sensor LAND ROVER FRELANDER 2 2006 Owners Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1274 of 3229

Publi s hed: 11-May-2011

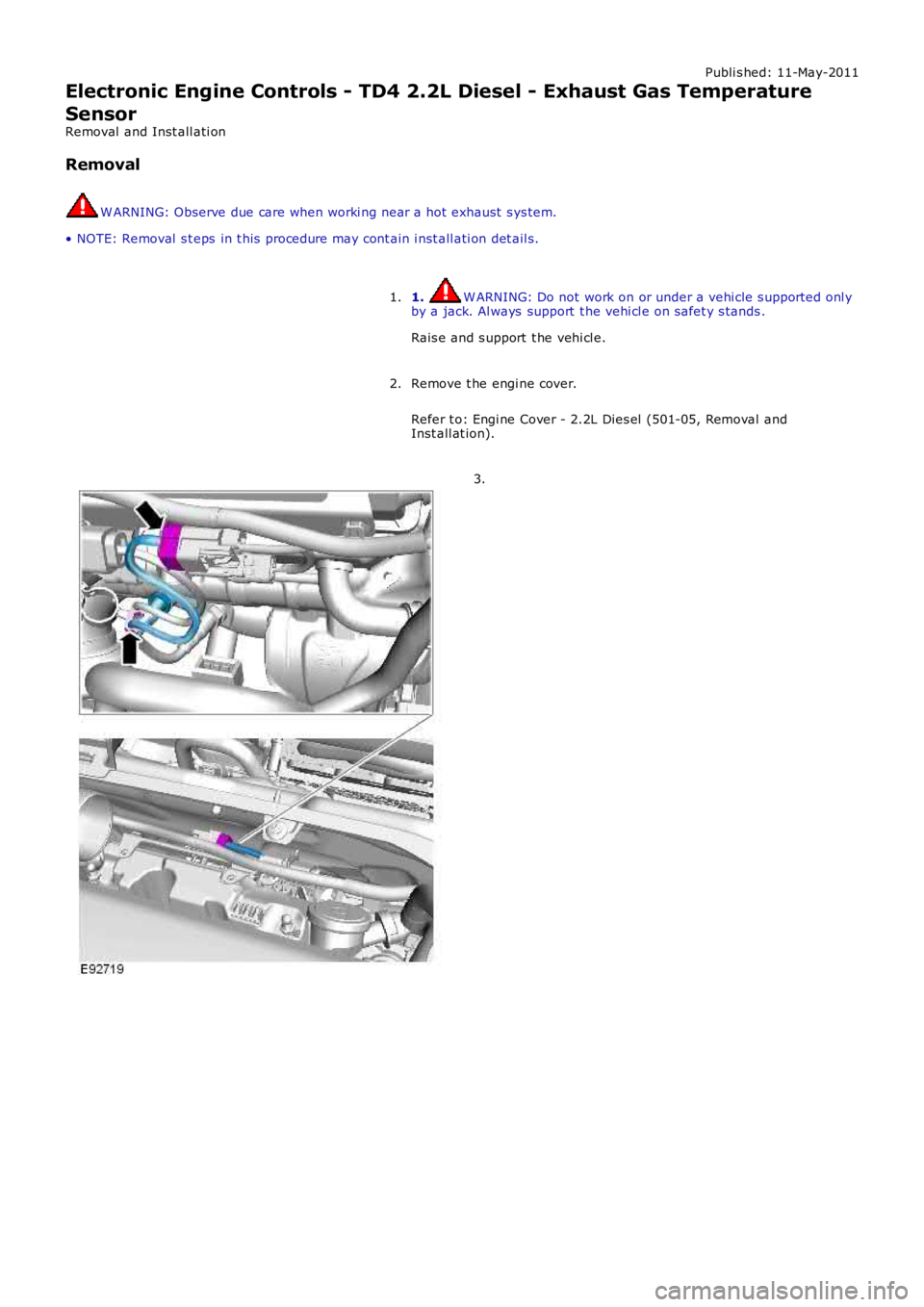

Electronic Engine Controls - TD4 2.2L Diesel - Exhaust Gas Temperature

Sensor

Removal and Inst all ati on

Removal

W ARNING: Observe due care when worki ng near a hot exhaust s ys tem.

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

1. W ARNING: Do not work on or under a vehi cle s upported onl yby a jack. Al ways support t he vehi cl e on s afet y s tands .

Rais e and s upport t he vehi cl e.

1.

Remove t he engi ne cover.

Refer t o: Engi ne Cover - 2.2L Dies el (501-05, Removal andInst all at ion).

2.

3.

