warning LAND ROVER FREELANDER 2001 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 431 of 1007

INTERMEDIATE REDUCTION DRIVE

41-28 REPAIRS

Seal - pinion gear housing - KV6 - Non

NAS

$% 41.29.11

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Drain fluid from IRD.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

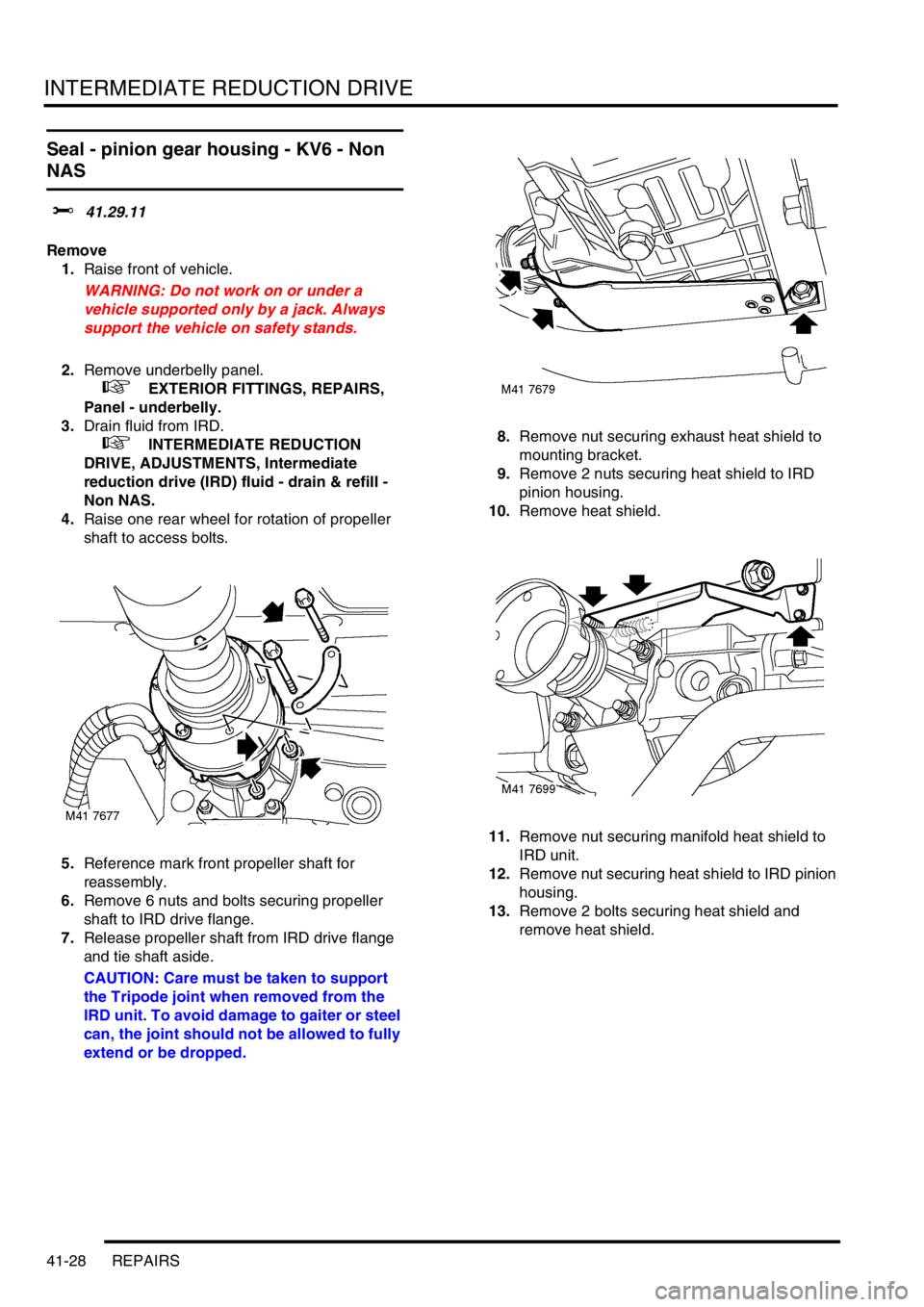

4.Raise one rear wheel for rotation of propeller

shaft to access bolts.

5.Reference mark front propeller shaft for

reassembly.

6.Remove 6 nuts and bolts securing propeller

shaft to IRD drive flange.

7.Release propeller shaft from IRD drive flange

and tie shaft aside.

CAUTION: Care must be taken to support

the Tripode joint when removed from the

IRD unit. To avoid damage to gaiter or steel

can, the joint should not be allowed to fully

extend or be dropped.8.Remove nut securing exhaust heat shield to

mounting bracket.

9.Remove 2 nuts securing heat shield to IRD

pinion housing.

10.Remove heat shield.

11.Remove nut securing manifold heat shield to

IRD unit.

12.Remove nut securing heat shield to IRD pinion

housing.

13.Remove 2 bolts securing heat shield and

remove heat shield.

Page 433 of 1007

INTERMEDIATE REDUCTION DRIVE

41-30 REPAIRS

Seal - pinion gear housing - KV6 - NAS

$% 41.29.11

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Remove front exhaust pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - NAS.

4.Drain fluid from IRD.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) lubrication system -

drain & refill - NAS.

5.Raise one rear wheel for rotation of propeller

shaft to access bolts.

6.Reference mark front propeller shaft for

reassembly.

7.Remove 6 nuts and bolts securing propeller

shaft to IRD drive flange.

8.Release propeller shaft from IRD drive flange

and tie shaft aside.

CAUTION: Care must be taken to support

the Tripode joint when removed from the

IRD unit. To avoid damage to gaiter or steel

can, the joint should not be allowed to fully

extend or be dropped.

