engine LAND ROVER FRELANDER 2 2006 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 420 of 3229

Publi s hed: 11-May-2011

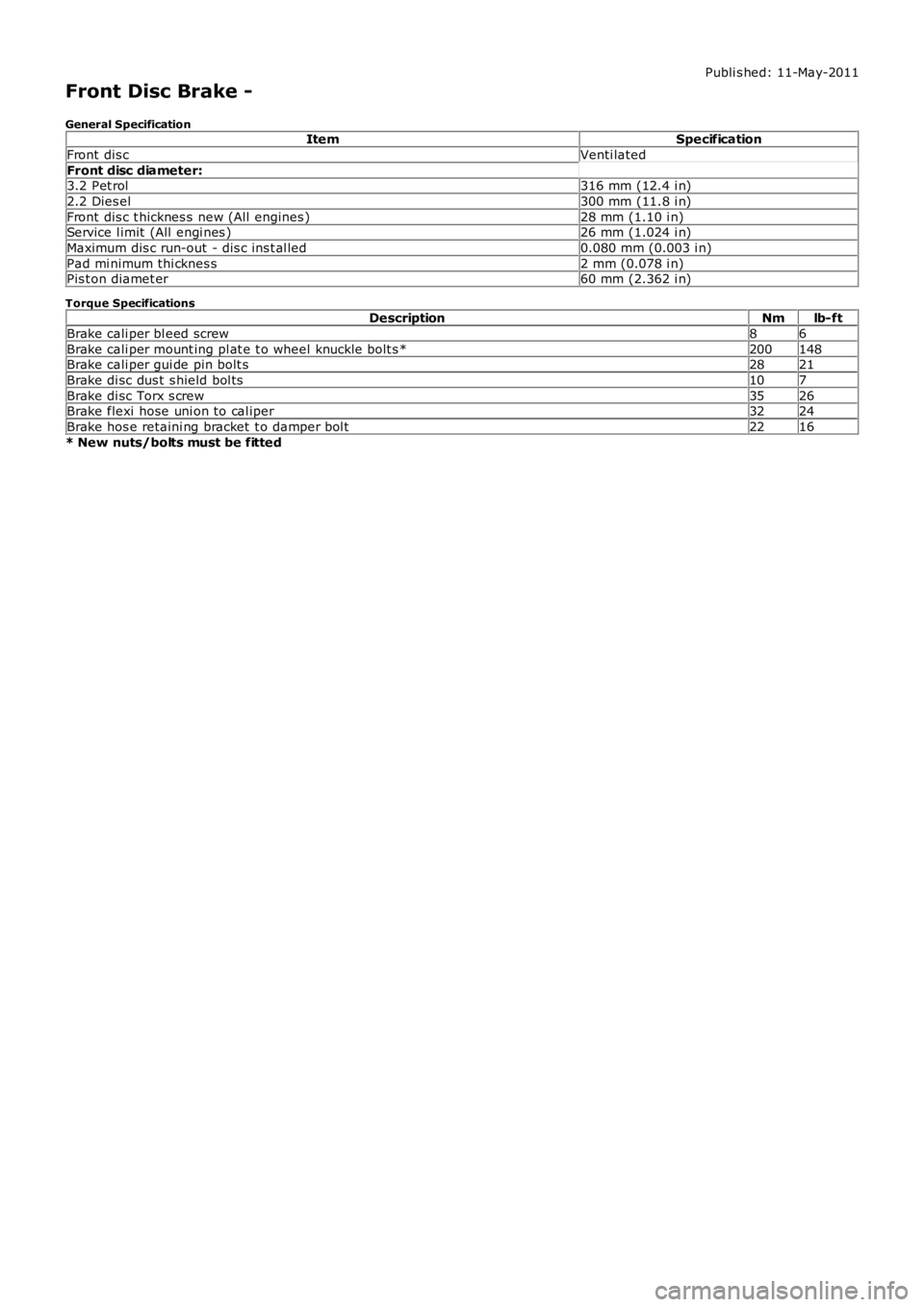

Front Disc Brake -

General SpecificationItemSpecification

Front dis cVenti lated

Front disc diameter:3.2 Pet rol316 mm (12.4 i n)

2.2 Dies el300 mm (11.8 i n)

Front dis c t hicknes s new (All engines )28 mm (1.10 i n)Service l imit (All engi nes )26 mm (1.024 i n)

Maximum dis c run-out - dis c ins t al led0.080 mm (0.003 i n)

Pad mi nimum thi cknes s2 mm (0.078 i n)Pis t on diamet er60 mm (2.362 i n)

Torque SpecificationsDescriptionNmlb-ft

Brake cali per bl eed screw86

Brake cali per mount ing pl at e t o wheel knuckle bolt s *200148Brake cali per gui de pin bolt s2821

