sensor LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1932 of 3229

Publi s hed: 11-May-2011

Exterior Lighting - Headlamps

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the ext erior l ighti ng s ys t em, refer to t he Des cript ion and Operat ion secti on 417-00 - Ext eriorLighti ng of the workshop manual.

Safety Information

• W ARNINGS:

The Xenon Headl amp s ys tem generat es up t o 28,000 volt s . Make sure t hat t he headl amps are swit ched off beforeworki ng on the sys tem. Fai lure to foll ow t his i ns t ructi on may l ead to fat al it y.

The followi ng s afety precaut ions mus t be fol lowed when working on t he Xenon Headl amp Sys tem:

DO NOT att empt any procedures on t he Xenon Headlamps or circui ts when the sys tem is energi zed.Handl ing of t he xenon bul b mus t be performed us i ng sui table protect ive equipment, e.g. gl oves and goggles . Theglas s part of t he bulb mus t not be t ouched.Only operat e t he lamp in a mounted condit ion i n t he reflect or.All s afet y procedures and precaut ions mus t be foll owed to prevent pers onal injury.

CAUTION: Xenon bulbs mus t be dis pos ed of as hazardous was te.

There are ins t ructi ons on the correct procedures for Xenon Headlamp Sys t em repai rs in t he manual, refer to secti on 100-00- General Informat ion, Standard W orks hop Pract ices of t he works hop manual .

Inspection And Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

1. Verify t he cus t omer concern.

Note that int ermi tt ent fault report s may be due t o t he cycli ng operati on of the fi eld effect trans is t ors (FETs )

1.

2. Vis ually ins pect for obvious mechani cal or electrical fault s .2.

Visual Inspection Chart

MechanicalElectricalHeadlamp(s) condit ion and i ns t allat ionBulb(s) and ins tall ati onBulb hol der(s ) and i nst all at ionLight ing cont rol s wi tch and i ns t allat ionLeft -hand St eering Col umn Mult ifunct ion Swi tch andi ns t allat ion

Fus esRel aysW iring harnes sLoos e or corroded connector(s )Bat tery juncti on box (BJB)Cent ral juncti on box (CJB)Adapt ive Front Lighti ng Syst em (AFS)modul eHeadlamp Power modul esIns trument Clus ter (IPC)St eeri ng Angl e Sensor Module (SASM)Transmis si on Control Module (TCM)Engine Cont rol Module (ECM)Ant i-lock Brake Sys tem Modul eAi r Suspens ion Control Modul eLocal Int erconnect Net work (LIN) ci rcuit sCont roll er area network (CAN) ci rcuit s

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep.3.

4. Us e the approved di agnos ti c s ys t em or a s can t ool t o ret rieve any diagnos t ic t rouble codes (DTCs ) before movingont o t he sympt om chart or DTC i ndex.

Becaus e t he DTCs are st ored i n more t han one modul e, a complete vehi cl e read i s recommendedMake s ure t hat all DTCs are cl eared fol lowing recti fi cat ion

4.

DTC Index

Adaptive Front Lighting System (AFS) Control Module

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

Page 2070 of 3229

8-TCM

9-Engi ne Cont rol Module (ECM)

10-Diagnos t ic s ocket11-Occupant Cl ass i fi cat ion Sensor (OCS - NAS onl y

COMPONENT LOCATION - MOST

Page 2161 of 3229

(Ignit ion). The forward facing light s ensor moni tors the ambi ent light l evel at the front of t he vehi cl e; the rearward facingli ght sens or moni tors t he li ght l evel coming from t he rear of the vehicle. W hen li ght from the rear of the vehicle exceedst he ambient li ght l evel from the front of t he vehi cl e, the aut omat ic di mmi ng circuit darkens t he i nt eri or mirror s urface.

Automat ic di mmi ng is i nhi bit ed when revers e gear is sel ect ed to provide t he dri ver wi th maximum vis ion. On vehicles wi thautomat ic t rans mis s ion, t he revers e gear s ignal i s provided by t he TCM vi a t he high s peed Cont rol ler Area Net work (CAN)bus to the CJB. The CJB then provi des a power feed t o t he mirror. On vehicles wi th manual t rans mis s ion, the revers e gears ignal is provi ded by a t ransmis s ion s wit ch t hat i s hardwi red t o t he CJB.

Cabin Humidity Sensor

Dependi ng on the vehicl e s pecificati on, t he automat ic di mmi ng int erior mirror may als o i ncorporate a cabi n humidi tys ens or. The cabin humi dit y s ens or is locat ed i n the mirror rear cas ing near to the wi nds hiel d, and provi des the ATC modul ewit h i nformati on regarding the probabil it y of winds hield mis t ing. Thi s i nformat ion is us ed to vary t he automat ic operat ionof the cl imat e cont rol s yst em.For addit ional informat ion, refer t o: Cont rol Component s (412-01 Cli mat e Cont rol , Descripti on and Operat ion).

