sensor LAND ROVER FRELANDER 2 2006 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 978 of 3229

Publi s hed: 11-May-2011

Fuel Charging and Controls - I6 3.2L Petrol - Fuel Charging and Controls

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the fuel chargi ng and cont rol s, refer t o the relevant Descri pti on and Operat ion s ect ion in t heworks hop manual .REFER to: Fuel Chargi ng and Controls (303-04A Fuel Chargi ng and Cont rol s - I6 3.2L Pet rol, Des cri pt ion and Operati on).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

• NOTE: For di agnos t ic purpos es the cyli nders are divided i nt o t wo banks: Bank 1 - Cyl inder numbers 1, 2 and 3. Bank 2 -Cylinders 4, 5 and 6

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

Visual Inspection

MechanicalElectricalFuel l evelFuel l eaksDamaged fuel l inesDamaged push connect fit t ingsFuel contami nati on/grade/quali tyThrot tl e bodyDamaged fuel t ank fi ller pipe capDamaged fuel t ank fi ller pipe

FusesLoos e or corroded elect rical connect orsHarnes s esSensor(s )Engine Control Modul e (ECM)

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart, al ternat ively, check forDi agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.4.

Symptom Chart

SymptomPossible CauseAction

Engine cranks , but does not fi reEngine breat her s ys temdis connected/res trictedIgni ti on s ys t emFuel s ys temElectronic engine control

Ens ure the engine breat her sys tem isfree from rest ri ct ion and is correct lyi nst all edFor igni ti on sys t em t est s .REFER t o: Engi ne Ignit ion (303-07AEngine Ignit ion, Diagnosi s and Test ing).For fuel s yst em tes ts .REFER t o: Fuel Tank and Lines (310-01AFuel Tank and Li nes - I6 3.2L Petrol,Di agnos is and Tes t ing).Read DTCs and refer t o DTC Index forel ect ronic engine cont rol tes t s.REFER t o: Elect roni c Engi ne Cont rol s(303-14A Elect ronic Engine Cont rols - I63.2L Petrol , Diagnosi s and Test ing).

Engine cranks and fires , but wil lnot s tartEvaporati ve emis s ions purgevalveFuel pumpSpark pl ugsHT s hort t o ground (t racki ng)check rubber boots forcracks/damageIgni ti on s ys t em

For purge valve t es ts .REFER t o: Evaporat ive Emi ss i ons (303-13Evaporati ve Emis s ions , Diagnosi s andTes ti ng).For fuel s yst em tes ts .REFER t o: Fuel Tank and Lines (310-01AFuel Tank and Li nes - I6 3.2L Petrol,Di agnos is and Tes t ing).For igni ti on sys t em t est s .REFER t o: Engi ne Ignit ion (303-07AEngine Ignit ion, Diagnosi s and Test ing).

Di fficul t col d s t artEngine coolant level/ant i-freeze cont entBatt eryElectronic engine controlsFuel pumpPurge valve

Check t he engi ne cool ant l evel andcondit ion.REFER t o: Specificati ons (303-03AEngine Cool ing - I6 3.2L Pet rol ,Specificat ions ).Ens ure the bat tery is i n a full y chargedand s ervi ceable condit ionRead DTCs and refer t o DTC Index forel ect ronic engine cont rol tes t s.

Page 998 of 3229

C-HP pipe connecti on – fuel rail t o inject or (4 off)

1-Fuel rail

2-PCV3-Fuel rail press ure sens or

The fuel rai l is manufact ured from forged st eel and secured t o t he cyl inder head with 2 fixings . The fuel rai l st orespres s urized fuel from t he HP pump, and prevent s pres s ure fluct uat ions i n the HP s ys tem. A fuel rail pres s ure s ens or and aPW M PCV are ins tall ed int o t he bore at each end of the fuel rail . The pres s ure s ensor i s ins tal led at t he acces sory dri veend of the fuel rail ; the PCV ins tal led at t he transmis s ion end of t he fuel rai l.

High-pres sure fuel pipes connect t he fuel rai l t o t he HP pump and fuel inject ors . A l eak-off pipe connect s the fuel rail t ot he fuel fi lt er return circui t.

The common fuel rail, fuel press ure s ens or and PCV form an int egral as s embly, and mus t not be separat ed. If a faultoccurs that requires component renewal, t hen t he compl ete fuel rail as s embl y mus t be renewed.

