sensor LAND ROVER FRELANDER 2 2006 Manual PDF

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1205 of 3229

t he ignit ion t imingt he engi ne load.

The ECM moni tors the MAF s ens or for faul ts and can s t ore fault rel ated codes. Thes e can be ret ri eved us ing a Land Roverapproved diagnos t ic s yst em.

Int ake Air Temperat ure (IAT) Sens or

The IAT s ens or measures the temperat ure of t he i nt ake air entering t he engine. The sens or is a temperat ure dependantres is t or (t hermi st or). The thermis t or i s a NTC sens or element. The el ement resi s tance decreas es as t he s ens ort emperature increas es. The ECM suppli es the sens or wit h a 5V reference volt age and a ground and meas ures the returneds ignal as a t emperature.

The res is t ance i n t he s ens or changes wi th i ntake air t emperat ure. A l ow i nt ake air temperature wi ll res ult i n a hi gh vol tagebeing returned t o t he ECM and hi gh int ake ai r temperature wil l ret urn a low volt age reading of bet ween 0 - 5V.

The ECM moni tors the IAT s ens or for fault s and can s tore faul t relat ed codes . Thes e can be retrieved us ing a Land Roverapproved diagnos t ic s yst em. If the IAT s ensor fails , t he ECM us es a defaul t temperature val ue usi ng the fuel railpres s ure/t emperat ure s ensor.

Knock Sensors

Two knock sens ors are located on the front of t he engi ne and are each s ecured to threaded holes in t he engine cylinderblock wit h a bol t. The knock sens ors are us ed by t he ECM t o monit or combus ti on knocking or vibrati on generat ed byignit ion combus ti on. The knock s ens ors are each connected t o t he ECM via a t wis t ed pai r of wires which reduces electricalint erference di s rupti ng t he si gnal produced.

Each knock s ens or cont ains a pei zo-ceramic crys t al whi ch produces a vol tage when an ext ernal force appli es pres s ure orload on it . W hen t he engi ne is runni ng, compres s ion waves produced by t he combus t ion proces s, creat es pres sure waveswhich pas s t hrough the engine cyli nder bl ock. Thes e press ure waves are detected by the knock s ens ors and the defl ect ionof the crys t al caus ed by the pres sure waves caus es the sens ors t o produce an out put s ignal. The s i gnals are pas s ed to theECM whi ch compares them wit h s tored mapped s ignal s i n it s memory.

The ECM can t hen det ermine when t he correct combus t ion occurs i n indivi dual cyl inders . If incorrect combus t ion detonat ionis det ect ed, the ECM can retard t he ignit ion ti ming on that cyl inder for a number of combus ti on cycl es . The i gni ti on ti mingwil l be gradually ret urned t o it s opti mal s et t ings. If t he knock is st il l det ected the ECM wi ll i ncreas e t he i nject ion period,which has a cooli ng effect on t hat cyl inder.

The s ignals from the knock s ens ors are us ed i n conjunct ion wi th the CMP sens ors and t he CKP s ens or t o det ermi ne theignit ion cycle and t herefore i dent ify which cylinder is knocki ng. The ECM is programmed to us e i gni ti on maps bas ed on highqual it y 95-98 RO N fuel . If fuel of a poor qual it y s uch as 91 RON i s us ed the engi ne may s uffer from knock (pinking) for aperi od of ti me. The ECM is capable of l earning and adapti ng to the l ow grade fuel and wil l modi fy it s int ernal ignit ionmapping t o compens at e for t he low grade fuel . Thi s feat ure of t he ECM i s called adapt ion.

If one or bot h knock s ensors fai l or the s ignal becomes i mplaus ible, t he ECM wi ll cancel clos ed loop cont rol of t he ignit ions ys t em. The ECM wi ll us e a defaul t 's afe' ignit ion map to ens ure the pre-det onat ion does not damage the engine bys ett ing maxi mum retard cont rol on s park advance. The dri ver may not ice 'pinking' under certai n dri vi ng condi ti ons and alos s of performance. The ECM monit ors t he knock s ens ors for fault s and can st ore fault relat ed codes . Thes e can beret ri eved us i ng a Land Rover approved diagnos t ic s ys tem.

Engine Coolant Temperature (ECT) Sensor

Page 1206 of 3229

The ECT s ens or is locat ed i n t he thermost at hous ing, on t he front of the engine, below t he i nl et manifol d. The ECT s ens oris a t hermis t or type s ens or us ed by the ECM t o monit or the engine coolant t emperature. The ECM uses t he t emperatureinformat ion for the foll owi ng functi ons:

regulat e t he inject ion peri ods et engi ne idle target s peedcont rol t he engi ne cool ing fan(s )determine operat ion of t he A/C compres sordetermine operat ion of t he purge valve and catal yt ic convert er heat ing funct ion.

The s ens or is a Negat ive Temperat ure Co-efficient (NTC) thermis tor element . The element res is t ance decreas es as thes ens or t emperature increas es. The ECM suppli es the sens or wit h a 5V reference volt age and a ground and meas ures theret urned s ignal as a t emperature.