Page 1276 of 3229

Publi s hed: 11-May-2011

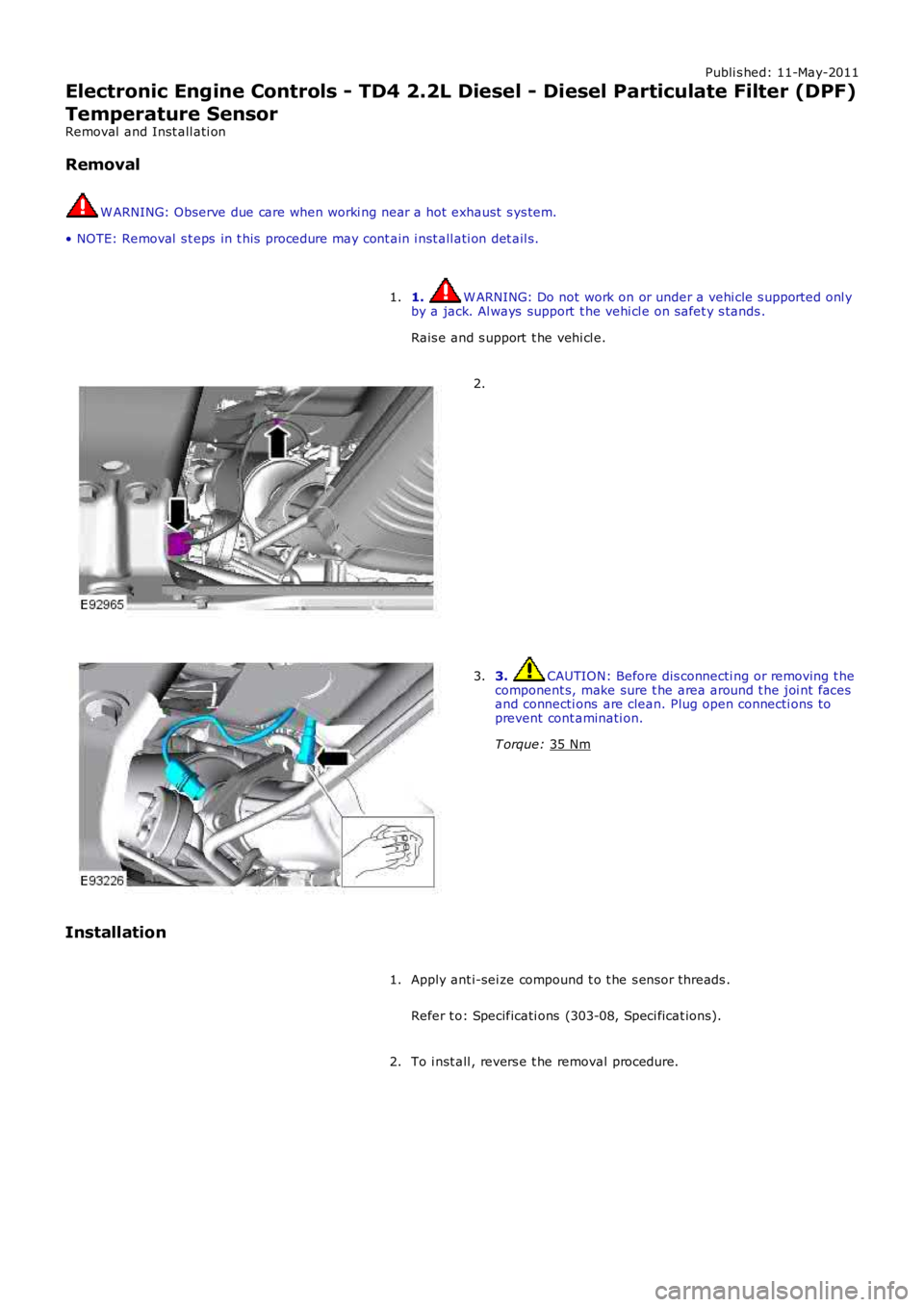

Electronic Engine Controls - TD4 2.2L Diesel - Diesel Particulate Filter (DPF)

Temperature Sensor

Removal and Inst all ati on

Removal W ARNING: Observe due care when worki ng near a hot exhaust s ys tem.

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

1. W ARNING: Do not work on or under a vehi cle s upported onl y

by a jack. Al ways support t he vehi cl e on s afet y s tands .

Rais e and s upport t he vehi cl e.

1. 2.

3. CAUTION: Before dis connecti ng or removing t he

component s, make sure t he area around t he joi nt faces

and connecti ons are clean. Plug open connecti ons to

prevent cont aminati on.

T orque: 35 Nm 3.

Installation Apply ant i-sei ze compound t o t he s ens or threads .

Refer t o: Specificati ons (303-08, Speci ficat ions).

1.

To i nst all , revers e t he removal procedure.

2.