Fuel Rail Pressure Sensor

The fuel rai l pres sure s ens or is mount ed i n t he end of the fuel rail (access ory drive end) and connected to t he ECM vi a t heengi ne harnes s. The press ure sens or is provi ded wit h a 5V power s upply, ground and signal connect ions . The fuel railpres s ure s ensor i s a pi ezo-res is ti ve type s ens or contai ni ng an actuati ng diaphragm. Deflect ion of t he diaphragm provides aproport ional si gnal (output) volt age t o t he ECM, dependant on t he fuel pres s ure wit hin t he fuel rai l.

Pressure Sensor ParametersPressure Sensor Output VoltageFuel Rail Pressure

0.5V230 bar (3,336 ps i)

4.5V1,600 bar (23,206 ps i)The ECM compares t he s ens or s ignal vol tage t o s tored memory val ues, i n order t o cal cul ate the actual fuel pres s urepres ent in t he fuel rail. The ECM then us es t he fuel rai l press ure informat ion t o cont rol t he operati ng posi ti on of the VCVand PCV.For addit ional informat ion, refer t o: Electroni c Engi ne Controls - 2.2L Dies el (303-14 El ect ronic Engine Cont rols - 2.2LDies el, Des cript ion and Operat ion).

Pressure Control Valve (PCV)

The PCV i s mounted i n t he end of the fuel rail (trans mi s si on end) and connect ed t o the ECM via t he engine harnes s . ThePCV i s a s olenoid-operat ed valve cont rol led by a 12V PW M si gnal . The ECM operat es the PCV to adjus t t he fuel pres s urewit hin the fuel rail . Rel ieved fuel is direct ed through t he fuel rail leak-off pipe t o t he fuel fi lt er ret urn circui t. The l eak-offfuel als o provi des cooli ng and lubricat ion for t he PCV.For addit ional informat ion, refer t o: Electroni c Engi ne Controls - 2.2L Dies el (303-14 El ect ronic Engine Cont rols - 2.2LDies el, Des cript ion and Operat ion).

The PCV i s normall y open when t he s ol enoi d is not energi zed by the ECM. The resi s tance val ue of the PCV sol enoi d coi l is3.6 ohms at 20°C (68°F).

The PCV i s als o us ed by t he ECM t o provide di rect cont rol of the fuel sys tem, in t he fol lowi ng si tuat ions :

Duri ng s udden t rans ient phas es i n engine s peed (s uddenl y li ft ing off the accel erat or pedal, for example) where VCVact ion is not s ufficient to affect t he s uppl y of fuel to the fuel rail .To cont rol fuel press ure in t he event that the VCV fai ls .Duri ng the fuel heat ing period, when supply fuel temperat ure is l ess than 40°C (104°F). The VCV i s ful ly opened byt he ECM and t he HP pump compres s es a maximum quanti ty of fuel t o rais e t he fuel t emperature. The PCV is t henmodulat ed by the ECM to provide l eak-off fuel from the fuel rail t o t he fuel fi lt er ret urn circui t. The fuel i s t henrecircul ated t hrough t he fuel fi lt er and back t o t he HP pump.W hen t he fuel s uppl y t emperature is greater t han 70°C (158°F). The PCV is modul ated by t he ECM t o releas e fuelrai l pres sure, s ubs equentl y decreasi ng the fuel temperat ure to protect the fuel sys tem component s. Leak-off fuelfrom the fuel rail is direct ed to the fuel fil ter return ci rcuit and back t o the fuel tank.Duri ng engi ne s hut down t o progres s ively coll aps e fuel rail pres s ure.

FUEL INJECTORS

Page 1027 of 3229

At low engi ne s peed t he volume of exhaust gas l eavi ng the engine is l ow. The vanes are moved toward the cl osed pos it iont o direct t he exhaus t gas fl ow t o t he out s ide edge of t he turbine wheel. The clos ed posi ti on of the vanes creates ares t ri ct ion t o t he gas fl ow and i ncreas es t he gas vel oci ty to the t urbine wheel . The turbi ne wheel s peed is increas ed,cons equent ly producing more charge ai r (boos t pres sure) from t he compres sor.

B - Moderate Engine Speed

As engine s peed and exhaus t gas vol ume increas e, the vanes are moved to the open posit ion t o direct t he exhaus t gasfl ow t oward t he center of the turbi ne wheel . The vanes do not rest ri ct the exhaus t gas flow and therefore exhaus t gasveloci ty is dependant on engine s peed. The t urbi ne wheel s peed is maintai ned due to the i ncreas ed velocit y of t he gas esleaving t he engine and being di rected t oward the center area of t he t urbine wheel .