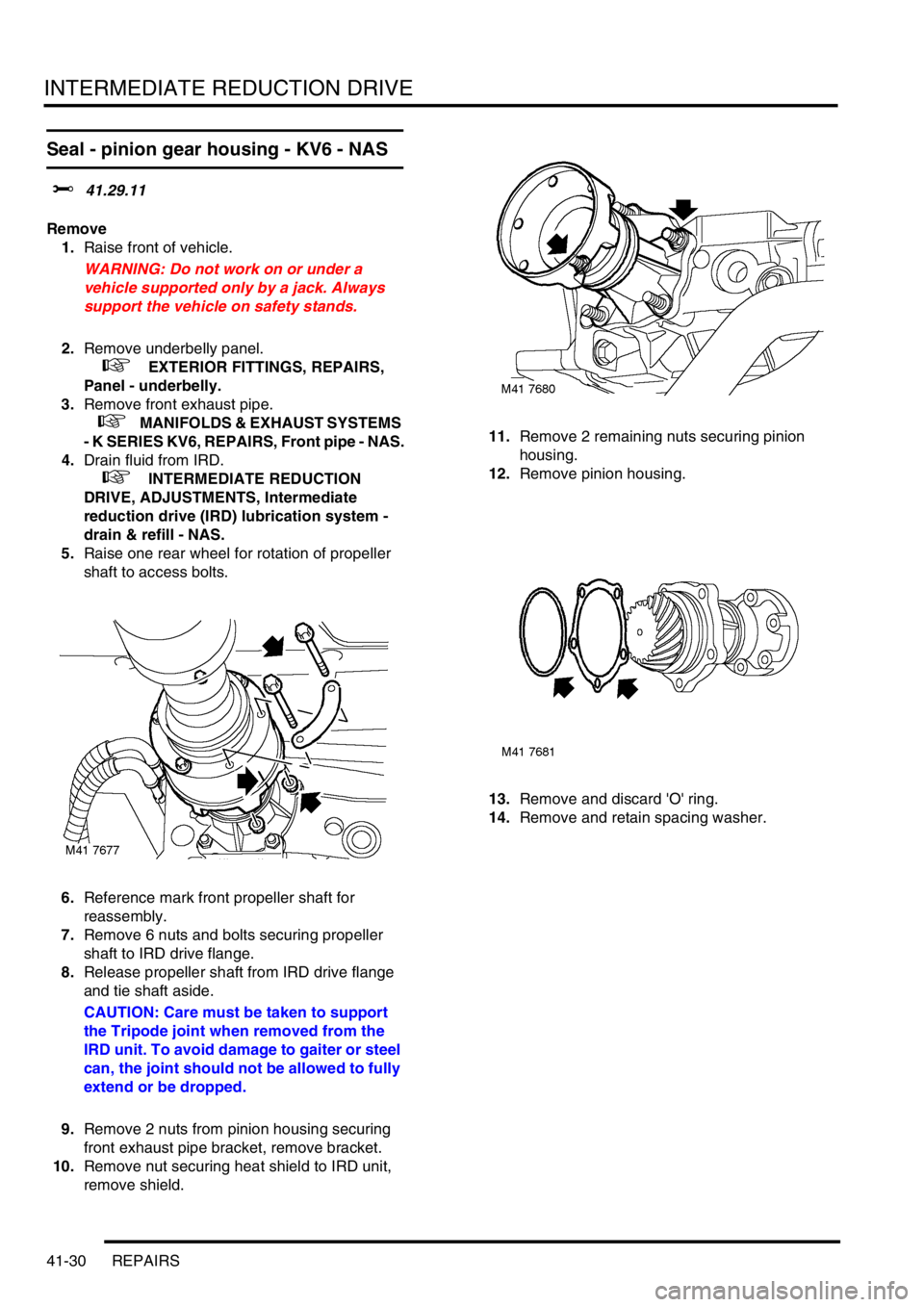

9.Remove 2 nuts from pinion housing securing

front exhaust pipe bracket, remove bracket.

10.Remove nut securing heat shield to IRD unit,

remove shield.11.Remove 2 remaining nuts securing pinion

housing.

12.Remove pinion housing.

13.Remove and discard 'O' ring.

14.Remove and retain spacing washer.

Page 437 of 1007

AUTOMATIC GEARBOX - JATCO

44-2 ADJUSTMENTS

Gearbox fluid - drain & refill

$% 44.24.02

Drain

1.Position vehicle on ramp.

WARNING: Observe due care when draining

gearbox fluid as the fluid can be very hot.

2.Apply handbrake and position chocks under

front and rear wheels.

3.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

4.Position container under gearbox.

NOTE: The fluid should be drained with the

transmission at normal operating temperature.

