warning LAND ROVER FREELANDER 2001 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 353 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-32 REPAIRS

Tank - NAS

$% 19.55.01

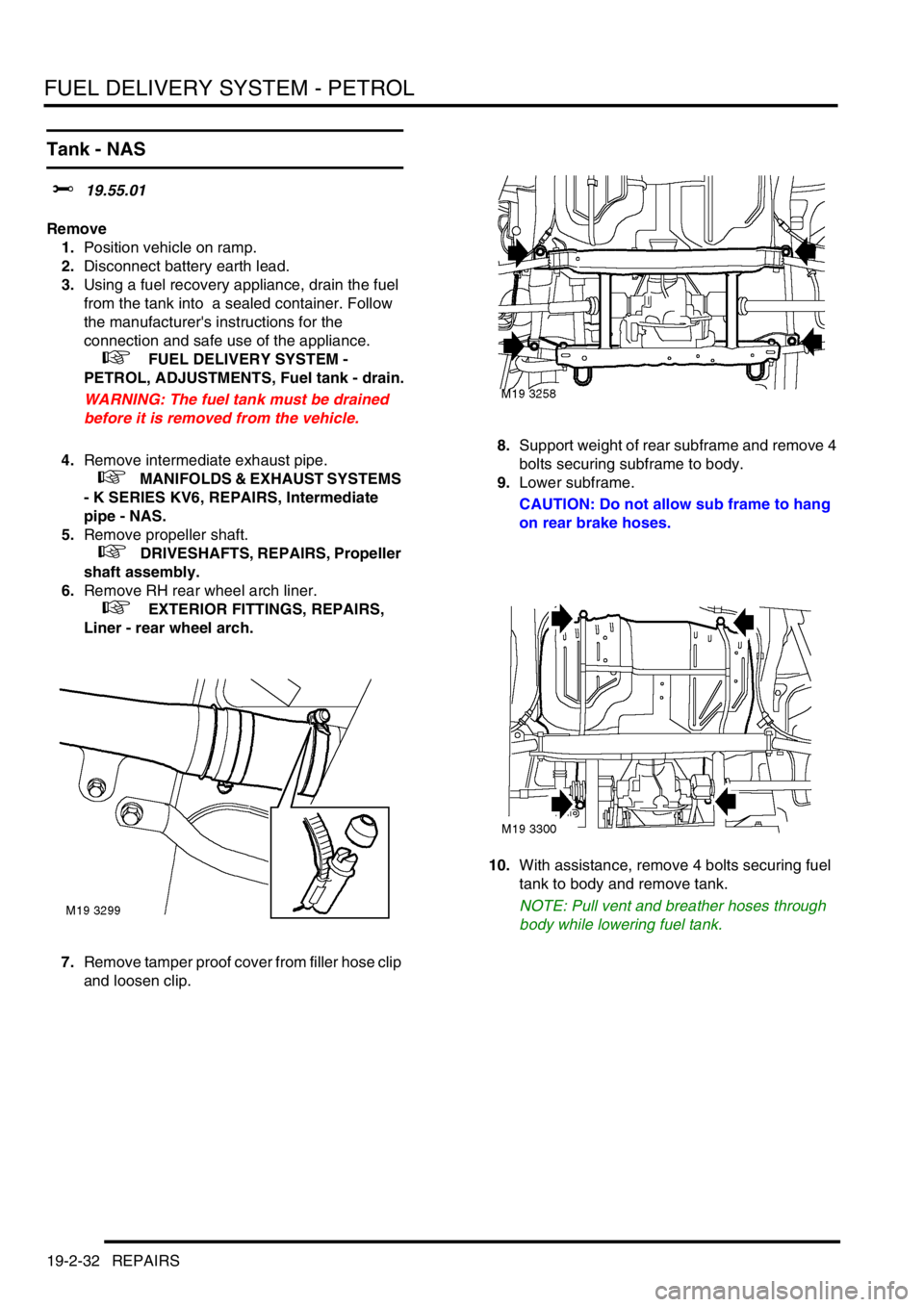

Remove

1.Position vehicle on ramp.

2.Disconnect battery earth lead.

3.Using a fuel recovery appliance, drain the fuel

from the tank into a sealed container. Follow

the manufacturer's instructions for the

connection and safe use of the appliance.

+ FUEL DELIVERY SYSTEM -

PETROL, ADJUSTMENTS, Fuel tank - drain.

WARNING: The fuel tank must be drained

before it is removed from the vehicle.

4.Remove intermediate exhaust pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Intermediate

pipe - NAS.

5.Remove propeller shaft.

+ DRIVESHAFTS, REPAIRS, Propeller

shaft assembly.

6.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

7.Remove tamper proof cover from filler hose clip

and loosen clip.8.Support weight of rear subframe and remove 4

bolts securing subframe to body.

9.Lower subframe.

CAUTION: Do not allow sub frame to hang

on rear brake hoses.

10.With assistance, remove 4 bolts securing fuel

tank to body and remove tank.

NOTE: Pull vent and breather hoses through

body while lowering fuel tank.