C - Maximum Engine Speed

At maximum engine s peed the volume of exhaus t gas leavi ng t he engi ne is hi gh. The vanes are moved toward the full yopen pos i ti on and do not affect t he gas vel oci ty. The exhaus t gas fl ow contacts t he center area of t he t urbine wheel tomaint ain t he t urbine wheel s peed and boos t pres s ure from the compress or.

Over-Boost Pressure

Duri ng periods of medi um t o hard accelerat ion, the turbocharger is requi red t o produce a l imit ed period of over-boos tpres s ure from the compress or to meet the current engi ne fueli ng requirement. The ECM wil l reques t and all ow t he REA t omove t he variable vanes t oward t he clos ed posi ti on t o increas e t he vel oci ty of t he already high-s peed turbine wheel. Theover-boos t condit ion is all owed by t he ECM for t he l imi ted period.

Barometric Pressure Sensor

At high al ti tude t he t urbocharger wi ll functi on normal ly, but due t o t he l ower ambi ent ai r pres sure t he turbi ne andcompres sor may tend t o over-speed. A baromet ri c pres sure s ensor i s located i n t he ECM t o prevent over-boost andposs i bl e engine damage occurri ng under t hes e condit ions. The ECM opens t he vari abl e vanes earlier duri ng t he openi ngphas e to s uit the al ti tude of t he vehi cl e.

T urbocharger Lubrication

The rapi d accelerat ion and decelerat ion demands of t he turbocharger rel y on a s t eady flow of cl ean oil. The oi l suppli ed byt he engi ne lubri cat ion s ys tem provides l ubricati on to the t urbocharger shaft and bearings, whi le al so act ing as a cool antfor t he t urbocharger cent er hous i ng.

To mai nt ain the l ife expect ancy of t he turbocharger, t he engine oil mus t be replenished at regular s ervice i nt ervals wit ht he recommended qual it y and quant it y of oil . The oi l mus t have a free-fl ow t hrough the turbocharger and an unres trict edret urn to t he engine oi l pan.

Page 1106 of 3229

CAUTION: To avoid damage/malfuncti oni ng of the BMS module, always us e a s uit able body ground point rather thant he bat t ery negat ive terminal when connect ing a s lave power supply.

For addit ional informat ion, refer t o: Batt ery (414-01 Bat tery, Mounti ng and Cables , Diagnos is and Tes t ing).

Gear Neutral Sensor

A PLCD (permanent magnet l inear cont act les s dis placement) s ensor i s located on the exterior of the trans mi s si on cas i ngand hardwired t o t he ECM. The sens or’s functi on is t o det ect t hat neut ral gear has been s elected wi thi n a cali bratedwindow.

No cali brati on is neces sary for t he Gear Neut ral Sensor upon repl acement, i t is however monit ored and a DTC wil l belogged s houl d a fault occur. Fault codes can be diagnos ed us ing Land Rover approved di agnos ti c equi pment.

Linear Clutch Sensor

To ens ure an engine res tart during a St op/St art cycl e does not del ay the get away demands of cit y dri ving, the engine i sres t art ed in approximately 800 mil li seconds . This i s achi eved through t he li near clut ch s ens or triggeri ng an engine rest artwhen t he cl utch pedal is at t he s tart of i ts downward t ravel. So whil e t he dri ver conti nues t o depres s t he clutch t hrought he res t of it s t ravel t he engine rest art i s already i n progress .

The li near clut ch s ens or is a PLCD (permanent magnet li near contactl es s di spl acement) type and i s located on t he clut chmas ter cylinder and hardwired t o t he CJB. The s ensor provi des t he CJB wi th a cont inuous input of the clut ch pedal ’sposi ti on; this informati on is relayed t o t he ECM on t he high-speed CAN bus . The ‘t op of travel ’ si gnal i s used to aut horizean automat ic engine res tart if all ot her s ys tem condit ions are approved.

The li near clut ch s ens or als o provides a ‘bott om of t ravel’ s ignal near t he end of the cl ut ch pedal ’s t ravel. This si gnal i sus ed if t he engi ne s tal ls and i s a requi rement t o authori ze a s tal l recovery. This is unique funct ion t hat allows the enginet o res t art automat ically if all ot her s ys tem condit ions are approved. For addi ti onal i nformat ion refer t o t he Stall Recoverys ect ion, below.

