engine LAND ROVER FRELANDER 2 2006 Owners Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 623 of 3229

One s olenoid cont rols t he valves for cylinders 1, 2 and 4 whils t t he other cont rols t he valves for cylinders 3, 5 and 6. The solenoidstherefore cont rol 6 valves each (when t he engine has 2 int ake valves and 2 exhaus t valves per cylinder).

The pos it ion of the s olenoids valves , on or off, are cont rolled by t he ECMFor addit ional information, refer t o: Elect ronic Engine Cont rols (303-14A Elect ronic Engine Controls - I6 3.2L Pet rol, Des cript ion andOperation)..

The inner t appet works like a hydraulic t appet , which compens at es for any wear. The valve clearance is t herefore '0'.

The exhaus t cams haft is convent ional and has a lift ing height of 10.0 mm. The t appets are mechanical (i.e. have valve clearance).

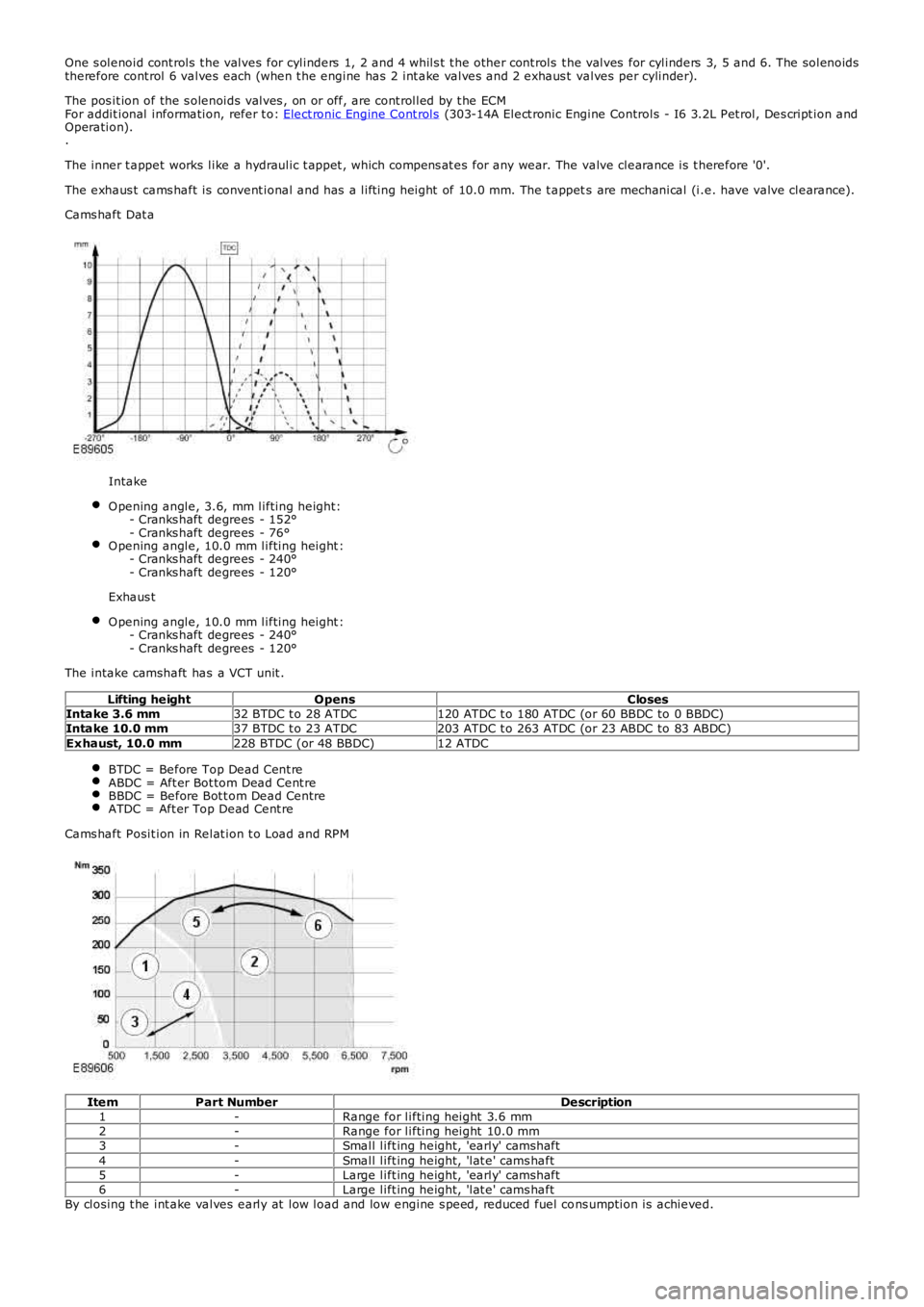

Cams haft Dat a

Intake

O pening angle, 3.6, mm lifting height:- Cranks haft degrees - 152°- Cranks haft degrees - 76°O pening angle, 10.0 mm lifting height :- Cranks haft degrees - 240°- Cranks haft degrees - 120°

Exhaus t

O pening angle, 10.0 mm lifting height :- Cranks haft degrees - 240°- Cranks haft degrees - 120°

The intake camshaft has a VCT unit .

Lifting heightOpensClosesIntake 3.6 mm32 BTDC t o 28 ATDC120 ATDC t o 180 ATDC (or 60 BBDC to 0 BBDC)Intake 10.0 mm37 BTDC t o 23 ATDC203 ATDC t o 263 ATDC (or 23 ABDC to 83 ABDC)Exhaust, 10.0 mm228 BTDC (or 48 BBDC)12 ATDC

BTDC = Before Top Dead Cent reABDC = Aft er Bot tom Dead Cent reBBDC = Before Bot t om Dead CentreATDC = Aft er Top Dead Cent re

Cams haft Posit ion in Relat ion t o Load and RPM

ItemPart NumberDescription1-Range for lifting height 3.6 mm2-Range for lifting height 10.0 mm3-Small lift ing height, 'early' camshaft4-Small lift ing height, 'lat e' cams haft5-Large lift ing height, 'early' camshaft6-Large lift ing height, 'lat e' cams haftBy closing t he int ake valves early at low load and low engine s peed, reduced fuel cons umption is achieved.

Page 625 of 3229

For addit ional information, refer t o: Elect ronic Engine Cont rols (303-14A Elect ronic Engine Controls - I6 3.2L Pet rol, Des cript ion andOperation).

