warning LAND ROVER FREELANDER 2001 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 175 of 1007

MAINTENANCE

10-28 MAINTENANCE

Steering

Check

1.Check/tighten steering unit and steering rod

ball joint fixings.

2.Check condition of ball joints and dust covers.

3.Check steering rack bellows for any signs of

leakage.

Road Test

There are two purposes for conducting a road test.

Firstly, to ensure the work completed within the

dealership meets the standards required as laid

down by dealership processes. Secondly, for a

skilled technician to assess the general condition of

the vehicle and report any conditions that the

customer should be made aware of.

CAUTION: Two wheel dynamometer tests must

not be carried out. Four wheel dynamometer

tests must be restricted to 3 mph (5 kph).

Engine Start

1.Check for correct operation of starter switch.

Ensure the engine starts in a correct manner.

Leave the engine running.

Starter Inhibitor Switch – (Automatic only)

1.Select 'D' gear lever position.

2.Check that engine will not start.

3.Select 'R' gear lever position and repeat start

check.

4.Check that engine will start in 'P' and 'N'

positions.

Selector Cable – (Automatic only)

1.Check for correct setting of gear selector cable.

Engine Performance and Throttle Operation

1.Start engine and check that it starts easily.

2.Check that 'oil pressure' and 'no charge'

warning lamps extinguish.

3.Check that throttle pedal movement is free and

unrestricted.

4.Check that engine is responsive to throttle

movement.

Clutch and Gear Selection –

(Manual only, normal driving conditions)

1.Check that clutch engages smoothly without

judder, slipping or noise.

2.Check for abnormal transmission noise.

3.Check for smooth quiet gear changes and that

gear selected engages easily.

Page 176 of 1007

MAINTENANCE

MAINTENANCE 10-29

Gear Change and Parking Pawl Engagement –

(Automatic only, normal driving conditions)

1.Select 'R' and check for smooth take up.

2.Select 'D' and check for smooth up-changes of

ratio from rest.

3.Slow down vehicle and check for smooth down-

changes of ratio.

4.Stop vehicle on a slope.

5.Select 'P' and release handbrake.

6.Check that vehicle does not move and that

selector does not slip out of 'P'.

7.Carry out a similar check with vehicle facing in

the opposite direction.

Steering

1.With vehicle stationary, turn steering from lock

to lock. Check for smooth operation and ensure

there is no undue noise from the power steering

pump or drive belt.

Suspension

1.Check for noise, irregularity in ride (e.g.

dampers) and wheel imbalance.

Foot brake

1.Check for pedal effort, travel, braking

efficiency, pulling and binding.

Handbrake

1.Apply handbrake firmly, check travel and

ratchet hold and release.

Instruments

1.Check for correct operation of all instruments

and warning devices where practical.

Body

1.Check for abnormal body noise.

Seat Belts

1.Check for operation of inertia reels.Road Test

1.Drive vehicle on a short road test. Check all

vehicle systems for correct operation. Pay

particular attention to:

lEngine noise

lGearbox noise

lSuspension noise

lBody noise

lBraking system operation

lGear selection

lEngine performance

2.Where possible, check for correct operation of

Hill Descent Control (HDC) system. This should

not be carried out if excessive journey time is

required.

3.After road test, carry out a final inspection of the

vehicle on vehicle ramps.

4.Check all underbonnet fluid levels and top-up if

necessary.