A magnet ins ide the clut ch mas ter cylinder provides t he posi ti on indicator for the linear cl utch s ensor. For t his reason, ift he mas ter cyl inder is replaced the correct replacement mas t er cyli nder mus t be i dent ified and fit t ed.

The t wo exis ti ng clutch pos it ion-s wi tches, l ocat ed on t he cl utch pedal hous ing and us ed as i nput s for vari ous vehi cl es ys t ems , are al so ut il ized by t he Stop/Start sys tem for pl aus ibi lit y checks .

If a fault develops wi th the l inear cl utch s ensor a DTC wil l be logged in the CJB.

• NOTE: The Stop/Start sys tem wil l not funct ion correctl y if t he dri ver rest s t hei r foot on t he clut ch pedal whil e dri vi ng t hevehi cl e.

Brake Vacuum Sensor

Page 1136 of 3229

Publi s hed: 11-May-2011

Engine Emission Control - TD4 2.2L Diesel - Engine Emission Control

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the engine emis s ion control s ys tems , refer to the relevant Des cri pt ion and Operati on s ect ionin the workshop manual.REFER to: Engine Emi s si on Cont rol (303-08B Engine Emi ss i on Cont rol - TD4 2.2L Dies el, Des cript ion and Operat ion).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

Visual InspectionMechanicalElectrical

EGR valveEGR pi pes /hos esVacuum s ys t emEngine breat her s ys tem

W i ring harnes sElect rical connect or(s)Fus es (s )

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart, al ternat ively, check forDi agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.4.

Symptom Chart

SymptomPossible CauseActionRough idl e, l ack of power under accel erati on,exces s ive fuel consumpt ion, exces s ive blacks moke

EGR valve s t uckCheck EGR valve for correct operati on.Check for relat ed DTCs and refer t o t he DTCIndex

Exces s ive engine bl ow-by/crankcas e press ureEngine breat her s ys temblocked/res trict edExces s ive engine wear

Check engine breat her s ys tem forbl ockage/res t ri ct ion. Check for exces si veengine wearREFER t o: Engi ne (303-00 Engi ne Sys t em -General Informati on, Di agnos is andTes t ing).

DTC Index

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve addi ti onalinformat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al ways take t he res is t ance of t he DMMleads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

DT CDescriptionPossible CauseAction

P040500Exhaus t Gas Recirculat ionSensor A Circuit LowEGR Valve pos it ion s ensorvol tage below lower li mitCarry out t he pinpoint t est s as sociat ed wit hthis DTC usi ng t he manufacturer approveddi agnos ti c s yst emP040600Exhaus t Gas Recirculat ionSensor A Circuit Hi ghEGR Valve pos it ion s ensorvol tage above upper l imi tCarry out t he pinpoint t est s as sociat ed wit hthis DTC usi ng t he manufacturer approveddi agnos ti c s yst em

P042E00Exhaus t Gas Recirculat ionControl St uck OpenEGR Valve s tuck duri ng normalengi ne running - at tempt t ouns t ick valve unsucces s ful

Check/clear EGR valve fromobs t ructi on/s ti cking

Page 1173 of 3229

DT CDescriptionPossible CausesAction

sys t em

P007200Ambi ent Ai r TemperatureSensor Ci rcuit LowAmbi ent ai r temperature s ens or ci rcuit -s hort t o ground, open circuitCarry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t em

P007300Ambi ent Ai r TemperatureSensor Ci rcuit HighAmbi ent ai r temperature s ens or ci rcuit -s hort t o powerCarry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t em

P009700Intake Air Temperat ureSensor 2 Ci rcuit LowIntake ai r temperat ure sens or vol tagebel ow lower l imi tCarry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t emP009800Intake Air Temperat ureSensor 2 Ci rcuit Hi ghIntake ai r temperat ure sens or vol tageabove upper l imi tCarry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t emP010000Mas s or Volume Ai r Flow ACircui tMAF Sens or s ignal circui t - s hort t oground, power, open circui tCarry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t em

P010221Mas s or Volume Ai r Flow ACircui t LowAi r fl ow PW M raw s ignal above upperl imitCarry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t em

P010226Mas s or Volume Ai r Flow ACircui t LowAi r fl ow PW M correct ed si gnal aboveupper li mitCarry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t em

