engine LAND ROVER FRELANDER 2 2006 Manual PDF

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 523 of 3229

W hen t he brake pedal is rapi dly press ed.W hen t he brake pedal is pres s ed hard enough t o bri ng t he front brakes i nto ABS operati on.

W hen t he brake pedal is rapi dly press ed, the ABS modul e i ncreas es t he hydraul ic press ure to al l of the brakes unt il t het hreshol d for ABS operat ion i s reached. This act ion appli es the maxi mum braking effort for the avail abl e t racti on. The ABSmodule moni tors for t he s udden appli cat ion of t he brakes , us i ng inputs from t he brake pedal s wi tch and from the press ures ens or wit hin the HCU. W it h t he brake pedal pres s ed, if t he rat e of increas e of hydraul ic press ure exceeds thepredetermined l imi t, t he ABS modul e invokes emergency braki ng.

W hen t he brake pedal is pres s ed hard enough t o bri ng t he front brakes i nto ABS operati on, t he ABS module increas es thehydraulic press ure to the rear brakes up to the ABS thres hold.

EBA operat ion cont inues unti l the driver rel eas es t he brake pedal , s uffi cientl y for t he hydraulic press ure in the HCU to dropbelow a threshold val ue s tored in t he ABS modul e.

Engine Drag-Torque Control

EDC prevents wheel s li p caus ed by any of t he fol lowing:

A s udden decreas e i n engine t orque when t he accelerator is suddenly released.The s udden engagement of t he clutch after a downs hift on manual t rans mi ss ion vehicl es .A downs hift us i ng the CommandShift functi on on automat ic t rans mi ss ion vehicl es .

W hen t he ABS module det ects t he ons et of wheel s lip wit hout t he brakes being appli ed, t he ABS module s ignal s t he ECMvia t he high speed CAN bus t o reques t a moment ary increase in engine torque.

Hill Descent Control

HDC us es engine braking and brake int ervent ion to control the vehicle speed and accel erati on duri ng low speed off-roaddescents , and in low grip on-road condit ions. General ly, equal pres s ure i s applied to al l 4 brakes , but pres s ure to individualbrakes may be modi fi ed by t he ABS and DSC funct ions to ret ain t he vehi cles s tabil it y. Sel ect ion of t he HDC funct ion i scont rol led by t he HDC s wi tch l ocat ed on t he fl oor consol e. HDC operates at vehicle speeds up t o 50 km/h (31 mph).

W ARNING: Incorrect us e of the HDC functi on may compromis e t he s tabil it y of the vehicle, resul ti ng in a dangerousand uncont roll ed hil l des cent . Pres si ng t he cl utch pedal and/or driving wit h t he trans mi s si on in 'Neutral' whil e HDC i sact ive, wi ll prevent engine braking from ass is t ing t he vehicle. The brakes wil l overheat and i nduce t he HDC fade outs trategy. In this condit ion t here will be no cont rol over t he vehi cl e duri ng a des cent .

• NOTE: W i th the HDC functi on s elect ed, HDC i s operati ve even when the clut ch pedal is pres sed or t he t rans mis s ion i s int he 'Neutral' posi ti on. It is not recommended t o drive t he vehi cl e furt her t han is abs olut el y neces s ary wi th HDC s elected,and t he cl utch pedal press ed/ or the t rans mi ss i on in 'Neut ral '.

On manual transmis s ion vehicles , HDC may be us ed i n firs t and reverse gears only. Once the vehicle is movi ng, t he clut chpedal i s to be ful ly releas ed. The vehicle i s not recommended to be dri ven wit h HDC act ive and t he transmis si on in'Neut ral'.

On aut omati c trans mi s si on vehi cl es, HDC may be us ed i n 'D' dri ve, 'R' revers e and CommandShi ft '1' only. W hen in 'D', t heTCM wi ll automat icall y s el ect t he mos t appropri ate gear. The vehicle is not recommended t o be driven wit h HDC act ive andt he trans mi s si on in 'Neutral'.

HDC i s able t o be sel ect ed at speeds up t o 80 km/h (50 mph), but wi ll only be enabled at s peeds bel ow 50 km/h (31 mph).

W hen HDC is s elect ed:

At s peeds up t o 50 km/h (31 mph), the HDC informat ion i ndi cat or lamp i s permanentl y i llumi nated i f a valid gear i ss elect ed.At s peeds bet ween 50 to 80 km/h (31 to 50 mph), t he HDC i nformat ion indicator lamp fl ashes and on vehicles wit ht he high l ine i ns t rument clus ter, a mes s age advis i ng that t he s peed i s t oo high i s dis played in the mes s age cent er.If the HDC swit ch is pres s ed whil e t he vehi cl e s peed is great er than 80 km/h (50 mph), the HDC informat ionindicat or l amp wi ll not il lumi nat e and HDC will not be s elected.If the s peed reaches 80 km/h (50 mph) or more, a warni ng chi me i s s ounded, the HDC functi on is swi tched off, t heinformat ion i ndi cat or lamp is exti ngui shed and, on vehicles wi th the hi gh li ne ins trument cl ust er, a mess ageadvi s ing t hat HDC has been swi tched off i s dis played i n the mess age center.

For addit ional informat ion, refer t o:

Ins trument Clus ter (413-01 Ins t rument Clus t er, Descripti on and Operat ion),Informat ion and Mes s age Cent er (413-08 Informati on and Mes sage Cent er, Descripti on and Operat ion).

W hen HDC is enabled, the ABS module calculat es a t arget speed and compares t his wi th the act ual vehicle s peed. The ABSmodule t hen operates the HCU in t he acti ve braking mode as required, t o achi eve and maint ain t he t arget speed.Operat ion of t he vehi cl e s toplamps during HDC is controll ed by the CJB.

Applying t he foot brake during acti ve braking may res ult i n a puls e being felt t hrough t he brake pedal.

The t arget speed vari es bet ween mi nimum and maximum values for each gear and t rans miss ion range, dependi ng on driverinputs through t he foot pedals . If the foot pedals are not operated, t he ABS module adopts a default t arget s peed:

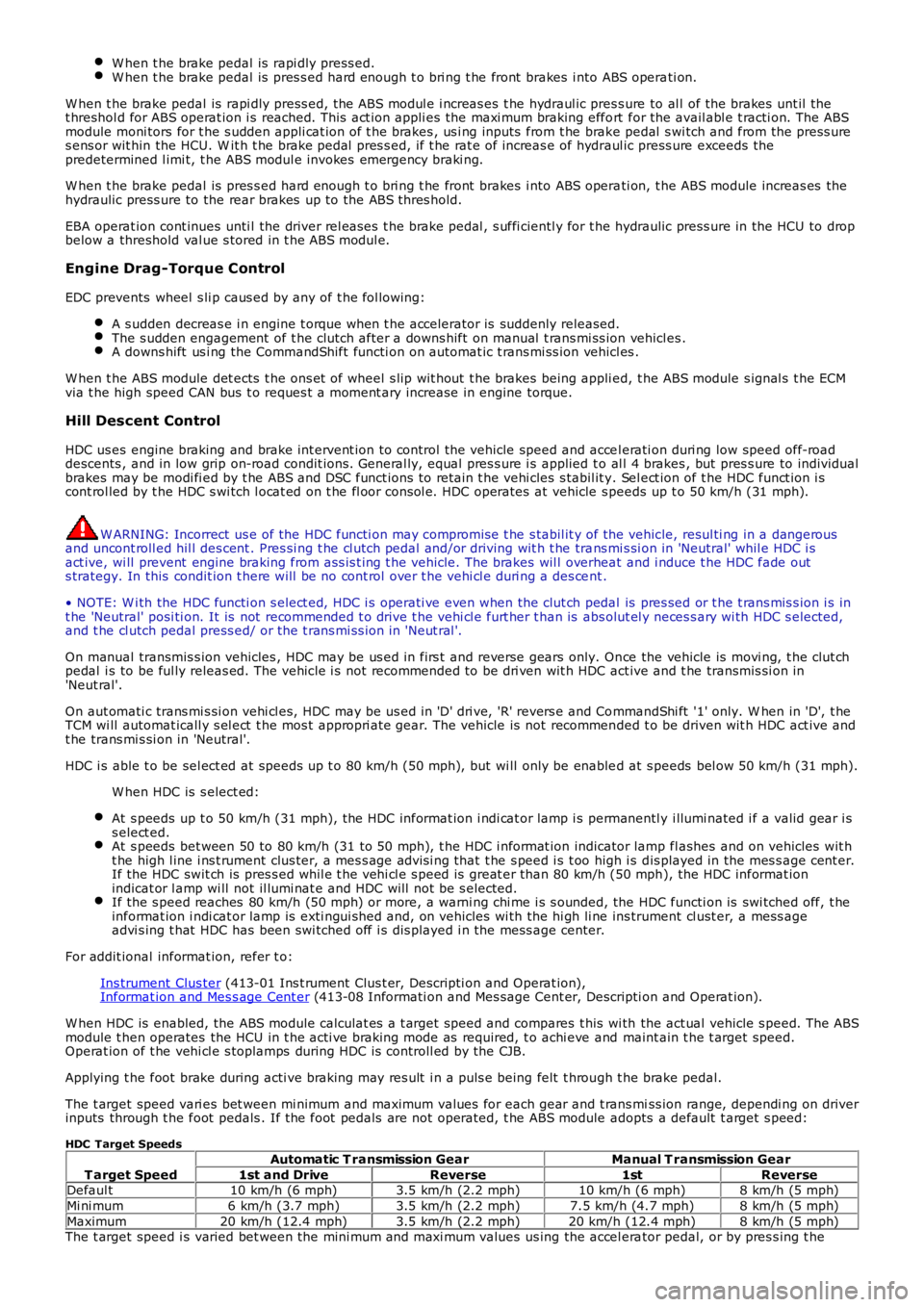

HDC Target Speeds

T arget Speed

Automatic T ransmission GearManual T ransmission Gear

1st and DriveReverse1stReverseDefaul t10 km/h (6 mph)3.5 km/h (2.2 mph)10 km/h (6 mph)8 km/h (5 mph)

Mi ni mum6 km/h (3.7 mph)3.5 km/h (2.2 mph)7.5 km/h (4.7 mph)8 km/h (5 mph)

Maximum20 km/h (12.4 mph)3.5 km/h (2.2 mph)20 km/h (12.4 mph)8 km/h (5 mph)The t arget speed i s varied bet ween the mini mum and maxi mum values us ing the accel erator pedal, or by pres s ing t he

Page 524 of 3229

s peed control '+' and '-' but t ons (dependant on vehi cl e s peci fi cat ion). The HDC Target speed wi ll als o vary depending ont he Terrai n Respons e™ mode sel ect ed.

Duri ng changes of target s peed, the ABS modul e li mit s vehicle decelerat ion and accelerat ion t o -0.5 met ers per s econd

s quared (m/s2) (-1.64 feet per s econd squared (ft/s2)); and +0.5 m/s2 (+1.64 ft/s2) res pect ively.

To provide a s afe t rans it ion from acti ve braking t o brakes off, the ABS module i nvokes a fade out st rat egy that graduall yrel eas es t he braking effort during act ive braking. The fade out s t rat egy occurs i f any of t he fol lowi ng condit ions i s detectedduri ng act ive braki ng:

HDC i s s elected off us i ng the HDC s wit ch.Failure of a component us ed by HDC, but not crit ical t o fade out funct ion.Accelerator pedal pres s ed when t rans mis s ion i s i n neut ral .Brakes overheat .

If fade out is i nvoked becaus e of HDC de-s el ect ion or component failure, the HDC functi on is cancel led by t he ABS module.If fade out is i nvoked becaus e t he accelerator pedal i s pres s ed wit h t he t ransmis s ion i n neut ral , or because of brakeoverheat , t he HDC funct ion remains in s tandby and res umes operati on when t he accelerat or pedal is releas ed or the brakeshave cooled.

The fade out s t rategy i ncreas es t he t arget speed at a cons tant accelerati on rat e of 0.5 m/s2 (1.64 ft/s2), unti l themaximum t arget speed i s reached, or unti l no act ive braki ng is required for 0.5 second. If t he accelerat or pedal is

posi ti oned wit hin t he range t hat infl uences t arget s peed, the accelerat ion rate is increas ed t o 1.0 m/s2 (3.3 ft /s2).

W hen fade out is i nvoked becaus e of component fai lure, a warning chime is sounded and the HDC informat ion i ndi cat orlamp is ext inguis hed. The HDC warning i ndicat or lamp is t hen il lumi nat ed (on low-li ne ins trument cl ust er), or a mes s ageadvi s ing of t he fault i s dis played in the mess age cent er (on hi gh-l ine i ns t rument clus ter).

For addit ional informat ion, refer t o:

Ins trument Clus ter (413-01 Ins t rument Clus t er, Descripti on and Operat ion),Informat ion and Mes s age Cent er (413-08 Informati on and Mes sage Cent er, Descripti on and Operat ion).

W hen fade out is i nvoked becaus e of brake overheat, on vehicles wi th the hi gh-li ne ins t rument clus ter, a mes sage advis ingt hat HDC is t emporarily unavail abl e is di s pl ayed. On vehicles wit h t he low-line ins trument cl us t er, t he HDC warningindicat or l amp flas hes . At t he end of fade out, t he HDC informati on indicat or flas hes. The flas hing warni ng and informat ionindicat or l amps, and/or di spl ayed mes s age cont inue whi le HDC remai ns sel ect ed, unt il t he brakes have cooled.

For addit ional informat ion, refer t o:

Ins trument Clus ter (413-01 Ins t rument Clus t er, Descripti on and Operat ion),Informat ion and Mes s age Cent er (413-08 Informati on and Mes sage Cent er, Descripti on and Operat ion).

To monit or for brake overheat, t he ABS modul e monit ors t he amount of braking acti vi ty and, from thi s, es ti mat es thet emperature of each brake. If the es t imat ed temperature of any brake exceeds a pres et li mit , t he ABS module i nvokes t hefade out s t rategy. Aft er the fade out cycle, t he HDC funct ion i s re-enabl ed when the ABS modul e es ti mates that all of thebrake t emperatures are at l ess than 64% of the preset t emperat ure l imi t.

Roll Stability Control

The RSC funct ion us es the brakes and the engine t o at tempt t o rest ore vehicle s tabilit y, i f the vehicle is forced i nt o ahars h maneuver t hat ri sks i t ti pping over.

The ABS module monit ors dri ver i nput s and vehicle behavior usi ng various powert rai n s ignals and t he i nput s from thewheel s peed s ens ors, t he s teering angle s ens or, the roll rate sens or, yaw rate and lateral accel erat ion s ensors. Thes einputs are compared wit h modeled behavi or and, if t he vehicle behavior reaches a given ris k level, t he ABS module cut st he engi ne power, or brakes one or more wheels suffi ci ent ly to al low the vehicle to regain s t abi li ty and hel p the driverremai n i n cont rol .

W hi le t he i gni ti on is energi zed, RSC i s permanentl y enabl ed even if t he DSC functi on is sel ect ed off.

Terrain Response™ System Integration

The Terrai n Res pons e™ funct ion integrat es t he ABS and other vehicle s ys tem cont rol modules t o as si s t the vehicle whendri vi ng off-road or during di fficult s urface condit ions . Terrai n Respons e is act ivated when the rotary cont rol s wit ch is s et t oa Terrain Res ponse special program.

W hen a Terrai n Respons e s peci al program i s acti vat ed, t he ABS module along wi th ot her vehicle s ys t em control modul eswil l operate in accordance wi th programmed software maps . The s oftware maps al low t he ABS s ys tem to functi on wit h at hreshol d that wi ll as si s t the s elected Terrai n Respons e s pecial program.For addit ional informat ion, refer t o: Ride and Handli ng Opti mizat ion (204-06 Ride and Handli ng Opt imi zat ion, Descripti onand Operat ion).