Page 204 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-27

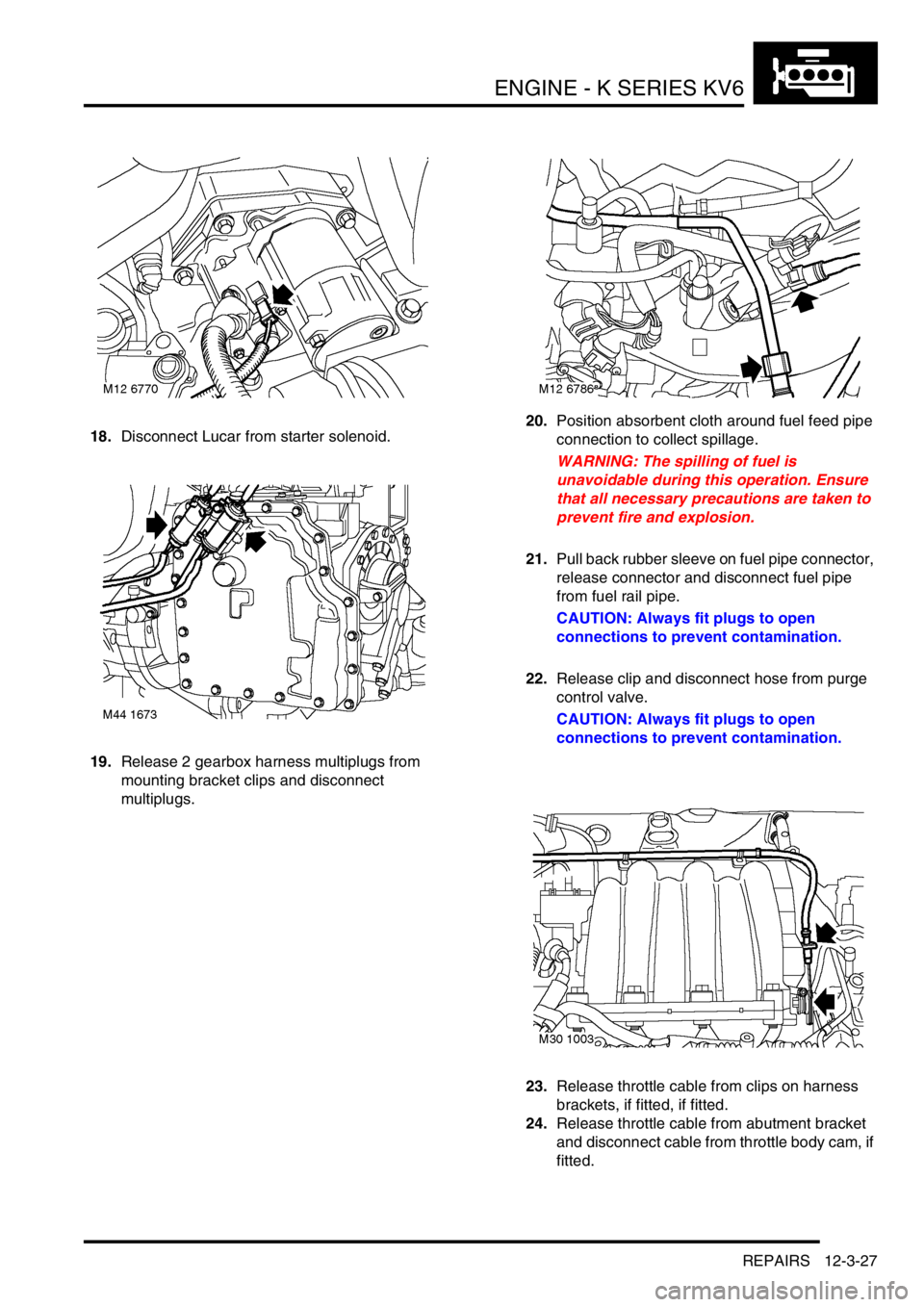

18.Disconnect Lucar from starter solenoid.

19.Release 2 gearbox harness multiplugs from

mounting bracket clips and disconnect

multiplugs.20.Position absorbent cloth around fuel feed pipe

connection to collect spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

21.Pull back rubber sleeve on fuel pipe connector,

release connector and disconnect fuel pipe

from fuel rail pipe.

CAUTION: Always fit plugs to open

connections to prevent contamination.

22.Release clip and disconnect hose from purge

control valve.

CAUTION: Always fit plugs to open

connections to prevent contamination.

23.Release throttle cable from clips on harness

brackets, if fitted, if fitted.

24.Release throttle cable from abutment bracket

and disconnect cable from throttle body cam, if

fitted.