P010322Mas s or Volume Ai r Flow ACircui t HighAi r fl ow PW M raw s ignal above upperl imitCarry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t em

P010327Mas s or Volume Ai r Flow ACircui t HighAi r fl ow PW M correct ed si gnal aboveupper li mitCarry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t emP011200Intake Air Temperat ureSensor 1 Ci rcuit LowIntake ai r temperat ure sens or 1 circuit -s hort t o groundCarry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t emP110222Mas s Air Fl ow Sens or inRange But Lower ThanExpect ed

Ai r Mass (meas ured) is too l ow (notpl aus i bl e) wit h calculated reference ai rmass during overrun: rati o ofcalculat ed/act ual too hi gh

Carry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t em

P110321Mas s Air Fl ow Sens or inRange But Higher ThanExpect ed

Ai r Mass (meas ured) is too hi gh (notpl aus i bl e) wit h calculated reference ai rmass during overrun: rati o ofcalculat ed/act ual too l ow

Carry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t em

P222700Baromet ri c Pres s ure Ci rcuitRange/PerformanceAt mos pheric Press ure Sens or defect iveIns tal l a new module, refer to thenew module/component ins tall ati onnot e at t he t op of the DTC Index.REFER t o: Powert rain Cont rol Module(PCM) (303-14, Removal andIns tal lat ion).

Page 1195 of 3229

Publi s hed: 11-May-2011

Electronic Engine Controls - I6 3.2L Petrol -

ItemSpecification

Heated oxygen s ens or (H02S)removal *Apply W D40 or equi val ent

Heated oxygen s ens or (H02S)t hreadsApply s uit abl e high temperat ure ant i-s ei ze compound t o t hreads of sens or (Cas trolOpti mol)

* Apply to area around sensor threads prior to attempting to remove sensor

General SpecificationItemSpecification

Engine management system:

MakeDens oCamshaft position sensor:

MakeDens o

TypeMRE (hal l affect)Crankshaft position sensor:

MakeDens o

TypeVariable reluctance

Torque Specifications

DescriptionNmlb-ftCams haft pos it ion (CMP) sens or bol t+107

Catal ys t moni tor s ens or4533

Catal ys t moni tor s ens or harnes s s upport bol t65Cranks haft posi ti on (CKP) s ensor Torx bol t107

Engine control modul e (ECM) bracket bolt s64

Flywheel sens or bol t107Flywheel sens or bracket s crews107

Fuel rail pres s ure s ens or65

Heated oxygen s ens or (H02S)++4533Knock sens or ret ai ning bolt2014

Mas s air flow (MAF) s ens or Torx s crews21

+ Apply clean engine oil to a new CMP sensor O-ring seal

++ Apply anti-seize lubricant to threads of sensor - See Lubricants

Page 1202 of 3229

12-Res trai nts Cont rol Module (RCM)

13-Knock sens ors (2 off)