Page 528 of 3229

Publi s hed: 11-May-2011

Steering System - General Information - Steering System

Diagnosi s and Tes ti ng

Principle of Operation

For a detail ed descripti on of the st eering sys tem, refer t o t he rel evant Des cript ion and Operat ion s ecti on in the works hopmanual. REFER to:

Steeri ng Sys t em (211-00 St eering Sys tem - General Informat ion, Diagnos i s and Test ing),Power St eering (211-02 Power Steeri ng, Des cri pti on and Operati on),Steeri ng Linkage (211-03 St eering Li nkage, Descripti on and Operat ion),Steeri ng Column (211-04 St eering Col umn, Des cri pti on and Operati on).

Inspection and Verification

1. Verify t he cus t omer concern by operat ing t he s yst em.1.

2. Vis ually ins pect for obvious s igns of damage and s ys t em i ntegri ty.2.

Visual Inspection

MechanicalCheck the t ires for correct press ure, s ize and t read pat ternCheck for wheel rim and t ire damageCheck road wheel securi tyCheck the power s teeri ng fluid level and t he hydraulic ci rcuit for flui d leaksCheck the power s teeri ng pump drive belt condi ti on and t ens ionCheck the power s teeri ng pump for securi ty, wear, damage and exces s ive nois eCheck the s t eering gear as sembl y for damage, wear and s ecurit yCheck the hydrauli c pipes and cool er li nes for damage and correct rout ingCheck the s t eering joint s for damage, excess i ve play, wear and s ecurit yCheck the s t eering column and joi nt s for damage, exces s ive play, wear and securi ty

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep.3.

4. If t he concern is not vis uall y evi dent , verify t he s ymptom and refer t o t he Symptom Chart .4.

Symptom Chart

• NOTE: If a component is sus pect and t he vehicle remains under the manufact urer warrant y, refer t o t he W arrant y Policyand Procedures manual (s ect ion B1.2), or determine i f any prior approval programme is i n operat ion, prior t o t heins t al lat ion of a new component.

SymptomPossible CauseAction

St eering wandersExces s ive free pl ay in t hes teering s yst emSt eering geometryi ncorrect ly al igned

Check for excess i ve movement or play i n t he s teeri ng s yst em wit hthe engine running. Check for pl ay at several different s t eeringpos i ti ons . Carry out st eeri ng geomet ry and alignment checks .REFER t o: Four-W heel Al ignment (204-00 Sus pens i on Sys t em -General Informati on, General Procedures ).St eering pull s t o t hel eft or ri ghtSt eering/s us pens ioncomponent s damaged,bent, l oos eSt eering geometryi ncorrect ly al igned

Check s t eering and s us pens ion component s for damage/correctins tal lati on. Carry out s t eering geometry and ali gnment checks .REFER t o: Four-W heel Al ignment (204-00 Sus pens i on Sys t em -General Informati on, General Procedures ).

St eering feel snotchy when t urningfrom lock to lock

St eering or s uspens ions wivel joi nt s s eizedSt eering t ie rod end jointsor t rack rod i nner joint ss eizedSt eering column orunivers al joi nt s s eizedSt eering gear int ernalcomponent s mi sal igned,worn or damaged

Dis connect the s t eering gear from the s us pens ion. Check forfreedom of movement i n t he s us pensi on. Di s connect t he s teeringcol umn from the s t eering gear. Check t he st eeri ng col umn anduni vers al joint s for freedom of movement. Check the s t eeringgear for freedom of movement . Rect ify as neces s ary.

St eering feel s t ightand does nots elf-center

Power st eeri nghydrauli cs noi syoperat ion

Power st eeri ng fl uid l evell ow or cont aminatedPower st eeri ng fl uidaerat edPower st eeri ng hos est wis t ed or res tricted

Check and t op-up t he power st eering fl ui d l evel if requi red.REFER t o: Power St eeri ng Sys t em Bl eeding (211-00 St eeringSys t em - General Informat ion, General Procedures ).Check for contaminated flui d. Check for air i ngres s int o t hesys t em. Check t he power s t eering hos es for t wis t ing orres trict ions. Recti fy as neces sary.

Power st eeri ng pumpnois yPower st eeri ng fl uid l evell ow or cont aminatedPump i nternal component sworn or damaged

Check and t op-up t he power st eering fl ui d l evel if requi red.REFER t o: Power St eeri ng Sys t em Bl eeding (211-00 St eeringSys t em - General Informat ion, General Procedures ).Check for contaminated flui d. Check for exces s ive pump noi se.Ins tal l a new pump as required. Refer t o t he new componentins tal lati on note at t he t op of the Sympt om Chart

Page 530 of 3229

Publi s hed: 11-May-2011

Steering System - General Information - Power Steering System Bleeding

General Procedures

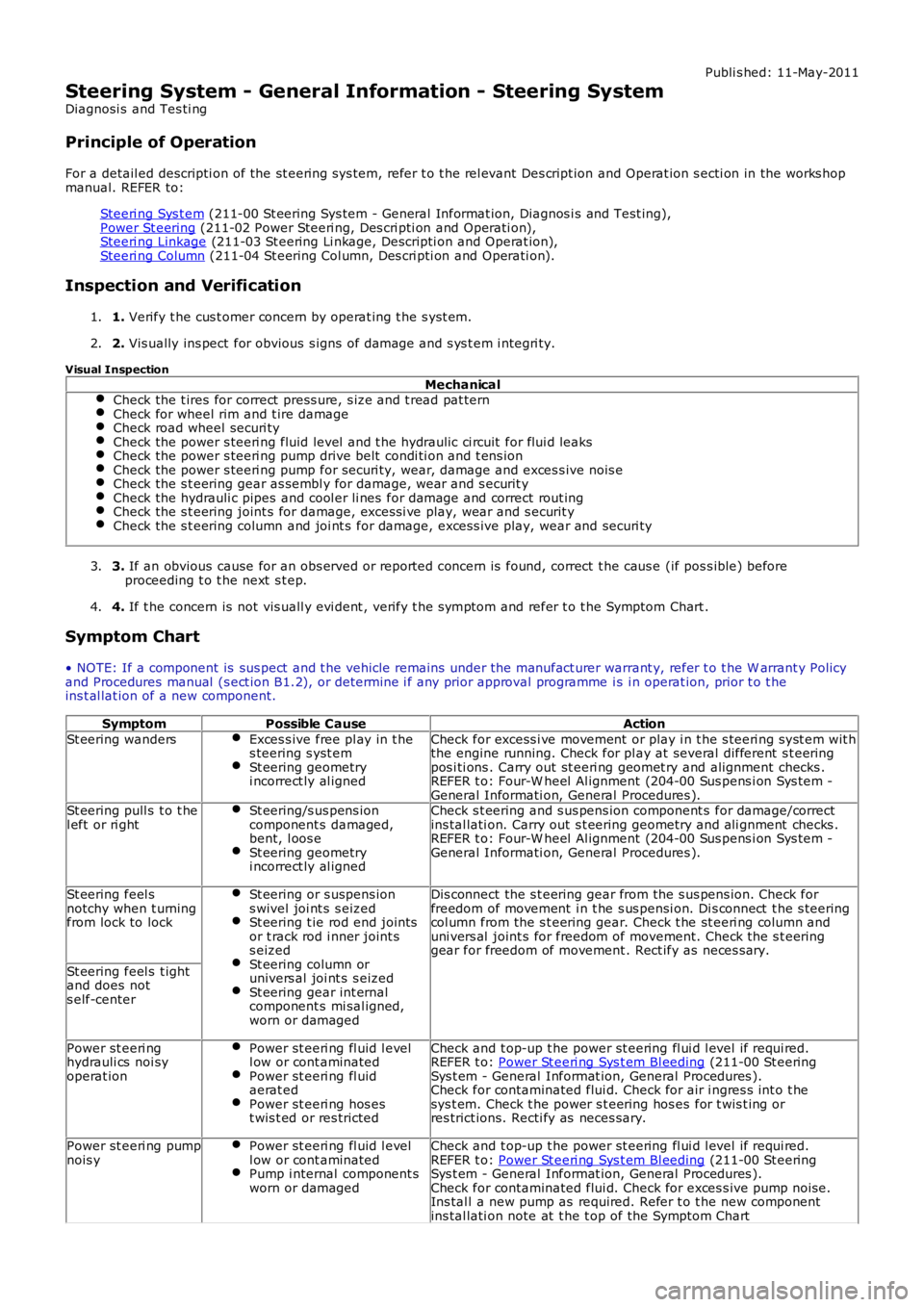

Clean power s teering fluid res ervoir around t he fi ll er cap and flui di ndi cat or.1.