The ECT s ens or is important to the correct running of t he engi ne as a richer mixt ure i s required at low engi ne cool antt emperatures for efficient s tarti ng and s mooth cold running. As t he engi ne cool ant temperat ure i ncreas es , the ECM usest he temperat ure si gnal from the sens or to l ean off t he fuel mi xt ure to maint ai n optimum emis s ions and performance.

The ECM moni tors the ECT sens or for faul ts and can s t ore faul t rel at ed codes . These can be ret ri eved us ing a Land Roverapproved diagnos t ic s yst em. If the ECT sens or fail s, t he ECM us es a defaul t val ue of 90°C (194°F). The electric fan cont rolmodule i s s ent a default coolant temperat ure val ue of 105°C (221°F) and s wit ches t he cooling fan on permanent ly.

Engine Oil Level/Temperature Sensor

The engi ne oil l evel/t emperature s ens or is locat ed on t he unders ide of t he engi ne and is secured i n t he engi ne oil pan wi th3 s crews and i s s eal ed wi th an O-ring s eal. The ECM suppli es the s ens or wit h a 5V reference volt age and two wires s uppl yt he temperat ure and oi l level si gnal s back t o t he ECM.

Two t ypes of engine oi l level /t emperat ure s ensor are us ed. On earli er model s a capacit ive oi l level s ens or i s fit ted and wasrepl aced by an ul trasound l evel s ens or on l at er models . The principl e of the temperat ure s ens or i s t he s ame in bot h s ens ort ypes . The sens ors can be i dent ified by di fferences in t he s ens or housi ngs ; t he capacit ive s ensor has t he electricalconnector moulded s quare t o t he bas e of the s ens or, t he ult ras oni c s ens or has the connect or moulded at a s li ght angle tot he bas e of t he s ens or.

The ECM us es both the oi l l evel and t emperature s ignals t o calculat e t he oil level. Temporary oil level changes caus ed byhil l driving or cornering are taken i nt o account by t he ECM us ing addit ional informat ion s uch as vehi cl e s peed and engi neload.

Engi ne Oi l Level Sens or - Capacit ance Type

The engi ne oil l evel s ens or compris es t wo capaci ti ve gauge el ement s . Thes e meas ure the resi s tance to elect rical currentpass i ng through t he engine oi l.

There are t wo capacit ors , one meas uring t he permit ti vi ty of t he oil and a second with t wo pl at es s et verti cal ly meas uri ngt he hei ght . The s econd capaci tor wil l have a proport ion of oil and ai r bet ween t he plates and s i nce t he permit ti vi ty of ai r isdifferent t o t hat of oi l, t he permi tt ivit y readi ng wil l change as t he level of oi l decreas es and the ai r between t he plat e gapincreas es. This permi tt ivit y readi ng is compared t o t hat of the oi l (t aken by t he first capaci tor) and an oil level is derived.

Engi ne Oi l Level Sens or - Ult ras ound Type

Page 1207 of 3229

The engi ne oil l evel s ens or us es an ult ras oni c puls e, which is refl ect ed back from the s urface of t he oil . The ti me i t takesfor t his s i gnal t o ret urn t o t he s ensor i s turned int o a PW M s ignal and is s ent to the ECM. The ECM det ermi nes the ti met aken for the ul trasonic pul se si gnal t o be recei ved and calculat es it i nto an oil level fi gure.

Engi ne Oi l Temperat ure Sens or

The engi ne oil t emperature s ensor i s a Pos it ive Temperat ure Co-effi ci ent (PTC) thermis t or el ement . The element res i st anceincreas es as t he sens or temperat ure decreas es. The ECM s uppli es t he sens or wit h a 5V reference vol tage and a ground andmeas ures t he ret urned s ignal as a t emperature. A low oil temperature wil l res ult in a l ow volt age bei ng ret urned t o t heECM and hi gh oil temperature wil l ret urn a hi gh volt age reading.

The ECM moni tors the engine oi l level/temperat ure sens or for fault s and can s tore faul t rel at ed codes . These can beret ri eved us i ng a Land Rover approved diagnos t ic s ys tem. If the sens or fail s , the ECM us es t he engine cool ant temperat ures ens or s ignal val ue as a s ubst it ute.

Manifold Absolute Pressure (MAP) Sensor

The MAP s ensor i s located i n t he lower part of t he int ake manifol d. The MAP s ens or meas ures t he abs olut e pres s ure in t heint ake manifol d. The sens or is a semi -conduct or type s ens or which responds t o pres s ure acti ng on a membrane wi thin thes ens or, al tering t he output volt age. The s ens or receives a 5V reference vol tage and a ground from t he ECM and returns as ignal of bet ween 0.5 - 4.5V t o t he ECM. A low pres sure ret urns a low vol tage s ignal to the ECM and a high press ureret urns a hi gh volt age.

The MAP s ensor det ect s quick pres s ure changes i n t he int ake mani fol d aft er the el ectri c thrott le. The s ignal is us ed inconjunct ion wi th the MAF sens or si gnal t o calculate the injecti on peri od.

The ECM moni tors the engine MAP s ens or for faul ts and can st ore fault related codes. Thes e can be ret ri eved us i ng a LandRover approved diagnost ic sys tem. If t he s ens or fai ls , the ECM uses t he MAF/IAT s ensor s i gnal value as a subs ti tut e.