Brake di sc dus t s hield bol ts107

Brake di sc Torx s crew3526Brake flexi hose uni on to cal iper3224

Brake hos e retaini ng bracket t o damper bol t2216

* New nuts/bolts must be fitted

Page 433 of 3229

Publi s hed: 11-May-2011

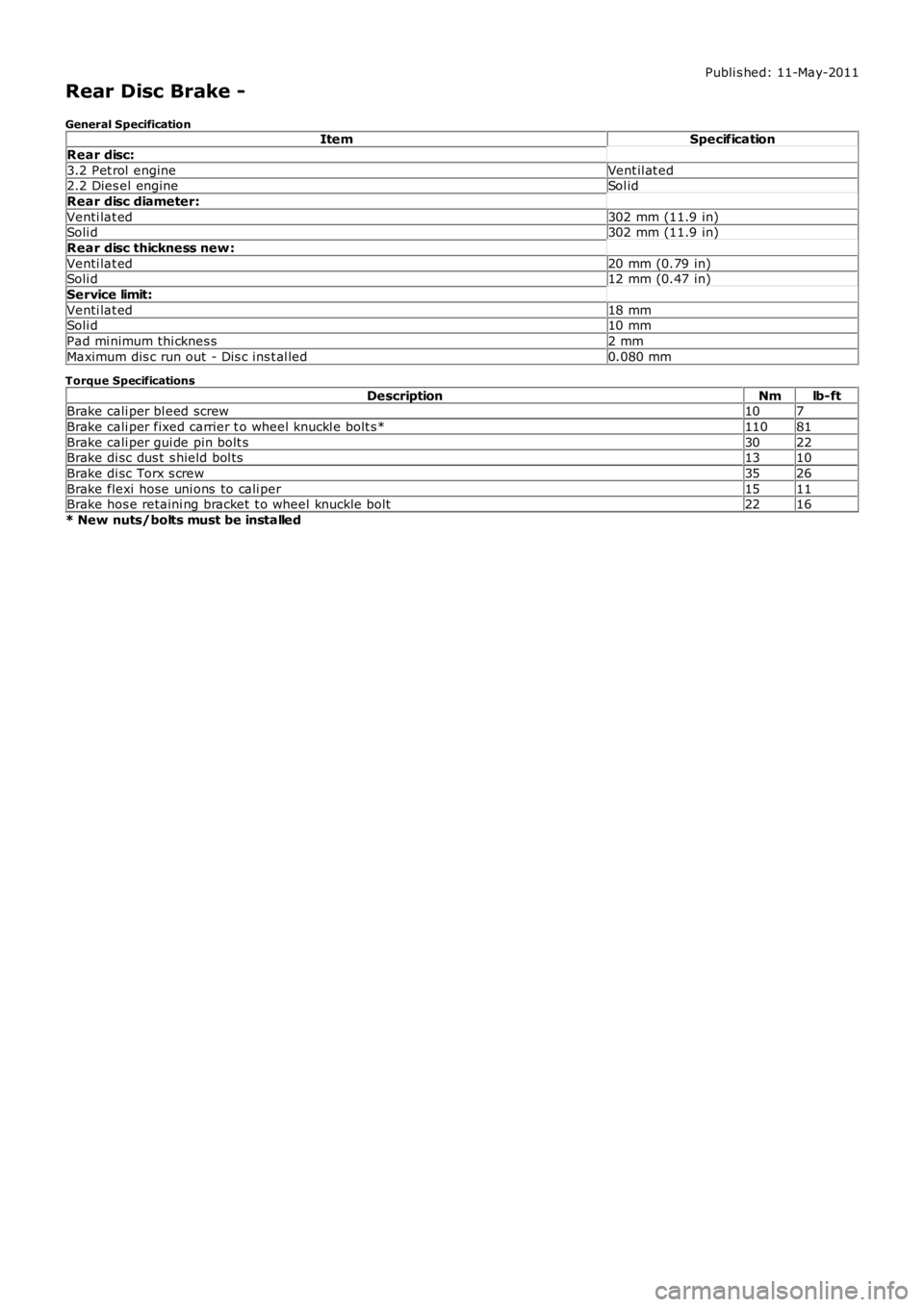

Rear Disc Brake -

General SpecificationItemSpecification

Rear disc:

3.2 Pet rol engineVent il at ed2.2 Dies el engineSol id

Rear disc diameter:

Venti lat ed302 mm (11.9 in)Soli d302 mm (11.9 in)

Rear disc thickness new :

Venti lat ed20 mm (0.79 in)Soli d12 mm (0.47 in)

Service limit:

Venti lat ed18 mmSoli d10 mm

Pad mi nimum thi cknes s2 mm

Maximum dis c run out - Dis c ins t al led0.080 mm

Torque Specifications

DescriptionNmlb-ftBrake cali per bl eed screw107

Brake cali per fixed carrier t o wheel knuckl e bolt s*11081

Brake cali per gui de pin bolt s3022Brake di sc dus t s hield bol ts1310

Brake di sc Torx s crew3526

Brake flexi hose uni ons to cali per1511Brake hos e retaini ng bracket t o wheel knuckle bolt2216

* New nuts/bolts must be installed

Page 470 of 3229

3-St opl amp s wit ch

4-Hydrauli c pipes

5-Integrat ed Hydrauli c Cont rol Unit (HCU) and Anti -l ock Brake Sys t em (ABS) modul e6-Brake mast er cyl inder and flui d res ervoir

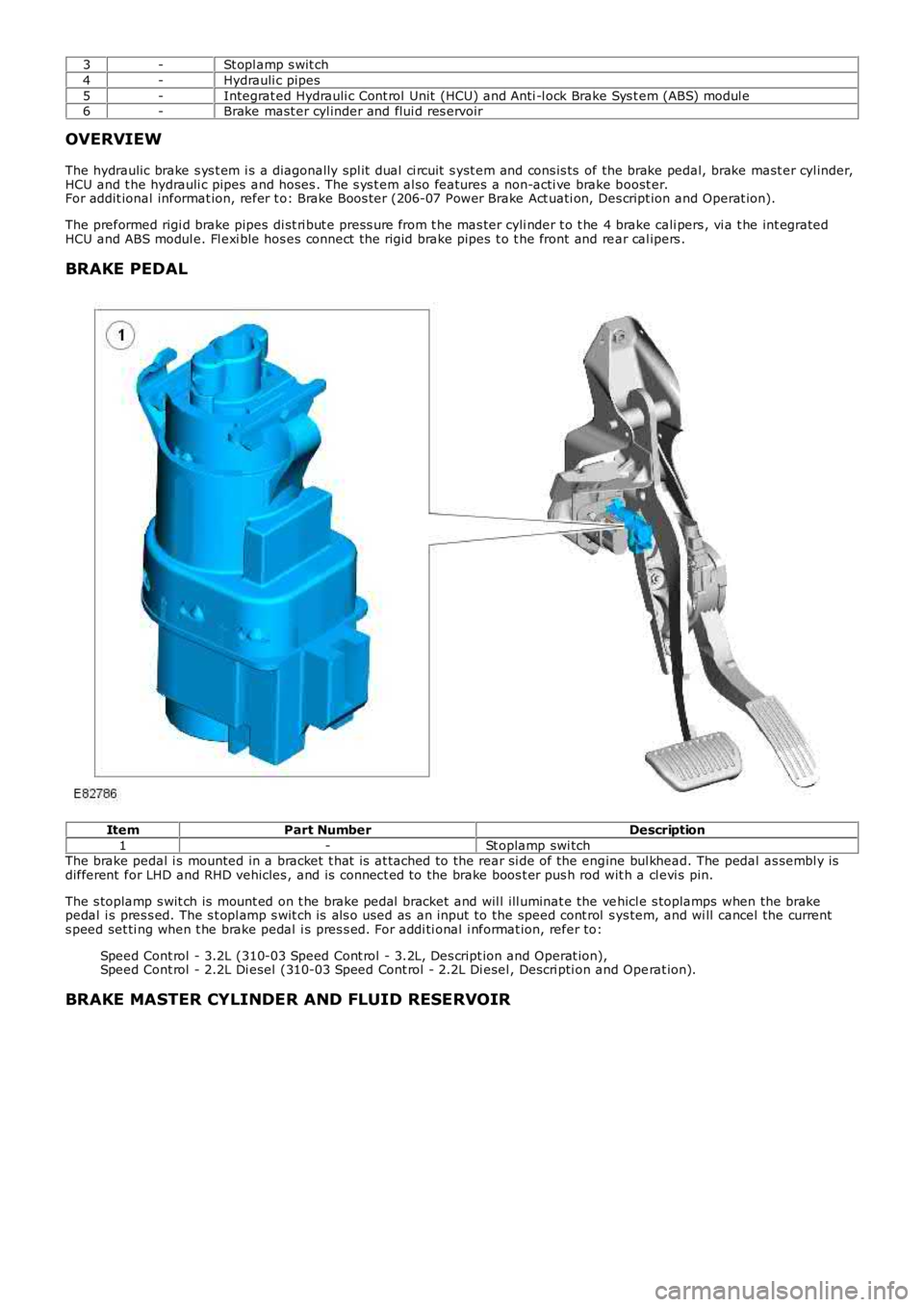

OVERVIEW

The hydraulic brake s ys t em i s a diagonally spl it dual ci rcuit s yst em and cons is ts of the brake pedal, brake mast er cyl inder,HCU and t he hydrauli c pipes and hoses . The s ys t em al so features a non-acti ve brake boost er.For addit ional informat ion, refer t o: Brake Boos ter (206-07 Power Brake Act uati on, Des cript ion and Operat ion).

