ECU LAND ROVER FREELANDER 2001 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 222 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-45

Arm assembly - engine mounting RH

$% 12.45.06

Remove

1.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

2.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

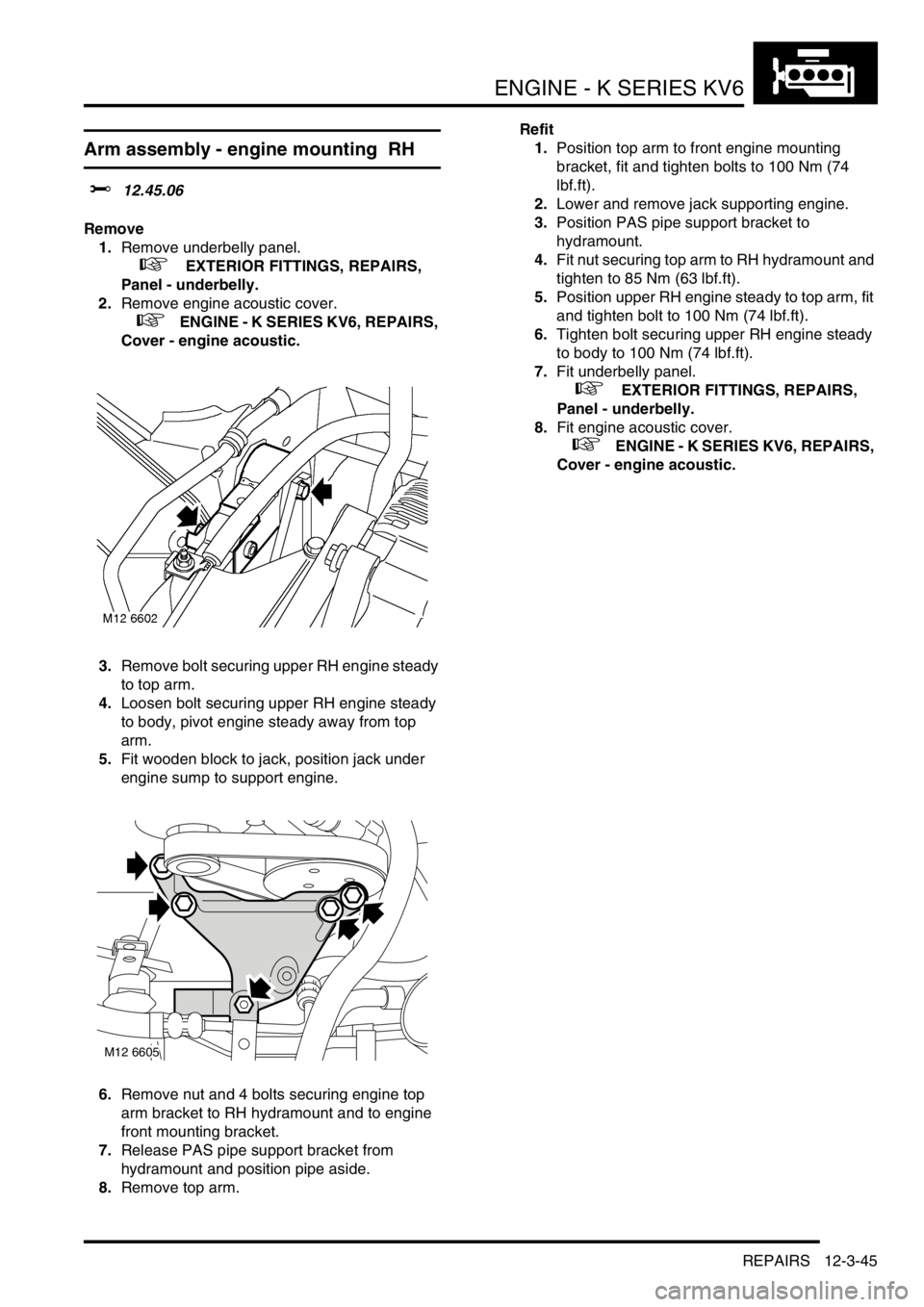

3.Remove bolt securing upper RH engine steady

to top arm.

4.Loosen bolt securing upper RH engine steady

to body, pivot engine steady away from top

arm.

5.Fit wooden block to jack, position jack under

engine sump to support engine.

6.Remove nut and 4 bolts securing engine top

arm bracket to RH hydramount and to engine

front mounting bracket.

7.Release PAS pipe support bracket from

hydramount and position pipe aside.

8.Remove top arm.Refit

1.Position top arm to front engine mounting

bracket, fit and tighten bolts to 100 Nm (74

lbf.ft).

2.Lower and remove jack supporting engine.

3.Position PAS pipe support bracket to

hydramount.

4.Fit nut securing top arm to RH hydramount and

tighten to 85 Nm (63 lbf.ft).

5.Position upper RH engine steady to top arm, fit

and tighten bolt to 100 Nm (74 lbf.ft).

6.Tighten bolt securing upper RH engine steady

to body to 100 Nm (74 lbf.ft).

7.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

8.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

M12 6605

Page 223 of 1007

ENGINE - K SERIES KV6

12-3-46 REPAIRS

Engine mounting - LH

$% 12.45.11

Remove

1.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Remove battery carrier.

+ CHARGING AND STARTING,

REPAIRS, Carrier - battery.

