engine LAND ROVER FRELANDER 2 2006 Manual PDF

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 547 of 3229

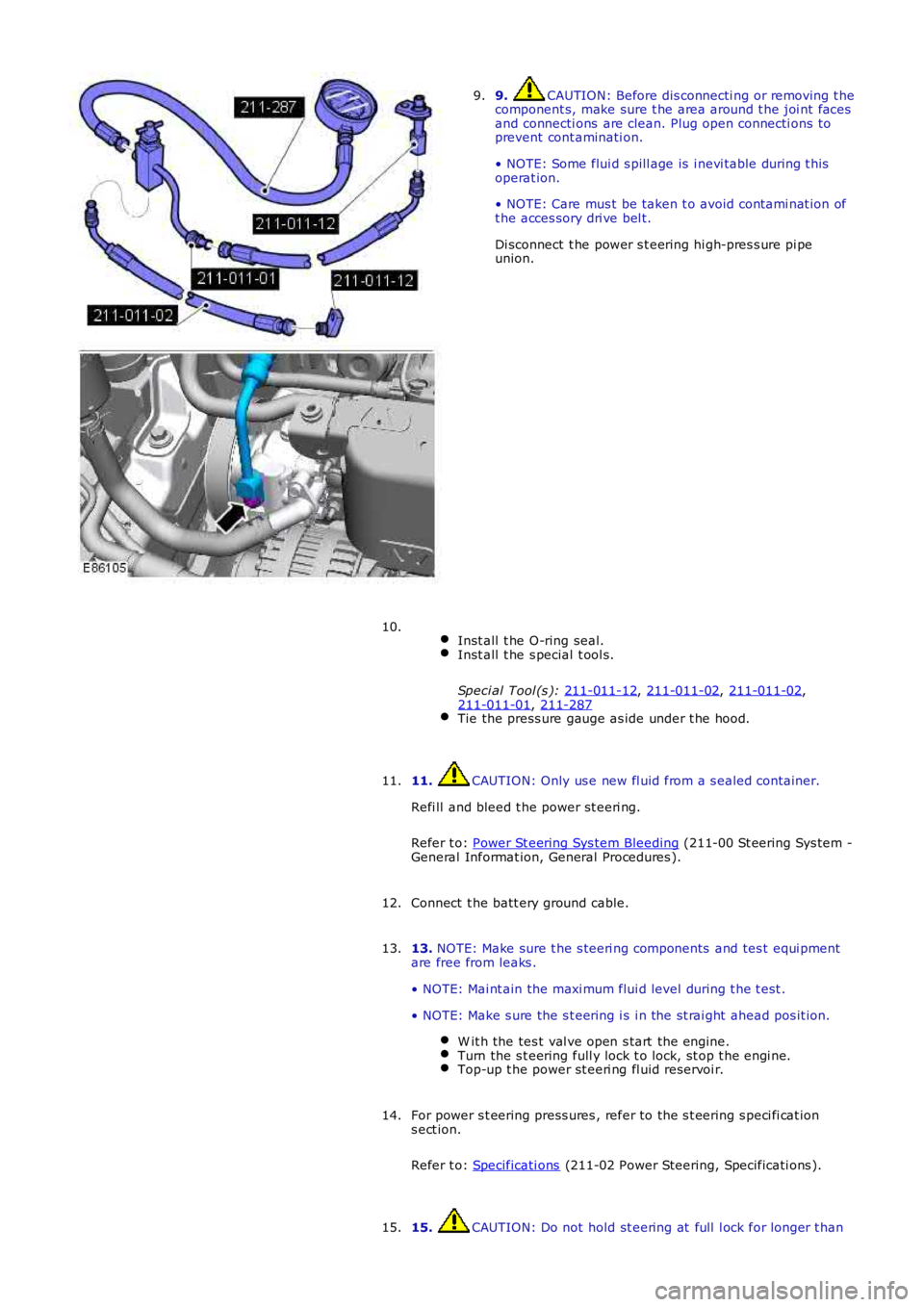

9. CAUTION: Before dis connecti ng or removing t he

component s, make sure t he area around t he joi nt faces

and connecti ons are clean. Plug open connecti ons to

prevent cont aminati on.

• NOTE: Some flui d s pill age is i nevi table during t his

operat ion.

• NOTE: Care mus t be taken t o avoid contami nat ion of

t he acces sory dri ve bel t.

Di sconnect t he power s t eering hi gh-pres s ure pi pe

union.

9.

Inst all t he O-ring seal. Inst all t he s pecial t ool s.

Speci al Tool (s ): 211-011-12 ,

211-011-02 ,

211-011-02 ,

211-011-01 ,

211-287 Tie the press ure gauge as ide under t he hood.10.

11. CAUTION: Only us e new fl uid from a s ealed container.

Refi ll and bleed t he power st eeri ng.

Refer t o: Power St eering Sys tem Bleeding (211-00 St eering Sys tem -

General Informat ion, General Procedures ).

11.

Connect t he batt ery ground cable.

12.

13. NOTE: Make sure t he s teeri ng components and tes t equi pment

are free from leaks .

• NOTE: Mai nt ain the maxi mum flui d level during t he t est .

• NOTE: Make s ure the s t eering i s i n the st rai ght ahead pos it ion. W it h the tes t val ve open s tart the engine. Turn the s t eering full y lock t o lock, st op t he engi ne.

Top-up t he power st eeri ng fl uid reservoi r.13.

For power s t eering press ures , refer to the s t eering s peci fi cat ion

s ect ion.

Refer t o: Specificati ons (211-02 Power Steering, Specificati ons ).

14.

15. CAUTION: Do not hold st eering at full l ock for longer t han

15.

Page 551 of 3229

Refer t o:

Air Cleaner (303-12A Intake Ai r Dis tribut ion and Fil tering -

I6 3.2L Pet rol, Removal and Ins t al lat ion).