Page 1281 of 3229

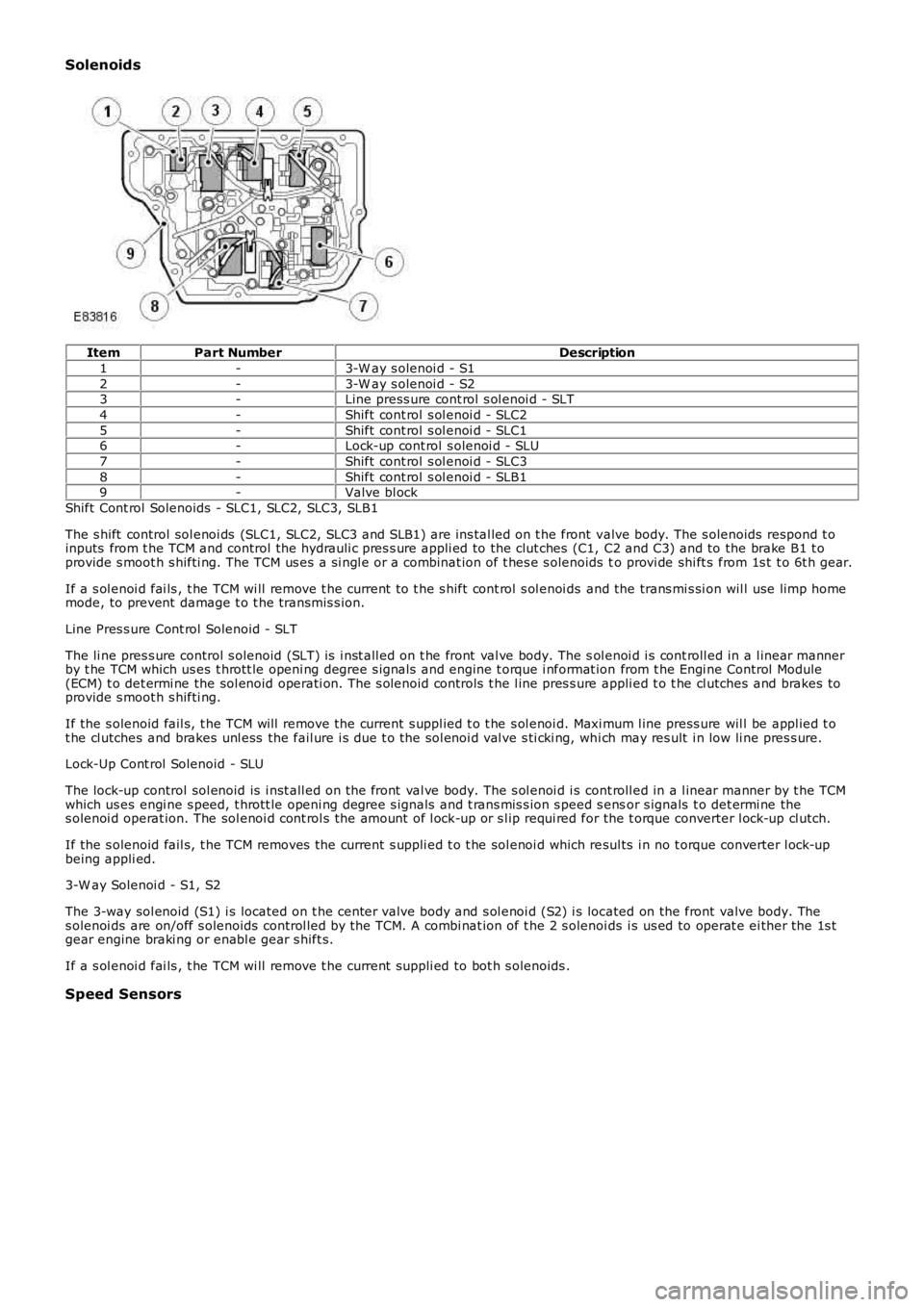

Solenoids

ItemPart NumberDescription

1-3-W ay s olenoi d - S1

2-3-W ay s olenoi d - S23-Line press ure cont rol s ol enoi d - SLT

4-Shift cont rol s ol enoi d - SLC2

5-Shift cont rol s ol enoi d - SLC16-Lock-up cont rol s olenoi d - SLU

7-Shift cont rol s ol enoi d - SLC3

8-Shift cont rol s ol enoi d - SLB19-Valve bl ock

Shift Cont rol Solenoids - SLC1, SLC2, SLC3, SLB1

The s hift control sol enoi ds (SLC1, SLC2, SLC3 and SLB1) are ins tal led on t he front valve body. The s olenoids respond t oinputs from t he TCM and control the hydrauli c pres s ure appli ed to the clut ches (C1, C2 and C3) and to the brake B1 t oprovide s moot h s hifti ng. The TCM us es a si ngl e or a combinat ion of t hes e s olenoids to provi de shi ft s from 1s t t o 6t h gear.

If a s ol enoi d fai ls , t he TCM wi ll remove t he current t o t he s hift cont rol s ol enoi ds and the trans mi s si on wil l use limp homemode, to prevent damage t o t he transmis s ion.

Line Pres s ure Cont rol Solenoid - SLT

The li ne pres s ure control s olenoid (SLT) is i nst all ed on t he front val ve body. The sol enoi d i s cont roll ed in a l inear mannerby t he TCM which us es t hrott le openi ng degree s ignals and engine t orque i nformat ion from t he Engi ne Control Module(ECM) t o det ermi ne the sol enoid operati on. The s olenoid controls t he l ine pres s ure appli ed t o t he cl utches and brakes toprovide s moot h s hifti ng.

If the s olenoid fail s, t he TCM will remove the current s uppl ied t o t he s ol enoi d. Maxi mum l ine press ure wil l be appl ied t ot he cl utches and brakes unl ess the fail ure i s due t o the sol enoi d val ve s ti cki ng, whi ch may res ult i n low li ne pres s ure.

Lock-Up Cont rol Solenoid - SLU

The lock-up control sol enoid is i nst all ed on t he front val ve body. The s ol enoi d i s cont roll ed in a l inear manner by t he TCMwhich us es engi ne s peed, t hrott le openi ng degree s ignals and t rans mis s ion s peed s ensor s ignals t o det ermi ne thes olenoi d operat ion. The sol enoi d cont rol s the amount of l ock-up or s l ip requi red for the t orque converter l ock-up cl utch.

If the s olenoid fail s, t he TCM removes the current s uppli ed t o t he sol enoi d which resul ts i n no t orque converter l ock-upbeing appli ed.

3-W ay Solenoi d - S1, S2

The 3-way sol enoid (S1) i s located on t he center valve body and s ol enoi d (S2) i s located on the front valve body. Thes olenoi ds are on/off s olenoids control led by the TCM. A combi nat ion of t he 2 s olenoids i s us ed to operat e ei ther the 1s tgear engine braki ng or enabl e gear s hift s.

If a s ol enoi d fai ls , t he TCM wi ll remove t he current s uppli ed to bot h s olenoids .