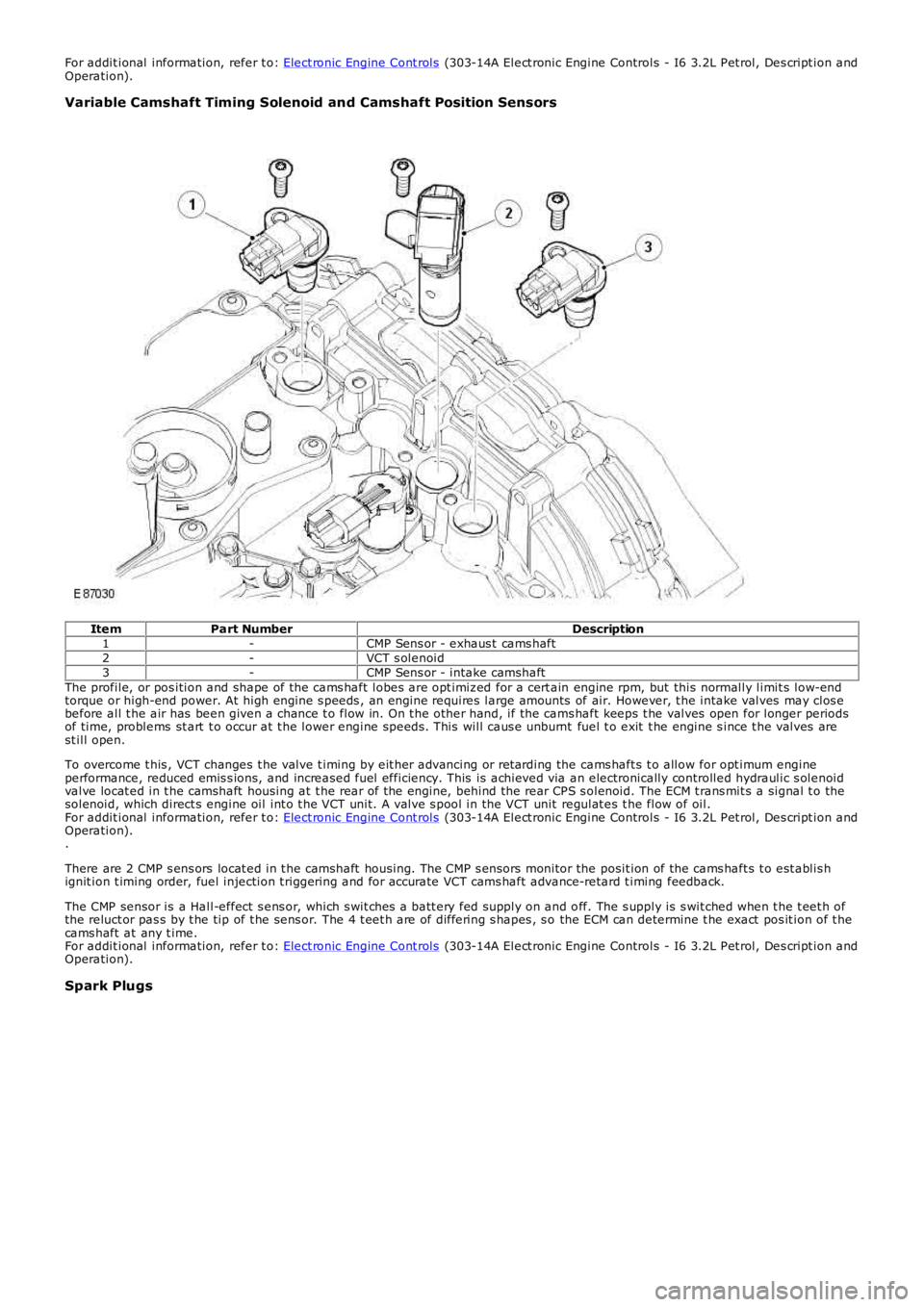

Variable Camshaft Timing Solenoid and Camshaft Position Sensors

ItemPart NumberDescription1-CMP Sens or - exhaus t cams haft2-VCT s olenoid3-CMP Sens or - intake camshaftThe profile, or pos ition and shape of the cams haft lobes are opt imiz ed for a cert ain engine rpm, but this normally limit s low-endtorque or high-end power. At high engine s peeds , an engine requires large amounts of air. However, t he intake valves may clos ebefore all t he air has been given a chance t o flow in. On t he other hand, if the cams haft keeps t he valves open for longer periodsof time, problems st art t o occur at t he lower engine speeds . This will caus e unburnt fuel t o exit t he engine s ince t he valves arest ill open.

To overcome t his , VCT changes t he valve t iming by eit her advancing or ret arding the cams haft s t o allow for opt imum engineperformance, reduced emis s ions, and increased fuel efficiency. This is achieved via an electronically controlled hydraulic s olenoidvalve locat ed in t he camshaft housing at t he rear of t he engine, behind the rear CPS s olenoid. The ECM t rans mit s a signal t o thesolenoid, which direct s engine oil int o t he VCT unit. A valve s pool in the VCT unit regulat es t he flow of oil.For addit ional information, refer t o: Elect ronic Engine Cont rols (303-14A Elect ronic Engine Controls - I6 3.2L Pet rol, Des cript ion andOperation)..

There are 2 CMP s ens ors locat ed in t he camshaft housing. The CMP s ensors monitor the posit ion of the cams haft s t o est ablis hignit ion t iming order, fuel injection t riggering and for accurate VCT cams haft advance-retard t iming feedback.

The CMP sensor is a Hall-effect s ens or, which s wit ches a batt ery fed supply on and off. The s upply is s wit ched when t he t eet h ofthe reluct or pas s by t he tip of t he sens or. The 4 t eet h are of differing s hapes , s o the ECM can determine t he exact pos it ion of t hecams haft at any t ime.For addit ional information, refer t o: Elect ronic Engine Cont rols (303-14A Elect ronic Engine Controls - I6 3.2L Pet rol, Des cript ion andOperation).

