sensor LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1525 of 3229

Publi s hed: 11-May-2011

Exhaust System - TD4 2.2L Diesel -

Lubricants, Fluids, Sealers and AdhesivesItemSpecification

Heated oxygen s ens or (H02S) removal*W D40 or s uit able al ternat ive

Heated oxygen s ens or (H02S) t hreadsApply s uit able hi gh temperat ure ant i-s ei ze compound t o t hreads of s ens or* Apply to area around sensor threads prior to attempting to remove sensor

General Specification

ItemSpecificationCatal yt ic convert ers -t ype/locat ionAn oxidizi ng cat alyti c convert er is fit t ed in t he front s ect ion of t he exhaus t s ys t em

Exhaus t manifold -Locat ionA mani fold ass embly is fit ted to t he cylinder head.

Exhaus t s yst emStai nl ess st eel exhaust s ys tem s uppl ied as t wo s eparate ass embli es. Front s ecti on incorporat inga catal yt ic converter and a rear s ect ion i ncorporat ing a rear s il encer

Torque Specifications

DescriptionNmlb-ft

Catal yt ic convert er t o center s ect ion retai ning clamp4030Catal yt ic convert er t o t urbocharger hous ing retaini ng clamp107

Exhaus t manifold el bow t o EGR cool er2518

Exhaus t manifold heat s hield bol ts107Exhaus t manifold heat s hield nut s107

Exhaus t manifold retai ni ng nuts2418

Exhaus t manifold retai ni ng s tuds75Exhaus t s upport bracket s t o s ubframe / fl oor2518

Heated oxygen s ens or (H02S)++4533

+ Apply anti-seize lubricant to threads of sensor - See Lubricants

Page 1533 of 3229

DPF Air Management Module

The DPF air management modul e control s t he fol lowing funct ions :

EGR controlTurbocharger boos t pres sure cont rolInt ake air t emperature and pres s ure control.

Duri ng act ive regenerat ion, t he EGR operat ion i s dis abl ed and t he cl osed-loop acti vat ion of t he t urbocharger boostcont rol ler is calculat ed. The ai r management module cont rols the ai r in t he int ake manifol d t o a predet ermi ned level ofpres s ure and t emperat ure. Thi s cont rol i s required t o achi eve the correct i n-cylinder condi ti ons for s table and robustcombus t ion of t he post i njected fuel.

The module controls t he i nt ake air t emperature by actuati ng t he EGR t hrott le and by adjus tment of t he turbocharger boos tpres s ure control.

DPF Co-ordinator Module

The DPF co-ordi nat or module react s t o a regenerat ion reques t from the s upervis or module by i nit iat ing and co-ordi nat ingt he foll owing DPF regenerat ion reques t s :

EGR cut-offTurbocharger boos t pres sure cont rolEngi ne load i ncreaseControl of air press ure and temperat ure in t he i nt ake manifoldFuel i njecti on cont rol.

W hen t he s upervis or modul e i ss ues a regenerat ion reques t , the co-ordinator module reques t s EGR cut-off and aregenerat ion s peci fi c turbocharger boos t pres s ure control. It then wai ts for a feedback s ignal from t he EGR s ys t emconfirming that the EGR val ve is cl osed.

W hen t he EGR valve i s clos ed, t he co-ordi nator module i nit iat es reques t s t o increas e engine l oad by cont roll ing t he i nt akeair t emperature and pres s ure.

Once confirmati on is recei ved that int ake condit ions are cont rol led or a cali brati on t ime has expired, the co-ordinatormodule t hen changes t o a s t ate awai ti ng an accelerator pedal release manoeuver from t he dri ver. If t his occurs or acal ibrat ion ti me has expired, t he co-ordi nat or modul e generates a request t o control fuel injecti ons to increas e exhaus tgas temperature.