Check the power s teeri ng fluid, if aerat ed, wait unti l fl ui d i s freefrom bubbles then t op-up res ervoi r to UPPER l evel mark wit hrecommended fluid.

2.

3. CAUTION: Flui d mus t always be pres ent in theres ervoi r during bl eeding.

Remove t he fi ll er cap and fil l t o t he MAX level mark.

3.

Inst all t he fi ll er cap.4.

St art t he engi ne and allow to run for 10 s econds, s t op t he engi ne.5.

Check the power s teeri ng fluid, if aerat ed, wait unti l fl ui d i s freefrom bubbles then t op-up res ervoi r to UPPER l evel mark wit hrecommended fluid.

6.

St art t he engi ne and turn s teering ful ly lock to lock, s t op the engine.7.

Check and top-up power s t eering fluid level.8.

St art and run the engine for 2 mi nut es , turn the st eeri ng full y l ock t ol ock.9.

Check and top-up power s t eering fluid level.10.

Page 533 of 3229

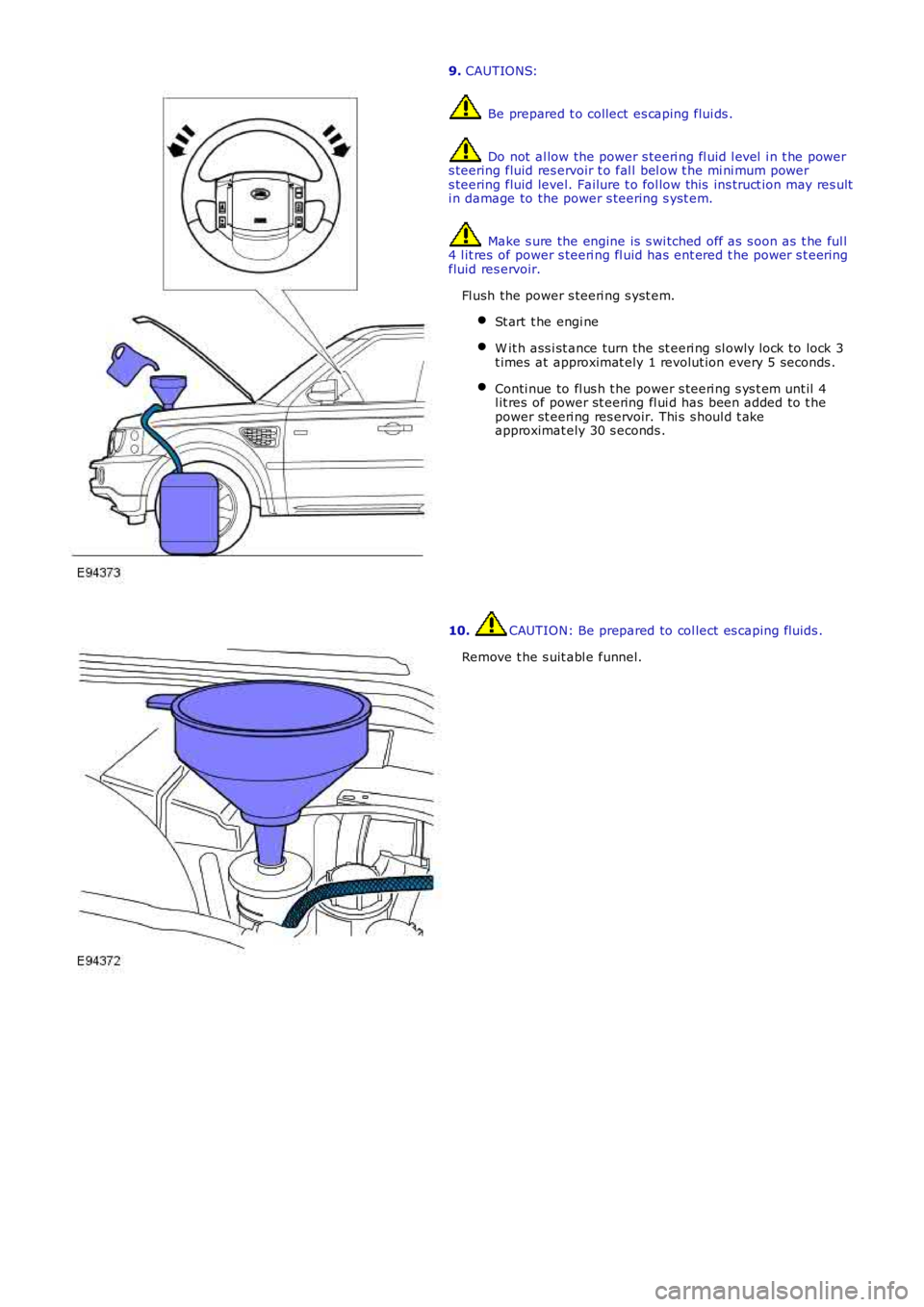

9. CAUTIONS:

Be prepared t o collect es caping flui ds .

Do not al low the power s teeri ng fl uid l evel i n t he powers teering fluid res ervoir t o fal l bel ow t he mi ni mum powers teering fluid level. Failure t o fol low this ins truct ion may res ulti n damage to the power s teering s yst em.

Make s ure the engine is s wi tched off as s oon as t he ful l4 l it res of power s teeri ng fl uid has ent ered t he power s t eeringfluid res ervoir.

Fl ush the power s teeri ng s yst em.

St art t he engi ne

W it h ass i st ance turn the st eeri ng sl owly l ock to lock 3t imes at approximat ely 1 revolut ion every 5 seconds .

Conti nue to fl us h t he power s teeri ng s ys t em unt il 4l it res of power st eering fl ui d has been added to t hepower st eeri ng res ervoir. Thi s s houl d t akeapproximat ely 30 s econds .

10. CAUTION: Be prepared to col lect es caping fluids .

Remove t he s uit abl e funnel.