Page 355 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-34 REPAIRS

Filler neck

$% 19.55.07

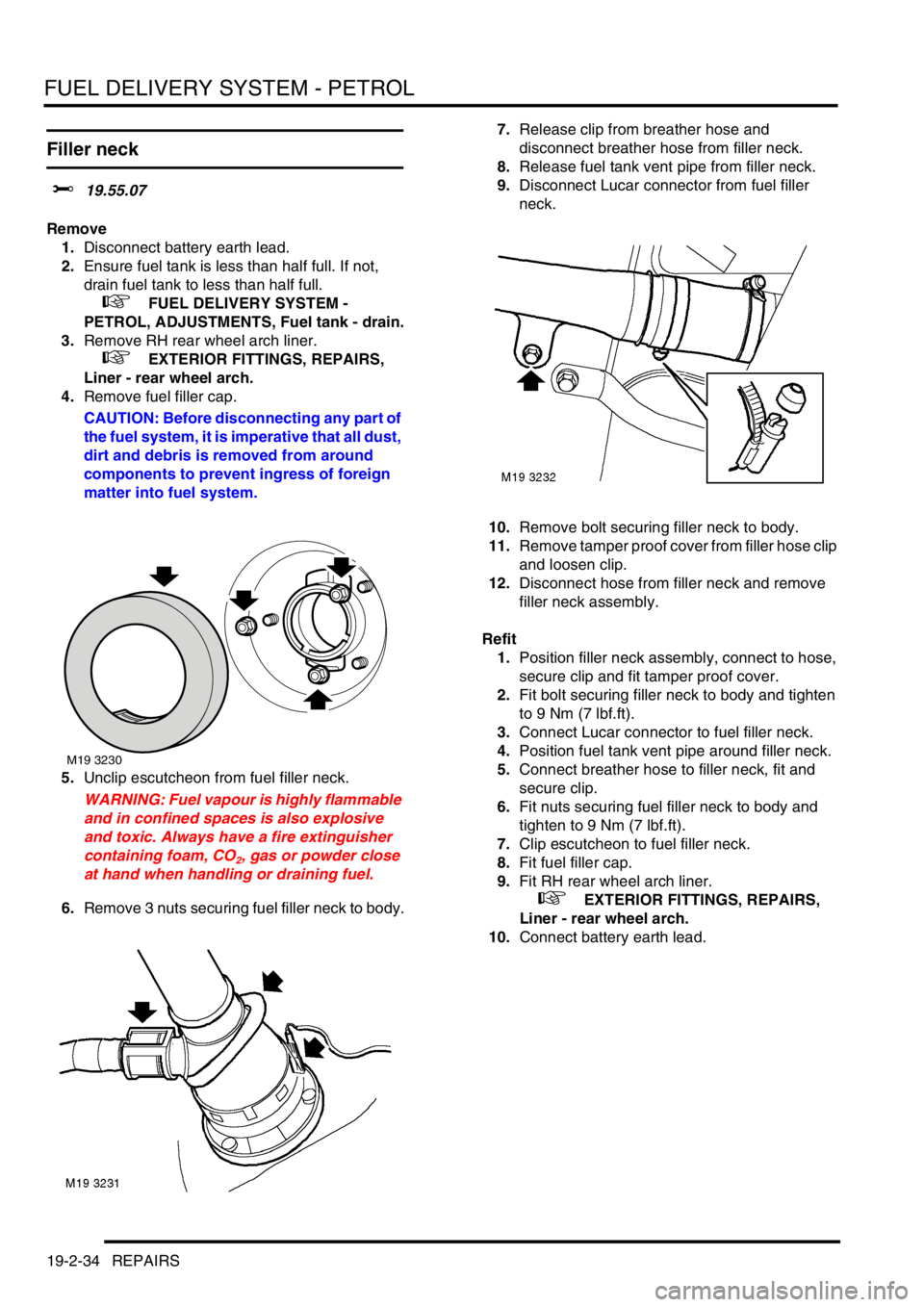

Remove

1.Disconnect battery earth lead.

2.Ensure fuel tank is less than half full. If not,

drain fuel tank to less than half full.

+ FUEL DELIVERY SYSTEM -

PETROL, ADJUSTMENTS, Fuel tank - drain.

3.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

4.Remove fuel filler cap.

CAUTION: Before disconnecting any part of

the fuel system, it is imperative that all dust,

dirt and debris is removed from around

components to prevent ingress of foreign

matter into fuel system.

5.Unclip escutcheon from fuel filler neck.

WARNING: Fuel vapour is highly flammable

and in confined spaces is also explosive

and toxic. Always have a fire extinguisher

containing foam, CO

2, gas or powder close

at hand when handling or draining fuel.

6.Remove 3 nuts securing fuel filler neck to body.7.Release clip from breather hose and

disconnect breather hose from filler neck.

8.Release fuel tank vent pipe from filler neck.

9.Disconnect Lucar connector from fuel filler

neck.

10.Remove bolt securing filler neck to body.

11.Remove tamper proof cover from filler hose clip

and loosen clip.

12.Disconnect hose from filler neck and remove

filler neck assembly.

Refit

1.Position filler neck assembly, connect to hose,

secure clip and fit tamper proof cover.

2.Fit bolt securing filler neck to body and tighten

to 9 Nm (7 lbf.ft).

3.Connect Lucar connector to fuel filler neck.

4.Position fuel tank vent pipe around filler neck.

5.Connect breather hose to filler neck, fit and

secure clip.

6.Fit nuts securing fuel filler neck to body and

tighten to 9 Nm (7 lbf.ft).

7.Clip escutcheon to fuel filler neck.

8.Fit fuel filler cap.

9.Fit RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

10.Connect battery earth lead.