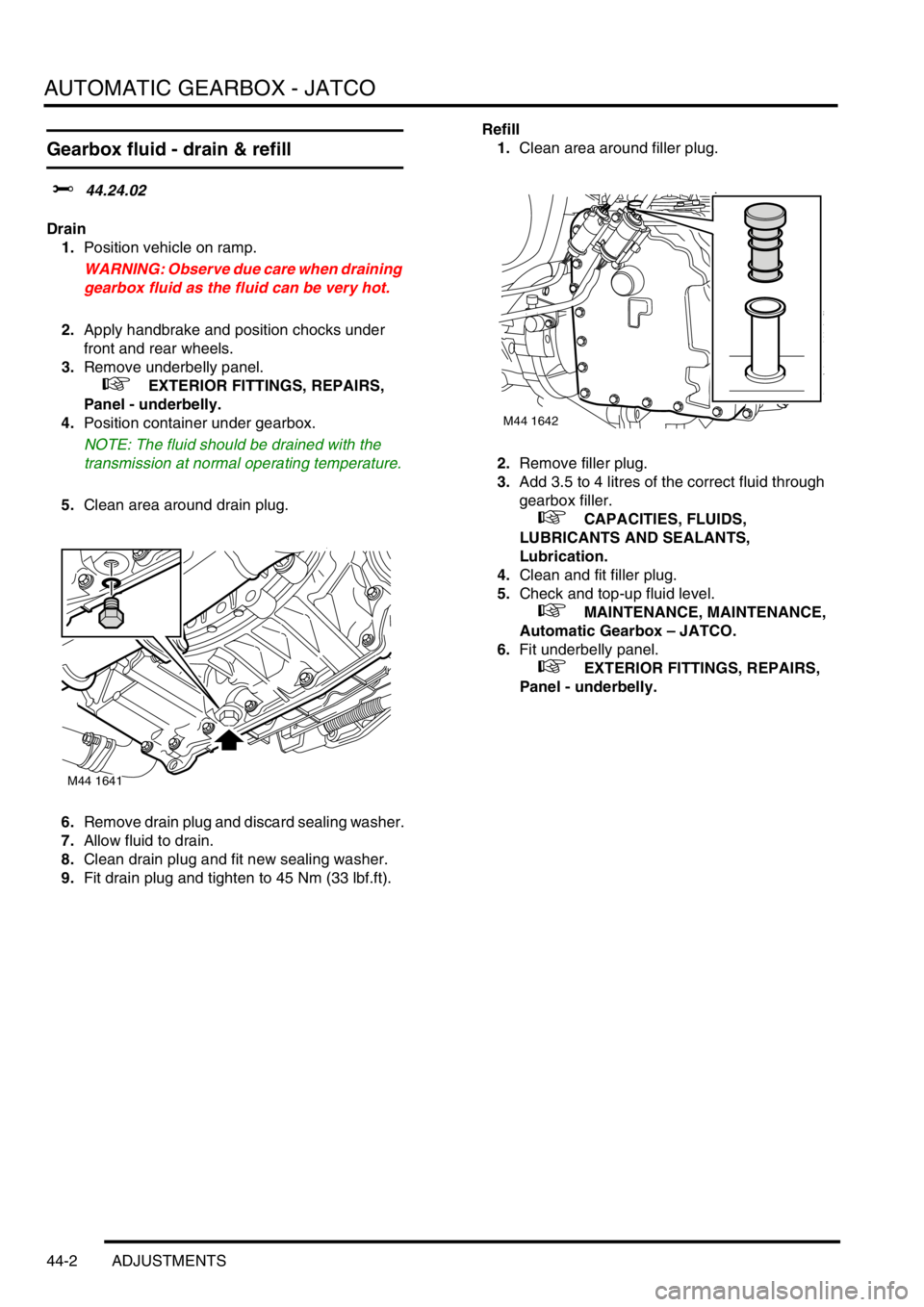

5.Clean area around drain plug.

6.Remove drain plug and discard sealing washer.

7.Allow fluid to drain.

8.Clean drain plug and fit new sealing washer.

9.Fit drain plug and tighten to 45 Nm (33 lbf.ft).Refill

1.Clean area around filler plug.

2.Remove filler plug.

3.Add 3.5 to 4 litres of the correct fluid through

gearbox filler.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

4.Clean and fit filler plug.

5.Check and top-up fluid level.

+ MAINTENANCE, MAINTENANCE,

Automatic Gearbox – JATCO.

6.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

M44 1641

M44 1642

Page 440 of 1007

AUTOMATIC GEARBOX - JATCO

REPAIRS 44-5

REPAIRS

Selector housing

$% 44.15.04

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

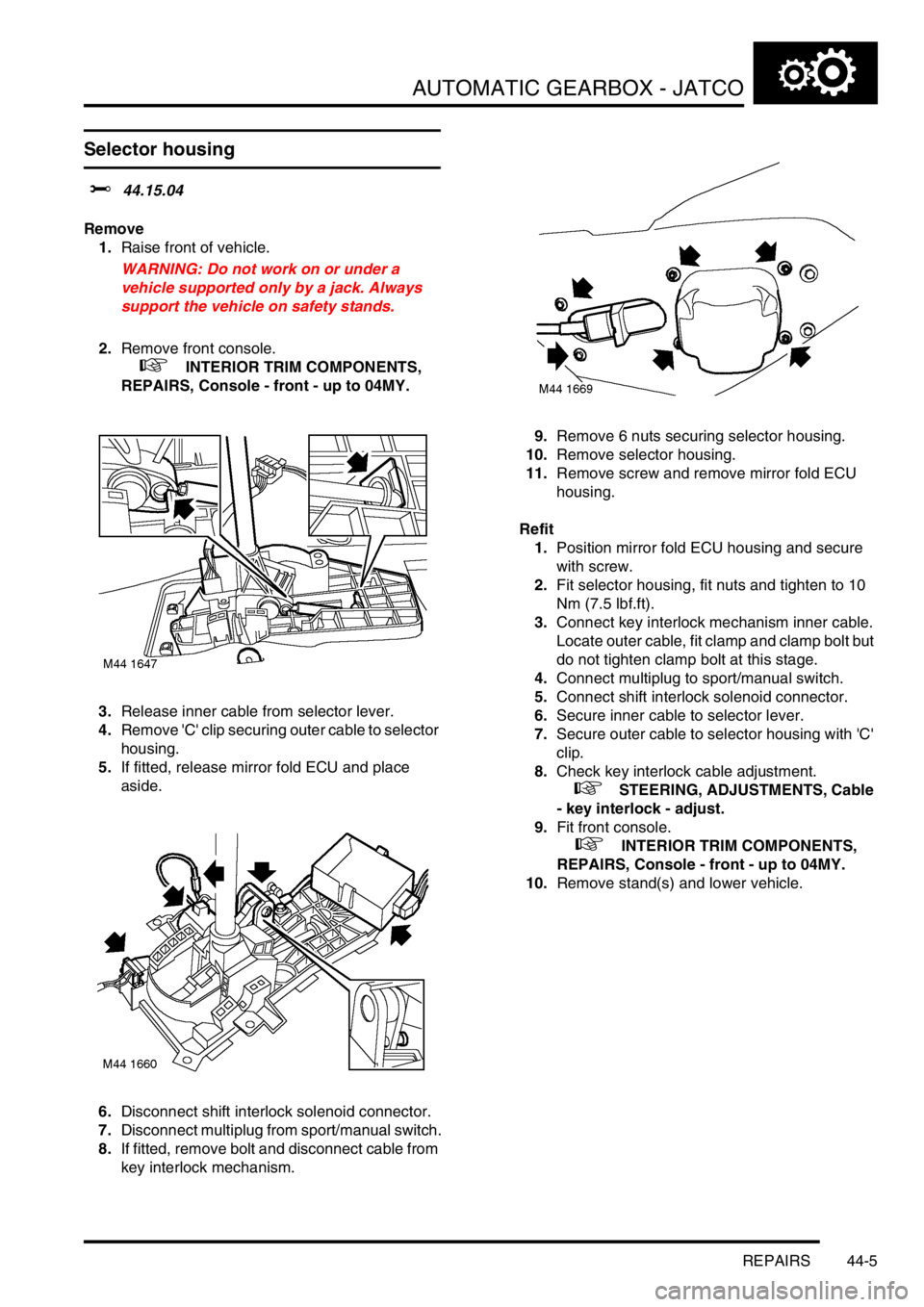

3.Release inner cable from selector lever.