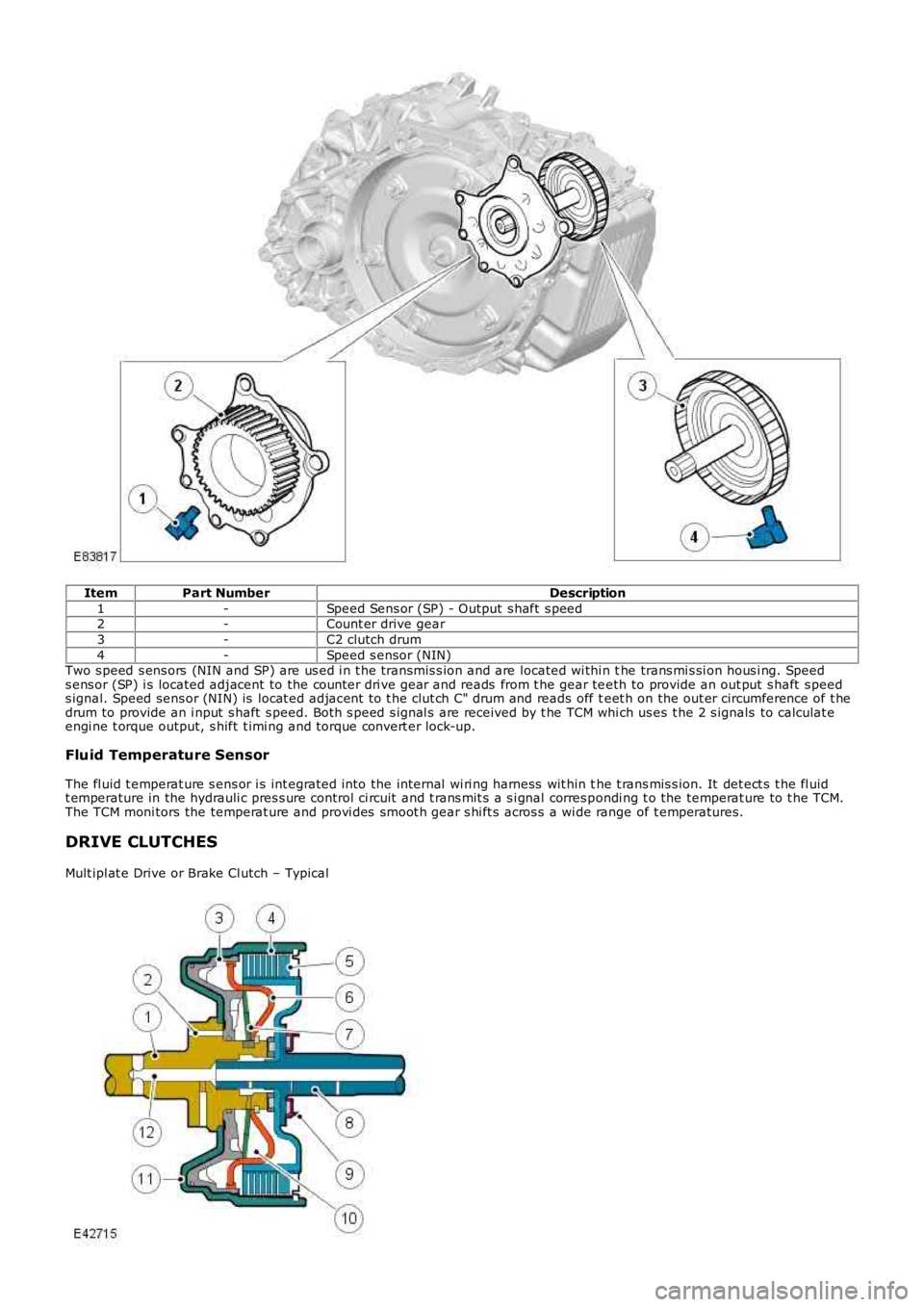

Speed Sensors

Page 1282 of 3229

ItemPart NumberDescription

1-Speed Sens or (SP) - Output s haft s peed2-Count er drive gear

3-C2 clutch drum

4-Speed s ensor (NIN)Two s peed s ens ors (NIN and SP) are us ed i n t he transmis s ion and are located wi thi n the trans mi s si on hous i ng. Speeds ens or (SP) i s located adjacent to the counter dri ve gear and reads from t he gear teeth to provide an out put s haft s peeds ignal. Speed sens or (NIN) is locat ed adjacent to t he clut ch C" drum and reads off teet h on the out er circumference of t hedrum to provide an i nput s haft s peed. Bot h s peed s ignal s are received by t he TCM which us es t he 2 s ignals to calculat eengi ne t orque output, s hift t imi ng and torque convert er lock-up.

Fluid Temperature Sensor

The fl uid t emperat ure s ens or i s int egrated into the internal wi ri ng harness wit hin the t rans mis s ion. It det ect s t he fl uidt emperature in the hydrauli c pres s ure control ci rcuit and t rans mit s a s i gnal corres pondi ng t o the temperat ure to t he TCM.The TCM moni tors the temperat ure and provi des smoot h gear s hi ft s acros s a wi de range of t emperatures.

DRIVE CLUTCHES

Mult ipl at e Drive or Brake Cl utch – Typical

Page 1318 of 3229

Publi s hed: 11-May-2011

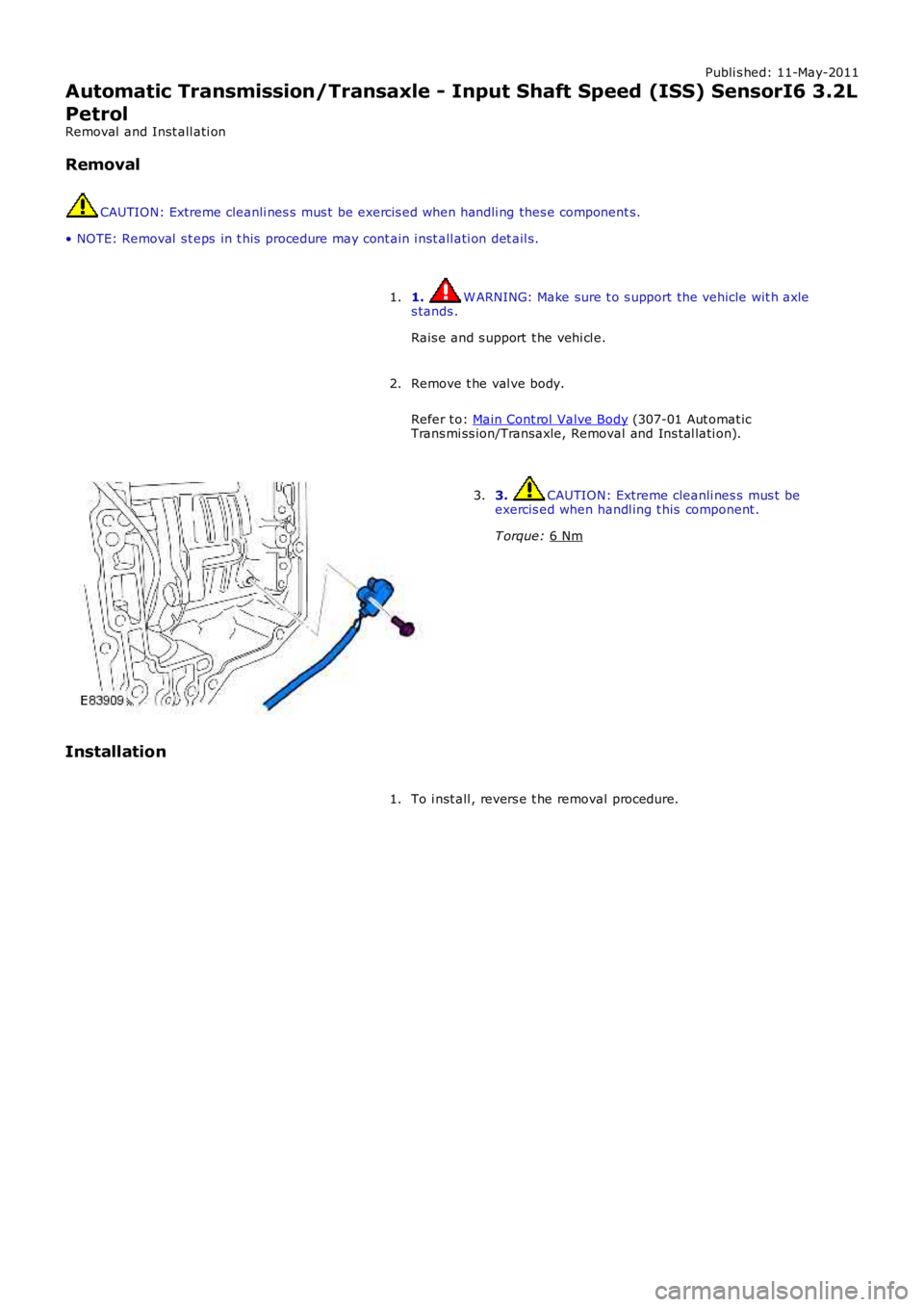

Automatic Transmission/Transaxle - Input Shaft Speed (ISS) SensorI6 3.2L

Petrol

Removal and Inst all ati on

Removal CAUTION: Extreme cleanli nes s mus t be exercis ed when handli ng thes e component s.