The preformed rigi d brake pipes di st ri but e press ure from t he mas ter cyli nder t o t he 4 brake cali pers , vi a t he int egratedHCU and ABS modul e. Fl exi ble hos es connect the rigid brake pipes t o t he front and rear cal ipers .

BRAKE PEDAL

ItemPart NumberDescription

1-St oplamp swi tchThe brake pedal i s mounted in a bracket t hat is at tached to the rear si de of the engine bul khead. The pedal as sembl y isdifferent for LHD and RHD vehicles , and is connect ed to the brake boos t er pus h rod wit h a cl evi s pin.

The s toplamp s wit ch is mount ed on t he brake pedal bracket and wil l ill uminat e the vehicl e s toplamps when the brakepedal i s pres s ed. The s t opl amp s wit ch is al s o used as an input to the speed cont rol s ys tem, and wi ll cancel the currents peed set ti ng when t he brake pedal i s pres s ed. For addi ti onal i nformat ion, refer to:

Speed Cont rol - 3.2L (310-03 Speed Cont rol - 3.2L, Des cript ion and Operat ion),Speed Cont rol - 2.2L Di esel (310-03 Speed Cont rol - 2.2L Di esel , Descri pti on and Operat ion).

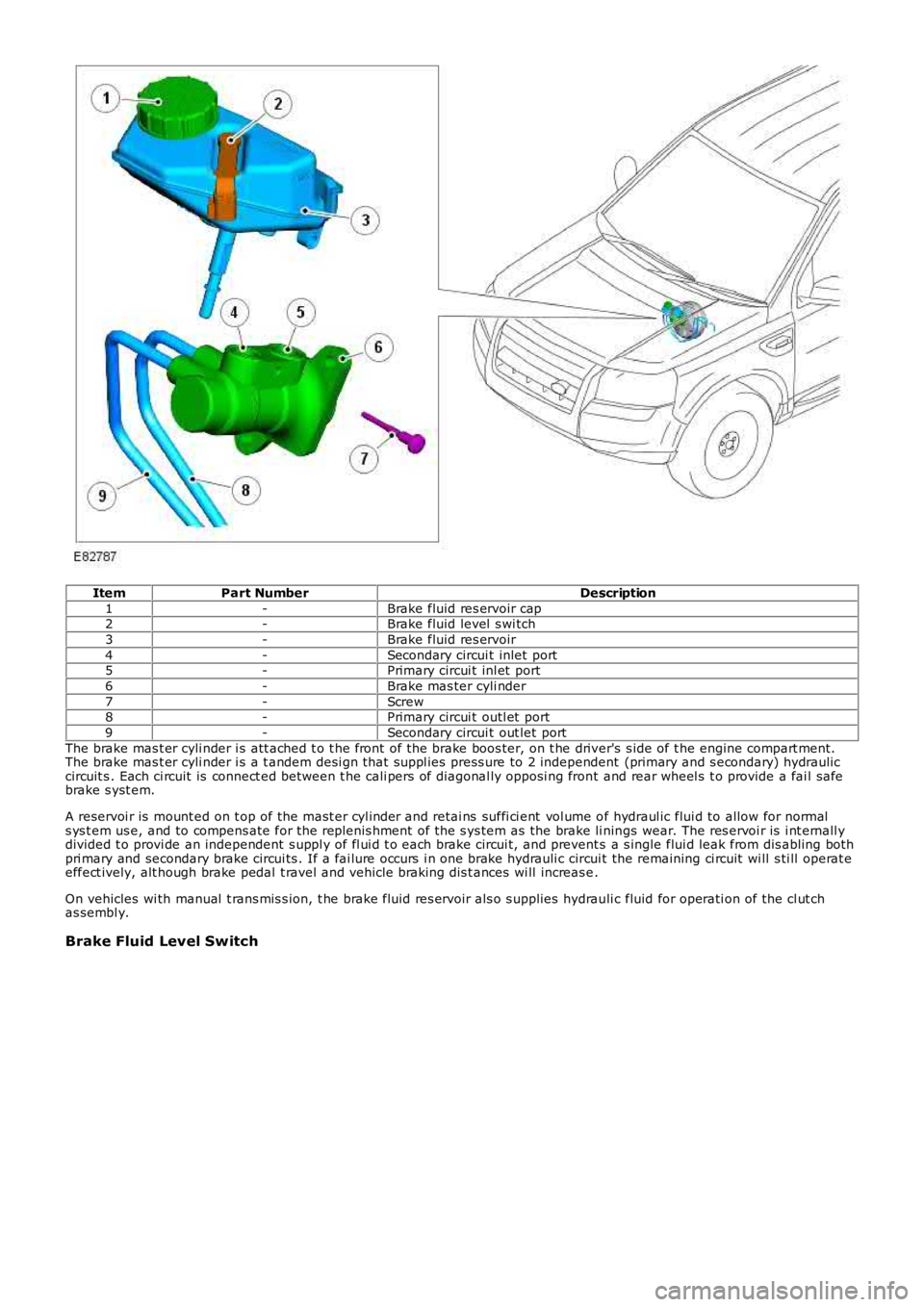

BRAKE MASTER CYLINDER AND FLUID RESERVOIR

Page 471 of 3229

ItemPart NumberDescription

1-Brake fluid res ervoir cap2-Brake fluid level s wi tch

3-Brake fluid res ervoir

4-Secondary circui t inlet port5-Primary circui t inl et port

6-Brake mas ter cyli nder

7-Screw8-Primary circui t outl et port

9-Secondary circui t out let port

The brake mas t er cyli nder i s att ached t o t he front of the brake boos ter, on t he driver's s ide of t he engine compart ment.The brake mas t er cyli nder i s a t andem desi gn that s uppl ies press ure to 2 independent (primary and s econdary) hydrauliccircuit s . Each ci rcuit is connect ed between t he cali pers of diagonal ly opposi ng front and rear wheel s t o provide a fai l safebrake s yst em.