4.Remove 'C' clip securing outer cable to selector

housing.

5.If fitted, release mirror fold ECU and place

aside.

6.Disconnect shift interlock solenoid connector.

7.Disconnect multiplug from sport/manual switch.

8.If fitted, remove bolt and disconnect cable from

key interlock mechanism.9.Remove 6 nuts securing selector housing.

10.Remove selector housing.

11.Remove screw and remove mirror fold ECU

housing.

Refit

1.Position mirror fold ECU housing and secure

with screw.

2.Fit selector housing, fit nuts and tighten to 10

Nm (7.5 lbf.ft).

3.Connect key interlock mechanism inner cable.

Locate outer cable, fit clamp and clamp bolt but

do not tighten clamp bolt at this stage.

4.Connect multiplug to sport/manual switch.

5.Connect shift interlock solenoid connector.

6.Secure inner cable to selector lever.

7.Secure outer cable to selector housing with 'C'

clip.

8.Check key interlock cable adjustment.

+ STEERING, ADJUSTMENTS, Cable

- key interlock - adjust.

9.Fit front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

10.Remove stand(s) and lower vehicle.

Page 441 of 1007

AUTOMATIC GEARBOX - JATCO

44-6 REPAIRS

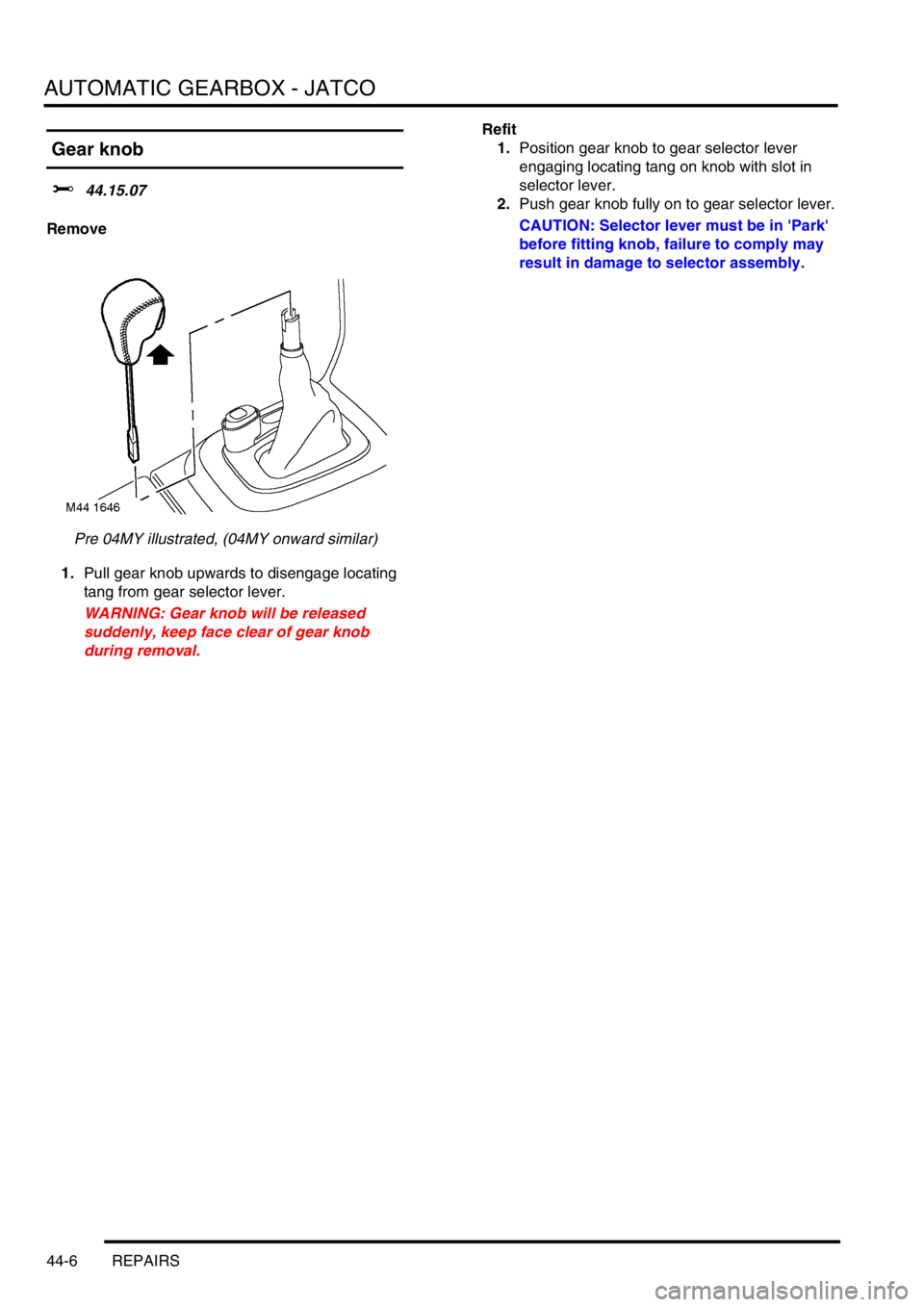

Gear knob

$% 44.15.07

Remove

Pre 04MY illustrated, (04MY onward similar)

1.Pull gear knob upwards to disengage locating

tang from gear selector lever.

WARNING: Gear knob will be released

suddenly, keep face clear of gear knob

during removal.Refit

1.Position gear knob to gear selector lever

engaging locating tang on knob with slot in

selector lever.

2.Push gear knob fully on to gear selector lever.

CAUTION: Selector lever must be in 'Park'

before fitting knob, failure to comply may

result in damage to selector assembly.