Page 535 of 3229

Publ is hed: 05-Dec-2011

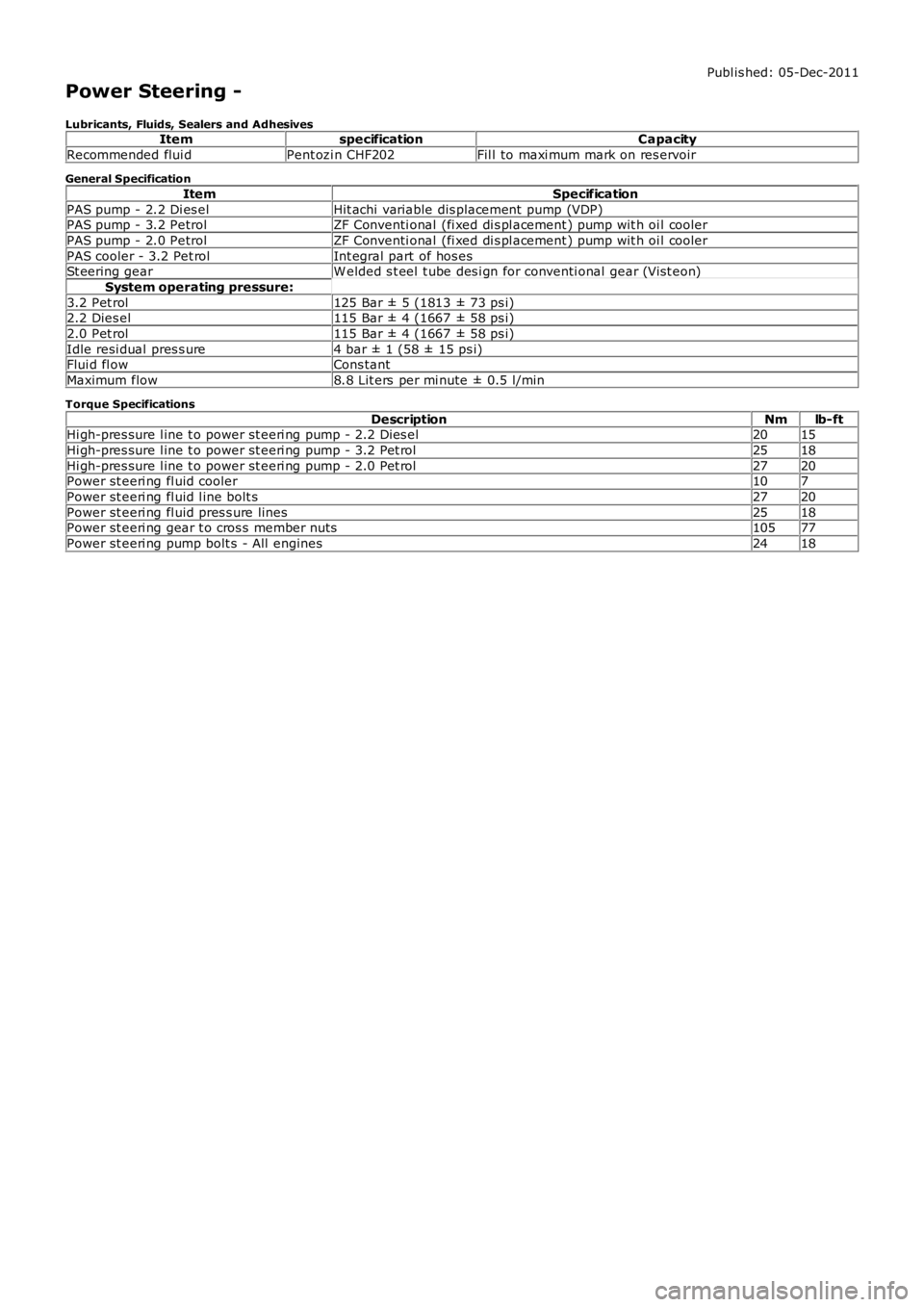

Power Steering -

Lubricants, Fluids, Sealers and AdhesivesItemspecificationCapacity

Recommended flui dPent ozi n CHF202Fil l to maxi mum mark on res ervoir

General Specification

ItemSpecification

PAS pump - 2.2 Di es elHit achi variable dis placement pump (VDP)PAS pump - 3.2 PetrolZF Conventi onal (fi xed di s pl acement ) pump wit h oi l cooler

PAS pump - 2.0 PetrolZF Conventi onal (fi xed di s pl acement ) pump wit h oi l cooler

PAS cooler - 3.2 Pet rolInt egral part of hos esSt eering gearW elded s t eel t ube des i gn for conventi onal gear (Vi st eon)

System operating pressure:

3.2 Pet rol125 Bar ± 5 (1813 ± 73 ps i)2.2 Dies el115 Bar ± 4 (1667 ± 58 ps i)

2.0 Pet rol115 Bar ± 4 (1667 ± 58 ps i)

Idle resi dual pres s ure4 bar ± 1 (58 ± 15 ps i)Flui d fl owCons tant

Maximum flow8.8 Lit ers per mi nute ± 0.5 l/min

Torque Specifications

DescriptionNmlb-ftHi gh-pres sure l ine t o power st eeri ng pump - 2.2 Dies el2015

Hi gh-pres sure l ine t o power st eeri ng pump - 3.2 Pet rol2518

Hi gh-pres sure l ine t o power st eeri ng pump - 2.0 Pet rol2720Power st eeri ng fl uid cooler107

Power st eeri ng fl uid l ine bolt s2720

Power st eeri ng fl uid pres s ure lines2518Power st eeri ng gear t o cros s member nuts10577

Power st eeri ng pump bolt s - All engines2418

Page 537 of 3229

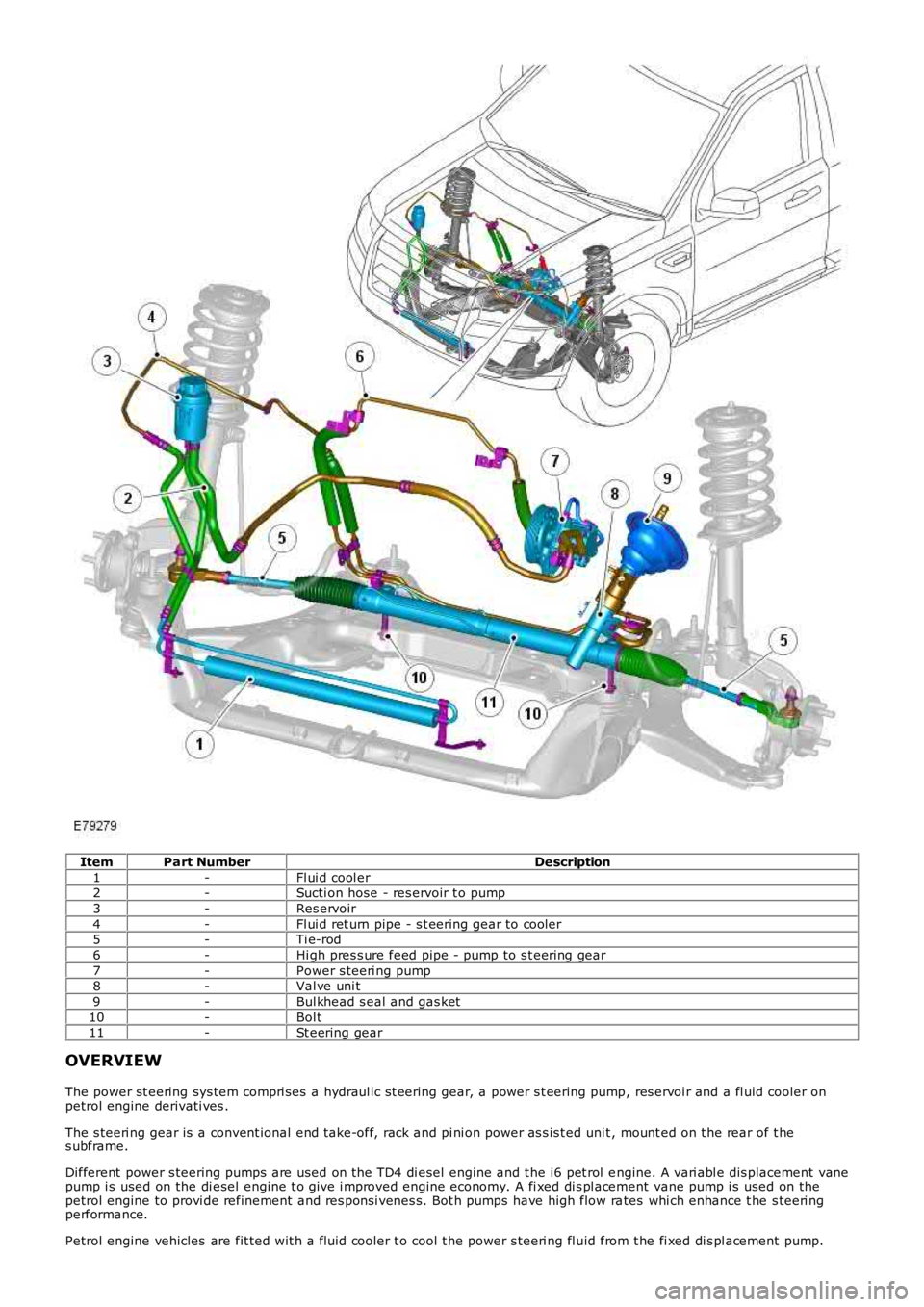

ItemPart NumberDescription

1-Fl ui d cool er2-Sucti on hose - res ervoir t o pump

3-Res ervoir

4-Fl ui d ret urn pipe - s t eering gear to cooler5-Ti e-rod

6-Hi gh pres s ure feed pipe - pump to s t eering gear

7-Power s teeri ng pump8-Val ve uni t

9-Bul khead s eal and gas ket

10-Bol t11-St eering gear

OVERVIEW

The power st eering sys tem compri ses a hydraul ic s t eering gear, a power s t eering pump, res ervoi r and a fl uid cooler onpetrol engine derivati ves .

