warning LAND ROVER FREELANDER 2001 Manual Online

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 516 of 1007

STEERING

REPAIRS 57-23

Ball joint - track rod

$% 57.55.07

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove front road wheel.

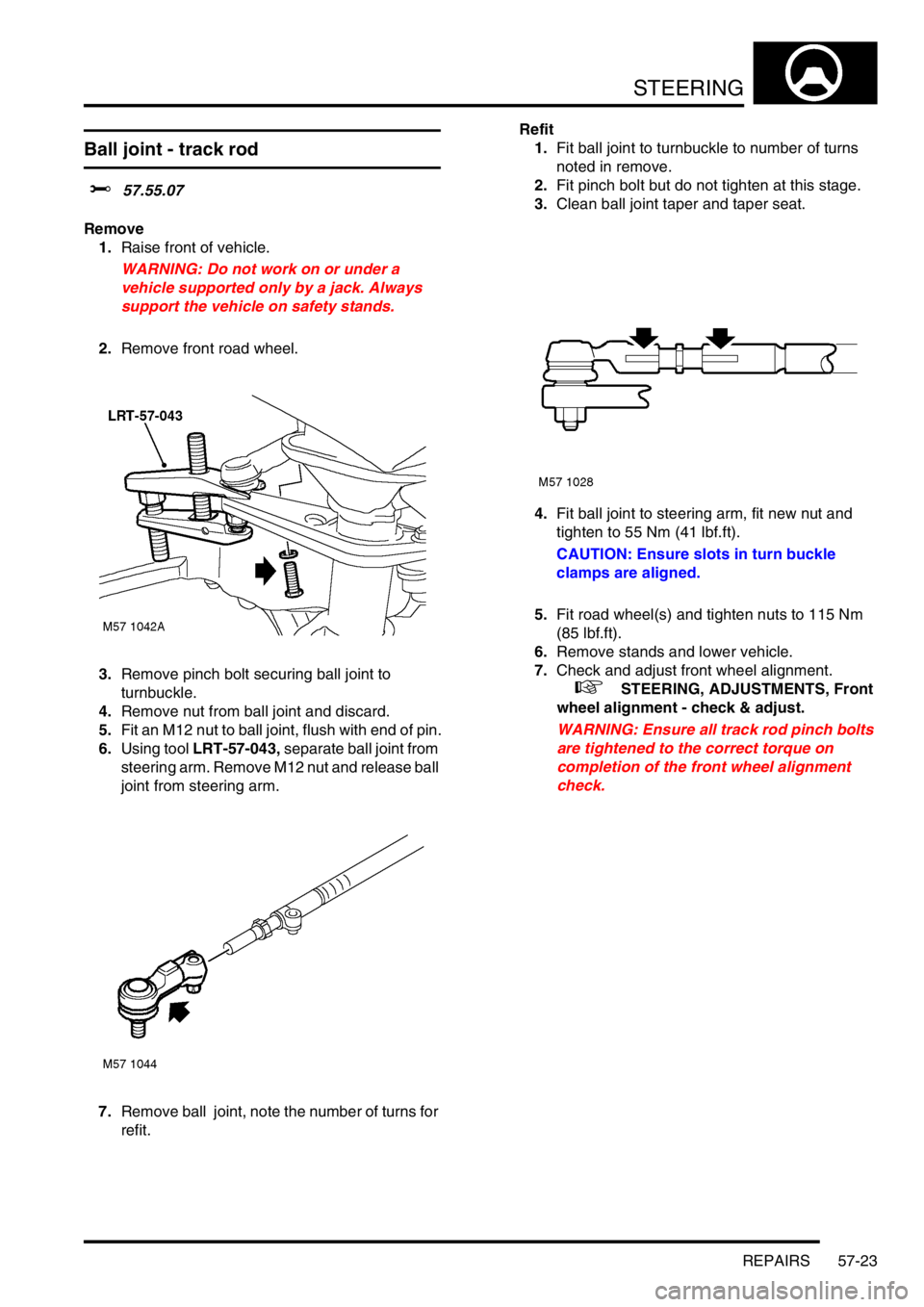

3.Remove pinch bolt securing ball joint to

turnbuckle.

4.Remove nut from ball joint and discard.

5.Fit an M12 nut to ball joint, flush with end of pin.

6.Using tool LRT-57-043, separate ball joint from

steering arm. Remove M12 nut and release ball

joint from steering arm.

7.Remove ball joint, note the number of turns for

refit.Refit

1.Fit ball joint to turnbuckle to number of turns

noted in remove.

2.Fit pinch bolt but do not tighten at this stage.

3.Clean ball joint taper and taper seat.

4.Fit ball joint to steering arm, fit new nut and

tighten to 55 Nm (41 lbf.ft).

CAUTION: Ensure slots in turn buckle

clamps are aligned.

5.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

6.Remove stands and lower vehicle.

7.Check and adjust front wheel alignment.

+ STEERING, ADJUSTMENTS, Front

wheel alignment - check & adjust.