A reservoi r is mount ed on t op of the mast er cyl inder and retai ns suffi ci ent vol ume of hydraul ic flui d to allow for normals ys t em us e, and to compens ate for the replenis hment of the s ys tem as the brake li nings wear. The res ervoi r is i nt ernall ydivided t o provi de an independent s uppl y of fl ui d t o each brake circui t, and prevents a s ingle flui d leak from dis abling bot hpri mary and secondary brake circui ts . If a fai lure occurs i n one brake hydrauli c circui t the remaining ci rcuit wi ll s ti ll operat eeffect ively, alt hough brake pedal t ravel and vehicle braking dis t ances wi ll increas e.

On vehicles wi th manual t rans mis s ion, t he brake fluid res ervoir als o s upplies hydrauli c fluid for operati on of the cl ut chas sembl y.

Brake Fluid Level Switch

Page 485 of 3229

Publi s hed: 11-May-2011

Power Brake Actuation - Brake Booster

Des cript ion and Operat ion

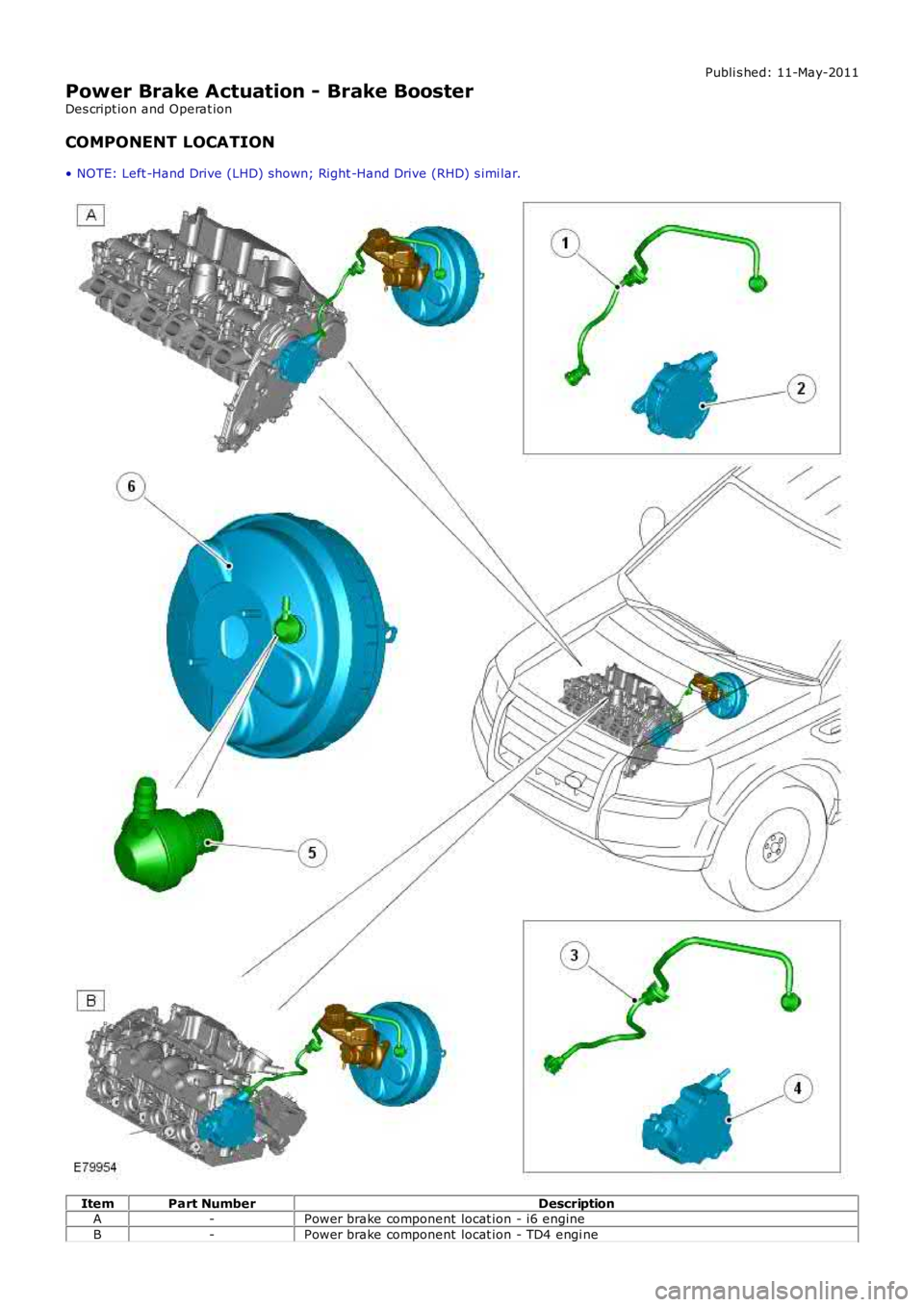

COMPONENT LOCATION

• NOTE: Left -Hand Drive (LHD) shown; Right -Hand Drive (RHD) s imi lar.

ItemPart NumberDescriptionA-Power brake component locat ion - i6 engine

B-Power brake component locat ion - TD4 engi ne

Page 486 of 3229

1-Vacuum pi pe - i 6 engi ne

2-Vacuum pump - i6 engi ne

3-Vacuum pi pe - TD4 engine (up t o 2010 MY )4-Vacuum pump - TD4 engine

5-Check valve

6-Brake boost er

OVERVIEW

Power as s is t ance for the braki ng s ys t em i s provided by a vacuum operat ed, non-act ive brake boos ter.

The brake boost er is a compact unit t hat occupi es les s s pace than a convent ional brake boos t er, improving t he vehi cl escras h performance charact eri st ics . The uni t is ins tall ed wi th t andem diaphragms that are 203.20 mm (8.00 in) and 228.60mm (9.00 in) i n diamet er and operate as a s ingle uni t.

The unit i s located on t he driver's si de of the engine compartment , and is s ealed t o t he bulkhead wit h a gas ket ands ecured wit h 4 s t uds and locki ng nuts . The brake boost er act uati ng pus h rod i s att ached t o t he brake pedal wit h a clevispin. The boost er out put rod l ocat es in the primary pis ton of t he brake mast er cyl inder.For addit ional informat ion, refer t o: Hydraulic Brake Actuati on (206-06 Hydraulic Brake Act uati on, Des cri pt ion andOperat ion).

VACUUM COMPONENTS

For bot h t he i6 gas oli ne and TD4 dies el engi nes , t he vacuum requi red for brake booster operati on is creat ed by a vacuumpump mount ed at the rear of t he cylinder head. The vacuum pump i s dri ven by the i ntake cams haft.

A rigi d plas ti c pipe connect s the vacuum pump t o a check valve ins t al led on the front chamber of t he brake boost er. Thepipe l engt h and rout ing is different for LHD and RHD model s.