Page 442 of 1007

AUTOMATIC GEARBOX - JATCO

REPAIRS 44-7

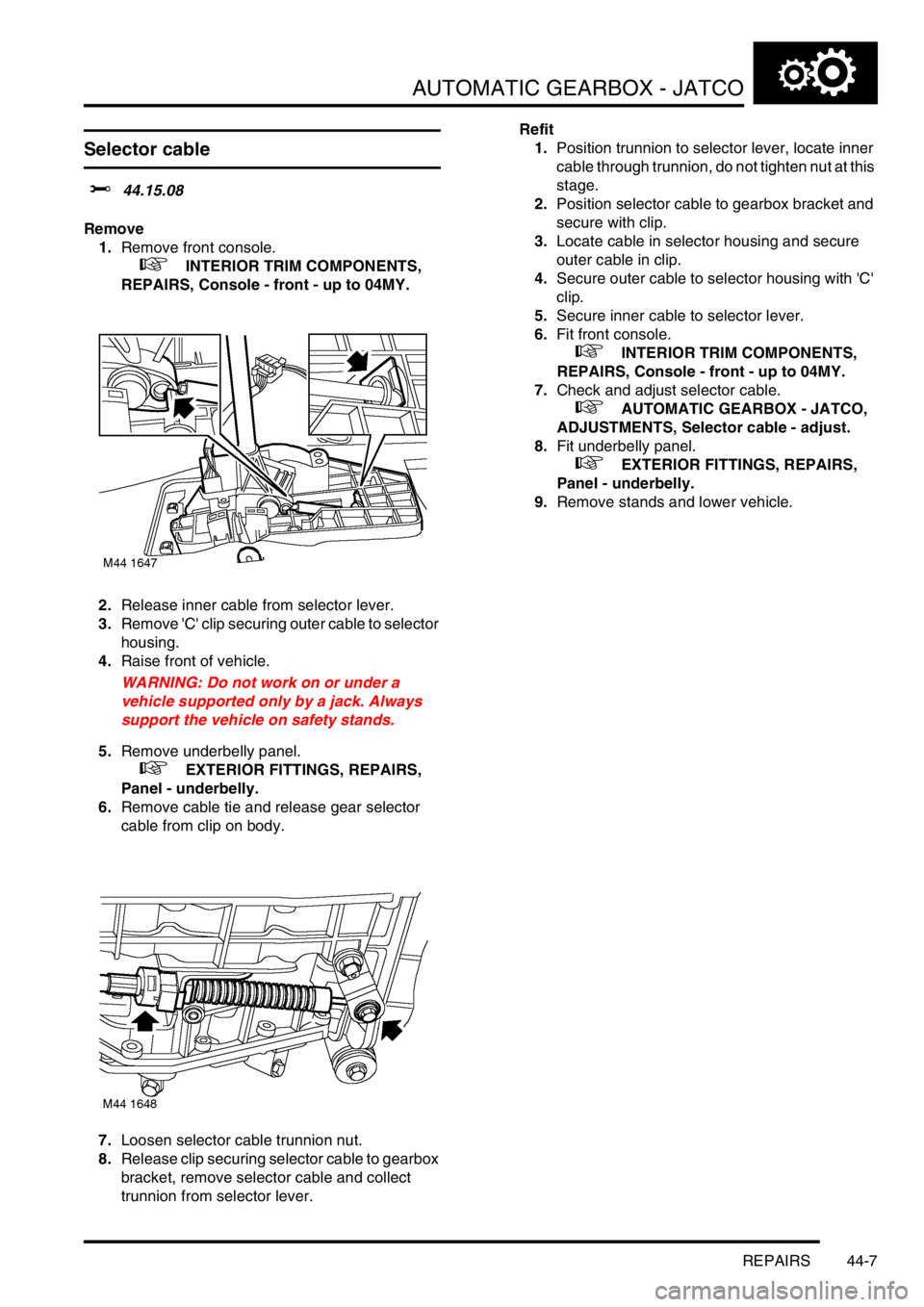

Selector cable

$% 44.15.08

Remove

1.Remove front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

2.Release inner cable from selector lever.

3.Remove 'C' clip securing outer cable to selector

housing.

4.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

5.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

6.Remove cable tie and release gear selector

cable from clip on body.

7.Loosen selector cable trunnion nut.

8.Release clip securing selector cable to gearbox

bracket, remove selector cable and collect

trunnion from selector lever.Refit

1.Position trunnion to selector lever, locate inner

cable through trunnion, do not tighten nut at this

stage.

2.Position selector cable to gearbox bracket and

secure with clip.

3.Locate cable in selector housing and secure

outer cable in clip.

4.Secure outer cable to selector housing with 'C'

clip.

5.Secure inner cable to selector lever.

6.Fit front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

7.Check and adjust selector cable.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Selector cable - adjust.

8.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

9.Remove stands and lower vehicle.