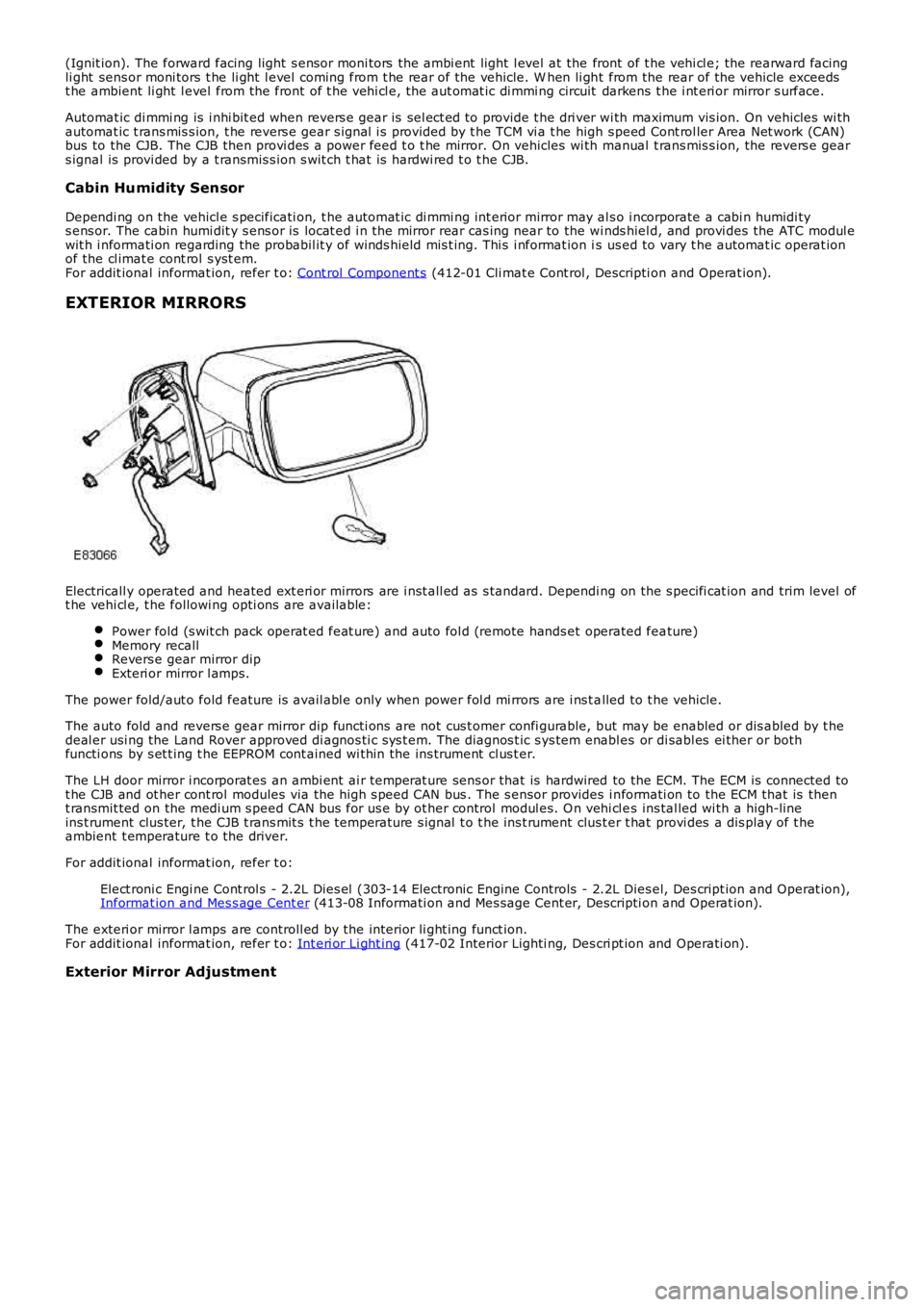

EXTERIOR MIRRORS

Electricall y operated and heated ext eri or mirrors are i nst all ed as s tandard. Depending on the s pecifi cat ion and trim level oft he vehi cl e, t he followi ng opti ons are available:

Power fold (s wit ch pack operat ed feat ure) and auto fol d (remote hands et operated feature)Memory recallRevers e gear mirror dipExteri or mirror l amps.

The power fold/aut o fold feature is avail abl e only when power fol d mi rrors are i ns t alled to t he vehicle.

The auto fold and revers e gear mirror dip functi ons are not cus t omer confi gurable, but may be enabled or dis abled by t hedeal er usi ng the Land Rover approved di agnos ti c s ys t em. The diagnos t ic s ys tem enabl es or di sabl es ei ther or bothfuncti ons by s et t ing t he EEPROM cont ained wi thin the ins trument cl us t er.

The LH door mirror i ncorporat es an ambi ent ai r temperat ure sens or that is hardwired to the ECM. The ECM is connected tot he CJB and ot her cont rol modules via the hi gh s peed CAN bus . The s ensor provides i nformati on to the ECM that is thent ransmit ted on the medi um s peed CAN bus for us e by ot her control modul es. O n vehi cl es ins tal led wi th a high-lineins t rument clus ter, t he CJB t rans mit s t he temperature s ignal t o t he ins t rument clus ter t hat provi des a dis play of t heambient t emperature t o the driver.

For addit ional informat ion, refer t o:

Elect roni c Engi ne Cont rol s - 2.2L Dies el (303-14 Electronic Engine Controls - 2.2L Dies el, Des cript ion and Operat ion),Informat ion and Mes s age Cent er (413-08 Informati on and Mes sage Cent er, Descripti on and Operat ion).

The exteri or mirror l amps are controll ed by the interior li ght ing funct ion.For addit ional informat ion, refer t o: Int eri or Li ght ing (417-02 Interior Lighti ng, Des cri pt ion and Operati on).