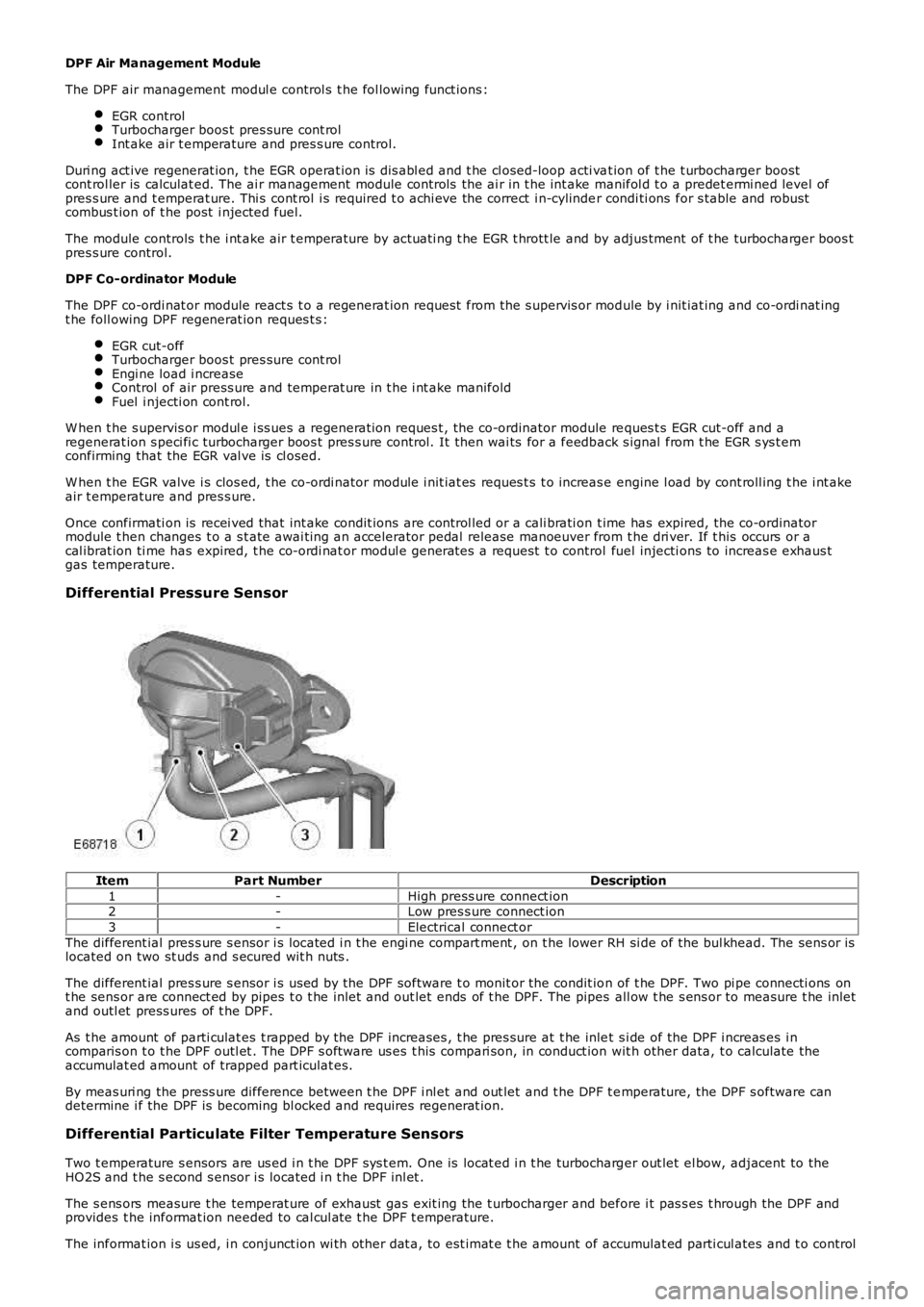

Differential Pressure Sensor

ItemPart NumberDescription

1-High press ure connect ion2-Low pres s ure connect ion

3-Electrical connect or

The different ial pres s ure s ensor i s located i n t he engi ne compart ment , on t he lower RH si de of the bul khead. The sens or islocated on two st uds and s ecured wit h nuts .

The different ial pres s ure s ensor i s us ed by the DPF software t o monit or the condit ion of t he DPF. Two pi pe connecti ons ont he sens or are connect ed by pipes t o t he inlet and out let ends of t he DPF. The pipes all ow t he s ens or to measure t he inletand outl et press ures of t he DPF.

As t he amount of parti culat es t rapped by the DPF increases , t he pres sure at t he inlet s i de of the DPF i ncreas es i ncomparis on t o t he DPF outl et . The DPF s oft ware us es t his compari son, in conduct ion wit h other data, t o calculate theaccumulat ed amount of trapped part iculat es.

By meas uri ng the press ure difference between t he DPF i nl et and out let and t he DPF t emperature, the DPF s oftware candetermine i f the DPF is becoming bl ocked and requires regenerat ion.

Differential Particulate Filter Temperature Sensors

Two t emperature s ensors are us ed i n t he DPF s ys t em. One is locat ed i n t he turbocharger out let el bow, adjacent to theHO2S and t he s econd s ensor i s located i n t he DPF inl et .

The s ens ors measure t he temperat ure of exhaust gas exit ing the t urbocharger and before i t pas s es t hrough the DPF andprovides t he informat ion needed to cal cul at e t he DPF t emperature.

The informat ion i s us ed, i n conjunct ion wi th other dat a, to est imat e t he amount of accumulat ed parti cul ates and t o control

Page 1548 of 3229

Publi s hed: 11-May-2011

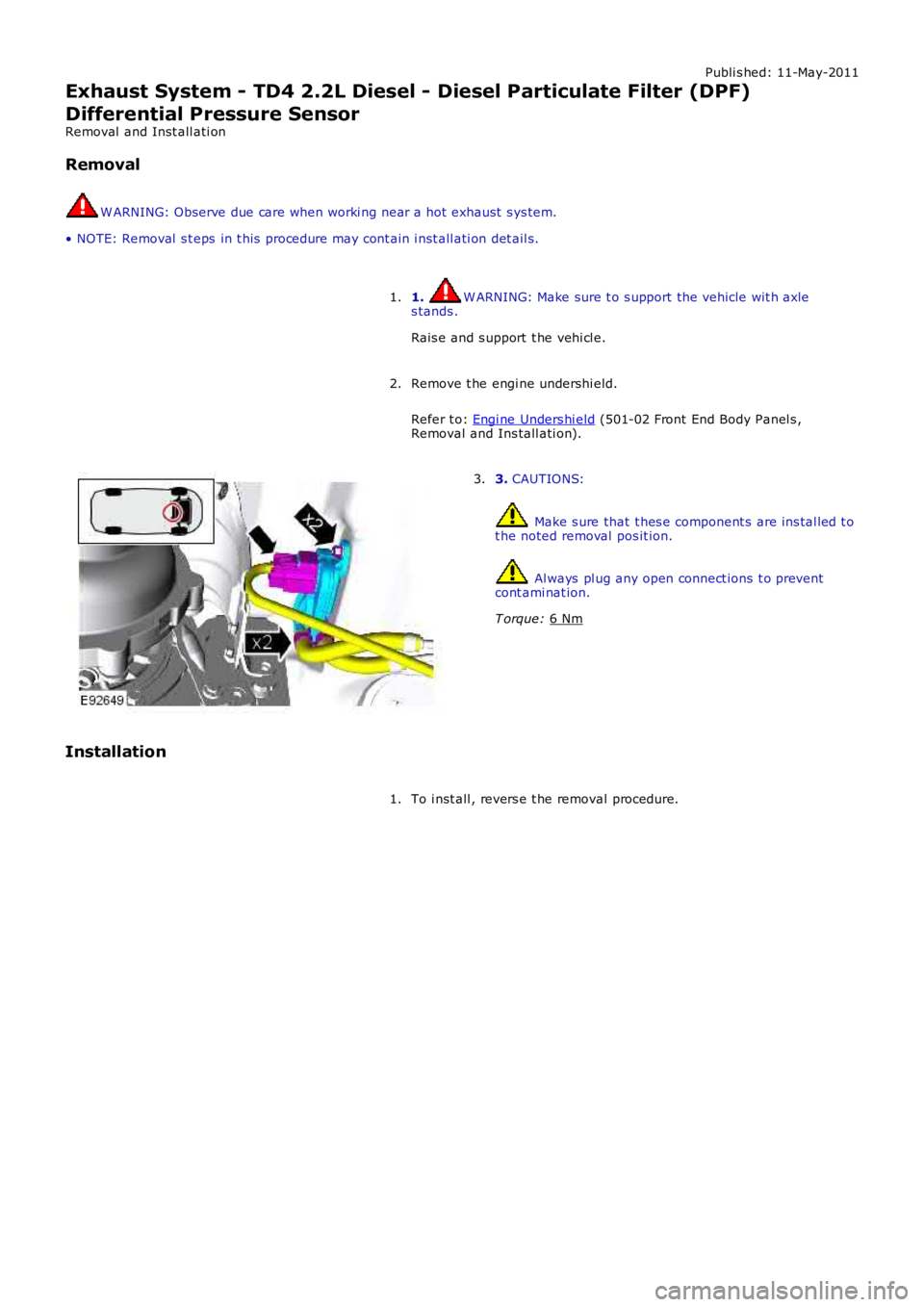

Exhaust System - TD4 2.2L Diesel - Diesel Particulate Filter (DPF)

Differential Pressure Sensor

Removal and Inst all ati on

Removal W ARNING: Observe due care when worki ng near a hot exhaust s ys tem.