Spark Plugs

Page 627 of 3229

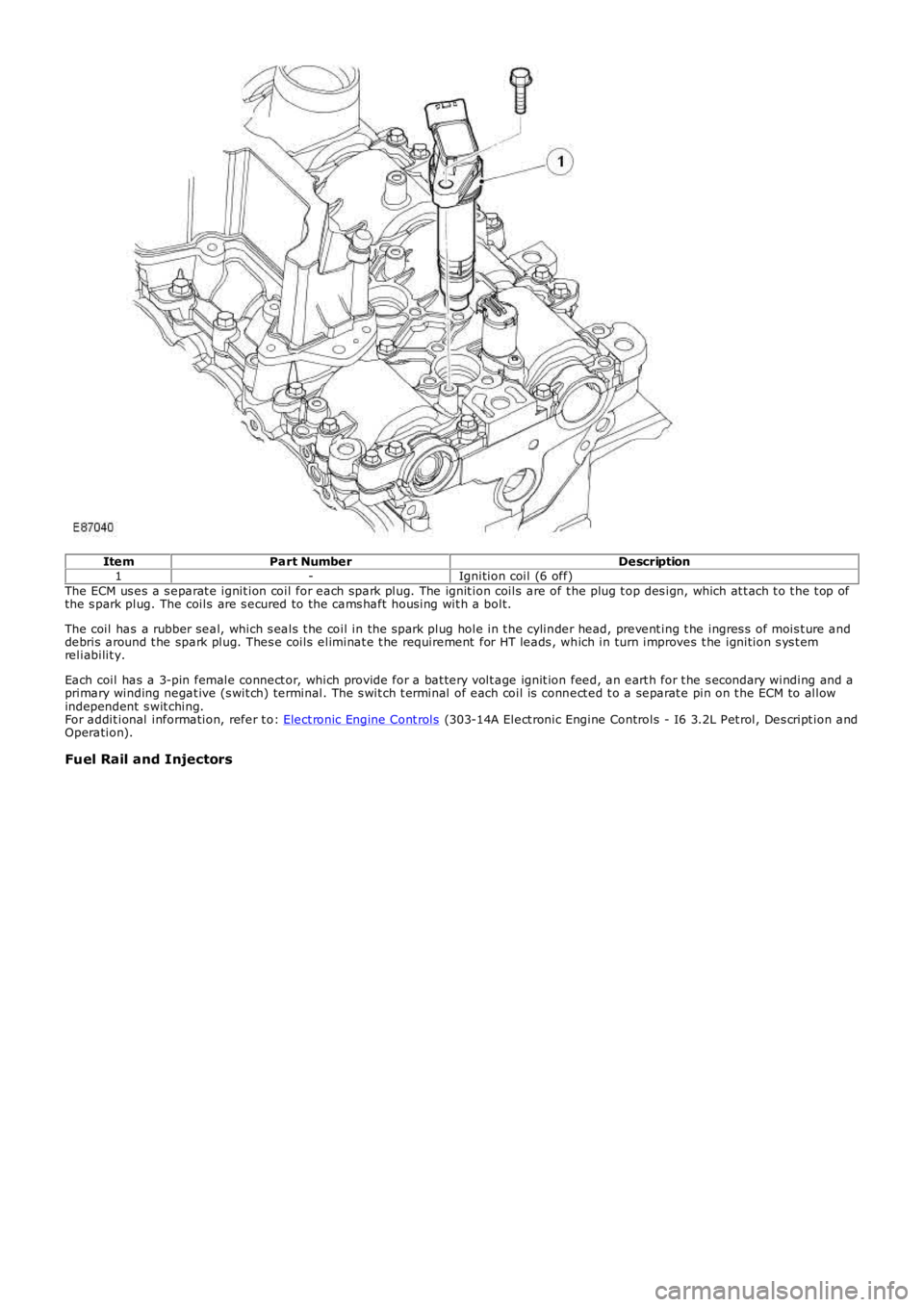

ItemPart NumberDescription1-Ignition coil (6 off)The ECM us es a s eparat e ignit ion coil for each spark plug. The ignit ion coils are of t he plug t op des ign, which at t ach t o t he t op ofthe s park plug. The coils are s ecured to the cams haft hous ing wit h a bolt.

The coil has a rubber seal, which s eals t he coil in the s park plug hole in t he cylinder head, prevent ing t he ingres s of mois t ure anddebris around t he spark plug. Thes e coils eliminat e t he requirement for HT leads , which in turn improves t he ignition s ys t emreliabilit y.

Each coil has a 3-pin female connect or, which provide for a bat tery volt age ignit ion feed, an eart h for t he s econdary winding and aprimary winding negat ive (s wit ch) terminal. The s wit ch t erminal of each coil is connect ed t o a separat e pin on t he ECM to allowindependent s wit ching.For addit ional information, refer t o: Elect ronic Engine Cont rols (303-14A Elect ronic Engine Controls - I6 3.2L Pet rol, Des cript ion andOperation).