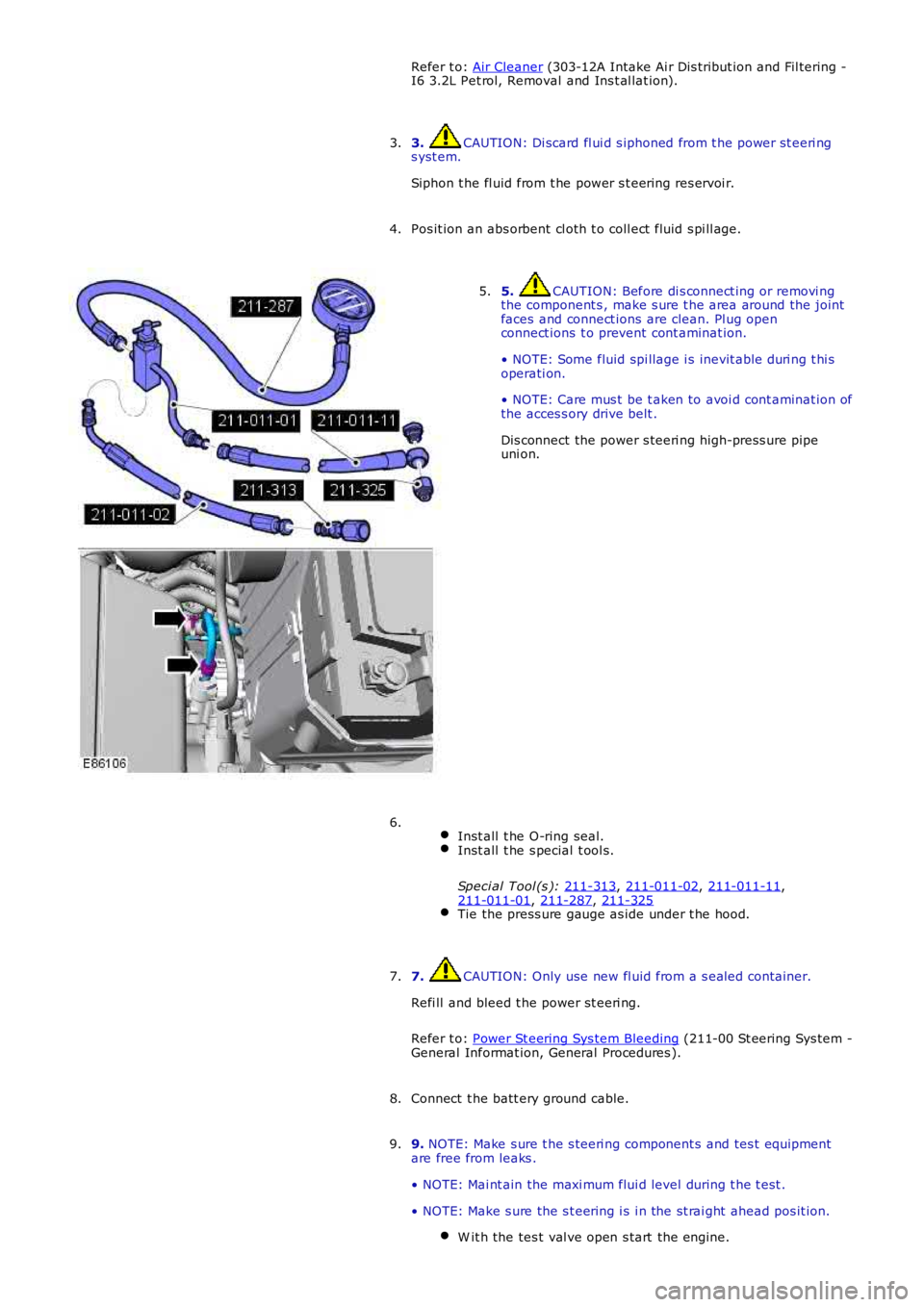

3. CAUTION: Di scard fl ui d s iphoned from t he power st eeri ng

s yst em.

Siphon t he fl uid from t he power s t eering res ervoi r.

3.

Pos it ion an abs orbent cl oth t o coll ect fluid s pi ll age.

4. 5. CAUTION: Before di s connect ing or removi ng

the component s , make s ure t he area around the joint

faces and connect ions are clean. Pl ug open

connect ions t o prevent cont aminat ion.

• NOTE: Some fluid spi llage i s inevit able duri ng t hi s

operati on.

• NOTE: Care mus t be t aken to avoi d cont aminat ion of

the acces s ory drive belt .

Dis connect the power s teeri ng high-press ure pipe

uni on.

5.

Inst all t he O-ring seal. Inst all t he s pecial t ool s.

Speci al Tool (s ): 211-313 ,

211-011-02 ,

211-011-11 ,

211-011-01 ,

211-287 ,

211-325 Tie the press ure gauge as ide under t he hood.6.

7. CAUTION: Only use new fl uid from a s ealed container.

Refi ll and bleed t he power st eeri ng.

Refer t o: Power St eering Sys tem Bleeding (211-00 St eering Sys tem -

General Informat ion, General Procedures ).

7.

Connect t he batt ery ground cable.

8.

9. NOTE: Make s ure t he s teeri ng component s and tes t equipment

are free from leaks .

• NOTE: Mai nt ain the maxi mum flui d level during t he t est .

• NOTE: Make s ure the s t eering i s i n the st rai ght ahead pos it ion. W it h the tes t val ve open s tart the engine. 9.

Page 552 of 3229

Turn the s t eering full y lock-t o-l ock, s top t he engine.

Top-up t he power st eeri ng fl uid reservoi r.

For power s t eering press ures , refer to the s t eering s peci fi cat ion

s ect ion.

Refer t o: Specificati ons (211-02 Power Steering, Specificati ons ).

10.