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

1. W ARNING: Make sure t o s upport the vehicle wit h axle

s tands .

Rais e and s upport t he vehi cl e.

1.

Remove t he engi ne undershi eld.

Refer t o: Engi ne Unders hi eld (501-02 Front End Body Panel s ,

Removal and Ins tall ati on).

2. 3.

CAUTIONS: Make s ure that t hes e component s are ins tal led t o

t he noted removal pos it ion. Al ways pl ug any open connect ions t o prevent

cont ami nat ion.

T orque: 6 Nm 3.

Installation To i nst all , revers e t he removal procedure.

1.

Page 1579 of 3229

Publi s hed: 11-May-2011

Fuel Tank and Lines - TD4 2.2L Diesel -

C apacitiesItemCapacity (liters/gallons)

Fuel t ank68.0/14.9

General Specification

ItemSpecification

Fuel del ivery modulePAG ModuleLocat ionin the RH si de of the tank

Maximum output @12.5 vol ts160l /hr

Operat ing press ure0.2 BarFuel t ank s ender unit sMAgnet ic Pas s ive Pos it ion Sensor (MAPPS)

Torque Specifications

DescriptionNmlb-ft

Degas nipple1511Fuel fil ter brackets2518

Fuel fil ter cover nut s97

Fuel fil ter t o ret aini ng bracket bolt97Fuel press ure pipe t o block107

Fuel pump bol ts2216

Fuel t ank bolt s*2518Fuel t ank fi ll er pi pe bracket s107

* New nuts/bolts must be fitted

Page 1593 of 3229

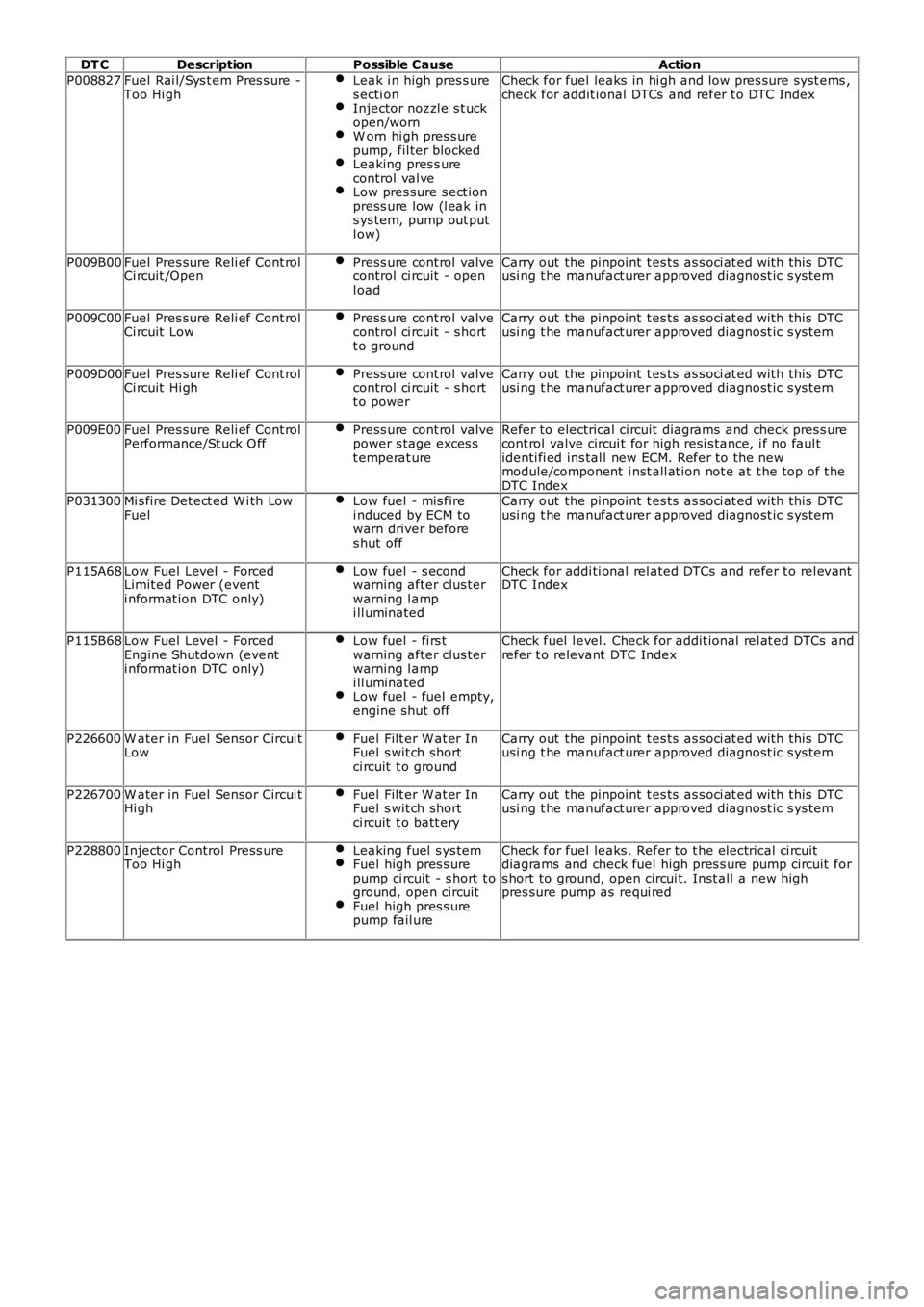

DT C

Description Possible Cause Action

P008827 Fuel Rai l/Sys t em Pres s ure -

Too Hi gh Leak i n high pres s ure

s ecti on Injector nozzl e s t uck

open/worn W orn hi gh pres s ure

pump, fil ter blocked Leaking pres s ure

control val ve Low pres sure s ect ion

press ure low (l eak in

s ys tem, pump out put

l ow) Check for fuel leaks in hi gh and low pres sure s yst ems ,

check for addit ional DTCs and refer t o DTC Index

P009B00 Fuel Pres sure Reli ef Cont rol

Ci rcuit /Open Press ure cont rol valve

control ci rcuit - open

l oad Carry out the pi npoint t es ts as s oci at ed wi th this DTC

usi ng t he manufact urer approved diagnost ic s ys tem

P009C00 Fuel Pres sure Reli ef Cont rol

Ci rcuit Low Press ure cont rol valve

control ci rcuit - s hort

t o ground Carry out the pi npoint t es ts as s oci at ed wi th this DTC

usi ng t he manufact urer approved diagnost ic s ys tem

P009D00 Fuel Pres sure Reli ef Cont rol

Ci rcuit Hi gh Press ure cont rol valve

control ci rcuit - s hort

t o power Carry out the pi npoint t es ts as s oci at ed wi th this DTC

usi ng t he manufact urer approved diagnost ic s ys tem

P009E00 Fuel Pres sure Reli ef Cont rol

Performance/St uck O ff Press ure cont rol valve

power s tage exces s