Page 214 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-37

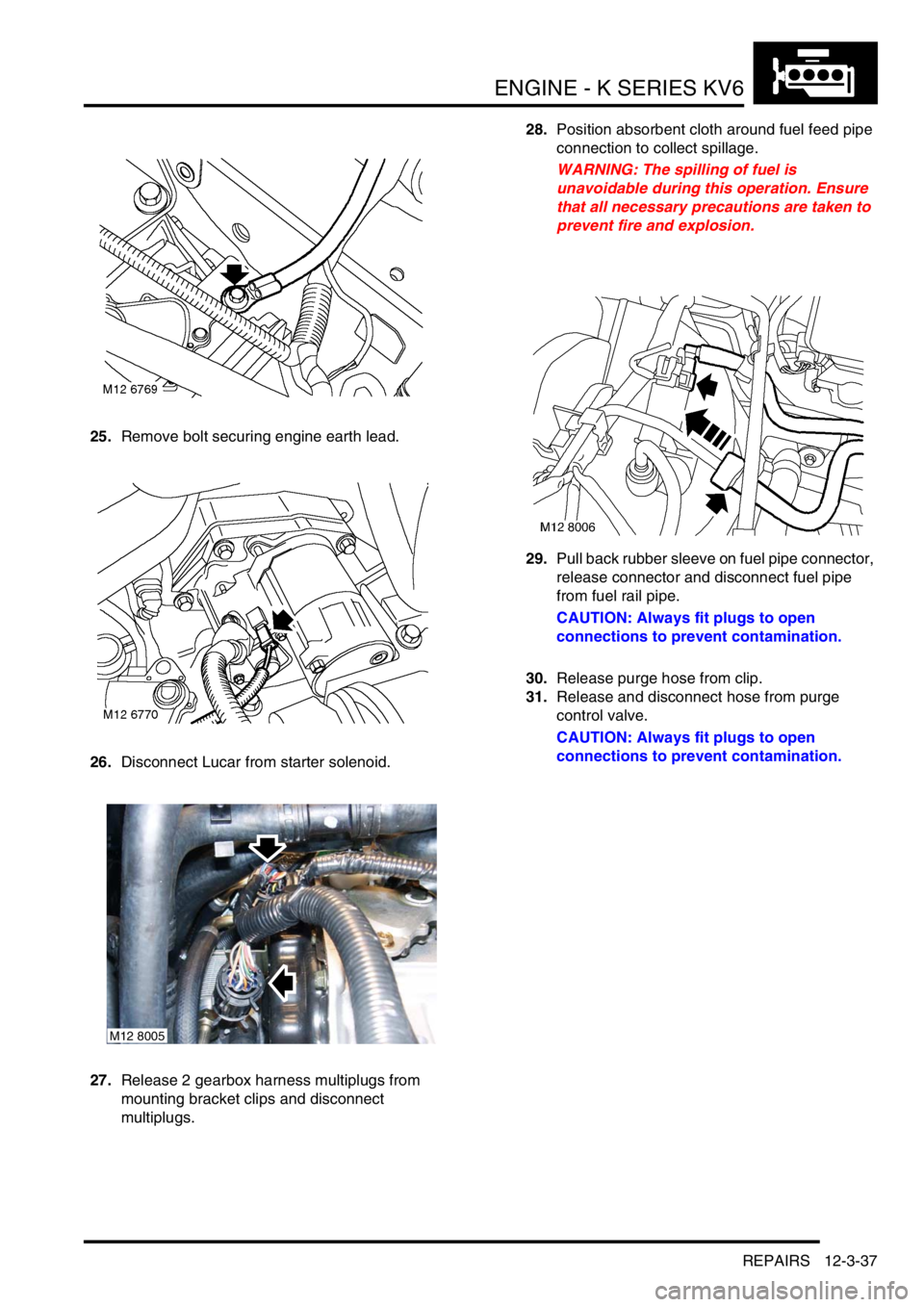

25.Remove bolt securing engine earth lead.

26.Disconnect Lucar from starter solenoid.

27.Release 2 gearbox harness multiplugs from

mounting bracket clips and disconnect

multiplugs.28.Position absorbent cloth around fuel feed pipe

connection to collect spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

29.Pull back rubber sleeve on fuel pipe connector,

release connector and disconnect fuel pipe

from fuel rail pipe.

CAUTION: Always fit plugs to open

connections to prevent contamination.

30.Release purge hose from clip.

31.Release and disconnect hose from purge

control valve.

CAUTION: Always fit plugs to open

connections to prevent contamination.