Exterior Mirror Adjustment

Page 2347 of 3229

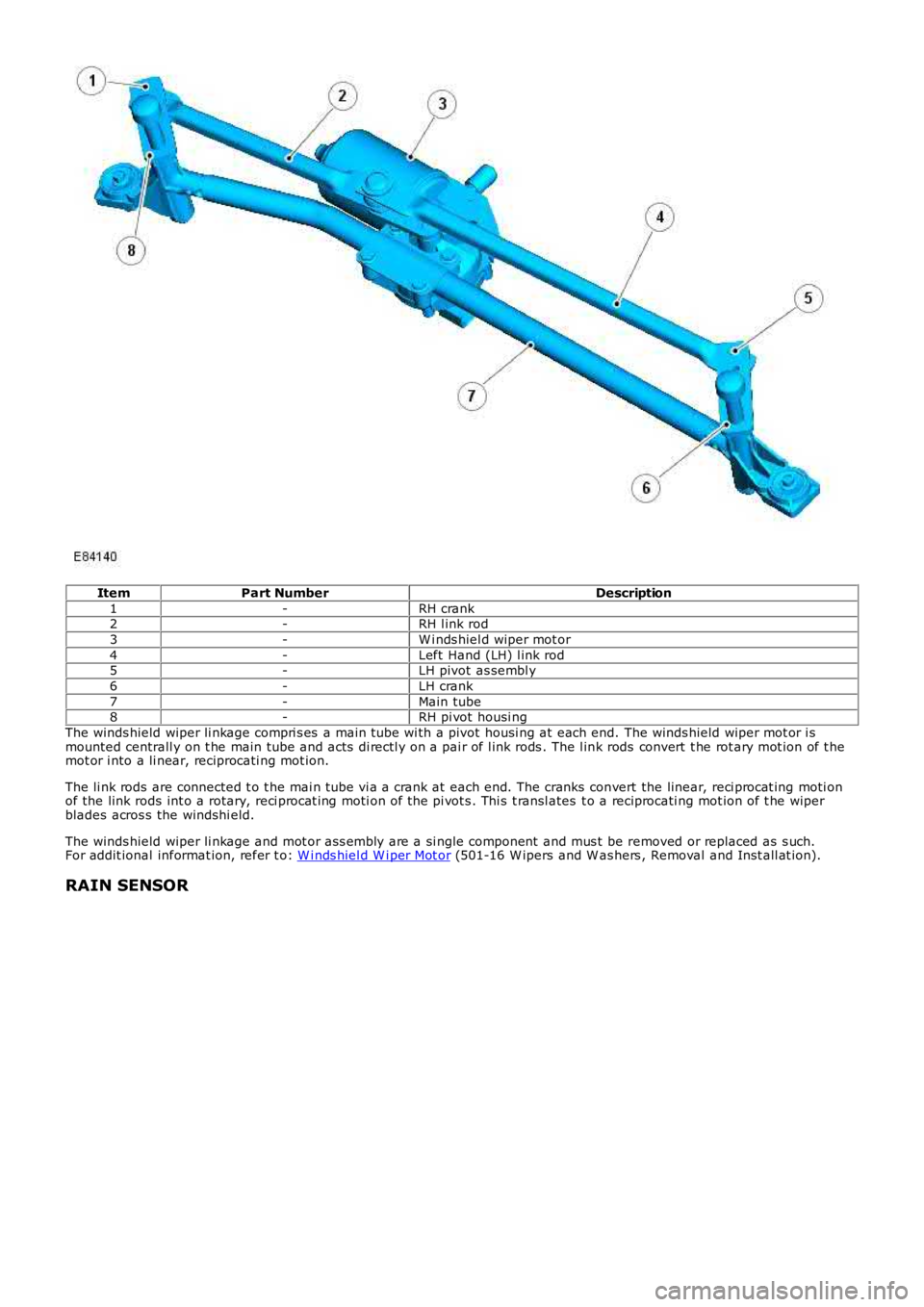

ItemPart NumberDescription

1-RH crank2-RH l ink rod

3-W i nds hiel d wiper mot or

4-Left Hand (LH) l ink rod5-LH pivot as sembl y

6-LH crank

7-Main tube8-RH pi vot housi ng

The winds hield wiper li nkage compri s es a main tube wi th a pivot housi ng at each end. The winds hield wiper mot or i smounted centrall y on t he main tube and acts di rectl y on a pai r of l ink rods . The l ink rods convert t he rot ary mot ion of t hemot or i nto a li near, reciprocati ng mot ion.

The li nk rods are connected t o t he mai n tube vi a a crank at each end. The cranks convert the linear, reci procat ing moti onof the link rods int o a rotary, reci procat ing moti on of the pi vot s . Thi s t ransl ates t o a reciprocati ng mot ion of t he wiperblades acros s the windshi eld.

The winds hield wiper li nkage and mot or ass embly are a si ngle component and mus t be removed or replaced as s uch.For addit ional informat ion, refer t o: W i nds hiel d W i per Mot or (501-16 W ipers and W as hers , Removal and Inst all at ion).