M19 3230

Page 366 of 1007

COOLING SYSTEM - K SERIES KV6

ADJUSTMENTS 26-3-1

COOLING SYS TEM - K SER IES KV6 ADJUST ME NTS

Coolant - drain and refill

$% 26.10.01

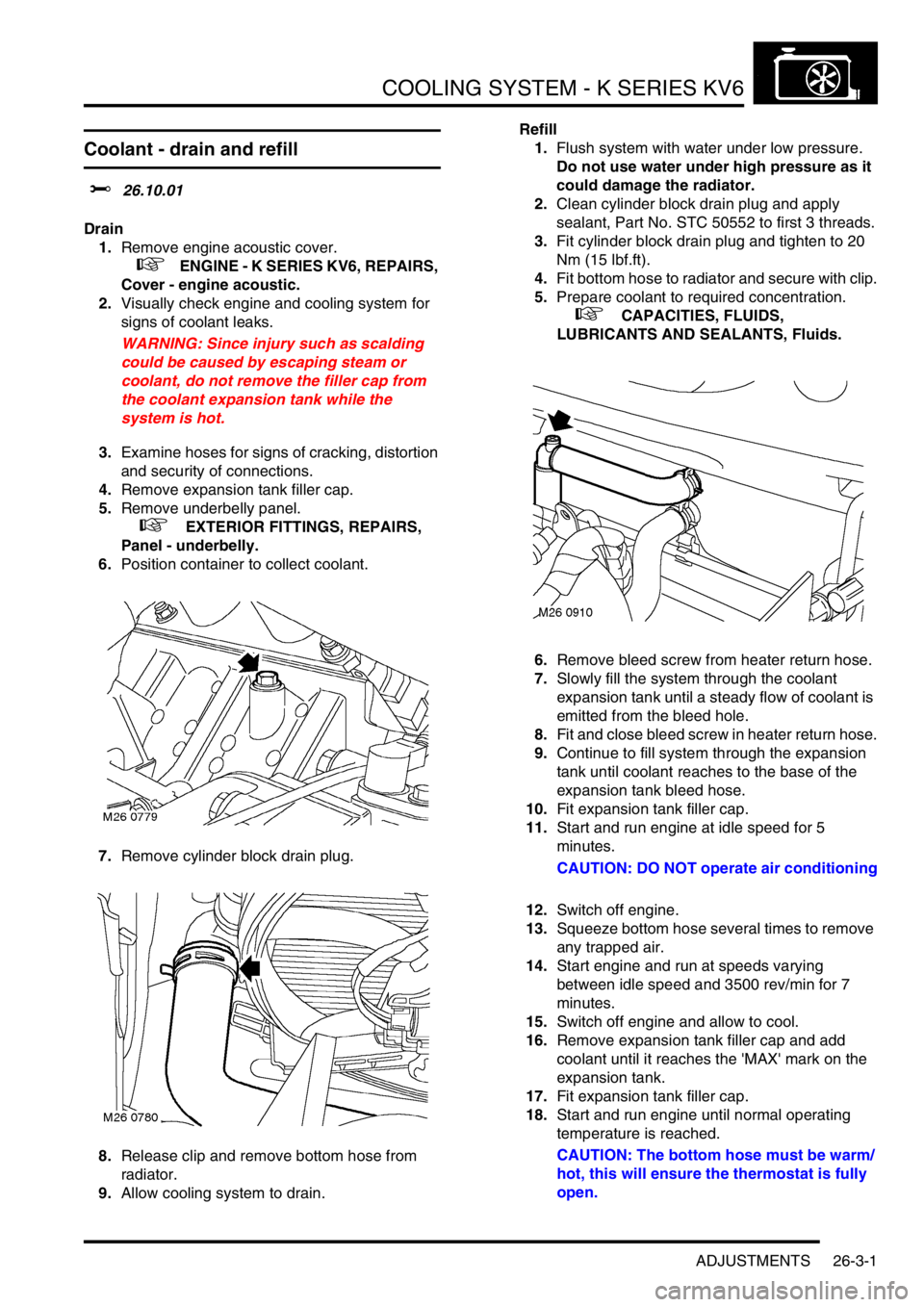

Drain

1.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Visually check engine and cooling system for

signs of coolant leaks.

WARNING: Since injury such as scalding

could be caused by escaping steam or

coolant, do not remove the filler cap from

the coolant expansion tank while the

system is hot.

3.Examine hoses for signs of cracking, distortion

and security of connections.

4.Remove expansion tank filler cap.

5.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

6.Position container to collect coolant.

7.Remove cylinder block drain plug.

8.Release clip and remove bottom hose from

radiator.

9.Allow cooling system to drain.Refill

1.Flush system with water under low pressure.

Do not use water under high pressure as it

could damage the radiator.

2.Clean cylinder block drain plug and apply

sealant, Part No. STC 50552 to first 3 threads.

3.Fit cylinder block drain plug and tighten to 20

Nm (15 lbf.ft).

4.Fit bottom hose to radiator and secure with clip.

5.Prepare coolant to required concentration.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS, Fluids.

6.Remove bleed screw from heater return hose.

7.Slowly fill the system through the coolant

expansion tank until a steady flow of coolant is

emitted from the bleed hole.

8.Fit and close bleed screw in heater return hose.

9.Continue to fill system through the expansion

tank until coolant reaches to the base of the

expansion tank bleed hose.

10.Fit expansion tank filler cap.

11.Start and run engine at idle speed for 5

minutes.

CAUTION: DO NOT operate air conditioning

12.Switch off engine.

13.Squeeze bottom hose several times to remove

any trapped air.

14.Start engine and run at speeds varying

between idle speed and 3500 rev/min for 7

minutes.

15.Switch off engine and allow to cool.

16.Remove expansion tank filler cap and add

coolant until it reaches the 'MAX' mark on the

expansion tank.

17.Fit expansion tank filler cap.

18.Start and run engine until normal operating

temperature is reached.

CAUTION: The bottom hose must be warm/

hot, this will ensure the thermostat is fully

open.