WARNING: Ensure all track rod pinch bolts

are tightened to the correct torque on

completion of the front wheel alignment

check.

Page 517 of 1007

STEERING

57-24 REPAIRS

Track rod

$% 57.55.09

Remove

1. Td4 & KV6 models: Remove steering rack.

+ STEERING, REPAIRS, Power

steering rack.

2.Remove Torx bolt securing track rod to PAS

rack. Discard Torx bolt.

3.Remove track rod and spacer.

CAUTION: Note orientation of spacers

before dismantling.

4.Hold track rod securely and loosen pinch bolt in

track rod end.

NOTE: Do not carry out further dismantling if

component is removed for access only.

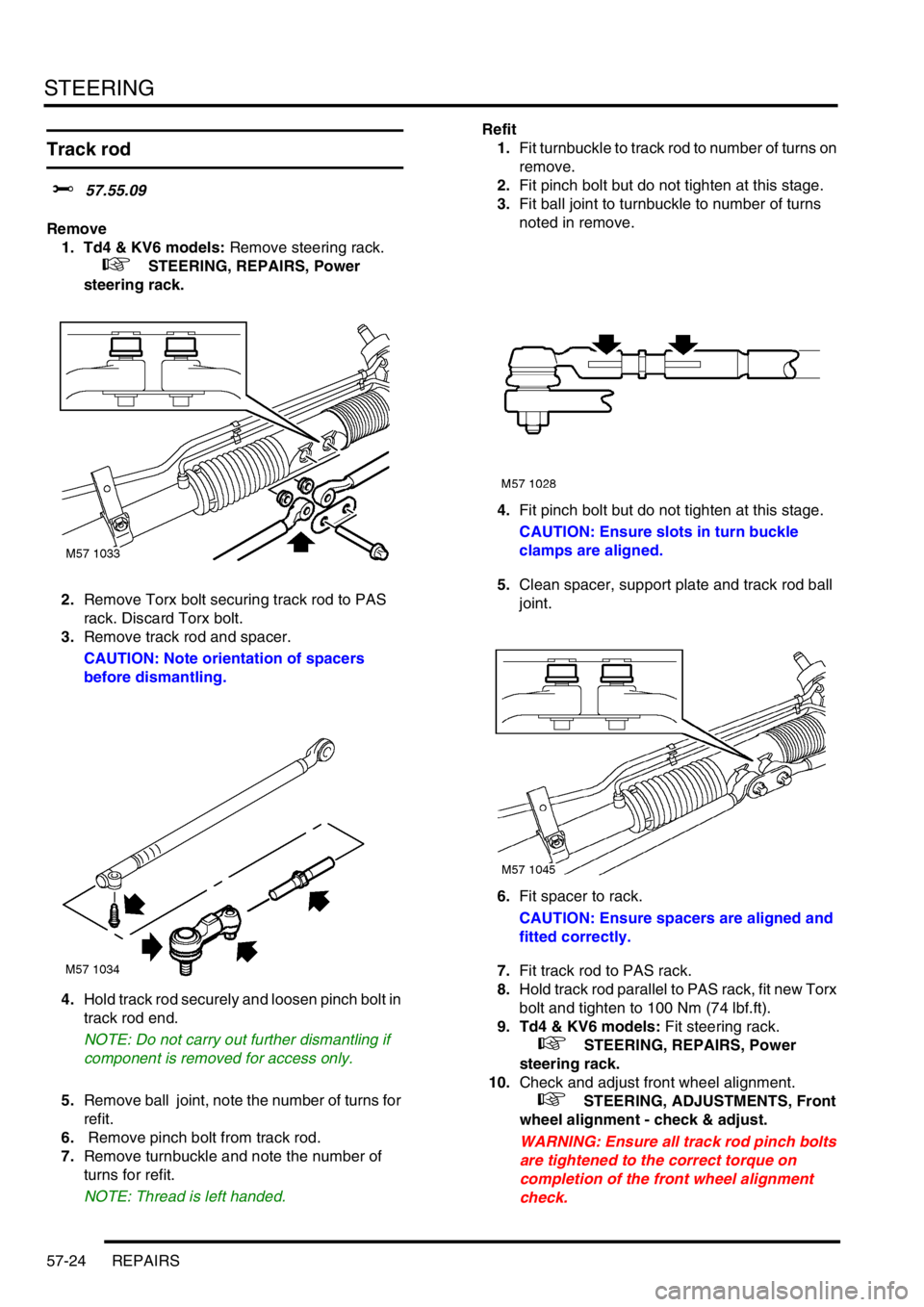

5.Remove ball joint, note the number of turns for

refit.

6. Remove pinch bolt from track rod.

7.Remove turnbuckle and note the number of

turns for refit.

NOTE: Thread is left handed.Refit

1.Fit turnbuckle to track rod to number of turns on

remove.

2.Fit pinch bolt but do not tighten at this stage.

3.Fit ball joint to turnbuckle to number of turns

noted in remove.

4.Fit pinch bolt but do not tighten at this stage.