RAIN SENSOR

Page 2357 of 3229

Publi s hed: 11-May-2011

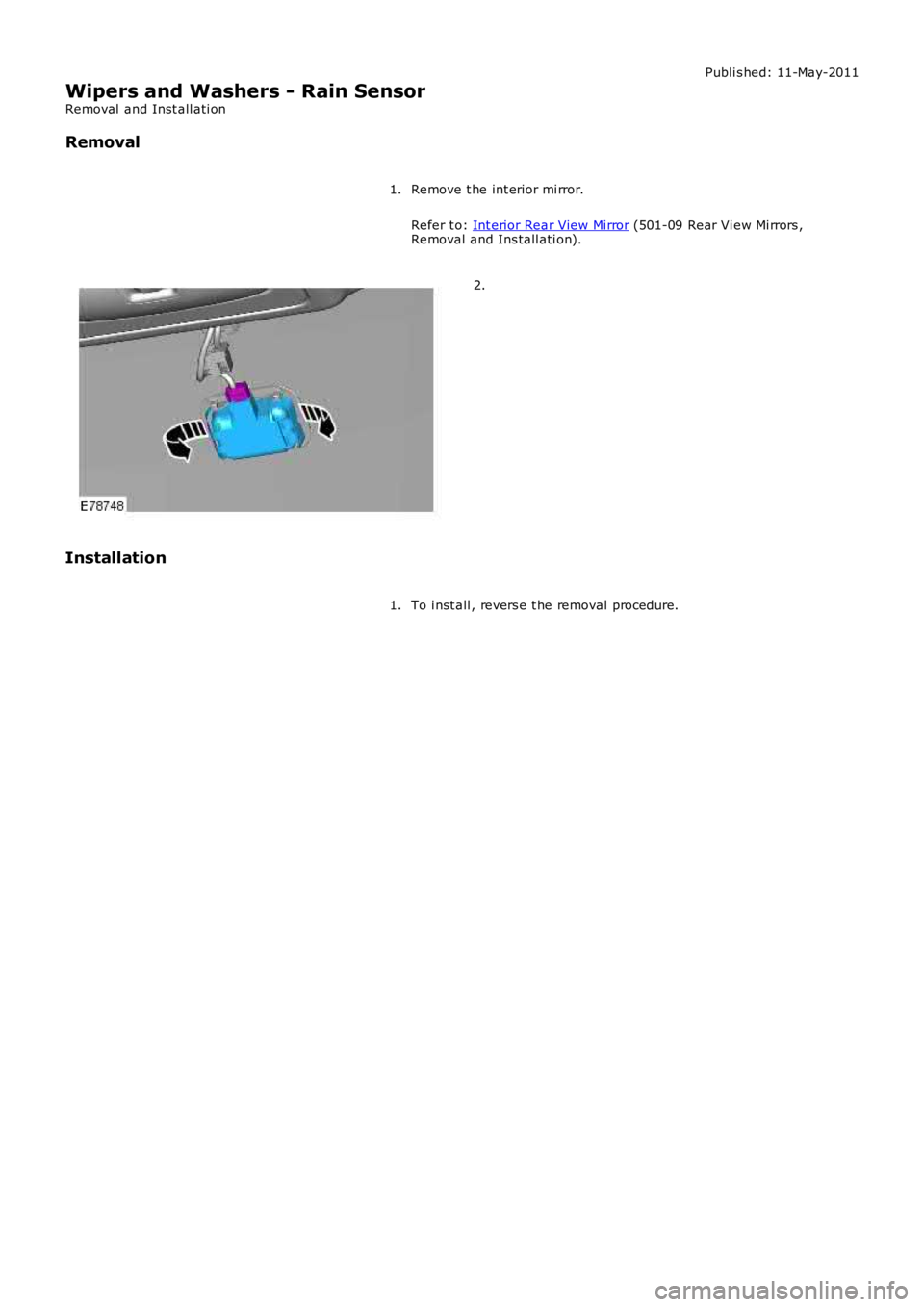

Wipers and Washers - Rain Sensor

Removal and Inst all ati on

Removal

Remove t he int erior mi rror.

Refer t o: Int erior Rear View Mirror (501-09 Rear Vi ew Mi rrors ,Removal and Ins tall ati on).

1.

2.

Installation

To i nst all , revers e t he removal procedure.1.

Page 2453 of 3229

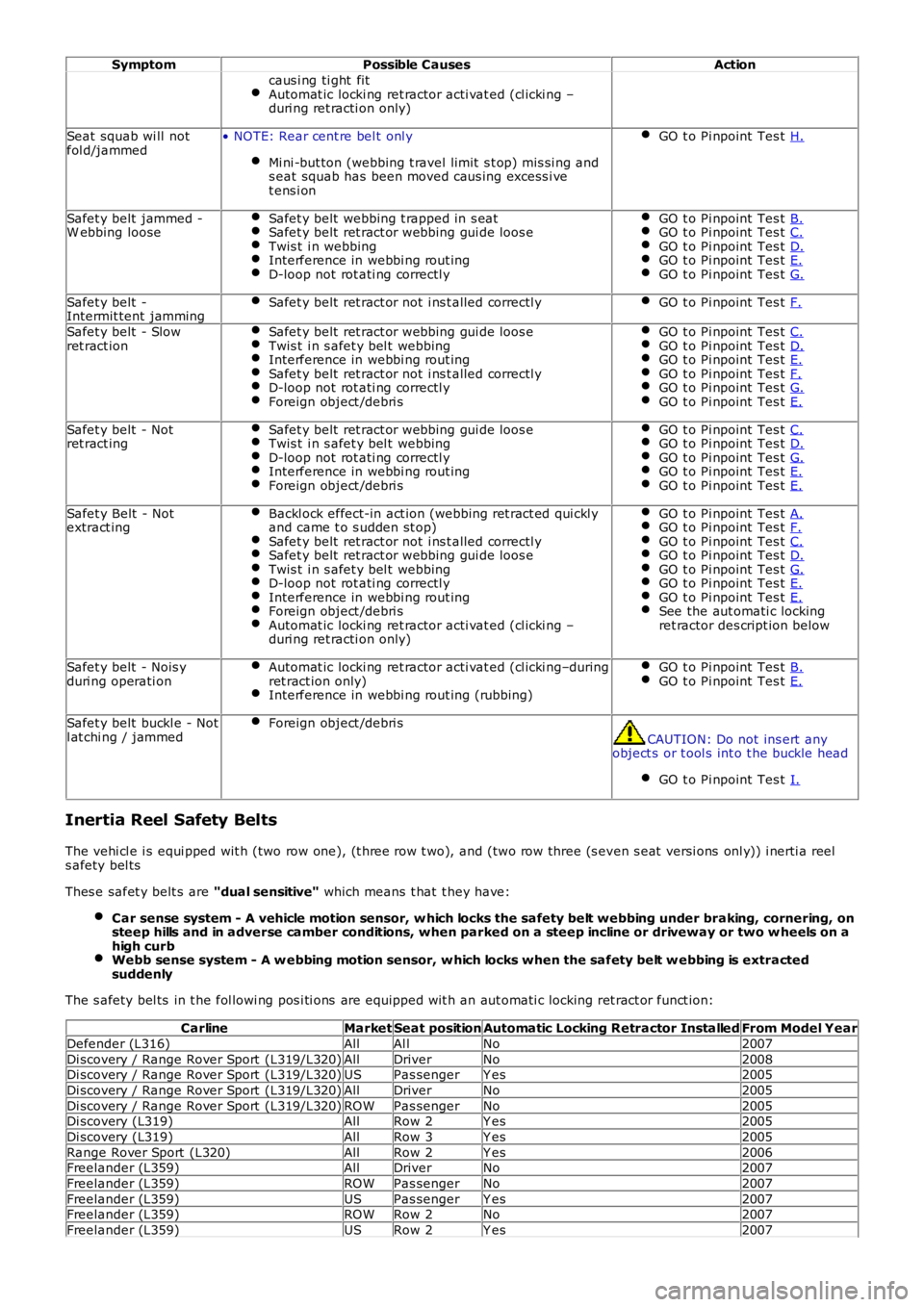

SymptomPossible CausesAction

caus i ng ti ght fitAutomat ic locki ng ret ractor acti vat ed (cl icki ng –duri ng ret racti on only)

Seat squab wi ll notfol d/jammed• NOTE: Rear cent re bel t onl y

Mi ni -but ton (webbing t ravel limit s t op) mis si ng ands eat squab has been moved caus ing excess i vet ens i on

GO t o Pi npoint Tes t H.

Safet y belt jammed -W ebbing looseSafet y belt webbing t rapped in s eatSafet y belt ret ract or webbing gui de loos eTwis t i n webbingInterference in webbi ng rout ingD-loop not rot ati ng correctl y

GO t o Pi npoint Tes t B.GO t o Pi npoint Tes t C.GO t o Pi npoint Tes t D.GO t o Pi npoint Tes t E.GO t o Pi npoint Tes t G.