14-Fuel rail t emperature/pres s ure s ens or15-Clockspring

16-Terrain respons e cont rol module

17-Trans mis s ion Cont rol Module (TCM)18-ABS module

19-Diagnos ti c socket

20-CJB

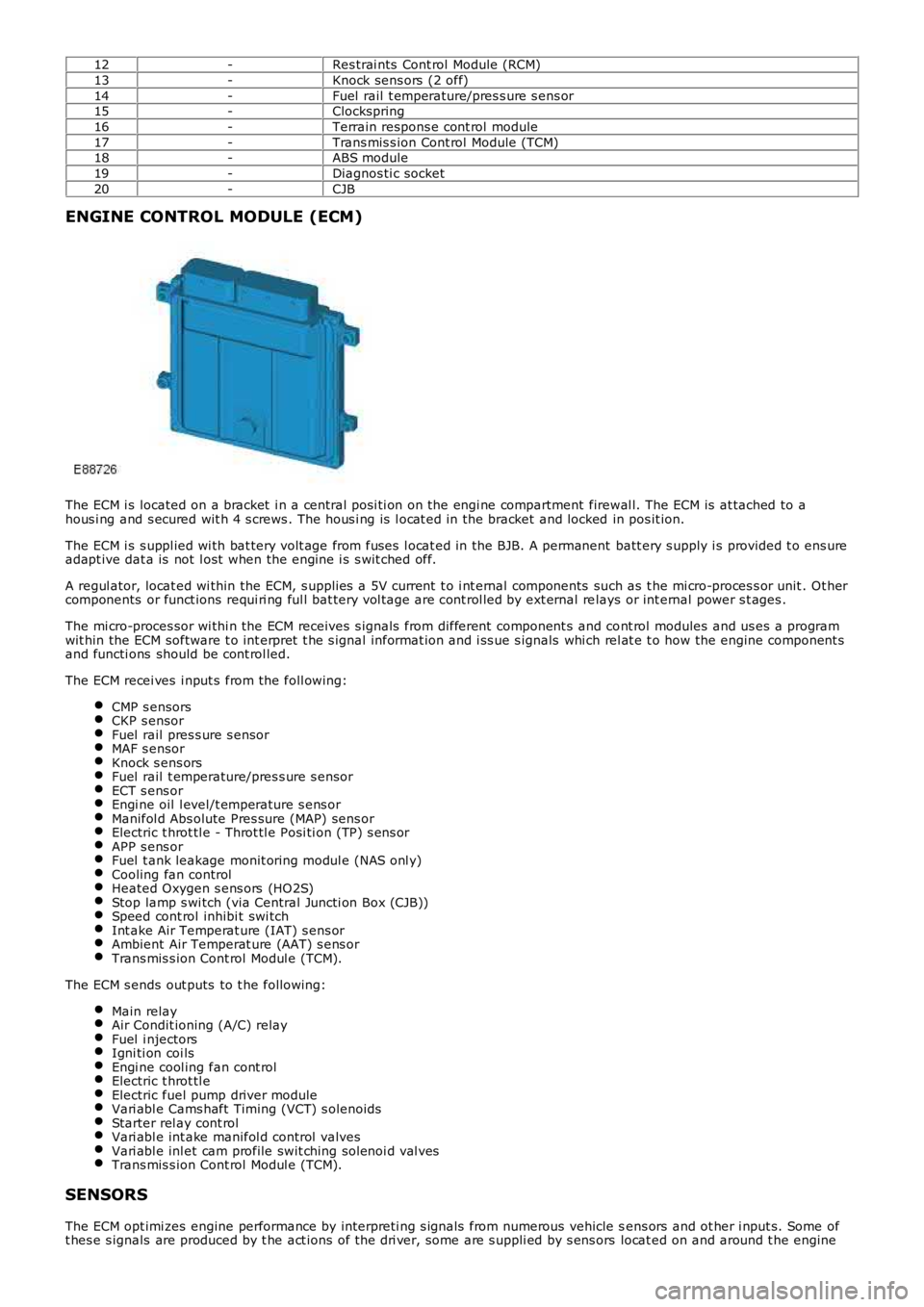

ENGINE CONTROL MODULE (ECM)

The ECM i s located on a bracket i n a central pos i ti on on the engi ne compartment firewal l. The ECM is at tached to ahous i ng and s ecured wit h 4 s crews . The hous i ng is l ocat ed in the bracket and locked in pos it ion.

The ECM i s s uppl ied wi th bat tery volt age from fuses l ocat ed in the BJB. A permanent batt ery s upply i s provided t o ens ureadapt ive dat a is not l ost when the engine i s s wit ched off.

A regul ator, locat ed wi thin the ECM, s upplies a 5V current t o i nt ernal components such as t he mi cro-proces s or unit . Ot hercomponents or funct ions requi ri ng ful l bat tery vol tage are cont rol led by ext ernal relays or int ernal power s t ages .

The mi cro-proces sor wi thi n the ECM receives s ignals from different component s and cont rol modules and us es a programwit hin the ECM software t o int erpret t he s ignal informat ion and i ss ue s ignals whi ch rel at e t o how the engine component sand functi ons should be cont rol led.

The ECM recei ves i nput s from the foll owing:

CMP s ensorsCKP s ensorFuel rail pres s ure s ensorMAF s ensorKnock s ens orsFuel rail t emperature/pres s ure s ensorECT s ens orEngi ne oil l evel/t emperature s ens orManifol d Abs olute Pres sure (MAP) sens orElectric t hrot tl e - Throt tl e Posi ti on (TP) s ens orAPP s ens orFuel t ank leakage monit oring modul e (NAS onl y)Cooling fan controlHeated Oxygen s ens ors (HO2S)Stop lamp s wi tch (via Central Juncti on Box (CJB))Speed cont rol inhibi t swi tchInt ake Air Temperat ure (IAT) s ens orAmbient Air Temperat ure (AAT) s ens orTrans mis s ion Cont rol Modul e (TCM).