CAUTION: Ensure slots in turn buckle

clamps are aligned.

5.Clean spacer, support plate and track rod ball

joint.

6.Fit spacer to rack.

CAUTION: Ensure spacers are aligned and

fitted correctly.

7.Fit track rod to PAS rack.

8.Hold track rod parallel to PAS rack, fit new Torx

bolt and tighten to 100 Nm (74 lbf.ft).

9. Td4 & KV6 models: Fit steering rack.

+ STEERING, REPAIRS, Power

steering rack.

10.Check and adjust front wheel alignment.

+ STEERING, ADJUSTMENTS, Front

wheel alignment - check & adjust.

WARNING: Ensure all track rod pinch bolts

are tightened to the correct torque on

completion of the front wheel alignment

check.

Page 520 of 1007

FRONT SUSPENSION

REPAIRS 60-1

FRONT SUSPENSION REPAIRS

Anti roll bar

$% 60.10.01

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel(s).

3.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

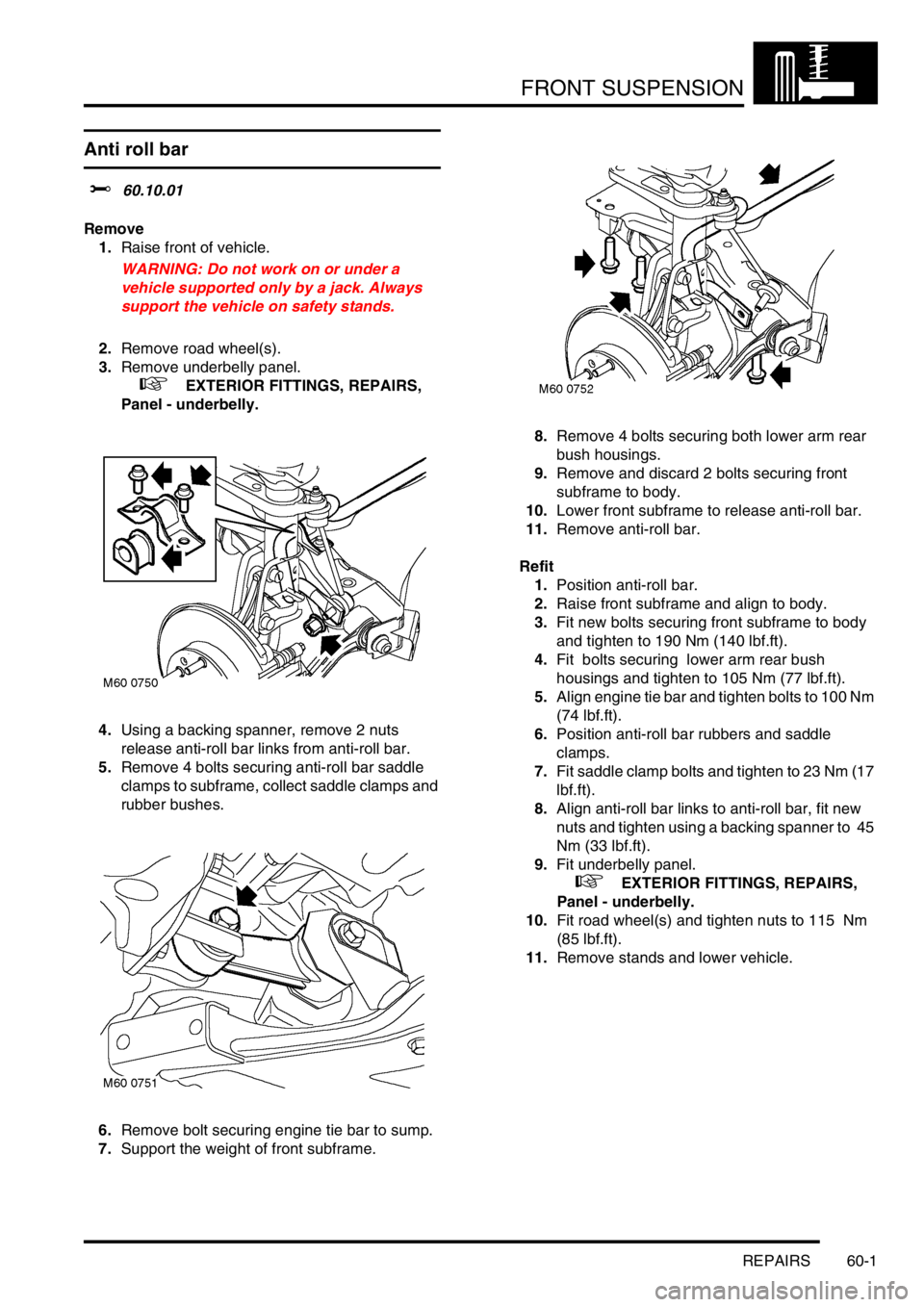

4.Using a backing spanner, remove 2 nuts

release anti-roll bar links from anti-roll bar.

5.Remove 4 bolts securing anti-roll bar saddle

clamps to subframe, collect saddle clamps and

rubber bushes.

