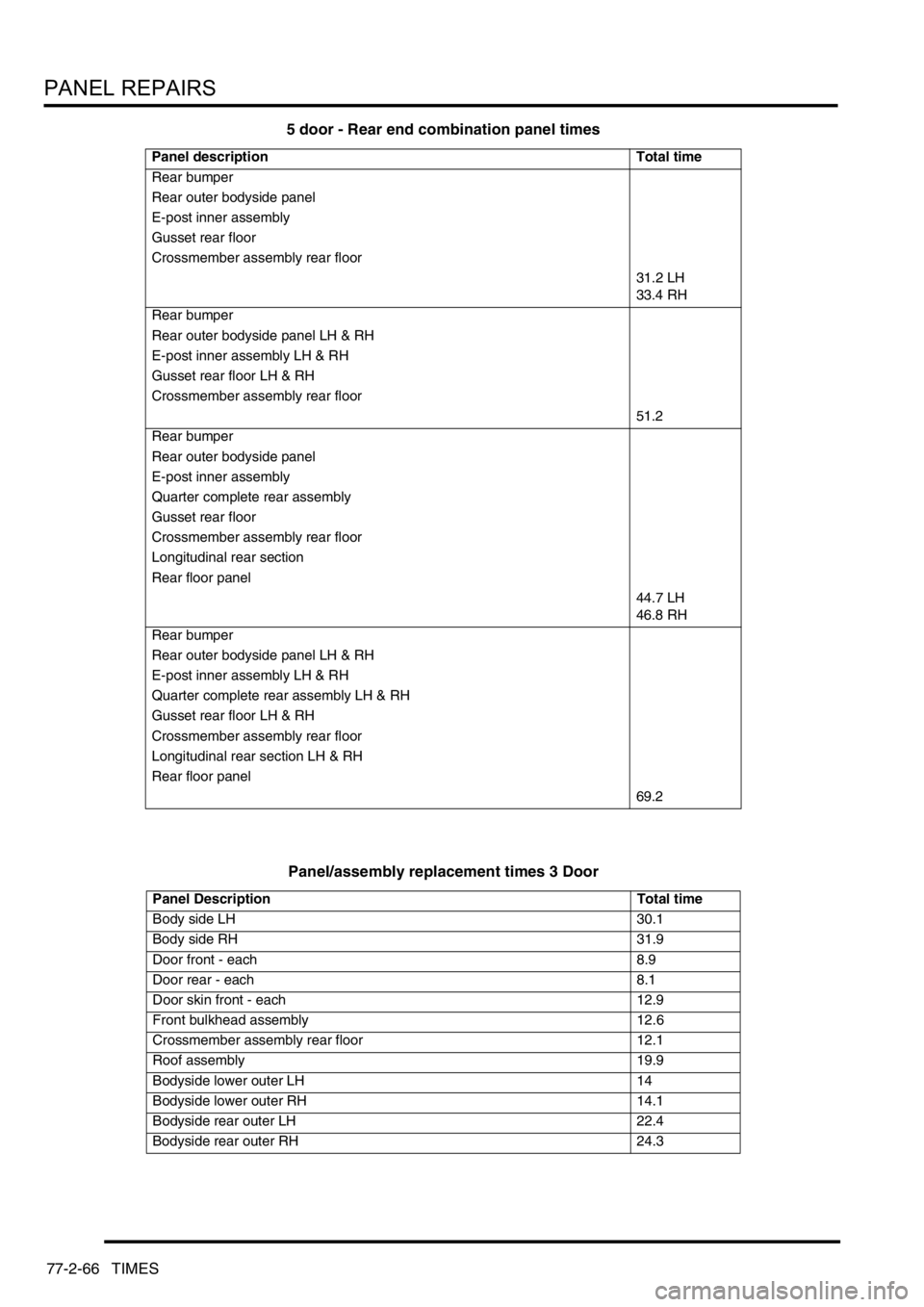

5 door - Rear end combination panel times

Panel/assembly replacement times 3 Door

Panel description Total time

Rear bumper

Rear outer bodyside panel

E-post inner assembly

Gusset rear floor

Crossmember assembly rear floor

31.2 LH

33.4 RH

Rear bumper

Rear outer bodyside panel LH & RH

E-post inner assembly LH & RH

Gusset rear floor LH & RH

Crossmember assembly rear floor

51.2

Rear bumper

Rear outer bodyside panel

E-post inner assembly

Quarter complete rear assembly

Gusset rear floor

Crossmember assembly rear floor

Longitudinal rear section

Rear floor panel

44.7 LH

46.8 RH

Rear bumper

Rear outer bodyside panel LH & RH

E-post inner assembly LH & RH

Quarter complete rear assembly LH & RH

Gusset rear floor LH & RH

Crossmember assembly rear floor