The s teeri ng gear is a convent ional end take-off, rack and pi ni on power as s is t ed unit , mount ed on t he rear of t hes ubframe.

Different power s teering pumps are used on the TD4 di esel engine and t he i6 pet rol engine. A vari abl e dis placement vanepump i s used on the di esel engine t o give i mproved engine economy. A fi xed di s pl acement vane pump i s used on thepetrol engine to provi de refinement and res pons i venes s. Bot h pumps have high flow rates whi ch enhance t he s teeri ngperformance.

Petrol engine vehicles are fit ted wit h a fluid cooler t o cool t he power s teeri ng fl uid from t he fi xed di s pl acement pump.

Page 540 of 3229

diamet er in i ts central sect ion. The smal ler diamet er allows the t ors ion bar t o t wist in res pons e t o t orque appli ed from t hes teeri ng wheel in relati on t o t he grip of the t yres on t he road surface. The pi nion s haft has machined t eet h on it s cent raldiamet er whi ch mat e wit h t eeth on the s t eering gear rack. A s lot , machi ned in t he upper end of t he pini on s haft mateswit h t he dog-t oot h on the i nput s haft . The pinion s haft l ocat es in the pi ni on housi ng and rot ates on bal l and roll erbearings .

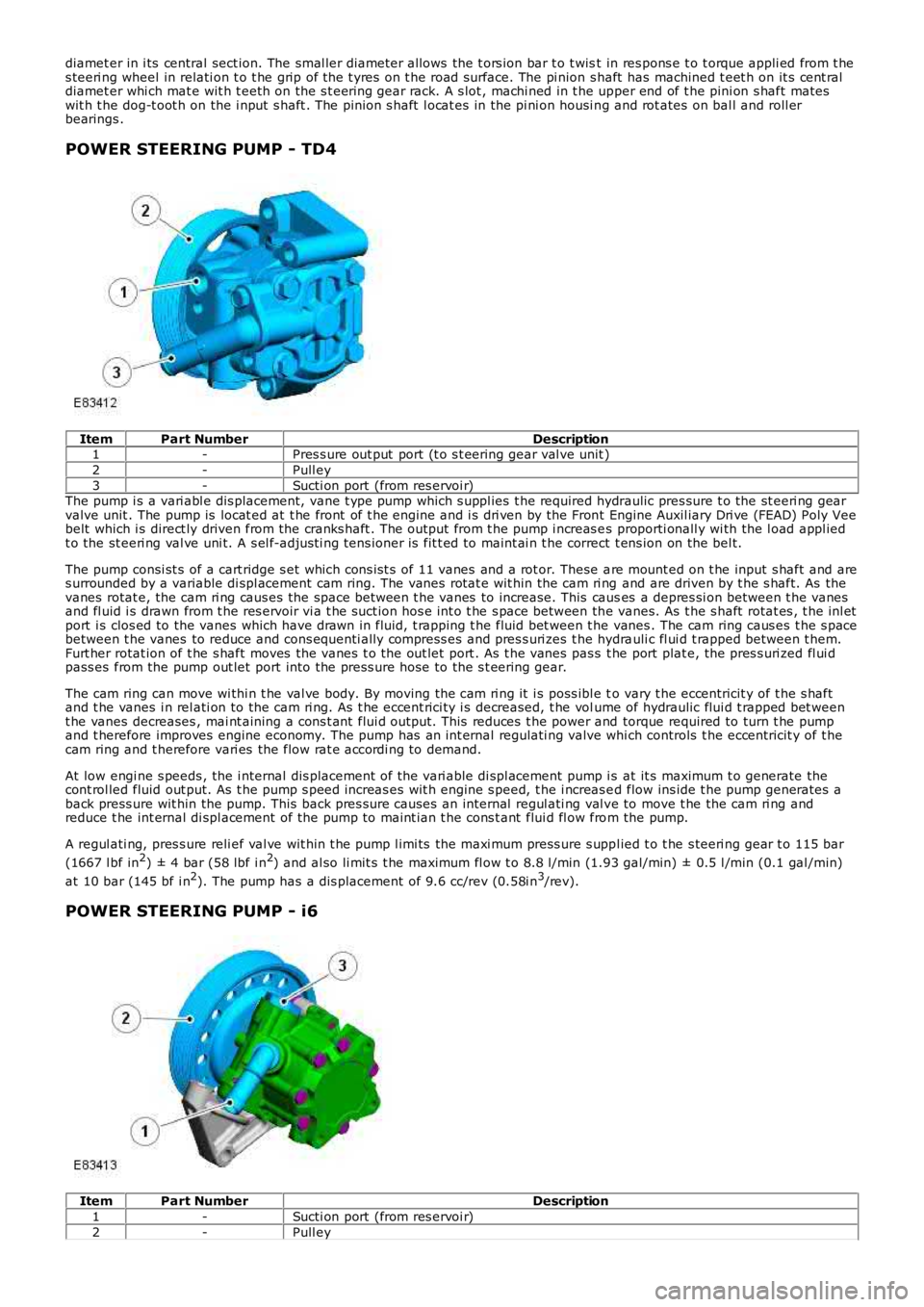

POWER STEERING PUMP - TD4

ItemPart NumberDescription1-Pres s ure out put port (t o s t eering gear val ve unit )

2-Pull ey

3-Sucti on port (from res ervoi r)The pump i s a vari abl e dis placement, vane t ype pump which s uppl ies t he required hydraulic pres sure t o the st eeri ng gearvalve unit . The pump is locat ed at t he front of t he engine and i s dri ven by the Front Engine Auxil iary Dri ve (FEAD) Poly Veebelt which i s direct ly driven from the cranks haft . The out put from t he pump i ncreas es proporti onall y wi th the l oad appl iedt o the st eeri ng val ve uni t. A s el f-adjus ti ng tens ioner is fit t ed to maint ai n t he correct t ens ion on the bel t.

The pump consi st s of a cart ridge s et which cons is t s of 11 vanes and a rot or. These are mount ed on t he input s haft and ares urrounded by a variable di spl acement cam ring. The vanes rotat e wit hin the cam ri ng and are driven by t he s haft. As thevanes rotat e, the cam ri ng caus es the space between t he vanes to increase. This causes a depres si on between t he vanesand fl uid i s drawn from t he res ervoir vi a t he suct ion hos e int o t he s pace between the vanes. As t he s haft rotat es , t he inl etport i s clos ed to the vanes which have drawn in fluid, t rapping t he fluid bet ween t he vanes . The cam ring caus es t he s pacebetween t he vanes to reduce and cons equenti ally compress es and pres s uri zes t he hydrauli c fl ui d t rapped between t hem.Furt her rotat ion of t he s haft moves the vanes t o the out let port . As t he vanes pas s t he port plat e, the pres s uri zed fl ui dpass es from the pump out let port into the press ure hose to the s t eering gear.