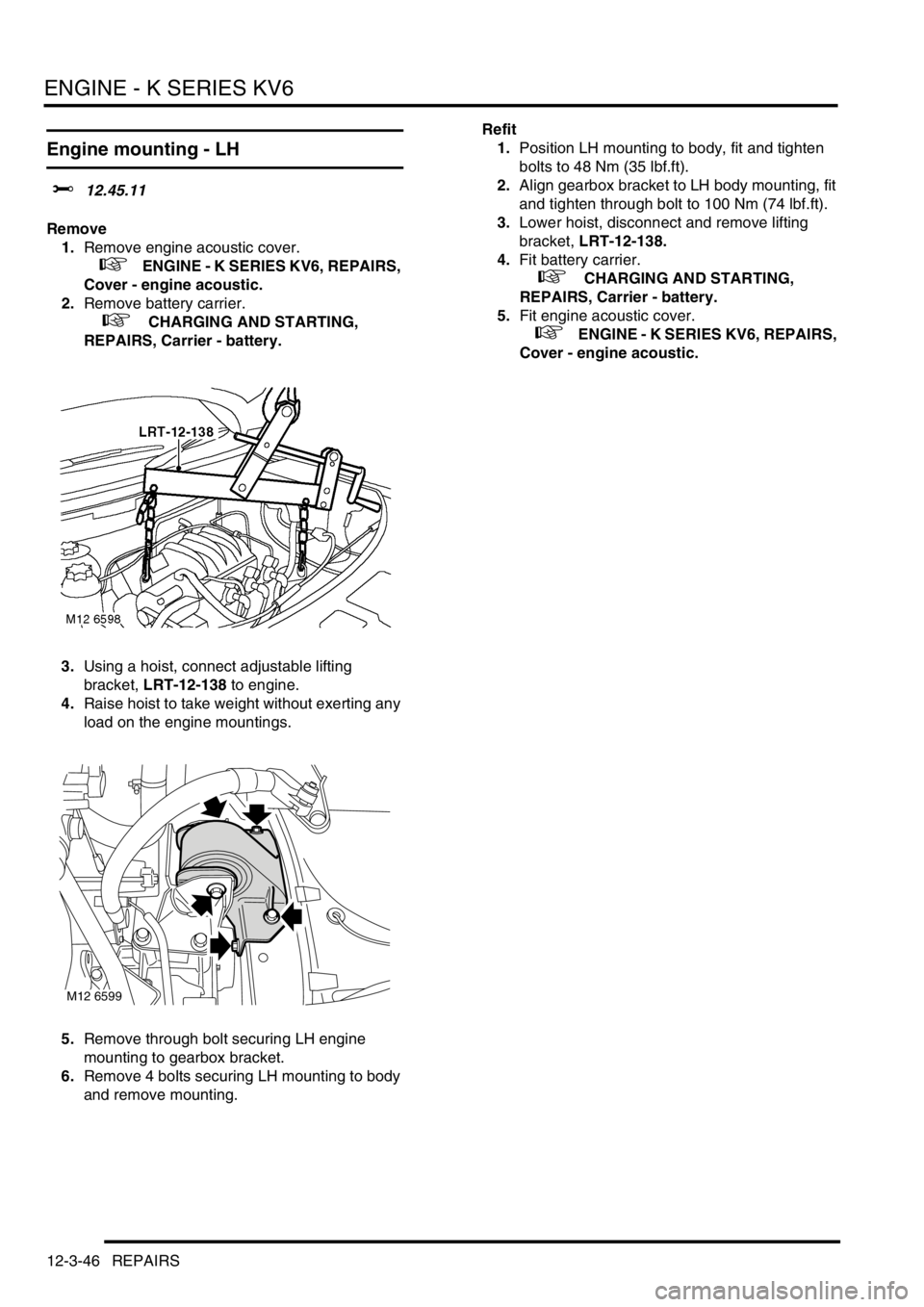

3.Using a hoist, connect adjustable lifting

bracket, LRT-12-138 to engine.

4.Raise hoist to take weight without exerting any

load on the engine mountings.

5.Remove through bolt securing LH engine

mounting to gearbox bracket.

6.Remove 4 bolts securing LH mounting to body

and remove mounting.Refit

1.Position LH mounting to body, fit and tighten

bolts to 48 Nm (35 lbf.ft).

2.Align gearbox bracket to LH body mounting, fit

and tighten through bolt to 100 Nm (74 lbf.ft).

3.Lower hoist, disconnect and remove lifting

bracket, LRT-12-138.

4.Fit battery carrier.

+ CHARGING AND STARTING,

REPAIRS, Carrier - battery.

5.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

M12 6599

Page 224 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-47

Hydramount - engine - RH

$% 12.45.12

Remove

1.Remove top arm.

+ ENGINE - K SERIES KV6, REPAIRS,

Arm assembly - engine mounting RH.

2.Position 3 pegs on LRT-12-169 into 3 slots in

hydramount.

3.Connect a suitable socket bar to LRT-12-169,

loosen and remove hydramount and LRT-12-

169.

Refit

1.Clean hydramount and body mating faces.

2.Position hydramount to body.

3.Position 3 pegs on LRT-12-169 into 3 slots in

hydramount.

4.Tighten hydramount to 85 Nm (63 lbf.ft).

5.Fit top arm.

+ ENGINE - K SERIES KV6, REPAIRS,

Arm assembly - engine mounting RH.