6.Remove bolt securing engine tie bar to sump.

7.Support the weight of front subframe.8.Remove 4 bolts securing both lower arm rear

bush housings.

9.Remove and discard 2 bolts securing front

subframe to body.

10.Lower front subframe to release anti-roll bar.

11.Remove anti-roll bar.

Refit

1.Position anti-roll bar.

2.Raise front subframe and align to body.

3.Fit new bolts securing front subframe to body

and tighten to 190 Nm (140 lbf.ft).

4.Fit bolts securing lower arm rear bush

housings and tighten to 105 Nm (77 lbf.ft).

5.Align engine tie bar and tighten bolts to 100 Nm

(74 lbf.ft).

6.Position anti-roll bar rubbers and saddle

clamps.

7.Fit saddle clamp bolts and tighten to 23 Nm (17

lbf.ft).

8.Align anti-roll bar links to anti-roll bar, fit new

nuts and tighten using a backing spanner to 45

Nm (33 lbf.ft).

9.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

10.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

11.Remove stands and lower vehicle.

Page 521 of 1007

FRONT SUSPENSION

60-2 REPAIRS

Ball joint link - anti roll bar

$% 60.10.04

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel.

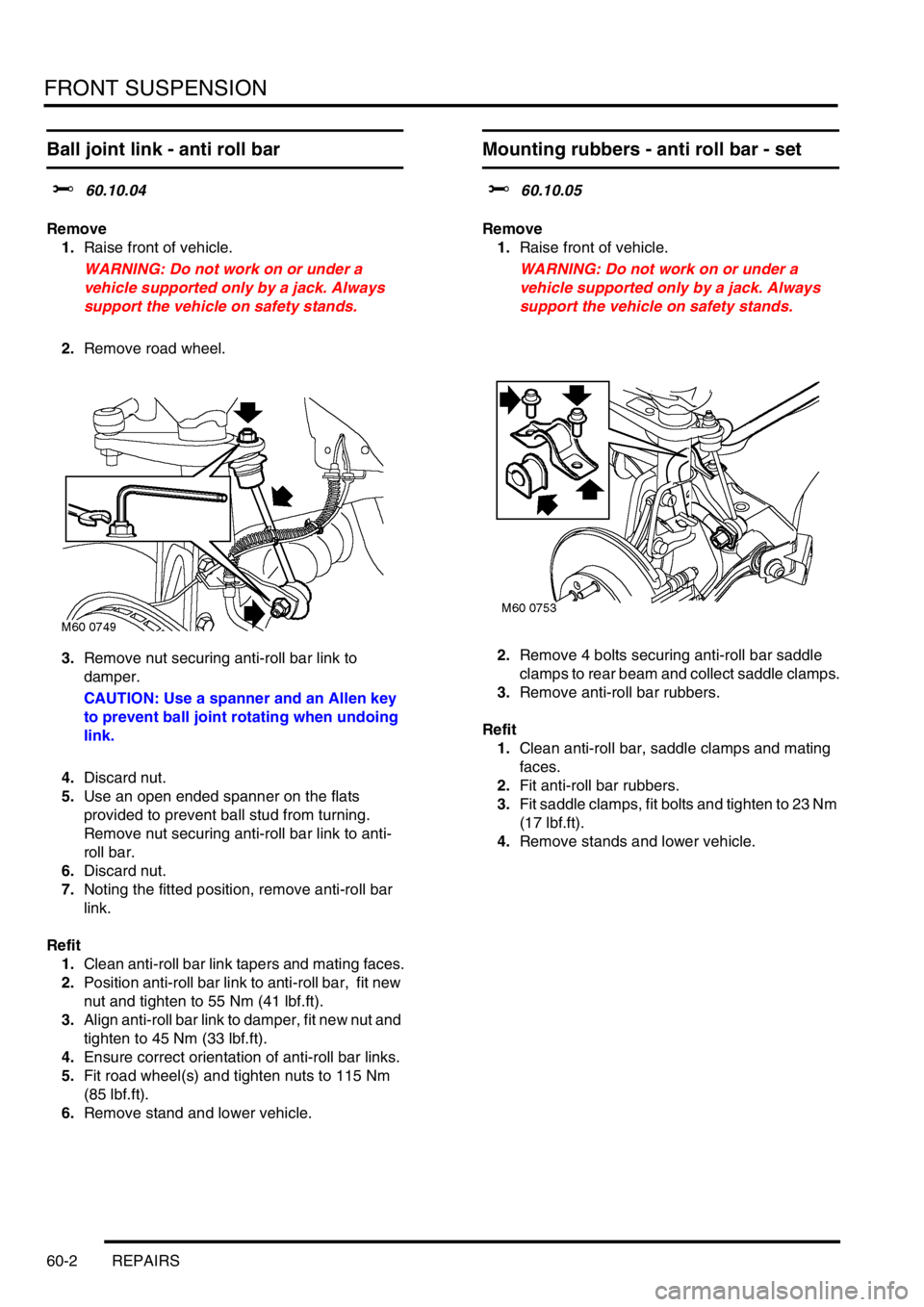

3.Remove nut securing anti-roll bar link to

damper.