t emperat ure Refer to electrical ci rcuit diagrams and check pres s ure

cont rol valve circui t for high resi s tance, i f no faul t

identi fi ed ins tal l new ECM. Refer to the new

module/component i nst all at ion not e at t he top of t he

DTC Index

P031300 Mi s fire Det ect ed W i th Low

Fuel Low fuel - mis fire

i nduced by ECM to

warn driver before

s hut off Carry out the pi npoint t es ts as s oci at ed wi th this DTC

usi ng t he manufact urer approved diagnost ic s ys tem

P115A68 Low Fuel Level - Forced

Limit ed Power (event

i nformat ion DTC only) Low fuel - s econd

warning after clus ter

warning l amp

i ll uminated Check for addi ti onal rel ated DTCs and refer t o rel evant

DTC Index

P115B68 Low Fuel Level - Forced

Engine Shutdown (event

i nformat ion DTC only) Low fuel - fi rs t

warning after clus ter

warning l amp

i ll uminated Low fuel - fuel empty,

engine shut off Check fuel l evel . Check for addit ional rel at ed DTCs and

refer t o relevant DTC Index

P226600 W ater in Fuel Sensor Circui t

Low Fuel Filt er W at er In

Fuel s wit ch short

ci rcuit t o ground Carry out the pi npoint t es ts as s oci at ed wi th this DTC

usi ng t he manufact urer approved diagnost ic s ys tem

P226700 W ater in Fuel Sensor Circui t

Hi gh Fuel Filt er W at er In

Fuel s wit ch short

ci rcuit t o batt ery Carry out the pi npoint t es ts as s oci at ed wi th this DTC

usi ng t he manufact urer approved diagnost ic s ys tem

P228800 Injector Control Press ure

Too Hi gh Leaking fuel s ys tem Fuel high pres s ure

pump ci rcuit - s hort t o

ground, open circuit Fuel high pres s ure

pump fail ure Check for fuel leaks. Refer t o t he electrical ci rcuit

diagrams and check fuel high pres s ure pump circuit for

s hort to ground, open circui t. Inst all a new high

pres sure pump as requi red

Page 1617 of 3229

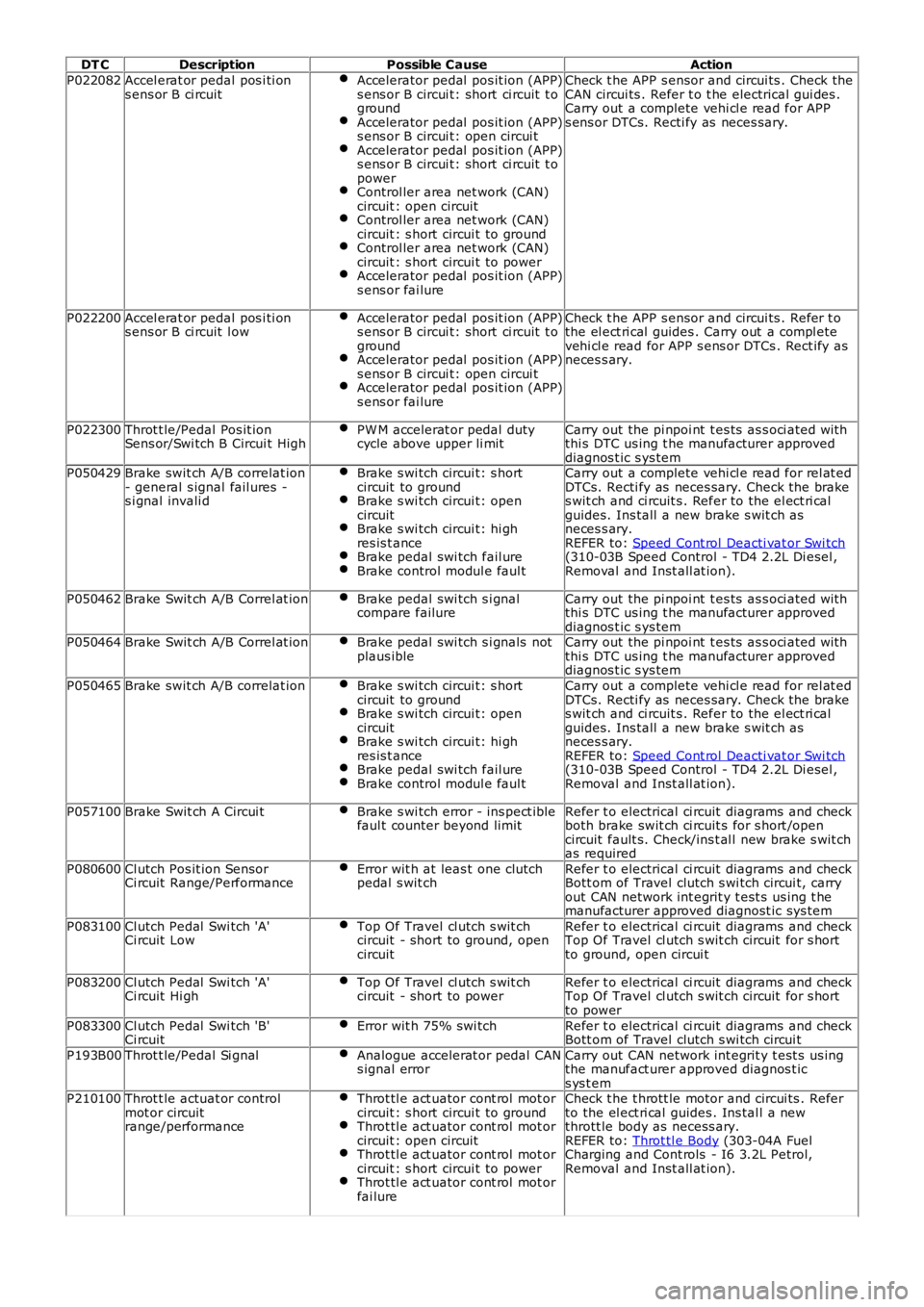

DT CDescriptionPossible CauseAction

P022082Accel erat or pedal pos i ti ons ens or B ci rcuitAccelerator pedal pos it ion (APP)s ens or B circui t: short ci rcuit t ogroundAccelerator pedal pos it ion (APP)s ens or B circui t: open circui tAccelerator pedal pos it ion (APP)s ens or B circui t: short ci rcuit t opowerControl ler area net work (CAN)circuit : open circuitControl ler area net work (CAN)circuit : s hort circui t to groundControl ler area net work (CAN)circuit : s hort circui t to powerAccelerator pedal pos it ion (APP)s ens or fai lure

Check t he APP s ensor and circui ts . Check theCAN circui ts . Refer t o t he electrical gui des .Carry out a complete vehi cl e read for APPs ens or DTCs. Recti fy as neces sary.