Page 379 of 1007

MANIFOLDS & EXHAUST SYSTEMS - K SERIES KV6

30-3-6 REPAIRS

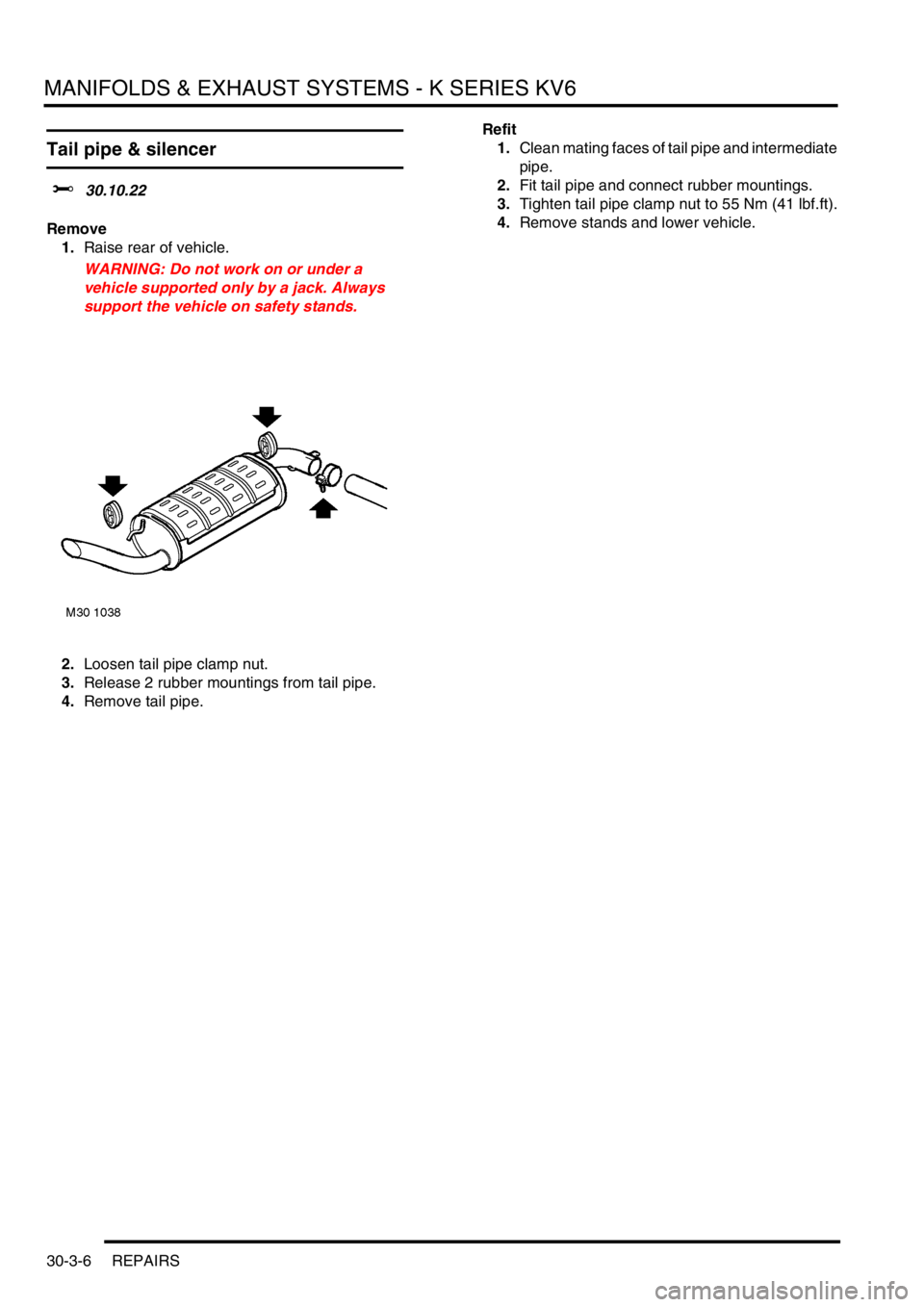

Tail pipe & silencer

$% 30.10.22

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Loosen tail pipe clamp nut.

3.Release 2 rubber mountings from tail pipe.

4.Remove tail pipe.Refit

1.Clean mating faces of tail pipe and intermediate

pipe.

2.Fit tail pipe and connect rubber mountings.

3.Tighten tail pipe clamp nut to 55 Nm (41 lbf.ft).

4.Remove stands and lower vehicle.

Page 386 of 1007

MANIFOLDS & EXHAUST SYSTEMS - K SERIES KV6

REPAIRS 30-3-13

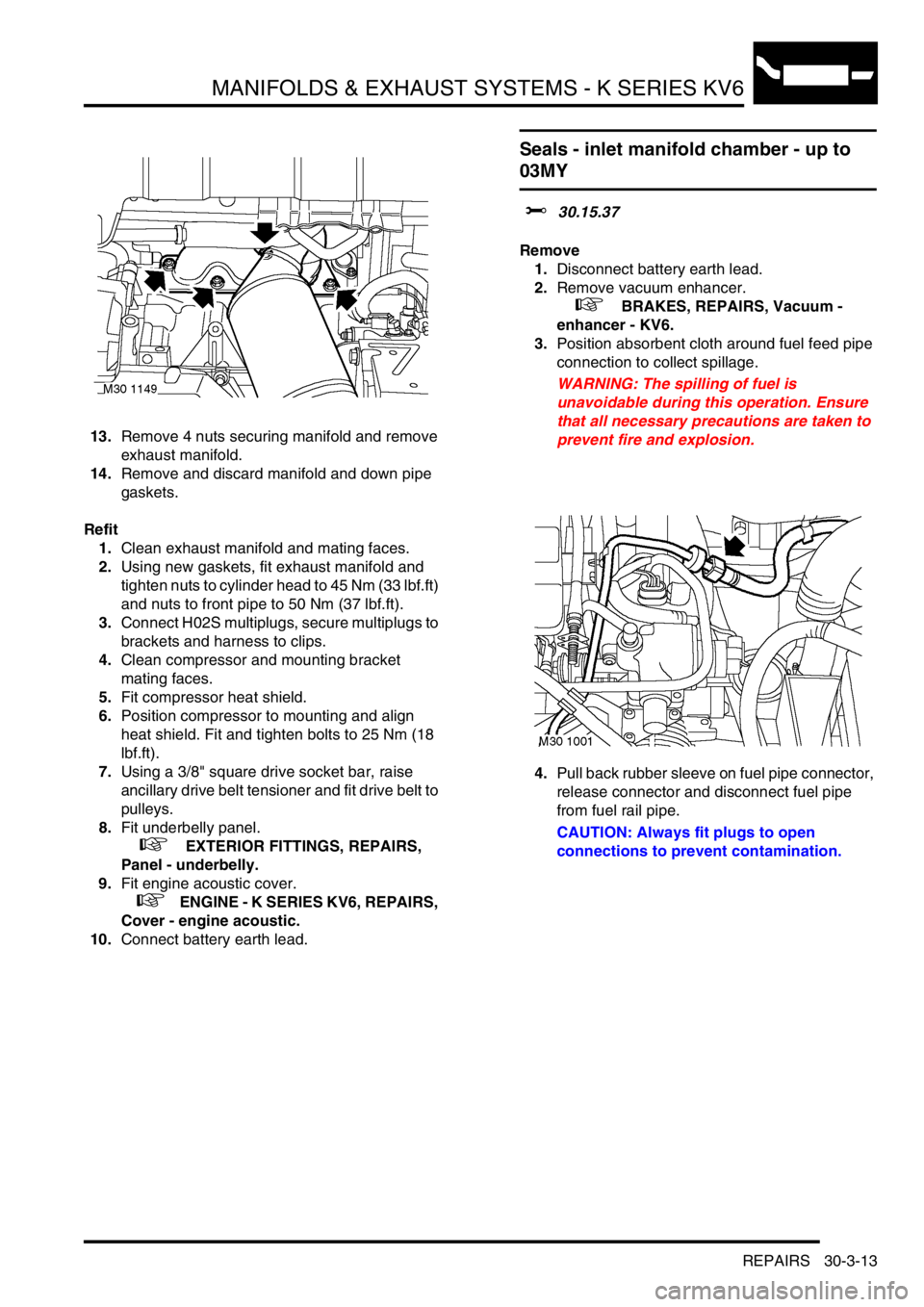

13.Remove 4 nuts securing manifold and remove

exhaust manifold.

14.Remove and discard manifold and down pipe

gaskets.

Refit

1.Clean exhaust manifold and mating faces.

2.Using new gaskets, fit exhaust manifold and

tighten nuts to cylinder head to 45 Nm (33 lbf.ft)

and nuts to front pipe to 50 Nm (37 lbf.ft).

3.Connect H02S multiplugs, secure multiplugs to

brackets and harness to clips.

4.Clean compressor and mounting bracket

mating faces.

5.Fit compressor heat shield.

6.Position compressor to mounting and align

heat shield. Fit and tighten bolts to 25 Nm (18

lbf.ft).