Electric Throttle

The electric t hrot tl e is locat ed at t he entrance of t he int ake manifol d and is secured t o t he manifold wit h four Torx headbolt s. The t hrot tl e als o provi des for t he connect ion of t he air cleaner hous ing out let pipe which is secured t o t he t hrott lebody wit h a cl ip.

The electric t hrot tl e compri ses t he t hrott le body, a round throt t le di sc whi ch is act uat ed by a damper mot or and a thrott leposi ti on s ens or. The el ect ri c thrott le is control led by the ECM and recei ves pos i ti onal s ignals from the TP s ens or. If afai lure of the mot or occurs , t he thrott le di s c is returned to it s cl osed pos it ion by the s prings, wi th li mit ed engine s peedavai lable to the driver.

Spindle Damper Mot or

The mot or i s a DC damper motor which drives a gear wheel and t wo s pri ngs ; one for opening and one for cl osi ng. Themot or rotat es the spi ndl e t o which t he t hrott le dis c is at t ached. PW M s i gnals from the ECM control the damper mot or t oadjus t the pos it ion of t he t hrott le dis c, regul ati ng the amount of air ent ering the i nlet manifold for combus ti on.

Movement of t he mot or is achieved by changing t he polarit y of the power s uppl y to the DC mot or, all owing i t to beoperated in bot h direct ions . The throt tl e dis c and t he mot or has two maxi mum pos it ions ; t hrott le di s c cl osed which all owsmi ni mal air flow t hrough t he electric t hrot tl e int o t he int ake manifol d and t hrott le dis c open which all ows maximum air flow

Page 1208 of 3229

int o t he int ake manifol d.

Throt tl e Posi ti on (TP) Sensor

The TP s ensor i s hous ed i n t he elect ric t hrott le ass embly and is us ed t o check t he posi ti on of the throt t le di sc. Twopermanent magnet s i n t he sens or connect ed t o t he thrott le di sc affect t wo Hall effect sens ors . As t he s pi ndl e i s rot atedt he magnet s rot ate around t he Hall effect s ensors and produce offset analogue s ignals back t o t he ECM. The ECMcompares t hes e s ignals to st ored values t o ens ure t hat they s how an accurate throt tle dis c pos it ion. The offset s i gnals aret hat one Hal l effect s ens or produces a higher vol tage as t he t hrott le angl e increas es and the ot her sens or produces alower volt age as the throt tl e angle i ncreases .

The ECM performs a s elf t est and a cal ibrat ion routi ne on the throt t le di sc pos it ion at each igni ti on cycle. This i s achi evedby t he ECM poweri ng the damper mot or to full y clos e t he throt t le di sc and then ful ly open t he t hrott le dis c.

The ECM moni tors the DC damper motor and t he TP s ens or for faul ts and can st ore fault related codes. Thes e can beret ri eved us i ng a Land Rover approved diagnos t ic s ys tem.

Accelerator Pedal Position (APP) Sensor

The APP s ens or is locat ed on t he accel erator pedal . The s ens or compris es a pl ast ic hous ing whi ch cont ai ns t wopotenti ometers and an analogue/digit al convert er. The potent iomet ers are connect ed to a common shaft which is act uat edby movement of the accel erator pedal.

The APP s ens or provides t he ECM and t he CJB wi th i nformati on rel at ing to t he pos it ion of t he accelerat or pedal . The ECMus es this informati on t o act uate the damper mot or i n t he electric t hrot tl e as sembl y t o move t he thrott le di sc to the correctangl e i n rel ati on to the pedal pos it ion.

The APP s ens or receives a fus ed 12V s upply from t he CJB, whi ch is controll ed by the ignit ion relay in the BJB. The CJB als oprovides t he s ens or wit h a ground. The s ens or provi des two out puts ; t he anal ogue output i s t rans mit ted di rectl y t o t heCJB, whi ch in t urn is s ues the s ignal to the ECM on t he CAN bus , the s econd out put is t he Puls e W idth Modul ati on (PW M)s ignal whi ch is trans mi tt ed direct ly to t he ECM. Both the analogue and PW M s ignals trans mi t the s ame pos it ionalinformat ion.

The ECM us es t he PW M si gnal t o calcul ate the requi red pos it ion of t he electric t hrottl e dis c i n t he electric t hrot tl e. In t heevent of a fail ure of t he PW M si gnal , the ECM uses the analogue s ignal recei ved from t he CJB as a replacement . If t heanal ogue si gnal i s als o i ncorrect or mis s ing, the ECM li mit s t he maximum engi ne s peed to 2000 rpm.

The PW M and the analogue s ignal are us ed for di agnos ing fault s wit h t he APP s ensor. If t he ECM det ect s a di fferencebetween t he analogue and PW M si gnal s a faul t code is s t ored. The ECM wil l use the s ignal wi th t he l owes t value forelectric t hrot tl e cont rol . The APP s ens or pos i ti on and any st ored fault codes can be read us ing a Land Rover approveddiagnost ic s ys tem.

Heated Oxygen (HO2S) Sensors

Page 1210 of 3229

The ECM us es t he informati on from the downs tream HO2S t o enhance the s ignals from t he upst ream HO2S.