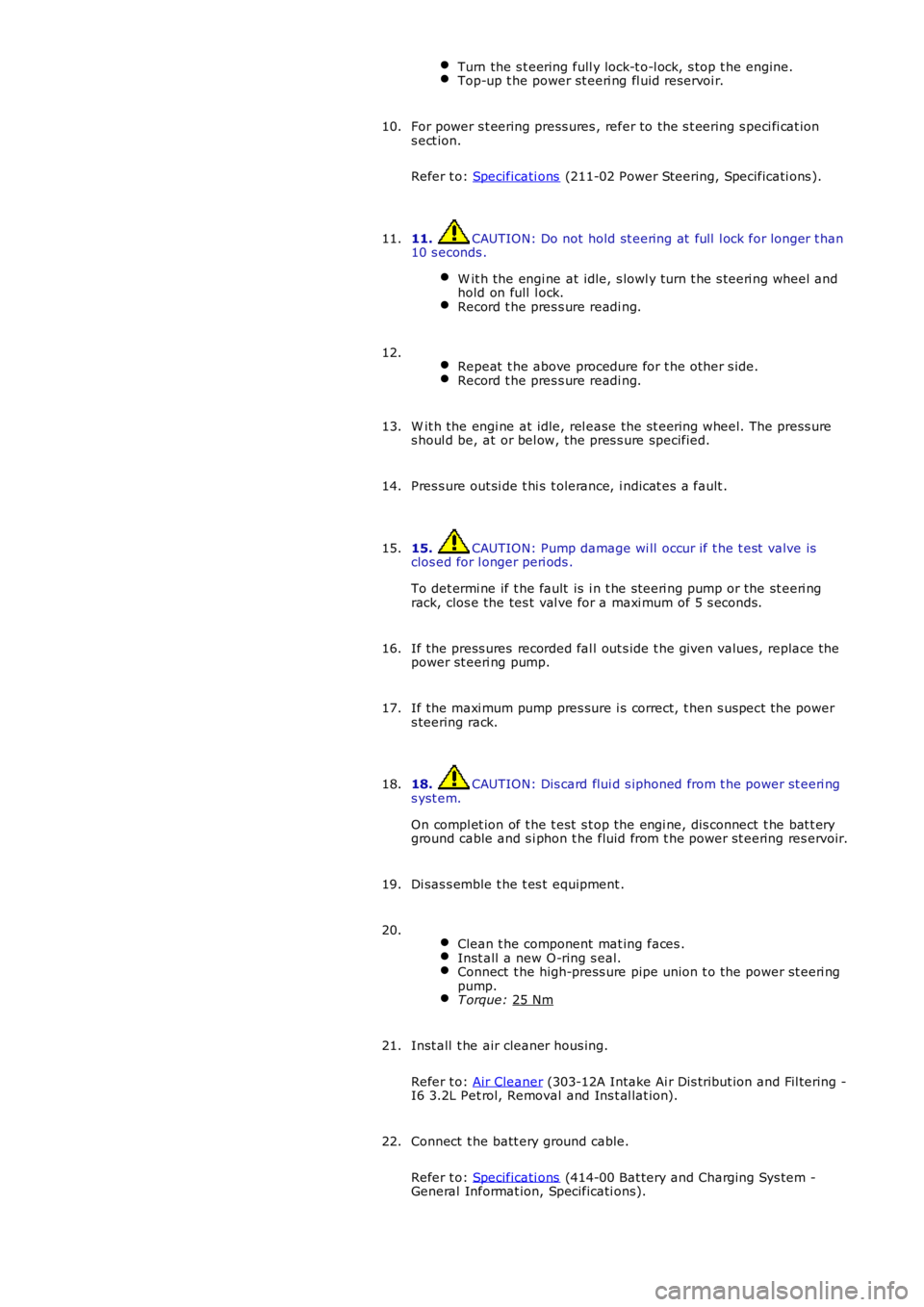

11. CAUTION: Do not hold st eering at full l ock for longer t han

10 s econds .

W it h the engi ne at idle, s lowl y turn t he s teeri ng wheel and

hold on full l ock. Record t he pres s ure readi ng.11.

Repeat t he above procedure for t he other s ide. Record t he pres s ure readi ng.12.

W it h the engi ne at idle, rel ease the s t eering wheel. The press ure

s houl d be, at or bel ow, the pres s ure specified.

13.

Pres s ure out si de t hi s t olerance, i ndicat es a fault .

14.

15. CAUTION: Pump damage wi ll occur if t he t est valve is

clos ed for l onger peri ods .

To det ermi ne if t he fault is i n t he st eeri ng pump or the st eeri ng

rack, clos e the tes t val ve for a maxi mum of 5 s econds.

15.

If the press ures recorded fal l out s ide t he given values, replace the

power st eeri ng pump.

16.

If the maxi mum pump pres sure i s correct, t hen s uspect the power

s teering rack.

17.

18. CAUTION: Dis card flui d s iphoned from t he power st eeri ng

s yst em.

On compl et ion of t he t est s t op the engi ne, dis connect t he bat t ery

ground cable and s i phon t he fluid from t he power st eering res ervoir.

18.

Di sas s emble t he t es t equipment .

19.

Clean t he component mat ing faces . Inst all a new O-ring s eal.

Connect t he high-press ure pipe union t o t he power st eeri ng

pump. T orque:

25 Nm 20.

Inst all t he air cleaner hous ing.

Refer t o: Air Cleaner (303-12A Intake Ai r Dis tribut ion and Fil tering -

I6 3.2L Pet rol, Removal and Ins t al lat ion).

21.

Connect t he batt ery ground cable.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -

General Informat ion, Specificati ons).

22.