P022200Accel erat or pedal pos i ti ons ens or B ci rcuit l owAccelerator pedal pos it ion (APP)s ens or B circui t: short ci rcuit t ogroundAccelerator pedal pos it ion (APP)s ens or B circui t: open circui tAccelerator pedal pos it ion (APP)s ens or fai lure

Check t he APP s ensor and circui ts . Refer t othe el ect ri cal guides . Carry out a compl etevehi cl e read for APP s ens or DTCs . Rect ify asneces s ary.

P022300Throt t le/Pedal Pos it ionSens or/Swi tch B Circui t HighPW M accelerat or pedal dutycycle above upper li mitCarry out the pi npoi nt t es ts as s oci ated wi ththi s DTC us ing t he manufacturer approveddiagnos t ic s ys temP050429Brake swit ch A/B correlat ion- general s ignal fail ures -s i gnal invali d

Brake s wi tch circui t: s hortcircuit to groundBrake s wi tch circui t: opencircuitBrake s wi tch circui t: hi ghres is t anceBrake pedal swi tch fail ureBrake control modul e faul t

Carry out a complete vehi cl e read for rel at edDTCs. Recti fy as neces sary. Check the brakes wit ch and ci rcuit s . Refer to the el ect ri calguides. Ins tall a new brake s wit ch asneces s ary.REFER to: Speed Cont rol Deacti vat or Swi tch(310-03B Speed Control - TD4 2.2L Di esel ,Removal and Inst all at ion).

P050462Brake Swit ch A/B Correl at ionBrake pedal swi tch s i gnalcompare failureCarry out the pi npoi nt t es ts as s oci ated wi ththi s DTC us ing t he manufacturer approveddiagnos t ic s ys temP050464Brake Swit ch A/B Correl at ionBrake pedal swi tch s i gnals notplaus ibleCarry out the pi npoi nt t es ts as s oci ated wi ththi s DTC us ing t he manufacturer approveddiagnos t ic s ys tem

P050465Brake swit ch A/B correlat ionBrake s wi tch circui t: s hortcircuit to groundBrake s wi tch circui t: opencircuitBrake s wi tch circui t: hi ghres is t anceBrake pedal swi tch fail ureBrake control modul e faul t

Carry out a complete vehi cl e read for rel at edDTCs. Recti fy as neces sary. Check the brakes wit ch and ci rcuit s . Refer to the el ect ri calguides. Ins tall a new brake s wit ch asneces s ary.REFER to: Speed Cont rol Deacti vat or Swi tch(310-03B Speed Control - TD4 2.2L Di esel ,Removal and Inst all at ion).

P057100Brake Swit ch A Circui tBrake s wi tch error - ins pect iblefaul t counter beyond limitRefer t o electrical ci rcuit diagrams and checkboth brake swit ch ci rcuit s for s hort /opencircuit fault s. Check/ins t al l new brake s wit chas required

P080600Cl utch Pos it ion SensorCi rcuit Range/PerformanceError wit h at leas t one clutchpedal s wit chRefer t o electrical ci rcuit diagrams and checkBott om of Travel clutch s wi tch circui t, carryout CAN network int egrit y t est s us ing t hemanufacturer approved diagnost ic sys tem

P083100Cl utch Pedal Swi tch 'A'Ci rcuit LowTop Of Travel cl utch s wit chcircuit - short to ground, opencircuit

Refer t o electrical ci rcuit diagrams and checkTop Of Travel cl utch s wit ch circuit for s hortto ground, open circui t

P083200Cl utch Pedal Swi tch 'A'Ci rcuit Hi ghTop Of Travel cl utch s wit chcircuit - short to powerRefer t o electrical ci rcuit diagrams and checkTop Of Travel cl utch s wit ch circuit for s hortto power

P083300Cl utch Pedal Swi tch 'B'Ci rcuitError wit h 75% swi tchRefer t o electrical ci rcuit diagrams and checkBott om of Travel clutch s wi tch circui t

P193B00Throt t le/Pedal Si gnalAnalogue accelerat or pedal CANs ignal errorCarry out CAN network int egrit y t est s us ingthe manufact urer approved diagnos t ics ys t emP210100Throt t le actuat or controlmot or circuitrange/performance

Throt tl e act uator cont rol mot orcircuit : s hort circui t to groundThrot tl e act uator cont rol mot orcircuit : open circuitThrot tl e act uator cont rol mot orcircuit : s hort circui t to powerThrot tl e act uator cont rol mot orfai lure

Check t he t hrott le motor and circui ts . Referto the el ect ri cal guides . Ins tal l a newthrott le body as necess ary.REFER to: Throt tl e Body (303-04A FuelCharging and Cont rols - I6 3.2L Petrol,Removal and Inst all at ion).

Page 1628 of 3229

Publi s hed: 11-May-2011

Climate Control System - General Information -

C limate C ontrolT ypeDescription

Heati ng, venti lat ion and ai rcondi ti oni ng unitManual s ingle zone or a dual zone aut omati c s yst em fit t ed. Bot h s ys t emscont roll ed by ATC module.Compressor:

3.2L Pet rolZexel-Valeo KC-88 external ly control led variable di spl acement A/C compres sor

2.2L Dies elVis teon VS16 i nternal ly control led variable di spl acement A/C compres sor

Lubricants, Fluids, Sealers and AdhesivesItemSpecification

Compres s or oi lW SH-M1C321-B

RefrigerantR134a (CF³CH²F)

General SpecificationItemDescription

Compres s or - 3.2L PetrolZexel -Valeo KC-88

Compres s or - 2.2L Di es elVis t eon VS16Sensor locations:

Ambi ent t emperat ure s ensorLH Door mirror

Cabin t emperat ure s ens or (dual zones yst ems only)Mount ed behind a gril l on the drivers si de of the ins trument panel, adjacentthe st eeri ng col umn.

cabi n humi di ty sens or (Opt ional fit )located wi thi n t he int erior mi rror and compris es 3 i ndi vidual el ement s

Evaporati ve temperat ure sens orMount ed on t he LH s i de of the heater casi ngHi gh pres sure s ens orLocat ed bet ween t he condenser and t he t hermos tat ic expans ion val ve

Poll ut ion sens orRH s ide of t he heater casi ng.