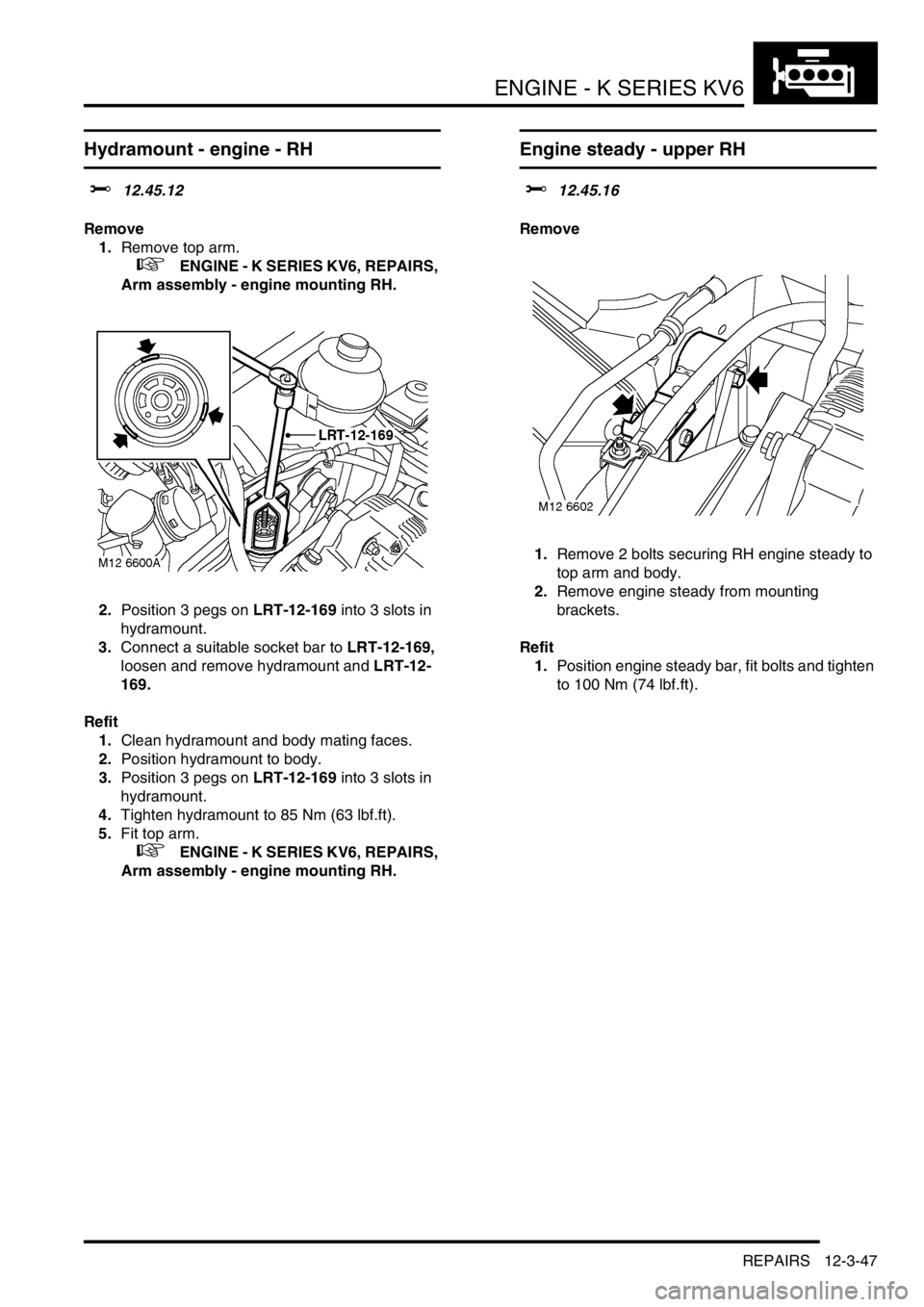

Engine steady - upper RH

$% 12.45.16

Remove

1.Remove 2 bolts securing RH engine steady to

top arm and body.

2.Remove engine steady from mounting

brackets.

Refit

1.Position engine steady bar, fit bolts and tighten

to 100 Nm (74 lbf.ft).

Page 225 of 1007

ENGINE - K SERIES KV6

12-3-48 REPAIRS

Engine steady - lower

$% 12.45.17

Remove

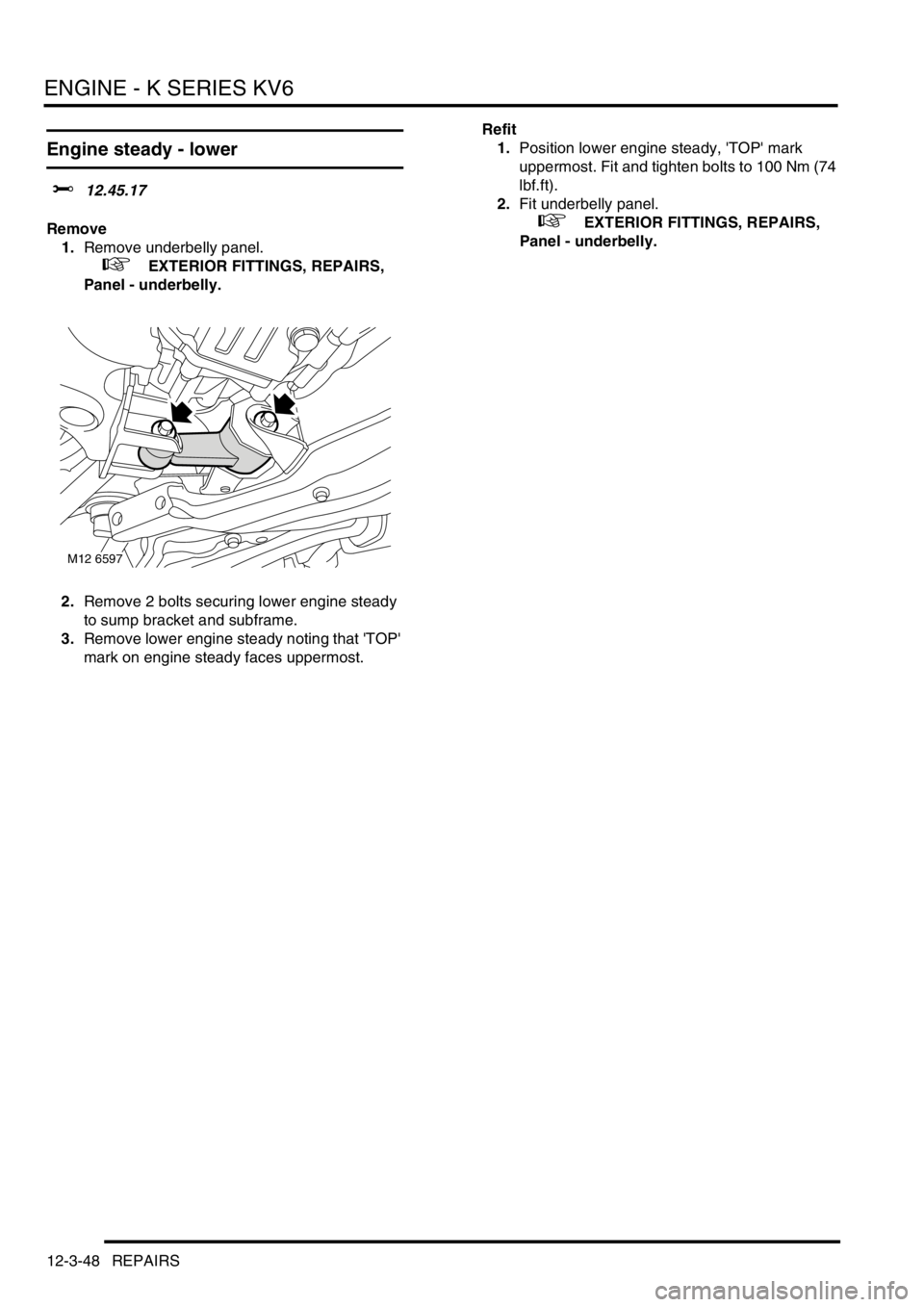

1.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

2.Remove 2 bolts securing lower engine steady

to sump bracket and subframe.