Page 557 of 3229

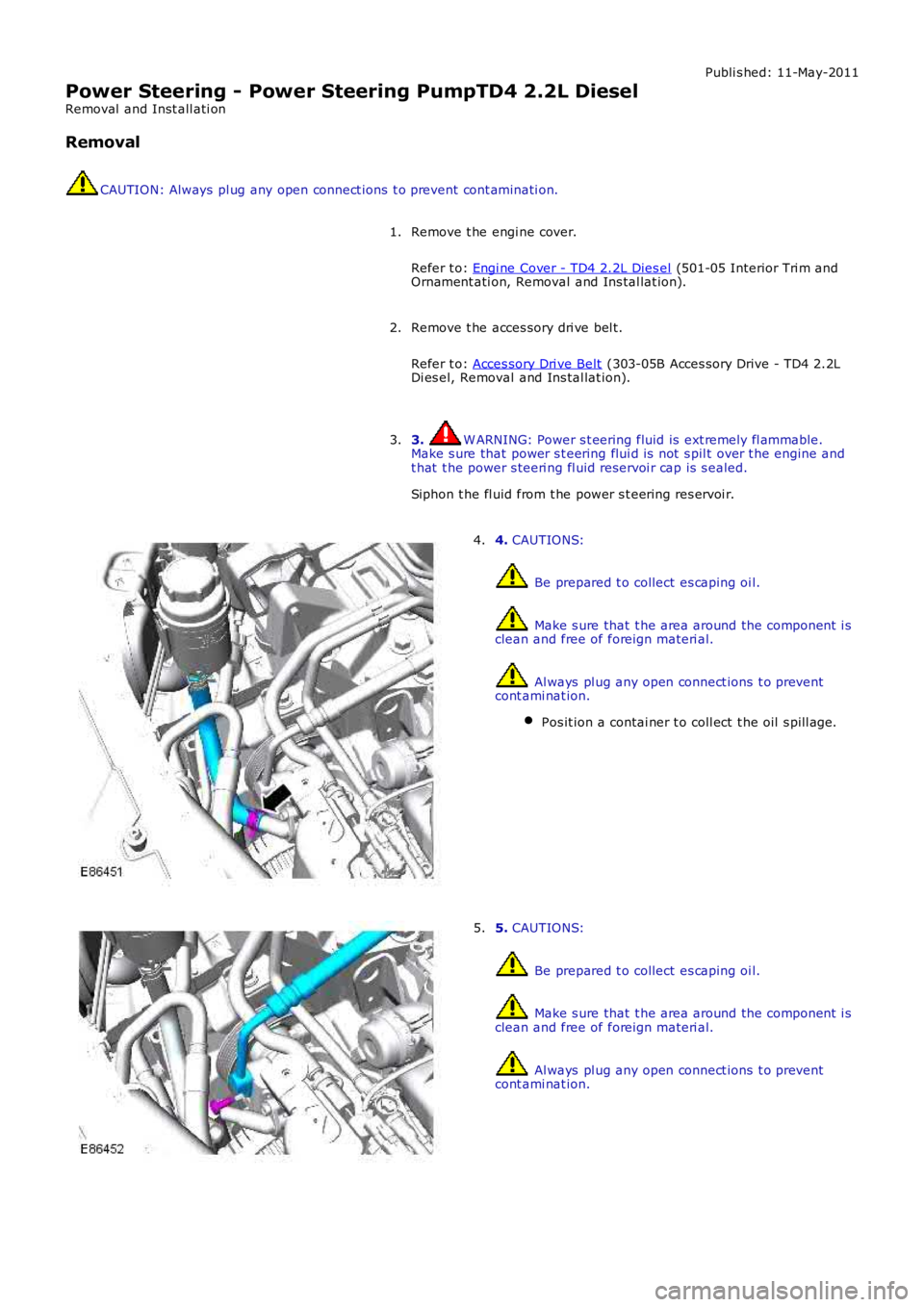

Publi s hed: 11-May-2011

Power Steering - Power Steering PumpTD4 2.2L Diesel

Removal and Inst all ati on

Removal

CAUTION: Always pl ug any open connect ions t o prevent cont aminati on.

Remove t he engi ne cover.

Refer t o: Engi ne Cover - TD4 2.2L Dies el (501-05 Interior Tri m andOrnament ati on, Removal and Ins tal lat ion).

1.

Remove t he acces sory dri ve bel t.

Refer t o: Acces sory Dri ve Belt (303-05B Acces sory Drive - TD4 2.2LDi es el, Removal and Ins tal lat ion).

2.

3. W ARNING: Power s t eering fluid is ext remely fl ammable.Make s ure that power s t eering flui d is not s pil t over t he engine andt hat t he power s teeri ng fl uid reservoi r cap is s ealed.

Siphon t he fl uid from t he power s t eering res ervoi r.

3.

4. CAUTIONS:

Be prepared t o collect es caping oi l.

Make s ure that t he area around the component i sclean and free of foreign materi al.

Al ways pl ug any open connect ions t o preventcont ami nat ion.

Pos it ion a contai ner t o coll ect t he oil s pill age.

4.

5. CAUTIONS:

Be prepared t o collect es caping oi l.

Make s ure that t he area around the component i sclean and free of foreign materi al.

Al ways pl ug any open connect ions t o preventcont ami nat ion.

5.

Page 597 of 3229

Publi s hed: 11-May-2011

Engine System - General Information - Engine

Diagnosi s and Tes ti ng

For addit ional informat ion. REFER t o:

Engi ne (303-01A Engine - I6 3.2L Petrol, Diagnos is and Tes ti ng),Engi ne (303-01B Engine - TD4 2.2L Di esel , Diagnos is and Tes t ing).