Page 444 of 1007

AUTOMATIC GEARBOX - JATCO

REPAIRS 44-9

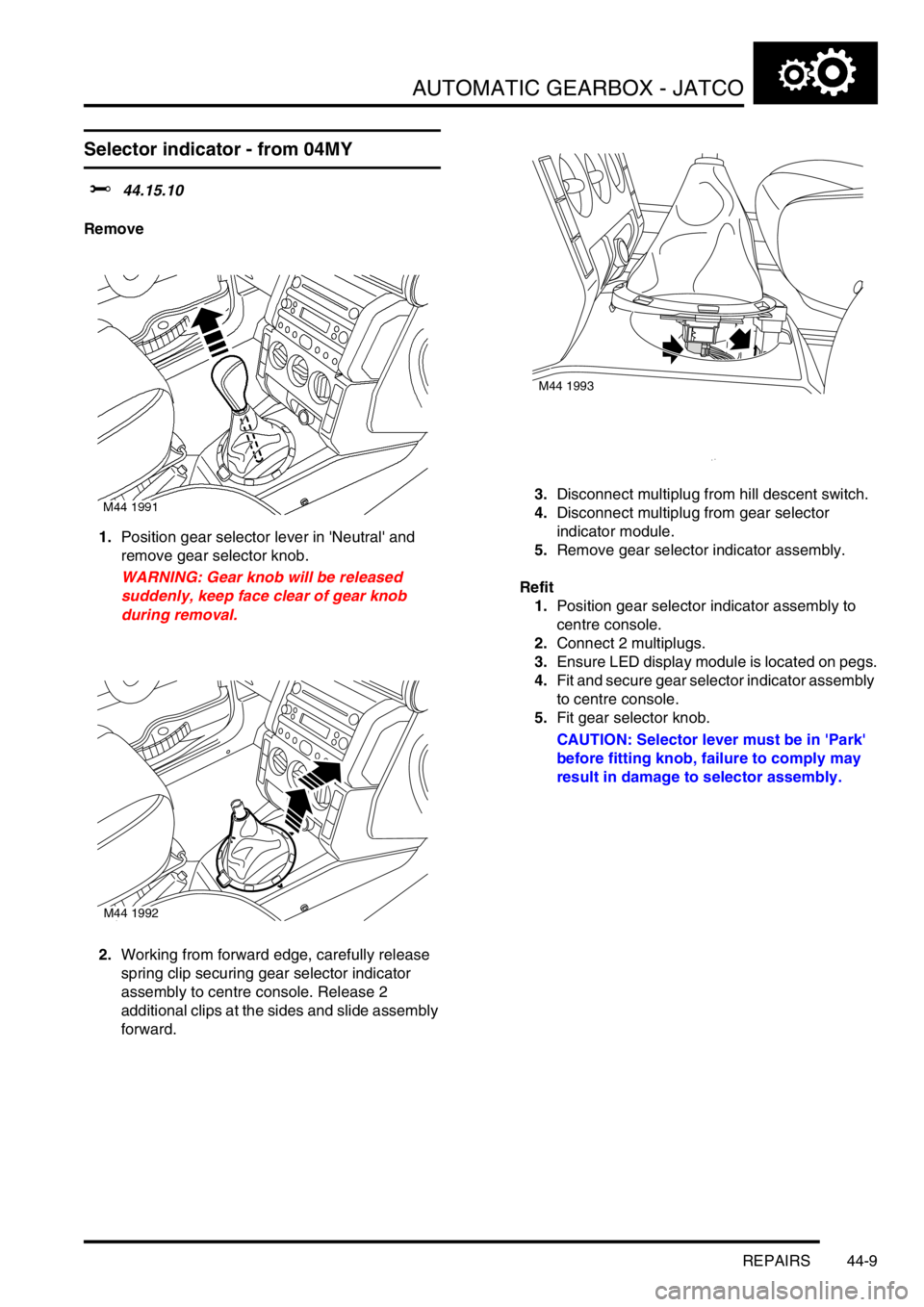

Selector indicator - from 04MY

$% 44.15.10

Remove

1.Position gear selector lever in 'Neutral' and

remove gear selector knob.

WARNING: Gear knob will be released

suddenly, keep face clear of gear knob

during removal.

2.Working from forward edge, carefully release

spring clip securing gear selector indicator

assembly to centre console. Release 2

additional clips at the sides and slide assembly

forward.3.Disconnect multiplug from hill descent switch.

4.Disconnect multiplug from gear selector

indicator module.

5.Remove gear selector indicator assembly.

Refit

1.Position gear selector indicator assembly to

centre console.

2.Connect 2 multiplugs.

3.Ensure LED display module is located on pegs.

4.Fit and secure gear selector indicator assembly

to centre console.

5.Fit gear selector knob.

CAUTION: Selector lever must be in 'Park'

before fitting knob, failure to comply may

result in damage to selector assembly.