CAUTION: Use a spanner and an Allen key

to prevent ball joint rotating when undoing

link.

4.Discard nut.

5.Use an open ended spanner on the flats

provided to prevent ball stud from turning.

Remove nut securing anti-roll bar link to anti-

roll bar.

6.Discard nut.

7.Noting the fitted position, remove anti-roll bar

link.

Refit

1.Clean anti-roll bar link tapers and mating faces.

2.Position anti-roll bar link to anti-roll bar, fit new

nut and tighten to 55 Nm (41 lbf.ft).

3.Align anti-roll bar link to damper, fit new nut and

tighten to 45 Nm (33 lbf.ft).

4.Ensure correct orientation of anti-roll bar links.

5.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

6.Remove stand and lower vehicle.

Mounting rubbers - anti roll bar - set

$% 60.10.05

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove 4 bolts securing anti-roll bar saddle

clamps to rear beam and collect saddle clamps.

3.Remove anti-roll bar rubbers.

Refit

1.Clean anti-roll bar, saddle clamps and mating

faces.

2.Fit anti-roll bar rubbers.

3.Fit saddle clamps, fit bolts and tighten to 23 Nm

(17 lbf.ft).

4.Remove stands and lower vehicle.

Page 522 of 1007

FRONT SUSPENSION

REPAIRS 60-3

Bearing - hub

$% 60.25.14

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel.

3.Release stake in drive shaft nut.

4.With an assistant applying brakes, remove and

discard drive shaft hub nut.

5.Remove clip securing RH brake hose to

support bracket, release hose from bracket.

Release ABS sensor and pad wear sensor

harnesses from bracket.6.Remove 2 bolts securing brake caliper to hub.

Release caliper from hub and tie aside.

CAUTION: Do not allow caliper to hang on

brake hose.

7.Mark brake disc to hub relationship.

8.Remove 2 screws securing brake disc and

remove brake disc.

Page 526 of 1007

FRONT SUSPENSION

REPAIRS 60-7

Damper

$% 60.30.02

Remove

1.Disconnect battery earth lead.

2.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Remove road wheel.

4.Remove clip securing brake hose to bracket on

damper.

5.Release ABS sensor harness and brake hose

from damper.

6.Release ABS sensor from hub.7.Remove 2 bolts securing brake caliper to hub.

Release caliper from hub and tie aside.

CAUTION: Do not allow caliper to hang on

brake hose.

8.Remove nut securing track rod to steering arm

and break taper joint using LRT-57-043.

Page 529 of 1007

FRONT SUSPENSION

60-10 REPAIRS

Refit

1.Inspect damper, spring mounting rubbers and

bearing for deterioration and damage.

2.Clean mating faces of spring, mounting and

mounting plate.

3.Clean damper shaft and bump stop plate.

4.Position spring and damper assembly to spring

compressor. Compress spring.

5.Fit damper to spring, ensure spring locates in

cut recess in damper plate.

6.Fit bump cup, bump stop and dust cover to

damper.

7.Fit spring aid and bump plate.

8.Fit mounting plate and rebound washer.

9.Using new nut, hold damper shaft with Allen

key and tighten nut to 57 Nm (42 lbf.ft).

CAUTION: Note alignment of top mounting,

spring and damper dust cover.

10.Release and remove spring from compressor.

11.Clean mating face of top mounting plate.

12.Position damper assembly and align top

mounting to body, fit nuts and tighten to 45 Nm

(33 lbf.ft).

13. LH side: Position fusebox, fit nuts and tighten

to 8 Nm (6 lbf.ft).

14. LH side: Connect positive and negative leads,

fit bolts and tighten to 8 Nm (6 lbf.ft).

15. LH side: Connect multiplug to fusebox.

16. RH side: Position coolant reservoir and secure

with bolt.

17.Fit hub to damper, fit nuts and bolts and tighten

to 205 Nm (151 lbf.ft).

18.Clean anti-roll bar link taper and mating face.

19.Connect anti-roll bar link, fit new nut and tighten

to 55 Nm (41 lbf.ft).

CAUTION: Use a spanner and an Allen key

to prevent ball joint rotating when undoing

link.

20.Clean track rod taper and mating face.

21.Connect track rod end to steering arm using

new nut and tighten nut to 55 Nm (41 lbf.ft).

22.Clean ABS sensor, smear sensor with an anti-

seize grease and fit sensor to hub.

CAUTION: Ensure ABS sensor is fully

located into hub, so that sensor touches

pole wheel teeth.

23.Position ABS harness and brake hose in

bracket and secure with clip.

24.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

25.Remove stand and lower vehicle.

26.Connect battery earth lead.

Lower arm assembly

$% 60.35.02

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel.

3.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

4.Release stake in drive shaft nuts.

5.With an assistant applying brakes, remove and

discard drive shaft hub nut.

6.Remove clip securing brake hose to bracket on

damper.