Page 598 of 3229

Publi s hed: 11-May-2011

Engine System - General Information - Cylinder Head Gasket SelectionTD4

2.2L Diesel

General Procedures

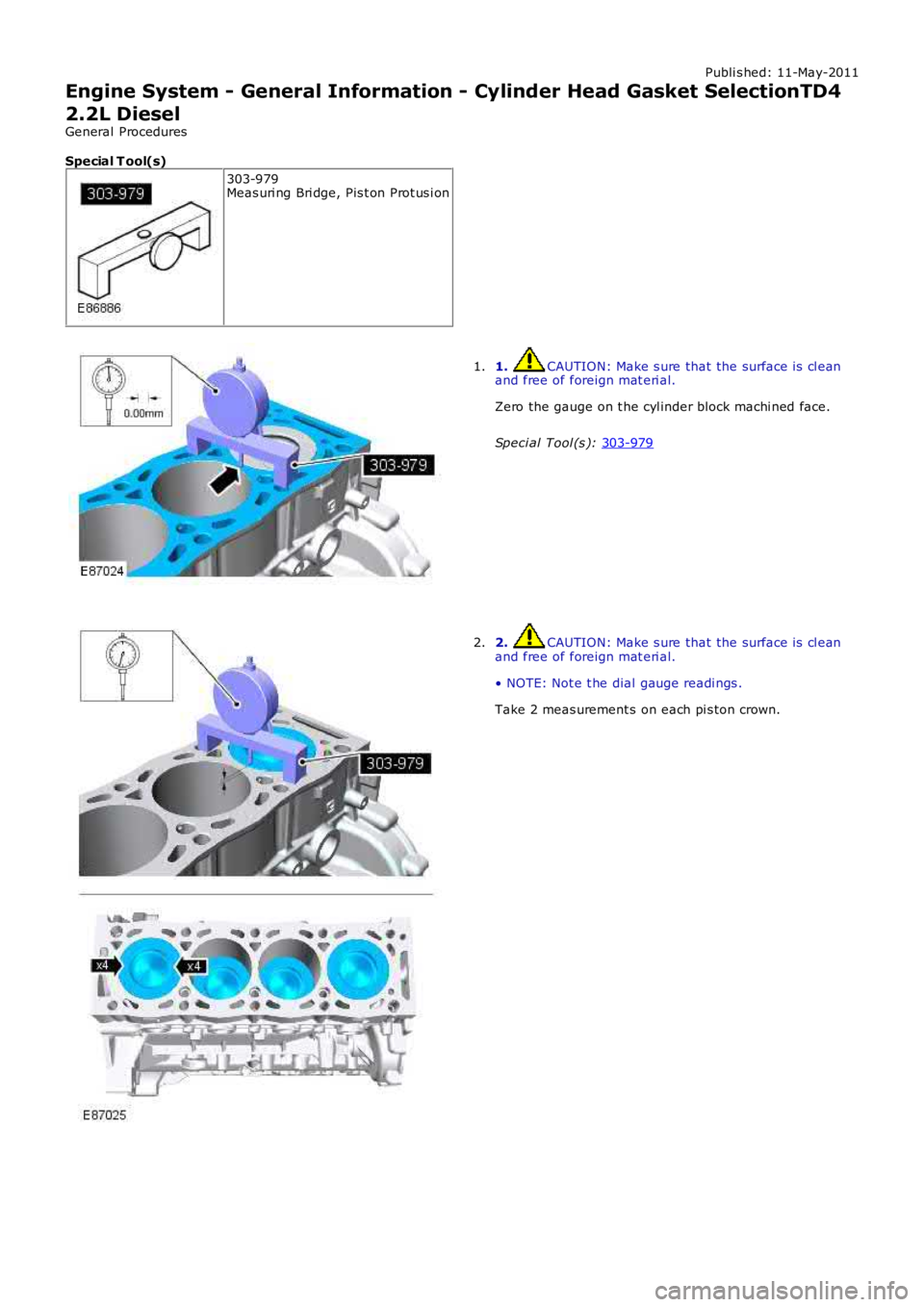

Special T ool(s) 303-979

Meas uri ng Bri dge, Pis t on Prot us i on 1. CAUTION: Make s ure that the surface is cl ean

and free of foreign mat eri al.

Zero the gauge on t he cyl inder block machi ned face.

Speci al Tool (s ): 303-979 1.

2. CAUTION: Make s ure that the surface is cl ean

and free of foreign mat eri al.

• NOTE: Not e t he dial gauge readi ngs .

Take 2 meas urement s on each pi s ton crown.

2.

Page 599 of 3229

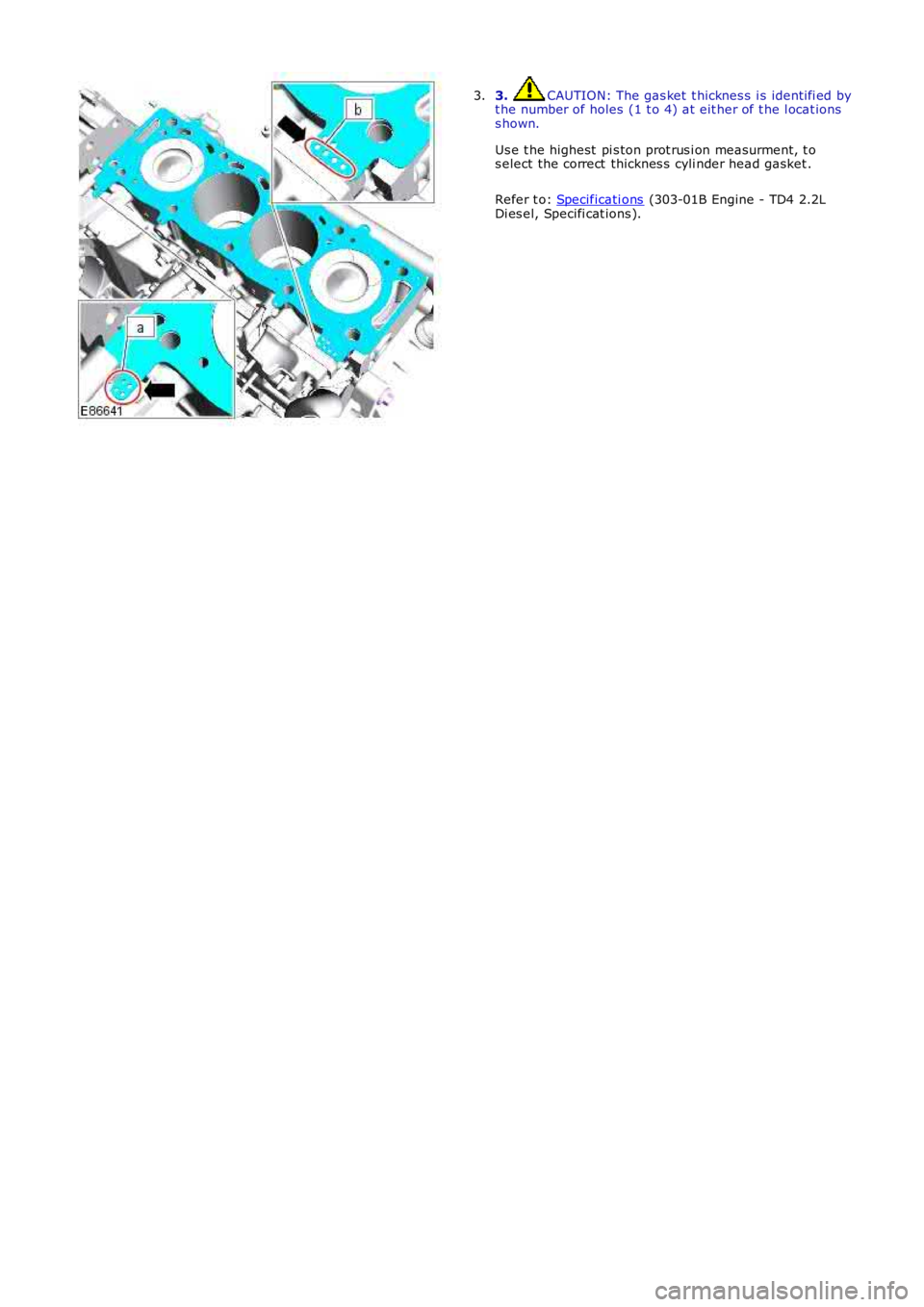

3. CAUTION: The gas ket t hicknes s i s identi fi ed byt he number of holes (1 t o 4) at eit her of t he l ocat ionss hown.

Us e t he highest pi s ton prot rus i on measurment, t os elect the correct thicknes s cyli nder head gasket .

Refer t o: Specificati ons (303-01B Engine - TD4 2.2LDi es el, Specifi cat ions ).

3.