The ECM s ends out puts to t he followi ng:

Main relayAir Condit ioning (A/C) relayFuel i njectorsIgni ti on coi lsEngi ne cool ing fan cont rolElectric t hrot tl eElectric fuel pump driver moduleVari abl e Cams haft Timing (VCT) s olenoidsStarter rel ay cont rolVari abl e int ake manifol d control valvesVari abl e inl et cam profile swit ching sol enoi d val vesTrans mis s ion Cont rol Modul e (TCM).

SENSORS

The ECM opt imi zes engine performance by interpreti ng s ignals from numerous vehicle sens ors and ot her i nput s. Some oft hes e s ignals are produced by t he act ions of t he dri ver, some are s uppli ed by s ens ors locat ed on and around t he engine

Page 1203 of 3229

and s ome are s uppli ed by ot her vehicle s ys tems .

Camshaft Position (CMP) Sensor

Two CMP sens ors are located i n t he camshaft hous ing at t he Left Hand (LH) end of the engine. The s ens ors are l ocat ed ina hole in t he housi ng and are secured wit h a s crew. There i s a CMP sens or for each cams haft .

The CMP s ensors monit or the pos it ion of t he cams hafts to es t abl is h i gni ti on t imi ng order, fuel i njecti on triggeri ng and foraccurat e Vari able Cams haft Ti ming (VCT) operati on. The ECM can al so use the CMP sensors t o det ermi ne which cylinderhas a mi s fi re or knock us i ng the CMP s ignal out put .

The CMP s ensor i s a Hal l-effect s ens or which s wi tches a 5V s upply from the ECM on and off. The s uppl y is s wi tched whent eet h machined onto a puls e wheel on the cams haft pas s by t he ti p of t he s ens or. The t eeth are of differing s hapes , s ot he ECM can determine t he exact pos it ion of t he camshaft at any t ime. W hen one of the t eeth pas s es by t he sens or ti p, as ignal is t rans mit t ed to the ECM which can vary between 0 and 5V. The si gnal i s high when a toot h is di rectl y adjacent t ot he sens or and is l ow when t he t oot h i s away from t he s ensor.

Failure of one or bot h of t he s ens ors wil l res ul t in the ECM usi ng a default map for i gni ti on t imi ng and knock cont rol wi ll bedis abled.

The ECM moni tors the sens or for correct functi on and can diagnos e and s t ore fault codes for s ens or fault s . Thes e can beret ri eved us i ng a Land Rover approved diagnos t ic s ys tem.

Crankshaft Position (CKP) Sensor

The CKP s ensor i s located on t he forward s ide of t he trans mi s si on t orque convert er hous ing, in li ne wit h t he engi nefl ywheel . The sens or is s ecured wi th a bol t int o a bracket att ached t o t he gear housing. A reluctor ring i s fi tt ed t o t heouter diamet er of t he cranks haft fl expl at e and t he s ens or reacts to the gaps i n the reluctor ring t o det ermi ne engi ne s peedand posi ti on informat ion. The s ens or has 2 wi res from the ECM s ens or ground and a feedback s ignal.

The CKP s ensor i s an inducti ve type s ensor which produces a s i nus oidal out put vol tage s i gnal. Thi s vol tage i s induced byt he proximi ty of t he moving reluctor ring gaps , whi ch exci te t he magneti c fl ux around t he ti p of t he s ens or when each gappass es . Thi s output volt age wil l i ncrease in magni tude and frequency as t he engine speed ri ses det ermi ned by an increas ein the s peed at which t he gaps on t he reluct or ring pas s t he s ens or. The s i gnal voltage can be as low as 0.1V at lowengi ne s peeds and up to 100V at hi gh engi ne s peeds . The ECM does not react t o t he output volt age (unles s t he vol tage i sextremely l ow or high), i nst ead it meas ures the t ime int ervals bet ween each puls e (signal frequency). The s ignal i sdetermined by t he number of gaps pas si ng t he sens or, and t he s peed at whi ch they pass. The reluctor ring has 2 gapsmi ss i ng to gi ve t he ECM a s ynchroni zat ion poi nt and det ermi ne t he pos i ti on of the cranks haft. The CKP sens or si gnal i sals o us ed for mis fi re det ect ion.