Fuel Rail and Injectors

Page 628 of 3229

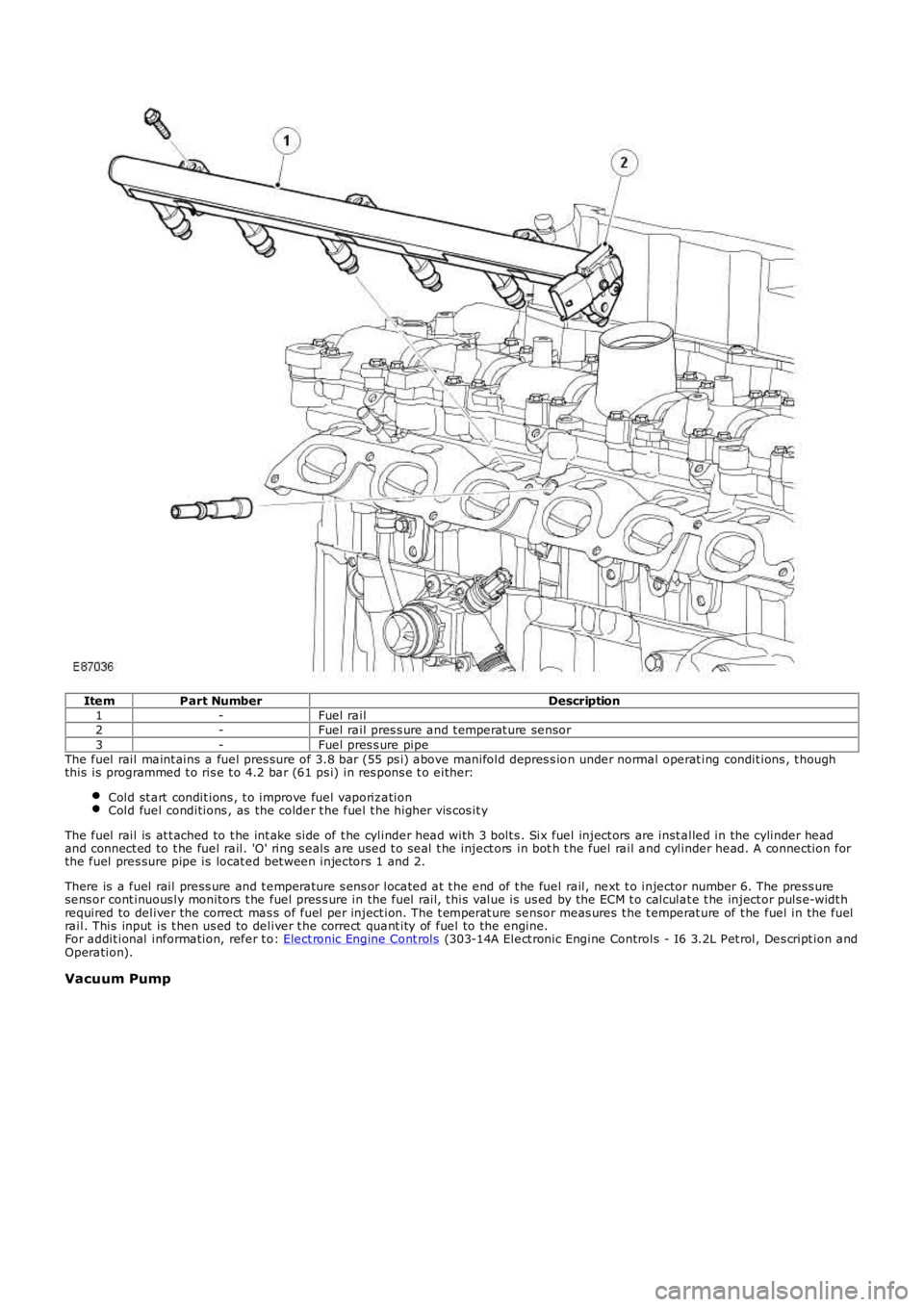

ItemPart NumberDescription1-Fuel rail2-Fuel rail pres s ure and t emperat ure sensor3-Fuel pres s ure pipeThe fuel rail maint ains a fuel pres sure of 3.8 bar (55 ps i) above manifold depres s ion under normal operat ing condit ions , t houghthis is programmed t o ris e t o 4.2 bar (61 ps i) in res pons e t o either:

Cold st art condit ions , t o improve fuel vaporiz ationCold fuel conditions , as the colder t he fuel t he higher vis cos it y

The fuel rail is at t ached to t he int ake s ide of t he cylinder head with 3 bolt s . Six fuel inject ors are inst alled in the cylinder headand connect ed to t he fuel rail. 'O' ring s eals are used t o seal t he inject ors in both t he fuel rail and cylinder head. A connection forthe fuel pres sure pipe is locat ed bet ween injectors 1 and 2.

There is a fuel rail press ure and t emperature s ens or located at t he end of t he fuel rail, next t o injector number 6. The press uresens or cont inuous ly monitors t he fuel pres s ure in the fuel rail, t his value is us ed by the ECM t o calculat e t he inject or puls e-widt hrequired to deliver the correct mas s of fuel per inject ion. The t emperat ure sensor meas ures t he t emperat ure of t he fuel in the fuelrail. This input is t hen us ed to deliver t he correct quant ity of fuel to the engine.For addit ional information, refer t o: Elect ronic Engine Cont rols (303-14A Elect ronic Engine Controls - I6 3.2L Pet rol, Des cript ion andOperation).

Vacuum Pump

Page 630 of 3229

5-Bolt (2 of)6-Variable tract valveThe intake manifold att aches t o t he cylinder head wit h 6 bolt s and t he oil pan with 2 bolt s .

The manifold is capable of varying both int ake tract length and plenum volume by means of 2 separat e valves .

At low engine s peeds , long int ake tract s are ut iliz ed to provide opt imum engine t orque. Short er t racts are us ed at medium s peeds ,again, t o optimiz e engine t orque for t he exist ing engine s peed range.

At higher engine s peeds the benefit s of opt imizing t he t ract lengt hs are outweighed by the necess it y of maintaining anappropriate supply of air to meet t he engines requirement s . Therefore, t he plenum valve is opened t o create a s ingle, largeplenum volume to provide t he maximum quant ity of air t o charge the engines cylinders.For addit ional information, refer t o: Int ake Air Dis tribut ion and Filtering (303-12A Int ake Air Dis t ribution and Filt ering - I6 3.2LPet rol, Des cript ion and O perat ion).