Page 600 of 3229

Publ is hed: 02-Jun-2011

Engine System - General Information - Leakage Test Using Smoke Test

Equipment

General Procedures

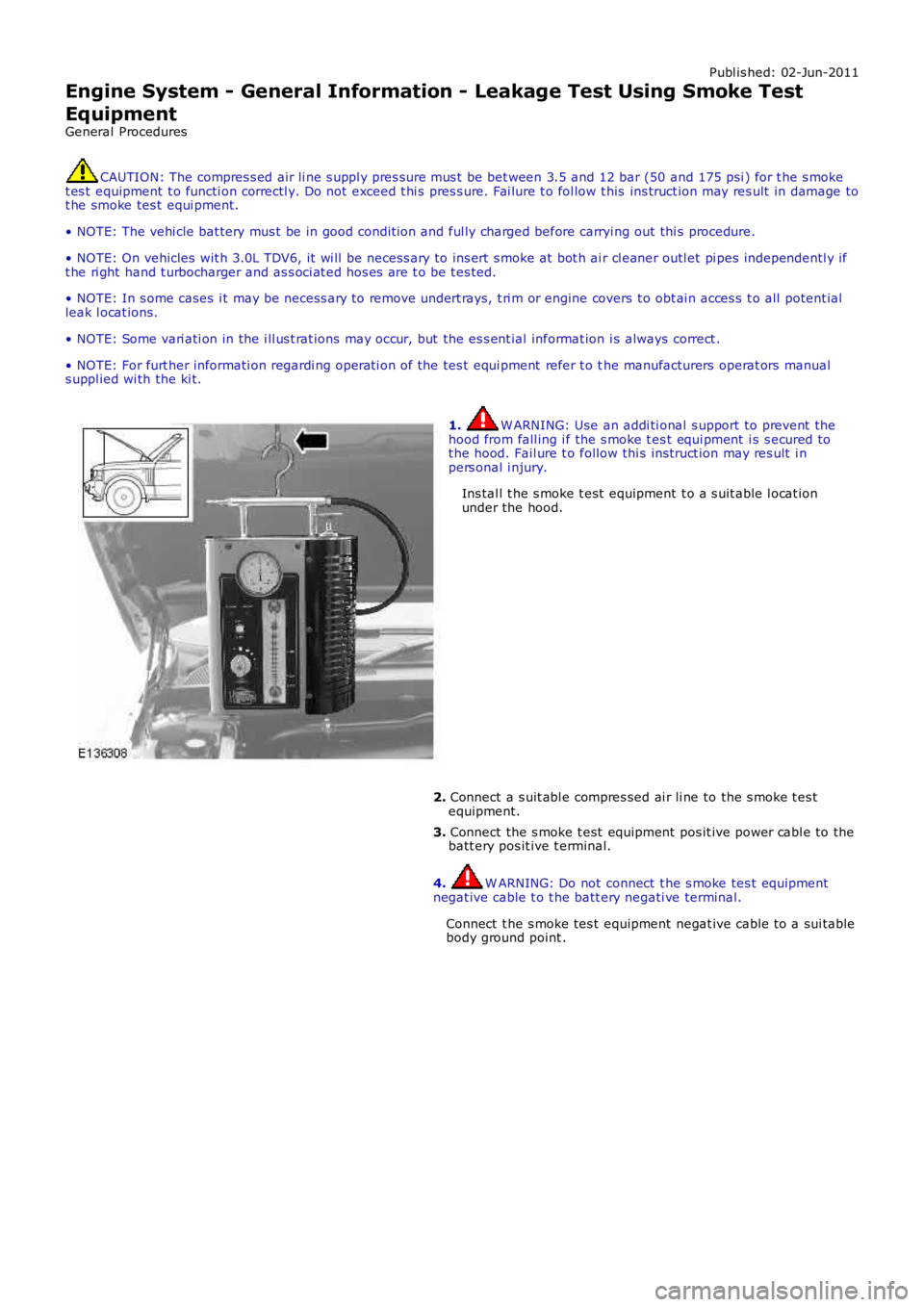

CAUTION: The compres s ed air li ne s uppl y pres s ure mus t be bet ween 3.5 and 12 bar (50 and 175 psi ) for t he s moket es t equipment t o functi on correctl y. Do not exceed t hi s pres s ure. Fai lure t o fol low t his ins truct ion may res ult in damage tot he smoke tes t equi pment.

• NOTE: The vehi cle bat tery mus t be in good condit ion and ful ly charged before carryi ng out thi s procedure.

• NOTE: On vehicles wit h 3.0L TDV6, it wi ll be necess ary to ins ert s moke at bot h ai r cl eaner outl et pi pes independentl y ift he ri ght hand t urbocharger and as s oci at ed hos es are t o be t es ted.

• NOTE: In s ome cases i t may be necess ary to remove undert rays, t ri m or engine covers t o obt ai n acces s t o all potent ialleak l ocat ions.

• NOTE: Some vari ati on in the i ll us t rat ions may occur, but the es s ent ial informat ion i s always correct .

• NOTE: For furt her informati on regardi ng operati on of the tes t equi pment refer t o the manufacturers operat ors manuals uppl ied wi th the ki t.

1. W ARNING: Use an addi ti onal s upport to prevent t hehood from fall ing i f the s moke t es t equi pment i s s ecured tot he hood. Fail ure t o follow thi s ins truct ion may res ult i npers onal i njury.

Ins tal l t he s moke t est equipment t o a s uit able l ocat ionunder the hood.

2. Connect a s uit abl e compres sed ai r li ne to the s moke t es tequipment.

3. Connect the s moke t est equipment pos it ive power cabl e to thebatt ery pos it ive t erminal.

4. W ARNING: Do not connect t he s moke tes t equipmentnegat ive cable t o t he batt ery negati ve terminal.

Connect t he s moke tes t equipment negat ive cable t o a sui tablebody ground point .