Safet y belt -Intermit tent jammingSafet y belt ret ract or not i ns t alled correctl yGO t o Pi npoint Tes t F.

Safet y belt - Slowret ract ionSafet y belt ret ract or webbing gui de loos eTwis t i n s afet y bel t webbingInterference in webbi ng rout ingSafet y belt ret ract or not i ns t alled correctl yD-loop not rot ati ng correctl yForeign object /debri s

GO t o Pi npoint Tes t C.GO t o Pi npoint Tes t D.GO t o Pi npoint Tes t E.GO t o Pi npoint Tes t F.GO t o Pi npoint Tes t G.GO t o Pi npoint Tes t E.

Safet y belt - Notret ract ingSafet y belt ret ract or webbing gui de loos eTwis t i n s afet y bel t webbingD-loop not rot ati ng correctl yInterference in webbi ng rout ingForeign object /debri s

GO t o Pi npoint Tes t C.GO t o Pi npoint Tes t D.GO t o Pi npoint Tes t G.GO t o Pi npoint Tes t E.GO t o Pi npoint Tes t E.

Safet y Belt - Notextract ingBackl ock effect-in act ion (webbing ret ract ed qui ckl yand came t o s udden st op)Safet y belt ret ract or not i ns t alled correctl ySafet y belt ret ract or webbing gui de loos eTwis t i n s afet y bel t webbingD-loop not rot ati ng correctl yInterference in webbi ng rout ingForeign object /debri sAutomat ic locki ng ret ractor acti vat ed (cl icki ng –duri ng ret racti on only)

GO t o Pi npoint Tes t A.GO t o Pi npoint Tes t F.GO t o Pi npoint Tes t C.GO t o Pi npoint Tes t D.GO t o Pi npoint Tes t G.GO t o Pi npoint Tes t E.GO t o Pi npoint Tes t E.See the aut omati c lockingret ractor des cript ion below

Safet y belt - Nois yduri ng operati onAutomat ic locki ng ret ractor acti vat ed (cl icki ng–duringret ract ion only)Interference in webbi ng rout ing (rubbing)

GO t o Pi npoint Tes t B.GO t o Pi npoint Tes t E.

Safet y belt buckl e - Notl at chi ng / jammedForeign object /debri s

CAUTION: Do not ins ert anyobject s or t ool s int o t he buckle head

GO t o Pi npoint Tes t I.

Inertia Reel Safety Belts

The vehi cl e i s equi pped wit h (two row one), (t hree row t wo), and (two row three (s even s eat versi ons onl y)) i nerti a reels afety bel ts

Thes e safet y belt s are "dual sensitive" which means t hat t hey have:

Car sense system - A vehicle motion sensor, w hich locks the safety belt webbing under braking, cornering, onsteep hills and in adverse camber conditions, when parked on a steep incline or driveway or two w heels on ahigh curbWebb sense system - A w ebbing motion sensor, w hich locks when the safety belt w ebbing is extractedsuddenly

The s afety bel ts in t he fol lowi ng pos i ti ons are equipped wit h an aut omati c locking ret ract or funct ion:

CarlineMarketSeat positionAutomatic Locking Retractor InstalledFrom Model Year

Defender (L316)AllAl lNo2007

Di scovery / Range Rover Sport (L319/L320)AllDriverNo2008Di scovery / Range Rover Sport (L319/L320)USPas sengerY es2005

Di scovery / Range Rover Sport (L319/L320)AllDriverNo2005

Di scovery / Range Rover Sport (L319/L320)ROWPas sengerNo2005Di scovery (L319)AllRow 2Y es2005

Di scovery (L319)AllRow 3Y es2005

Range Rover Sport (L320)AllRow 2Y es2006Freelander (L359)AllDriverNo2007

Freelander (L359)ROWPas sengerNo2007

Freelander (L359)USPas sengerY es2007Freelander (L359)ROWRow 2No2007

Freelander (L359)USRow 2Y es2007

Page 2480 of 3229

s eat , or an unres trained but very l ightwei ght adult , in bot h t hes e cas es the ai r bag would be di sabl ed. The occupantclas si fi cat ion s ens ing s yst em forms part of a s t rat egy t o control pas s enger air bag deployment depending on theoccupancy s cenario.

The occupant cl as s ificati on s ys t em has four pos s ible st ates :

Seat Empty: t he pass enger ai r bag, pas senger-s ide air bag and pas s enger s afety bel t buckle and pretens ioneroperati on is di s abl ed; t he pas senger air bag deact ivati on indicator i s not il luminated.Occupied Inhibit: when the seat is occupied by a smal l pers on, t he pass enger ai r bag, pas senger-s ide air bag andpass enger s afet y belt buckl e and pret ensi oner operat ion i s dis abled; the pas s enger air bag deact ivat ion i ndi cat or isil lumi nat ed.Occupied Allow: when t he s eat i s occupied by a large pers on; t he pas senger ai r bag and pass enger-s ide air bagoperati on is enabled, t he pas s enger ai r bag deacti vat ion i ndicat or is not i ll uminated. Pass enger s afet y belt andpret ens i oner operati on s tat us depends on t he s afet y bel t buckle s tat us :- acti ve for buckled,- inacti ve for unbuckled.Error: if a sys tem faul t is det ect ed; t he pas senger ai r bag is enabled t o deploy at 'st age-1' onl y, refer t o Air BagDual St age Inflat ors below. Pas senger-s ide air bag operat ion i s als o enabled; t he pas s enger air bag deacti vat ionindicat or i s not il lumi nat ed. Pas s enger s afety bel t and pret ens ioner operati on s tat us depends on t he s afety bel tbuckle s tat us :- acti ve for buckled,- inacti ve for unbuckled.

Occupancy Sensor Mod ule

The occupancy s ens or modul e is ins tall ed on t he undersi de of the front pas s enger s eat . The module s upplies a power feedt o the occupancy s ens or and monit ors the return vol tage t o det ermi ne if t he s eat i s occupied or not . The res ult ist ransmit ted t o t he RCM on the hi gh-s peed CAN. The occupancy s ens or module al so monitors for s hort and open circui ts int he occupancy s ensor. If i t det ect s a fault , the occupancy s ens or module t rans mi ts a fault mess age t o t he RCM.