The downst ream HO2S are si mi lar in their const ructi on t o t he ups t ream HO2S wit h t he except ion of t he out put si gnal t ot he ECM. The out put si gnal i s a binary s ignal where t he amplit ude of the si gnal curve changes consi derably when t heoxygen content in the exhaust gas s es changes . The oxygen content of t he exhaus t gas ses leaving t he catalyt ic converterare measured by comparing i t wit h ambi ent ai r drawn i nt o t he HO2S.

Stop Lamp Switch

The s top l amp s wi tch i s att ached t o t he brake pedal bracket, adjacent to the speed cont rol i nhi bit s wit ch. W hen the brakepedal i s pres s ed, a pl ate on the pedal moves away from t he s wit ch plunger al lowing the pl unger to ext end and completet he swit ch contact s.

The s wit ch receives a permanent , fus ed bat t ery volt age via t he BJB and t he CJB. The s wit ch is connect ed t o t he ECM whichprovides t he ground path. The ground (batt ery volt age s ignal) i s used by the ECM as a s wit ch operati on s ignal. The groundfrom the s wi tch i s rout ed vi a t he CJB to the ECM which all ows t he CJB to al s o determine t he s wit ch operati on.

The CJB uses the complet ed ground when t he s wit ch is operat ed t o act ivat e the st op lamps .

The ECM can diagnose the operat ion of t he s top lamp s wi tch and t he s tat us of the s witch can be read usi ng a Land Roverapproved diagnos t ic s yst em.

Ambient Air Temperature (AAT) Sensor

The AAT s ensor i s located i n t he undersi de of the Left Hand (LH) exterior door mirror. The s ens or i s a Negati veTemperature Co-effi ci ent (NTC) t hermis t or el ement. The element resi st ance decreas es as t he s ens or temperatureincreas es which produces a l ow s ignal vol tage. The ECM s uppl ies t he s ens or wit h a 5V reference vol tage and a ground andmeas ures t he ret urned s ignal vol tage as an out si de t emperature.

The AAT s ignal is us ed by t he ECM for a number of funct ions i ncludi ng engi ne cool ing fan cont rol and A/C compres sordis placement control. The ECM al s o transmit s a mes s age on t he high s peed CAN bus relati ng to the current out s idet emperature for us e by ot her control modul es .

The ECM can diagnose the operat ion of t he AAT s ensor and t he s ens or output values can be read us ing a Land Roverapproved diagnos t ic s yst em.

Fuel Pump Driver Module (FPDM)

Page 1215 of 3229

The s peed control inhibit swi tch i s att ached to t he brake pedal bracket , adjacent t o t he s top l amp s wit ch. W hen the brakepedal i s pres s ed, a pl ate on the pedal moves away from t he s wit ch plunger al lowing the pl unger to ext end and completet he swit ch contact s.

The s wit ch receives a power s upply from t he CJB which s enses the complet ed ground path when the s wi tch i s operated.The s wit ch has two functi ons ; it is us ed for s t art ing purpos es when the brake pedal mus t be pres s ed before engi necranking i s allowed and it is used t o s us pend speed cont rol operat ion when s peed cont rol i s act ive and t he brake pedal ispres s ed.

The CJB can diagnos e t he operat ion of t he speed control i nhibit s wi tch and t he s tat us of the s wi tch can read us ing a LandRover approved diagnost ic sys tem.

Main Relay

The main rel ay is l ocat ed in the BJB. The operati on of the mai n rel ay is cont roll ed by t he ECM which provi des a groundpath for the main relay coil , energi zing t he rel ay and cl osi ng t he rel ay cont act s.

The main rel ay suppli es bat t ery volt age to the foll owing engine s ensors and act uators:

Electric t hrot tl e - TP s ensor (via ECM)Fuel i njectorsIgni ti on coi lsCoil Capaci torVari abl e inl et cam profile swit ching sol enoi d - front and rearInt ake tract variable mani fol d mot orPlenum variable i ntake manifold motorHO2SPurge valveFuel t ank leakage monit oring pump (NAS onl y).

Air Conditioning (A/C) Pressure Sensor

The refri gerant pres sure s ens or provides t he Air Temperat ure Cont rol (ATC) module wit h a press ure input from t he highpres s ure s ide of t he refrigerant s ys t em. The refri gerant press ure s ens or is hardwired to the ECM, which us es t he s ignal t ocont rol operat ion of t he A/C compress or and to cal cul at e t he addit ional l oad on t he engi ne when t he A/C compress or isoperati ng.

The ECM al so broadcas ts the refrigerant high press ure val ue over t he high s peed Controller Area Network (CAN) bus t o t heCJB. The CJB relays the si gnal t o t he ATC module over t he medium speed CAN bus t o i ncreas e the amount of recircul at edair i f required.

Air Conditioning (A/C) Relay

The A/C rel ay is l ocat ed in the BJB. The operati on of the A/C relay i s cont roll ed by t he ECM whi ch provi des a ground pat hfor t he A/C rel ay coi l, energizi ng the relay and clos ing the relay cont acts .