The check valve mai ntains the vacuum neces s ary for brake boos t er operat ion and prevent s air from ent eri ng the frontchamber.

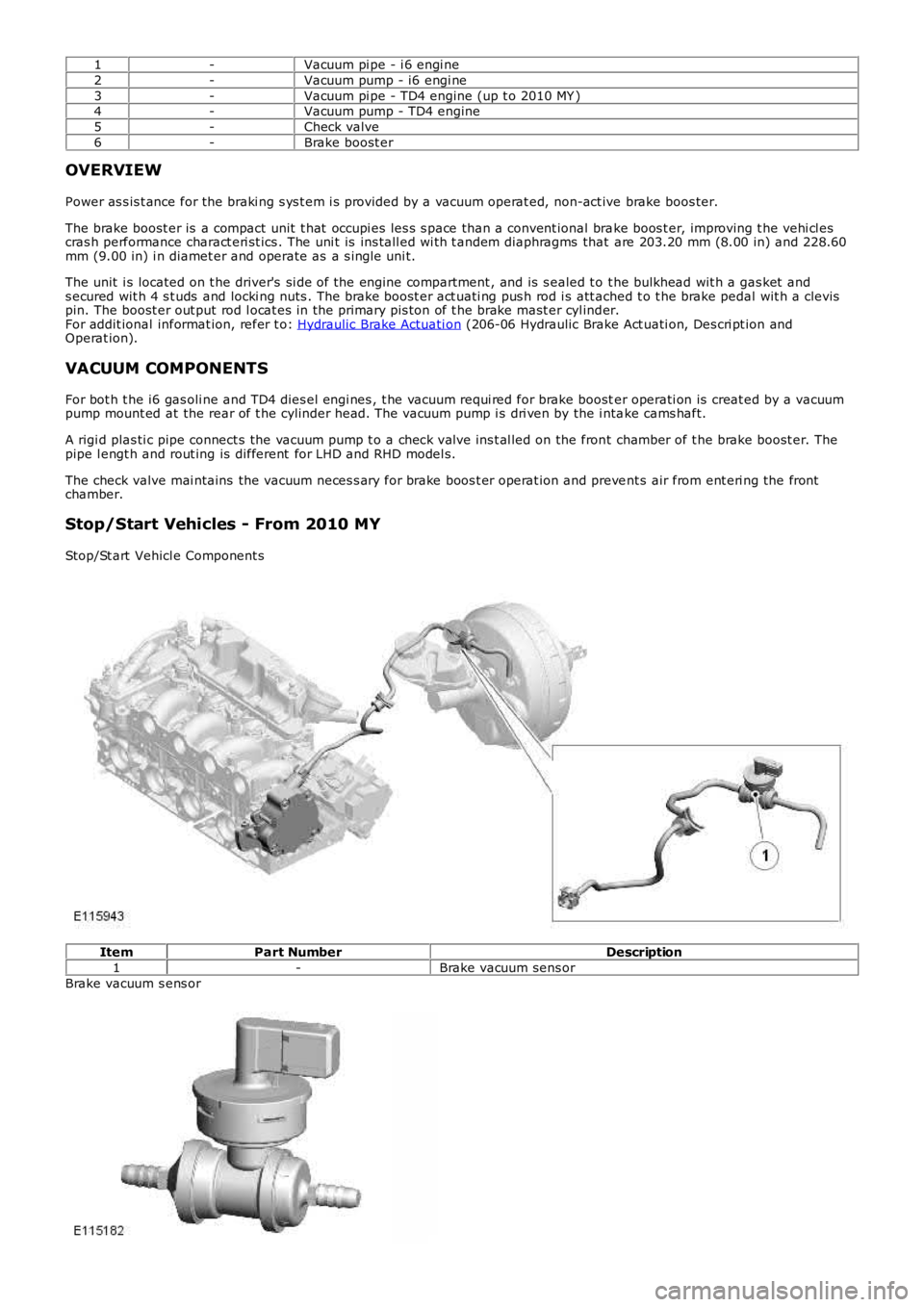

Stop/Start Vehicles - From 2010 MY

Stop/St art Vehicl e Component s

ItemPart NumberDescription

1-Brake vacuum sens or

Brake vacuum s ens or

Page 500 of 3229

1

2

Publi s hed: 11-May-2011

Anti-Lock Control - Anti-Lock Control

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the Ant i-lock Braking Sys t em (ABS), refer to the relevant Des cri pt ion and Operati on s ect ion i nt he works hop manual . REFER t o: Anti -Lock Cont rol - St abi li ty As s is t (206-09C Anti -Lock Cont rol - St abi lit y As s is t,Des cript ion and Operat ion).