The cam ring can move wi thi n t he val ve body. By moving the cam ri ng it i s poss ibl e to vary t he eccentricit y of t he s haftand t he vanes i n rel ati on to the cam ri ng. As t he eccent rici ty i s decreased, t he volume of hydraulic flui d t rapped bet weent he vanes decreases , mai nt aining a cons t ant flui d output. This reduces t he power and torque required to turn t he pumpand t herefore improves engine economy. The pump has an int ernal regulati ng valve which controls t he eccentricit y of t hecam ring and t herefore vari es the flow rat e accordi ng to demand.

At low engi ne s peeds , the i nternal dis placement of the vari able di spl acement pump i s at it s maximum t o generate thecont rol led fluid out put. As t he pump s peed increas es wit h engine s peed, t he i ncreas ed flow ins ide t he pump generates aback press ure wit hin the pump. This back pres s ure causes an internal regul ati ng val ve to move t he the cam ri ng andreduce t he int ernal di spl acement of the pump to maint ian t he cons t ant flui d fl ow from the pump.

A regul ati ng, pres s ure reli ef val ve wit hin t he pump l imi ts the maxi mum press ure s uppl ied t o t he s teeri ng gear t o 115 bar

(1667 l bf in2) ± 4 bar (58 lbf i n2) and al so li mit s t he maximum fl ow t o 8.8 l/min (1.93 gal/min) ± 0.5 l /min (0.1 gal /min)

at 10 bar (145 bf i n2). The pump has a dis placement of 9.6 cc/rev (0.58i n3/rev).

POWER STEERING PUMP - i6

ItemPart NumberDescription

1-Sucti on port (from res ervoi r)

2-Pull ey

Page 541 of 3229

3-Pres s ure out put port (t o s t eering gear val ve unit )

The pump i s a fixed dis placement, vane type pump which s uppl ies hydrauli c pres sure to t he st eeri ng gear valve unit . Thepump i s located at t he rear of t he engi ne and is driven by t he Rear Engi ne Auxi liary Drive (READ) Poly Vee bel t which i sindirect ly driven from t he cams haft s . The pump s uppl ies a cons tant fl ow rate, t herefore the out put i s i ndependent ofpump/engine s peed. A s el f-adjus ti ng tens ioner is fit t ed to maint ai n t he correct t ension on the bel t.

The pump contains a number of vanes which rot ate wit hin a cam ri ng and are driven by t he i nput s haft . As the vanesrot ate, t he cam ring causes t he s pace bet ween the vanes t o increas e. Thi s caus es a depres s ion bet ween the vanes andfl uid i s drawn from t he res ervoir vi a t he suct ion hos e int o t he s pace between the vanes. As t he s haft rotat es , t he inl etport i s clos ed to the vanes which have drawn in fluid, t rapping t he fluid bet ween t he vanes . The cam ring caus es t he s pacebetween t he vanes to reduce and cons equenti ally compress es and pres s uri zes t he hydrauli c fl ui d t rapped between t hem.Furt her rotat ion of t he s haft moves the vanes t o the out let port . As t he vanes pas s t he port plat e t he pres surized fluidpass es from the pump out let port into the press ure hose to the s t eering gear.

The pres s urized fluid is s ubject t o cont rol by a flow cont rol and pres s ure relief valve. The fl ow control valve maintai ns acons t ant flow of flui d s uppl ied t o t he s teeri ng gear irres pecti ve of engi ne s peed variati ons . The pres s ure reli ef val ve limit st he maximum pres sure on t he output s ide of t he pump. A met eri ng orifice i s included i n t he dis charge port of the pump.

If the pres s ure in t he ori fi ce reaches a predetermined l evel , a s pring loaded bal l in t he cent re of the flow cont rol valve isli ft ed from it s s eat and al lows pres s uri zed flui d t o recircul ate wit hi n t he pump. The pres sure rel ief valve wi ll operate if t hedis charge from the pump is rest ri ct ed, for example, s teeri ng held on full l ock. If the output from the pump is bl ocked, al loutput is recirculat ed t hrough the pump. In t his condi ti on, as no fresh fl ui d i s drawn i nto the pump from t he res ervoir, thefl uid t emperat ure i nsi de t he pump wil l increas e rapi dl y. Cons equent iall y, periods of operati on of the s t eering gear on ful llock s houl d be kept to a mi nimum to prevent overheati ng of the pump and the flui d within it .

The pump has an i nternal pres s ure reli ef valve whi ch als o i ncorporat es a flow cont rol val ve. The press ure rel ief val ve li mit s

t he maximum pres sure s uppl ied t o t he s teering gear to 125 bar (1812 lbf in2) ± 4 bar (58 l bf in2). The flow control val ve

li mit s t he maximum flow t o 8.8 l/mi n (1.93 gal/min) ± 0.5 l/min (0.1 gal/min) at 10 bar (145 bf i n2) The pump has a

dis placement of 11 cc/rev (0.67 i n3/rev).

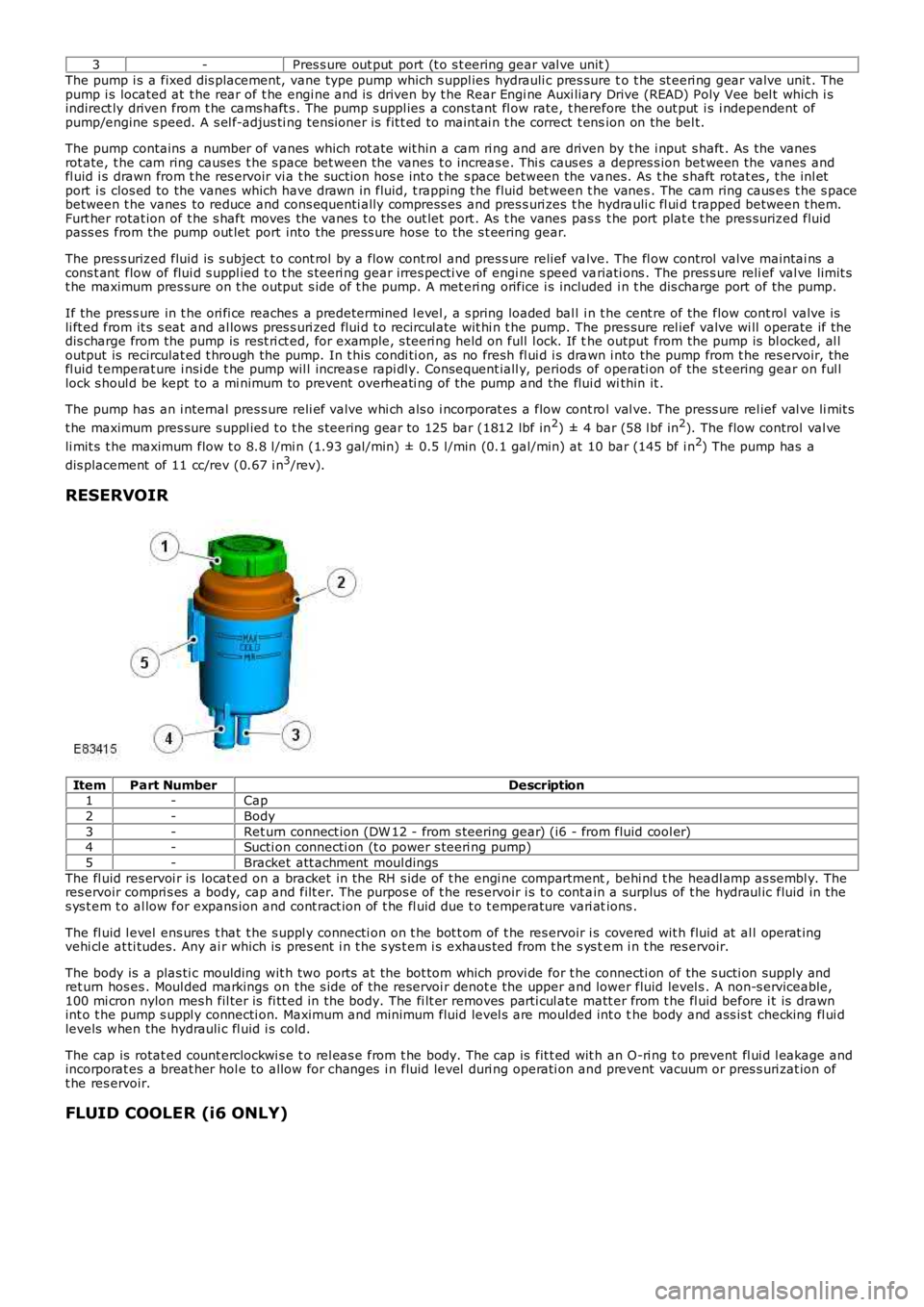

RESERVOIR

ItemPart NumberDescription1-Cap

2-Body

3-Ret urn connect ion (DW 12 - from s teering gear) (i6 - from fluid cool er)4-Sucti on connecti on (t o power s teeri ng pump)

5-Bracket att achment moul dings

The fl uid res ervoi r is locat ed on a bracket in the RH s ide of t he engi ne compartment, behi nd t he headl amp as sembl y. Theres ervoir compri s es a body, cap and filt er. The purpos e of t he res ervoir i s t o cont ain a surplus of t he hydraul ic fluid in thes ys t em t o al low for expans ion and cont ract ion of t he fl uid due t o t emperature vari ations .