W hen t he rel ay cont act s are clos ed, batt ery vol tage i s s uppl ied via the relay t o t he A/C compress or clut ch. The ECMcont rol s the operat ion of t he vari abl e dis placement compress or us ing a s i gnal li ne to t he compress or and received s ignalsfrom the A/C pres s ure sens or.

Air Conditioning Compressor Control

Compres s or di spl acement is cont roll ed by t he ECM bas ed on current evaporator t emperature and target evaporat ort emperature s ignals received from t he ATC module. From thes e values t he ECM calcul ates t he requi red compres s ordis placement and provi des a Puls e W idt h Modul ated (PW M) s i gnal t o t he compress or s olenoi d valve. The compress ors olenoi d valve i s mounted on the rear of t he compres s or and i nterprets the PW M s ignal as a dis placement val ue and alt erst he pos i ti on of the i nternal s wash plate accordi ngl y.

The ECM wi ll als o reduce t he dis placement of the A/C compres s or to i ts mini mum l evel i f 'ful l throt t le' or aut omati ct ransmis s ion 'ki ck down' is request ed. Thi s feat ure i s not pres ent on Gul f s pecificati on vehi cl es. Compress or clutchengagement is cont roll ed by t he ECM.

Engine Cooling Fan Control

The ECM has a hardwired connect ion wit h t he cooli ng fan cont rol module. The ECM output s a PW M s ignal to the fan cont rolmodule whi ch rel at es t o t he required fan s peed. The fan s peed is det ermi ned by factors s uch as engi ne coolantt emperature and A/C operati on. The fan cont rol module react s t o t he received s ignal by cont roll ing t he operat ing volt age of

Page 1223 of 3229

Publi s hed: 11-May-2011

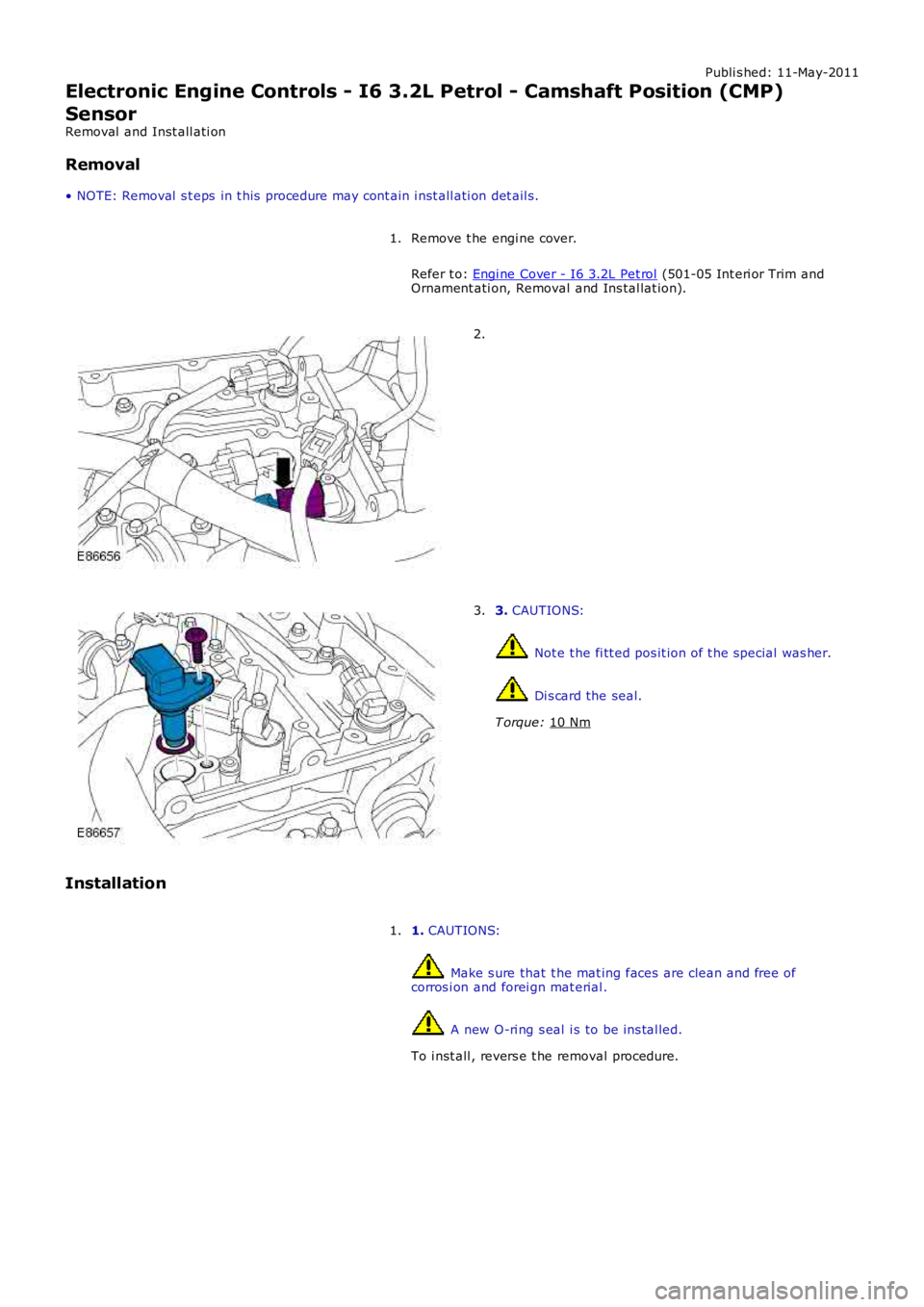

Electronic Engine Controls - I6 3.2L Petrol - Camshaft Position (CMP)

Sensor

Removal and Inst all ati on

Removal

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

Remove t he engi ne cover.