M44 1992

M44 1993

Page 466 of 1007

AUTOMATIC GEARBOX - JATCO

REPAIRS 44-31

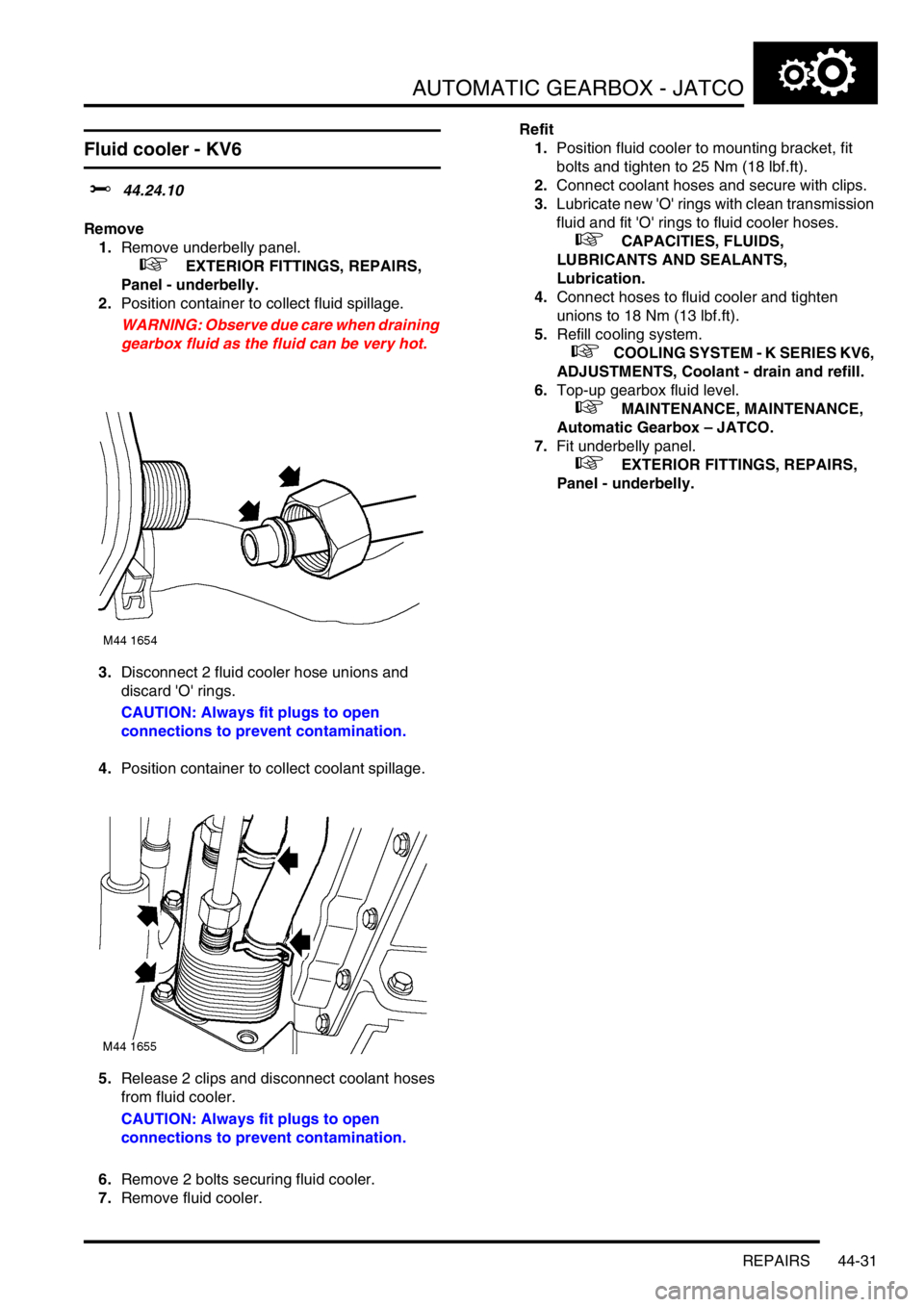

Fluid cooler - KV6

$% 44.24.10

Remove

1.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

2.Position container to collect fluid spillage.

WARNING: Observe due care when draining

gearbox fluid as the fluid can be very hot.

3.Disconnect 2 fluid cooler hose unions and

discard 'O' rings.

CAUTION: Always fit plugs to open

connections to prevent contamination.

4.Position container to collect coolant spillage.

5.Release 2 clips and disconnect coolant hoses

from fluid cooler.

CAUTION: Always fit plugs to open

connections to prevent contamination.

6.Remove 2 bolts securing fluid cooler.

7.Remove fluid cooler.Refit

1.Position fluid cooler to mounting bracket, fit

bolts and tighten to 25 Nm (18 lbf.ft).

2.Connect coolant hoses and secure with clips.

3.Lubricate new 'O' rings with clean transmission

fluid and fit 'O' rings to fluid cooler hoses.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

4.Connect hoses to fluid cooler and tighten

unions to 18 Nm (13 lbf.ft).

5.Refill cooling system.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

6.Top-up gearbox fluid level.

+ MAINTENANCE, MAINTENANCE,

Automatic Gearbox – JATCO.

7.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

Page 467 of 1007

AUTOMATIC GEARBOX - JATCO

44-32 REPAIRS

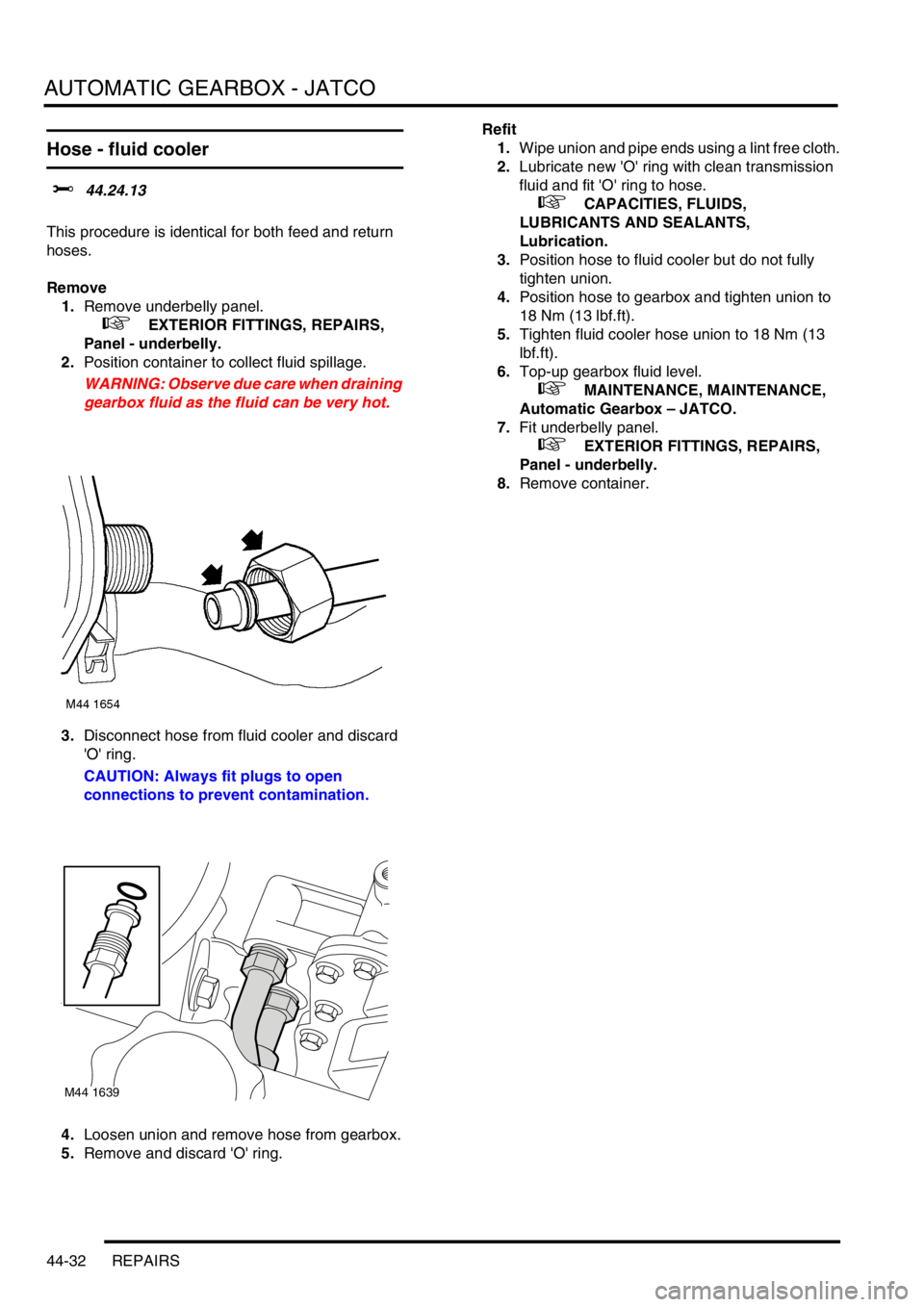

Hose - fluid cooler

$% 44.24.13

This procedure is identical for both feed and return

hoses.