3.Remove lower engine steady noting that 'TOP'

mark on engine steady faces uppermost.Refit

1.Position lower engine steady, 'TOP' mark

uppermost. Fit and tighten bolts to 100 Nm (74

lbf.ft).

2.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

M12 6597

Page 226 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-49

Torque converter drive plate

$% 12.53.13

Remove

1.Remove automatic gearbox.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Gearbox - KV6.

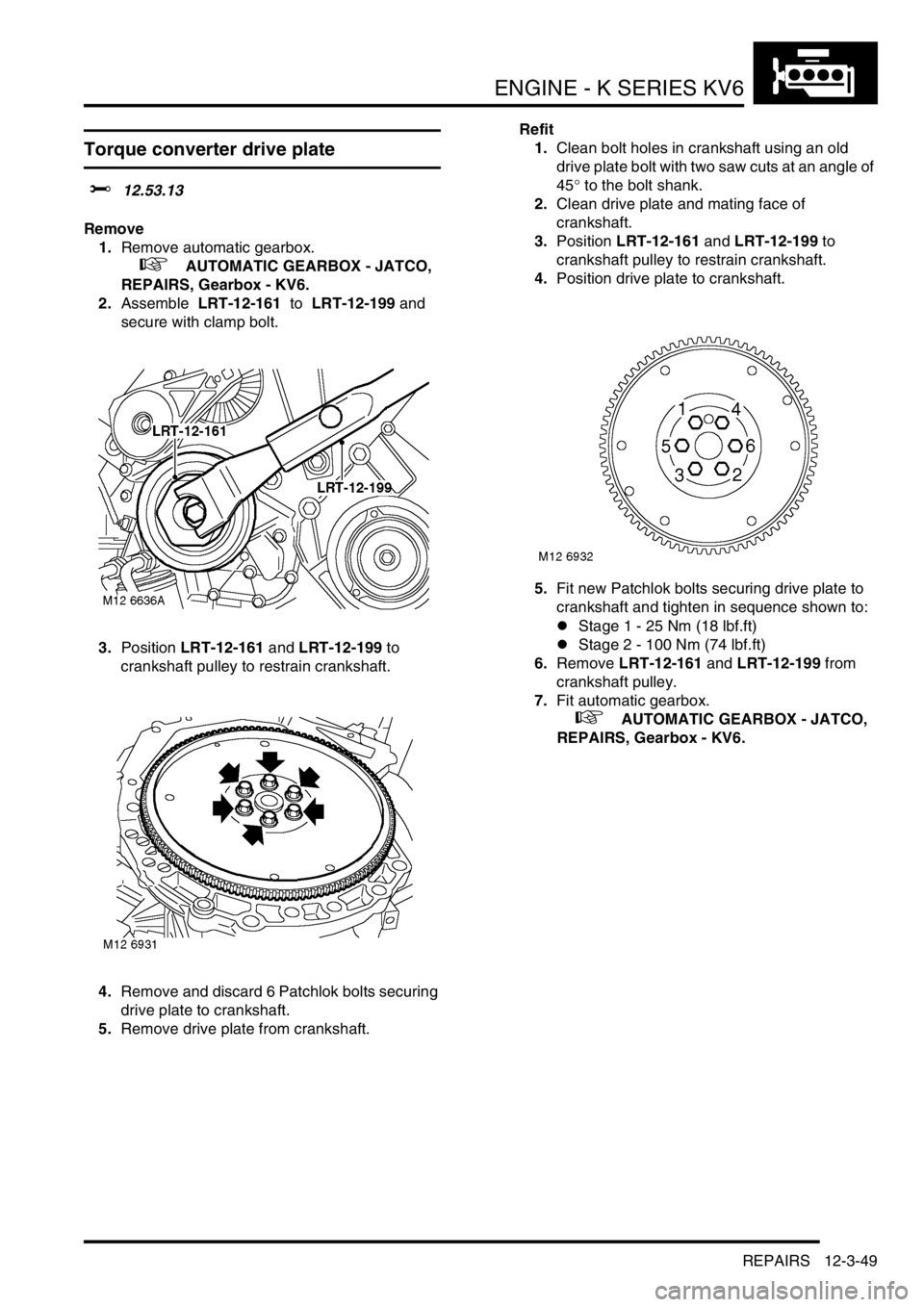

2.Assemble LRT-12-161 to LRT-12-199 and

secure with clamp bolt.

3.Position LRT-12-161 and LRT-12-199 to

crankshaft pulley to restrain crankshaft.

4.Remove and discard 6 Patchlok bolts securing

drive plate to crankshaft.

5.Remove drive plate from crankshaft.Refit

1.Clean bolt holes in crankshaft using an old

drive plate bolt with two saw cuts at an angle of

45° to the bolt shank.

2.Clean drive plate and mating face of

crankshaft.

3.Position LRT-12-161 and LRT-12-199 to

crankshaft pulley to restrain crankshaft.

4.Position drive plate to crankshaft.

5.Fit new Patchlok bolts securing drive plate to

crankshaft and tighten in sequence shown to:

lStage 1 - 25 Nm (18 lbf.ft)

lStage 2 - 100 Nm (74 lbf.ft)

6.Remove LRT-12-161 and LRT-12-199 from

crankshaft pulley.

7.Fit automatic gearbox.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Gearbox - KV6.

Page 228 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-51

Gasket - oil pump

$% 12.60.25

Remove

1.Disconnect battery earth lead.

2.Drain engine oil.

+ MAINTENANCE, MAINTENANCE,

Engine Oil and Filter – KV6.

3.Remove camshaft timing belt.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft timing belt.

4.Remove crankshaft gear.

5.Disconnect multiplug from oil pressure switch.

6.Loosen and remove oil cooler pipe unions from

oil filter housing, remove and discard 2 'O'

rings.