M12 8005

Page 227 of 1007

ENGINE - K SERIES KV6

12-3-50 REPAIRS

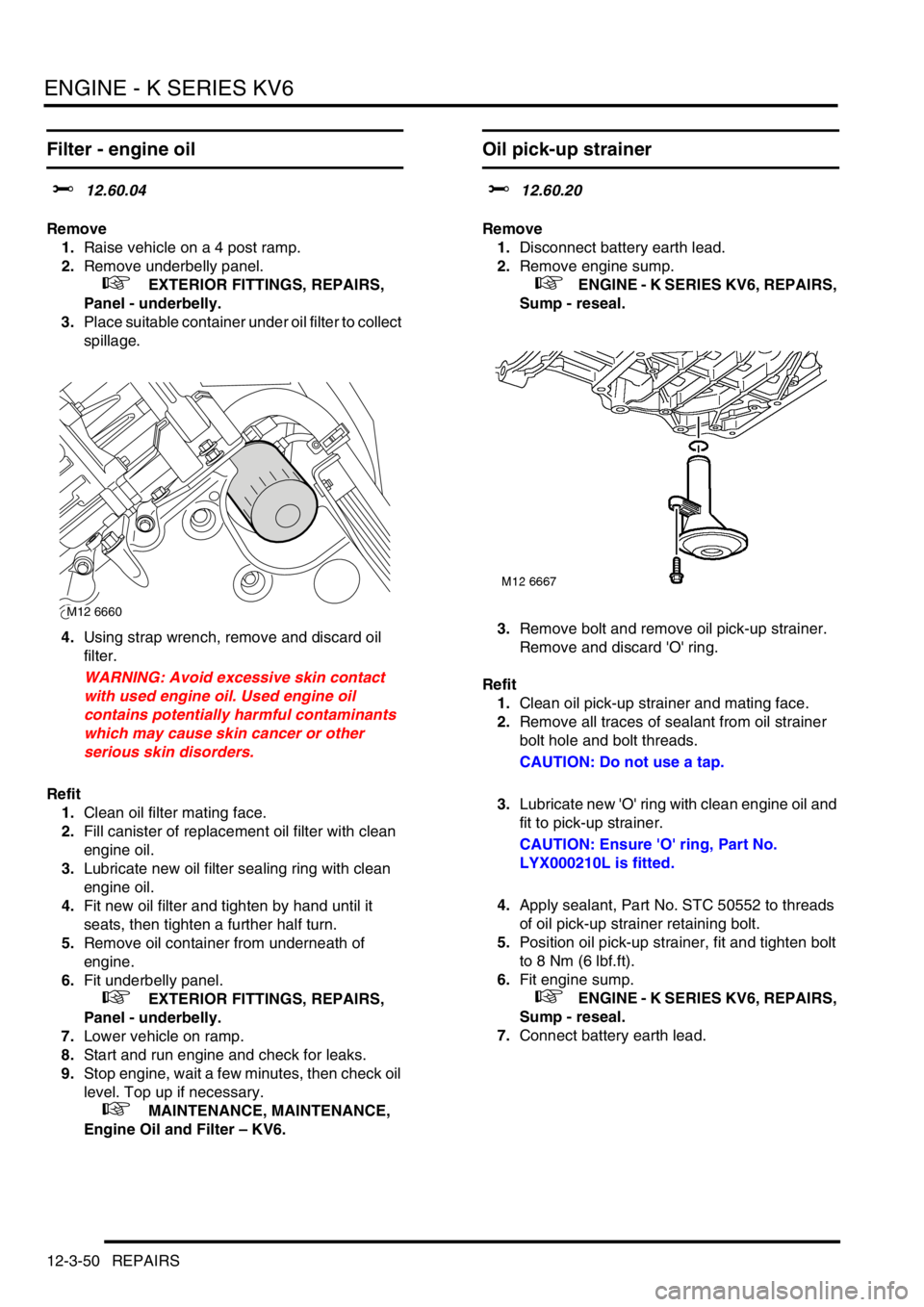

Filter - engine oil

$% 12.60.04

Remove

1.Raise vehicle on a 4 post ramp.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Place suitable container under oil filter to collect

spillage.

4.Using strap wrench, remove and discard oil

filter.

WARNING: Avoid excessive skin contact

with used engine oil. Used engine oil

contains potentially harmful contaminants

which may cause skin cancer or other

serious skin disorders.

Refit

1.Clean oil filter mating face.

2.Fill canister of replacement oil filter with clean

engine oil.

3.Lubricate new oil filter sealing ring with clean

engine oil.

4.Fit new oil filter and tighten by hand until it

seats, then tighten a further half turn.

5.Remove oil container from underneath of

engine.

6.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

7.Lower vehicle on ramp.

8.Start and run engine and check for leaks.

9.Stop engine, wait a few minutes, then check oil

level. Top up if necessary.

+ MAINTENANCE, MAINTENANCE,

Engine Oil and Filter – KV6.

Oil pick-up strainer

$% 12.60.20

Remove

1.Disconnect battery earth lead.

2.Remove engine sump.

+ ENGINE - K SERIES KV6, REPAIRS,

Sump - reseal.

3.Remove bolt and remove oil pick-up strainer.

Remove and discard 'O' ring.

Refit

1.Clean oil pick-up strainer and mating face.

2.Remove all traces of sealant from oil strainer

bolt hole and bolt threads.

CAUTION: Do not use a tap.

3.Lubricate new 'O' ring with clean engine oil and

fit to pick-up strainer.

CAUTION: Ensure 'O' ring, Part No.

LYX000210L is fitted.

4.Apply sealant, Part No. STC 50552 to threads

of oil pick-up strainer retaining bolt.

5.Position oil pick-up strainer, fit and tighten bolt

to 8 Nm (6 lbf.ft).

6.Fit engine sump.

+ ENGINE - K SERIES KV6, REPAIRS,

Sump - reseal.

7.Connect battery earth lead.