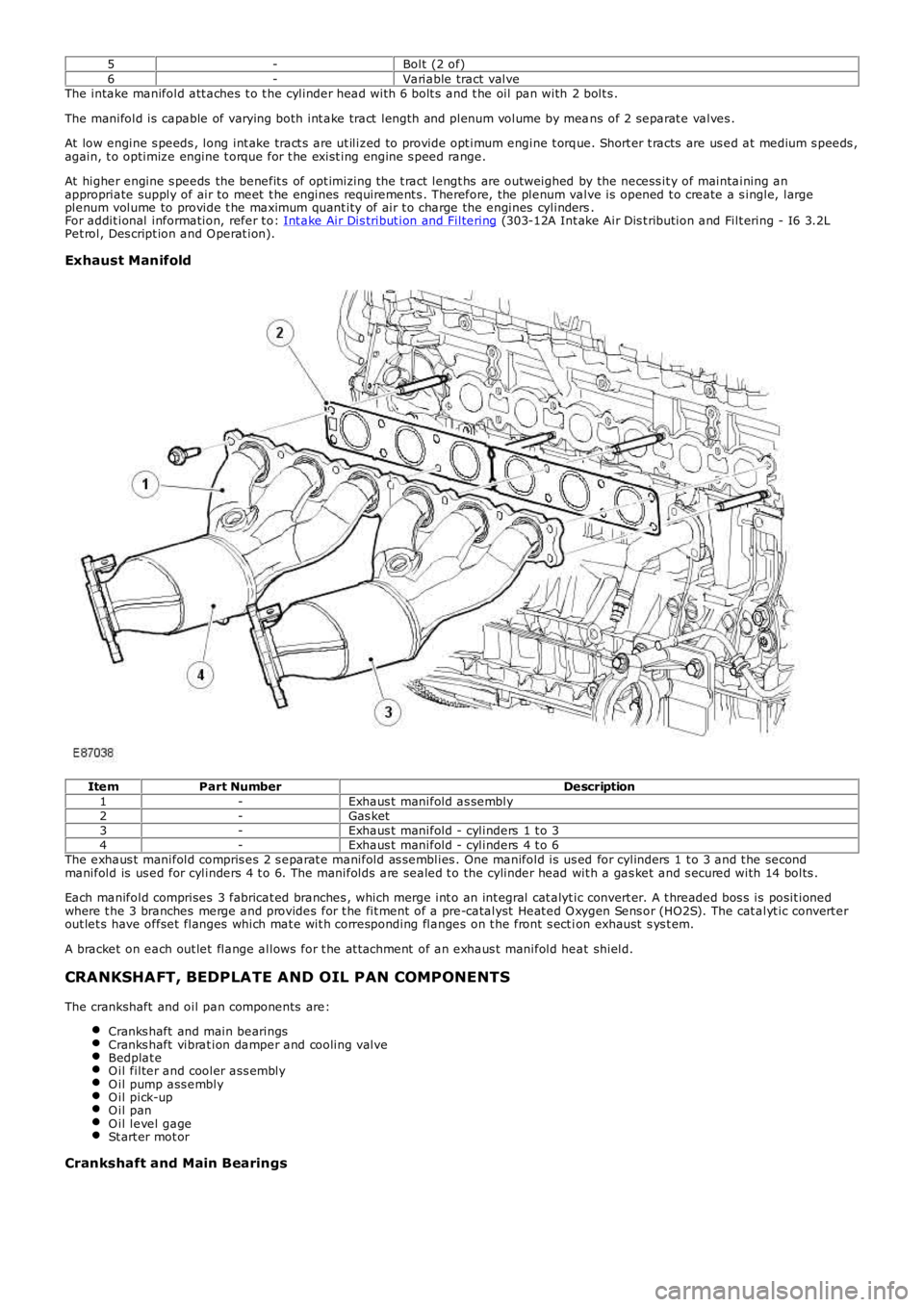

Exhaust Manifold

ItemPart NumberDescription1-Exhaus t manifold as sembly2-Gas ket3-Exhaus t manifold - cylinders 1 t o 34-Exhaus t manifold - cylinders 4 t o 6The exhaus t manifold compris es 2 s eparat e manifold as semblies . One manifold is us ed for cylinders 1 t o 3 and t he secondmanifold is us ed for cylinders 4 t o 6. The manifolds are sealed t o the cylinder head wit h a gas ket and s ecured with 14 bolts .

Each manifold comprises 3 fabricat ed branches , which merge int o an int egral cat alyt ic convert er. A t hreaded bos s is posit ionedwhere t he 3 branches merge and provides for t he fit ment of a pre-catalyst Heat ed O xygen Sens or (HO2S). The cat alyt ic convert erout let s have offset flanges which mat e wit h corresponding flanges on t he front s ect ion exhaust s ys t em.

A bracket on each out let flange allows for t he at t achment of an exhaus t manifold heat shield.

CRANKSHAFT, BEDPLATE AND OIL PAN COMPONENTS

The crankshaft and oil pan components are:

Cranks haft and main bearingsCranks haft vibrat ion damper and cooling valveBedplat eO il filter and cooler ass emblyO il pump ass emblyO il pick-upO il panO il level gageSt art er mot or

Crankshaft and Main Bearings

Page 633 of 3229

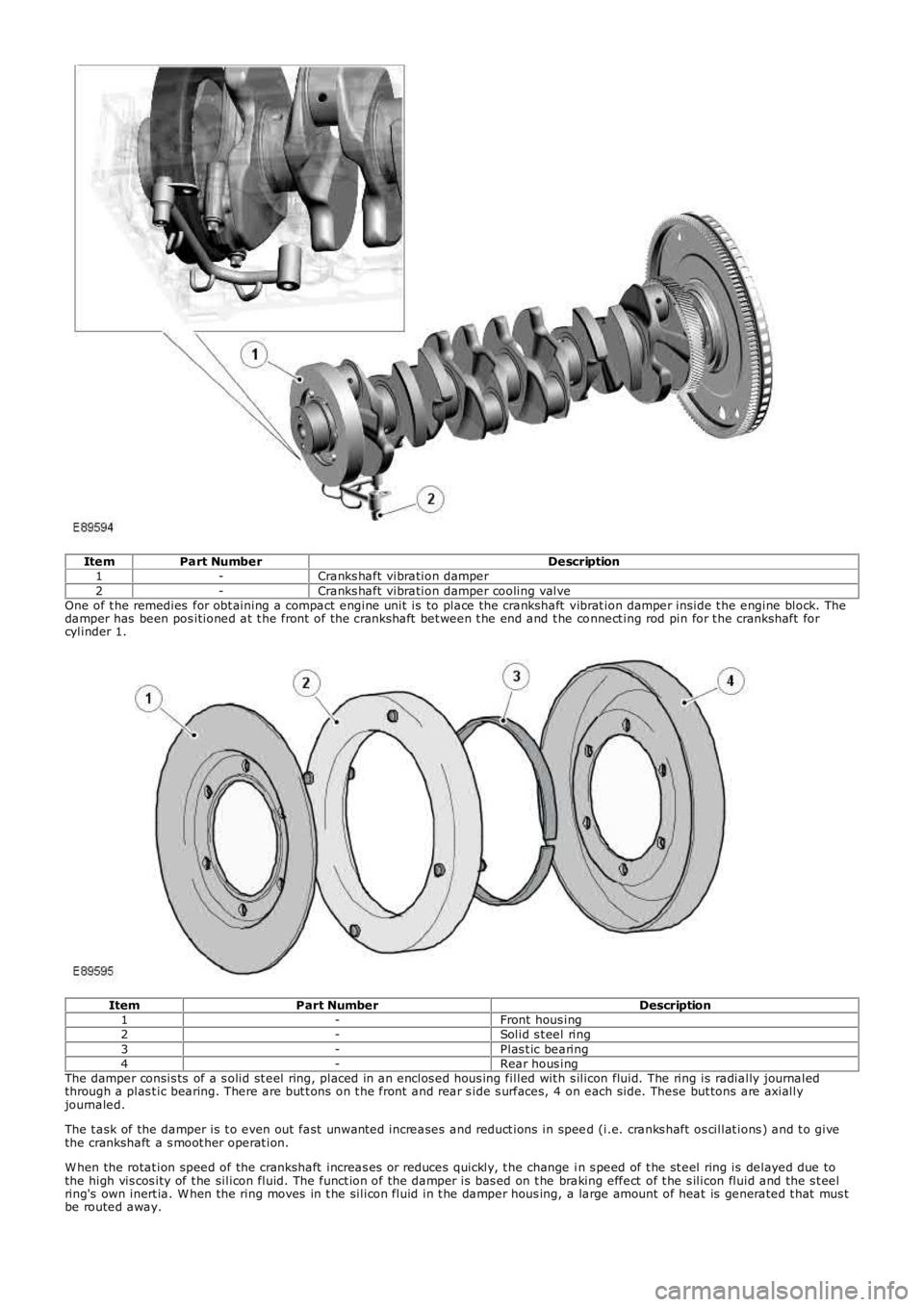

ItemPart NumberDescription1-Cranks haft vibration damper2-Cranks haft vibration damper cooling valveOne of t he remedies for obt aining a compact engine unit is to place the crankshaft vibrat ion damper inside t he engine block. Thedamper has been pos itioned at t he front of the crankshaft bet ween t he end and t he connect ing rod pin for t he crankshaft forcylinder 1.