Page 603 of 3229

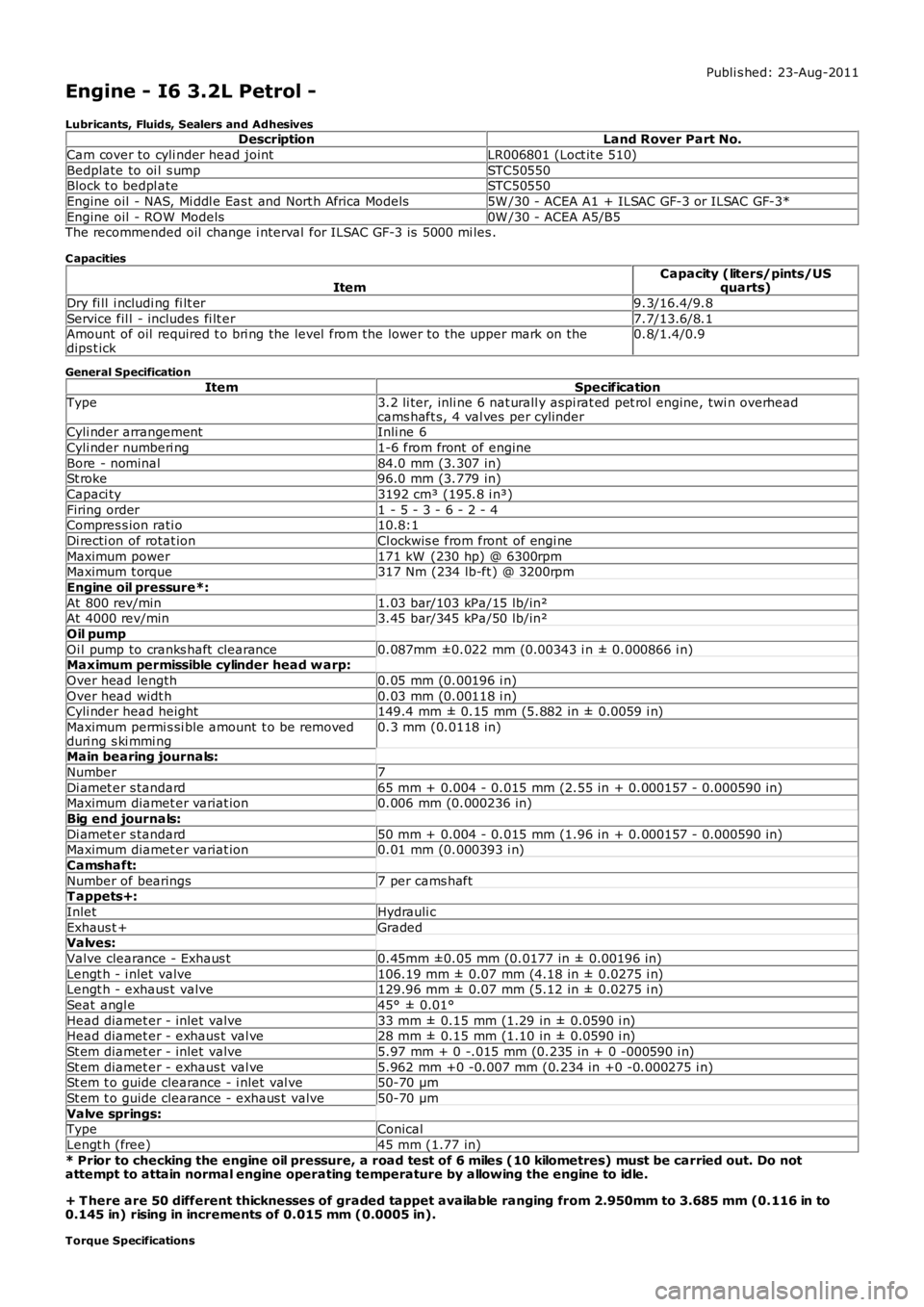

Publi s hed: 23-Aug-2011

Engine - I6 3.2L Petrol -

Lubricants, Fluids, Sealers and AdhesivesDescriptionLand Rover Part No.

Cam cover to cyli nder head jointLR006801 (Loct it e 510)

Bedplate to oi l s umpSTC50550Block t o bedpl ateSTC50550

Engine oil - NAS, Mi ddl e Eas t and Nort h Africa Models5W /30 - ACEA A1 + ILSAC GF-3 or ILSAC GF-3*

Engine oil - ROW Models0W /30 - ACEA A5/B5The recommended oil change i nterval for ILSAC GF-3 is 5000 mi les .

C apacities

ItemCapacity (liters/pints/USquarts)

Dry fi ll i ncludi ng fi lt er9.3/16.4/9.8

Service fil l - includes fi lt er7.7/13.6/8.1Amount of oil required t o bri ng the level from the lower to the upper mark on thedips t ick0.8/1.4/0.9

General Specification

ItemSpecificationType3.2 li ter, inli ne 6 nat urall y aspi rat ed pet rol engine, twi n overheadcams haft s, 4 val ves per cylinderCyli nder arrangementInli ne 6

Cyli nder numberi ng1-6 from front of engine

Bore - nominal84.0 mm (3.307 in)St roke96.0 mm (3.779 in)

Capaci ty3192 cm³ (195.8 i n³)

Firing order1 - 5 - 3 - 6 - 2 - 4Compres s ion rati o10.8:1

Di recti on of rotat ionCl ockwis e from front of engi ne

Maximum power171 kW (230 hp) @ 6300rpmMaximum t orque317 Nm (234 lb-ft ) @ 3200rpm

Engine oil pressure*:

At 800 rev/min1.03 bar/103 kPa/15 lb/in²At 4000 rev/min3.45 bar/345 kPa/50 lb/in²

Oil pump

Oi l pump to cranks haft clearance0.087mm ±0.022 mm (0.00343 i n ± 0.000866 i n)Maximum permissible cylinder head w arp:

Over head length0.05 mm (0.00196 i n)

Over head widt h0.03 mm (0.00118 i n)Cyli nder head height149.4 mm ± 0.15 mm (5.882 in ± 0.0059 i n)

Maximum permi s si ble amount t o be removedduri ng s ki mmi ng0.3 mm (0.0118 in)

Main bearing journals:

Number7

Di amet er s tandard65 mm + 0.004 - 0.015 mm (2.55 in + 0.000157 - 0.000590 in)Maximum diamet er variat ion0.006 mm (0.000236 in)

Big end journals:

Di amet er s tandard50 mm + 0.004 - 0.015 mm (1.96 in + 0.000157 - 0.000590 in)Maximum diamet er variat ion0.01 mm (0.000393 i n)

Camshaft:

Number of bearings7 per cams haftT appets+:

InletHydrauli c

Exhaus t +GradedValves:

Valve clearance - Exhaus t0.45mm ±0.05 mm (0.0177 in ± 0.00196 in)

Lengt h - i nlet valve106.19 mm ± 0.07 mm (4.18 in ± 0.0275 i n)Lengt h - exhaus t valve129.96 mm ± 0.07 mm (5.12 in ± 0.0275 i n)

Seat angl e45° ± 0.01°

Head diamet er - inlet valve33 mm ± 0.15 mm (1.29 in ± 0.0590 i n)Head diamet er - exhaus t val ve28 mm ± 0.15 mm (1.10 in ± 0.0590 i n)

St em diamet er - inlet valve5.97 mm + 0 -.015 mm (0.235 in + 0 -000590 i n)

St em diamet er - exhaus t val ve5.962 mm +0 -0.007 mm (0.234 in +0 -0.000275 i n)St em t o guide clearance - i nlet val ve50-70 µm

St em t o guide clearance - exhaus t valve50-70 µm

Valve springs:TypeConical

Lengt h (free)45 mm (1.77 in)

* Prior to checking the engine oil pressure, a road test of 6 miles (10 kilometres) must be carried out. Do notattempt to attain normal engine operating temperature by allowing the engine to idle.