7.Using strap wrench, remove and discard oil

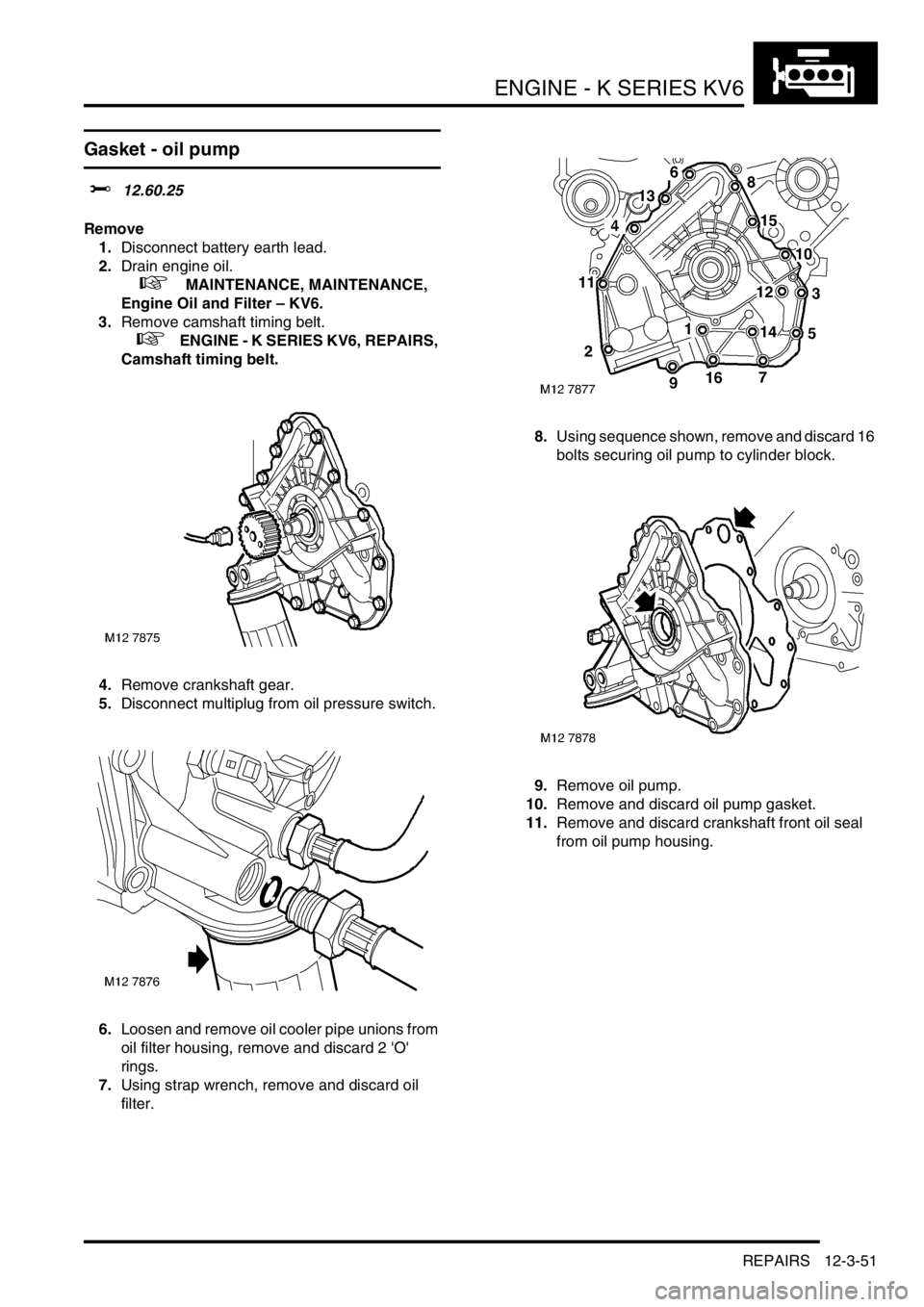

filter.8.Using sequence shown, remove and discard 16

bolts securing oil pump to cylinder block.

9.Remove oil pump.

10.Remove and discard oil pump gasket.

11.Remove and discard crankshaft front oil seal

from oil pump housing.

Page 230 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-53

Sump - reseal

$% 12.60.38

Remove

1.Disconnect battery earth lead.

2.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Drain engine oil.

+ MAINTENANCE, MAINTENANCE,

Engine Oil and Filter – KV6.