Safety Belt Tension Sensor

The s afety bel t tens ion s ens or i s a s t rai n-gauge type, encapsul at ed wi thi n the pas s enger s afet y belt anchor. The sens orconvert s t he force appl ied t o t he s afety bel t int o an elect rical s ignal. In the event t hat a chi ld-s eat is ins tall ed onto thefront pas s enger s eat, t he force appl ied t o t he pass enger s afet y belt i s reflected by the out put s i gnal from the s ensor,which provi des dat a t o s uppl ement that received from the occupancy s ens or. The occupancy sens or modul e proces ses t heinput data and makes i t avai lable to the rest rai nts control modul e, whi ch then makes t he neces s ary adjus t ments i nres pect of pas senger air bag deployment .

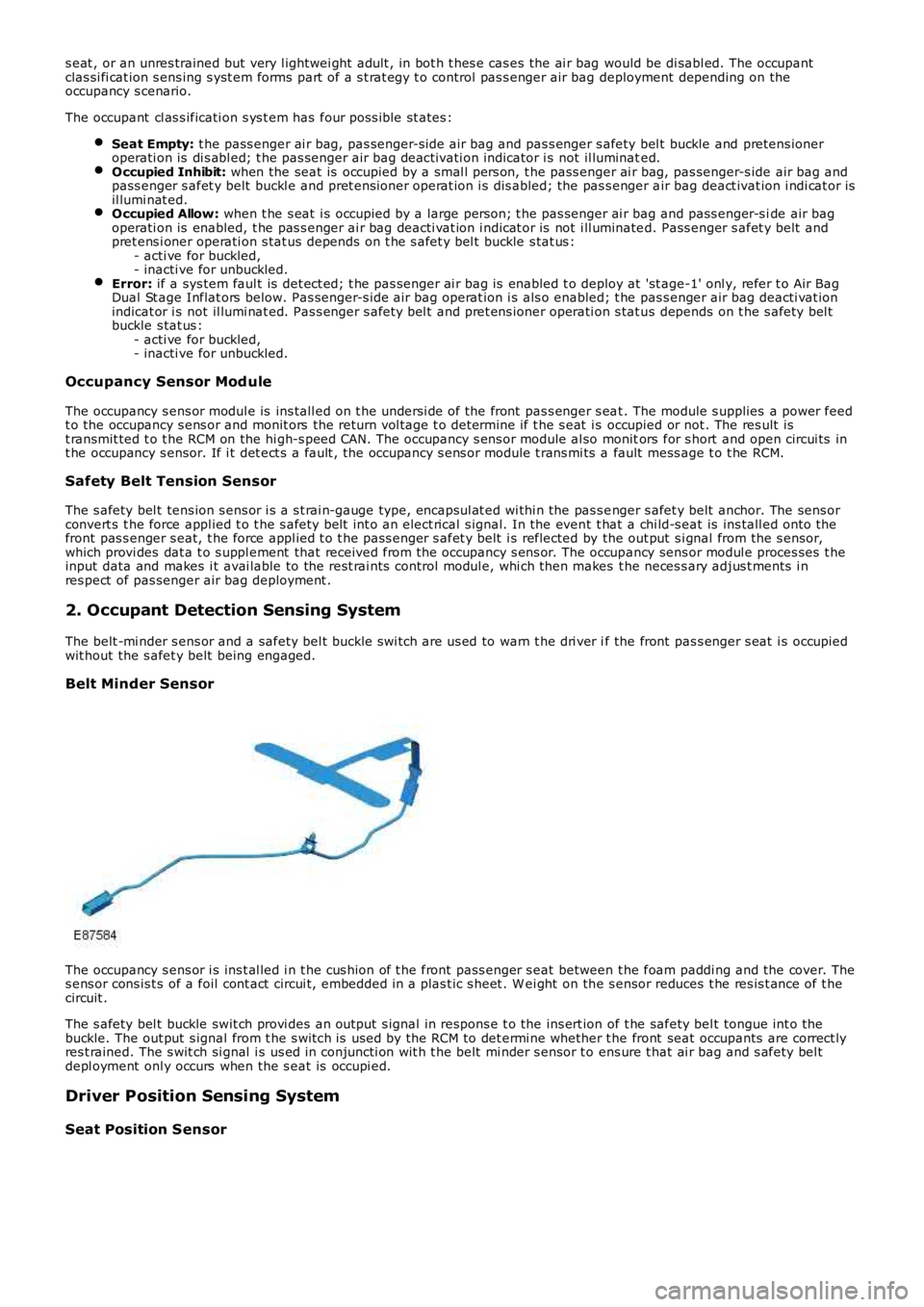

2. Occupant Detection Sensing System

The belt -mi nder s ens or and a safety bel t buckle s wi tch are us ed to warn t he dri ver if the front pas s enger s eat i s occupiedwit hout the s afet y belt being engaged.

Belt Minder Sensor

The occupancy s ens or i s ins t al led i n t he cus hion of t he front pass enger s eat between t he foam paddi ng and the cover. Thes ens or cons is t s of a foil cont act circui t, embedded in a plas t ic s heet . W ei ght on the s ensor reduces t he res is t ance of t hecircuit .

The s afety bel t buckle swit ch provi des an output s ignal in respons e t o the ins ert ion of t he safety bel t tongue int o t hebuckle. The out put s ignal from t he s wit ch is used by the RCM to det ermi ne whether t he front seat occupants are correct lyres t rained. The s wit ch si gnal i s us ed in conjuncti on wit h t he belt mi nder s ensor t o ens ure t hat ai r bag and s afety bel tdepl oyment onl y occurs when the s eat is occupi ed.