7.Using a 3/8" square drive socket bar, raise

ancillary drive belt tensioner and fit drive belt to

pulleys.

8.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

9.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

10.Connect battery earth lead.

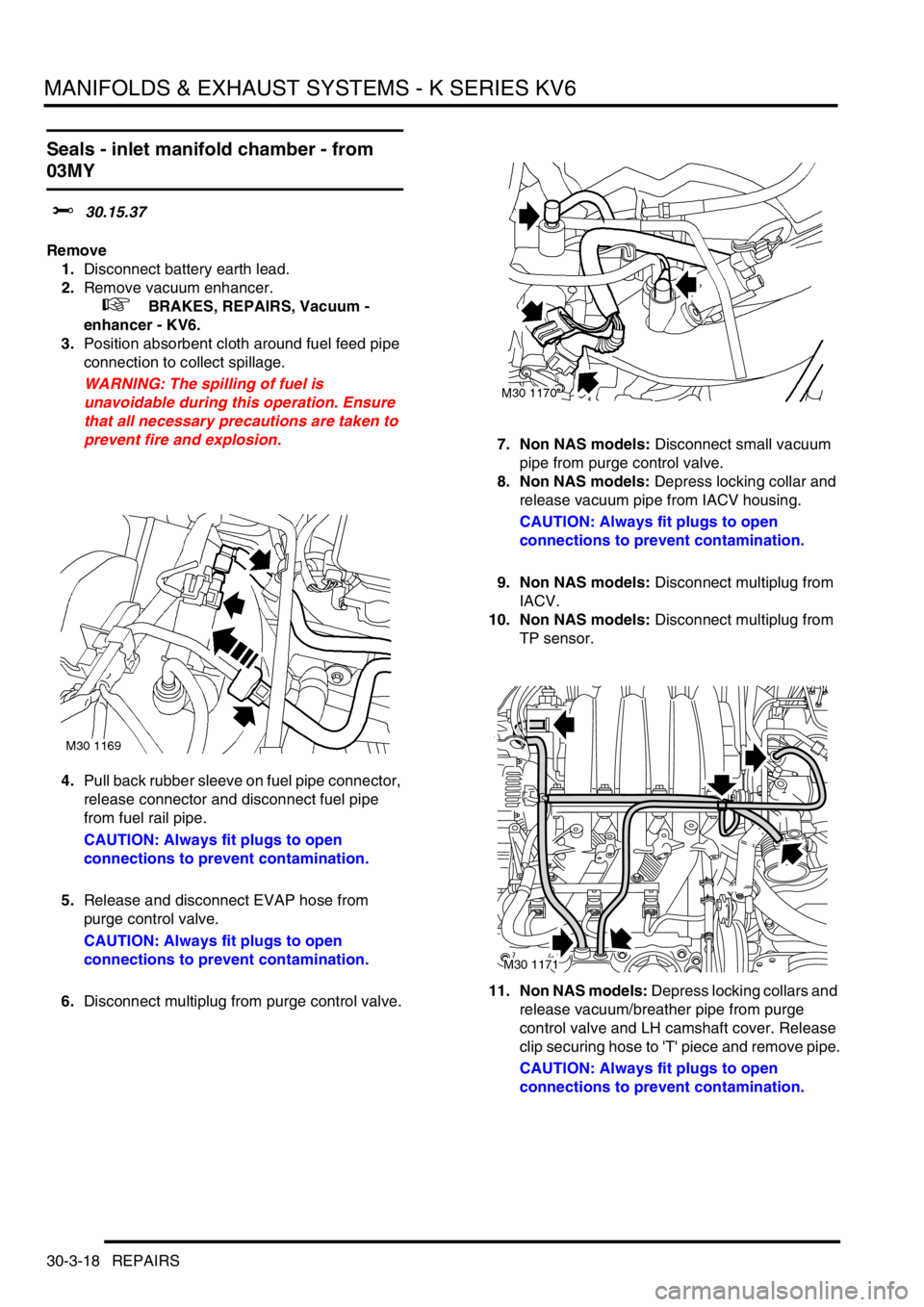

Seals - inlet manifold chamber - up to

03MY

$% 30.15.37

Remove

1.Disconnect battery earth lead.

2.Remove vacuum enhancer.

+ BRAKES, REPAIRS, Vacuum -

enhancer - KV6.

3.Position absorbent cloth around fuel feed pipe

connection to collect spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

4.Pull back rubber sleeve on fuel pipe connector,

release connector and disconnect fuel pipe

from fuel rail pipe.

CAUTION: Always fit plugs to open

connections to prevent contamination.

Page 391 of 1007

MANIFOLDS & EXHAUST SYSTEMS - K SERIES KV6

30-3-18 REPAIRS

Seals - inlet manifold chamber - from

03MY

$% 30.15.37

Remove

1.Disconnect battery earth lead.

2.Remove vacuum enhancer.

+ BRAKES, REPAIRS, Vacuum -

enhancer - KV6.

3.Position absorbent cloth around fuel feed pipe

connection to collect spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

4.Pull back rubber sleeve on fuel pipe connector,

release connector and disconnect fuel pipe

from fuel rail pipe.

CAUTION: Always fit plugs to open

connections to prevent contamination.

5.Release and disconnect EVAP hose from

purge control valve.

CAUTION: Always fit plugs to open

connections to prevent contamination.

6.Disconnect multiplug from purge control valve.7. Non NAS models: Disconnect small vacuum

pipe from purge control valve.

8. Non NAS models: Depress locking collar and

release vacuum pipe from IACV housing.

CAUTION: Always fit plugs to open

connections to prevent contamination.

9. Non NAS models: Disconnect multiplug from

IACV.

10. Non NAS models: Disconnect multiplug from

TP sensor.

11. Non NAS models: Depress locking collars and

release vacuum/breather pipe from purge

control valve and LH camshaft cover. Release

clip securing hose to 'T' piece and remove pipe.

CAUTION: Always fit plugs to open

connections to prevent contamination.