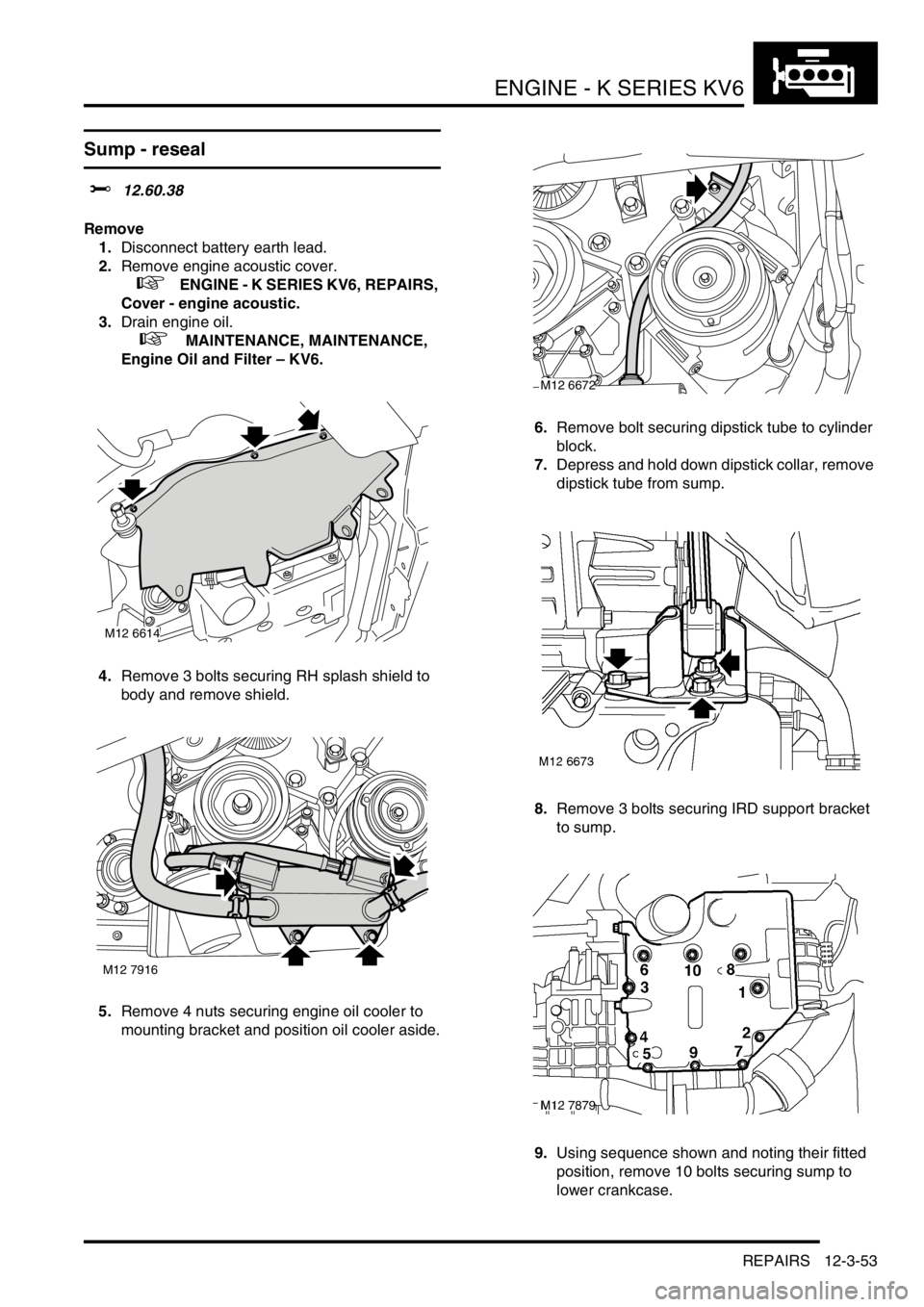

4.Remove 3 bolts securing RH splash shield to

body and remove shield.

5.Remove 4 nuts securing engine oil cooler to

mounting bracket and position oil cooler aside.6.Remove bolt securing dipstick tube to cylinder

block.

7.Depress and hold down dipstick collar, remove

dipstick tube from sump.

8.Remove 3 bolts securing IRD support bracket

to sump.

9.Using sequence shown and noting their fitted

position, remove 10 bolts securing sump to

lower crankcase.

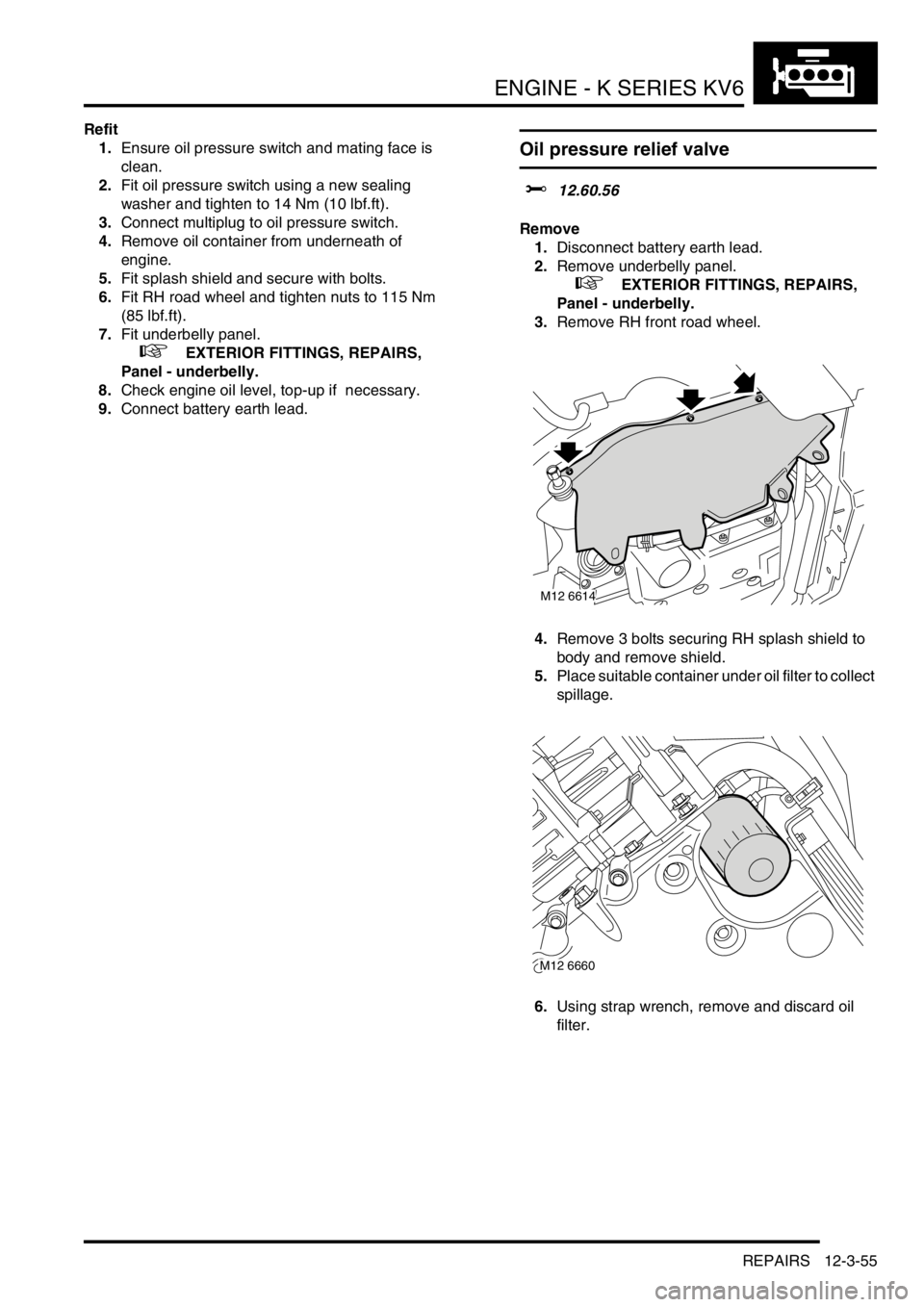

M12 6614

M12 7916

M12 6672

Page 231 of 1007

ENGINE - K SERIES KV6

12-3-54 REPAIRS

10.Using a mallet, gently tap sump sideways to

break sealant bond, remove sump.