M12 6660

Page 295 of 1007

EMISSION CONTROL

17-1-4 REPAIRS

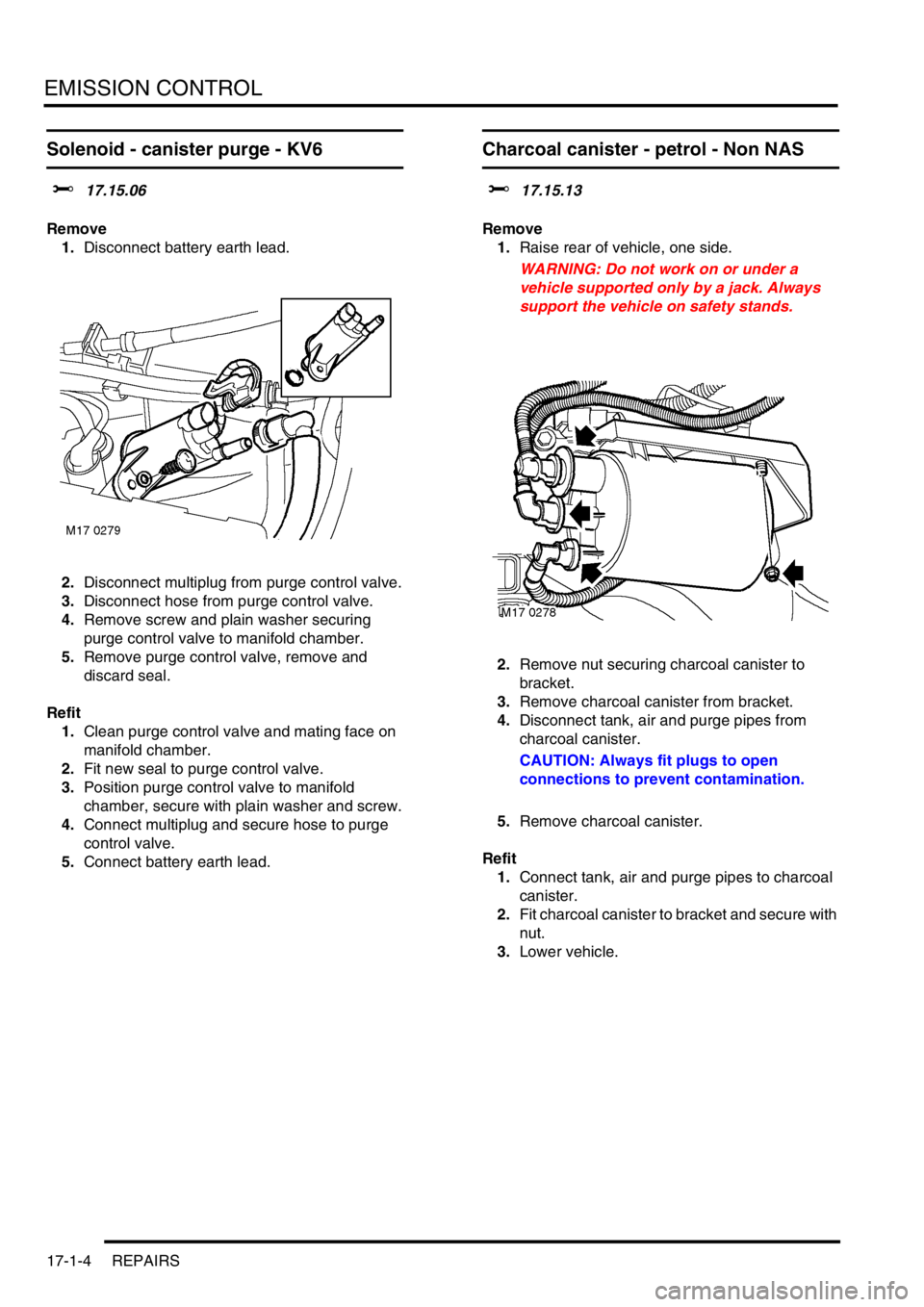

Solenoid - canister purge - KV6

$% 17.15.06

Remove

1.Disconnect battery earth lead.

2.Disconnect multiplug from purge control valve.

3.Disconnect hose from purge control valve.

4.Remove screw and plain washer securing

purge control valve to manifold chamber.

5.Remove purge control valve, remove and

discard seal.

Refit

1.Clean purge control valve and mating face on

manifold chamber.

2.Fit new seal to purge control valve.

3.Position purge control valve to manifold

chamber, secure with plain washer and screw.

4.Connect multiplug and secure hose to purge

control valve.

5.Connect battery earth lead.

Charcoal canister - petrol - Non NAS

$% 17.15.13

Remove

1.Raise rear of vehicle, one side.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove nut securing charcoal canister to

bracket.

3.Remove charcoal canister from bracket.

4.Disconnect tank, air and purge pipes from

charcoal canister.

CAUTION: Always fit plugs to open

connections to prevent contamination.

5.Remove charcoal canister.

Refit

1.Connect tank, air and purge pipes to charcoal

canister.

2.Fit charcoal canister to bracket and secure with

nut.

3.Lower vehicle.

Page 316 of 1007

ENGINE MANAGEMENT SYSTEM - SIEMENS

REPAIRS 18-3-11

5.Fit new Torx screws and wave washers, tighten

Torx screws to 1.5 Nm (1.1 lbf.ft).

6.Connect multiplug to TP sensor.

7.Operate throttle cable cam 2 or 3 times and

ensure that full travel to the throttle open and

the throttle closed positions is available.

8.Fit acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

9.Connect battery earth lead.

NOTE: A ‘throttle initialisation’ procedure

MUST be carried out using TestBook/T4

whenever the TP sensor is removed or

renewed.

Sensor - thermostat monitoring (TM) -

KV6 - NAS

$% 18.30.21

Remove

1.Disconnect battery earth lead.

2.Remove coolant expansion tank cap to release

pressure and refit cap.

WARNING: Since injury such as scalding

could be caused by escaping steam or

coolant, do not remove the filler cap from

the coolant expansion tank while the

system is hot.

3.Position absorbent cloth under TM sensor to

collect spillage.

4.Disconnect multiplug from TM sensor.

5.Release and remove sensor. Discard seal.

Refit

1.Clean sensor and mating face.

2.Using a new seal, fit and secure sensor.

3.Connect multiplug to sensor.

4.Remove absorbent cloth.

5.Check for leaks and fill expansion tank to 'MAX'

mark.

6.Connect battery earth lead.