Longitudinal rear section LH & RH

Rear floor panel

69.2

Panel Description Total time

Body side LH 30.1

Body side RH 31.9

Door front - each 8.9

Door rear - each 8.1

Door skin front - each 12.9

Front bulkhead assembly 12.6

Crossmember assembly rear floor 12.1

Roof assembly 19.9

Bodyside lower outer LH 14

Bodyside lower outer RH 14.1

Bodyside rear outer LH 22.4

Bodyside rear outer RH 24.3

Page 846 of 1007

CORROSION PREVENTION AND SEALING

SEALING 77-4-15

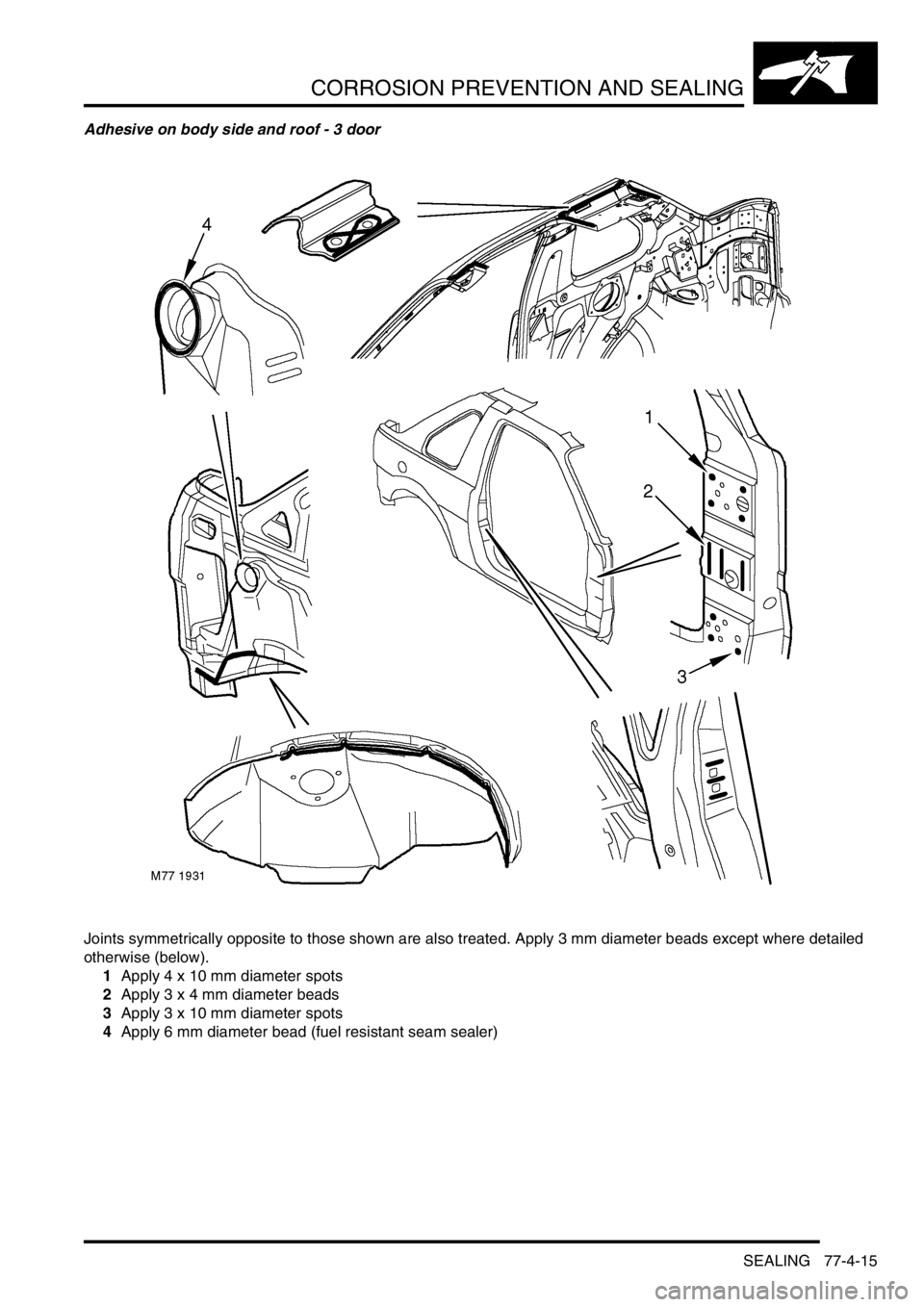

Adhesive on body side and roof - 3 door

Joints symmetrically opposite to those shown are also treated. Apply 3 mm diameter beads except where detailed

otherwise (below).

1Apply 4 x 10 mm diameter spots

2Apply 3 x 4 mm diameter beads

3Apply 3 x 10 mm diameter spots

4Apply 6 mm diameter bead (fuel resistant seam sealer)