7.Release ABS sensor harness and brake hose

from damper.

8.Release ABS sensor from hub.

Page 534 of 1007

FRONT SUSPENSION

REPAIRS 60-15

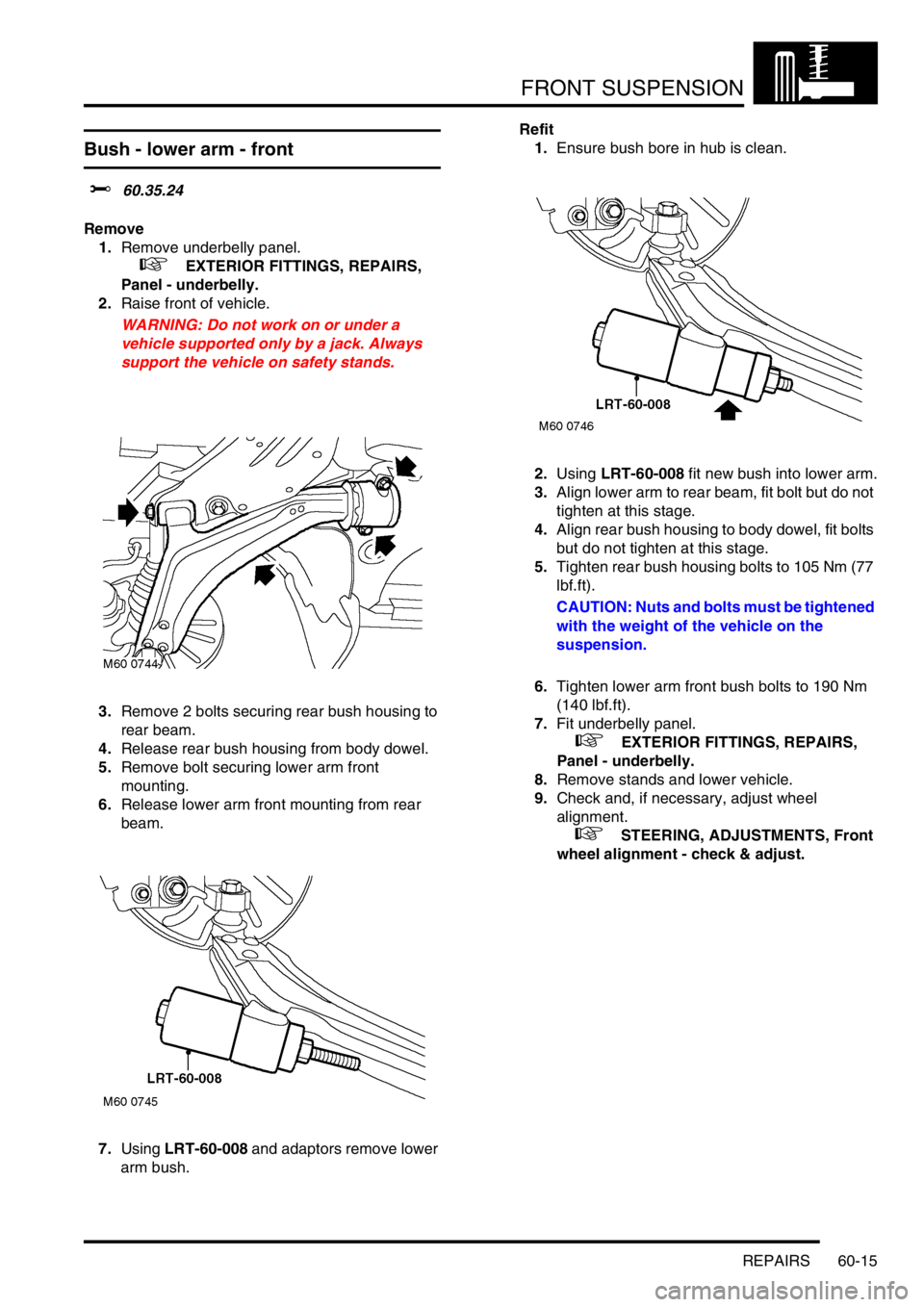

Bush - lower arm - front

$% 60.35.24

Remove

1.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

2.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Remove 2 bolts securing rear bush housing to

rear beam.

4.Release rear bush housing from body dowel.

5.Remove bolt securing lower arm front

mounting.

6.Release lower arm front mounting from rear

beam.

7.Using LRT-60-008 and adaptors remove lower

arm bush.Refit

1.Ensure bush bore in hub is clean.

2.Using LRT-60-008 fit new bush into lower arm.

3.Align lower arm to rear beam, fit bolt but do not

tighten at this stage.

4.Align rear bush housing to body dowel, fit bolts

but do not tighten at this stage.

5.Tighten rear bush housing bolts to 105 Nm (77

lbf.ft).

CAUTION: Nuts and bolts must be tightened

with the weight of the vehicle on the

suspension.

6.Tighten lower arm front bush bolts to 190 Nm

(140 lbf.ft).

7.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

8.Remove stands and lower vehicle.