Remove

1.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

2.Position container to collect fluid spillage.

WARNING: Observe due care when draining

gearbox fluid as the fluid can be very hot.

3.Disconnect hose from fluid cooler and discard

'O' ring.

CAUTION: Always fit plugs to open

connections to prevent contamination.

4.Loosen union and remove hose from gearbox.

5.Remove and discard 'O' ring.Refit

1.Wipe union and pipe ends using a lint free cloth.

2.Lubricate new 'O' ring with clean transmission

fluid and fit 'O' ring to hose.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

3.Position hose to fluid cooler but do not fully

tighten union.

4.Position hose to gearbox and tighten union to

18 Nm (13 lbf.ft).

5.Tighten fluid cooler hose union to 18 Nm (13

lbf.ft).

6.Top-up gearbox fluid level.

+ MAINTENANCE, MAINTENANCE,

Automatic Gearbox – JATCO.

7.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

8.Remove container.

M44 1639

Page 468 of 1007

DRIVESHAFTS

REPAIRS 47-1

DRIV ESHAFTS REPAIRS

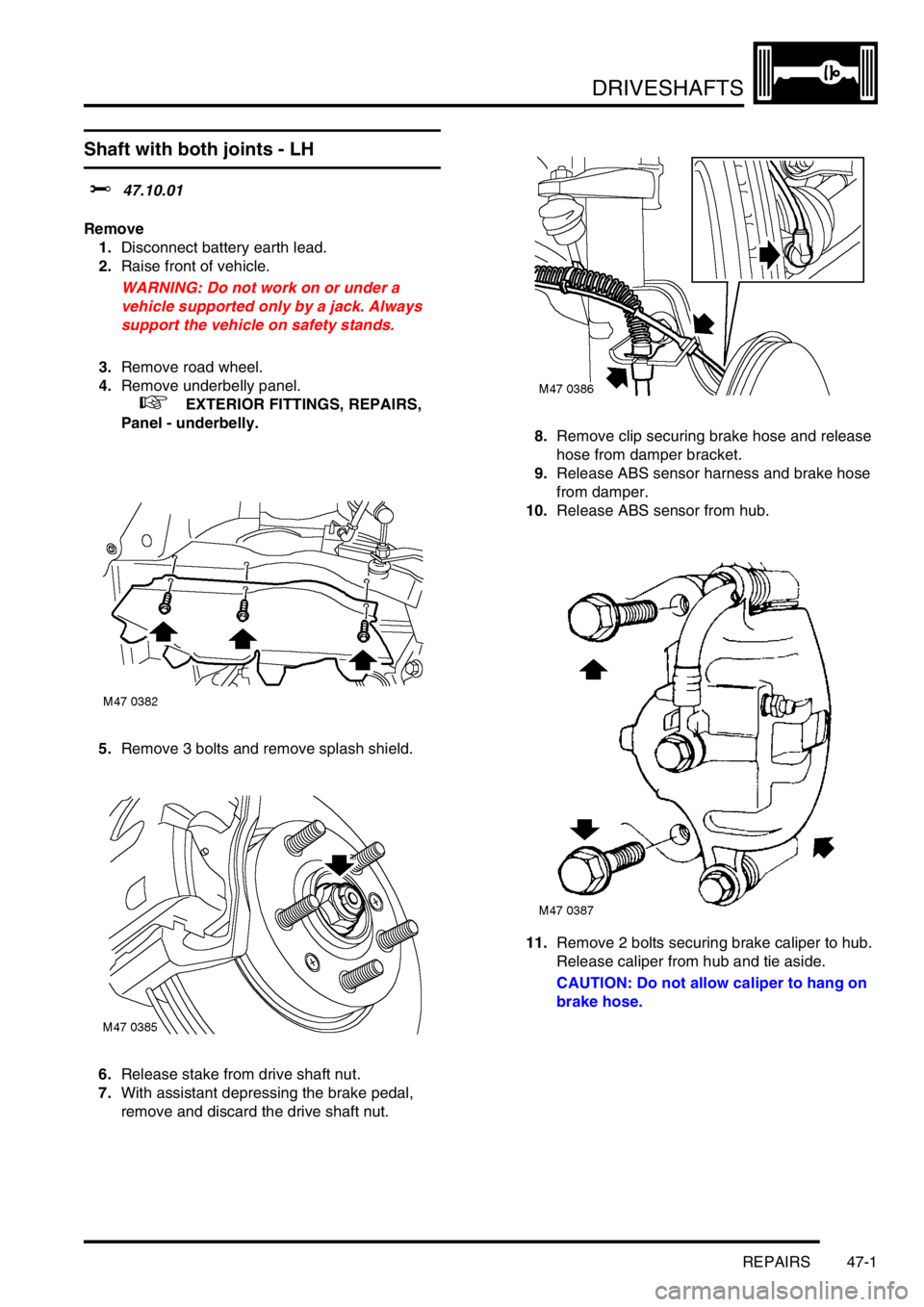

Shaft with both joints - LH

$% 47.10.01

Remove

1.Disconnect battery earth lead.

2.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Remove road wheel.

4.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

5.Remove 3 bolts and remove splash shield.

6.Release stake from drive shaft nut.

7.With assistant depressing the brake pedal,

remove and discard the drive shaft nut.8.Remove clip securing brake hose and release

hose from damper bracket.

9.Release ABS sensor harness and brake hose

from damper.

10.Release ABS sensor from hub.

11.Remove 2 bolts securing brake caliper to hub.

Release caliper from hub and tie aside.

CAUTION: Do not allow caliper to hang on

brake hose.