Solar s ens orCent er of das h t op

C apacitiesItemCapacity

Total s yst em capaci ty730 grams ± 10 grams

Page 1640 of 3229

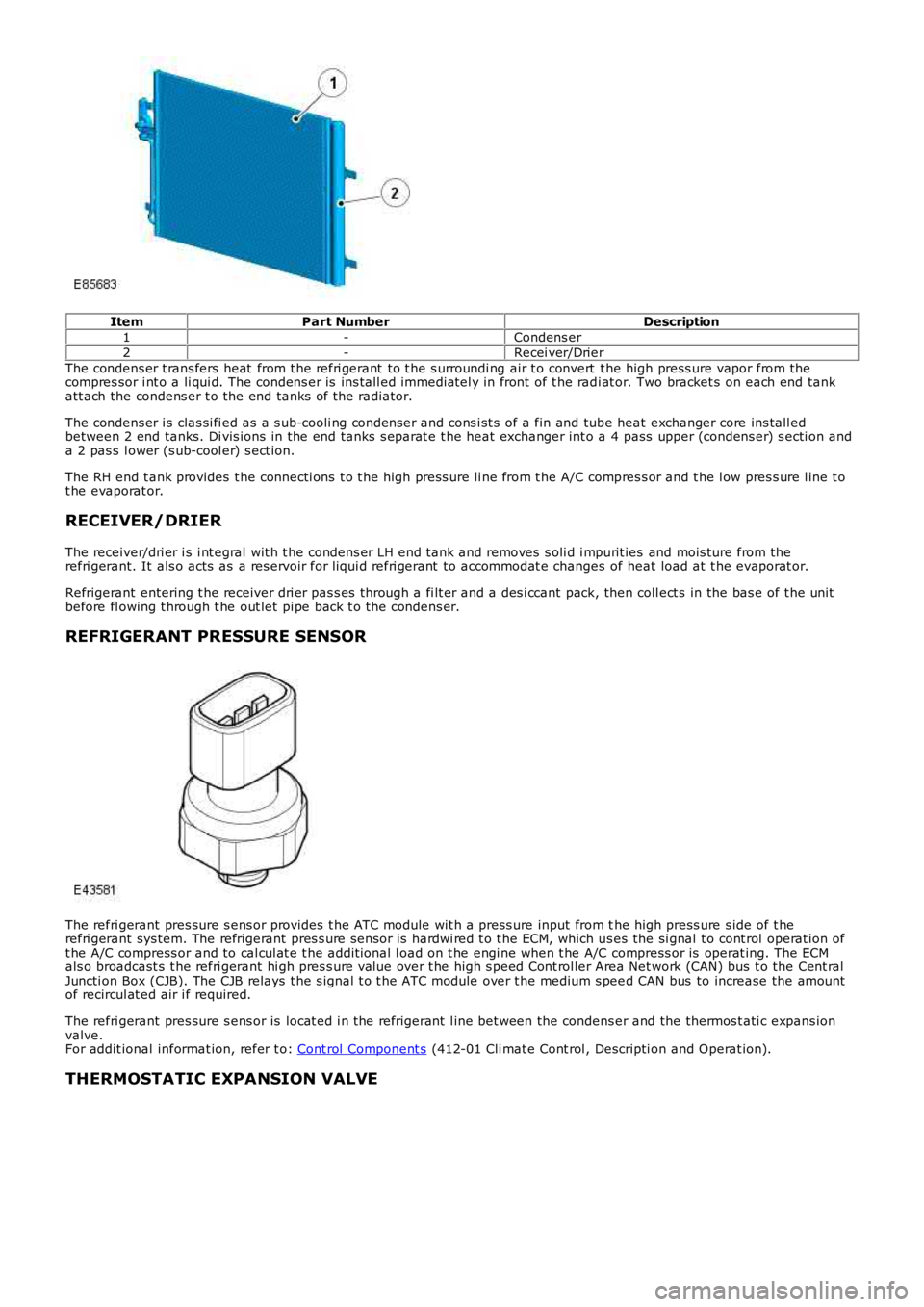

ItemPart NumberDescription

1-Condens er2-Recei ver/Drier

The condens er t rans fers heat from t he refri gerant to t he s urroundi ng air t o convert t he high press ure vapor from thecompres sor i nt o a li qui d. The condens er is ins tall ed immediatel y in front of t he radi at or. Two bracket s on each end tankatt ach the condens er t o the end tanks of the radiator.

The condens er i s clas si fi ed as a s ub-cooli ng condenser and cons i st s of a fin and tube heat exchanger core ins tall edbetween 2 end tanks. Di vis ions in the end tanks s eparat e t he heat exchanger int o a 4 pass upper (condens er) s ecti on anda 2 pas s l ower (s ub-cool er) s ect ion.

The RH end t ank provides t he connecti ons t o t he high press ure li ne from t he A/C compres s or and t he l ow pres s ure l ine t ot he evaporat or.

RECEIVER/DRIER

The receiver/dri er i s i nt egral wit h t he condens er LH end tank and removes s oli d i mpurit ies and mois ture from therefri gerant. It als o acts as a res ervoir for liqui d refri gerant to accommodat e changes of heat load at t he evaporat or.

Refrigerant entering t he receiver dri er pas s es through a fi lt er and a des i ccant pack, then coll ect s in the bas e of t he unitbefore fl owing t hrough t he out let pi pe back t o t he condens er.

REFRIGERANT PRESSURE SENSOR

The refri gerant pres sure s ens or provides t he ATC module wit h a press ure input from the high press ure s ide of t herefri gerant sys tem. The refrigerant pres s ure sens or is hardwi red t o t he ECM, which us es the si gnal t o cont rol operat ion oft he A/C compress or and to cal cul at e t he addit ional l oad on t he engi ne when t he A/C compress or is operat ing. The ECMals o broadcast s t he refri gerant hi gh pres s ure value over t he high s peed Cont rol ler Area Net work (CAN) bus t o the Cent ralJuncti on Box (CJB). The CJB relays t he s ignal t o t he ATC module over t he medium s peed CAN bus to increase the amountof recircul at ed air i f required.

The refri gerant pres sure s ens or is locat ed i n the refrigerant l ine bet ween the condens er and the thermos t ati c expans ionvalve.For addit ional informat ion, refer t o: Cont rol Component s (412-01 Cli mat e Cont rol , Descripti on and Operat ion).