9.Check and, if necessary, adjust wheel

alignment.

+ STEERING, ADJUSTMENTS, Front

wheel alignment - check & adjust.

Page 535 of 1007

FRONT SUSPENSION

60-16 REPAIRS

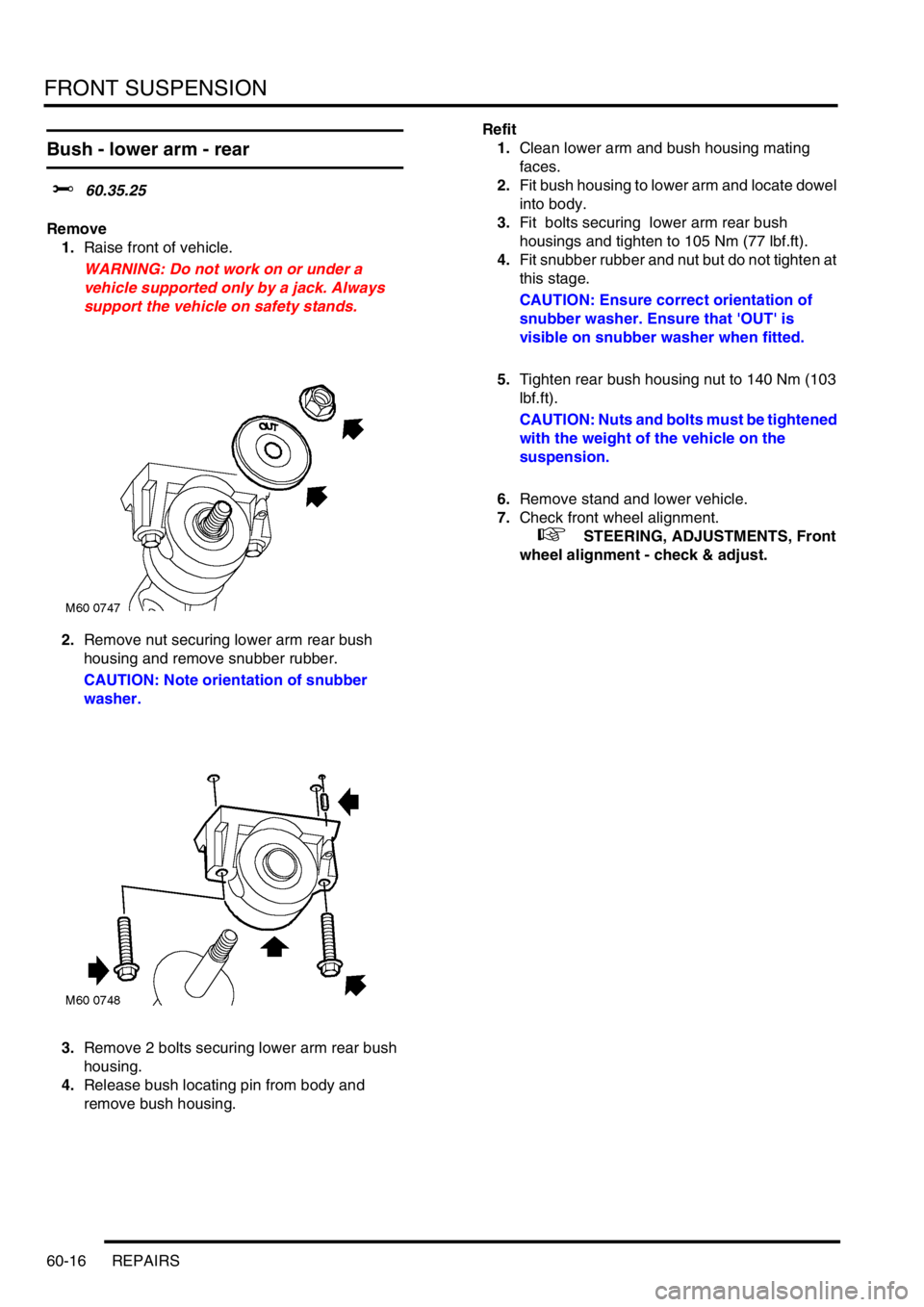

Bush - lower arm - rear

$% 60.35.25

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove nut securing lower arm rear bush

housing and remove snubber rubber.

CAUTION: Note orientation of snubber

washer.

3.Remove 2 bolts securing lower arm rear bush

housing.

4.Release bush locating pin from body and

remove bush housing.Refit

1.Clean lower arm and bush housing mating

faces.

2.Fit bush housing to lower arm and locate dowel

into body.

3.Fit bolts securing lower arm rear bush

housings and tighten to 105 Nm (77 lbf.ft).

4.Fit snubber rubber and nut but do not tighten at

this stage.

CAUTION: Ensure correct orientation of

snubber washer. Ensure that 'OUT' is

visible on snubber washer when fitted.

5.Tighten rear bush housing nut to 140 Nm (103

lbf.ft).

CAUTION: Nuts and bolts must be tightened

with the weight of the vehicle on the

suspension.