M30 1171

Page 404 of 1007

INTERMEDIATE REDUCTION DRIVE

ADJUSTMENTS 41-1

INTERMEDIATE RE DUCTION DRIVE ADJUST ME NTS

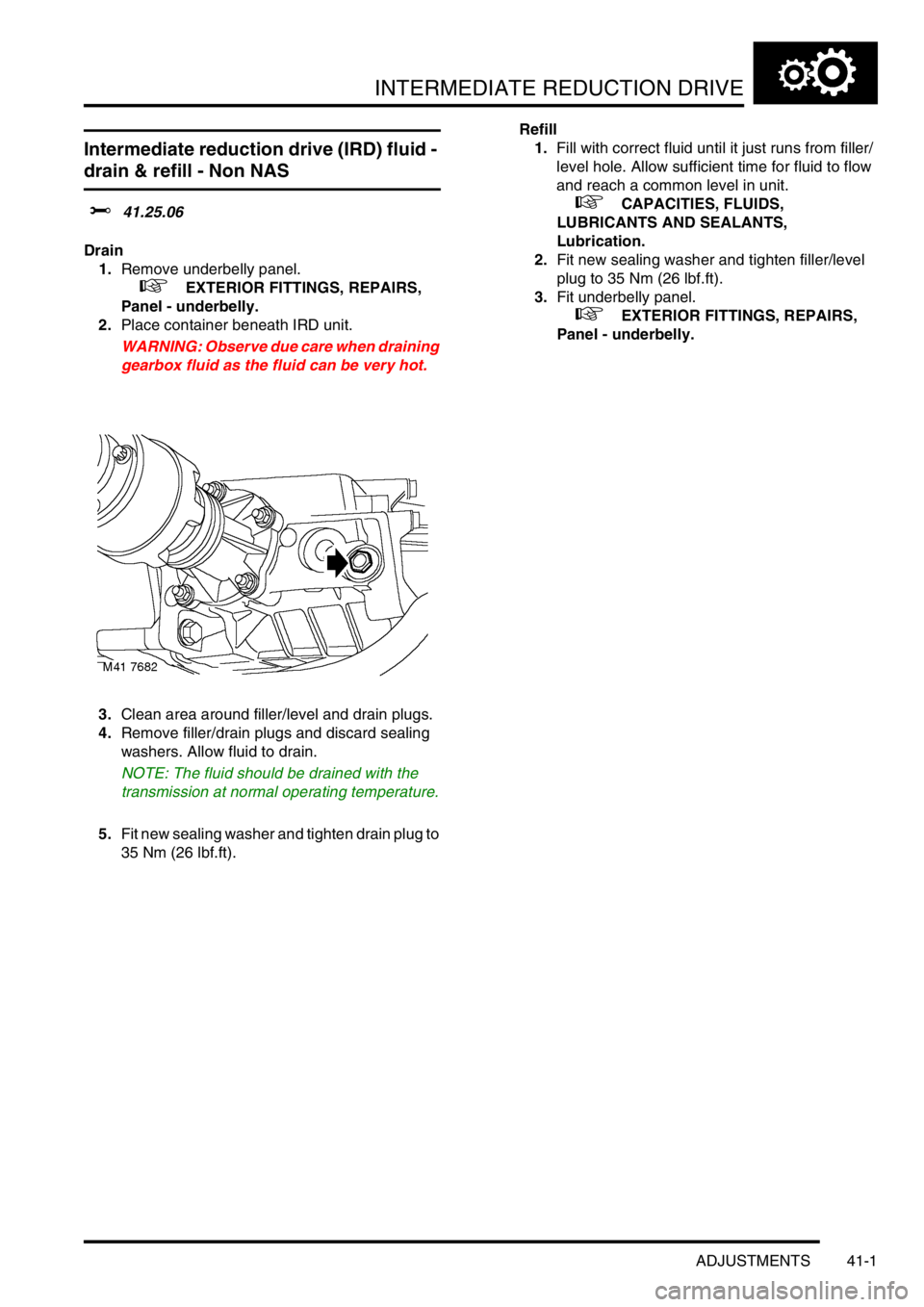

Intermediate reduction drive (IRD) fluid -

drain & refill - Non NAS

$% 41.25.06

Drain

1.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

2.Place container beneath IRD unit.

WARNING: Observe due care when draining

gearbox fluid as the fluid can be very hot.

3.Clean area around filler/level and drain plugs.

4.Remove filler/drain plugs and discard sealing

washers. Allow fluid to drain.

NOTE: The fluid should be drained with the

transmission at normal operating temperature.

5.Fit new sealing washer and tighten drain plug to

35 Nm (26 lbf.ft).Refill

1.Fill with correct fluid until it just runs from filler/

level hole. Allow sufficient time for fluid to flow

and reach a common level in unit.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

2.Fit new sealing washer and tighten filler/level

plug to 35 Nm (26 lbf.ft).