THERMOSTATIC EXPANSION VALVE

Page 1644 of 3229

Publishe d: 11-May-2011

Climate Control - Control ComponentsDescripti on a nd O pe ration

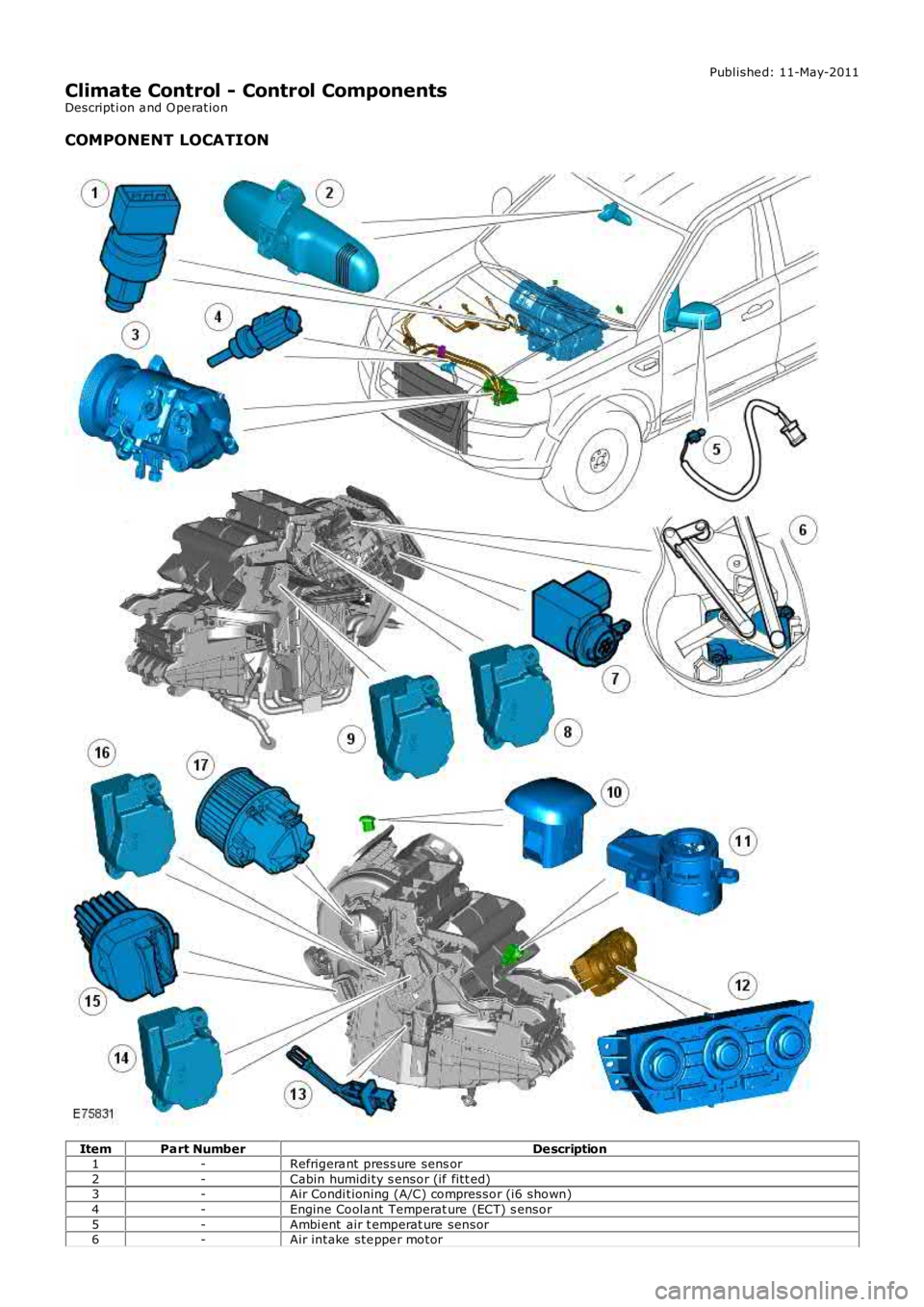

COMPONENT LOCATION

ItemPart NumberDe scription1-Refrigera nt press ure sens or2-Cabin humidi ty s ensor (if fitt ed)3-Air Condi tioning (A/C) compressor (i6 shown)4-Engine Coola nt Temperat ure (ECT) s ensor5-Ambi ent air t emperat ure sensor6-Air intake ste ppe r motor

Page 1645 of 3229

7-P ollution sensor (if fi tted)8-W indshie ld distri buti on (defrost) ste pper motor9-Right Hand (RH) tempera ture ble nd s tepper mot or10-Sunload s ens or11-Cabin temperature se nsor12-Automati c Te mpe rature Cont rol (ATC) modul e13-Evaporator te mpe rature s ens or14-Left Hand (LH) te mpe rature blend st eppe r motor15-Blowe r motor control module16-Face/feet dis tribution ste ppe r motor17-Blowe r motor