Page 848 of 1007

CORROSION PREVENTION AND SEALING

SEALING 77-4-17

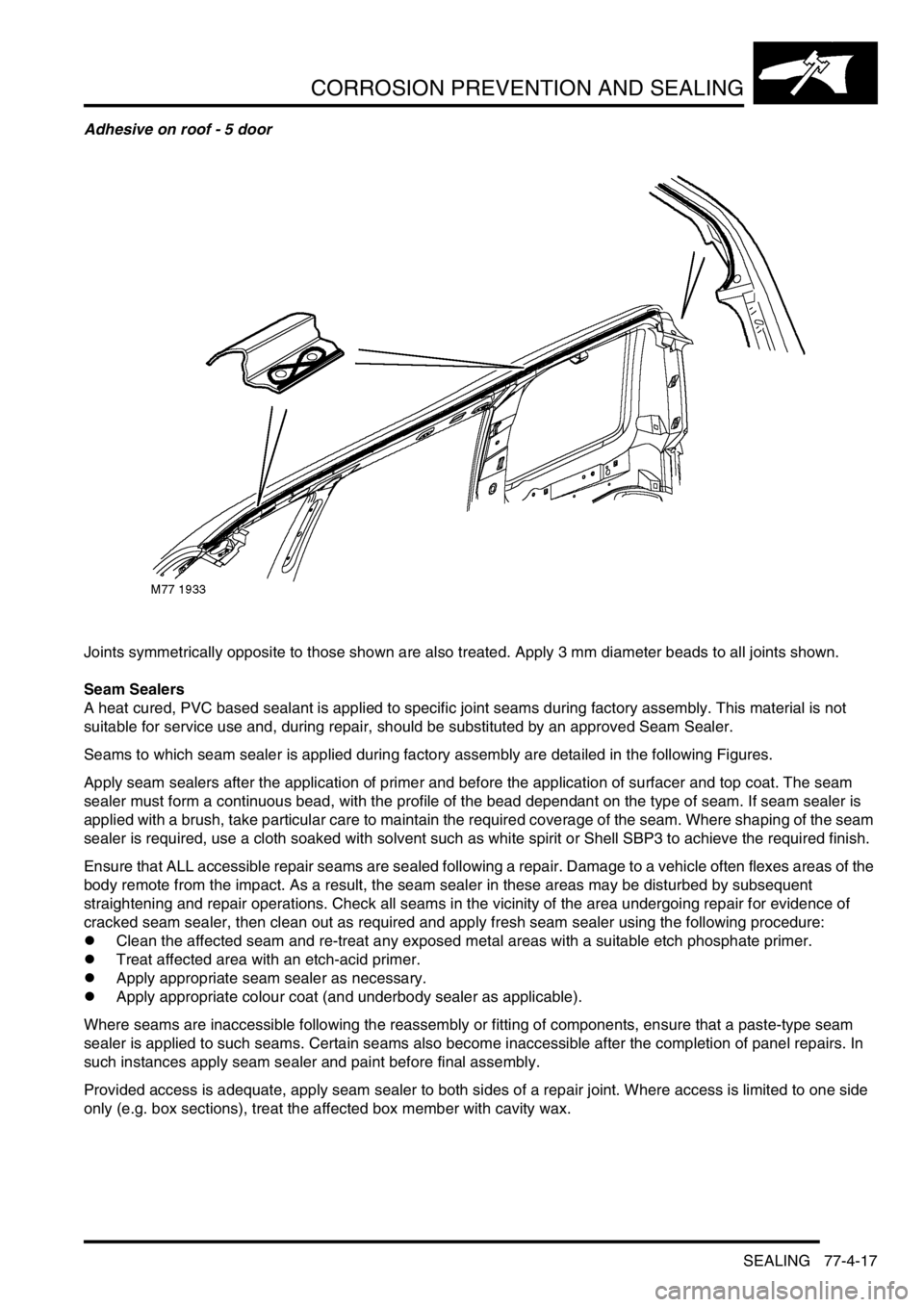

Adhesive on roof - 5 door

Joints symmetrically opposite to those shown are also treated. Apply 3 mm diameter beads to all joints shown.

Seam Sealers

A heat cured, PVC based sealant is applied to specific joint seams during factory assembly. This material is not

suitable for service use and, during repair, should be substituted by an approved Seam Sealer.

Seams to which seam sealer is applied during factory assembly are detailed in the following Figures.

Apply seam sealers after the application of primer and before the application of surfacer and top coat. The seam

sealer must form a continuous bead, with the profile of the bead dependant on the type of seam. If seam sealer is

applied with a brush, take particular care to maintain the required coverage of the seam. Where shaping of the seam

sealer is required, use a cloth soaked with solvent such as white spirit or Shell SBP3 to achieve the required finish.

Ensure that ALL accessible repair seams are sealed following a repair. Damage to a vehicle often flexes areas of the

body remote from the impact. As a result, the seam sealer in these areas may be disturbed by subsequent

straightening and repair operations. Check all seams in the vicinity of the area undergoing repair for evidence of

cracked seam sealer, then clean out as required and apply fresh seam sealer using the following procedure:

lClean the affected seam and re-treat any exposed metal areas with a suitable etch phosphate primer.

lTreat affected area with an etch-acid primer.

lApply appropriate seam sealer as necessary.

lApply appropriate colour coat (and underbody sealer as applicable).

Where seams are inaccessible following the reassembly or fitting of components, ensure that a paste-type seam

sealer is applied to such seams. Certain seams also become inaccessible after the completion of panel repairs. In

such instances apply seam sealer and paint before final assembly.

Provided access is adequate, apply seam sealer to both sides of a repair joint. Where access is limited to one side

only (e.g. box sections), treat the affected box member with cavity wax.