3.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

Page 405 of 1007

INTERMEDIATE REDUCTION DRIVE

41-2 ADJUSTMENTS

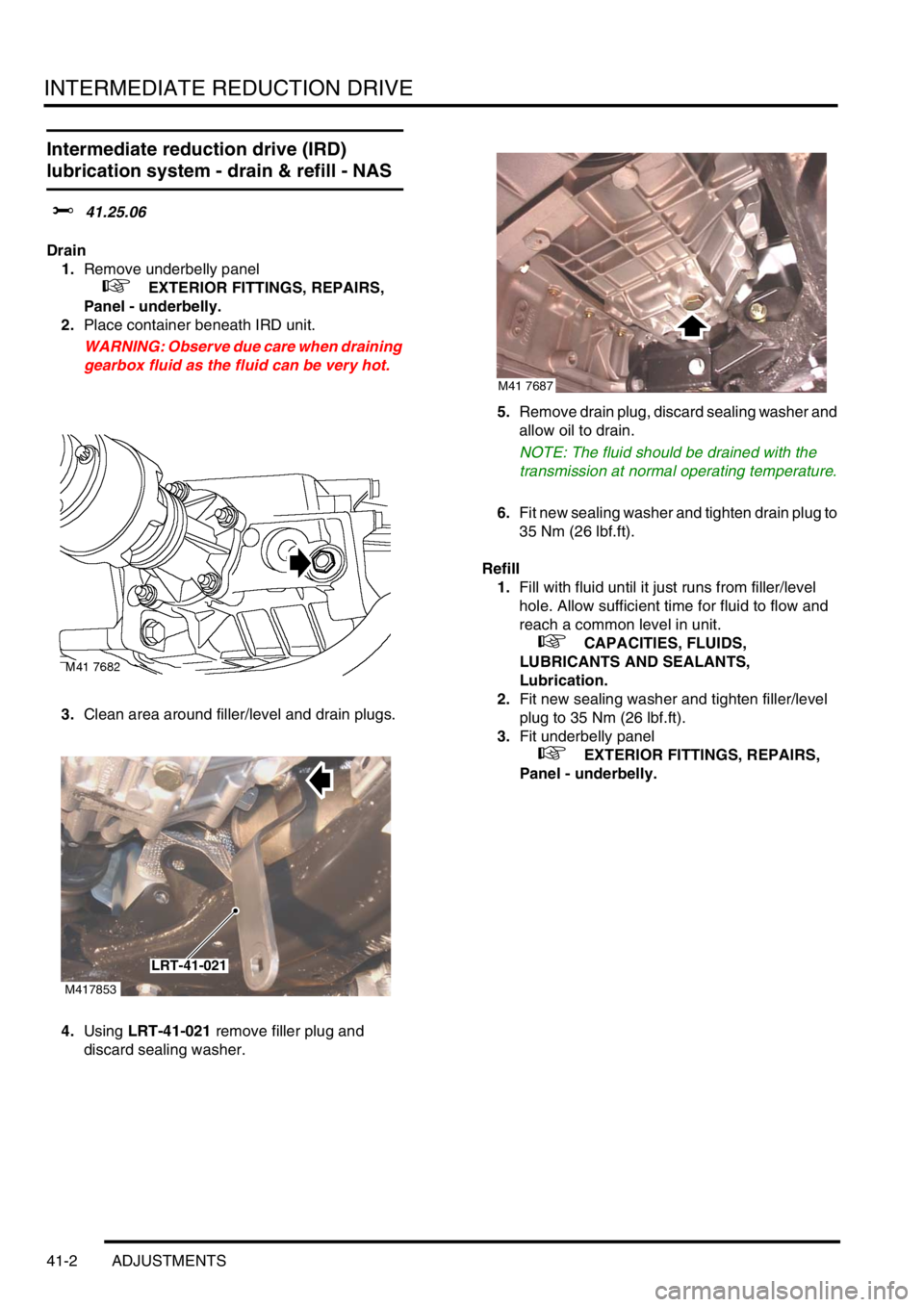

Intermediate reduction drive (IRD)

lubrication system - drain & refill - NAS

$% 41.25.06

Drain

1.Remove underbelly panel

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

2.Place container beneath IRD unit.

WARNING: Observe due care when draining

gearbox fluid as the fluid can be very hot.

3.Clean area around filler/level and drain plugs.

4.Using LRT-41-021 remove filler plug and

discard sealing washer.5.Remove drain plug, discard sealing washer and

allow oil to drain.

NOTE: The fluid should be drained with the

transmission at normal operating temperature.

6.Fit new sealing washer and tighten drain plug to

35 Nm (26 lbf.ft).

Refill

1.Fill with fluid until it just runs from filler/level

hole. Allow sufficient time for fluid to flow and

reach a common level in unit.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

2.Fit new sealing washer and tighten filler/level

plug to 35 Nm (26 lbf.ft).

3.Fit underbelly panel

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

M417853

LRT-41-021

M41 7687

Page 406 of 1007

INTERMEDIATE REDUCTION DRIVE

REPAIRS 41-3

REPAIRS

Intermediate reduction drive (IRD) unit -

Td4

$% 41.25.01.99

Remove

1.Disconnect battery earth lead.

2.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Remove rear beam.

+ FRONT SUSPENSION, REPAIRS,

Rear beam.

4.Remove exhaust front pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- Td4, REPAIRS, Exhaust pipe - front.

5.Drain fluid from IRD.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

6.Drain gearbox fluid.

+ MANUAL GEARBOX - GETRAG,

ADJUSTMENTS, Gearbox oil - drain and

refill.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Gearbox fluid - drain &

refill.