The s ignal produced by t he CKP s ensor i s crit ical to engi ne running. Failure of the sens or when the engine is runni ng wil lres ult i n t he engi ne s topping i mmediat ely. The engi ne can be res t arted us i ng s ignal s from the CMP s ens ors but t he engines peed will be limit ed to 3000 rpm and the Mal functi on Indicator Lamp (MIL) will be ill uminat ed.

The ECM moni tors the sens or for correct functi on and can diagnos e and s t ore fault codes for s ens or fault s . Thes e can beret ri eved us i ng a Land Rover approved diagnos t ic s ys tem.

Fuel Rail Pressure/Temperature Sensor

Page 1204 of 3229

The fuel rai l pres sure/t emperature s ens or is locat ed on t he LH end of t he fuel rai l. The ECM suppli es the combinedpres s ure and t emperat ure s ensor wi th a 5V reference volt age and a ground and meas ures t he ret urned s ignals for pres s ureand t emperature.

Fuel pres s ure

The fuel pres s ure s ens or i s a peizo res is tor t ype sens or. The s ensor receives a 5V reference vol tage from the ECM andproduces an anal ogue s i gnal of between 0 and 5V depending on the pres s ure sens ed. Low pres sure gives a l ow volt ageoutput and cons equent ly hi gh pres s ure gives a hi gher volt age output. The ECM uses t his press ure s ignal t o adjus t t he fuelpump module out put pres sure by s endi ng cont rol ling si gnal s t o the FPDM and for i nject or ti ming.

The ECM moni tors the fuel pres sure s ens or for faul ts and can st ore fault related codes. Thes e can be ret ri eved us i ng aLand Rover approved diagnos t ic s ys tem. Sensor operat ion can als o be checked us i ng a Land Rover approved diagnos t ics ys t em t o check fuel pres sure. If no fuel pres s ure is i n t he fuel rai l, t he s ens or wil l read and output at mospheri c pres s ure.

Fuel Temperat ure

The fuel t emperature s ens or is a Negat ive Temperat ure Co-efficient (NTC) sens or. The s ens i ng thermis t or el ementres is t ance decreas es as the sens or temperat ure increases . The ECM s upplies t he s ensor wi th a 5V reference volt age and aground and meas ures t he ret urned s ignal as a t emperature.

The res is t ance i n t he s ens or changes wi th fuel temperat ure. A l ow fuel t emperat ure wi ll res ult i n a hi gh volt age bei ngret urned t o t he ECM and high fuel temperat ure wil l return a l ow volt age reading of between 0 - 5V.

The ECM moni tors the fuel temperat ure sens or for fault s and can s tore faul t rel at ed codes . These can be ret rieved us ing aLand Rover approved diagnos t ic s ys tem. The ECM us es t he ECT t emperature s ignal as a default but only up to a maximumof 100°C (212°F).

Mass Air Flow (MAF)/Intake Air Temperature (IAT) Sensor

The MAF/IAT s ensor i s located i n t he out let pi pe from t he air cleaner hous ing. The combined MAF/IAT funct ions areconnected t o t he ECM on separat e wi res . The sens or has an ext ended moul ding whi ch is l ocat ed in a cent ral posi ti on in theair flow through t he air cleaner hous ing out let pipe, t hrough which t he air flow and t emperat ure are meas ured.

Mas s Air Flow (MAF) Sensor

The MAF s ensor meas ures t he mas s of air being drawn int o t he engi ne. The ai r mas s is calculat ed by t he cool ing effect ofinl et ai r pas s ing over a 'hot fil m' element cont ained wi thin the s ens or. The higher the ai r fl ow, the great er the cooli ngeffect on the el ement whi ch in t urn lowers the el ect ri cal res i st ance of t he 'hot film' el ement. The ECM us es t his resi s tancevalue t o calcul ate the ai r mass or vol ume of air flowing i nto the engine.

The MAF s ensor receives a bat tery volt age supply vi a t he ECM and t he main relay. The ECM provi des a ground and a s i gnalpath for the res is tance s ignal from t he 'hot film' sens or. The analogue s ignal from t he MAF s ens or varies bet ween 0.5 and5V. Low air flow gi ves a low vol tage and hi gh air fl ow gi ves a high volt age.

The MAF s ignal is us ed by t he ECM t o det ermi ne:

t he correct fuel quant it y (injecti on peri od) t o mai ntain the correct ai r/fuel rat io required for correct operat ion of t heengi ne and t he cat alys ts