ItemPart NumberDescription1-Front hous ing2-Solid s t eel ring3-Plas t ic bearing4-Rear hous ingThe damper consis ts of a s olid st eel ring, placed in an enclos ed hous ing filled wit h s ilicon fluid. The ring is radially journaledthrough a plas t ic bearing. There are but t ons on t he front and rear s ide s urfaces, 4 on each side. These but tons are axiallyjournaled.

The t ask of the damper is t o even out fast unwanted increases and reduct ions in speed (i.e. cranks haft os cillat ions ) and t o givethe crankshaft a s moot her operat ion.

W hen the rotat ion speed of the crankshaft increas es or reduces quickly, t he change in s peed of t he st eel ring is delayed due tothe high vis cos ity of t he silicon fluid. The funct ion of the damper is bas ed on t he braking effect of t he s ilicon fluid and the s t eelring's own inert ia. W hen the ring moves in t he silicon fluid in t he damper hous ing, a large amount of heat is generated t hat mus tbe routed away.

Page 634 of 3229

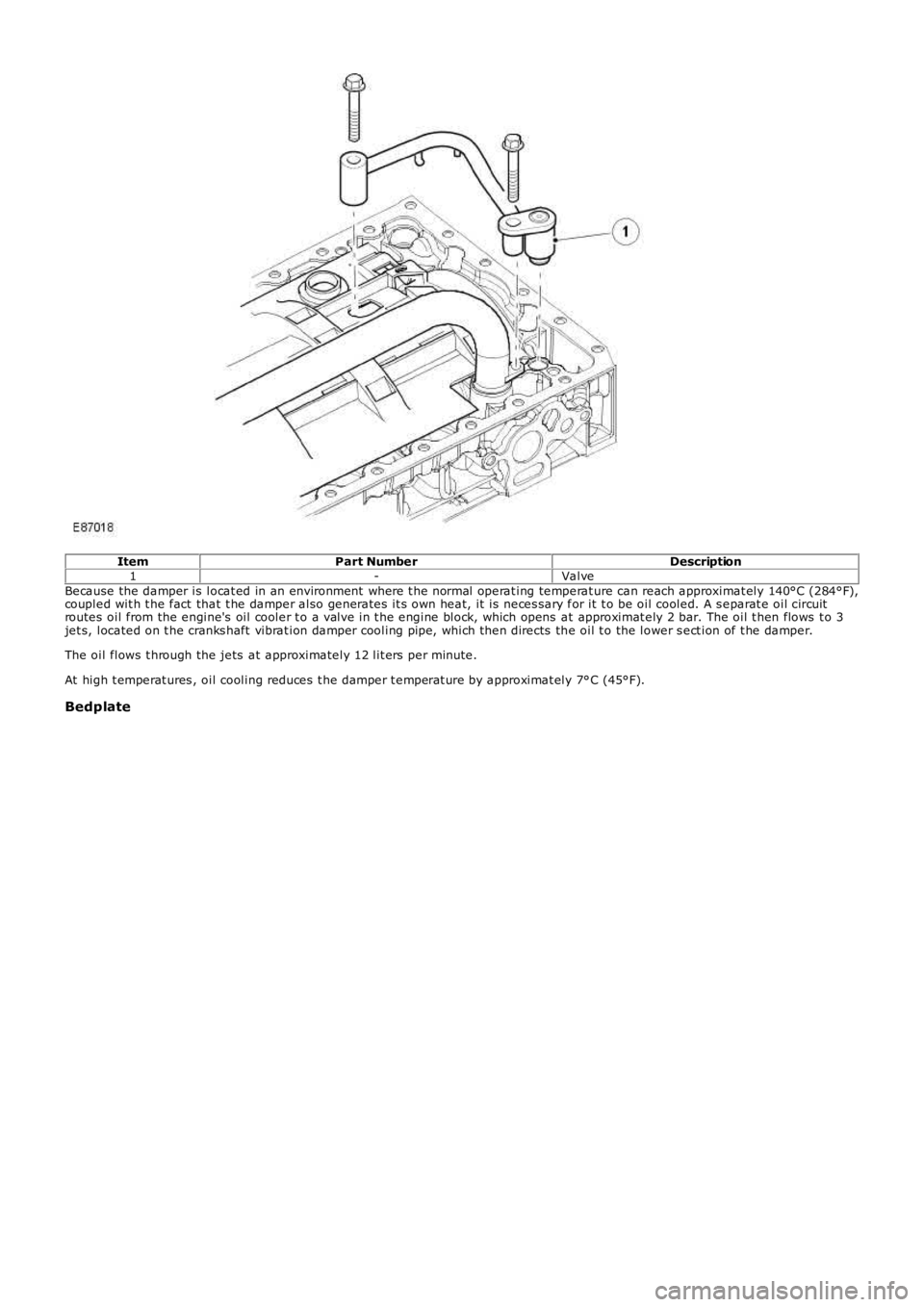

ItemPart NumberDescription1-ValveBecause the damper is locat ed in an environment where t he normal operat ing temperat ure can reach approximat ely 140°C (284°F),coupled wit h t he fact that t he damper also generates it s own heat, it is neces sary for it t o be oil cooled. A s eparat e oil circuitroutes oil from the engine's oil cooler t o a valve in t he engine block, which opens at approximat ely 2 bar. The oil t hen flows t o 3jet s, located on t he cranks haft vibrat ion damper cooling pipe, which then directs the oil t o the lower s ect ion of t he damper.

The oil flows t hrough the jets at approximately 12 lit ers per minute.