CAUTION: Do not lever between sump and

lower crankcase.

Refit

1.Using a suitable cleaning solvent, clean sump

and mating face on lower crankcase. DO NOT

use a metal scraper on sealing surfaces.

2.Apply a 2 mm (0.1 in) bead of sealant, Part No.

STC 4600 along centre of sump flange, then

spread to an even film using a roller.

CAUTION: To avoid contamination,

assembly must be completed immediately

after application of sealant.

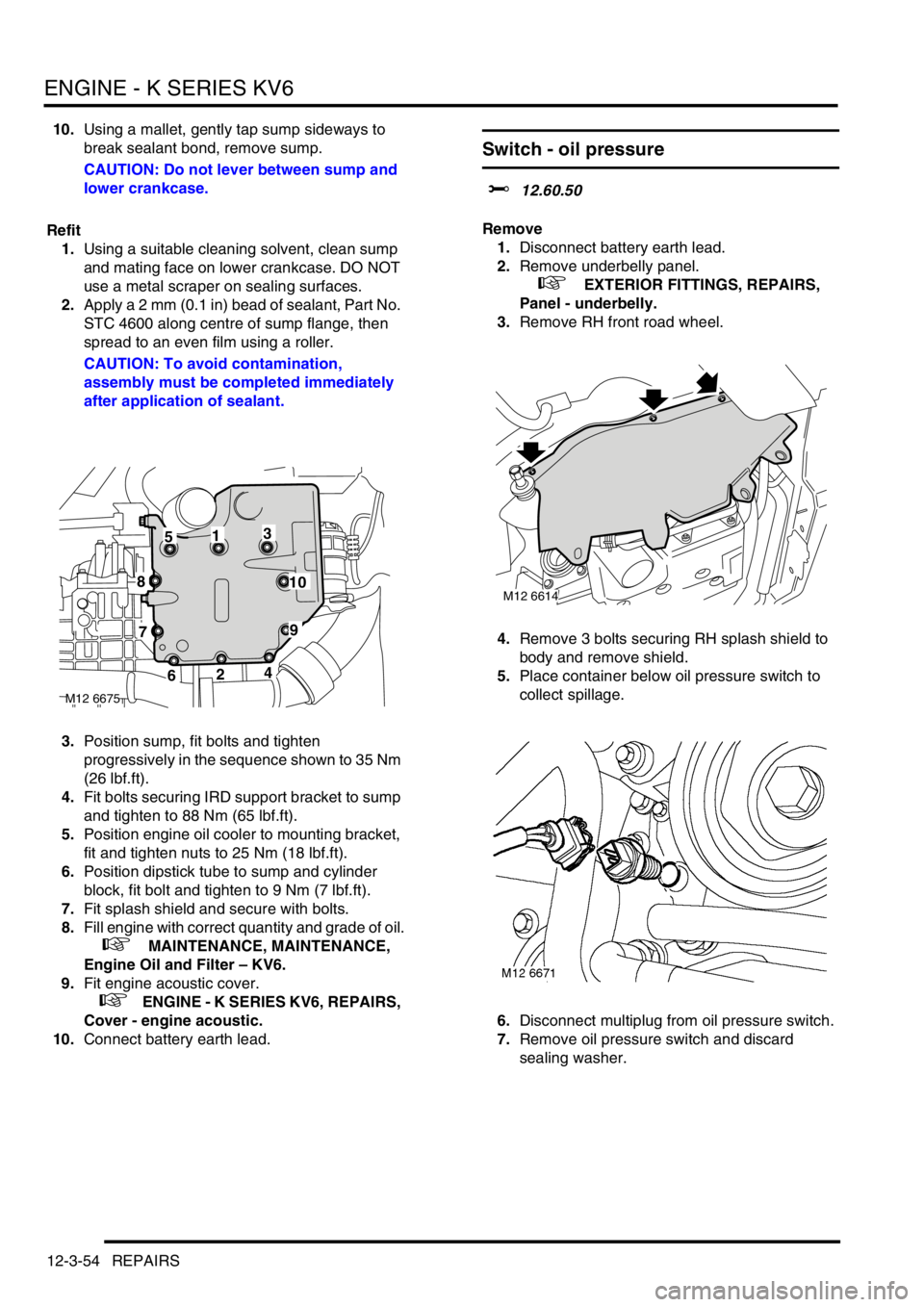

3.Position sump, fit bolts and tighten

progressively in the sequence shown to 35 Nm

(26 lbf.ft).

4.Fit bolts securing IRD support bracket to sump

and tighten to 88 Nm (65 lbf.ft).

5.Position engine oil cooler to mounting bracket,

fit and tighten nuts to 25 Nm (18 lbf.ft).

6.Position dipstick tube to sump and cylinder

block, fit bolt and tighten to 9 Nm (7 lbf.ft).

7.Fit splash shield and secure with bolts.

8.Fill engine with correct quantity and grade of oil.

+ MAINTENANCE, MAINTENANCE,

Engine Oil and Filter – KV6.

9.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

10.Connect battery earth lead.

Switch - oil pressure

$% 12.60.50

Remove

1.Disconnect battery earth lead.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Remove RH front road wheel.

4.Remove 3 bolts securing RH splash shield to

body and remove shield.

5.Place container below oil pressure switch to

collect spillage.

6.Disconnect multiplug from oil pressure switch.

7.Remove oil pressure switch and discard

sealing washer.

M12 6675

10

9

135

8

4

7

26

M12 6614

Page 232 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-55

Refit

1.Ensure oil pressure switch and mating face is

clean.

2.Fit oil pressure switch using a new sealing

washer and tighten to 14 Nm (10 lbf.ft).