Refer t o: Engi ne Cover - I6 3.2L Pet rol (501-05 Int eri or Trim and

Ornament ati on, Removal and Ins tal lat ion).

1. 2.

3.

CAUTIONS: Not e t he fi tt ed pos it ion of t he special was her.

Di s card the seal.

T orque: 10 Nm 3.

Installation 1. CAUTIONS: Make s ure that t he mat ing faces are clean and free of

corros i on and forei gn mat erial . A new O-ri ng s eal i s to be ins tal led.

To i nst all , revers e t he removal procedure.

1.

Page 1224 of 3229

Publi s hed: 11-May-2011

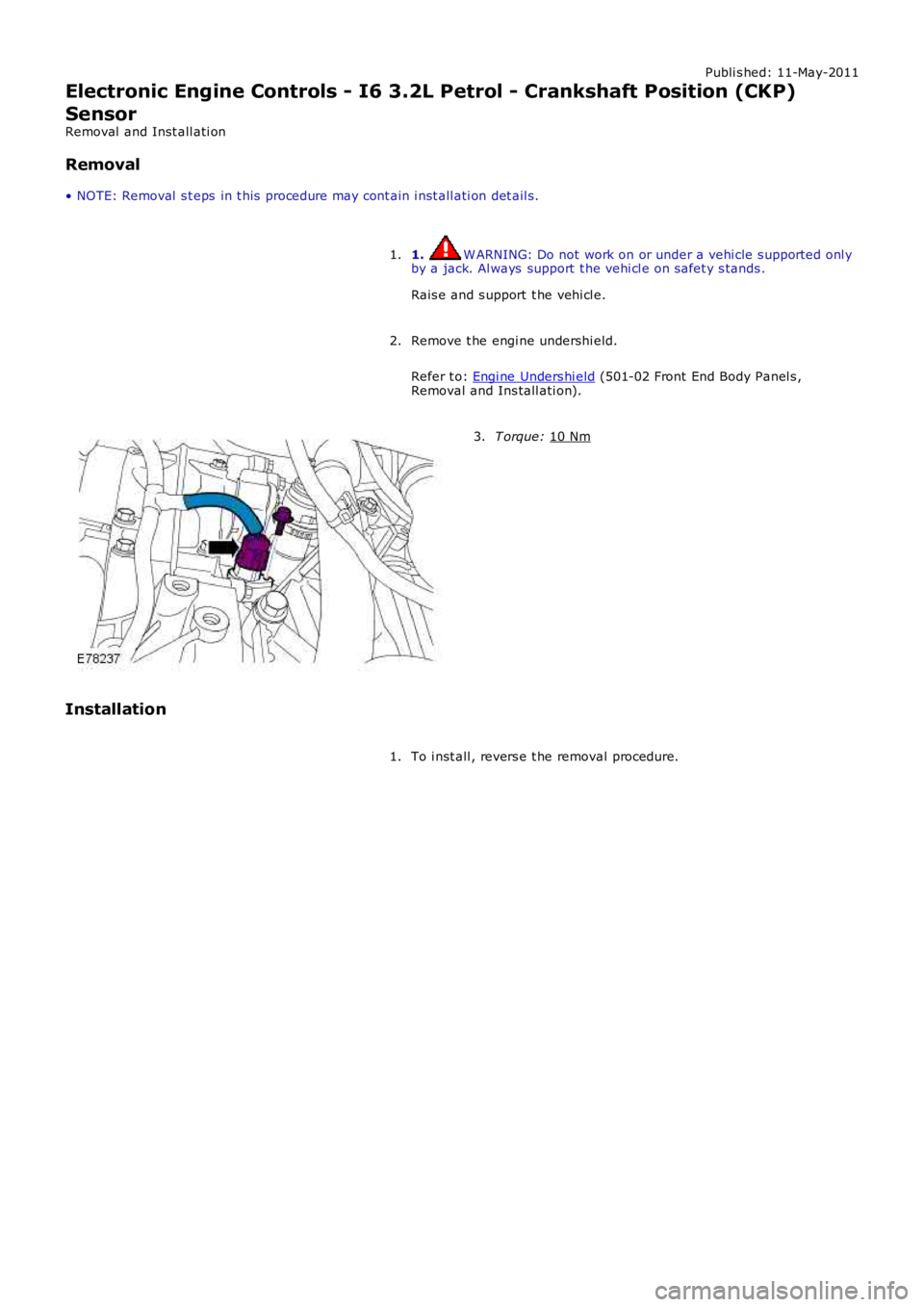

Electronic Engine Controls - I6 3.2L Petrol - Crankshaft Position (CKP)

Sensor

Removal and Inst all ati on

Removal

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

1. W ARNING: Do not work on or under a vehi cle s upported onl y

by a jack. Al ways support t he vehi cl e on s afet y s tands .