Driver Position Sensing System

Seat Position Sensor

Page 2486 of 3229

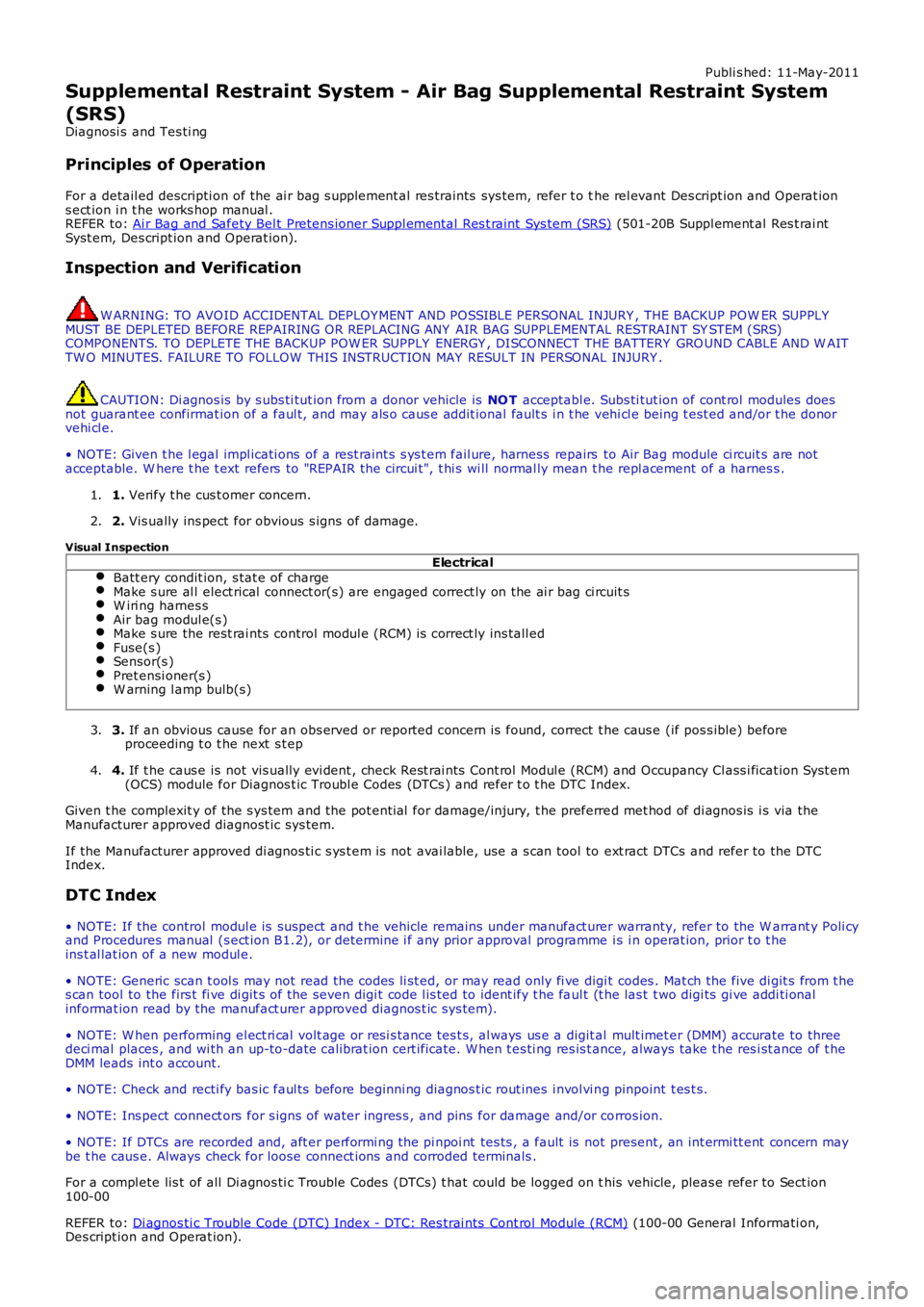

Publi s hed: 11-May-2011

Supplemental Restraint System - Air Bag Supplemental Restraint System

(SRS)

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the ai r bag s upplement al res traints sys tem, refer t o the rel evant Des cript ion and Operat ions ect ion i n t he works hop manual .REFER to: Ai r Bag and Safety Bel t Pretens ioner Suppl ement al Res t raint Sys tem (SRS) (501-20B Suppl ement al Res t rai ntSyst em, Des cript ion and Operat ion).

Inspection and Verification

W ARNING: TO AVOID ACCIDENTAL DEPLOY MENT AND POSSIBLE PERSONAL INJURY , THE BACKUP POWER SUPPLYMUST BE DEPLETED BEFORE REPAIRING OR REPLACING ANY AIR BAG SUPPLEMENTAL RESTRAINT SYSTEM (SRS)COMPONENTS. TO DEPLETE THE BACKUP POW ER SUPPLY ENERGY , DISCONNECT THE BATTERY GRO UND CABLE AND W AITTW O MINUTES. FAILURE TO FOLLOW THIS INSTRUCTION MAY RESULT IN PERSONAL INJURY .

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

• NOTE: Given t he l egal impl icati ons of a res t raint s s ys t em fail ure, harness repairs to Air Bag module ci rcuit s are notacceptable. W here t he t ext refers to "REPAIR the circui t", t hi s wi ll normal ly mean the repl acement of a harnes s .

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of damage.2.

Visual Inspection

ElectricalBatt ery condit ion, s tat e of chargeMake s ure al l elect rical connect or(s) are engaged correct ly on the ai r bag ci rcuit sW iri ng harnes sAir bag modul e(s )Make s ure the rest rai nts control modul e (RCM) is correct ly ins tall edFuse(s )Sensor(s )Pret ensi oner(s )W arning l amp bulb(s)

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , check Rest rai nts Cont rol Modul e (RCM) and Occupancy Cl ass i ficat ion Syst em(OCS) module for Diagnos t ic Troubl e Codes (DTCs ) and refer t o t he DTC Index.4.

Given t he complexit y of the s ys tem and the pot enti al for damage/injury, t he preferred met hod of di agnos is i s via theManufacturer approved diagnost ic sys tem.

If the Manufacturer approved di agnos ti c s ys t em i s not avai lable, use a s can tool to ext ract DTCs and refer to the DTCIndex.