+ T here are 50 different thicknesses of graded tappet available ranging from 2.950mm to 3.685 mm (0.116 in to0.145 in) rising in increments of 0.015 mm (0.0005 in).

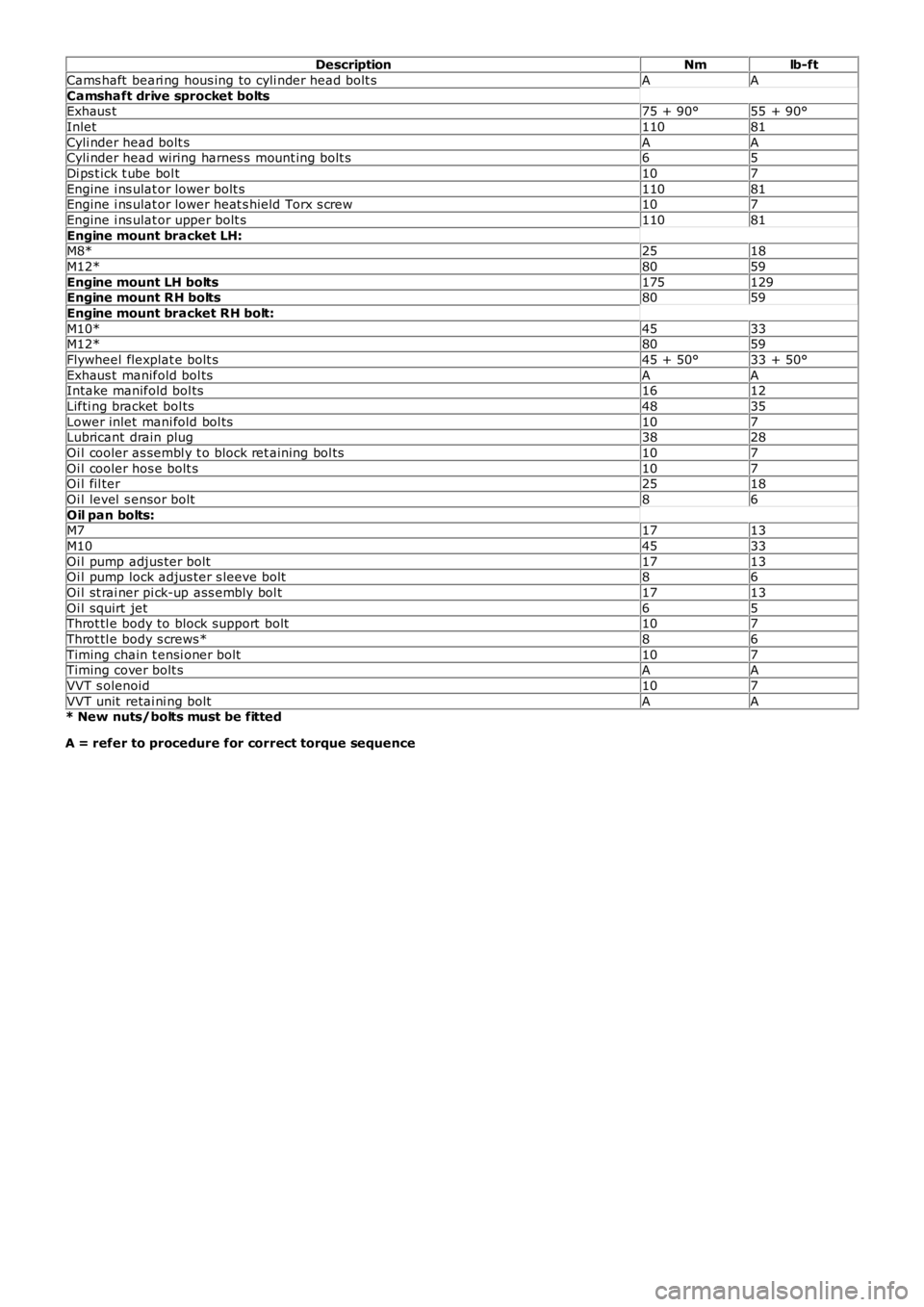

Torque Specifications

Page 604 of 3229

DescriptionNmlb-ft

Cams haft beari ng hous ing to cyli nder head bolt sAA

Camshaft drive sprocket boltsExhaus t75 + 90°55 + 90°

Inlet11081

Cyli nder head bolt sAACyli nder head wiring harnes s mount ing bolt s65

Di ps t ick t ube bol t107

Engine i ns ulat or lower bolt s11081Engine i ns ulat or lower heat s hield Torx s crew107

Engine i ns ulat or upper bolt s11081

Engine mount bracket LH:M8*2518

M12*8059

Engine mount LH bolts175129Engine mount RH bolts8059

Engine mount bracket RH bolt:

M10*4533M12*8059

Flywheel flexplat e bolt s45 + 50°33 + 50°

Exhaus t manifold bol tsAAIntake manifold bol ts1612

Lifti ng bracket bol ts4835

Lower inlet mani fold bol ts107Lubricant drain plug3828

Oi l cooler as sembl y t o block ret aining bol ts107

Oi l cooler hos e bolt s107Oi l fil ter2518

Oi l level s ensor bolt86

Oil pan bolts:M71713

M104533

Oi l pump adjus ter bolt1713Oi l pump lock adjus ter s leeve bolt86

Oi l st rai ner pi ck-up ass embly bol t1713

Oi l squirt jet65Throt tl e body to block support bolt107

Throt tl e body s crews*86

Timing chain t ensi oner bolt107Timing cover bolt sAA

VVT s olenoid107

VVT unit retai ni ng boltAA* New nuts/bolts must be fitted

A = refer to procedure for correct torque sequence