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

1. W ARNING: Make sure t o s upport the vehicle wit h axle

s tands .

Rais e and s upport t he vehi cl e.

1.

Remove t he val ve body.

Refer t o: Main Cont rol Valve Body (307-01 Aut omat ic

Trans mi ss ion/Transaxle, Removal and Ins tal lati on).

2. 3. CAUTION: Extreme cleanli nes s mus t be

exercis ed when handl ing t his component .

T orque: 6 Nm 3.

Installation To i nst all , revers e t he removal procedure.

1.

Page 1370 of 3229

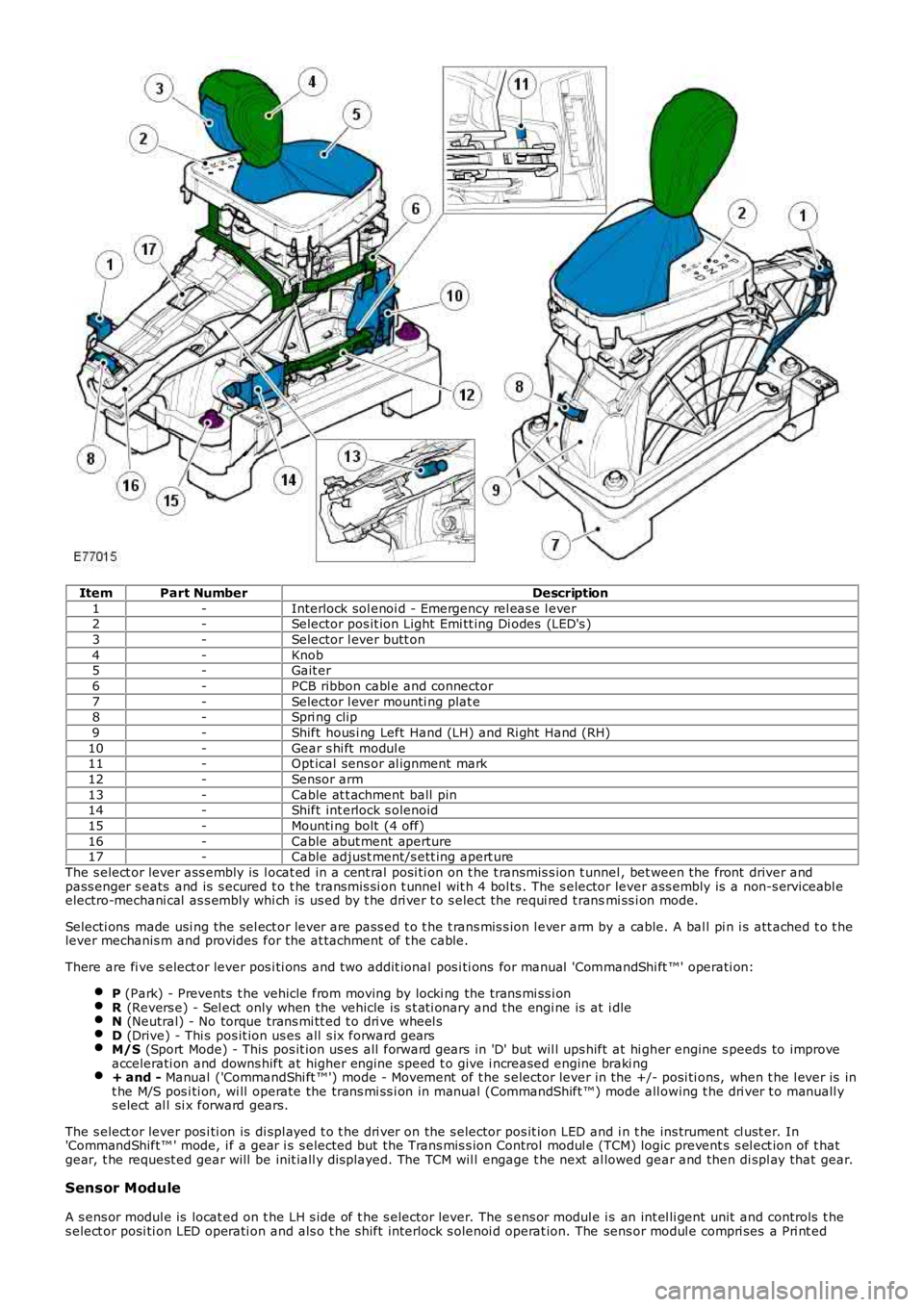

ItemPart NumberDescription

1-Interlock sol enoi d - Emergency rel eas e l ever2-Selector pos it ion Light Emi tt ing Di odes (LED's )

3-Selector l ever butt on

4-Knob5-Gait er

6-PCB ribbon cabl e and connector

7-Selector l ever mounti ng plat e8-Spri ng clip

9-Shift hous i ng Left Hand (LH) and Ri ght Hand (RH)

10-Gear s hi ft modul e11-Opt ical sens or al ignment mark

12-Sensor arm

13-Cable at t achment ball pin14-Shift int erlock s olenoid

15-Mounti ng bolt (4 off)

16-Cable abut ment aperture17-Cable adjust ment/s ett ing apert ure

The s elect or lever ass embly is l ocat ed in a cent ral posi ti on on t he t ransmis s ion t unnel , bet ween the front driver andpass enger s eats and is s ecured t o t he transmis si on t unnel wit h 4 bol ts . The s elector lever ass embly is a non-s erviceabl eelectro-mechani cal as s embly whi ch is us ed by t he dri ver t o s elect the requi red t ransmi ss i on mode.

Selecti ons made usi ng the sel ect or lever are pass ed t o t he t rans mis s ion l ever arm by a cable. A bal l pi n i s att ached t o t helever mechanis m and provides for the at tachment of t he cable.