Rais e and s upport t he vehi cl e.

1.

Remove t he engi ne undershi eld.

Refer t o: Engi ne Unders hi eld (501-02 Front End Body Panel s ,

Removal and Ins tall ati on).

2. T orque:

10 Nm 3.

Installation To i nst all , revers e t he removal procedure.

1.

Page 1225 of 3229

Publi s hed: 11-May-2011

Electronic Engine Controls - I6 3.2L Petrol - Engine Coolant Temperature

(ECT) Sensor

Removal and Inst all ati on

Removal

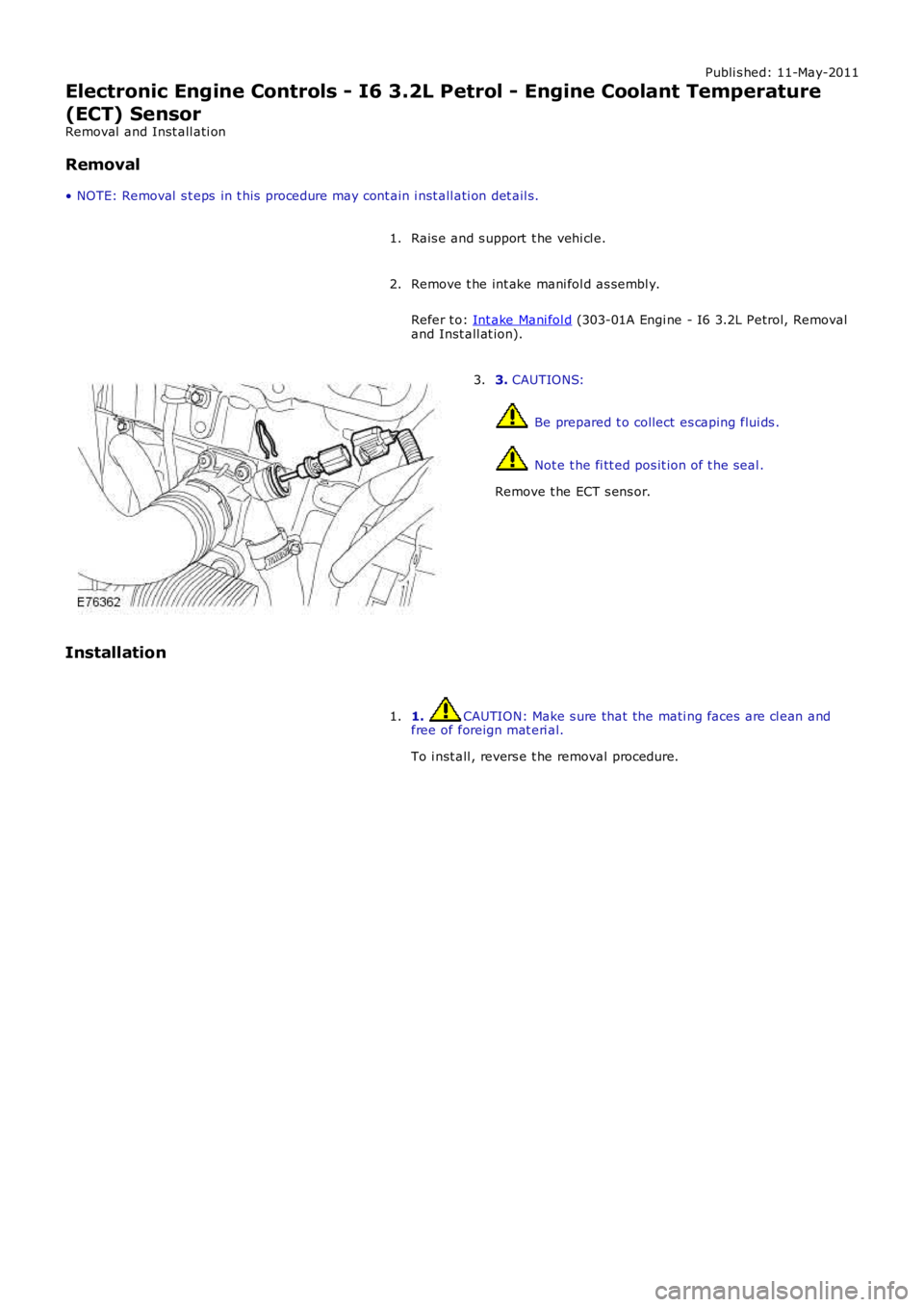

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

Rais e and s upport t he vehi cl e.1.

Remove t he int ake mani fol d as sembl y.

Refer t o: Int ake Mani fol d (303-01A Engi ne - I6 3.2L Petrol, Removaland Inst all at ion).

2.

3. CAUTIONS:

Be prepared t o collect es caping flui ds .

Not e t he fi tt ed pos it ion of t he seal .

Remove t he ECT s ens or.

3.

Installation

1. CAUTION: Make s ure that the mati ng faces are cl ean andfree of foreign mat eri al.

To i nst all , revers e t he removal procedure.

1.