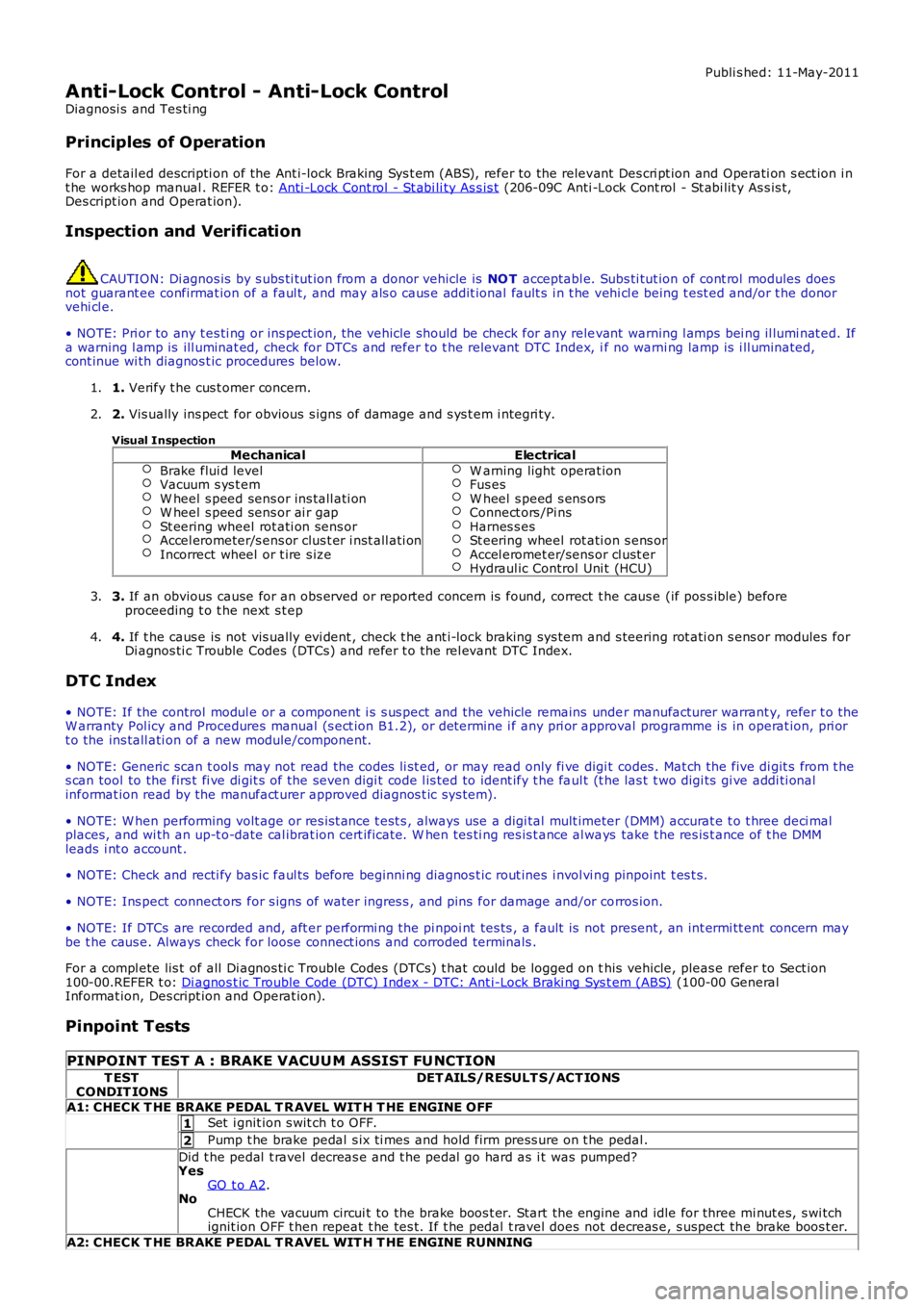

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

• NOTE: Pri or to any t es ti ng or ins pect ion, the vehicle should be check for any relevant warning l amps bei ng il lumi nat ed. Ifa warning l amp is ill uminat ed, check for DTCs and refer to t he relevant DTC Index, if no warni ng lamp is i ll uminated,cont inue wi th diagnos t ic procedures below.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of damage and s ys t em i ntegri ty.

Visual InspectionMechanicalElectrical

Brake flui d levelVacuum s ys t emW heel s peed sens or ins tall ati onW heel s peed sens or ai r gapSt eering wheel rot ati on sens orAccel erometer/s ens or clus t er i nst all ati onIncorrect wheel or t ire s ize

W arning light operat ionFus esW heel s peed s ens orsConnect ors /Pi nsHarnes s esSt eering wheel rot ati on s ens orAccel eromet er/sens or cl ust erHydraul ic Control Uni t (HCU)

2.

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , check t he ant i-lock braking sys tem and s teering rot ati on s ens or modules forDi agnos ti c Trouble Codes (DTCs) and refer t o t he rel evant DTC Index.4.

DTC Index

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve addi ti onalinformat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al ways take t he res is t ance of t he DMMleads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

For a compl ete lis t of all Di agnos ti c Trouble Codes (DTCs) t hat could be logged on this vehicle, pleas e refer to Sect ion100-00.REFER t o: Di agnos t ic Trouble Code (DTC) Index - DTC: Ant i-Lock Braki ng Sys t em (ABS) (100-00 GeneralInformat ion, Des cript ion and Operat ion).

Pinpoint Tests

PINPOINT TEST A : BRAKE VACUU M ASSIST FU NCTION

T ESTCONDIT IONSDET AILS/RESULT S/ACT IO NS

A1: CHECK T HE BRAKE PEDAL T R AVEL WIT H T HE ENGINE OFF

Set i gnit ion s wit ch t o OFF.

Pump t he brake pedal s ix ti mes and hold firm press ure on t he pedal .

Did t he pedal t ravel decreas e and t he pedal go hard as i t was pumped?YesGO t o A2.NoCHECK the vacuum circui t to the brake boos t er. Start the engine and idle for three mi nut es, s wi tchignit ion OFF t hen repeat t he tes t. If t he pedal t ravel does not decreas e, s uspect the brake boos t er.

A2: CHECK T HE BRAKE PEDAL T R AVEL WIT H T HE ENGINE RUNNING

Page 511 of 3229

3-Right -Hand (RH) rear wheel s peed s ens or

4-Steering wheel modul e (including s t eering angle sens or)

5-Left -Hand (LH) rear wheel s peed s ens or6-Sensor clus ter

7-LH front wheel speed s ensor

8-Int egrat ed Anti -l ock Brake Sys t em (ABS) modul e and Hydrauli c Cont rol Unit (HCU)9-RH front wheel speed s ensor

10-Central Junct ion Box (CJB)