M18 0764

Page 323 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-2 ADJUSTMENTS

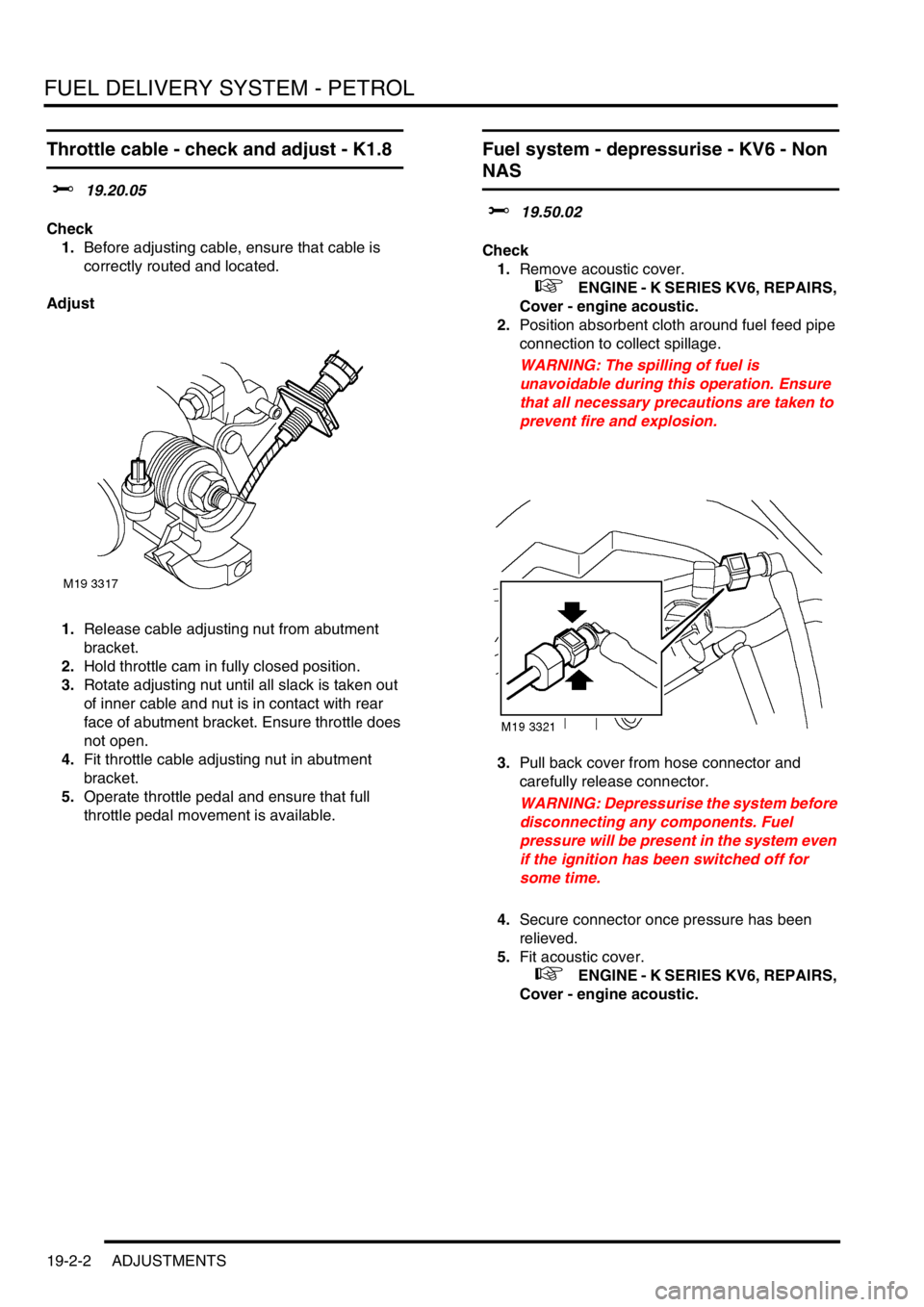

Throttle cable - check and adjust - K1.8

$% 19.20.05

Check

1.Before adjusting cable, ensure that cable is

correctly routed and located.

Adjust

1.Release cable adjusting nut from abutment

bracket.

2.Hold throttle cam in fully closed position.

3.Rotate adjusting nut until all slack is taken out

of inner cable and nut is in contact with rear

face of abutment bracket. Ensure throttle does

not open.

4.Fit throttle cable adjusting nut in abutment

bracket.

5.Operate throttle pedal and ensure that full

throttle pedal movement is available.

Fuel system - depressurise - KV6 - Non

NAS

$% 19.50.02

Check

1.Remove acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Position absorbent cloth around fuel feed pipe

connection to collect spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

3.Pull back cover from hose connector and

carefully release connector.

WARNING: Depressurise the system before

disconnecting any components. Fuel

pressure will be present in the system even

if the ignition has been switched off for

some time.

4.Secure connector once pressure has been

relieved.