3.Connect multiplug to oil pressure switch.

4.Remove oil container from underneath of

engine.

5.Fit splash shield and secure with bolts.

6.Fit RH road wheel and tighten nuts to 115 Nm

(85 lbf.ft).

7.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

8.Check engine oil level, top-up if necessary.

9.Connect battery earth lead.

Oil pressure relief valve

$% 12.60.56

Remove

1.Disconnect battery earth lead.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Remove RH front road wheel.

4.Remove 3 bolts securing RH splash shield to

body and remove shield.

5.Place suitable container under oil filter to collect

spillage.

6.Using strap wrench, remove and discard oil

filter.

M12 6614

M12 6660

Page 233 of 1007

ENGINE - K SERIES KV6

12-3-56 REPAIRS

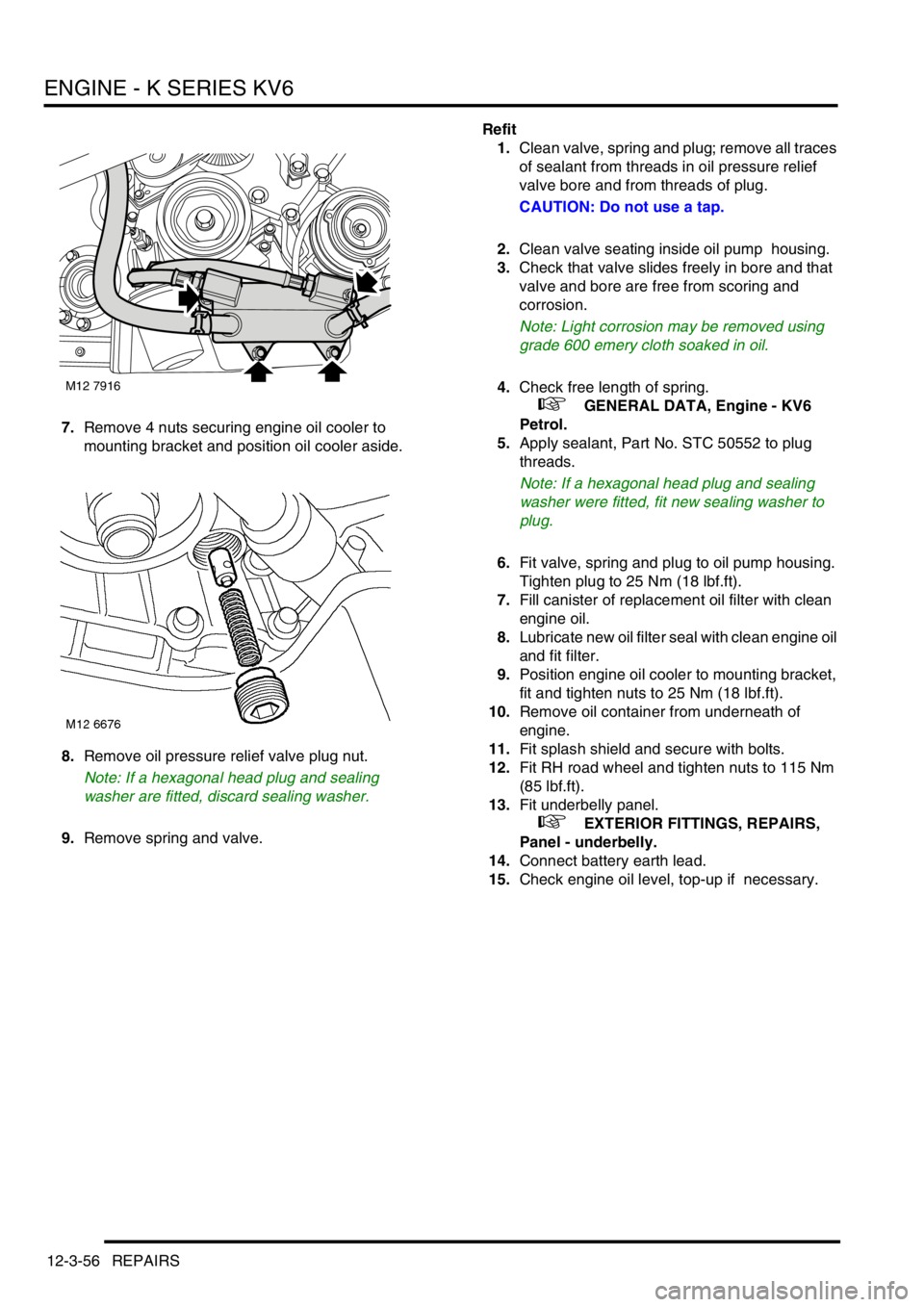

7.Remove 4 nuts securing engine oil cooler to

mounting bracket and position oil cooler aside.

8.Remove oil pressure relief valve plug nut.

Note: If a hexagonal head plug and sealing

washer are fitted, discard sealing washer.

9.Remove spring and valve.Refit

1.Clean valve, spring and plug; remove all traces

of sealant from threads in oil pressure relief

valve bore and from threads of plug.

CAUTION: Do not use a tap.

2.Clean valve seating inside oil pump housing.

3.Check that valve slides freely in bore and that

valve and bore are free from scoring and

corrosion.

Note: Light corrosion may be removed using

grade 600 emery cloth soaked in oil.

4.Check free length of spring.

+ GENERAL DATA, Engine - KV6

Petrol.

5.Apply sealant, Part No. STC 50552 to plug

threads.

Note: If a hexagonal head plug and sealing

washer were fitted, fit new sealing washer to

plug.

6.Fit valve, spring and plug to oil pump housing.

Tighten plug to 25 Nm (18 lbf.ft).

7.Fill canister of replacement oil filter with clean

engine oil.

8.Lubricate new oil filter seal with clean engine oil

and fit filter.

9.Position engine oil cooler to mounting bracket,

fit and tighten nuts to 25 Nm (18 lbf.ft).

10.Remove oil container from underneath of

engine.

11.Fit splash shield and secure with bolts.

12.Fit RH road wheel and tighten nuts to 115 Nm

(85 lbf.ft).

13.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

14.Connect battery earth lead.

15.Check engine oil level, top-up if necessary.

M12 7916