There are fi ve s elect or lever pos i ti ons and t wo addit ional pos i ti ons for manual 'CommandShi ft ™' operati on:

P (Park) - Prevents t he vehicle from moving by locki ng the trans mi ss i onR (Revers e) - Sel ect only when the vehicle is s t ati onary and the engi ne is at i dleN (Neutral) - No torque trans mi tt ed t o dri ve wheel sD (Drive) - Thi s pos it ion us es all s ix forward gearsM/S (Sport Mode) - This pos it ion us es all forward gears in 'D' but wil l ups hift at hi gher engine s peeds to improveaccelerati on and downs hift at higher engine speed t o give i ncreased engine braki ng+ and - Manual ('CommandShi ft ™') mode - Movement of t he s elector lever in the +/- posi ti ons, when t he l ever is int he M/S pos i ti on, wi ll operate the trans mi ss i on in manual (CommandShift ™) mode all owing t he dri ver t o manuall ys elect al l si x forward gears.

The s elect or lever pos i ti on is di spl ayed t o t he dri ver on the s elector pos it ion LED and i n t he ins trument cl ust er. In'CommandShift™ ' mode, i f a gear i s s elected but t he Trans mis s ion Control modul e (TCM) logic prevent s s el ect ion of t hatgear, t he request ed gear will be init iall y dis played. The TCM wil l engage t he next al lowed gear and then di spl ay that gear.

Sensor Module

A s ens or modul e is locat ed on t he LH s ide of t he s elector lever. The s ens or modul e is an int el li gent unit and controls t hes elect or posi ti on LED operati on and als o t he s hift interlock s olenoi d operat ion. The sens or modul e compri ses a Pri nt ed

Page 1392 of 3229

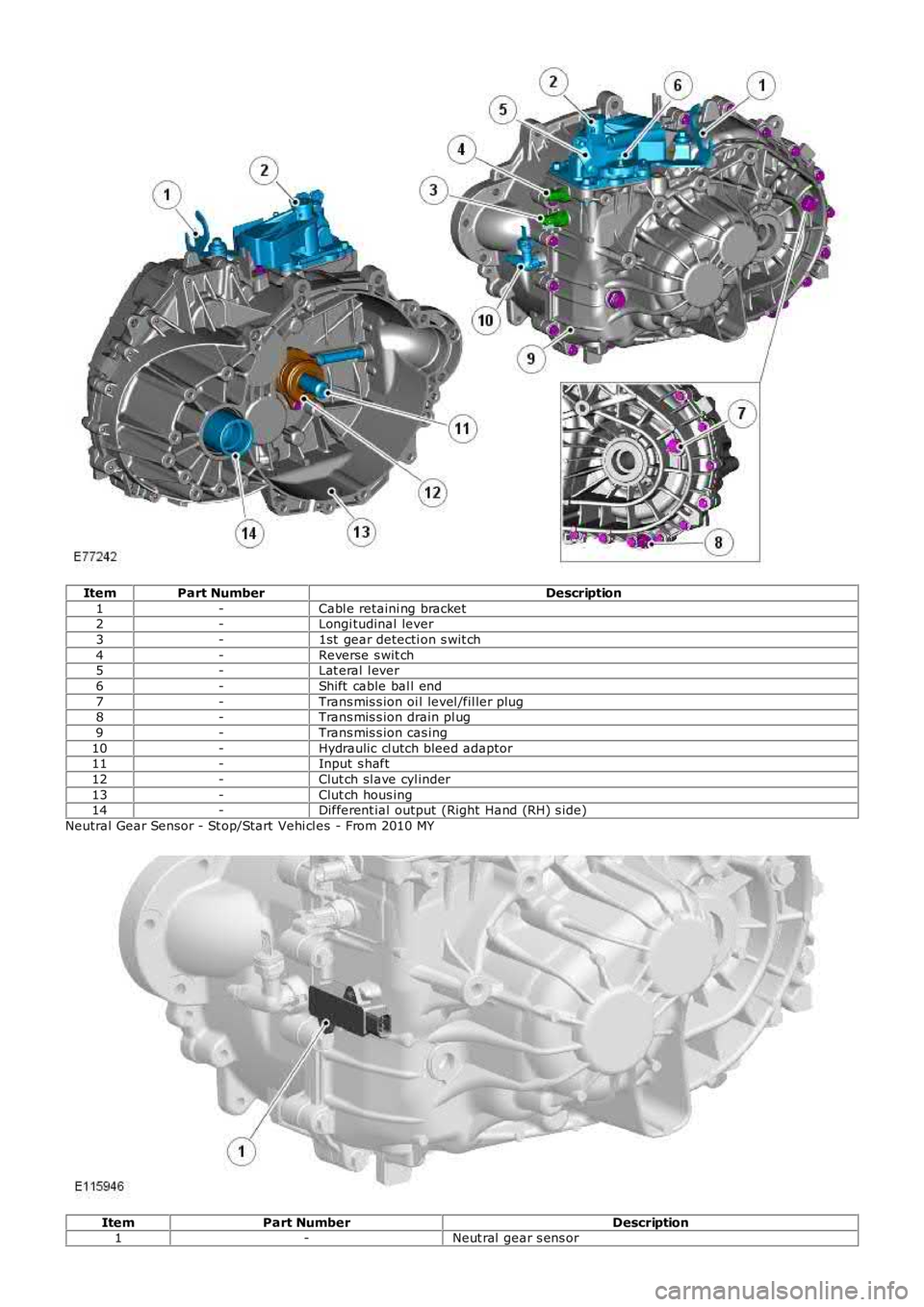

ItemPart NumberDescription

1-Cabl e retaini ng bracket2-Longi tudinal lever

3-1st gear detecti on s wit ch

4-Reverse s wit ch5-Lat eral l ever

6-Shift cable bal l end

7-Trans mis s ion oi l level /fil ler plug8-Trans mis s ion drain pl ug

9-Trans mis s ion cas ing

10-Hydraulic cl utch bleed adaptor11-Input s haft

12-Clut ch sl ave cyl inder

13-Clut ch hous ing14-Different ial output (Right Hand (RH) s ide)