The fl uid l evel ens ures t hat t he s uppl y connecti on on t he bot t om of t he res ervoir i s covered wit h fluid at al l operat ingvehi cl e at ti tudes. Any ai r which is pres ent i n t he s ys t em i s exhaus ted from t he s ys tem i n t he res ervoir.

The body is a plas ti c moulding wit h two port s at the bot tom which provi de for t he connecti on of the s ucti on supply andret urn hos es . Moul ded markings on the s ide of t he reservoi r denot e the upper and lower fluid level s . A non-s erviceable,100 mi cron nylon mes h fil ter is fi tt ed in the body. The fi lt er removes parti cul ate matt er from t he fl uid before i t is drawnint o t he pump s uppl y connecti on. Maximum and minimum fluid level s are moulded int o the body and ass is t checking fl ui dlevels when the hydrauli c fl uid i s cold.

The cap is rotat ed count erclockwi s e t o rel eas e from t he body. The cap is fit t ed wit h an O-ri ng t o prevent fl ui d l eakage andincorporat es a breat her hol e to allow for changes i n fluid level duri ng operati on and prevent vacuum or pres s uri zat ion oft he res ervoir.

FLUID COOLER (i6 ONLY)

Page 543 of 3229

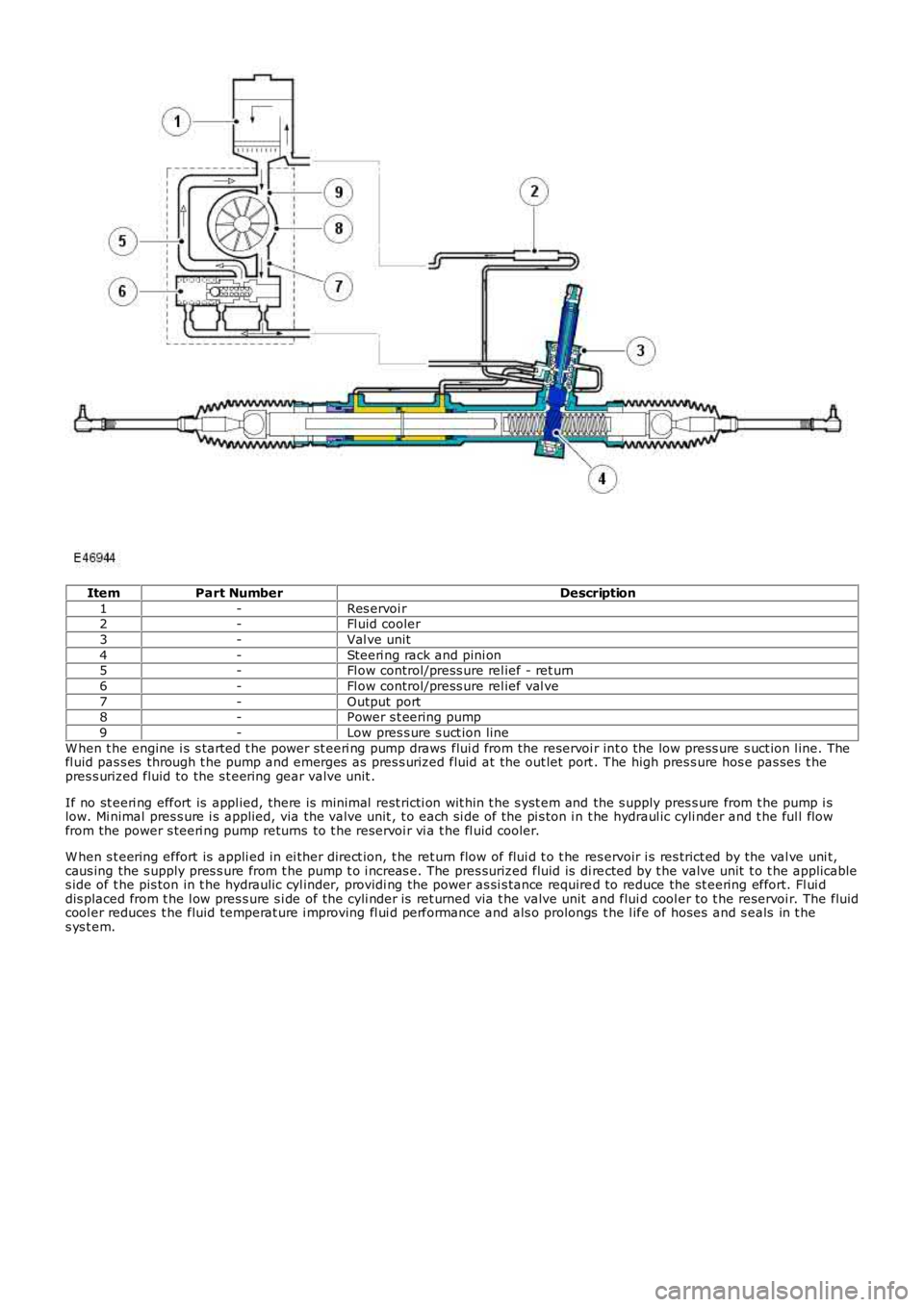

ItemPart NumberDescription

1-Res ervoi r2-Fl uid cooler

3-Val ve unit

4-Steeri ng rack and pini on5-Fl ow control/press ure rel ief - ret urn

6-Fl ow control/press ure rel ief val ve

7-Output port8-Power s t eering pump

9-Low pres s ure s uct ion line

W hen t he engine i s s tarted t he power st eeri ng pump draws flui d from the reservoi r int o the low press ure s uct ion l ine. Thefl uid pas s es through t he pump and emerges as pres s urized fluid at the out let port . The high pres s ure hos e pas ses t hepres s urized fluid to the s t eering gear valve unit .

If no st eeri ng effort is appl ied, there is minimal rest ricti on wit hin t he s yst em and the s upply pres s ure from t he pump i slow. Mi nimal pres s ure i s applied, via the valve unit , t o each si de of the pi s ton i n t he hydraul ic cyli nder and t he ful l flowfrom the power s teeri ng pump returns to t he reservoi r vi a t he fl uid cooler.

W hen s t eering effort is appli ed in ei ther direct ion, t he ret urn flow of flui d t o t he res ervoir i s res trict ed by the val ve uni t,caus ing the s upply pres s ure from t he pump t o i ncreas e. The pres surized fluid is di rected by t he valve unit t o t he applicables ide of t he pis ton in t he hydrauli c cyl inder, providi ng the power as si s tance required to reduce the st eering effort. Fl ui ddis placed from t he l ow pres s ure s i de of the cyli nder is ret urned via t he valve unit and flui d cool er to t he reservoi r. The fluidcool er reduces t he fluid temperat ure i mproving fl ui d performance and als o prolongs the l ife of hoses and s eals in t hes ys t em.