At high t emperat ures , oil cooling reduces t he damper t emperat ure by approximat ely 7°C (45°F).

Bedplate

Page 636 of 3229

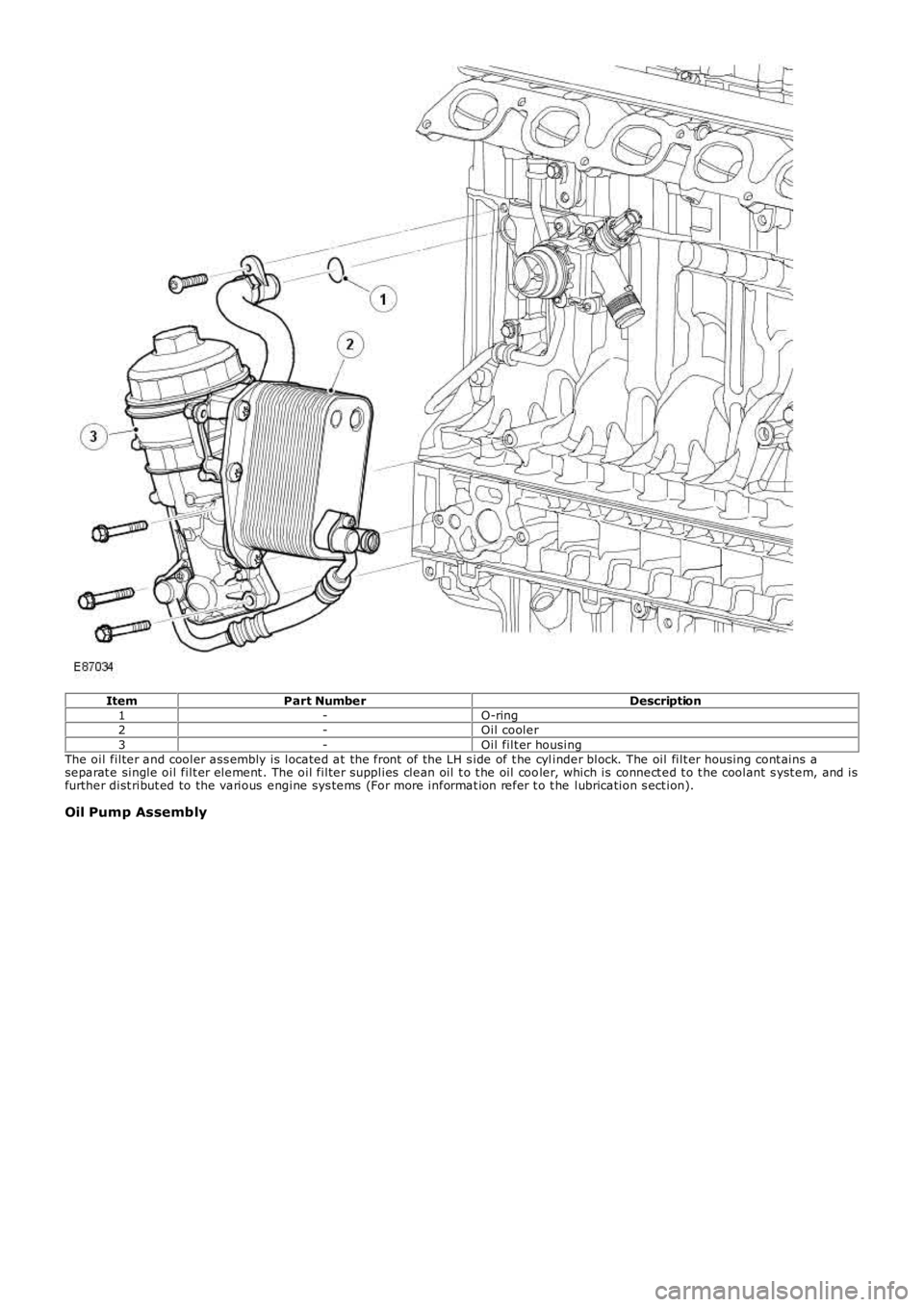

ItemPart NumberDescription1-O-ring2-Oil cooler3-Oil filt er housingThe oil filter and cooler ass embly is located at the front of the LH s ide of t he cylinder block. The oil filt er housing cont ains aseparat e single oil filt er element . The oil filter supplies clean oil t o t he oil cooler, which is connect ed t o t he coolant s yst em, and isfurther dist ribut ed to the various engine sys tems (For more informat ion refer t o t he lubrication s ect ion).