Neutral Gear Sensor - St op/Start Vehi cl es - From 2010 MY

ItemPart NumberDescription1-Neut ral gear s ens or

Page 1393 of 3229

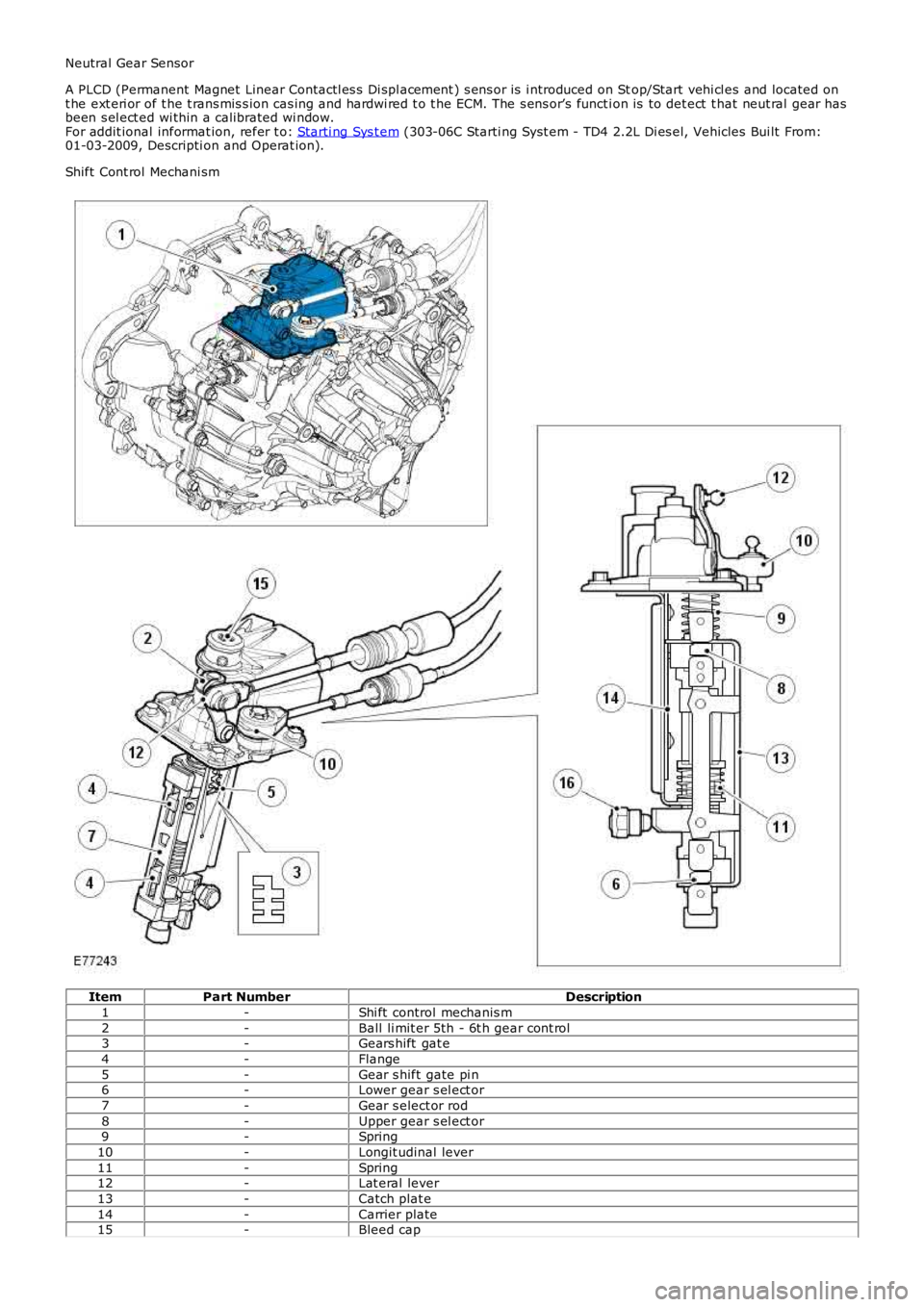

Neutral Gear Sensor

A PLCD (Permanent Magnet Linear Contactl es s Di s pl acement ) s ens or is i ntroduced on Stop/Start vehi cl es and located ont he ext eri or of t he t rans mis s ion cas ing and hardwi red t o t he ECM. The s ens or’s functi on is to det ect t hat neut ral gear hasbeen s el ect ed wi thin a calibrated wi ndow.For addit ional informat ion, refer t o: Starti ng Sys t em (303-06C Starti ng Syst em - TD4 2.2L Di es el, Vehicles Bui lt From:01-03-2009, Descripti on and Operat ion).

Shift Cont rol Mechani sm

ItemPart NumberDescription

1-Shi ft control mechanis m

2-Ball li mit er 5th - 6t h gear cont rol3-Gears hift gat e

4-Flange

5-Gear s hift gate pi n6-Lower gear s el ect or

7-Gear s elect or rod

8-Upper gear s el ect or9-Spring

10-Longit udinal lever

11-Spring12-Lat eral lever

13-Catch plat e

14-Carrier plate15-Bleed cap

Page 1416 of 3229

which i s hydraulicall y act uated from t he cl utch pedal.

Pres s ing t he clutch pedal pres surizes t he hydraul ic fluid in the mas t er cyli nder. The fl uid pres s ure is t rans ferred via a pipefrom the mas t er cyli nder t o t he s lave cyl inder in the t rans mis s ion. The fluid press ure operates t he s lave cylinder which i nt urn pus hes the fingers of t he clut ch cover, rel easi ng the driven pl at e and di sengagi ng t he dri ve from t he engi ne crankshaftt o the trans mi s si on.

A hydrauli c clutch bl eed adapt or i s l ocated on the front of t he transmis s ion. The adapt or provi des the connect ion betweent he pres sure pipe from t he mas ter cyl inder to the s l ave cyli nder. The adapt or contains a bleed s crew to purge t he cl utchhydraulic sys tem of air aft er s ervice repl acement of one of the hydrauli c components. The adaptor als o i ncl udes a peakt orque li mit er. This prevent s ins t ant clut ch engagement if t he dri ver accident all y rel eas es t he clutch l ever t o preventdamage to the driveli ne components .

Stop/Start Vehicles - From 2010 MY

Clut ch Mast er Cyl inder and Linear Cl utch Sensor

The li near clut ch s ens or, l ocat ed on t he cl utch mas t er cyli nder and hardwi red t o t he CJB, i s us ed to s ens e t he posi ti on oft he cl utch pedal. It is us ed in conjunct ion wi th ot her sens or out puts t o t ri gger an engine res tart, engine s t op or st allrecovery on St op/Start vehi cl es. It is al s o us ed along wit h t he first and revers e gear s wi tches to compl ete cl ut chplaus ibil it y.