Page 1226 of 3229

Publi s hed: 11-May-2011

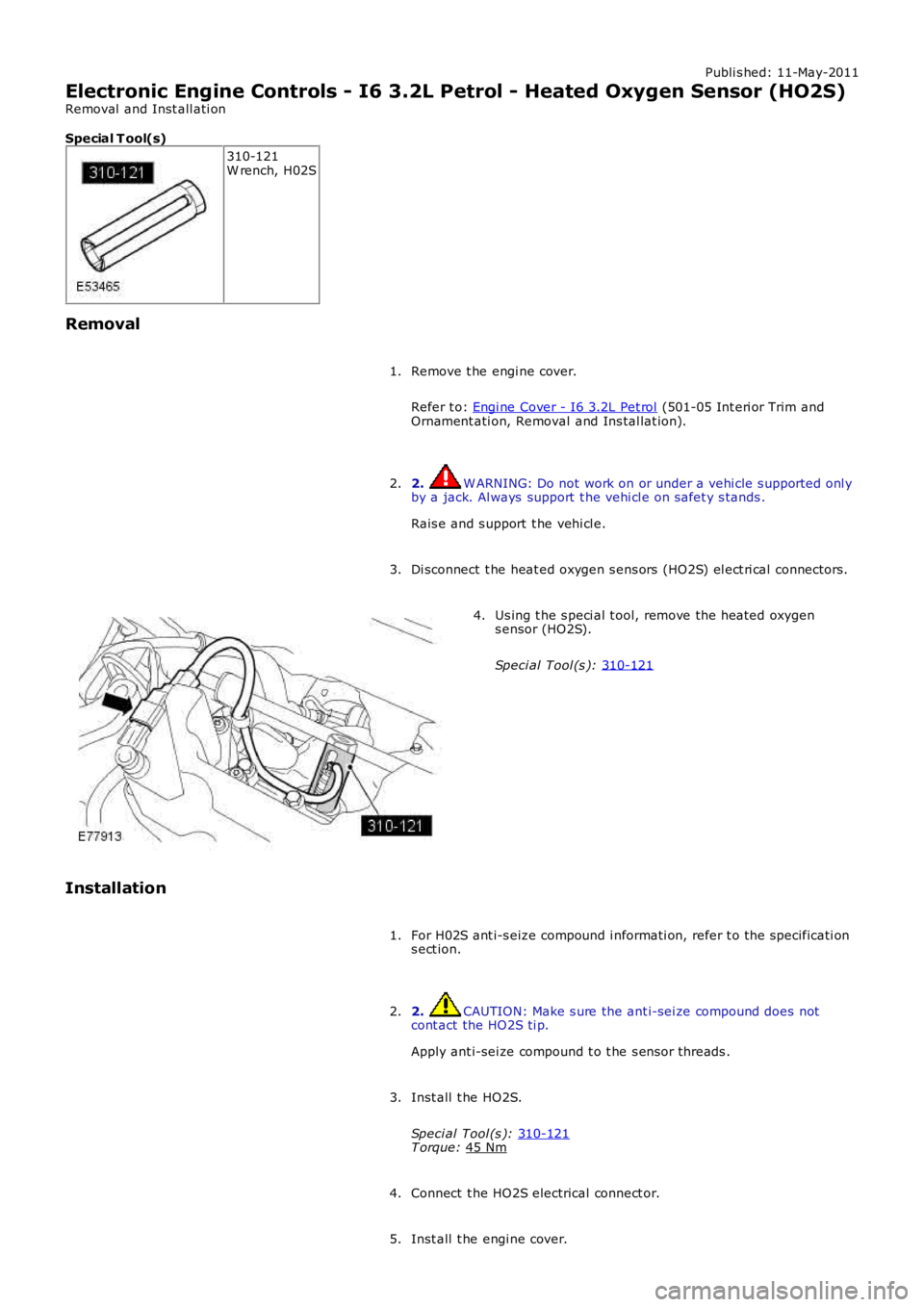

Electronic Engine Controls - I6 3.2L Petrol - Heated Oxygen Sensor (HO2S)

Removal and Inst all ati on

Special T ool(s) 310-121

W rench, H02S

Removal Remove t he engi ne cover.

Refer t o: Engi ne Cover - I6 3.2L Pet rol (501-05 Int eri or Trim and

Ornament ati on, Removal and Ins tal lat ion).

1.

2. W ARNING: Do not work on or under a vehi cle s upported onl y

by a jack. Al ways support t he vehi cl e on s afet y s tands .

Rais e and s upport t he vehi cl e.

2.

Di sconnect t he heat ed oxygen s ens ors (HO2S) el ect ri cal connectors .

3. Us ing t he s peci al t ool, remove the heated oxygen

s ensor (HO2S).

Speci al Tool (s ): 310-121 4.

Installation For H02S ant i-s eize compound i nformati on, refer t o the specificati on

s ect ion.

1.

2. CAUTION: Make s ure the ant i-sei ze compound does not

cont act the HO2S ti p.

Apply ant i-sei ze compound t o t he s ens or threads .

2.

Inst all t he HO2S.

Speci al Tool (s ): 310-121 T orque:

45 Nm 3.

Connect t he HO2S electrical connect or.

4.

Inst all t he engi ne cover.

5.