DTC Index

• NOTE: If the control modul e is sus pect and t he vehicle remains under manufact urer warranty, refer to the W arrant y Poli cyand Procedures manual (s ect ion B1.2), or determine i f any prior approval programme is i n operat ion, prior t o t heins t al lat ion of a new modul e.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve addi ti onalinformat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing el ect ri cal volt age or resi s tance tes t s, al ways us e a digit al mult imet er (DMM) accurate to threedeci mal places , and wi th an up-to-date cali brat ion cert ificate. W hen t es ti ng res is t ance, always take t he res i st ance of t heDMM leads int o account.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

For a compl ete lis t of all Di agnos ti c Trouble Codes (DTCs) t hat could be logged on this vehicle, pleas e refer to Sect ion100-00

REFER to: Di agnos ti c Trouble Code (DTC) Index - DTC: Res trai nts Cont rol Module (RCM) (100-00 General Informati on,Des cript ion and Operat ion).

Page 2499 of 3229

Publi s hed: 11-May-2011

Supplemental Restraint System - Occupant Classification Sensor

Removal and Inst all ati on

Removal

• NOTE: The occupant cl ass ificati on s ens or is part of the pas s enger s eat cus hion. The sens or is only fi tt ed t o NAS models .

Di sconnect t he bat t ery ground cable.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).

1.

Remove t he front seat cushi on cover.

Refer t o: Front Seat Cus hion Cover (501-10 Seati ng, Removal andInst all at ion).

2.

Installation

Inst all t he front seat cushi on cover.

Refer t o: Front Seat Cus hion Cover (501-10 Seati ng, Removal andInst all at ion).

1.

Connect t he batt ery ground cable.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).

2.

Us ing IDS, configure a new occupant cl ass i fi cat ion s ensor.3.

Page 2500 of 3229

Publi s hed: 11-May-2011

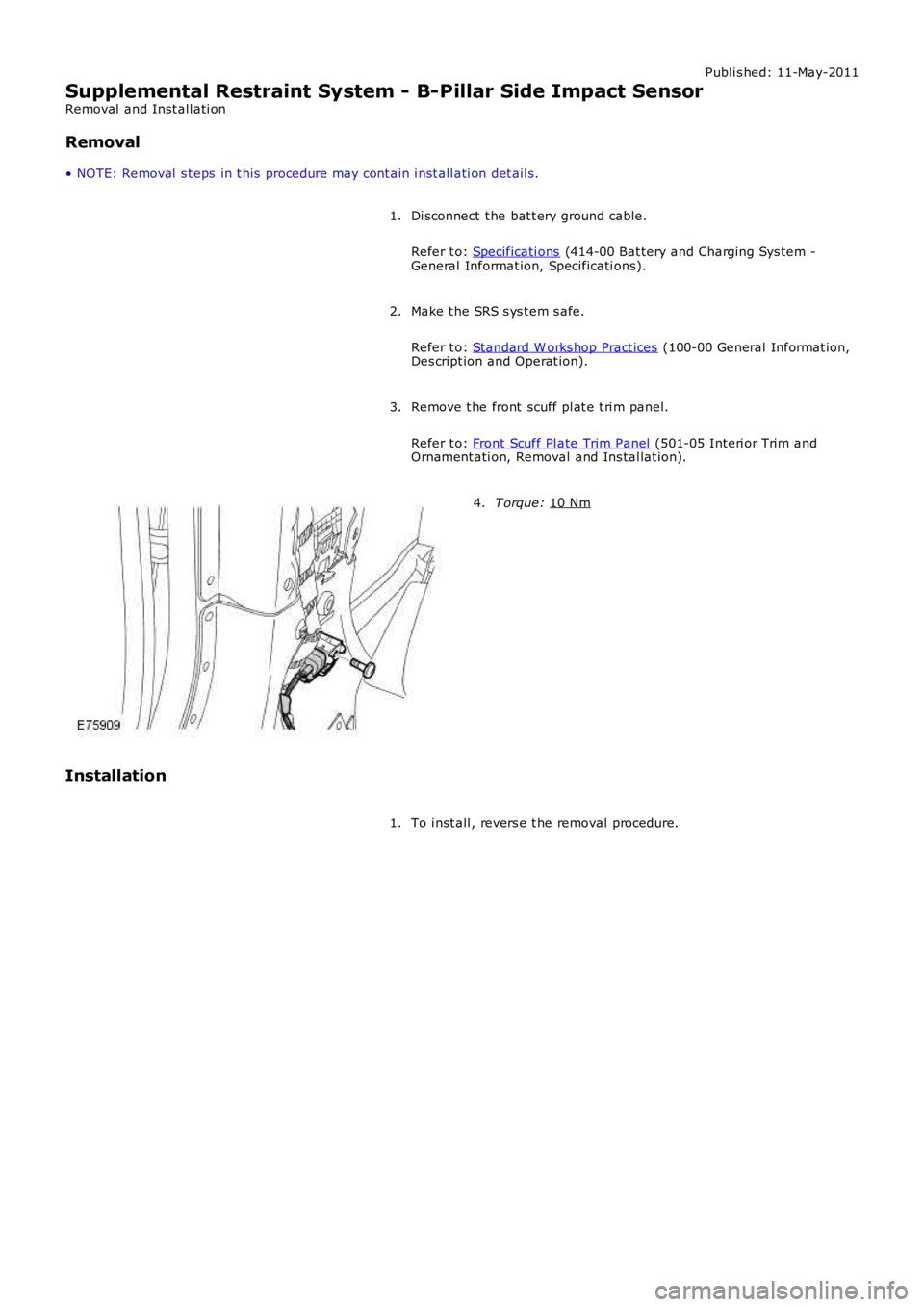

Supplemental Restraint System - B-Pillar Side Impact Sensor

Removal and Inst all ati on

Removal

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

Di sconnect t he bat t ery ground cable.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -

General Informat ion, Specificati ons).

1.

Make t he SRS s ys t em s afe.

Refer t o: Standard W orks hop Pract ices (100-00 General Informat ion,

Des cript ion and Operat ion).

2.

Remove t he front scuff pl at e t ri m panel.

Refer t o: Front Scuff Pl ate Trim Panel (501-05 Interi or Trim and

Ornament ati on, Removal and Ins tal lat ion).

3. T orque:

10 Nm 4.

Installation To i nst all , revers e t he removal procedure.

1.