5.Fit acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

Page 324 of 1007

FUEL DELIVERY SYSTEM - PETROL

ADJUSTMENTS 19-2-3

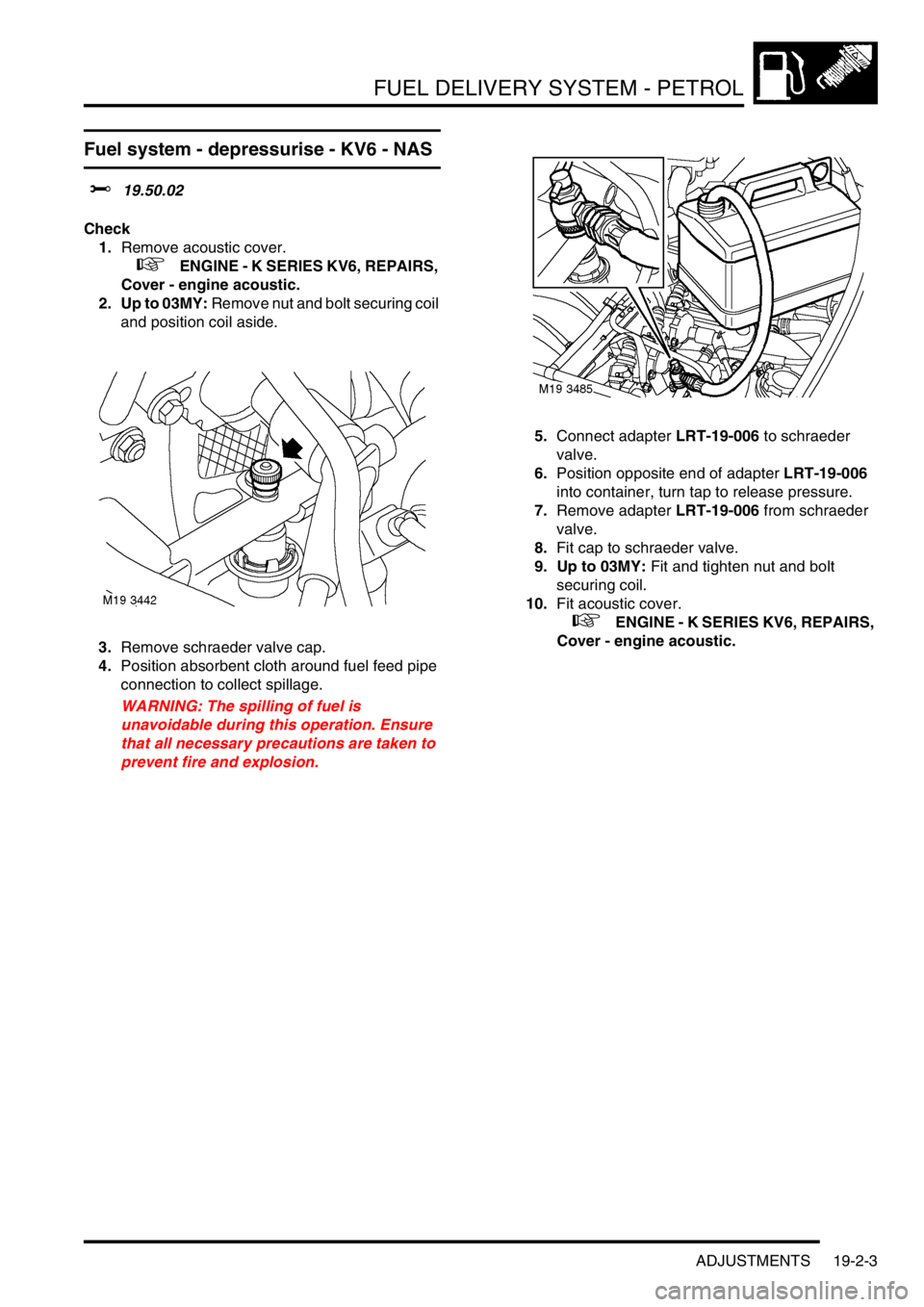

Fuel system - depressurise - KV6 - NAS

$% 19.50.02

Check

1.Remove acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2. Up to 03MY: Remove nut and bolt securing coil

and position coil aside.

3.Remove schraeder valve cap.

4.Position absorbent cloth around fuel feed pipe

connection to collect spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.5.Connect adapter LRT-19-006 to schraeder

valve.

6.Position opposite end of adapter LRT-19-006

into container, turn tap to release pressure.

7.Remove adapter LRT-19-006 from schraeder

valve.

8.Fit cap to schraeder valve.

9. Up to 03MY: Fit and tighten nut and bolt

securing coil.

10.Fit acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

Page 325 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-4 ADJUSTMENTS

Fuel system - depressurise - K1.8

$% 19.50.02

Check

1.Position absorbent cloth around fuel feed pipe

connection to collect spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

2.Disconnect fuel feed hose from fuel rail.

3.Connect feed hose to fuel rail once pressure

has relieved.