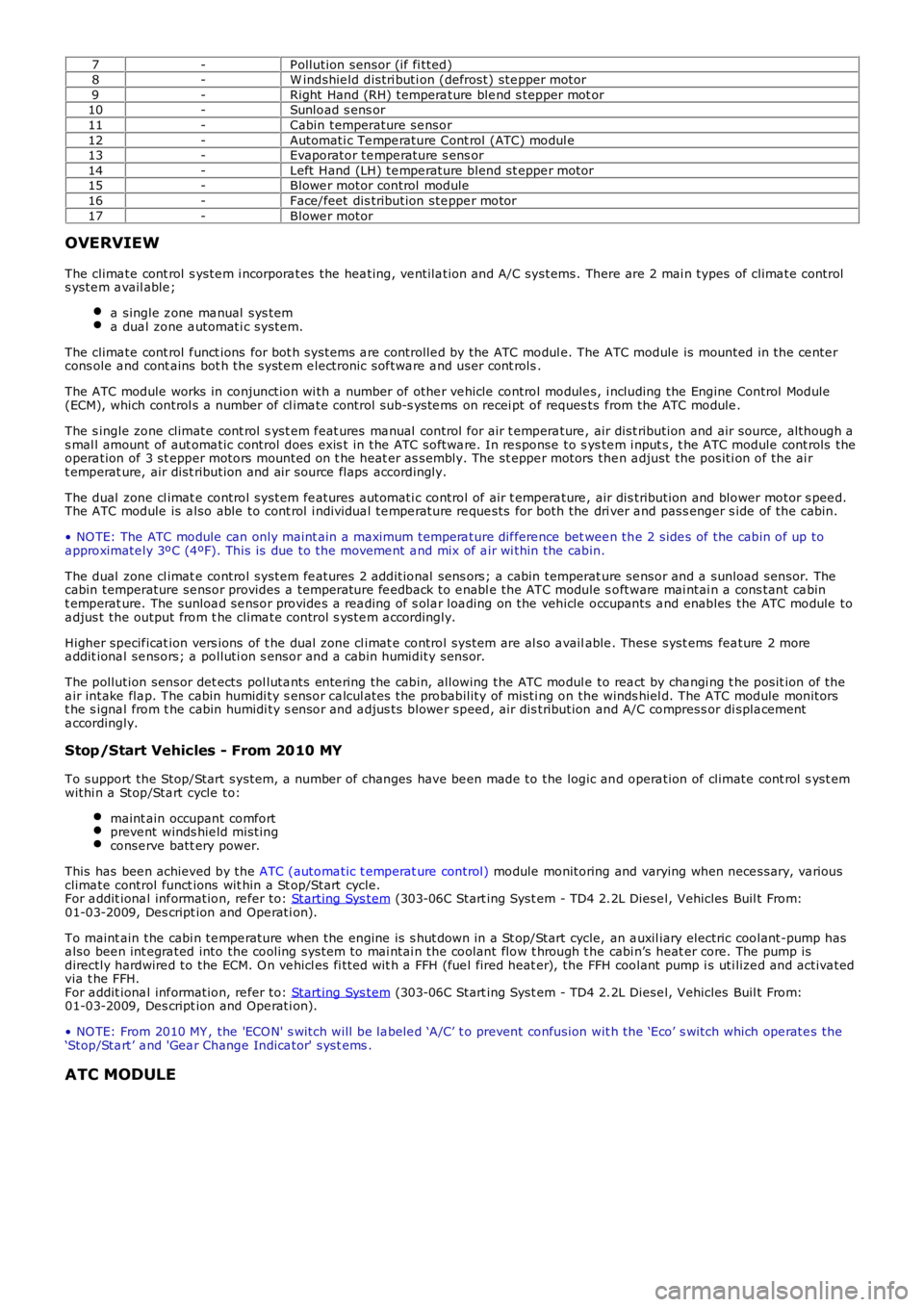

OVERVIEW

The clima te cont rol s yste m i ncorpora tes the hea ting, ve ntila tion and A/C systems. There are 2 mai n types of clima te controls yste m a vail able ;

a single z one ma nual sys tema dua l zone a utomati c system.

The clima te cont rol f unct ions for bot h systems a re controlle d by the ATC modul e. The ATC module is mounted in the ce nte rcons ole a nd cont ains bot h the syste m e lectronic sof twa re a nd user cont rols .

The ATC module works in conjunction wi th a number of othe r ve hicle control module s, i ncluding the Engine Control Module(ECM), which control s a number of cl ima te control sub-s yste ms on recei pt of reques ts f rom the ATC module .

The s ingle zone climate cont rol s yst em f eat ures ma nual control for air t empera ture , air dist ribution and air source, although as mal l amount of aut oma tic control does exis t in the ATC softwa re. In re sponse to s yste m i nput s, t he ATC module cont rols theopera tion of 3 st epper motors mounted on t he heat er as sembly. The st eppe r motors then a djust the positi on of the ai rt emperat ure, air dist ribution and air source flaps accordingly.

The dual zone cl imat e control system fe atures a utomati c control of air t empera ture , air dis tribution and blower motor s pee d.The ATC module is a lso able to cont rol i ndividua l te mpe rature re que sts for both the dri ver a nd pass enger s ide of the cabin.

• NO TE: The ATC module can only maint ain a maximum tempera ture dif fere nce bet wee n the 2 side s of the cabin of up toa pproximate ly 3ºC (4ºF). This is due to the moveme nt a nd mix of a ir wi thin the cabin.

The dual zone cl imat e control system fe atures 2 additional sens ors; a cabin temperature se nsor and a sunload sensor. Thecabin temperature se nsor provides a temperature fe edback to e nabl e the ATC module s oftware mai ntai n a cons tant ca bint emperat ure. The sunloa d se nsor provide s a rea ding of s ola r loa ding on the vehicle occupants a nd enables the ATC module toa djus t the output from t he clima te control s yste m a ccordingly.

Higher specif icat ion vers ions of t he dual zone cl imat e control system are al so a vailable . These syst ems fea ture 2 morea ddit iona l se nsors; a polluti on s ensor and a cabin humidity sensor.

The pollution sensor det ects pol luta nts ente ring the cabin, allowing the ATC modul e to rea ct by cha ngi ng t he posit ion of thea ir intake fla p. The cabin humidi ty s ensor ca lcul ates the probability of misti ng on the winds hiel d. The ATC module monitorst he s igna l from t he cabin humidi ty s ensor and a djus ts blowe r speed, air dis tribution and A/C compress or di spla cementa ccordingly.

Stop/Start Vehicles - From 2010 MY

To support the Stop/Start system, a number of changes have be en made to the logic and opera tion of climate cont rol s yst emwithi n a Stop/Sta rt cycle to:

maint ain occupant comfortpreve nt winds hie ld mistingconse rve batt ery power.

This has bee n achieved by the ATC (automa tic t emperat ure control) module monitoring and varying when nece ssary, va riousclima te control funct ions wit hin a St op/Start cycle.For a ddit iona l inf ormation, re fer to: Starting Sys tem (303-06C Start ing Syst em - TD4 2.2L Diese l, Vehicles Buil t From:01-03-2009, Des cript ion and Ope rati on).

To maint ain the cabi n te mpe rature when the engine is s hut down in a St op/Start cycle, an a uxil iary electric coolant-pump hasa lso bee n int egra ted into the cooling system to mai ntai n the coolant flow t hrough t he cabi n’s heat er core. The pump isdirectly hardwire d to the ECM. O n ve hicl es fi tted wit h a FFH (fue l fired heat er), the FFH coolant pump i s uti lize d and activa tedvia t he FFH.For a ddit iona l inf ormation, re fer to: Starting Sys tem (303-06C Start ing Syst em - TD4 2.2L Diese l, Vehicles Buil t From:01-03-2009, Des cript ion and Ope rati on).

• NO TE: From 2010 MY , the 'ECO N' s witch will be la bele d ‘A/C’ t o prevent confusion wit h the ‘Eco’ s witch which ope rate s the‘Stop/Sta rt’ a nd 'Gea r Change Indica tor' syst ems .

ATC MODULE