Oil Pump Assembly

Page 639 of 3229

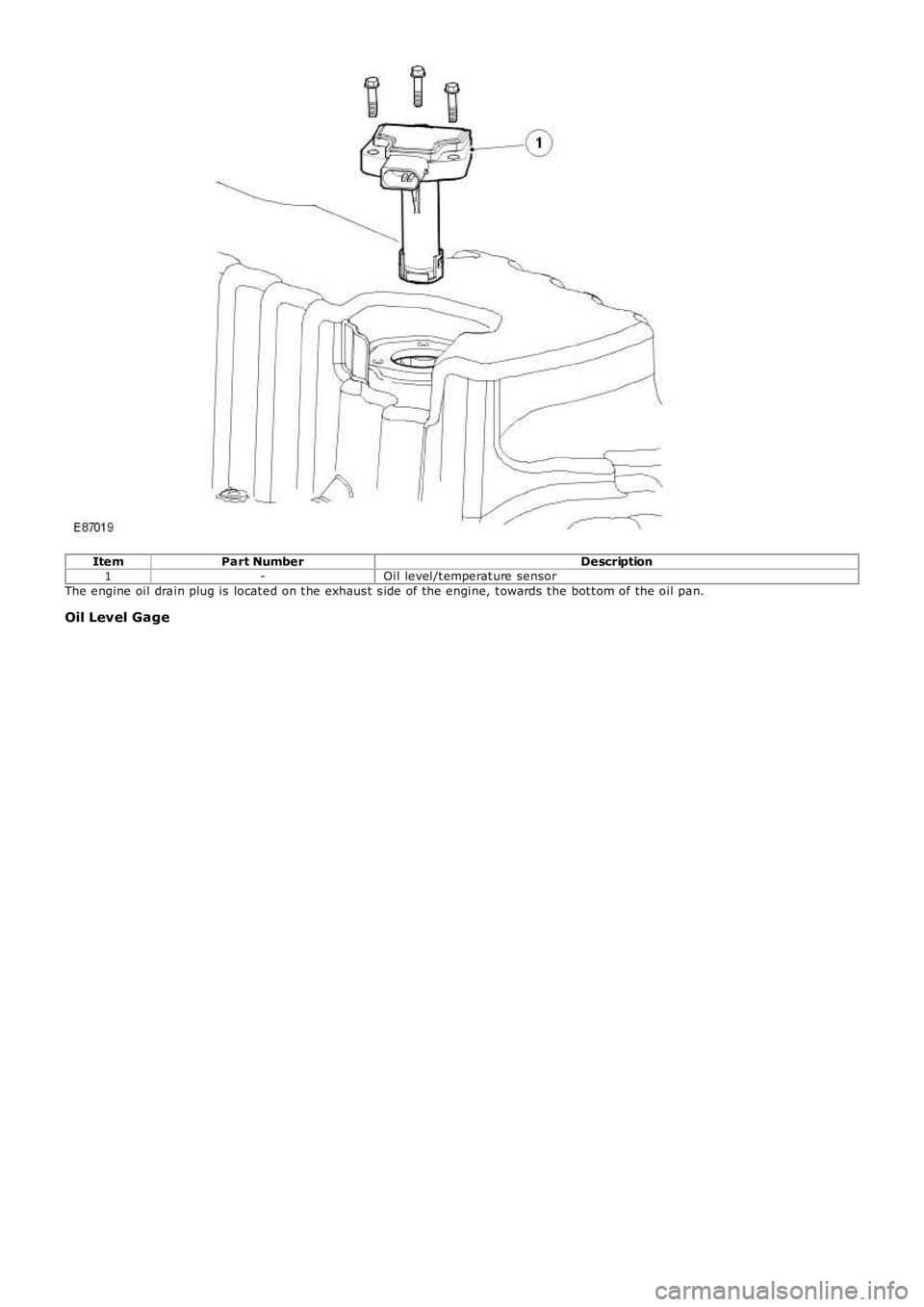

ItemPart NumberDescription1-Oil level/t emperat ure sensorThe engine oil drain plug is locat ed on t he exhaus t s ide of the engine, t owards t he bot t om of the oil pan.

Oil Level Gage

Page 640 of 3229

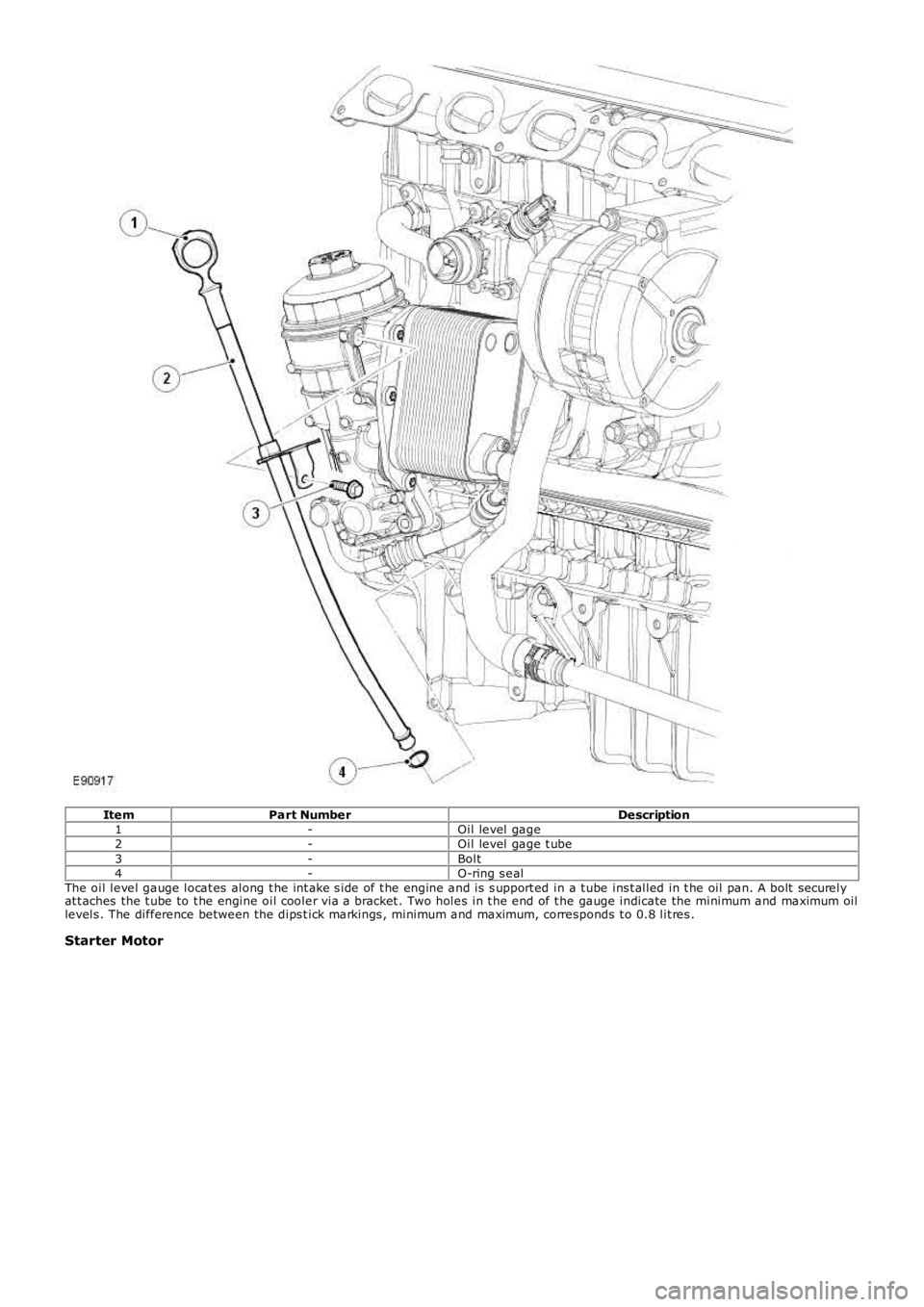

ItemPart NumberDescription1-Oil level gage2-Oil level gage t ube3-Bolt4-O-ring s ealThe oil level gauge locat es along t he int ake s ide of t he engine and is s upport ed in a t ube ins t alled in t he oil pan. A bolt s ecurelyat t aches the t ube to t he engine oil cooler via a bracket . Two holes in t he end of t he gauge indicate the minimum and maximum oillevels . The difference between the dips t ick markings , minimum and maximum, corresponds t o 0.8 lit res .

Starter Motor