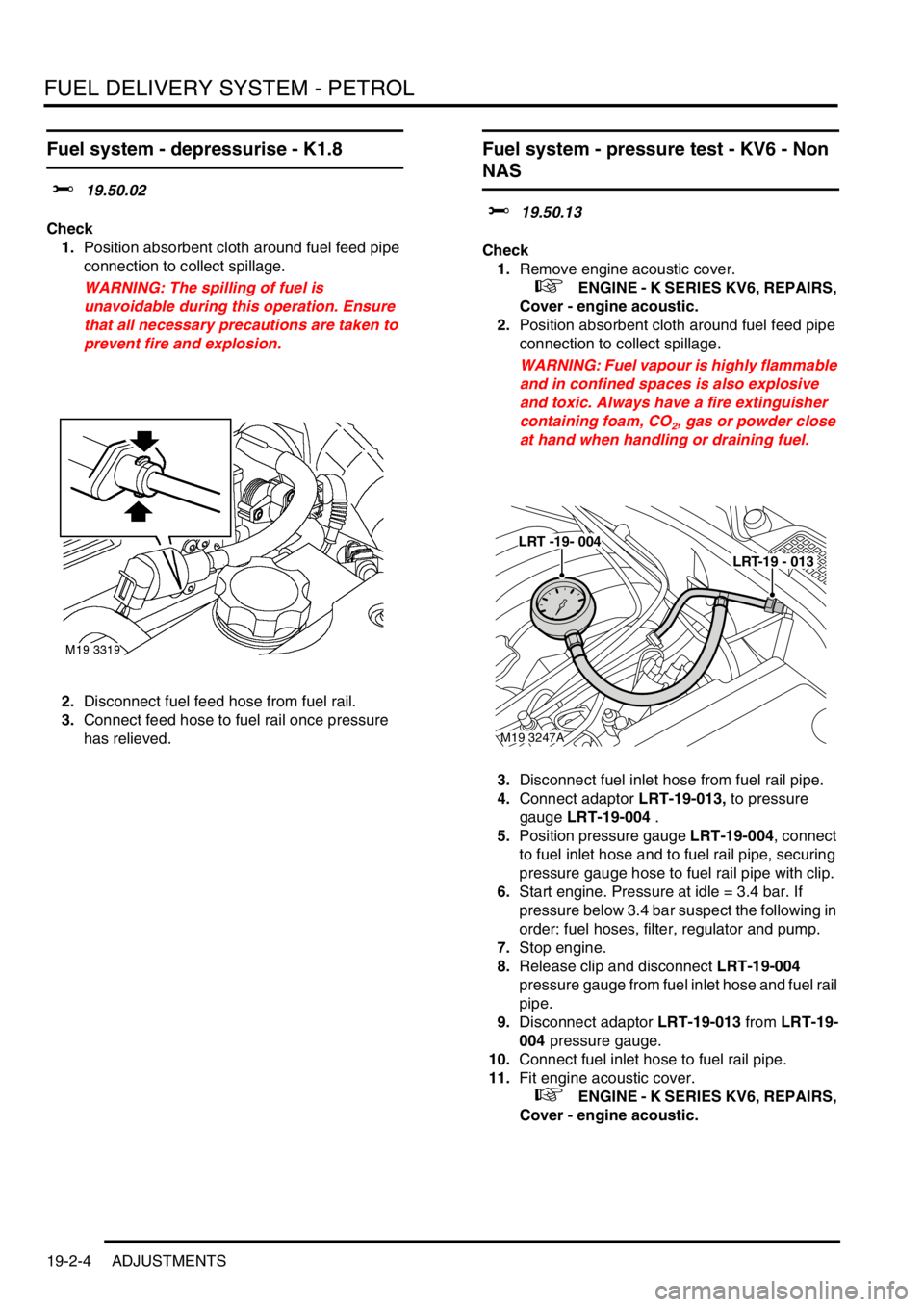

Fuel system - pressure test - KV6 - Non

NAS

$% 19.50.13

Check

1.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Position absorbent cloth around fuel feed pipe

connection to collect spillage.

WARNING: Fuel vapour is highly flammable

and in confined spaces is also explosive

and toxic. Always have a fire extinguisher

containing foam, CO

2, gas or powder close

at hand when handling or draining fuel.

3.Disconnect fuel inlet hose from fuel rail pipe.

4.Connect adaptor LRT-19-013, to pressure

gauge LRT-19-004 .

5.Position pressure gauge LRT-19-004, connect

to fuel inlet hose and to fuel rail pipe, securing

pressure gauge hose to fuel rail pipe with clip.

6.Start engine. Pressure at idle = 3.4 bar. If

pressure below 3.4 bar suspect the following in

order: fuel hoses, filter, regulator and pump.

7.Stop engine.

8.Release clip and disconnect LRT-19-004

pressure gauge from fuel inlet hose and fuel rail

pipe.

9.Disconnect adaptor LRT-19-013 from LRT-19-

004 pressure gauge.

10.Connect fuel inlet hose to fuel rail pipe.

11.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

M19 3247A

LRT-19 - 013

LRT -19- 004