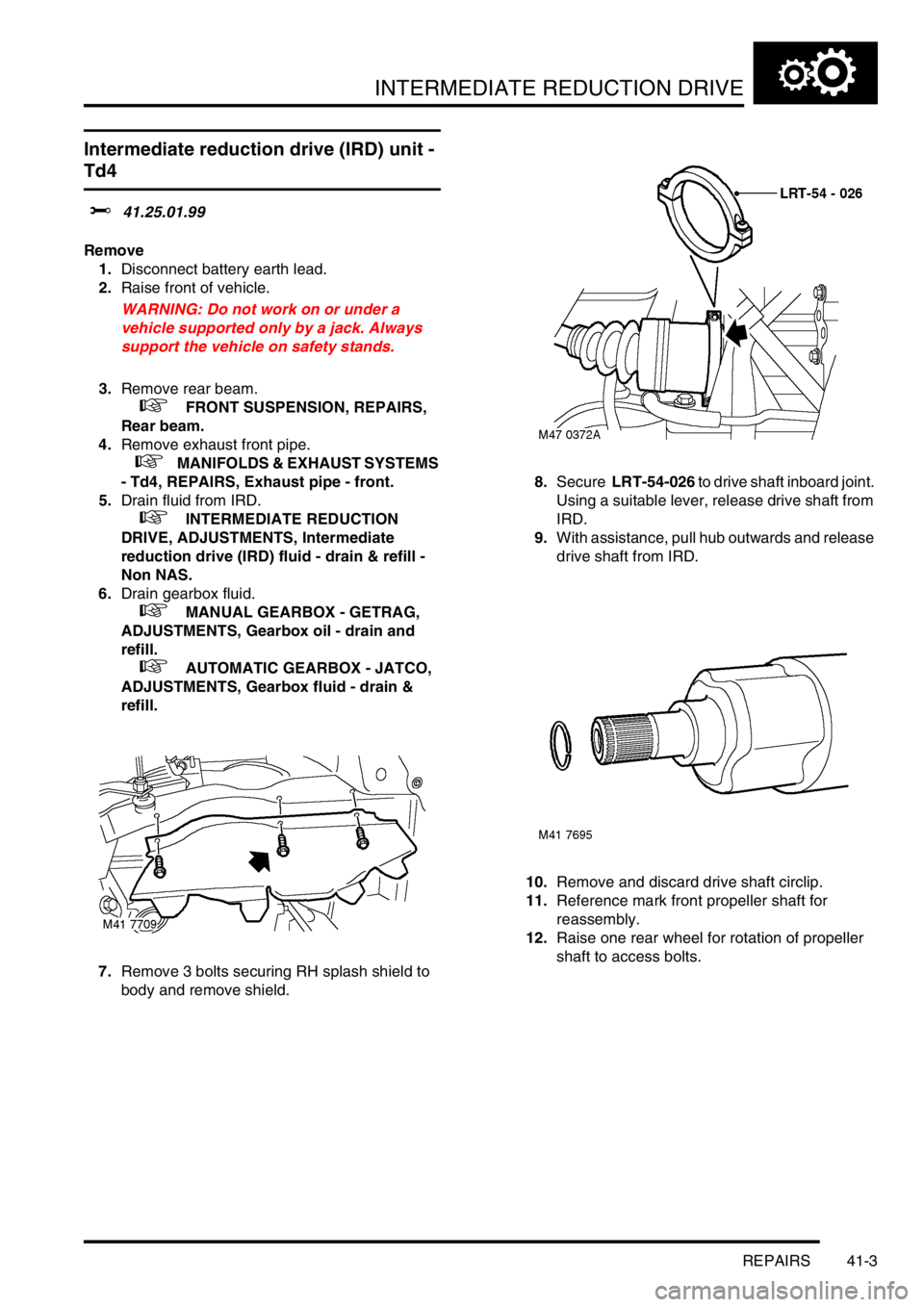

7.Remove 3 bolts securing RH splash shield to

body and remove shield.8.Secure LRT-54-026 to drive shaft inboard joint.

Using a suitable lever, release drive shaft from

IRD.

9.With assistance, pull hub outwards and release

drive shaft from IRD.

10.Remove and discard drive shaft circlip.

11.Reference mark front propeller shaft for

reassembly.

12.Raise one rear wheel for rotation of propeller

shaft to access bolts.

Page 428 of 1007

INTERMEDIATE REDUCTION DRIVE

REPAIRS 41-25

Seal - driveshaft - RH

$% 41.29.09

Remove

1.Remove RH drive shaft.

+ DRIVESHAFTS, REPAIRS, Shaft

with both joints - RH.

2.Carefully remove and discard oil seal, take care

not to damage oil seal recess.

Refit

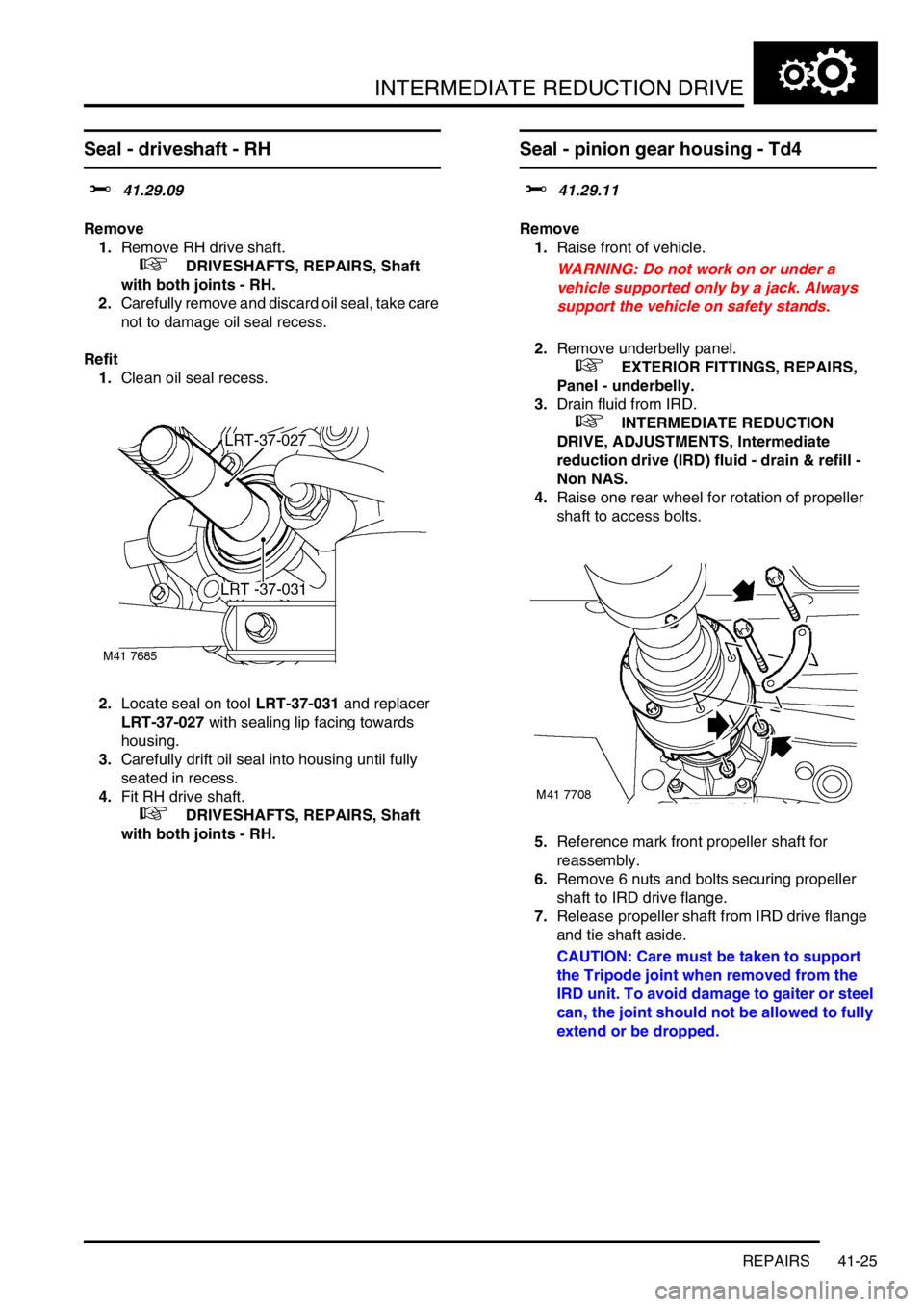

1.Clean oil seal recess.

2.Locate seal on tool LRT-37-031 and replacer

LRT-37-027 with sealing lip facing towards

housing.

3.Carefully drift oil seal into housing until fully

seated in recess.

4.Fit RH drive shaft.

+ DRIVESHAFTS, REPAIRS, Shaft

with both joints - RH.

Seal - pinion gear housing - Td4

$% 41.29.11

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Drain fluid from IRD.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

4.Raise one rear wheel for rotation of propeller

shaft to access bolts.

5.Reference mark front propeller shaft for

reassembly.

6.Remove 6 nuts and bolts securing propeller

shaft to IRD drive flange.

7.Release propeller shaft from IRD drive flange

and tie shaft aside.

CAUTION: Care must be taken to support

the Tripode joint when removed from the

IRD unit. To avoid damage to gaiter or steel

can, the joint should not be allowed to fully

extend or be dropped.