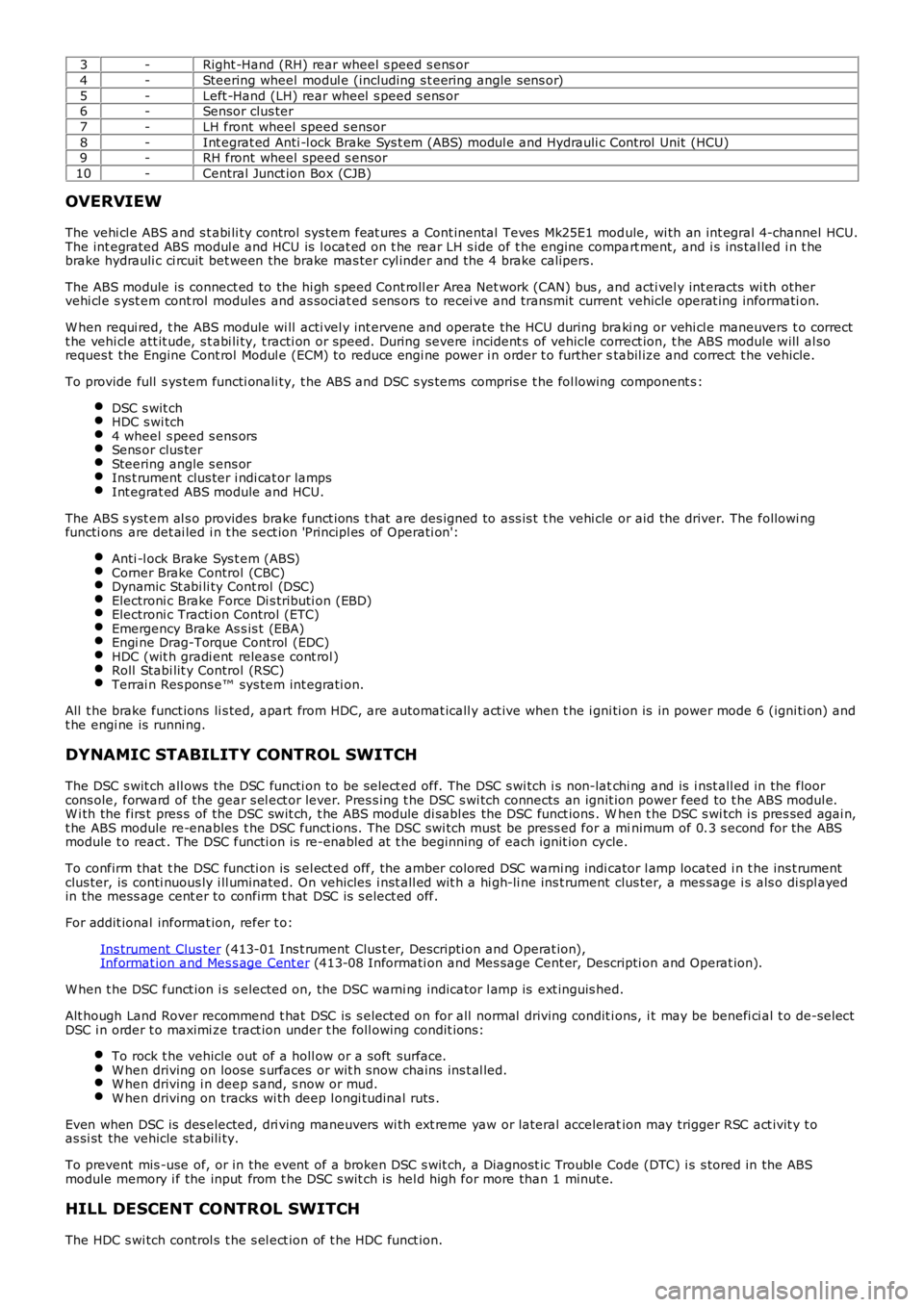

OVERVIEW

The vehi cl e ABS and s t abi li ty control sys tem feat ures a Cont inental Teves Mk25E1 module, wi th an int egral 4-channel HCU.The int egrated ABS modul e and HCU is l ocat ed on t he rear LH s ide of t he engine compart ment, and i s ins tal led i n t hebrake hydrauli c ci rcuit bet ween the brake mas ter cyl inder and the 4 brake calipers.

The ABS module is connect ed to the hi gh s peed Cont roll er Area Net work (CAN) bus , and acti vel y int eracts wi th othervehi cl e s yst em cont rol modules and as sociat ed s ens ors to recei ve and transmit current vehicle operat ing informati on.

W hen requi red, t he ABS module wi ll acti vel y int ervene and operate the HCU during braki ng or vehi cl e maneuvers t o correctt he vehi cl e att it ude, s t abi li ty, t racti on or speed. During severe incident s of vehicle correct ion, t he ABS module will al soreques t the Engine Cont rol Modul e (ECM) to reduce engi ne power i n order t o further stabil ize and correct t he vehicle.

To provide full s ys tem functi onali ty, t he ABS and DSC s ys tems compris e t he fol lowing component s :

DSC s wit chHDC s wi tch4 wheel s peed s ens orsSens or clus terSteering angle s ens orIns t rument clus ter i ndi cat or lampsInt egrat ed ABS module and HCU.

The ABS s yst em al s o provides brake funct ions t hat are des igned to ass is t t he vehi cle or aid the driver. The followi ngfuncti ons are det ai led i n t he s ect ion 'Principl es of Operati on':

Anti -l ock Brake Sys t em (ABS)Corner Brake Control (CBC)Dynamic St abi li ty Cont rol (DSC)Electroni c Brake Force Di s tributi on (EBD)Electroni c Tracti on Control (ETC)Emergency Brake As s is t (EBA)Engi ne Drag-Torque Control (EDC)HDC (wit h gradi ent releas e cont rol )Roll Stabi lit y Control (RSC)Terrai n Res pons e™ sys tem int egrati on.

All t he brake funct ions li s ted, apart from HDC, are automat icall y act ive when t he i gni ti on is in power mode 6 (igni ti on) andt he engi ne is runni ng.

DYNAMIC STABILITY CONTROL SWITCH

The DSC s wit ch all ows the DSC functi on to be s elect ed off. The DSC s wi tch i s non-latchi ng and is i nst all ed in the floorcons ole, forward of the gear s el ect or lever. Pres s ing t he DSC s wi tch connects an ignit ion power feed to t he ABS modul e.W i th the firs t pres s of the DSC swit ch, t he ABS module di sabl es the DSC funct ions . When t he DSC s wi tch i s pres sed agai n,t he ABS module re-enables t he DSC funct ions. The DSC swi tch must be press ed for a minimum of 0.3 s econd for the ABSmodule t o react . The DSC functi on is re-enabled at t he beginning of each ignit ion cycle.

To confirm that t he DSC functi on is sel ect ed off, the amber colored DSC warni ng indicator l amp located i n t he ins t rumentclus ter, is conti nuous ly i ll uminated. On vehicles i nst all ed wit h a hi gh-li ne ins t rument clus ter, a mes sage i s als o di spl ayedin the mess age cent er to confirm t hat DSC is s elect ed off.

For addit ional informat ion, refer t o:

Ins trument Clus ter (413-01 Ins t rument Clus t er, Descripti on and Operat ion),Informat ion and Mes s age Cent er (413-08 Informati on and Mes sage Cent er, Descripti on and Operat ion).

W hen t he DSC funct ion i s s elected on, t he DSC warni ng indicator l amp is ext inguis hed.

Alt hough Land Rover recommend t hat DSC is s elected on for all normal driving condit ions, i t may be benefi ci al t o de-sel ectDSC i n order t o maximi ze tract ion under t he foll owing condit ions:

To rock t he vehicle out of a holl ow or a s oft surface.W hen driving on loose s urfaces or wit h s now chains ins t al led.W hen driving i n deep s and, s now or mud.W hen driving on tracks wi th deep l ongi tudinal rut s .

Even when DSC is des elected, dri ving maneuvers wi th ext reme yaw or lateral acceleration may trigger RSC act ivit y t oas si st the vehicle st abili ty.

To prevent mis -use of, or in the event of a broken DSC s wit ch, a Diagnost ic Troubl e Code (DTC) i s s tored in the ABSmodule memory i f the input from t he DSC s wit ch is hel d high for more than 1 minut e.

HILL DESCENT CONTROL SWITCH

The HDC s wi tch control s t he s el ect ion of t he HDC funct ion.

Page 512 of 3229

The HDC s wi tch i s non-lat chi ng and is ins tall ed in the floor cons ole, forward of the gear s el ect or lever. Moment aril ypres s ing and releasi ng t he HDC s wit ch connects an ignit ion power feed t o t he ABS module. W it h t he fi rs t pres s and rel easeof the HDC s wit ch, t he ABS module enables operat ion of t he HDC funct ion. W hen t he HDC swi tch i s pres s ed and rel eas edagai n, the ABS modul e dis ables operat ion of t he HDC funct ion.