A magnet ins ide the clut ch mas ter cylinder provides t he posi ti on indicator for the linear cl utch s ensor. For t his reason, ift he mas ter cyl inder is replaced the correct replacement mas t er cyli nder mus t be i dent ified and fit t ed.For addit ional informat ion, refer t o: Starti ng Sys t em (303-06C Starti ng Syst em - TD4 2.2L Di es el, Vehicles Bui lt From:01-03-2009, Descripti on and Operat ion).

Linear Clutch Sens or

Page 1513 of 3229

Publi s hed: 11-May-2011

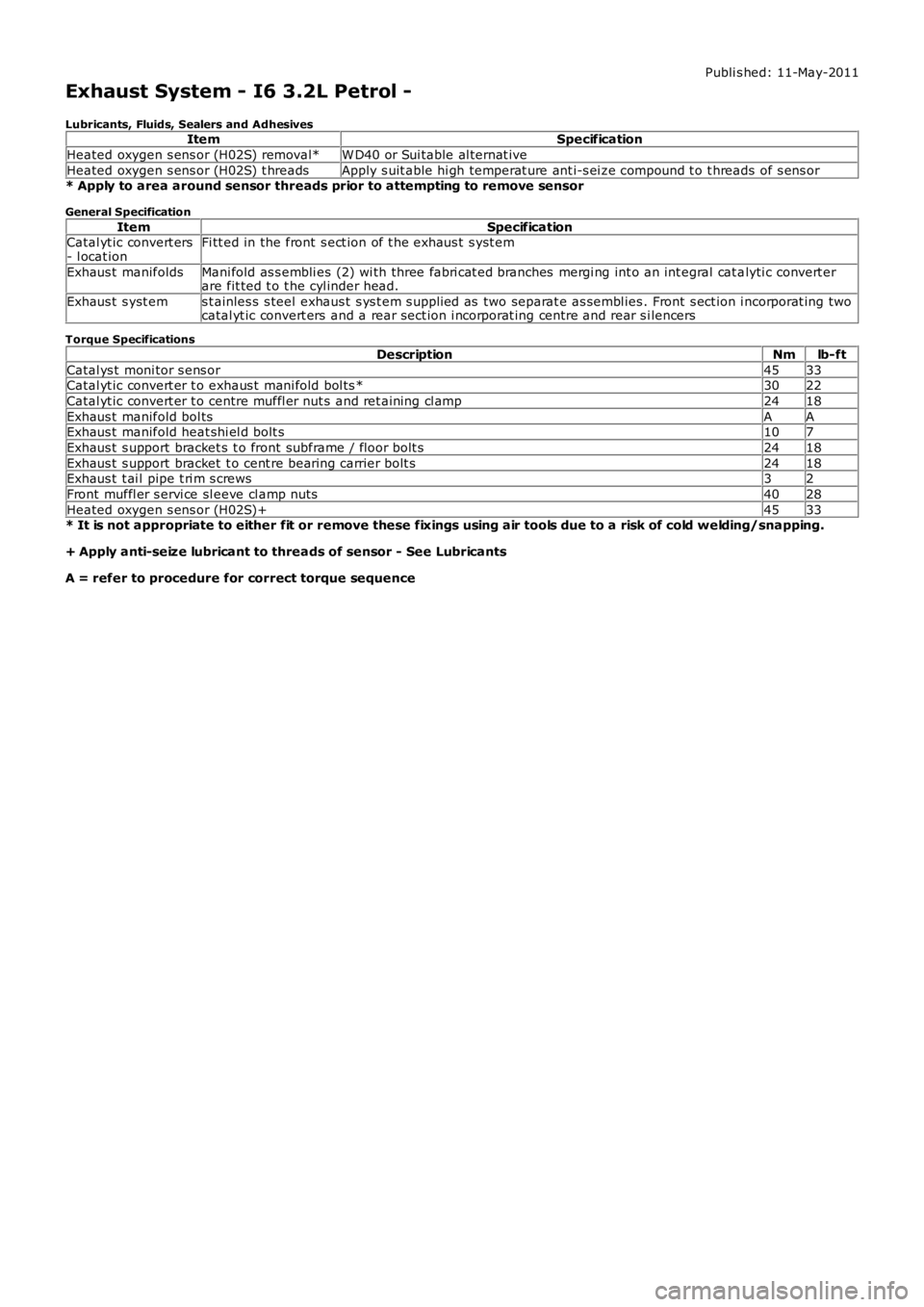

Exhaust System - I6 3.2L Petrol -

Lubricants, Fluids, Sealers and AdhesivesItemSpecification

Heated oxygen s ens or (H02S) removal*W D40 or Sui table al ternat ive

Heated oxygen s ens or (H02S) t hreadsApply s uit able hi gh temperat ure ant i-s ei ze compound t o t hreads of s ens or* Apply to area around sensor threads prior to attempting to remove sensor

General Specification

ItemSpecificationCatal yt ic convert ers- l ocat ionFi tt ed in the front s ect ion of t he exhaus t s yst em

Exhaus t manifoldsMani fold as s embli es (2) wi th three fabri cat ed branches mergi ng int o an int egral cat alyti c convert erare fit ted t o t he cyl inder head.

Exhaus t s yst ems t ainles s s teel exhaus t s ys t em s upplied as two separat e as sembl ies . Front s ect ion i ncorporat ing twocatal yt ic convert ers and a rear sect ion i ncorporat ing centre and rear s i lencers

Torque Specifications

DescriptionNmlb-ft

Catal ys t moni tor s ens or4533Catal yt ic convert er t o exhaus t mani fold bol ts *3022

Catal yt ic convert er t o centre muffl er nut s and ret aining cl amp2418

Exhaus t manifold bol tsAAExhaus t manifold heat shi el d bolt s107

Exhaus t s upport bracket s t o front subframe / floor bolt s2418

Exhaus t s upport bracket t o cent re bearing carrier bolt s2418Exhaus t t ai l pipe t ri m s crews32

Front muffl er s ervi ce sl eeve cl amp nuts4028

Heated oxygen s ens or (H02S)+4533* It is not appropriate to either fit or remove these fixings using air tools due to a risk of cold welding/snapping.

+ Apply anti-seize lubricant to threads of sensor - See Lubricants

A = refer to procedure for correct torque sequence