6.Remove stand and lower vehicle.

7.Check front wheel alignment.

+ STEERING, ADJUSTMENTS, Front

wheel alignment - check & adjust.

Page 536 of 1007

REAR SUSPENSION

REPAIRS 64-1

REAR SUSPENSION REPAIRS

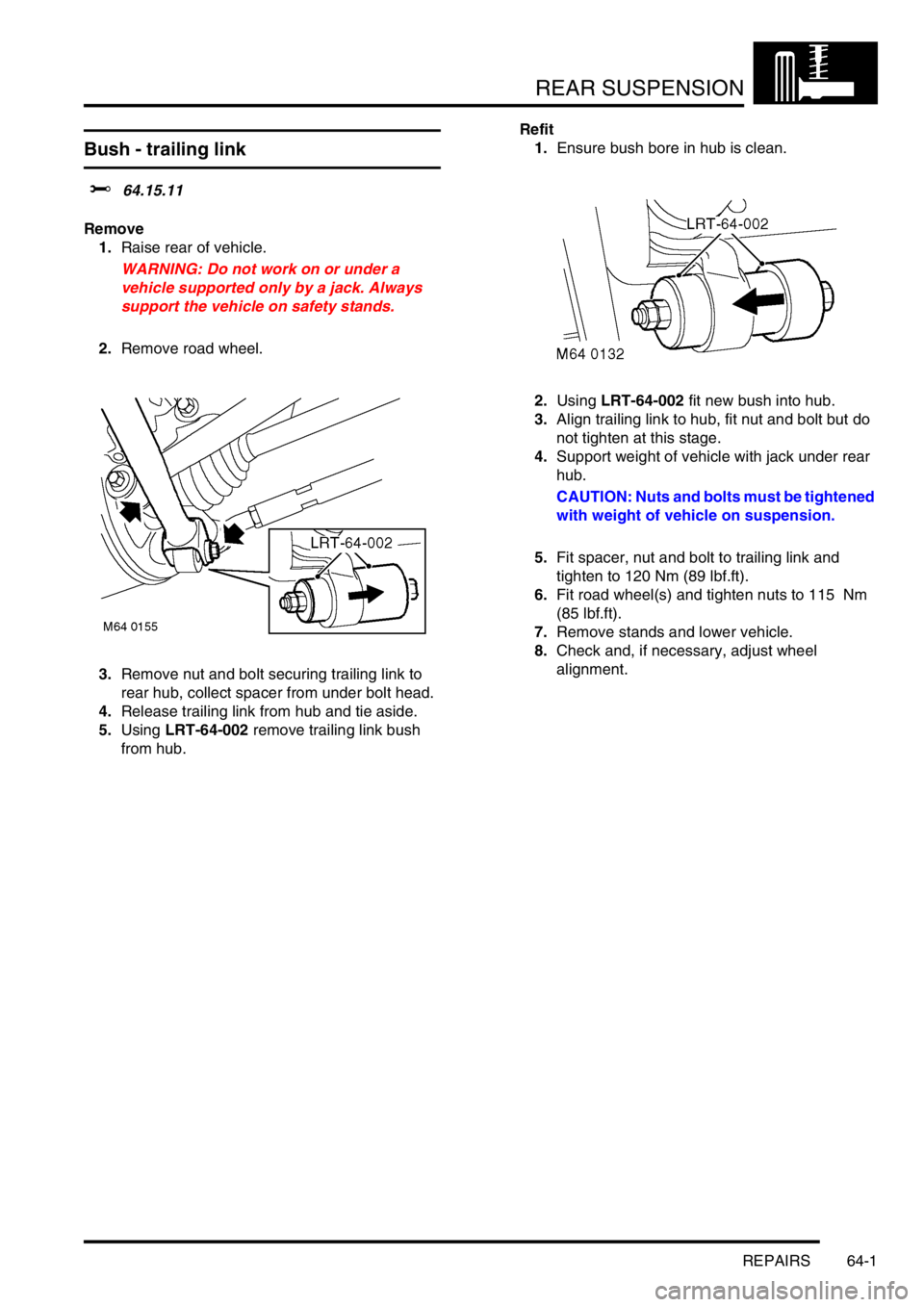

Bush - trailing link

$% 64.15.11

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel.

3.Remove nut and bolt securing trailing link to

rear hub, collect spacer from under bolt head.

4.Release trailing link from hub and tie aside.

5.Using LRT-64-002 remove trailing link bush

from hub.Refit

1.Ensure bush bore in hub is clean.

2.Using LRT-64-002 fit new bush into hub.

3.Align trailing link to hub, fit nut and bolt but do

not tighten at this stage.

4.Support weight of vehicle with jack under rear

hub.

CAUTION: Nuts and bolts must be tightened

with weight of vehicle on suspension.

5.Fit spacer, nut and bolt to trailing link and

tighten to 120 Nm (89 lbf.ft).

6.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

7.Remove stands and lower vehicle.

8.Check and, if necessary, adjust wheel

alignment.