To prevent mis -use of, or in the event of a broken HDC s wi tch, if t he s wit ch is press ed for more t han 10 s econds nochange of s tat e occurs. A DTC i s s tored in t he ABS module memory if t he input from the HDC swi tch i s held hi gh for moret han 1 mi nut e.

HDC Activating Stoplamps

Operat ion of t he vehi cl e s toplamps during HDC is controll ed by the CJB. The ABS module monit ors t he brake s yst emhydraulic press ure and request s t he CJB, vi a t he high s peed CAN bus, t o energi ze the s t opl amps duri ng act ive braki ng.

A press ure thres hold and ti me fil ter prevents t he s topl amps from fli ckeri ng whil e HDC i s braking.

Stop/St art Vehicl es - From 2010 MY

Acti vat ion of Hi ll Descent Cont rol wi ll deact ivate the St op/St art s yst em. However, if Hi ll Des cent Control i s acti vat ed whent he engi ne is s hutdown in a St op/St art cycl e t he engi ne wil l aut omati cal ly rest art . If during t his event the St op/St arts ys t em cannot det ect t he dri ver's occupancy, for exampl e eit her t he driver’s safety belt or door is unl at ched, t he engi newil l not res tart. The St op/Start sys tem wi ll request the driver to depres s t he clut ch to res tart the engine. The dri ver wi ll beinformed of t his by ‘RESTART REQUIRED PRESS CLUTCH’ being di spl ayed i n t he mes sage center.

The dri ver mus t respond t o t hi s reques t wit hin a li mit ed t ime period, or otherwi s e a convent ional engine res tart us i ng theignit ion swi tch will be requi red.For addit ional informat ion, refer t o: Starti ng Sys t em (303-06C Starti ng Syst em - TD4 2.2L Di es el, Vehicles Bui lt From:01-03-2009, Descripti on and Operat ion).

WHEEL SPEED SENSORS

Page 522 of 3229

12-LH front wheel s peed s ens or

13-RH rear wheel s peed sens or

14-Act ive On-Demand Coupling modul e15-ECM

16-Diagnost ic socket

17-Sens or clus ter18-Terrai n Res pons e™ control modul e

19-Trans mis s ion Cont rol Modul e (TCM) - aut omati c t rans mis s ion models onl y

20-CJB

PRINCIPLES OF OPERATION

Anti-Lock Brake System

ABS cont rol s t he s peed of all road wheel s t o ensure opti mum wheel s li p when braking at the adhesi on li mit . The wheelsare prevent ed from locki ng to ret ai n effecti ve st eeri ng cont rol of the vehicle.

The front brake pres s ures are modul ated s eparat el y for each wheel. The rear brake press ures are modulat ed by s elect low.Select low appli es the same pres sure t o both rear brakes, wi th the press ure level bei ng det ermined by t he wheel on thelower fri ct ion s urface. This maint ai ns rear s tabil it y on s pli t fricti on s urfaces .

Corner Brake Control

CBC i nfluences the brake pres sures , below and wit hin ABS thres holds , to counteract the yawing moment produced whenbraking i n a corner. CBC produces a correcti on t orque by li mi ti ng the brake pres sure on one s ide of t he vehicle.

Dynamic Stability Control

DSC us es brakes and powert rain torque control to as s is t i n maint aining the l ateral st abi lit y of t he vehi cl e. W hil e t heignit ion is energi zed t he DSC funct ion i s permanentl y enabl ed, unl es s s elect ed off us ing t he DSC s wit ch. Even i f DSC isdesel ect ed, driving maneuvers wi th ext reme yaw or lat eral accelerat ion may trigger RSC acti vi ty to as s is t t he vehi cl es tabil it y.

DSC enhances dri ving s afet y in abrupt maneuvers and in under-st eer or over-s teer s ituat ions t hat may occur in a bend. TheABS module monit ors t he yaw rat e and l ateral accel erati on of the vehicle, s t eering input , and then s elect ively appli esindivi dual brakes and s ignals for powertrain t orque adjus t ments t o reduce under-s teer or over-s teer.

In general:

In an under-s t eer s i tuati on; the i nner wheels are braked t o count eract the yaw movement t owards t he outer edgeof the bend.In an over-st eer si tuat ion; the out er wheel s are braked to prevent t he rear end of the vehicl e from pus hing t owardst he out er edge of t he bend.

The ABS module monit ors t he tracki ng s tabil it y of the vehicle usi ng inputs from t he wheel s peed s ens ors, t he s teeringangl e s ensor, and the yaw rat e and lat eral accelerat ion sens or. The t racki ng s tabil it y is compared wit h s t ored t arget dat a.W henever t he t racki ng s tabil it y devi ates from t he target dat a, t he ABS modul e int ervenes by appl yi ng the appropriat ebrakes.

The fol lowing interact ions occur i n an i nt erventi on s it uat ion:

High speed CAN s i gnal t o t he ECM, to reduce engine torque.High speed CAN s i gnal t o t he Act ive On-demand Coupl ing module, t o open t he locki ng torque of the centercoupl ing.Applicati on of braking t o t he appropri at e corner of the vehicl e.

Electronic Brake Force Distribution

EBD l imi ts the brake press ure appl ied t o t he rear wheels . W hen t he brakes are appl ied, the wei ght of t he vehicle t rans fersforwards , reduci ng t he abi li ty of t he rear wheels to t rans fer braki ng effort t o t he road s urface. This may caus e t he rearwheels t o s li p and make t he vehi cl e uns table.

EBD us es the ant i-lock braking hardware t o automat icall y opti mize t he pres s ure of t he rear brakes , bel ow t he point whereABS i s normall y i nvoked.

• NOTE: Only the rear brakes are control led by the EBD funct ion.

Electronic Traction Control

ETC att empt s to opt imize forward tract ion by reduci ng engi ne torque, or by applying t he brake of a spi nni ng wheel unt ilt racti on is regai ned.

ETC is act ivated if an i ndi vi dual wheel speed i s above that of the vehicle reference speed (pos i ti ve sl ip) and t he brakepedal i s not pres sed. The brake i s appl ied t o t he s pinning wheel, al lowing t he excess t orque t o be t rans mit t ed to thenon-s pinning wheels through t he dri ve li ne. If neces s ary, the ABS modul e als o s ends a hi gh speed CAN bus mess age t ot he ECM t o reques t a reducti on in engine torque.

W hen t he DSC funct ion i s s elected off us i ng the DSC s wit ch, t he engi ne t orque reducti on feature i s dis abl ed.

Emergency Brake Assist

EBA as si s ts t he driver in emergency braking si tuat ions by automat icall y maximi zi ng the appl ied braki ng effort . There aret wo s it uat ions when t he ABS module wil l invoke EBA: